Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "High color depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon black

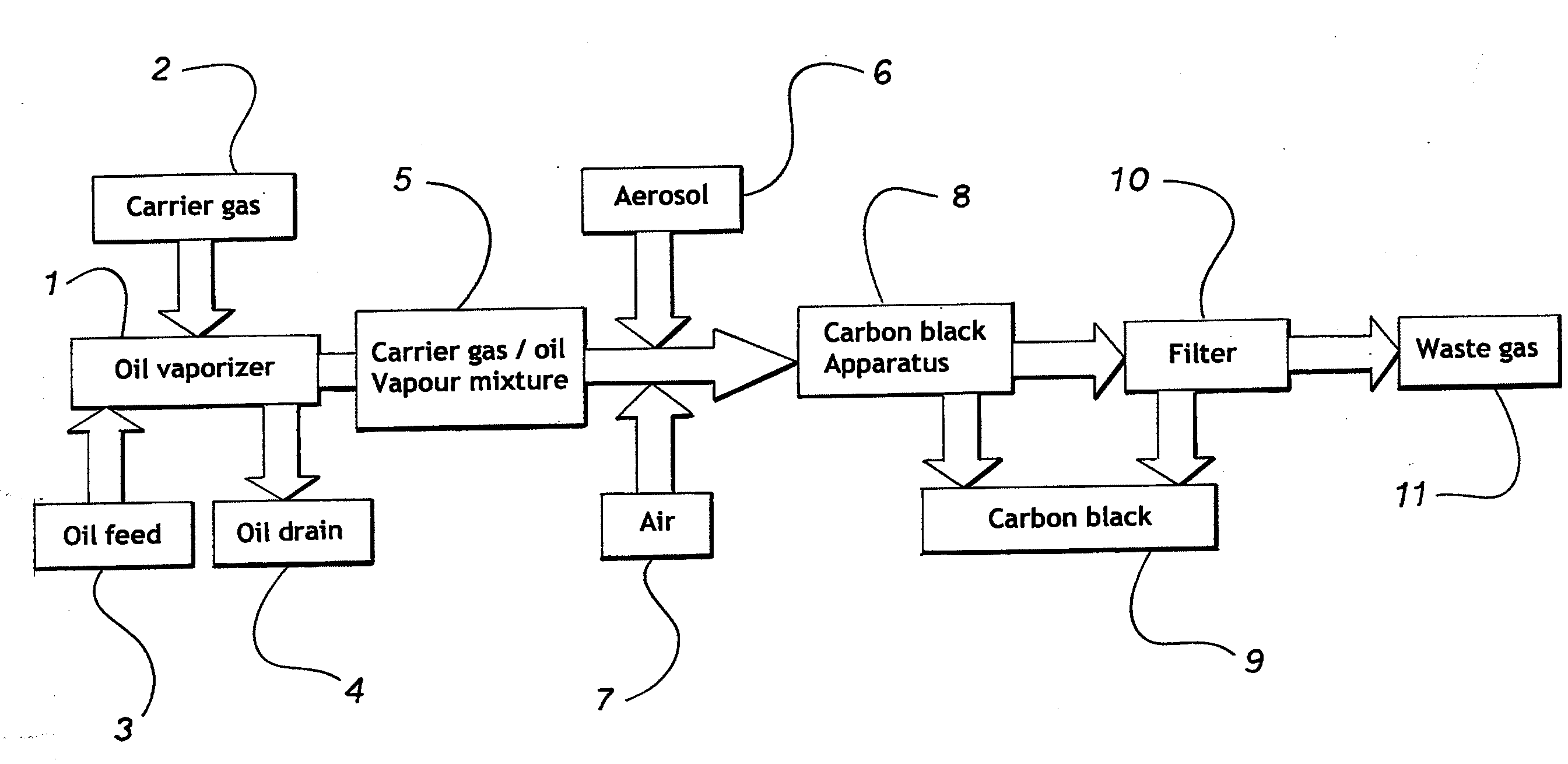

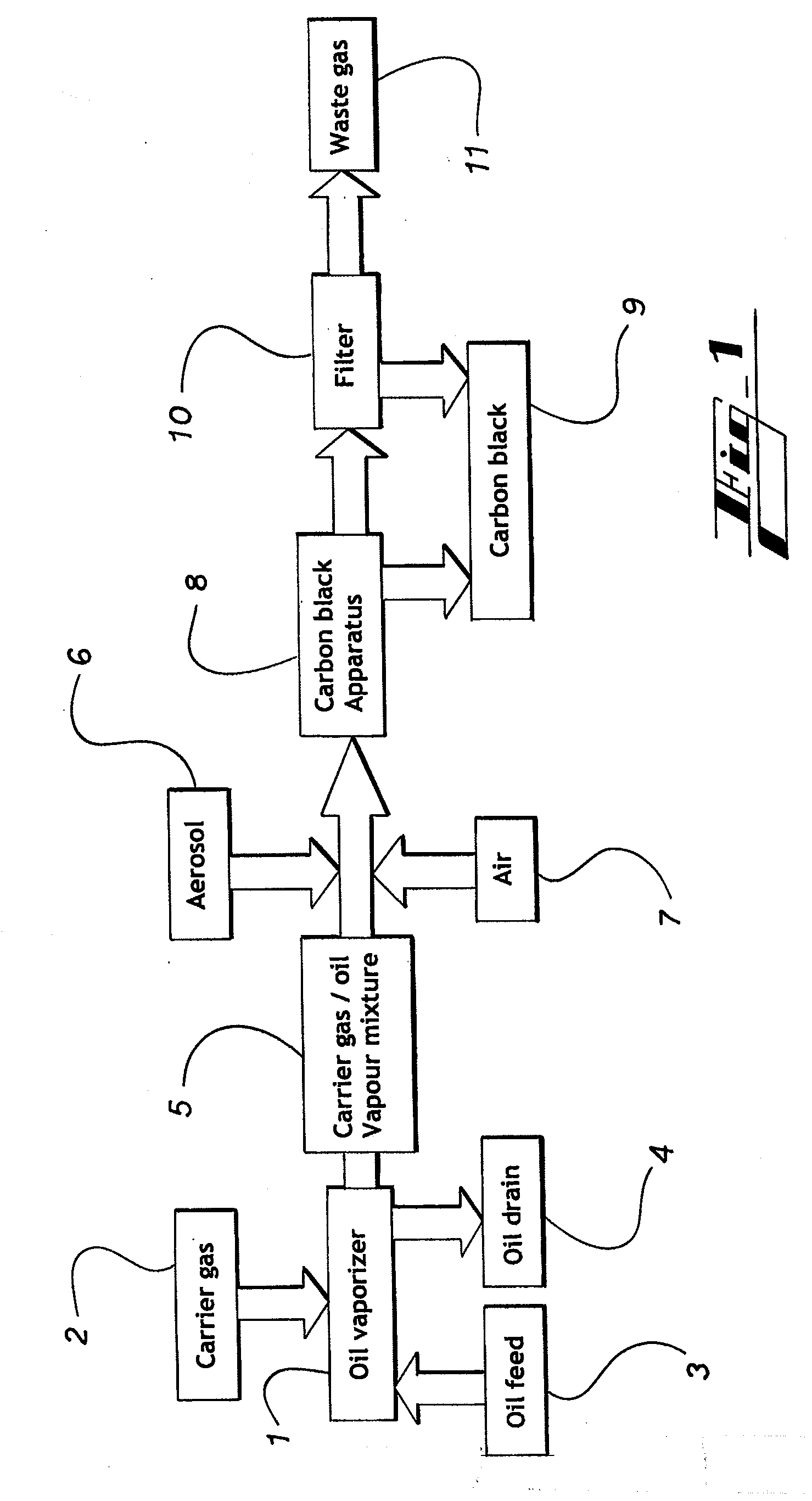

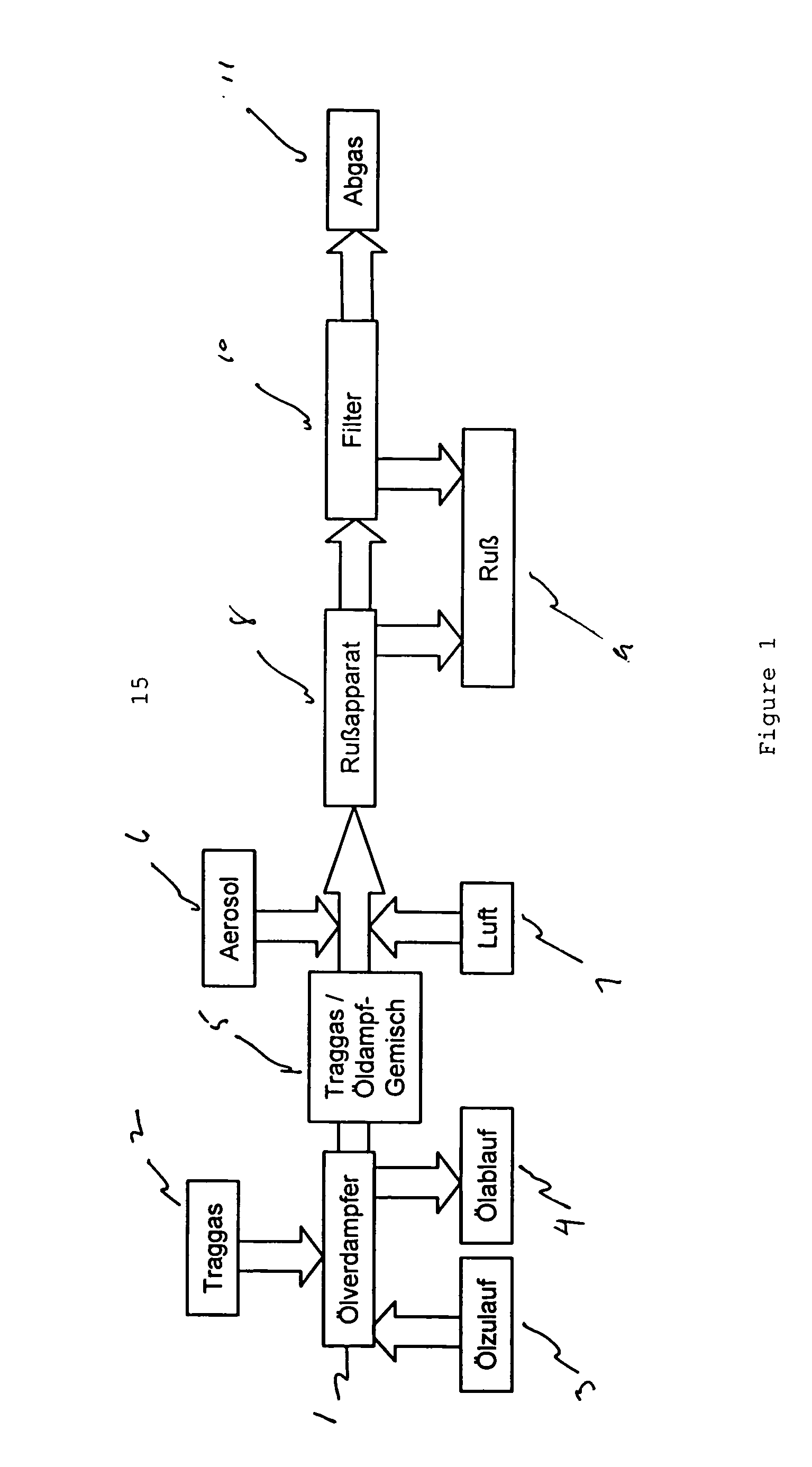

InactiveUS20090035210A1Low structural requirementsLow viscosityPigmenting treatmentAlkali metal halidesLacquerPrinting ink

Carbon black with an OAN, measured on the beaded carbon black, of less than 120 ml / 100 g. A process for the preparation of the carbon black is described, wherein a salt solution is converted into an aerosol and this is then introduced into the carbon black formation zone. The carbon black can be used in inks, paints, lacquers, printing inks and ink-jet inks, and for coloring plastics.

Owner:EVONIK CARBON BLACK GMBH

Carbon black

InactiveUS20050100502A1Low structural requirementsLow viscosityPigmenting treatmentAlkali metal halidesLacquerPrinting ink

Carbon black with an OAN, measured on the beaded carbon black, of less than 120 ml / 100 g. A process for the preparation of the carbon black is described, wherein a salt solution is converted into an aerosol and this is then introduced into the carbon black formation zone. The carbon black can be used in inks, paints, lacquers, printing inks and ink-jet inks, and for coloring plastics.

Owner:EVONIK DEGUSSA GMBH

Wool dyeing method using enzymic method

ActiveCN104264490AHigh color depthHigh fastnessBiochemical fibre treatmentDyeing processCelluloseProcess conditions

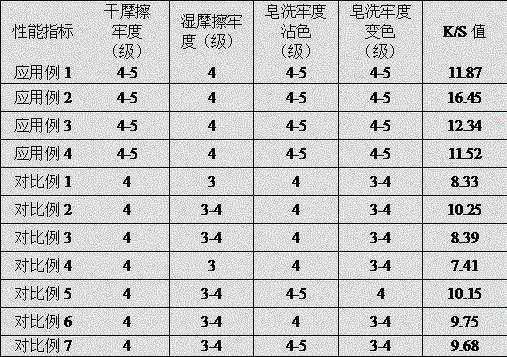

The invention discloses a wool dyeing method using an enzymic method. The wool dyeing method comprises the following steps of (1) enzyme treatment, namely, after wool washing, dipping a wool fiber product into a composite enzyme solution, wherein the technological conditions for enzyme treatment are as follows: papain is 10-12U / mL, polyphenol oxidase is 3-6U / mL, cellulose is 12-15U / mL, pH is 7, the temperature is 30-50 DEG C, the time is 0.5-1 hour, and the bath ratio is 1 to 10; (2) acid dyeing, namely, dyeing the wool fiber product after enzyme treatment in step (1) by acid dyes; and (3) washing aftertreatment, namely, washing dyed fabrics in the step (2) at 30-100 DEG C for 5-20 minutes in the bath ratio of 1 to (5-30).

Owner:CHANGXING GUOYUAN PRINTING & DYEING

Method for improving color fastness of protein fiber product through enzymic method

ActiveCN103911867AHigh color depthHigh fastnessBiochemical fibre treatmentDyeing processAfter treatmentTyrosine

The invention discloses a method for improving color fastness of a protein fiber product through an enzymic method. Tyrosine in silk, wool and other protein fibers is subjected to catalytic oxidation to generate quinonyl by means of polyphenol oxidase (tyrosinase, catechol oxidase and laccase), the quinonyl is further subjected to an addition reaction with amino-containing acid dyes, and the dyeing depth and color fastness of the fiber product are improved. The method comprises the following process steps: performing polyphenol oxidase treatment on protein fibers, dyeing through acid dyes and performing washing after-treatment, wherein the steps of enzyme treatment and dyeing can be performed in a two bath process or in a one-bath two-step method. The protein fiber modification conditions are mild, the color depth and color fastness of the dyed fiber products are improved, the chroma of dyeing waste liquor is reduced, the dye utilization rate is improved, and the requirements of the protein fiber products on clean dyeing production are met.

