Wirerope-accompanying cable vertical hoisting system and construction method thereof

A vertical hoisting and cable technology, applied in safety devices, hoisting devices, transportation and packaging, etc., can solve major engineering accidents, difficulties in laying high-voltage cables, lack of monitoring or intelligent limit, etc., to increase breaking stress, The effect of reducing the probability of hoisting accidents and avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

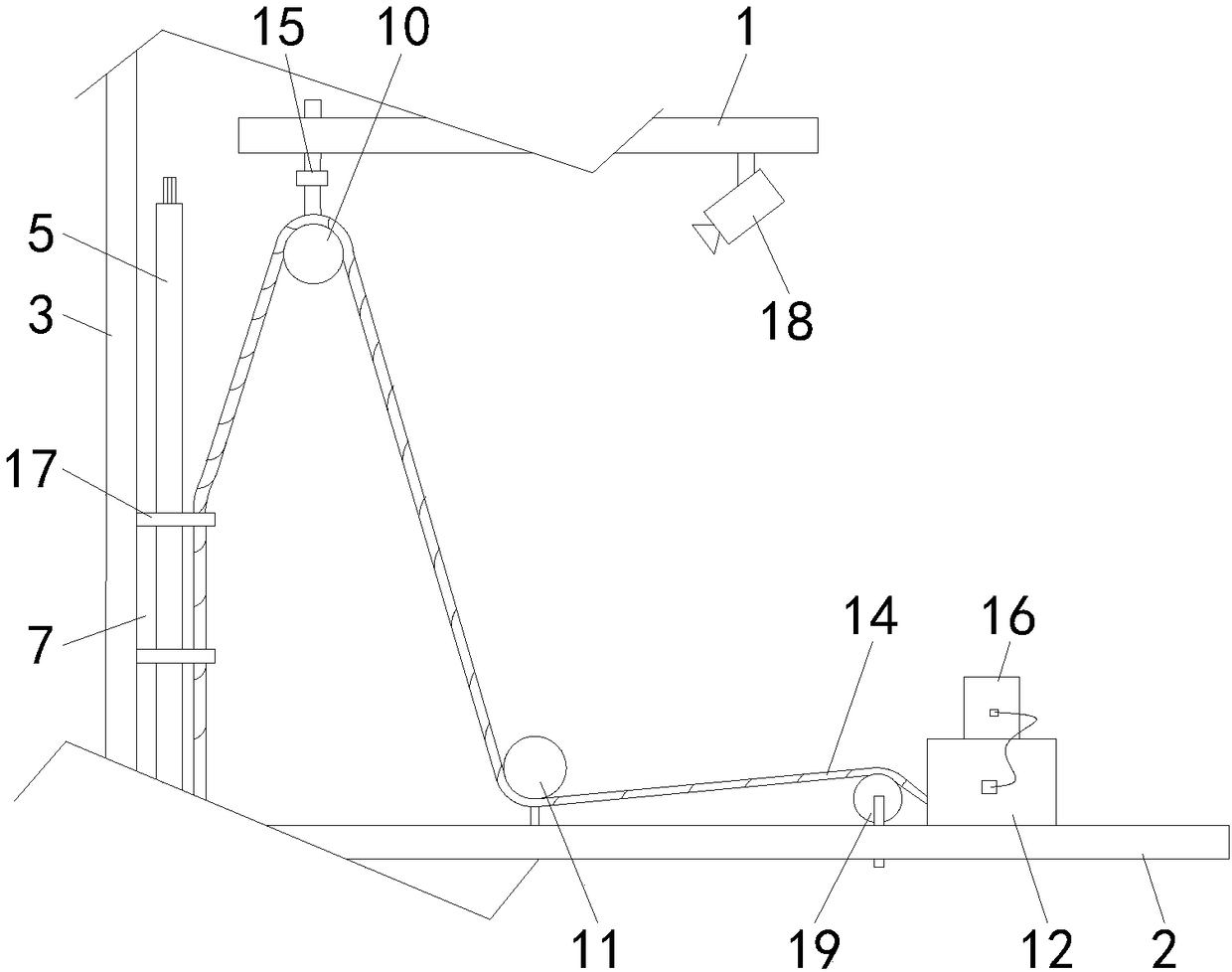

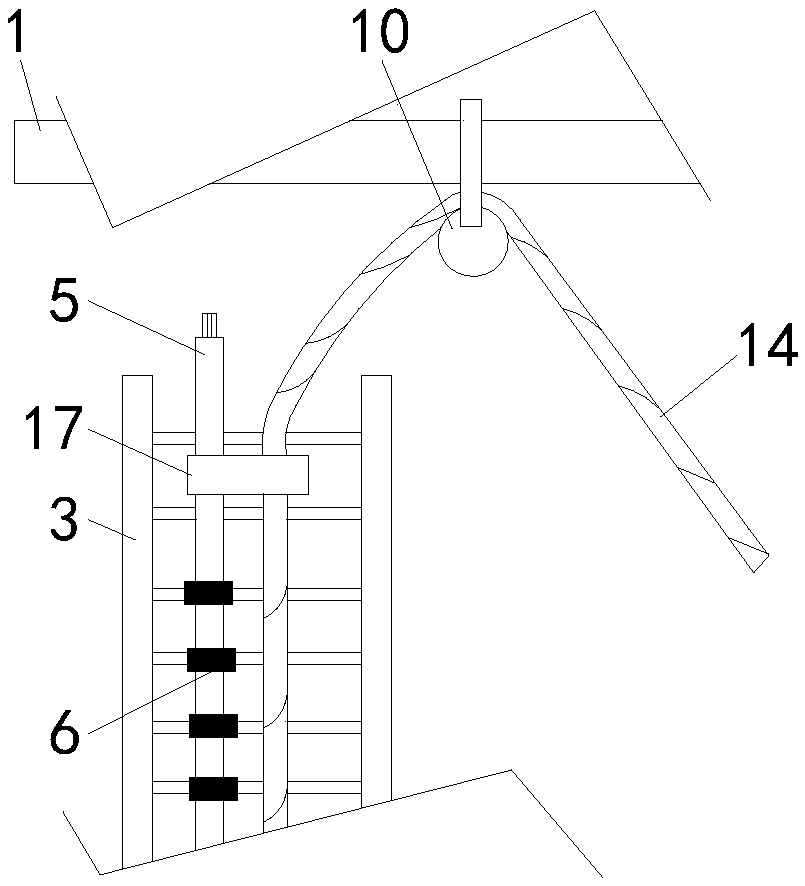

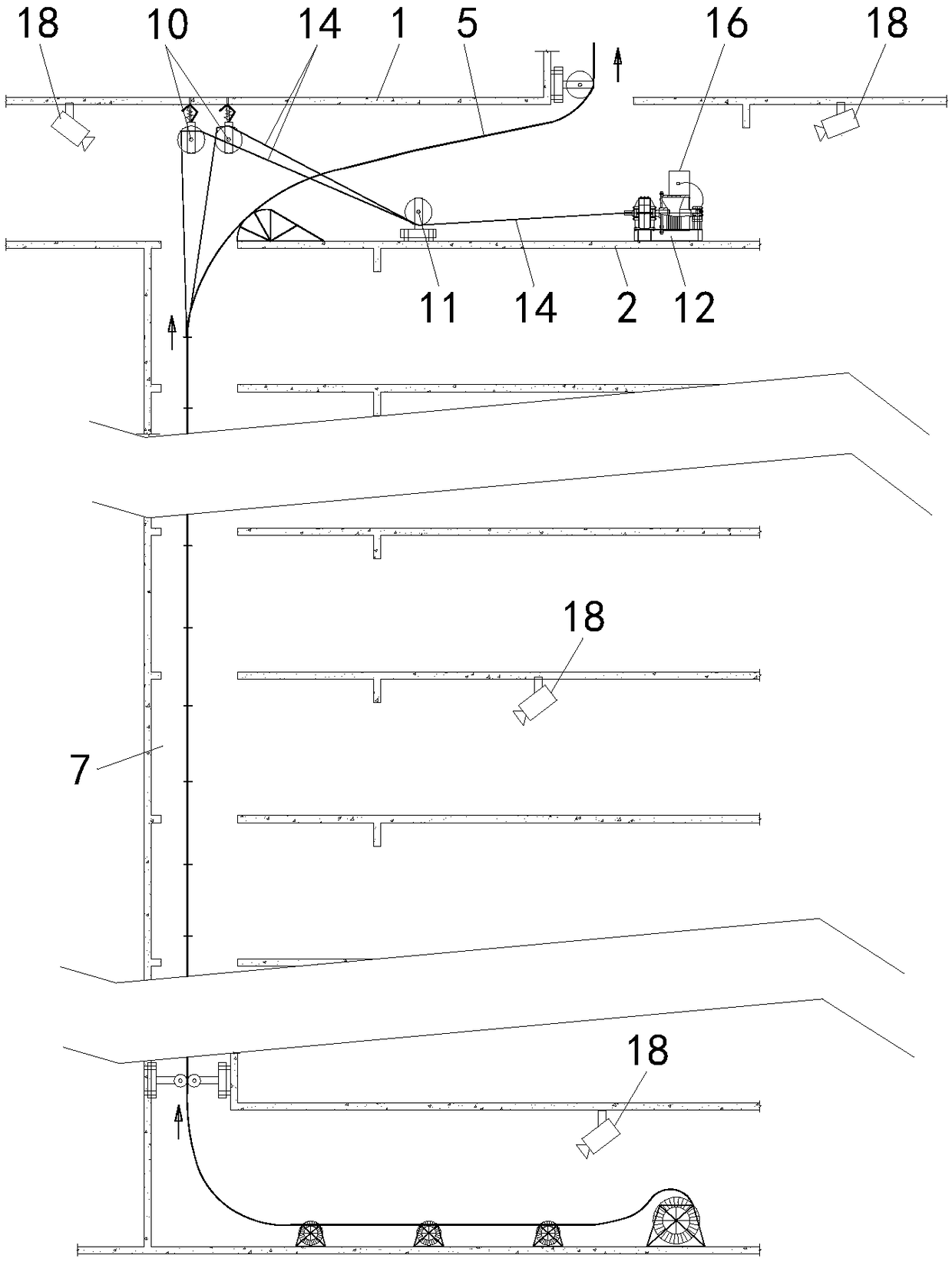

[0032] Embodiment 1: The high-voltage cable of this embodiment is a super-heavy cable and is used in super high-rise buildings. In order to increase the safety of hoisting, in combination with the analysis of the characteristics of the cable force, the high-voltage cable