The automatic double anchor cable blanking bending all-in-one machine

An automatic blanking and integrated machine technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems that tension jacks cannot be used together, do not have the anchor cable bending function, and the health of workers is damaged, so as to achieve cutting work High efficiency, small space occupied by equipment, and the effect of improving hoisting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

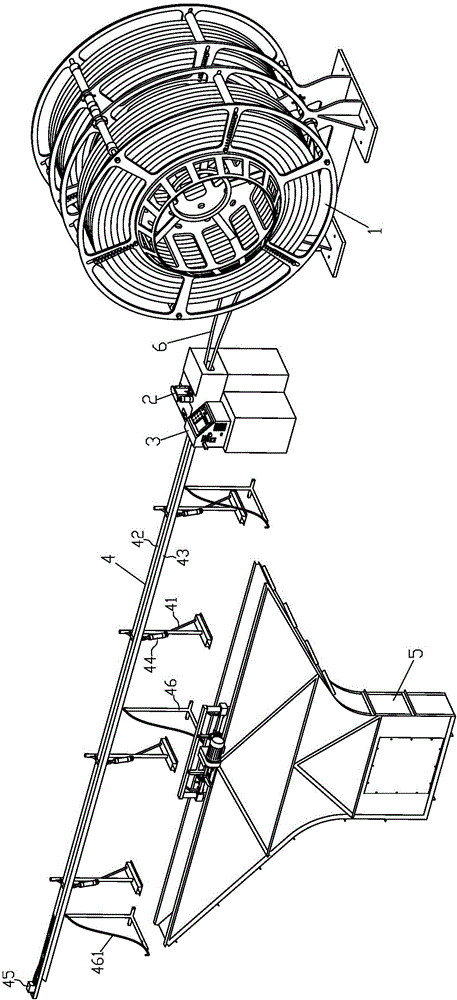

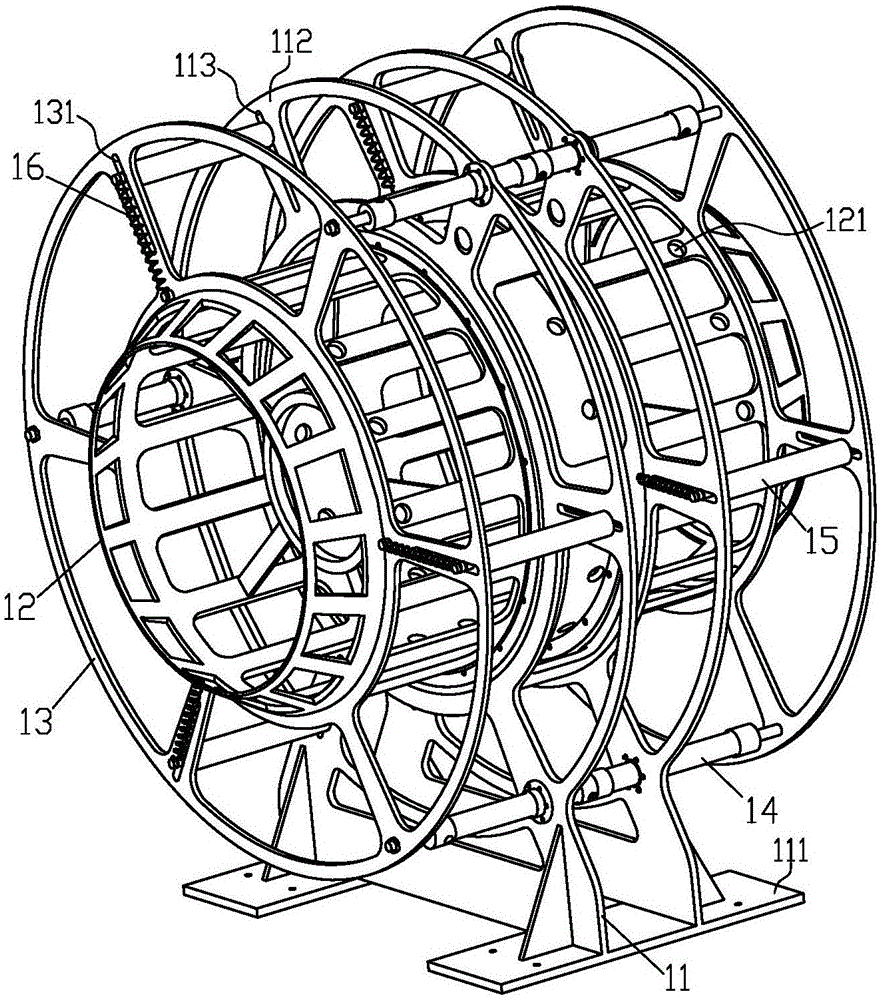

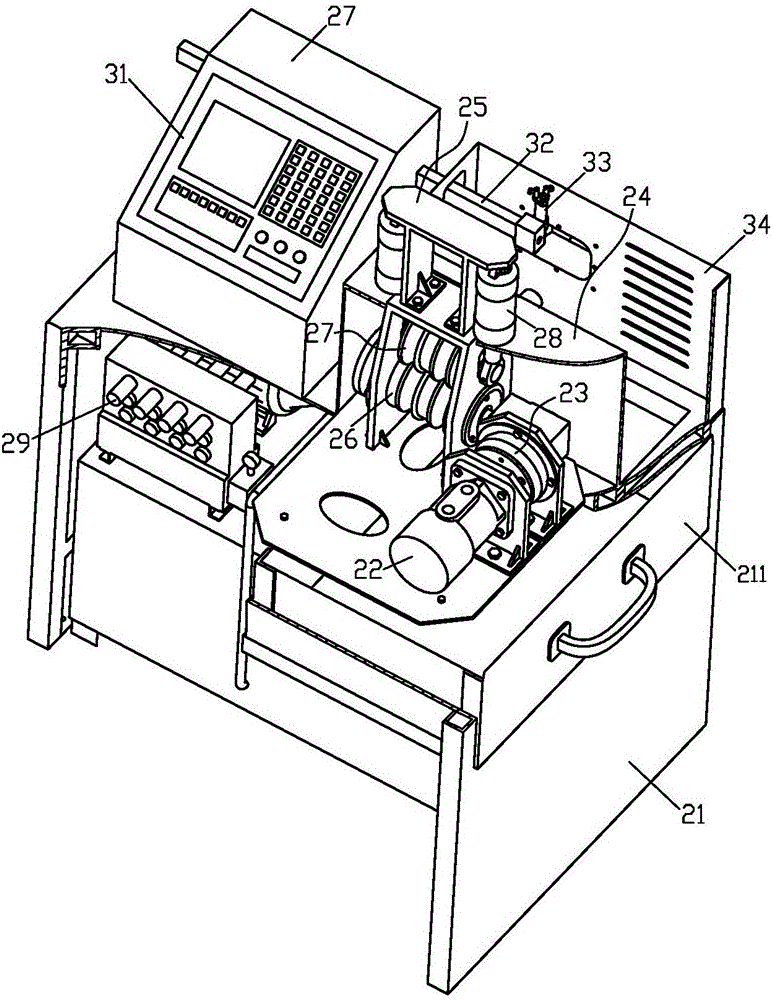

[0024] like figure 1 and image 3 As shown, the double-anchor cable automatic cutting and bending integrated machine includes a horizontal pay-off reel 1, a traction device 2, a cutting device 3, an unloading device 4 and a bending device connected to the electronic control air control hydraulic control system and sequentially connected through the anchor cable. device 5. Wherein, the horizontal pay-off reel 1 is a double-connected horizontal pay-off reel, which can place two rolls of anchor cables at the same time, and the axis of the pay-off reel is arranged horizontally; the traction device 2 and the cutting The device 3 is installed on the same frame, the traction device 2 is used for pulling and conveying the anchor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com