Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Guaranteed to run automatically" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

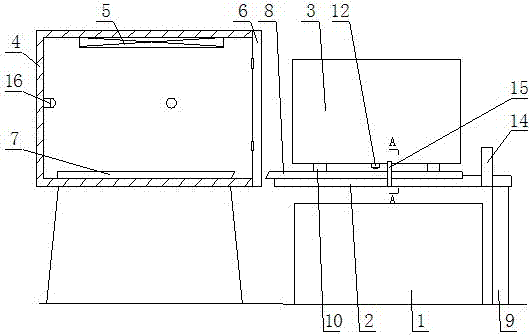

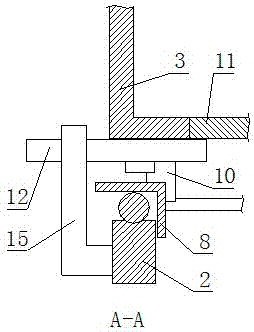

Ice cream vending machine

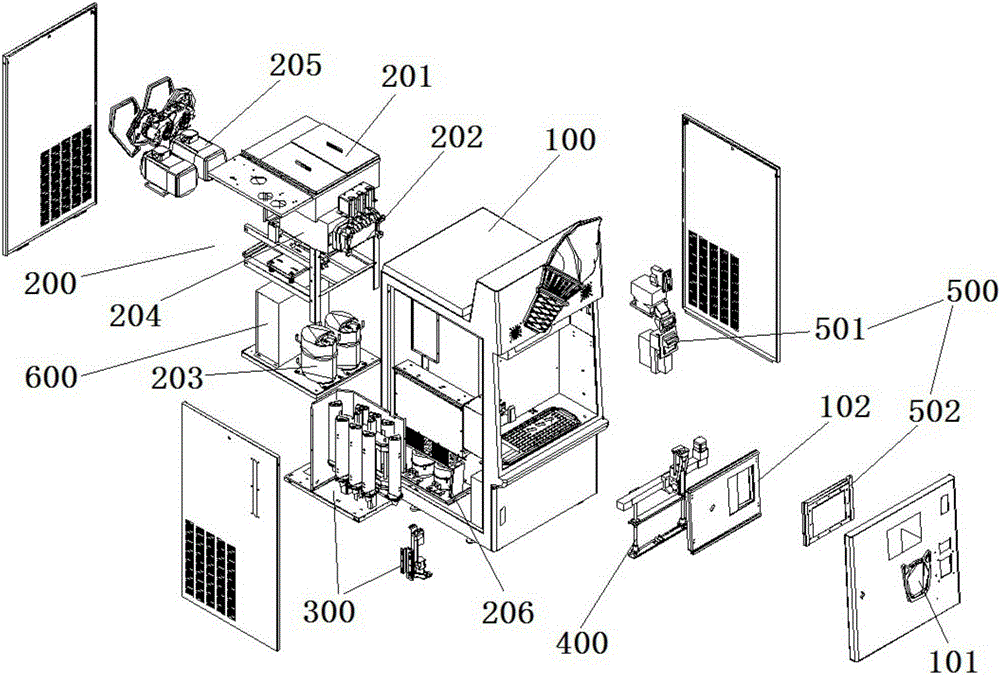