should be a built-in armored cable, which can withstand The minimum pulling force should be greater than that of YJV with the same diameter 32 type cables, the weight of a single high-voltage cable in this embodiment should not exceed 8 tons, and the hoisting height should not exceed 300 meters, which can also meet the design requirements of general super high-rise buildings. Combine below Figure 1 to Figure 3 Illustrate a kind of steel cable accompanying cable vertical hoisting system of the present invention, it is arranged between two floor slabs on the top floor of the building, namely between the bottom floor 2 and the top floor 1, it comprises: close to the cable well 7 and installed in At least one fi...

Embodiment 2

[0038] Embodiment two: combine below Figure 1 to Figure 3 Illustrate the construction method of hoisting high-voltage cables using a cable vertical hoisting system accompanied by steel cables of the present invention, the specific steps are as follows:

[0039] S1: Install the cable vertical hoisting system between the two floors on the top floor of the building, the first pulley 10 and the weight sensing device 15 are installed on the top floor 1, the second pulley 11, the gravity limiter 16 and the hoist 12 are installed on the bottom floor 2. The steel wire rope 14 of the winch 12 goes around the second pulley 11 and the first pulley 10 in turn, and is arranged in parallel with the high-voltage cable 5 and connected by a plurality of cable fixing fixtures 17;

[0040] S2: Start the winch 12 and tighten the wire rope 14. The high-voltage cable 5 is lifted upward along with the wire rope 14. The weight sensing device 15 converts the tension signal of the wire rope 14 attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com