Owner:无锡协新毛纺织股份有限公司

Dyeing and fishing method for brocade/viscose fiber/spandex knitting fabric

InactiveCN102444033AEmission reductionLow process temperatureFibre treatmentDyeing processEngineeringFishing

The present invention discloses a dyeing and fishing method for brocade / viscose fiber / spandex knitting fabric. The method comprises processes of open-width pre-shrinking, scouring and dyeing in one bath, low temperature neutralizing and soaping, acid dyeing, soaping, drying and softening finishing. The open-width pre-shrinking process is performed by adopting a steaming shrinking machine. The scouring and dyeing in one bath process comprises: adding 1-2 g / l of a refined degreasing agent, and 2-3 g / l of an aqueous solution of soda to a dye vat, treating for 15-20 minutes at a temperature of 60-80 DEG C, then adding an active dye, 25-70 g / l of sodium sulfate, and 20g-25 g / l of soda, dyeing for 50-70 minutes at the temperature of 60-65 DEG C. The dyeing and fishing method for the brocade / viscose fiber / spandex knitting fabric has characteristics of simple operation, treatment time saving and low energy consumption. With the method of the present invention, the amount of the sewage discharge can be effectively reduced, and the prepared finished product has good hand feeling and full color.

Owner:杭州天宇印染有限公司

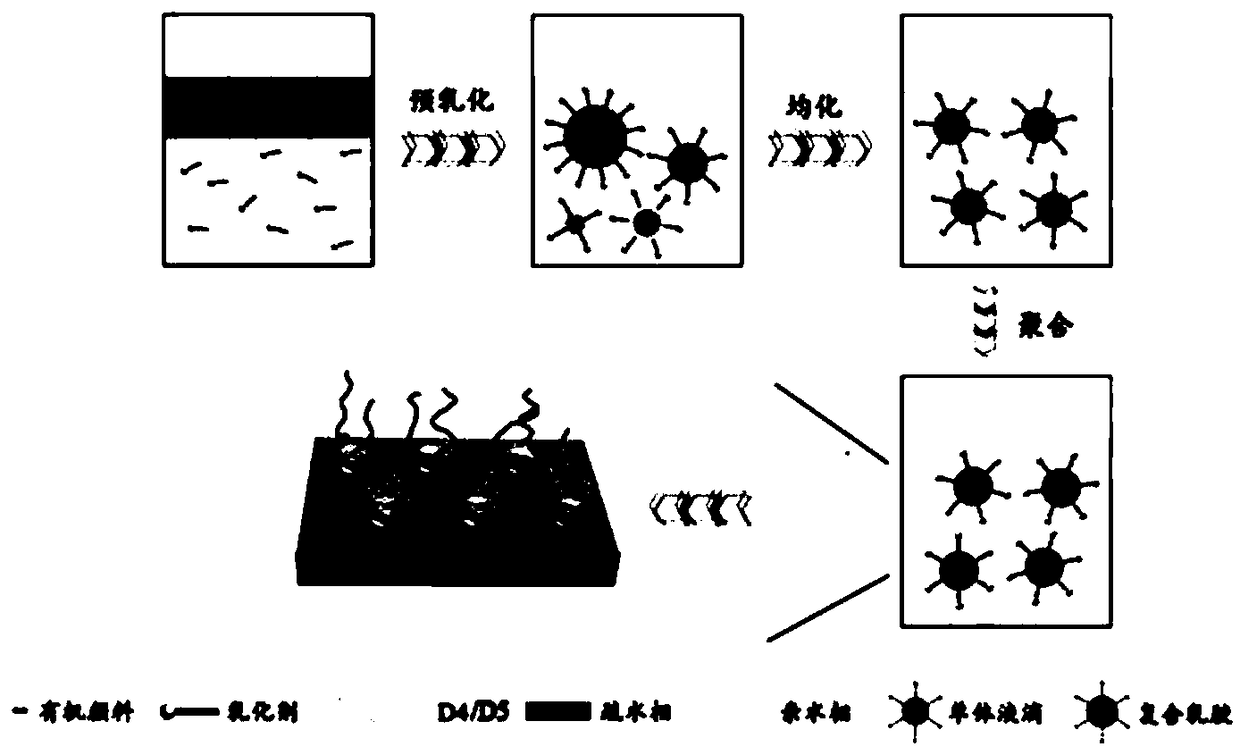

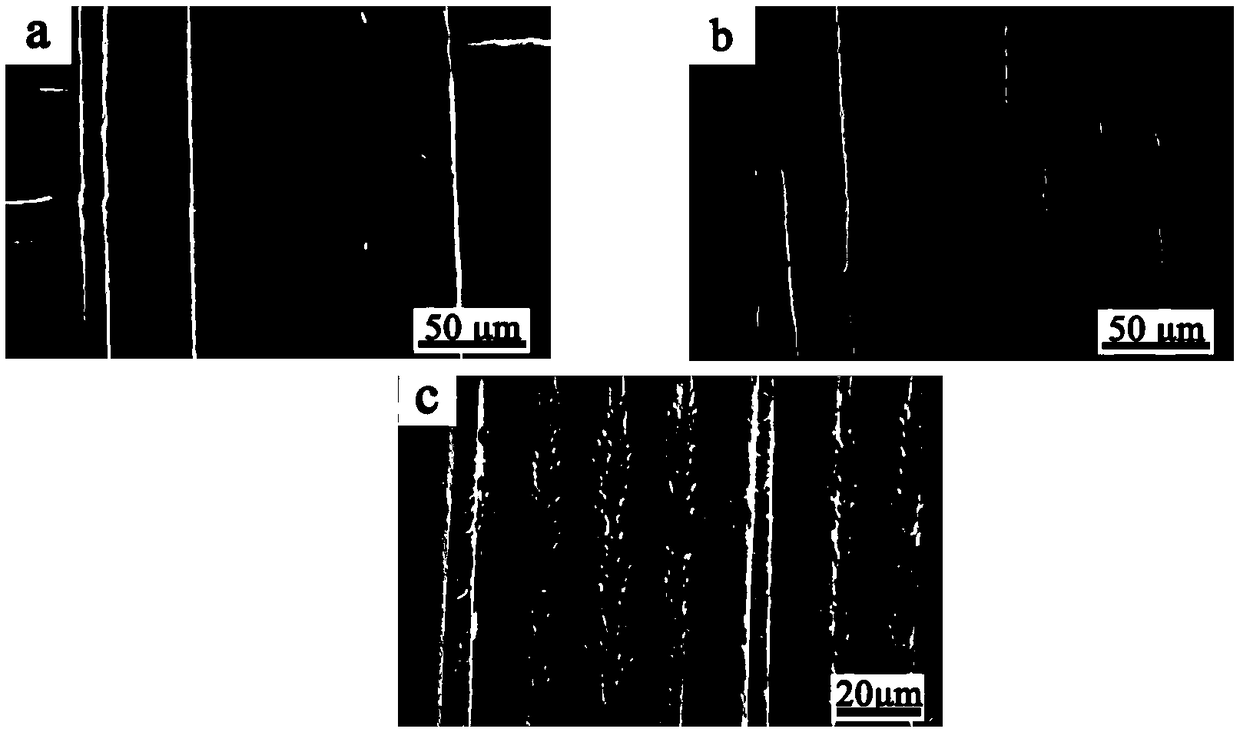

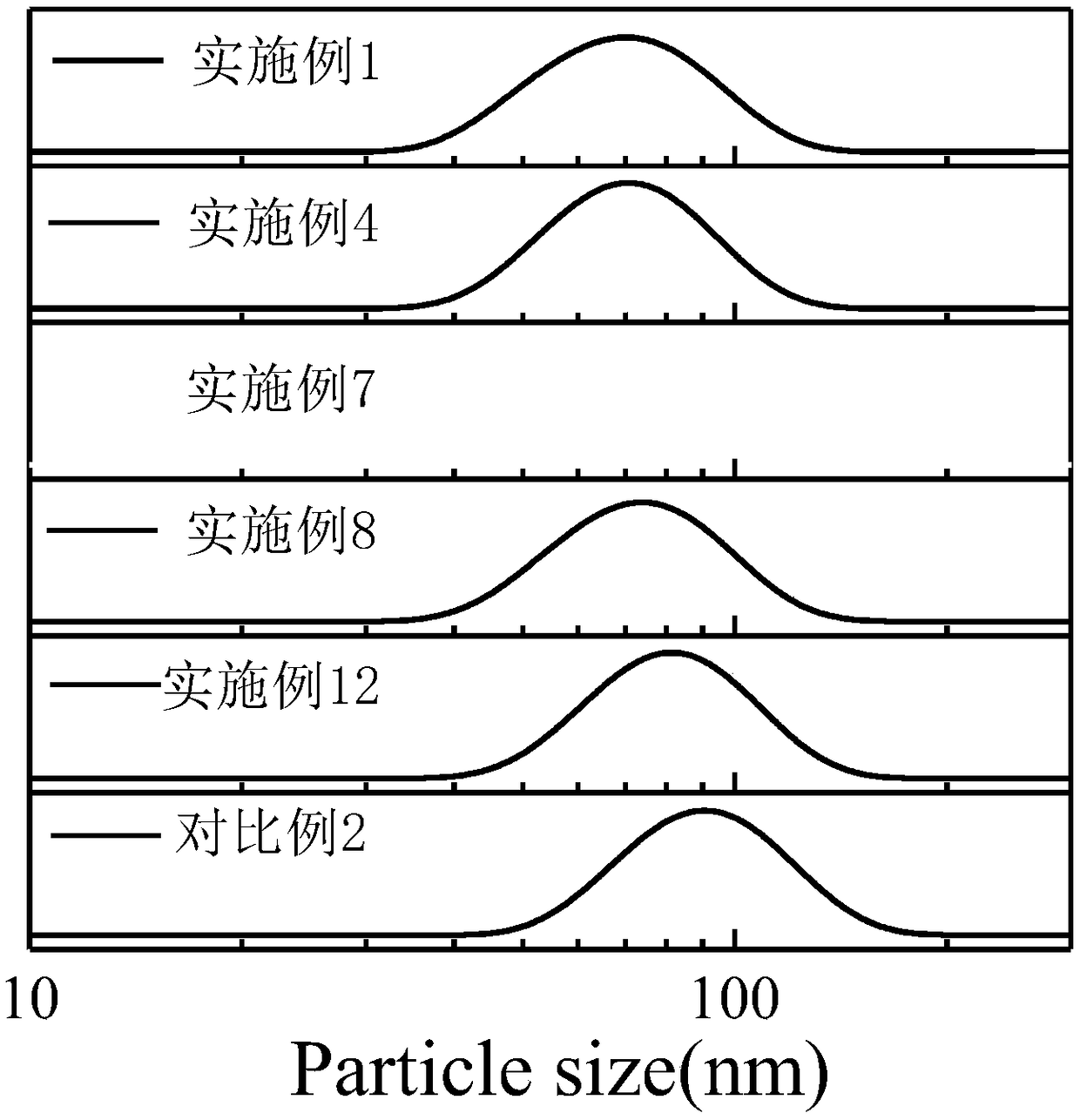

High-settling-resistant and high-color depth pigment nanocapsule coating as well as preparation method and application

ActiveCN108716141AChange densityImprove anti-settling performanceDyeing processCoatingsEmulsion polymerizationHigh color

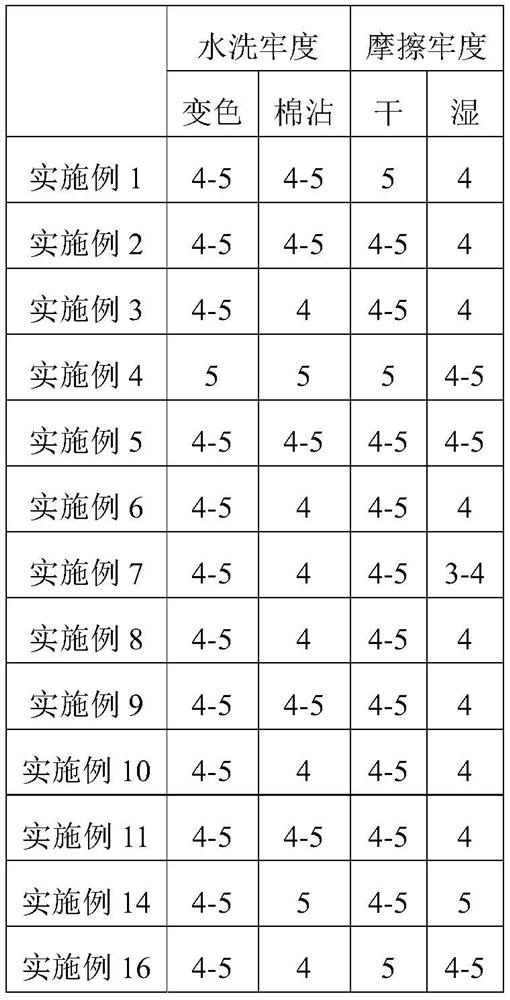

The invention discloses a high-settling-resistant and high-color depth pigment nanocapsule coating which has good settling resistance. The invention further discloses a preparation method of the high-settling-resistant and high-color depth pigment nanocapsule coating. The preparation method comprises the following steps: putting a great deal of low-density inert volatile decamethylcyclopentasiloxane or octamethylcyclotetrasiloxane into an acrylic monomer, and carrying out nano capsulation treatment on an organic pigment through fine emulsion polymerization, thereby obtaining a uniform and stable nano capsule coating. The coating is green and environmental-friendly in preparation process, easy in raw material obtaining, simple in process and high in color coating efficiency. The invention further provides application of the pigment nanocapsule coating to fabric coating printing, a dark fabric of which a K / S value is greater than or equal to 25 can be made, the air permeability retentionrate of the printed fabric is greater than 70%, the stiffness amplification of the printed fabric is less than 30%, the dry / wet friction resistance solidness of the printed fabric is greater than orequal to grade 4, and the objective hand feeling grade of the printed fabric is greater than or equal to 4.