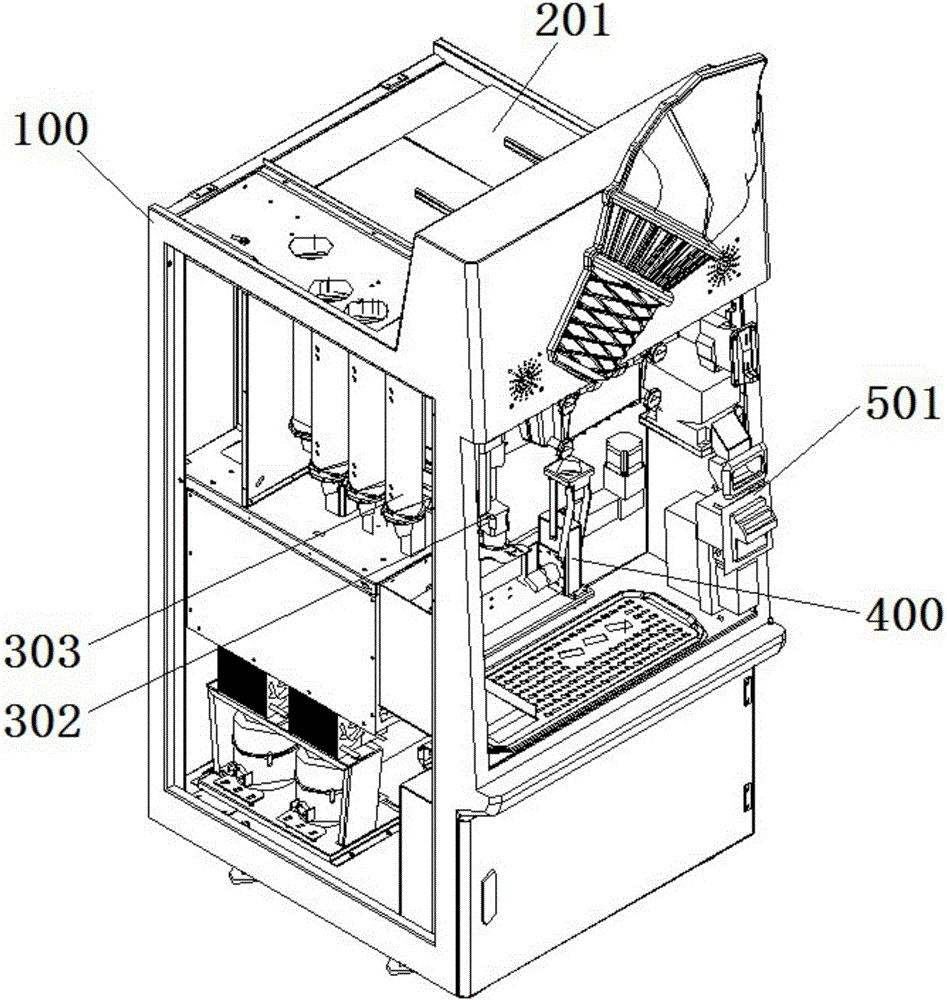

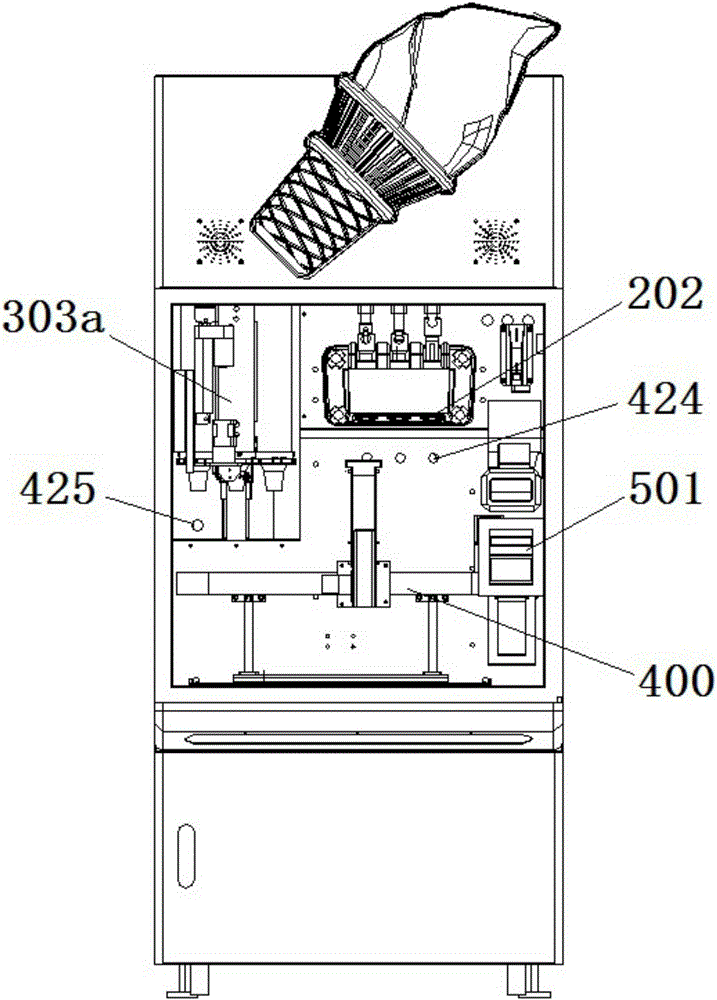

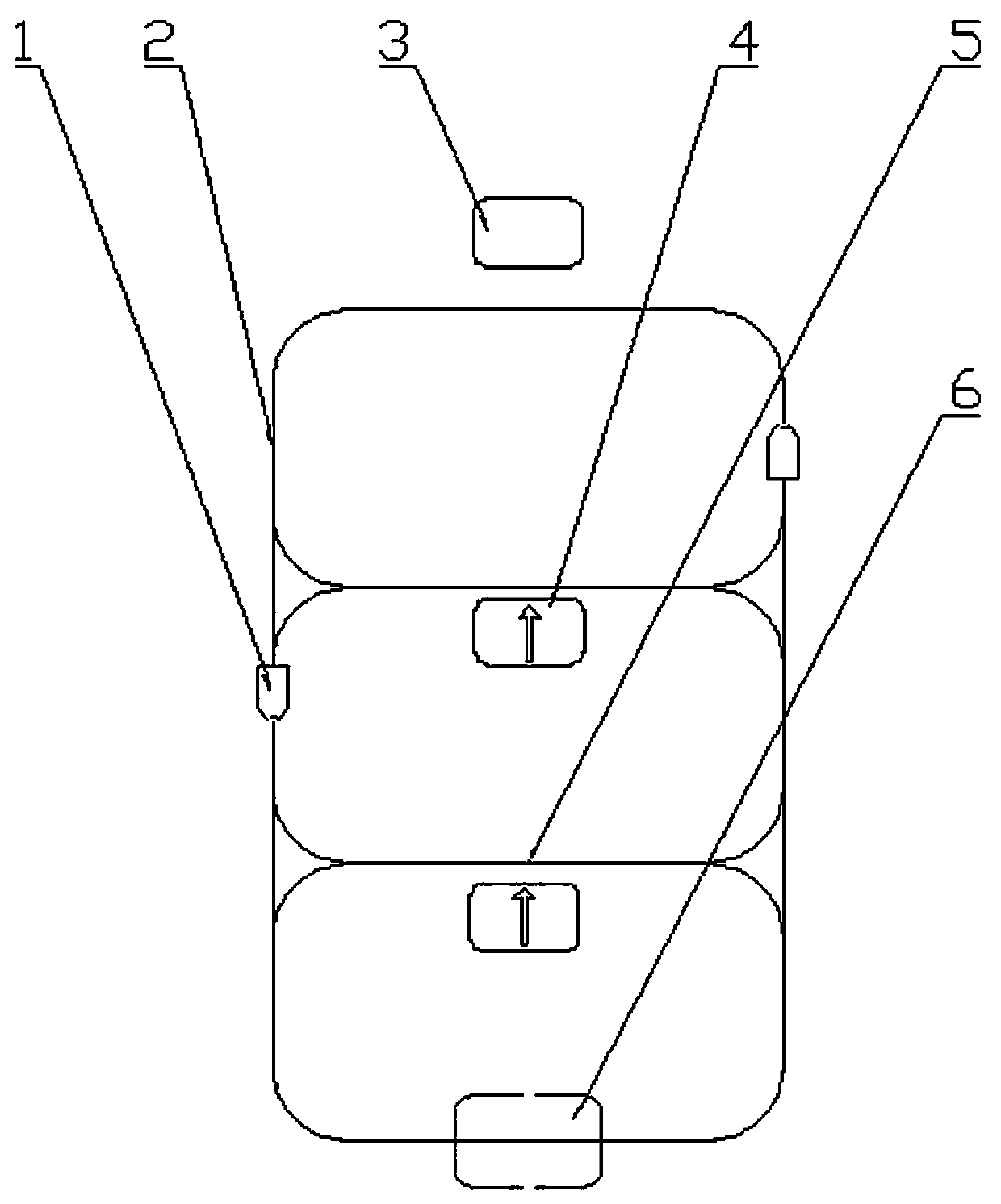

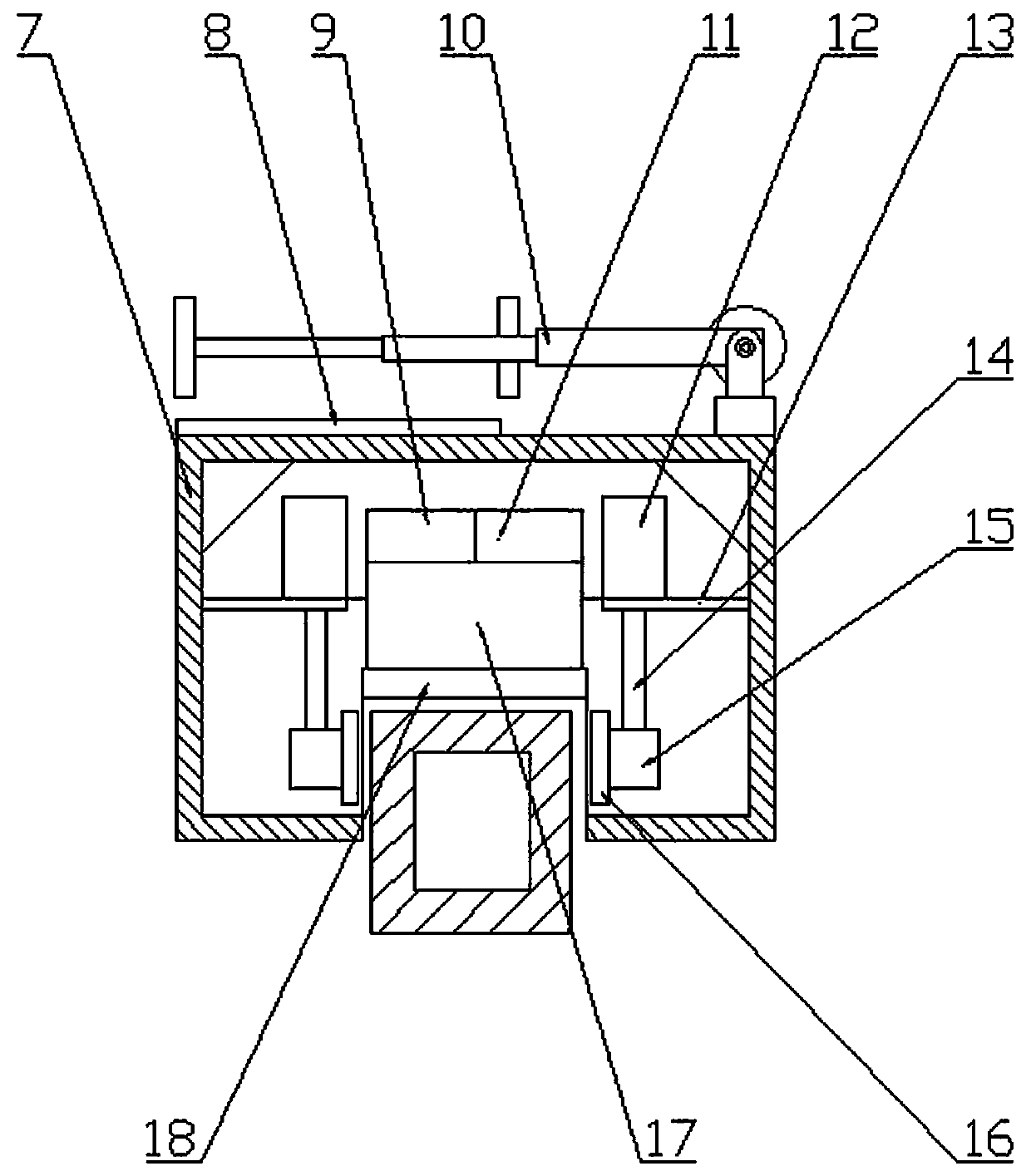

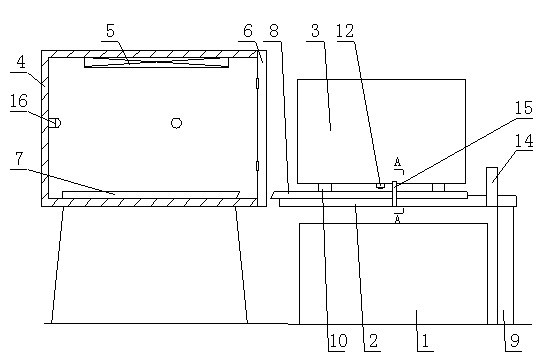

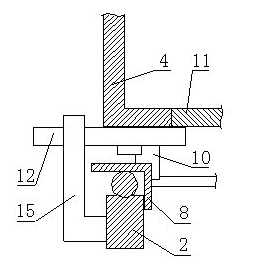

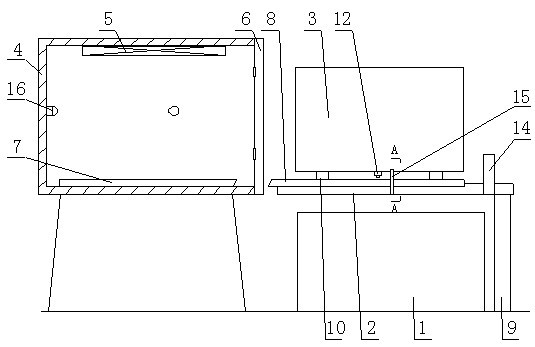

