Steel coil hoisting tool

A hoisting and tooling technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of potential safety hazards, low hoisting efficiency, steel coil cuts, etc., to achieve safe and reliable hoisting process, improve hoisting efficiency, coordination and Simple and quick effect of disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

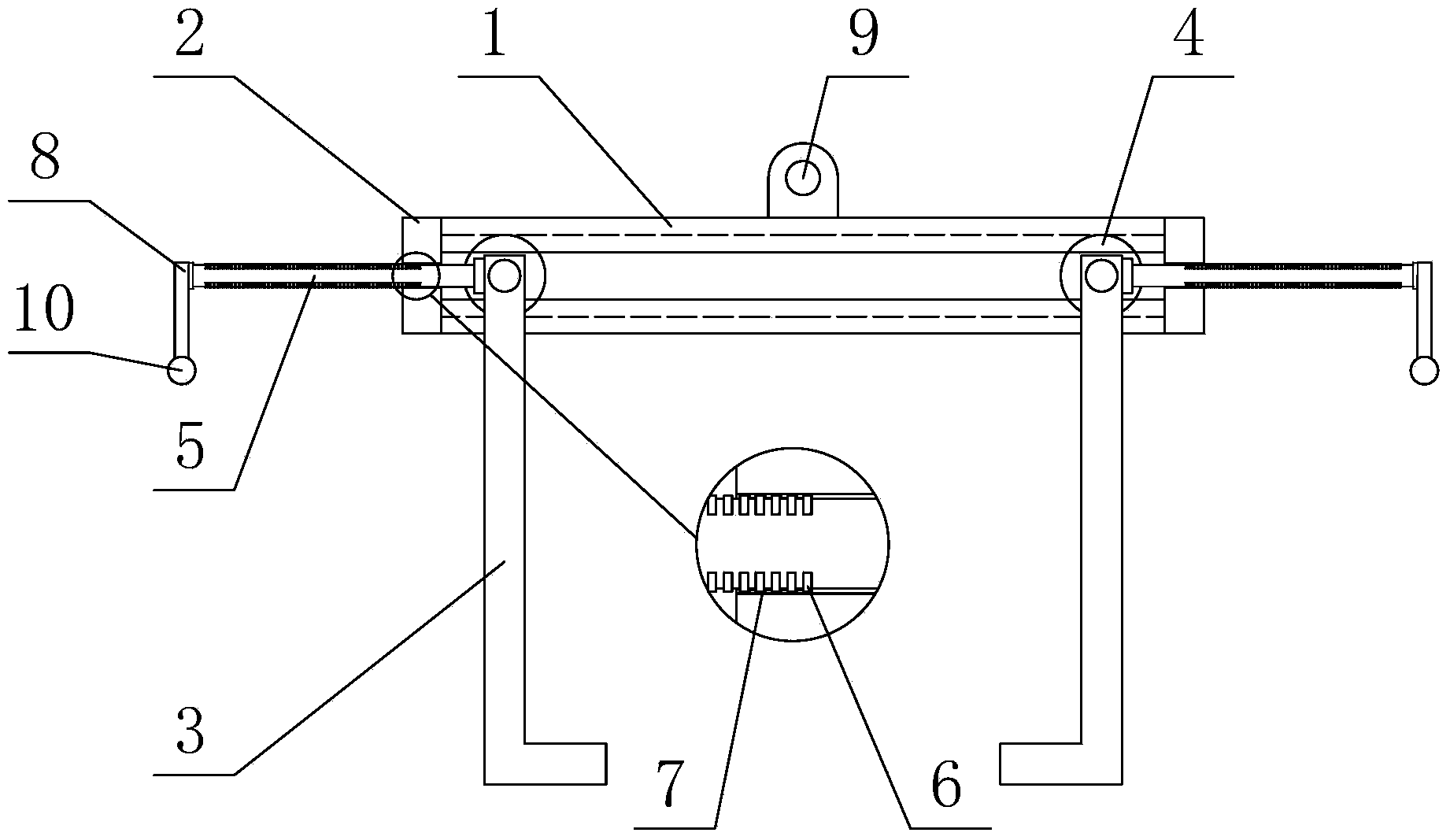

[0011] see figure 1 , a steel coil hoisting tool, comprising two parallel hoisting beams 1 and end plates 2 respectively located at both ends of the hoisting beams 1 for connecting the two hoisting beams 1, in this embodiment, the two hoisting beams 1 and the two The bar end plate 2 is welded to form a rectangular frame, and the hoisting beam 1 is a c-shaped steel with long grooves on it. The long slots of the two hoisting beams 1 are opposite, and two L-shaped hangers 3 are arranged between the two hoisting beams 1, and the L-shaped hangers 3 are respectively embedded in the lengths of the two hoisting beams 1 The rollers 4 in the groove are installed between the two hoisting beams 1 , the two rollers 4 are coaxial, and the L-shaped hanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com