Owner:ZHEJIANG NAMEI MATERIAL TECH

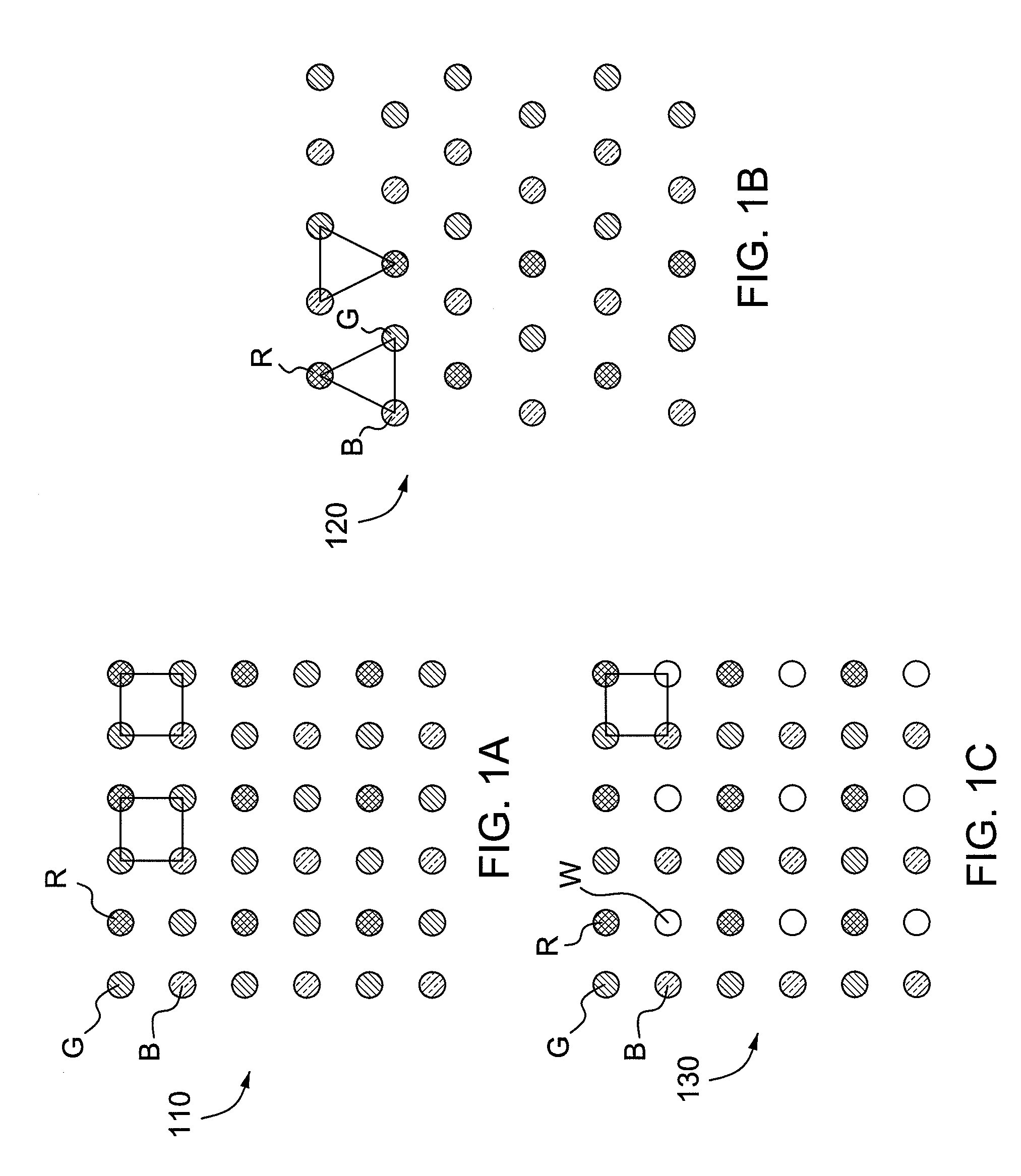

Flat panel display and driving method thereof

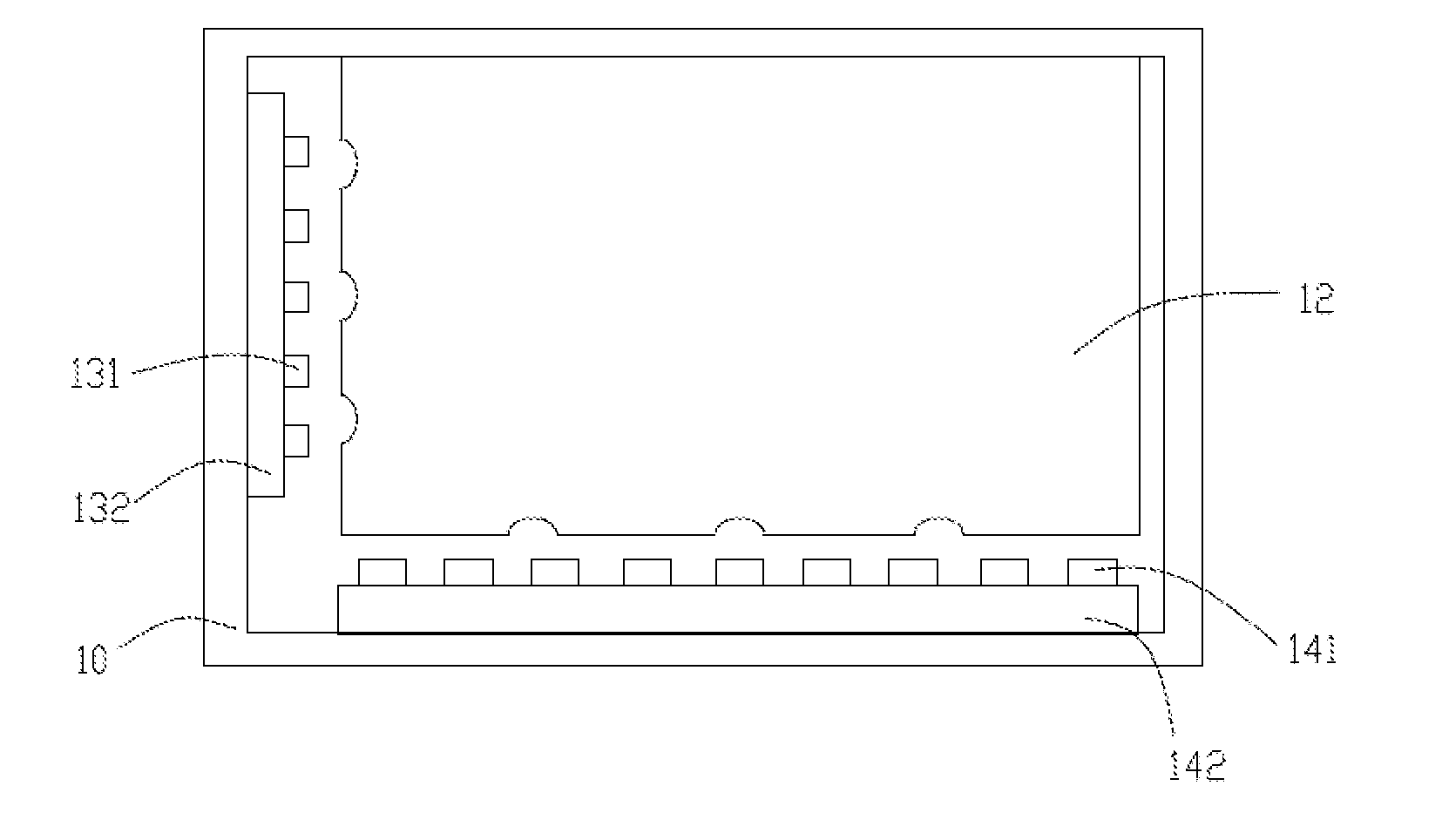

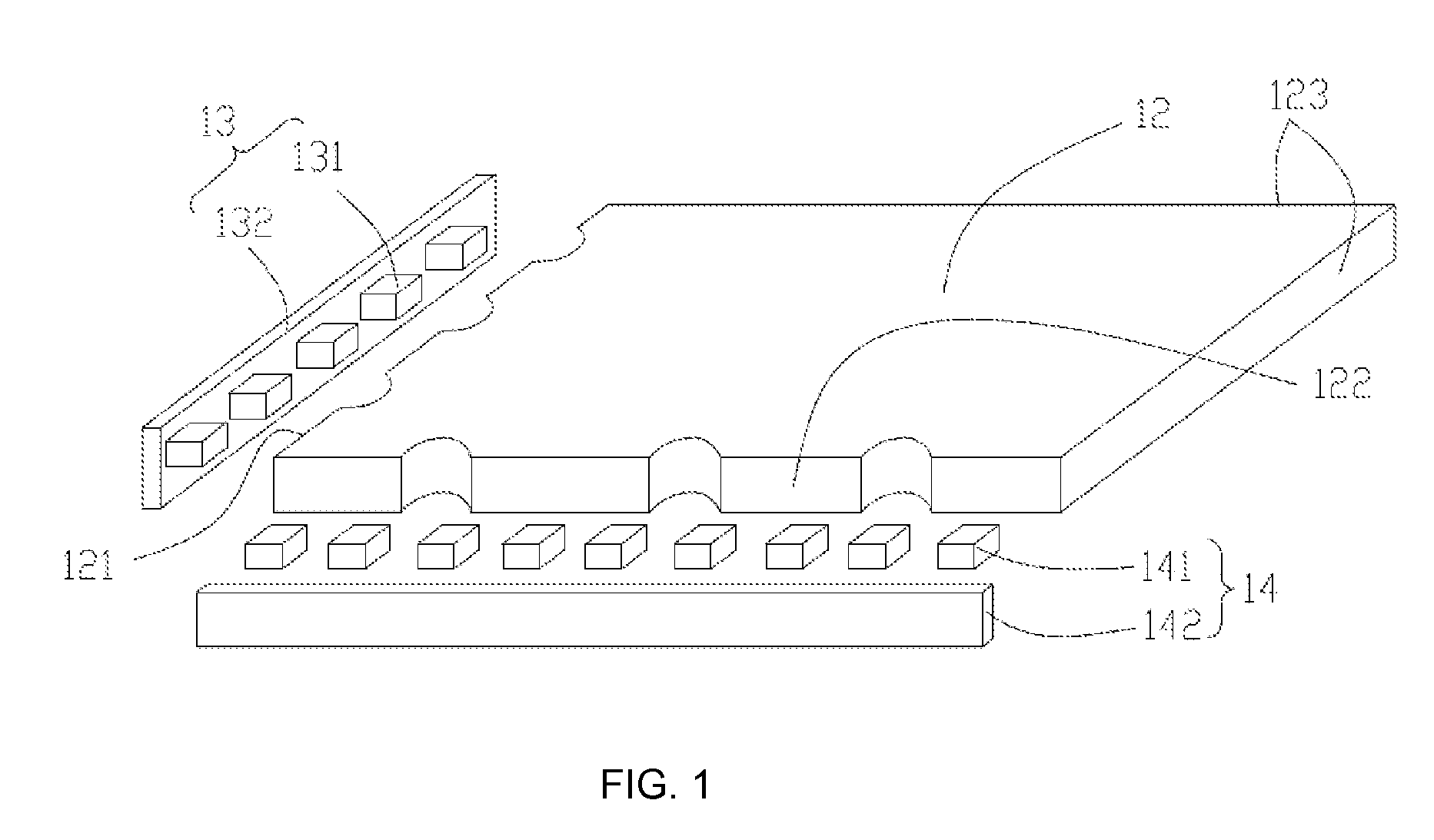

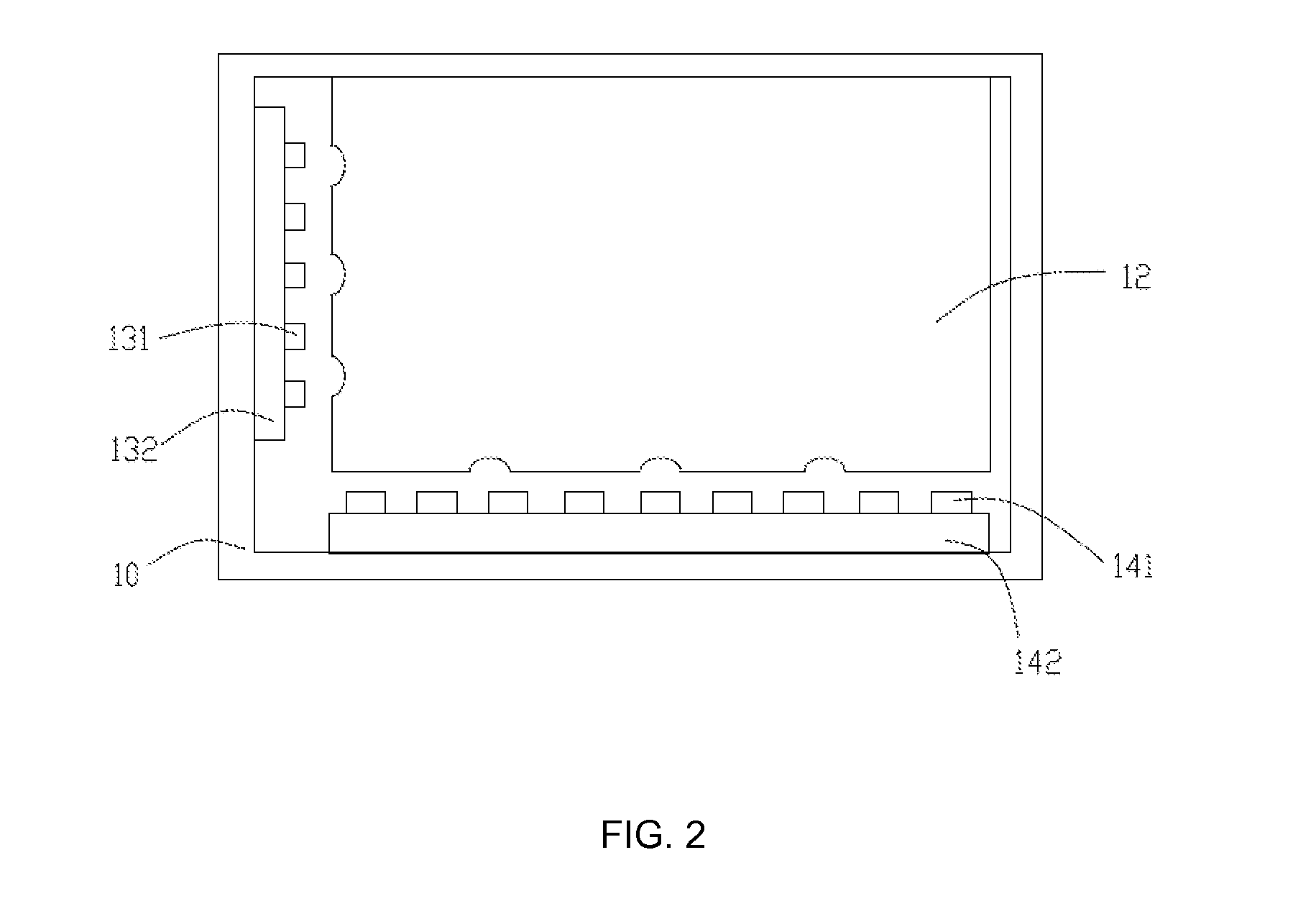

InactiveUS20080150881A1Improve image qualitySave powerStatic indicating devicesDynamic contrastDisplay device

The present invention provides a flat panel display, which is characterized by comprising a display panel; a backlight assembly having a plurality of light-emitting sources arranged in a predetermined pattern; and a driving circuit coupled to the display panel and the backlight assembly. The driving circuit could be operative to receive a first signal and determine a second signal according to the first signal and the predetermined pattern of the plurality of light-emitting sources; to use the second signal to control the light emission of the plurality of light-emitting sources; to determine a third signal according to the light-emitting results of the light-emitting sources controlled by the second signal, and drive the display panel by the third signal. The backlight assembly and flat panel display disclosed in the present invention could achieve the effects of improving quality, power saving, high dynamic contrast, and high color depth.