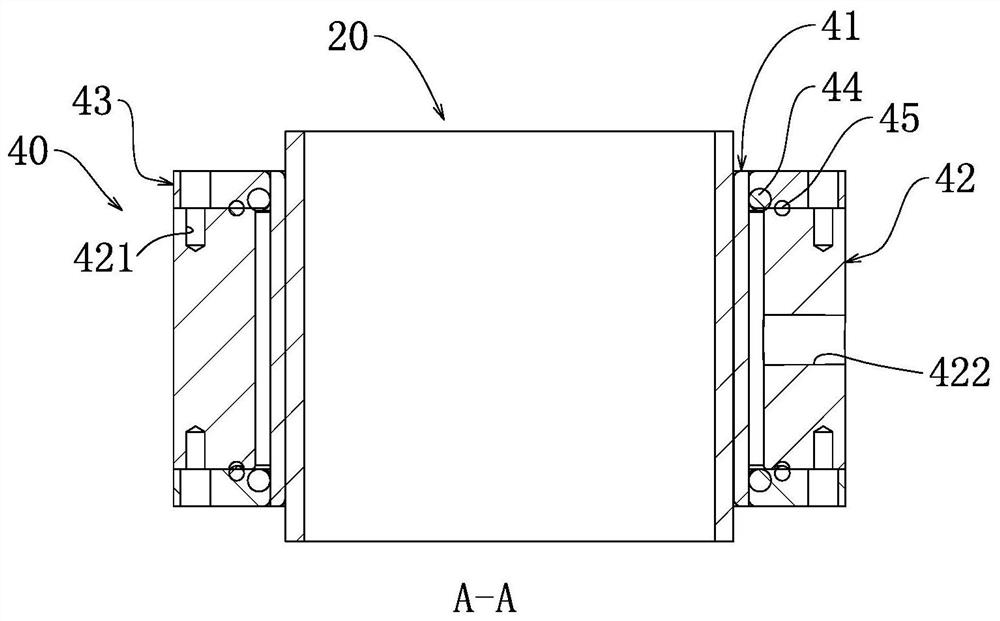

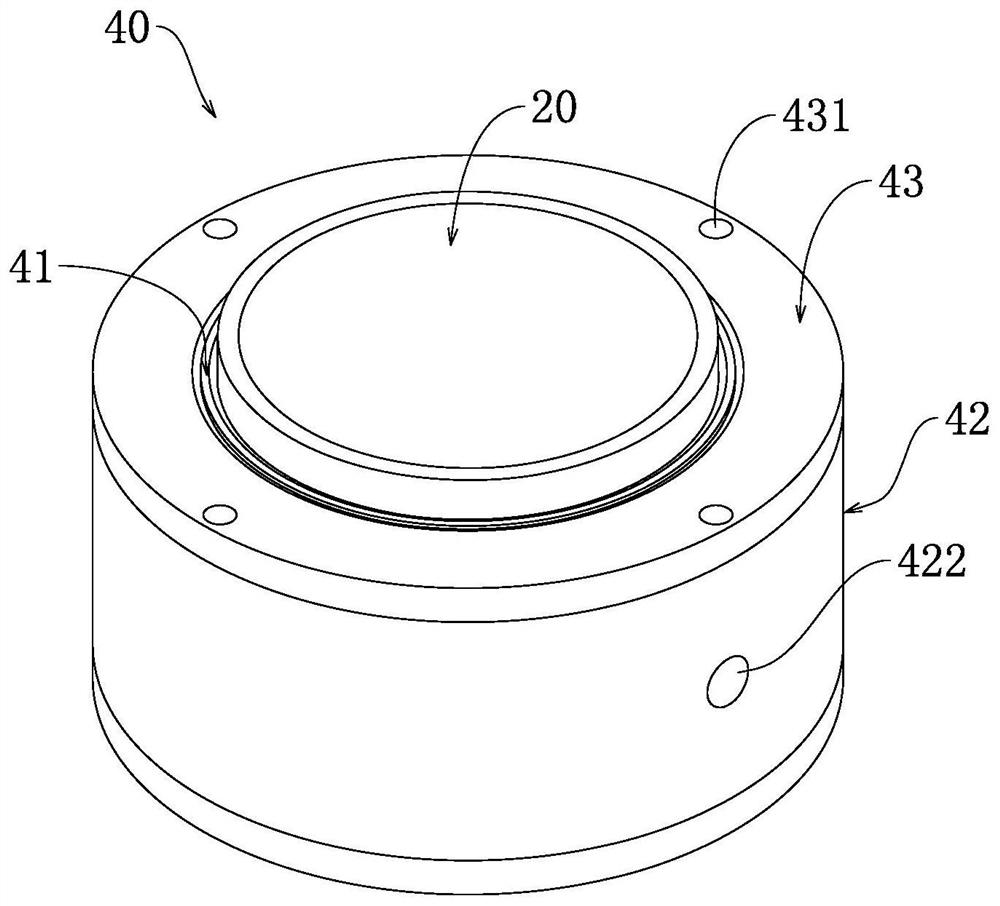

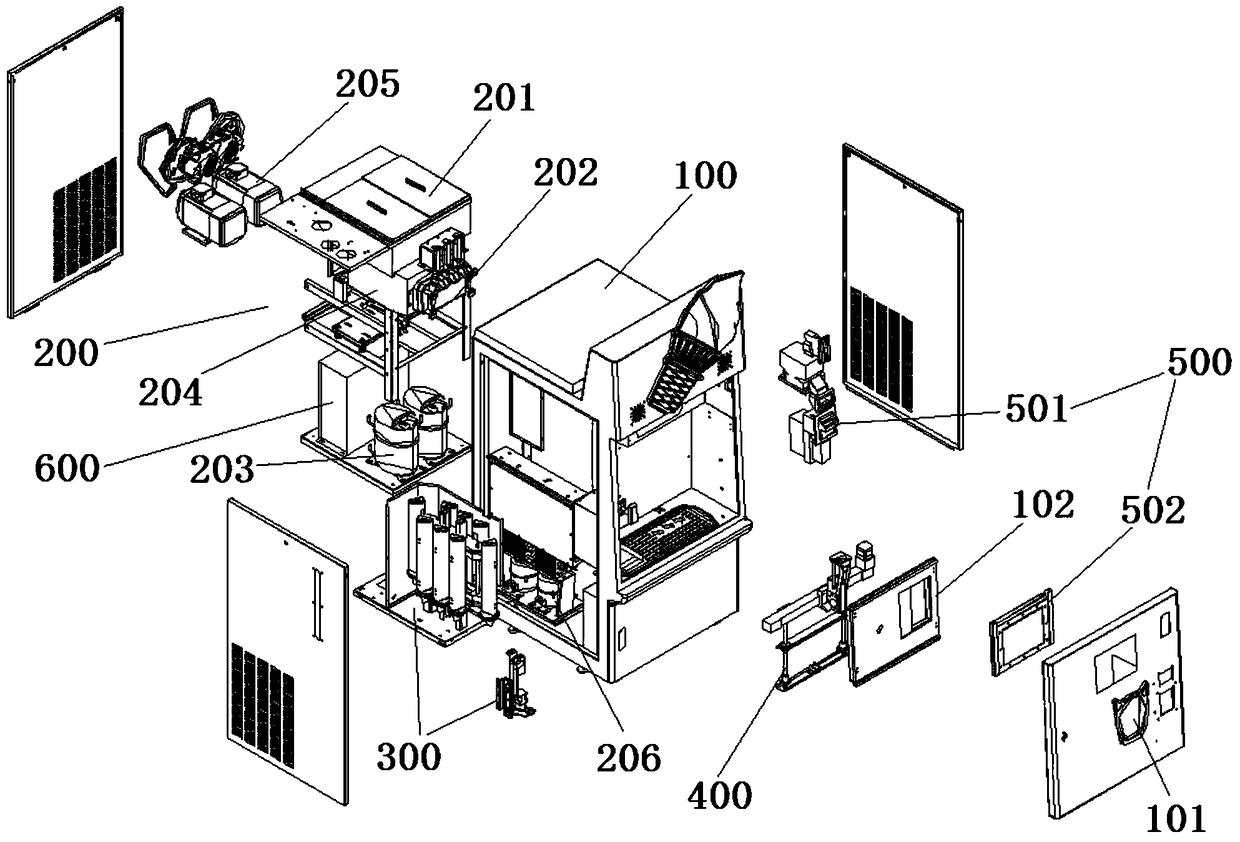

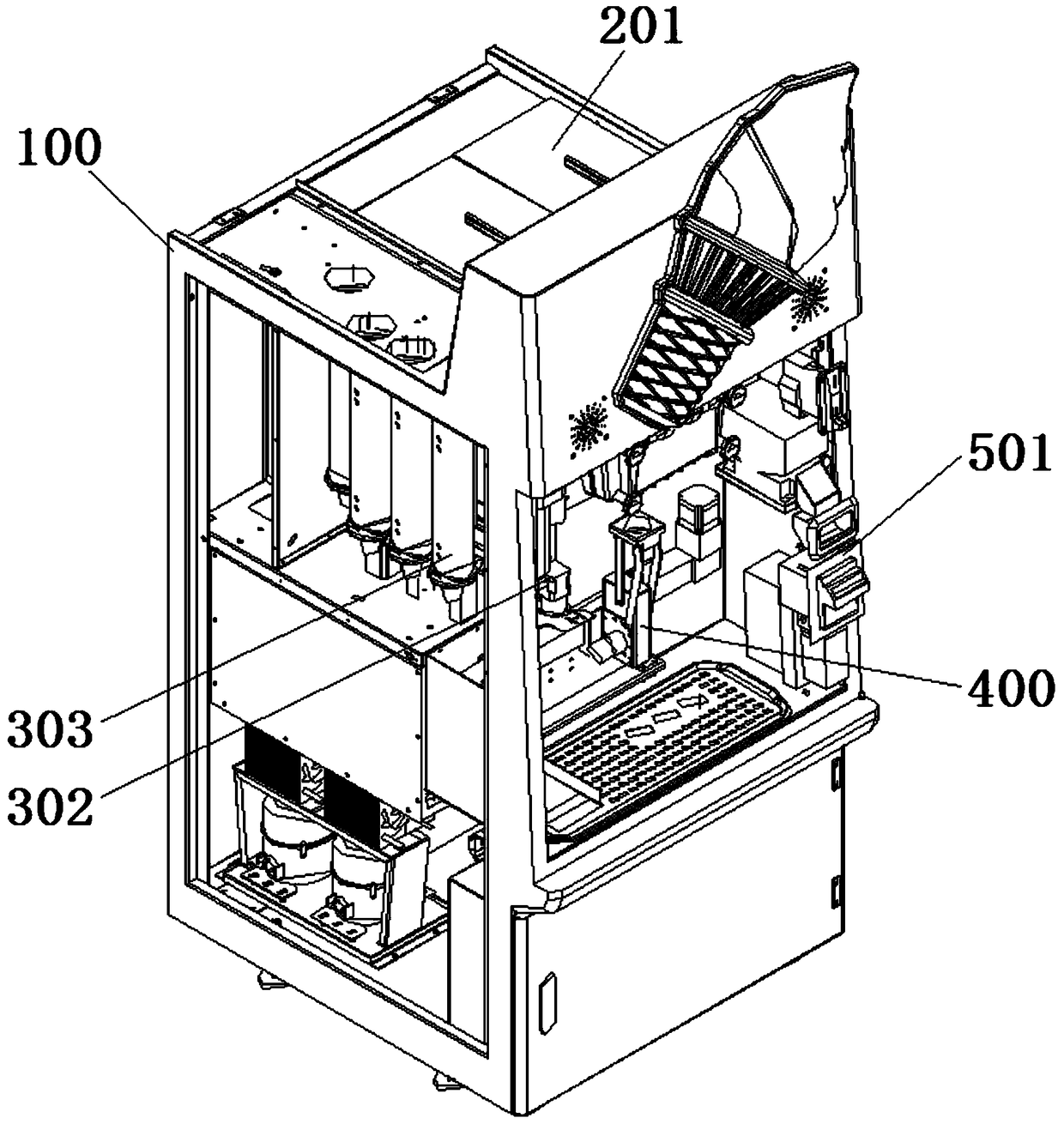

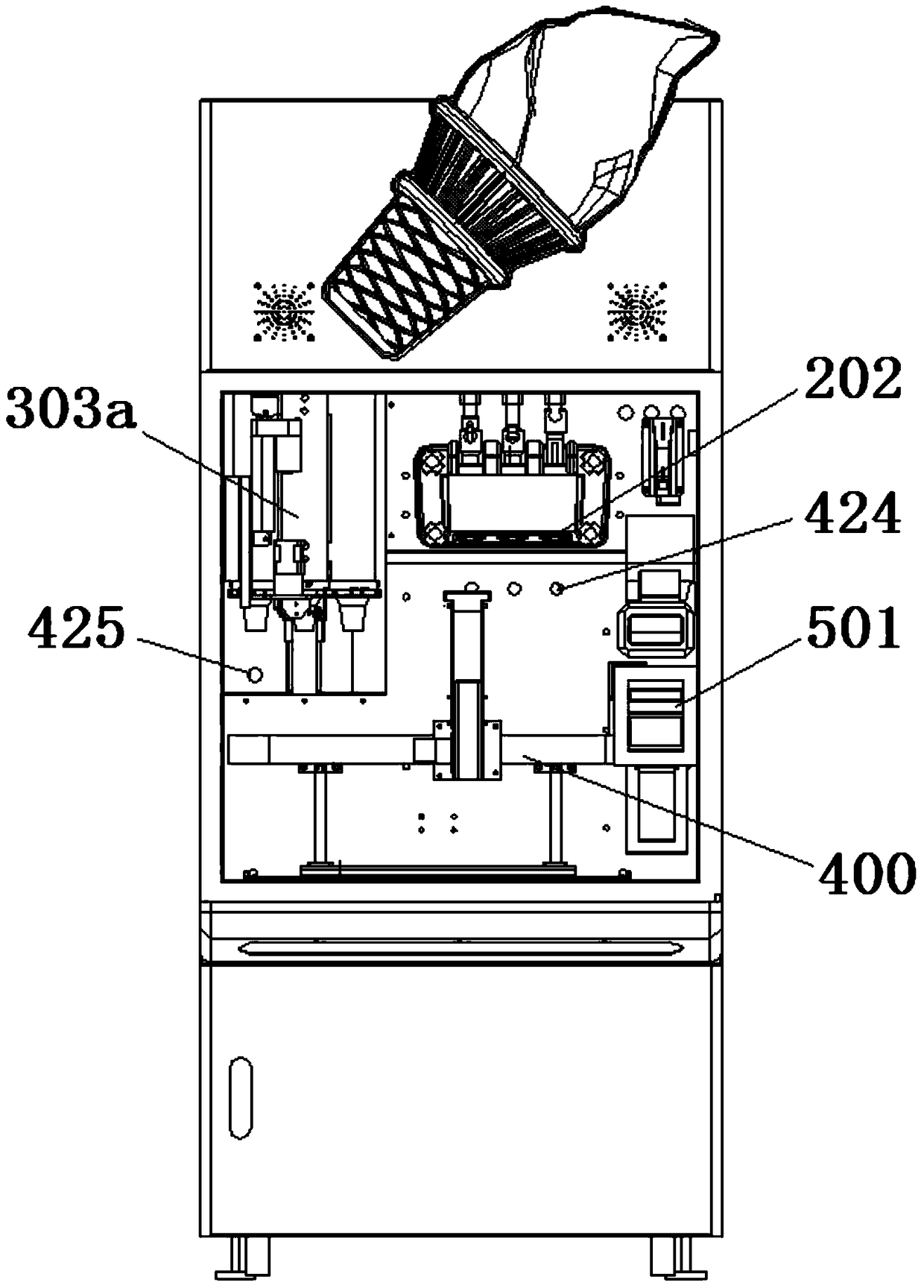

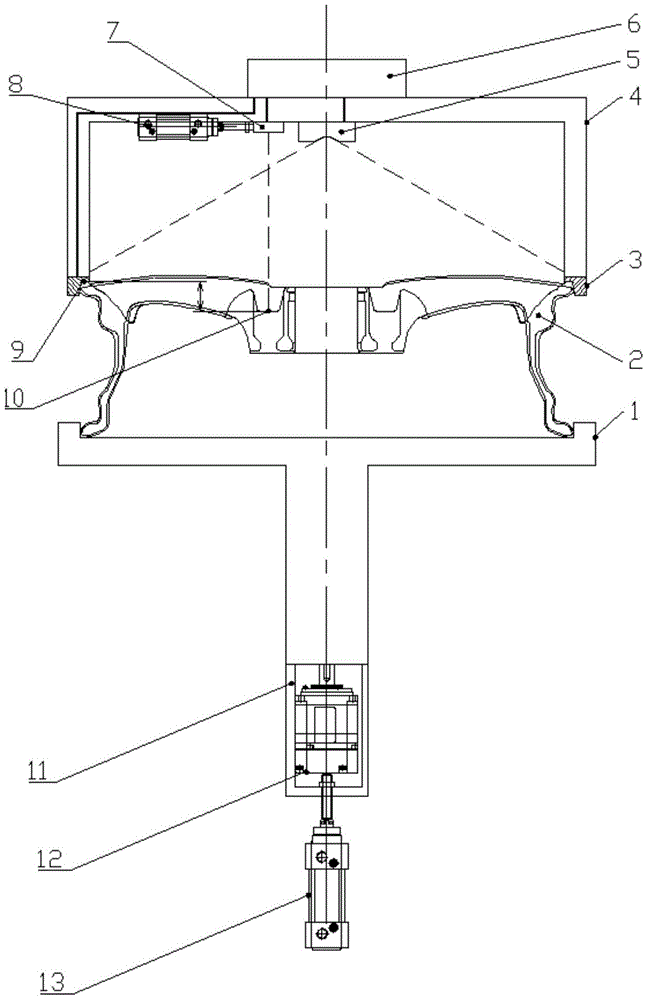

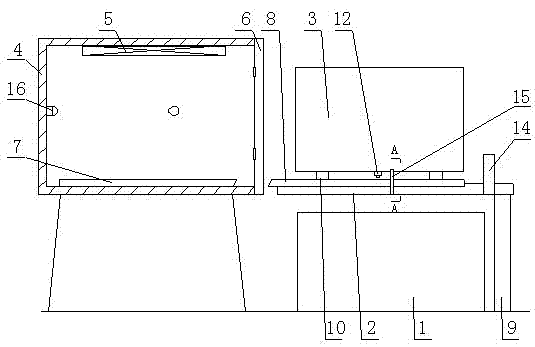

