Wood die comparison cutting device

A cutting device and mold technology, applied in wood processing equipment, manufacturing tools, special forming/shaping machines, etc., can solve the problems of low manual operation efficiency, unfavorable industrial production, unfavorable pass rate, etc., and improve cutting work Efficiency, expansion of industrial production, and the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

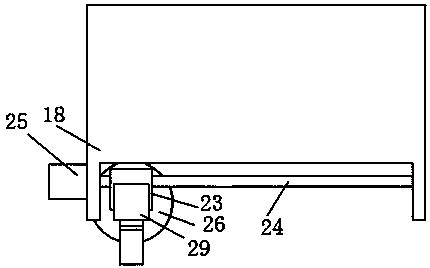

[0024] see Figure 1-3 , a wood mold contrast cutting device, comprising a workbench 1, the workbench 1 is provided with an installation cavity, and the middle part of the top surface of the workbench 1 is fixedly connected with a partition 19, and both sides of the partition 19 are symmetrically provided with a first rotating shaft 2, In addition, the two first rotating shafts 2 are rotatably connected with the workbench 1. The bottom ends of the two first rotating shafts 2 both pass through the workbench 1 and extend into the installation cavity. The extension ends of the two first rotating shafts 2 are fixedly socketed. There is a driven gear 6, a first motor 4 is fixedly installed at the bottom of the workbench 1, the output end of the first motor 4 extends into the installation cavity, and the extension end is fixedly sleeved with a driving ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com