Owner:HONG KONG APPLIED SCI & TECH RES INST

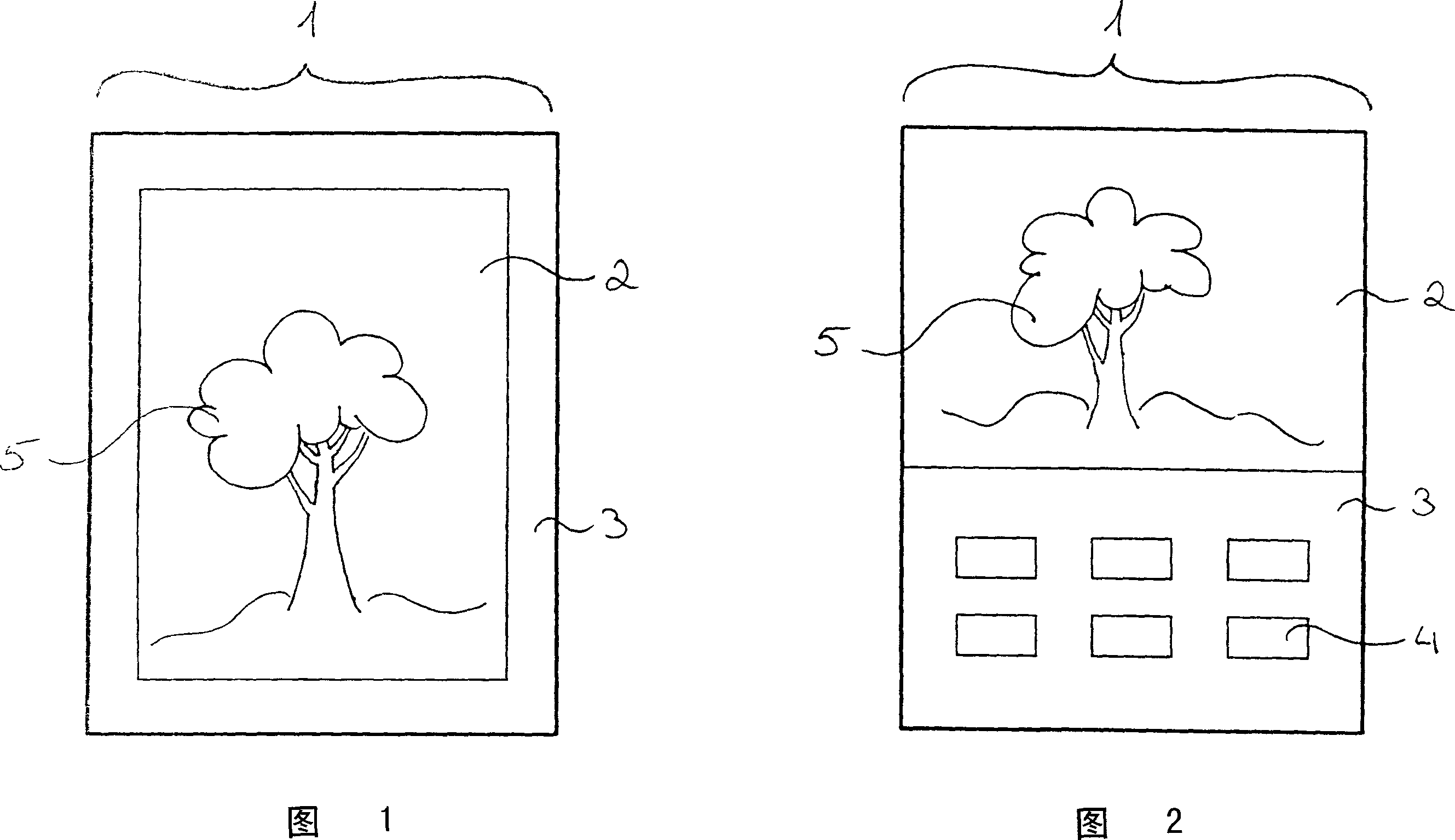

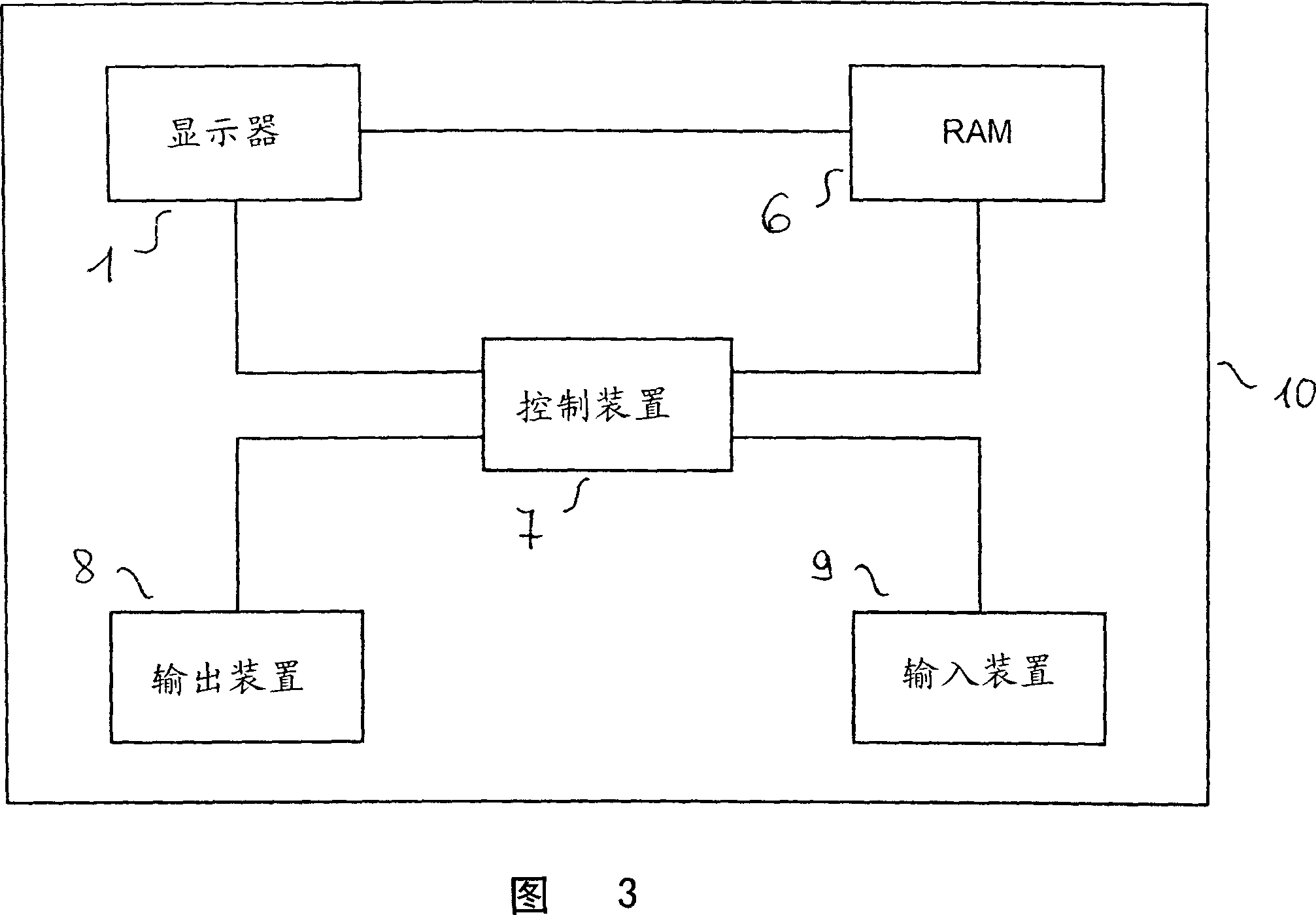

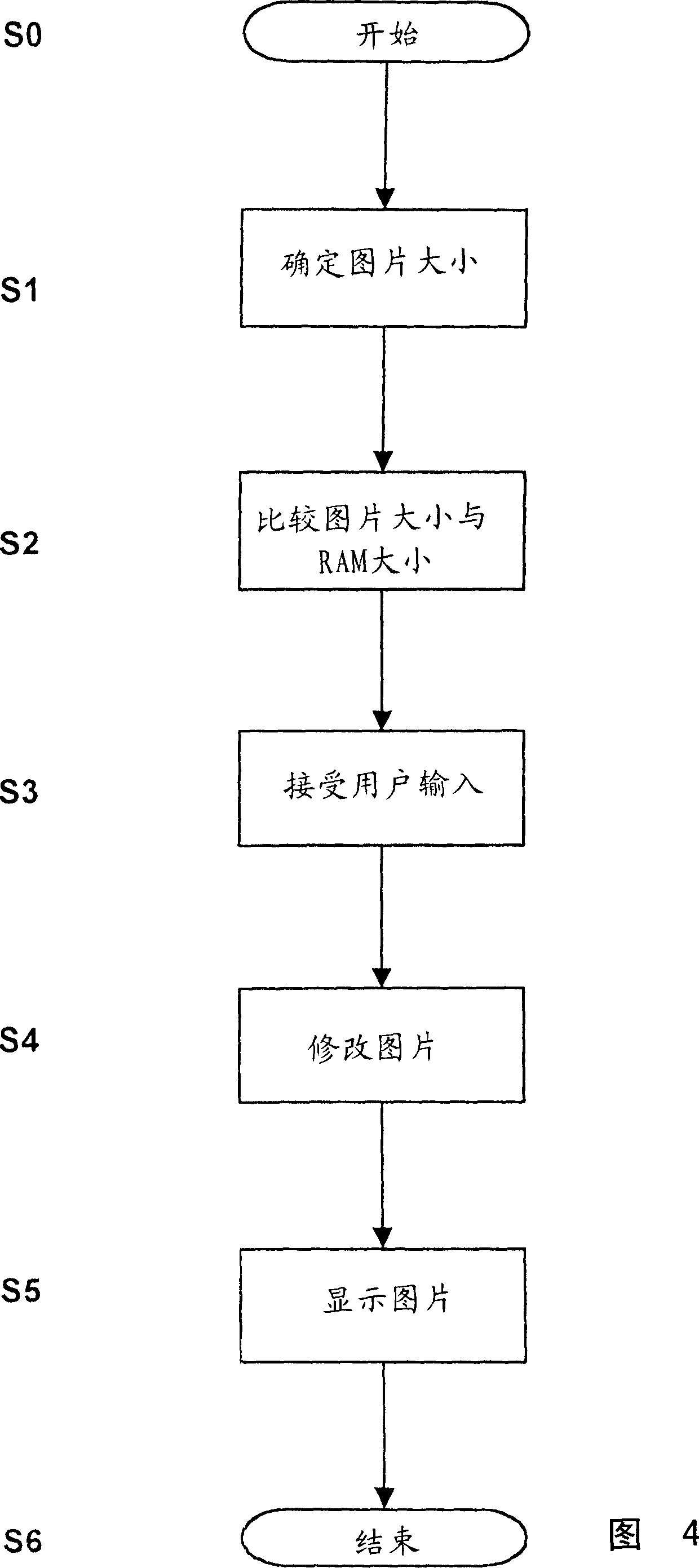

Display for a mobile terminal for wireless communication

InactiveCN1985291ANo power consumptionHigh color depthStatic indicating devicesInput/output processes for data processingTelecommunicationsDisplay device

The invention relates to a display for a mobile terminal for wireless communication comprising a first display area (2) with a high colour depth and a second display area (3) with a low colour depth. The invention further relates to a method for a display for a mobile terminal for wireless communication.

Owner:SONY ERICSSON MOBILE COMM AB

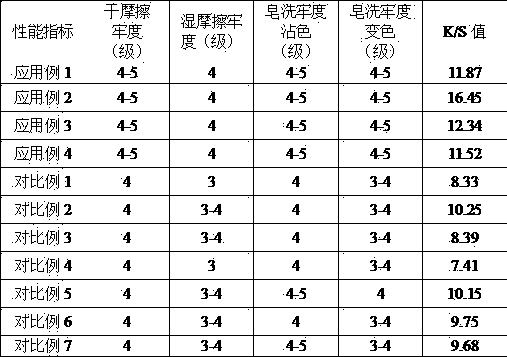

Fabric dyeing and deepening functional agent, preparation method and application thereof

The invention discloses a fabric dyeing and deepening functional agent, a preparation method and application thereof. The formula of the fabric dyeing and deepening functional agent comprises the following components in parts by weight: 1 to 5 parts of barbaloin, 1 to 5 parts of alkyl glycoside, 2 to 8 parts of flavonoid glycol and 70 parts of water; the preparation method for the fabric dyeing and deepening functional agent comprises the steps of mixing and uniformly stirring various components in the formula above, and standing; the fabric dyeing and deepening functional agent is applied to a dyeing process of a direct dye or an active dye of a fabric. The formula of the fabric dyeing and deepening functional agent disclosed by the invention is simple in component, environment-friendly and convenient to use; the dyeing process does not need to be changed and new equipment does not need to be added; the fabric dyeing and deepening functional agent can be widely applied to the direct dye or active dye dyeing of real silk, wool, cotton, hemp and recycled cellulose fibre fabrics and blended and interwoven fabrics; the colour depth and the colour fastness can be remarkably improved; meanwhile, the using amount of the dye can be reduced; the energy consumption and the sewage discharging can be reduced; the application prospect is wide.

Owner:SUZHOU INST OF TRADE & COMMERCE

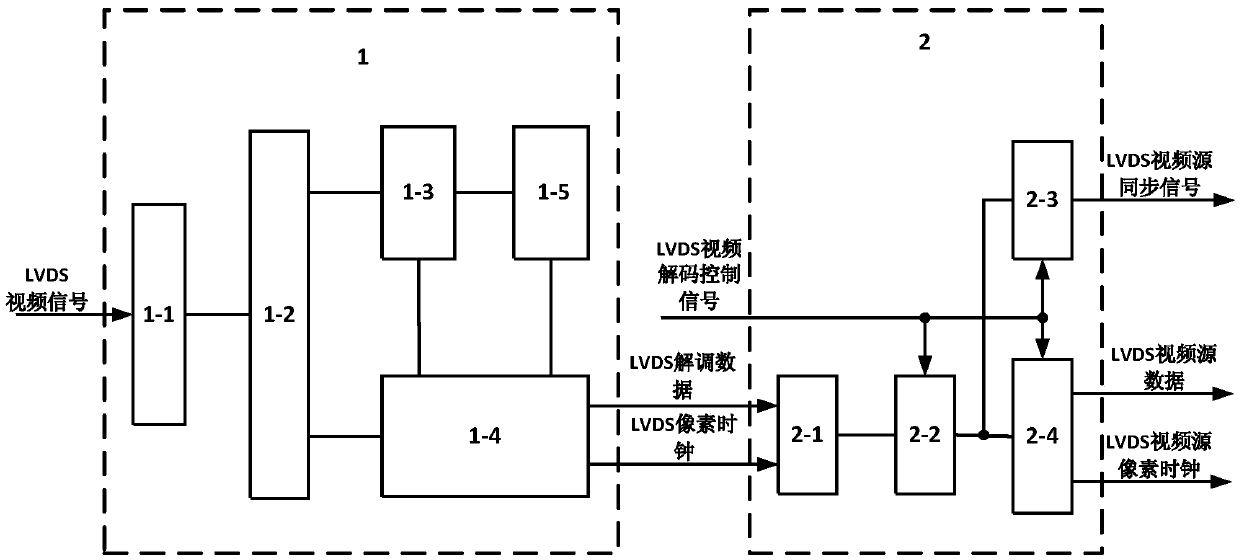

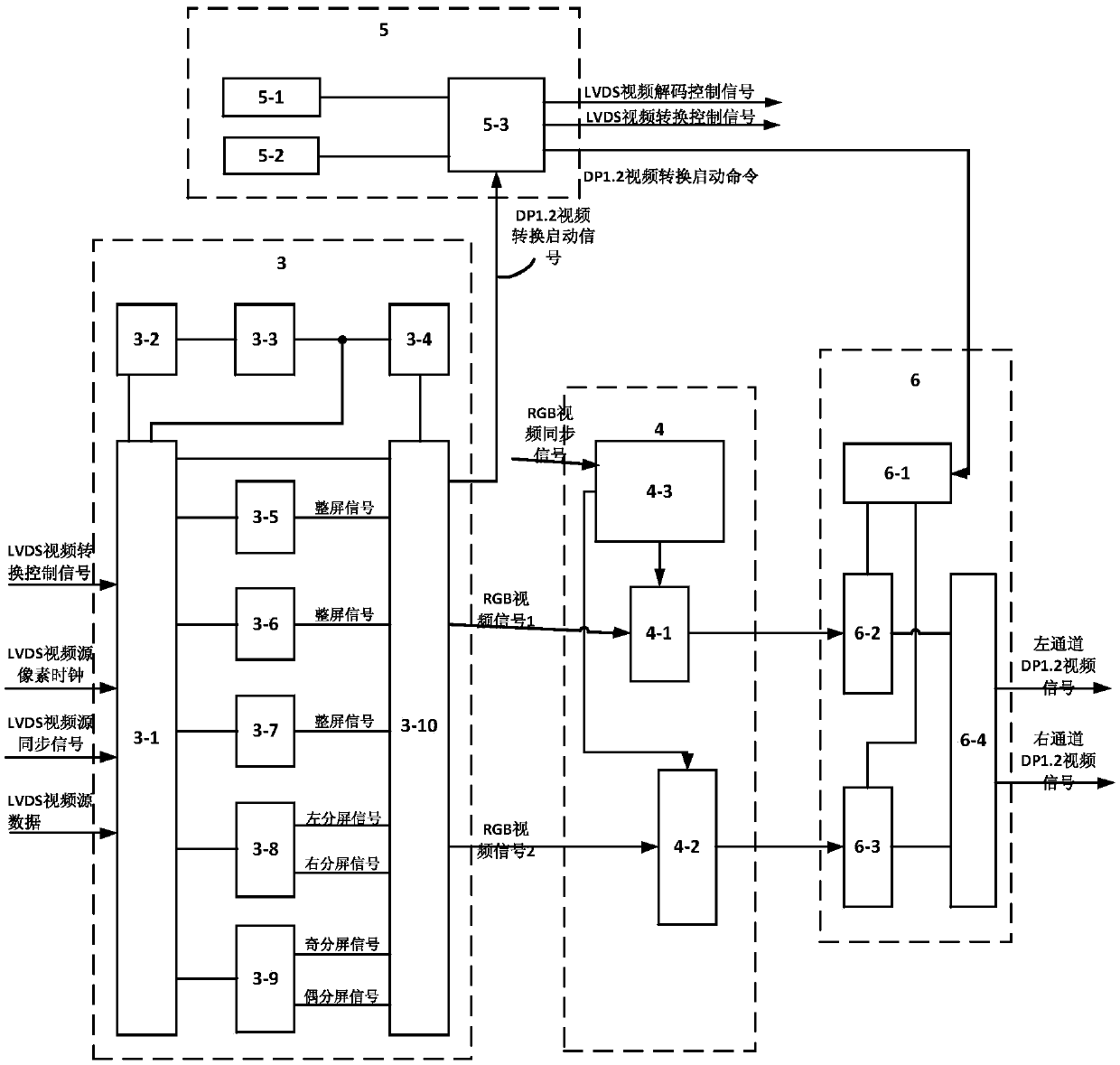

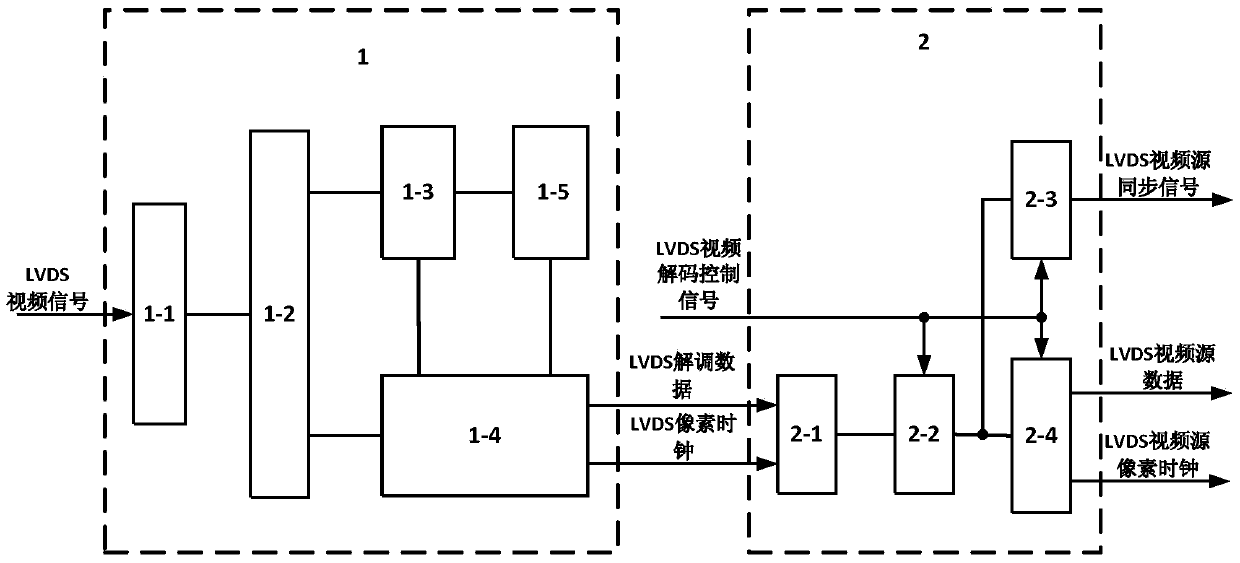

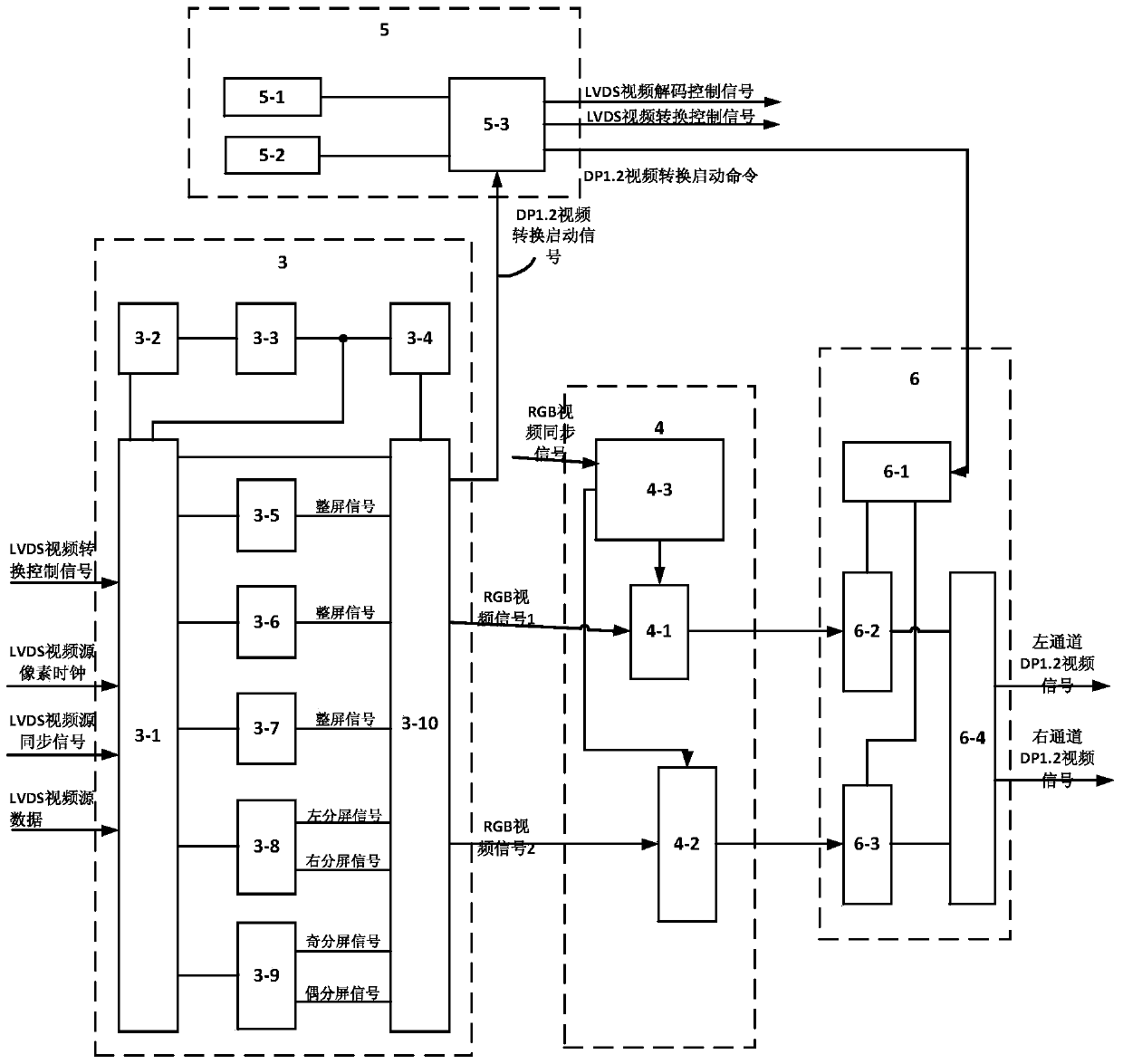

Method and system for converting LVDS video signal into DP1.2 video signal

ActiveCN105516632AIncrease display resolutionHigh color depthStatic indicating devicesConversion with cinematograph film standardInterference resistanceComputer architecture

The invention relates to a method and system for converting an LVDS video signal into a DP1.2 video signal, and the method comprises the steps: enabling the LVDS video signal to be converted into an RGB video signal; carrying out the buffering and frequency multiplication of the RGB video signal, and the outputting a frequency multiplication signal; carrying out the configuration and transformation of DP1.2 conversion of the outputted frequency multiplication signal according to a DP1.2 conversion configuration command and a DP1.2 conversion starting command, and obtaining a DP1.2 video signal. The method carries out the detection of the maximum DP1.2 video resolution, is high in integration degree, is reliable in operation, is strong in capability of interference resistance, is simple in operation, is economical and practical, can improve the detection reliability and efficiency of a DP1.2 liquid crystal module group, reduces the equipment cost and production cost, and will further facilitate the popularization of related display equipment.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

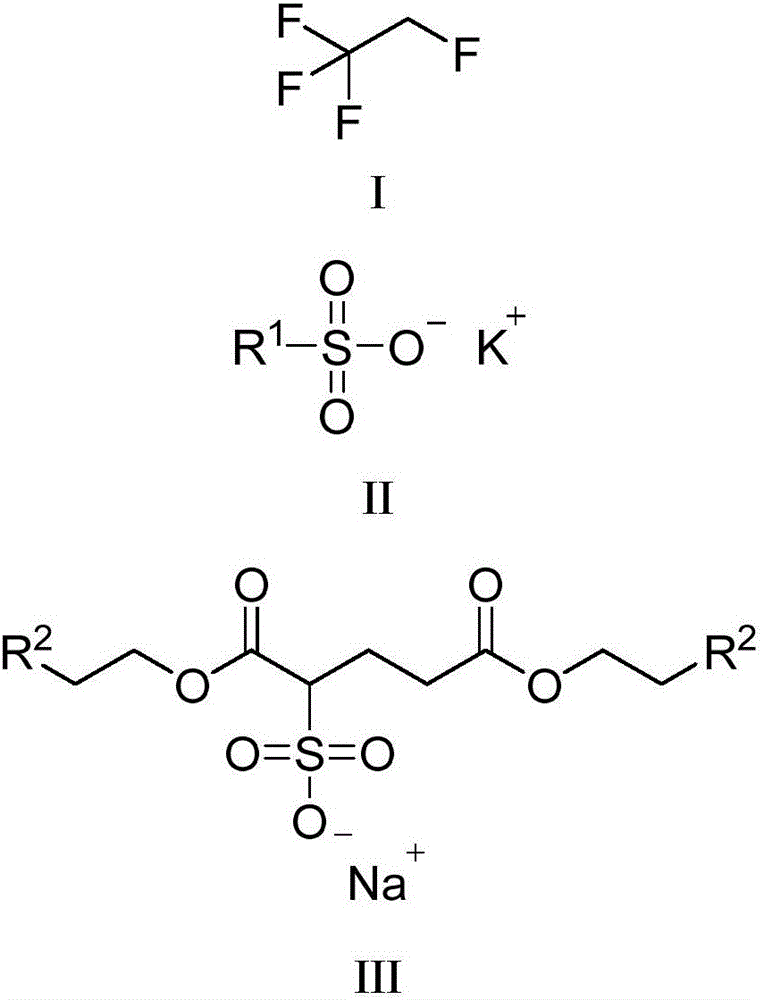

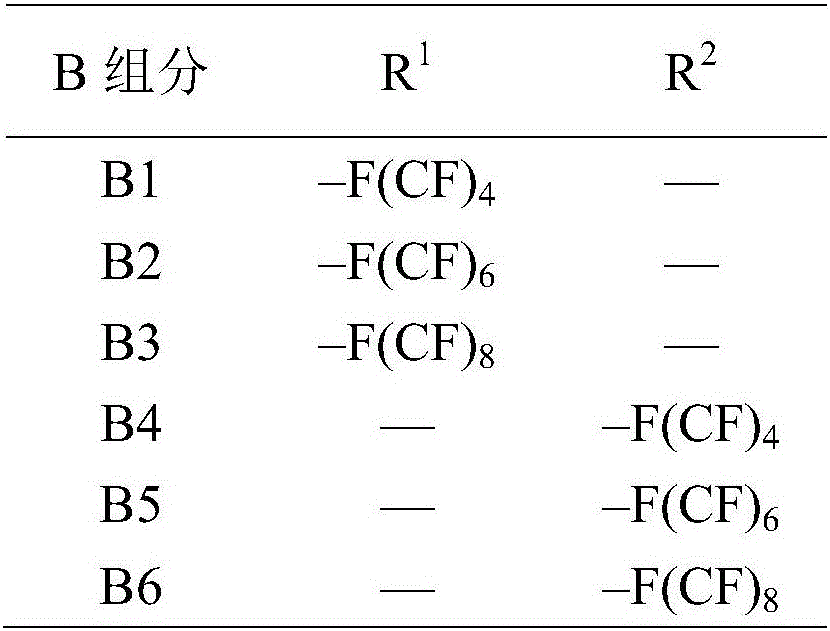

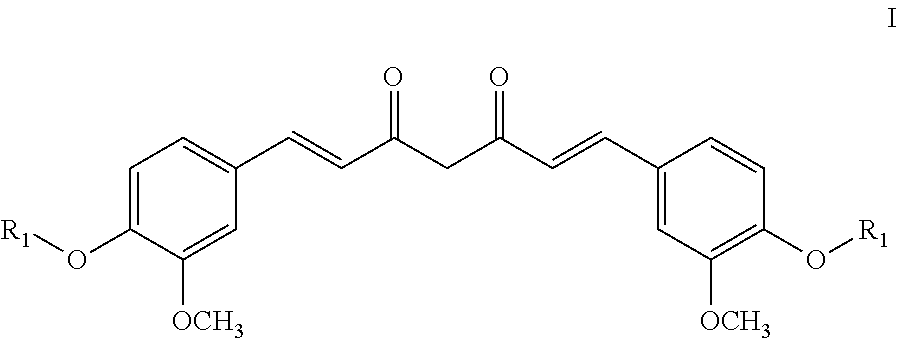

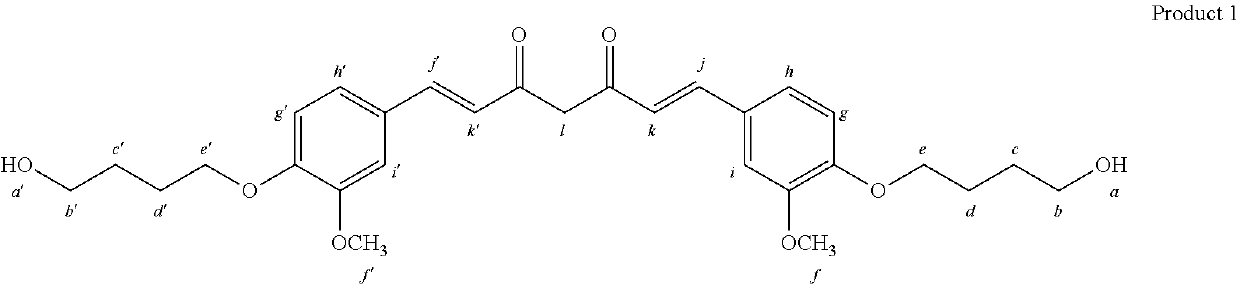

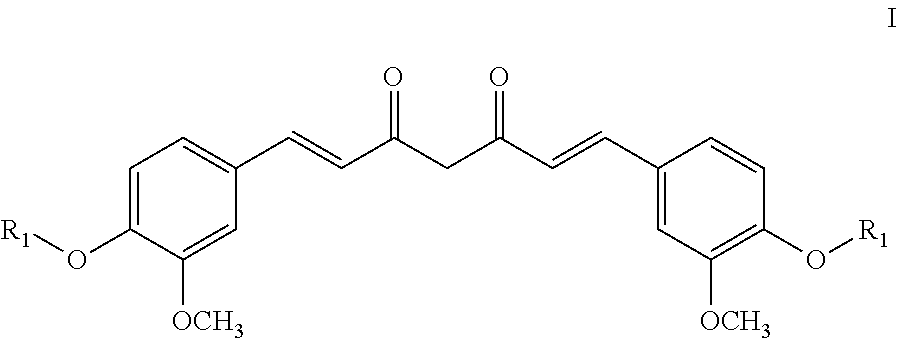

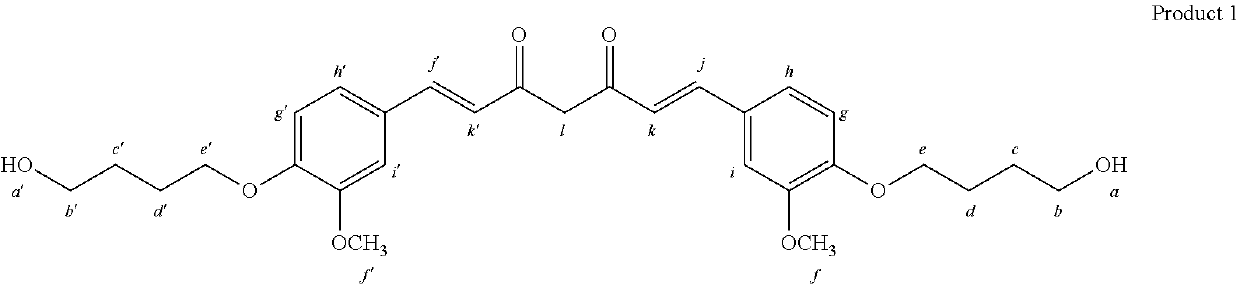

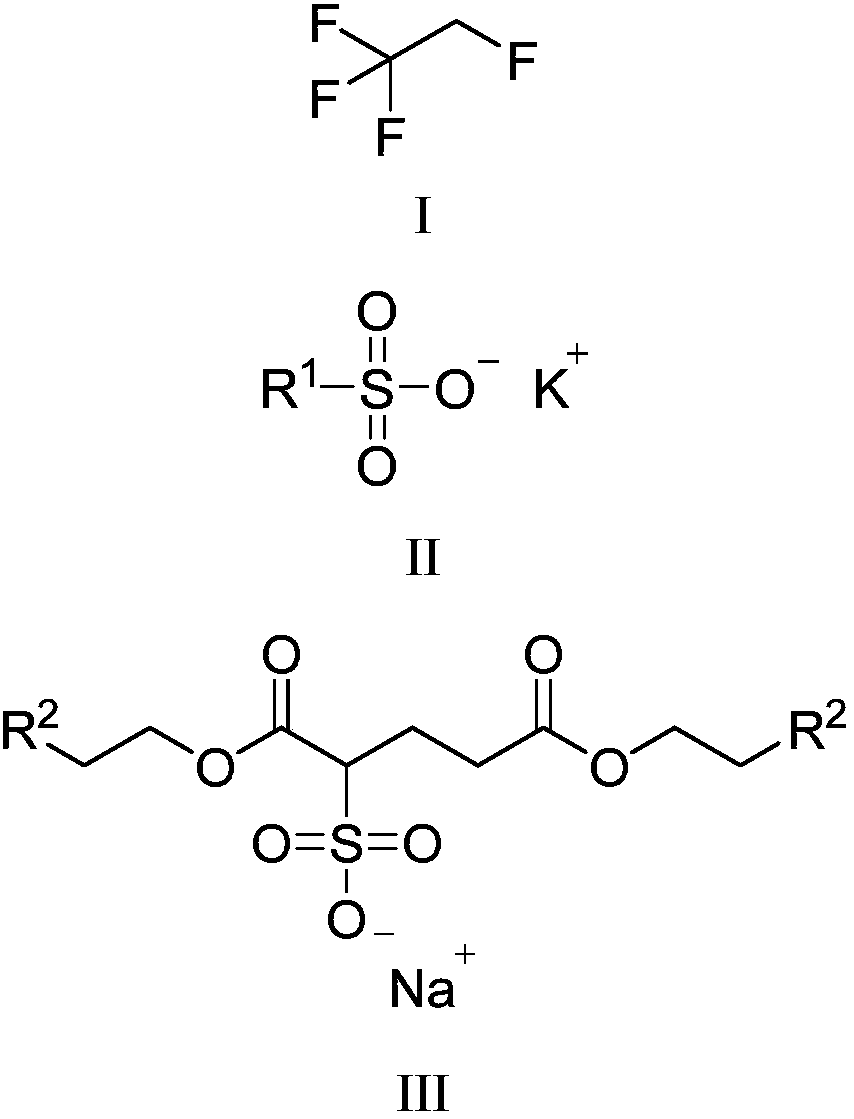

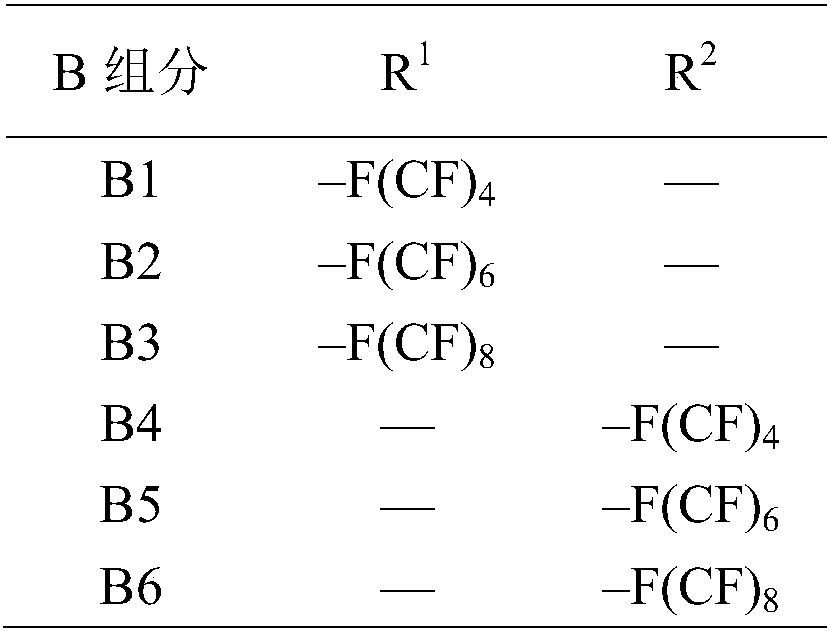

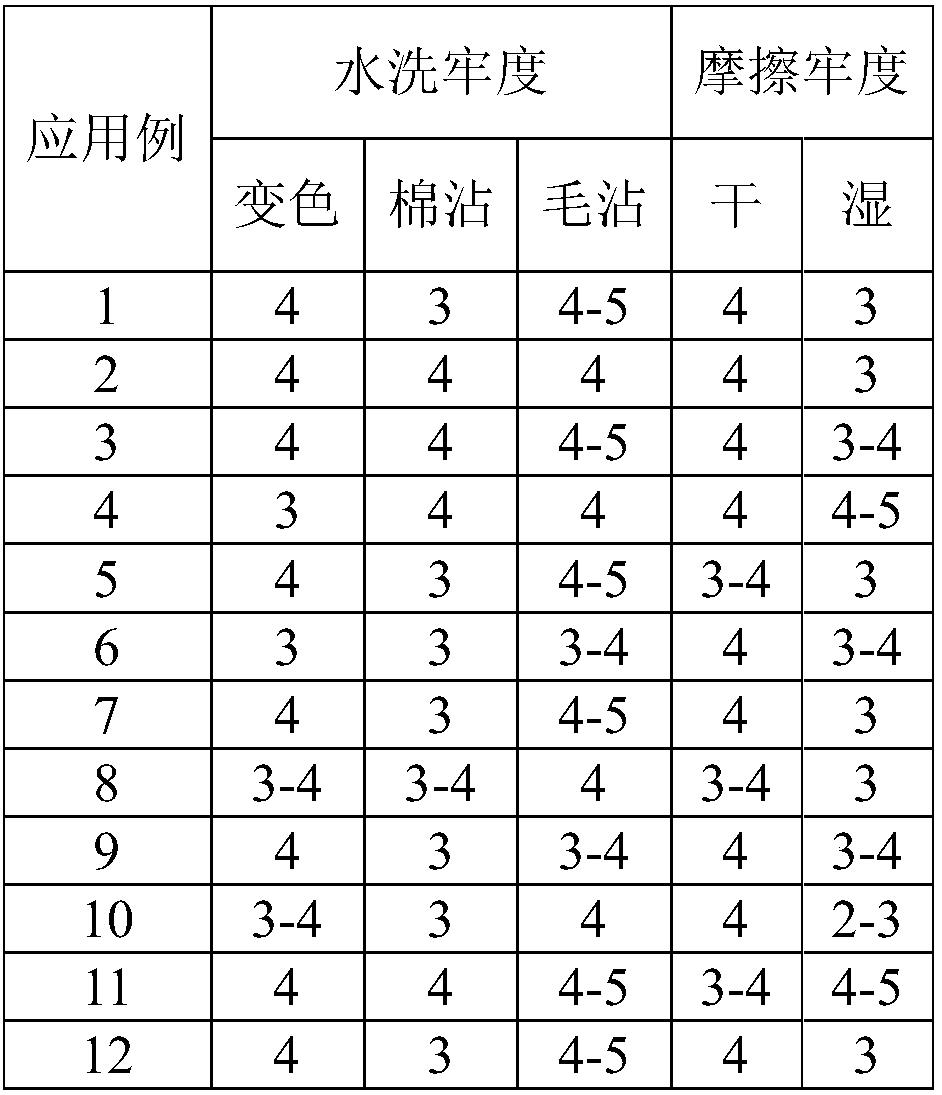

Dyeing auxiliary agent for dyeing supercritical carbon dioxide cotton fiber as well as preparation and application thereof

The invention relates to a dyeing auxiliary agent for dyeing supercritical carbon dioxide cotton fiber as well as a preparation and an application thereof, and belongs to the field of cotton fiber dyeing. The dyeing auxiliary agent for dyeing supercritical carbon dioxide cotton fiber is a composition, and the composition comprises the following components according to the mol ratio: 55-75% of a component A, and 25-45% of a component B, wherein the component A is a compound shown in a formula I, and the component B is one or several kinds of compounds shown in a formula II or a formula III, and R1 is -F(CF)4, -F(CF)6 or -F(CF)8; R2 is -F(CF)4, -F(CF)6 or -F(CF)8. The outstanding features of the dyeing auxiliary agent is that original dyeing technology of the cotton fabric is changed, natural dyes are used for dyeing cotton fiber, and the method has the characteristics of high color depth, high color fastness, clean production, and substantial economic benefits and environment benefits.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Whitening and cationic modification method based on one-bath two-stage process and application

The invention provides a whitening and cationic modification method based on a one-bath two-stage process and an application. The method comprises following steps: fiber and fabric are added to water,part of sodium percarbonate is added, then, alkali is added to regulate pH to be 11-12, and after the temperature is increased to 68-72 DEG C, remaining sodium percarbonate is added for whitening; after whitening, a cationic etherifying agent is added for modification, oxalic acid is added after the temperature is reduced to 38-42 DEG C, the temperature is increased to 58-62 DEG C, and whiteningand cationic modification are completed after neutralization and deoxygenization. According to the method, active oxygen free radicals are utilized for performing bleaching and impurity removal on thefiber and the fabric, meanwhile, double bonds in pigment are damaged by means of strong oxidizing property of alkyl free radicals, and therefore, the fiber and the fabric are faded; whiteness of thefabric and the fiber after pretreatment and bleaching can be increased by about 5 degrees. After the cationic modification of the fiber and the fabric, active bases capable of reacting with dye are increased, the dye-uptake and the exhaustion degree of the dye are increased, and the method has the effects of increasing color depth, reducing dyeing wastewater and the like.

Owner:MELEPHANT SUSTAINABILITY TECH HANGZHOU CO LTD

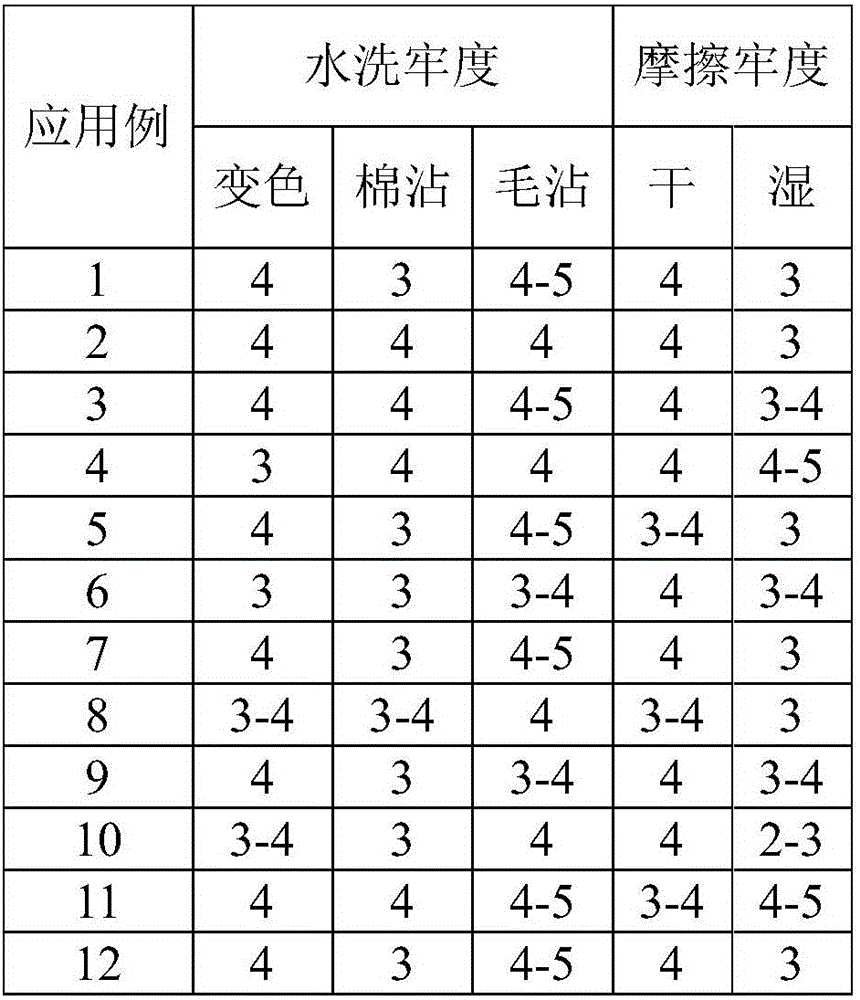

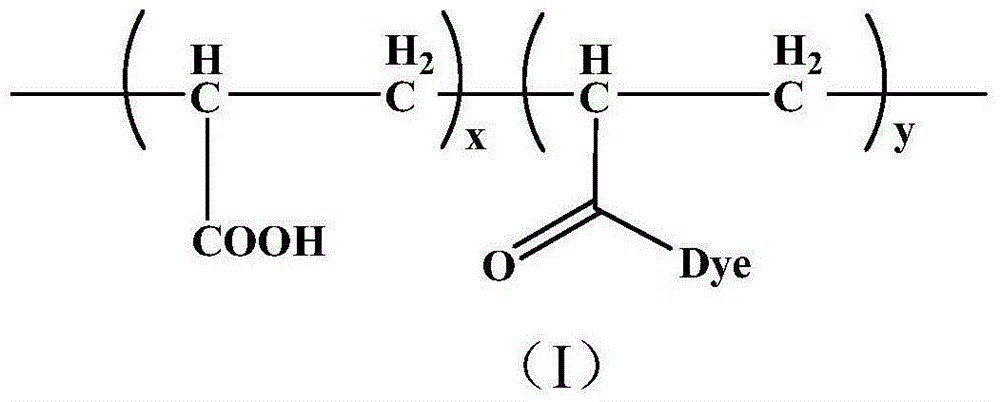

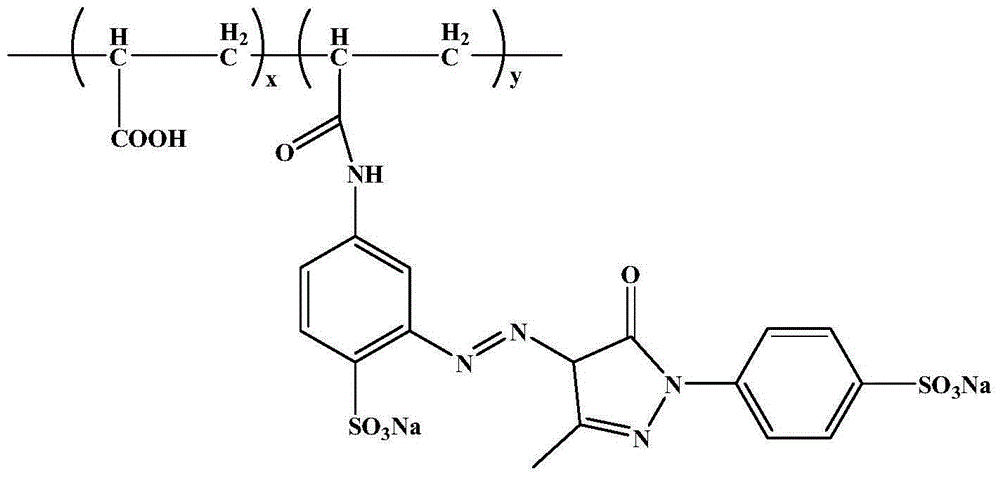

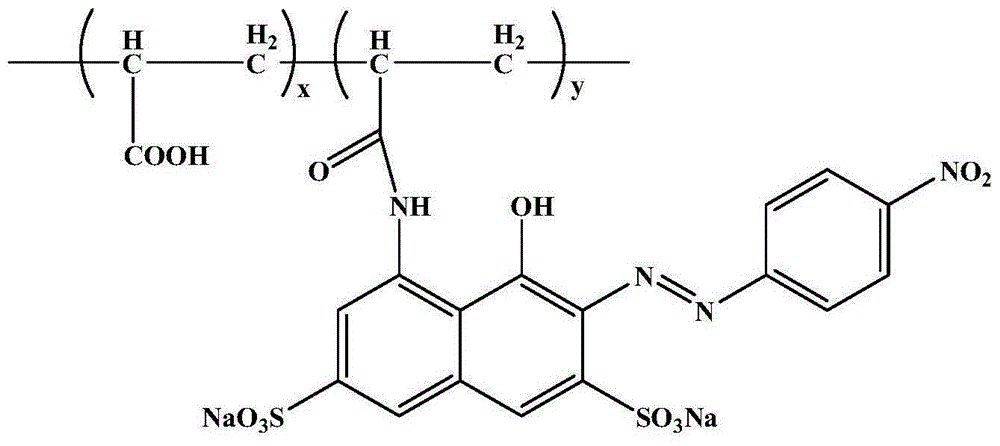

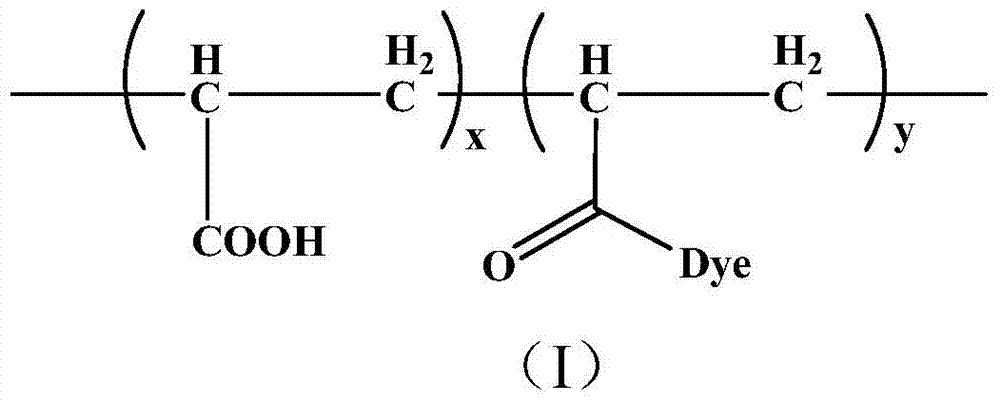

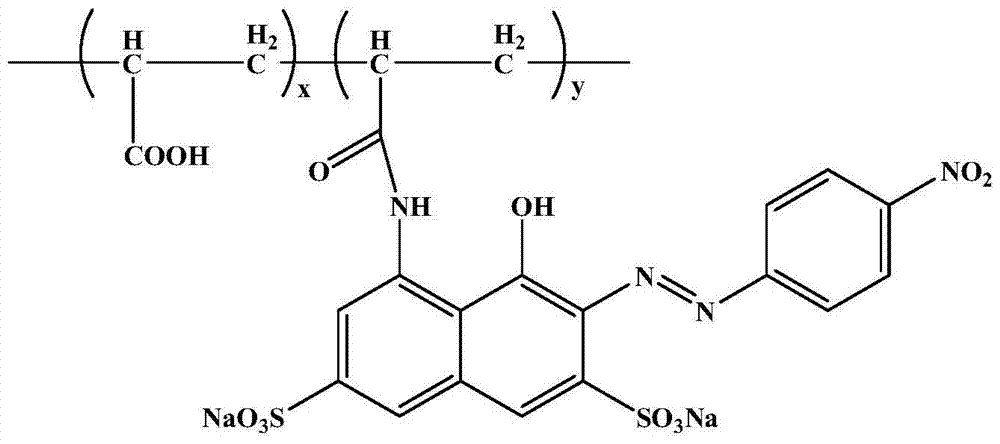

Pigment dyeing liquor for dyeing superfine fibers and method for improving dyeing color depth of superfine fibers

The invention discloses pigment dyeing liquor for dyeing superfine fibers and a method for improving dyeing color depth of the superfine fibers, belonging to the technical field of textile science. According to the invention, an acrylic macromolecular dye is added into the pigment dyeing liquor comprising a water-based pigment paste, an adhesive, a penetrant and other components, the uptake rate of the dye in the superfine fibers is enhanced by virtue of the characteristic that salt bonds can be easily formed between the macromolecular dye and the fibers, and the color depth of the superfine fibers is improved while the excellent color fastness is guaranteed by virtue of the characteristic that a main chain structure of the macromolecular dye is similar to a structure of the adhesive. The technology has the characteristics of simple dyeing process, little pollution, stable product quality, high color depth and the like, and has good application prospects.

Owner:SUZHOU SUNMUN TECH CO LTD

PLA cotton blended fabric

InactiveCN105887520AHigh color depthHigh fastnessBiochemical treatment with enzymes/microorganismsGrip property fibresCatechol oxidasePhytase

The invention discloses a novel PLA cotton blended fabric. The novel PLA cotton blended fabric is prepared through the steps of 1 preprocessing; 2, complex enzyme processing, wherein after preprocessing is performed, the polylactic acid / cotton blended fabric is subjected to dip processing in a complex enzyme, and according to the enzyme processing technological conditions, bromelain, phytase and catechol oxidase mixed processing is adopted; 3, aicd dyeing, wherein the polylactic acid / cotton blended fabric obtained after enzyme processing is performed in the step 2 is subjected to dyeing processing through acid dyes, and according to the dye liquor formula and conditions, the concentration of the acid dyes is 2-3 g / L, the concentration of anhydrous sodium sulphate is 1-2 g / L, peregal O / %(omf) is 0.3%, pH is 4, the temperature is kept to be 50 DEG C, the temperature is increased to 70-80 DEG C after 10 min and kept constant for 60-70 min, and the bath ratio is 1:25; 4, processing performed after washing, wherein the polylactic acid / cotton blended fabric dyed in the step 3 is washed under the temperature of 60-80 DEG C for 5-20 min, and the bath ratio is 1:(5-30).

Owner:CHANGXING BAOSHENG TEXTILE TECH CO LTD

PLA fiber-silk interwoven fabric

InactiveCN106012529AReduce energy consumptionThe treatment process is safe and environmentally friendlyDry-cleaning apparatus for textilesWrinkle resistant fibresTrehalosePolymer chemistry

The invention discloses a PLA (Polylactic Acid) fiber-silk interwoven fabric, which is prepared by the following steps: (1) pretreatment: 83dtexPLA / 88dtex PLA fiber-silk interwoven fabric is selected, put into a pretreatment solution, completely immersed, and maintained at 30-40 DEG C for 30-40 min, wherein the pretreatment solution is composed of 1% of trehalose, 0.05% of water-soluble chitosan and the balance of pure water; (2) compound enzyme treatment: the PLA fiber-silk interwoven fabric after pretreatment is immersed in a compound enzyme, wherein the process conditions of the enzyme treatment are as follows: 1 U / mL Bromelain, 6 U / mL phytase, 20-25 U / mL catechol oxidase, pH 7, temperature of 38 DEG C, time of 20-30 min, and a bath ratio of 1: 10; and (3) washing after-treatment: the PLA fiber-silk interwoven fabric after the enzyme treatment of step (2) is subjected to soaping treatment at 60-80 DEG C for 15-25 min at the bath ratio of 1:5.

Owner:CHANGXING BAOSHENG TEXTILE TECH CO LTD

Laser backlight lamp assembly, backlight module and display device

ActiveUS20170038520A1Improve conversion efficiencyHigh color depthMechanical apparatusLighting heating/cooling arrangementsPhosphorDisplay device

The present invention provides a laser backlight lamp assembly, having a LED light bar and a laser light bar at one side of the LED light bar, and a laser light source of the laser light bar is a green laser light diode; a LED lamp of the LED light bar has a base, a heat sinker installed in the base, a blue light lampwick fixed on the heat sinker and a light housing, and colloid containing fluoride red phosphor is filled inside the base, and the colloid covers the blue light lampwick, and the light housing covers the base and houses the colloid, and the laser light source of the laser light bar and the LED light bar illumine at the same time to be backlight lamps. The present invention further provides a backlight module and a display device.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Performance testing system and testing method for TOD (Triangle Orientation Discrimination threshold)

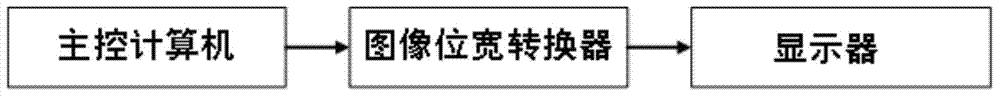

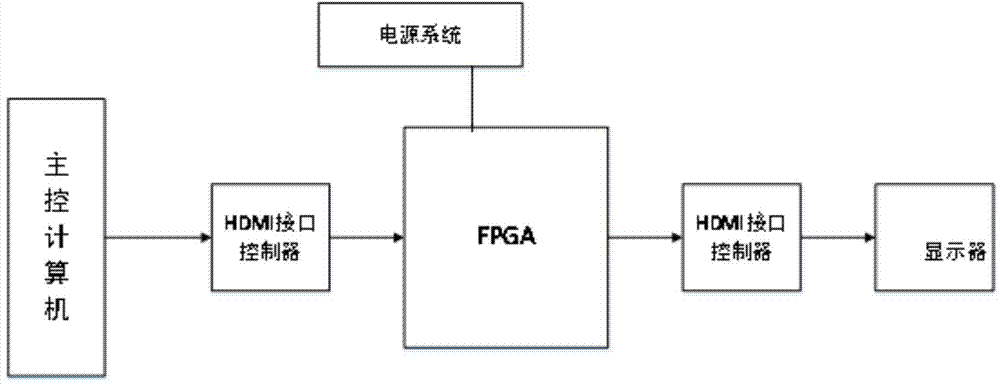

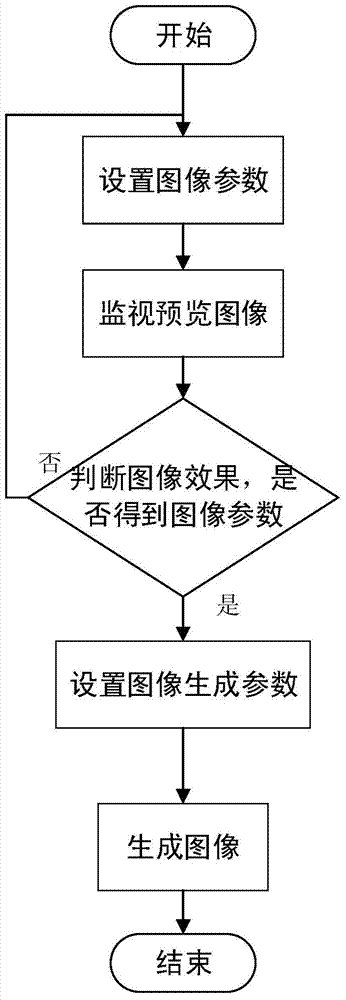

InactiveCN104270629AMinimum Contrast ReductionIncrease bit widthTelevision systemsDiscrimination thresholdDisplay device

The invention discloses a performance testing system and a testing method for a TOD (Triangle Orientation Discrimination threshold). The performance testing system comprises a main control computer, an image bit width converter and a display, wherein the main control computer comprises an image generating module and a TOD performance testing module; the image generating module is used for finishing parameter setting of a test image, generation of the image and preview of the image; the TOD performance testing module is used for finishing playing of the test image from the image generating module, recording a judgment result on the target direction of the test image, and transmitting the test image to the image bit width converter; and the image bit width converter is used for realizing bit width conversion of the test image. According to the performance testing system and the testing method, the bit width of the test image is increased from 8 bits to 10 bits or 12 bits by adopting the image bit width converter, and the minimum contrast is decreased from 1 / 256 to 1 / 1024, so that cost is reduced; and the color depth of the image is tested easily and conveniently by adopting the TOD, so that the minimum contract of the test image is decreased, and the testing correctness and the testing accuracy of the TOD are increased.

Owner:XIDIAN UNIV

Two-medium circulating dyeing method with high dye-uptake and color fastness

The invention relates to a two-medium circulating dyeing method with high dye-uptake and color fastness, and belongs to the field of fabric dyeing. The method comprises the following steps of pre-swelling fibers in a pad dyeing solution, and padding the pre-swollen fibers; putting the padded fibers into a supercritical carbon dioxide dyeing kettle, and dyeing the padded fibers; placing the dyed fibers in a cleaning tank to be cleaned in a solvent of a pad dyeing solution; and putting the cleaned fibers into a supercritical carbon dioxide drying kettle, and drying the cleaned fibers. Accordingto the method disclosed by the invention, the problems of dye hydrolysis, high solvent consumption, high circulation difficulty and the like are thoroughly avoided while high color depth and small chromatic aberration of the dyed fibers are ensured.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Dye for Dyeing Cotton Fiber in Supercritical Carbon Dioxide, Preparation Method and Application Thereof

ActiveUS20190233650A1High color fastnessClean manufacturingOrganic chemistryMethine/polymethine dyesFiberColour fastness

The present disclosure discloses a dye for industrialization of dyeing cotton fiber in supercritical carbon dioxide that can react with cotton fiber, wherein a preparation method therefor comprises the following steps: dissolving a hydroxyl-containing natural dye in an organic solvent, dropwise adding an alcohol compound containing a halogen group into a reaction system in the presence of an acid-binding agent, precipitating the product with another solvent after the reaction is completed, and then filtrating and drying to obtain the compound described. The obtained compound is used for dyeing cotton fiber in supercritical carbon dioxide. The dye provided by the present disclosure is capable of dyeing cotton fiber in supercritical carbon dioxide conditions, and has a better color fastness while dyeing the cotton fiber.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method and system for converting lvds video signal to dp1.2 video signal

ActiveCN105516632BIncrease display resolutionHigh color depthStatic indicating devicesConversion with cinematograph film standardInterference resistanceComputer architecture

The invention relates to a method and system for converting an LVDS video signal into a DP1.2 video signal, and the method comprises the steps: enabling the LVDS video signal to be converted into an RGB video signal; carrying out the buffering and frequency multiplication of the RGB video signal, and the outputting a frequency multiplication signal; carrying out the configuration and transformation of DP1.2 conversion of the outputted frequency multiplication signal according to a DP1.2 conversion configuration command and a DP1.2 conversion starting command, and obtaining a DP1.2 video signal. The method carries out the detection of the maximum DP1.2 video resolution, is high in integration degree, is reliable in operation, is strong in capability of interference resistance, is simple in operation, is economical and practical, can improve the detection reliability and efficiency of a DP1.2 liquid crystal module group, reduces the equipment cost and production cost, and will further facilitate the popularization of related display equipment.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

A method for enzymatic wool dyeing

ActiveCN104264490BHigh color depthHigh fastnessBiochemical fibre treatmentDyeing processCellulaseAcid dye

The invention discloses a method for enzymatic wool dyeing. The steps include: (1) Enzyme treatment: after scouring, soak wool fiber products in a compound enzyme solution; wherein, the enzymatic treatment process conditions are: papain 10- 12U / mL, polyphenol oxidase 3-6U / mL, cellulase 12-15U / mL, pH7, temperature 30-50°C, time 0.5-1h, bath ratio 1:10; (2) acid dyeing: the step (1) After enzymatic treatment, wool fiber products are dyed with acid dyes; (3) Post-washing treatment: wash the fabric after step (2) at 30-100°C for 5-20 minutes, and the liquor ratio is 1:5-30 .

Owner:CHANGXING GUOYUAN PRINTING & DYEING

Dyeing and fishing method for brocade/viscose fiber/spandex knitting fabric

InactiveCN102444033BReduce tensionLess prone to wrinklesFibre treatmentDyeing processEngineeringFishing

The present invention discloses a dyeing and fishing method for brocade / viscose fiber / spandex knitting fabric. The method comprises processes of open-width pre-shrinking, scouring and dyeing in one bath, low temperature neutralizing and soaping, acid dyeing, soaping, drying and softening finishing. The open-width pre-shrinking process is performed by adopting a steaming shrinking machine. The scouring and dyeing in one bath process comprises: adding 1-2 g / l of a refined degreasing agent, and 2-3 g / l of an aqueous solution of soda to a dye vat, treating for 15-20 minutes at a temperature of 60-80 DEG C, then adding an active dye, 25-70 g / l of sodium sulfate, and 20g-25 g / l of soda, dyeing for 50-70 minutes at the temperature of 60-65 DEG C. The dyeing and fishing method for the brocade / viscose fiber / spandex knitting fabric has characteristics of simple operation, treatment time saving and low energy consumption. With the method of the present invention, the amount of the sewage discharge can be effectively reduced, and the prepared finished product has good hand feeling and full color.

Owner:杭州天宇印染有限公司

Dye for dyeing cotton fiber in supercritical carbon dioxide, preparation method and application thereof

ActiveUS10745564B2Low color depthPoor color fastnessOrganic chemistryMethine/polymethine dyesColour fastnessOrganic solvent

The present disclosure discloses a dye for industrialization of dyeing cotton fiber in supercritical carbon dioxide that can react with cotton fiber, wherein a preparation method therefor comprises the following steps: dissolving a hydroxyl-containing natural dye in an organic solvent, dropwise adding an alcohol compound containing a halogen group into a reaction system in the presence of an acid-binding agent, precipitating the product with another solvent after the reaction is completed, and then filtrating and drying to obtain the compound described. The obtained compound is used for dyeing cotton fiber in supercritical carbon dioxide. The dye provided by the present disclosure is capable of dyeing cotton fiber in supercritical carbon dioxide conditions, and has a better color fastness while dyeing the cotton fiber.

Owner:DALIAN POLYTECHNIC UNIVERSITY

A fabric dyeing darkening functional agent and its preparation method and application

The invention discloses a fabric dyeing and deepening functional agent, a preparation method and application thereof. The formula of the fabric dyeing and deepening functional agent comprises the following components in parts by weight: 1 to 5 parts of barbaloin, 1 to 5 parts of alkyl glycoside, 2 to 8 parts of flavonoid glycol and 70 parts of water; the preparation method for the fabric dyeing and deepening functional agent comprises the steps of mixing and uniformly stirring various components in the formula above, and standing; the fabric dyeing and deepening functional agent is applied to a dyeing process of a direct dye or an active dye of a fabric. The formula of the fabric dyeing and deepening functional agent disclosed by the invention is simple in component, environment-friendly and convenient to use; the dyeing process does not need to be changed and new equipment does not need to be added; the fabric dyeing and deepening functional agent can be widely applied to the direct dye or active dye dyeing of real silk, wool, cotton, hemp and recycled cellulose fibre fabrics and blended and interwoven fabrics; the colour depth and the colour fastness can be remarkably improved; meanwhile, the using amount of the dye can be reduced; the energy consumption and the sewage discharging can be reduced; the application prospect is wide.

Owner:SUZHOU INST OF TRADE & COMMERCE

A kind of dyeing auxiliary agent for supercritical carbon dioxide cotton fiber dyeing and its preparation and application

The invention relates to a dyeing auxiliary agent for dyeing supercritical carbon dioxide cotton fiber as well as a preparation and an application thereof, and belongs to the field of cotton fiber dyeing. The dyeing auxiliary agent for dyeing supercritical carbon dioxide cotton fiber is a composition, and the composition comprises the following components according to the mol ratio: 55-75% of a component A, and 25-45% of a component B, wherein the component A is a compound shown in a formula I, and the component B is one or several kinds of compounds shown in a formula II or a formula III, and R1 is -F(CF)4, -F(CF)6 or -F(CF)8; R2 is -F(CF)4, -F(CF)6 or -F(CF)8. The outstanding features of the dyeing auxiliary agent is that original dyeing technology of the cotton fabric is changed, natural dyes are used for dyeing cotton fiber, and the method has the characteristics of high color depth, high color fastness, clean production, and substantial economic benefits and environment benefits.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Dyeing method of cotton product reduced dye with low bath ratio

The invention discloses a dyeing method of cotton product reduced dye with low bath ratio and belongs to the textile dyeing and finishing processing technical field. The dyeing method aims to solve problems of large consumption of dyestuffs during dyeing of conventional cotton product reduced dyes and difficult control of surface color uniformity of dyed objects. The dyeing method employs nitrogen as protective gas. Based on elimination of air in a dyeing device, uniform adsorption and diffusion of reduced dye leuco compound sodium salt on cotton fiber are achieved. Combined with water washing, oxidation and soaping, dyeing of cotton product reduced dye with low bath ratio is finished. The concrete technological process comprises steps: reduction and dissolution of a dye, elimination of air in a dyeing device, dyeing of the reduced dye, oxidation, soaping and drying. When the dyeing method is compared to conventional dyeing technologies, the dyeing uniformity of cotton product dyed objects is improved; the dyeing depth and the dyeing fastness are increased; the consumption of dyestuffs is decreased under condition of the same surface color depth of dyed objects; the discharge of dyeing waste water is reduced; the production energy consumption is lowered.

Owner:浙江环发纺织印染有限公司

A method for deepening the color appearance of pongee dyed fabrics

ActiveCN108004802BDefects that avoid prone to damageAvoid Damage DefectsDyeing processDisperse dyePre treatment

The invention relates to a method for deepening color appearance of polyester pongee dyeing fabric, and belongs to the technical field of textile dyeing and finishing. Ester bond hydrolase is used forperforming pretreatment on the polyester pongee fabric by taking polyester as a raw material, then disperse dyes are used for performing dyeing, and finally, amino silicon oil is used for performingpadding, baking and finishing so as to enable the color appearance of the polyester pongee dyeing fabric to be deepened. The method comprises the following technological processes: (1) performing pretreatment by a polyester pongee enzyme method; (2) performing dyeing by the disperse dyes; and (3) performing finishing by the amino silicon oil. Compared with the deepening method of direct padding inthe amino silicon oil or the deepening method of combining alkali weight reduction pretreatment and amino silicon oil padding and baking, by using the enzyme method under the conditions of low temperature and near neutral, the roughness of a fiber surface is increased, easy damage of alkali treatment is avoided, the influence to the environment is little, and carboxyl groups and hydroxyl groups generated on the fiber surface can form higher bonding force with the amino silicon oil, thereby being favorable for increasing the color depth of the polyester pongee dyeing fabric.

Owner:江苏大同宝富纺织科技有限公司

Method and application of one-bath two-step whitening and cationic modification

The method and application of a one-bath two-step method for whitening and cationic modification provided by the present invention include the following steps: adding fibers and fabrics to water, adding part of sodium percarbonate, adding alkali to adjust pH=11-12, and raising the temperature After reaching 68-72°C, add the remaining sodium percarbonate to whiten; And, after oxygen removal, complete whitening and cationic modification. The method uses active oxygen free radicals to bleach and remove impurities from fibers and fabrics, and at the same time destroys double bonds in pigments through the strong oxidizing properties of hydrocarbon radicals to make them fade. After pretreatment and bleaching of fabrics and fibers, the whiteness can be increased by about 5 degrees. After cationic modification of fibers and fabrics, active bases that can react with dyes are added, the dye uptake rate and exhaustion rate of dyes are improved, and the color depth is improved, and dyeing wastewater is reduced.

Owner:MELEPHANT SUSTAINABILITY TECH HANGZHOU CO LTD

Pigment dye solution for dyeing superfine fiber and method for improving color depth of superfine fiber dyeing

The invention discloses a paint dye solution for dyeing superfine fibers and a method for improving the color depth of superfine fiber dyeing, belonging to the field of textile science and technology. In the present invention, acrylic macromolecular dyes are added to the paint dyeing liquid containing water-based pigment paste, adhesives, penetrating agents and other components, and the characteristics of easy formation of salt bonds between macromolecular dyes and fibers are used to improve the super The uptake of dyes in fine fibers, and the use of the similarity between the main chain structure of macromolecular dyes and the binder structure, ensures excellent color fastness while improving the color depth of ultrafine fibers. This technology has the characteristics of simple dyeing process, less pollution, stable product quality, high color depth, etc., and has a good application prospect.

Owner:SUZHOU SUNMUN TECH CO LTD

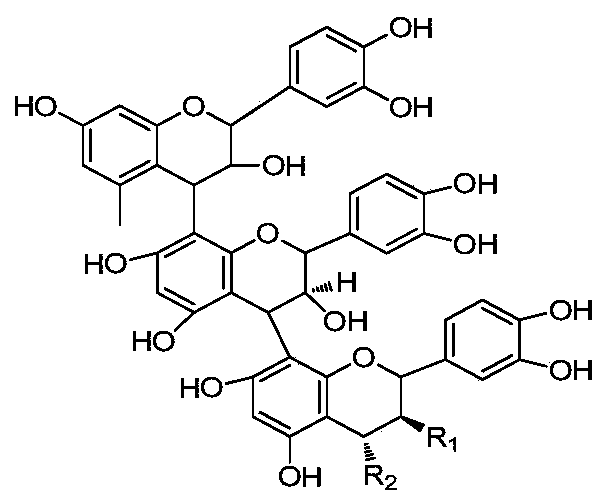

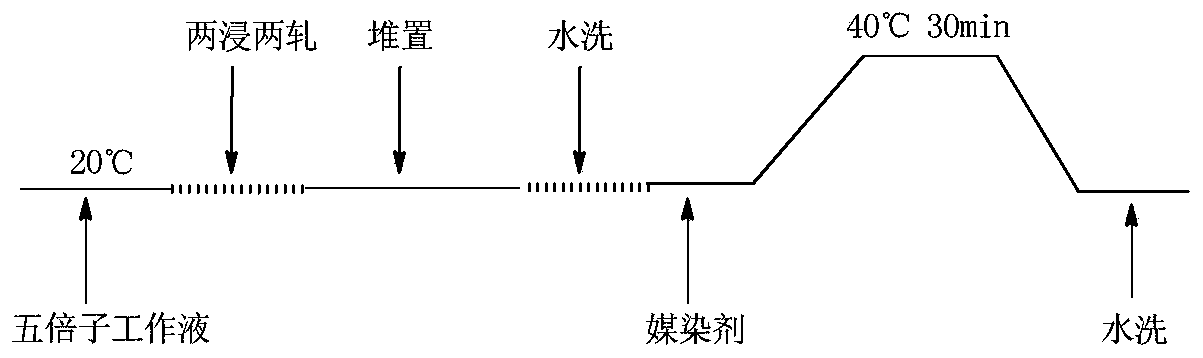

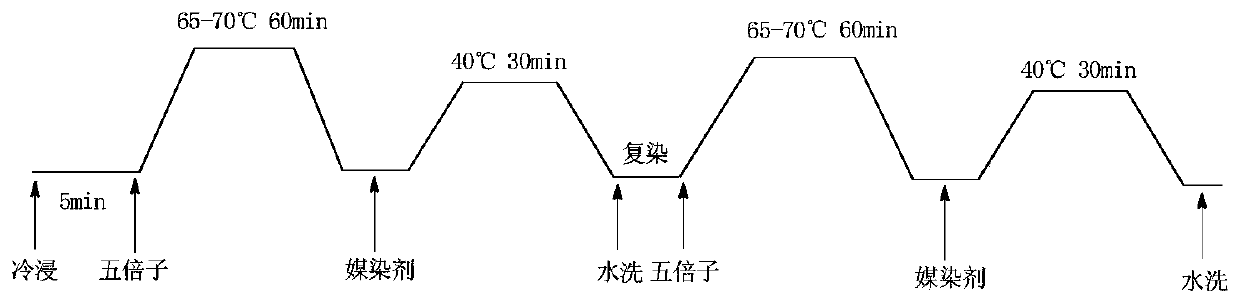

A cold pad-batch process for preparing gray-black pure linen fabric

The invention relates to the field of textile dyeing and particularly relates to a cold pad-batch process for preparing a grey black pure-flax fabric. The process comprises the steps: carrying out two-dipping two-rolling by using a gall nut natural dye according to a bath ratio of 1: 20 at the temperature of 20 DEG C, carrying out batching-up, and carrying out clean water washing for later use; carrying out constant temperature preserving for 30 minutes at the temperature of 40 DEG C according to a bath ratio of 1: 30 in a manner that the HAc concentration is 1g / L to 4g / L and the ferrous sulfate concentration is 3g / L to 7g / L, and carrying out water washing, soaping and baking, thereby preparing the grey black pure-flax fabric. According to the process, the natural dye is extracted from gall nuts which serve as a raw material; through a normal-temperature cold pad-batching process, the contact time of pigments and fibers is prolonged, and the infiltration performance of the pigments is improved; a grey black is achieved through mordant dyeing, and thus, the process will play a role in directing the large-scale production of plant dyed black flax fabrics.

Owner:CHANGZHOU MYSUN BIOLOGICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com