The invention provides an ice cream vending machine. The ice cream vending machine comprises a machine body and an ice cream making unit, a cone supply unit, a material receiving and goods delivery unit and an operating unit, which are installed on the machine body and are connected with a control unit, wherein the material receiving and goods delivery unit is arranged between the ice cream making unit and the cone supply unit and comprises a lifting support mechanism, a horizontal transport mechanism and a material receiving and goods delivery mechanism; the lifting support mechanism is installed in the machine body; the horizontal transport mechanism is installed on the lifting support mechanism and is driven by the lifting support mechanism to move up and down; the material receiving and goods delivery mechanism is installed on the horizontal transport mechanism and is driven by the horizontal transport mechanism to move left and right; when receiving materials, the material receiving and goods delivery mechanism can vertically place cones below discharge holes; and when delivering goods, the material receiving and goods delivery mechanism can obliquely place the cones toward the inside of the machine body and extend out of a goods delivery hole. The problem that traditional ice cream vending machines need to depend on manpower to hold the cones with hands to receive ice cream can be solved by adopting the ice cream vending machine.

Owner:GUANGZHOU GUANGSHEN ELECTRIC PROD CO LTD

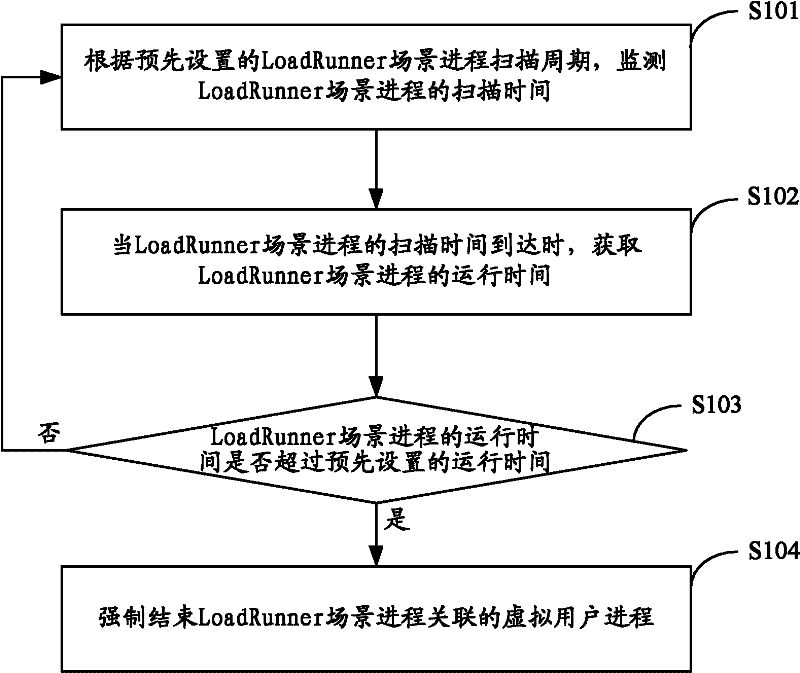

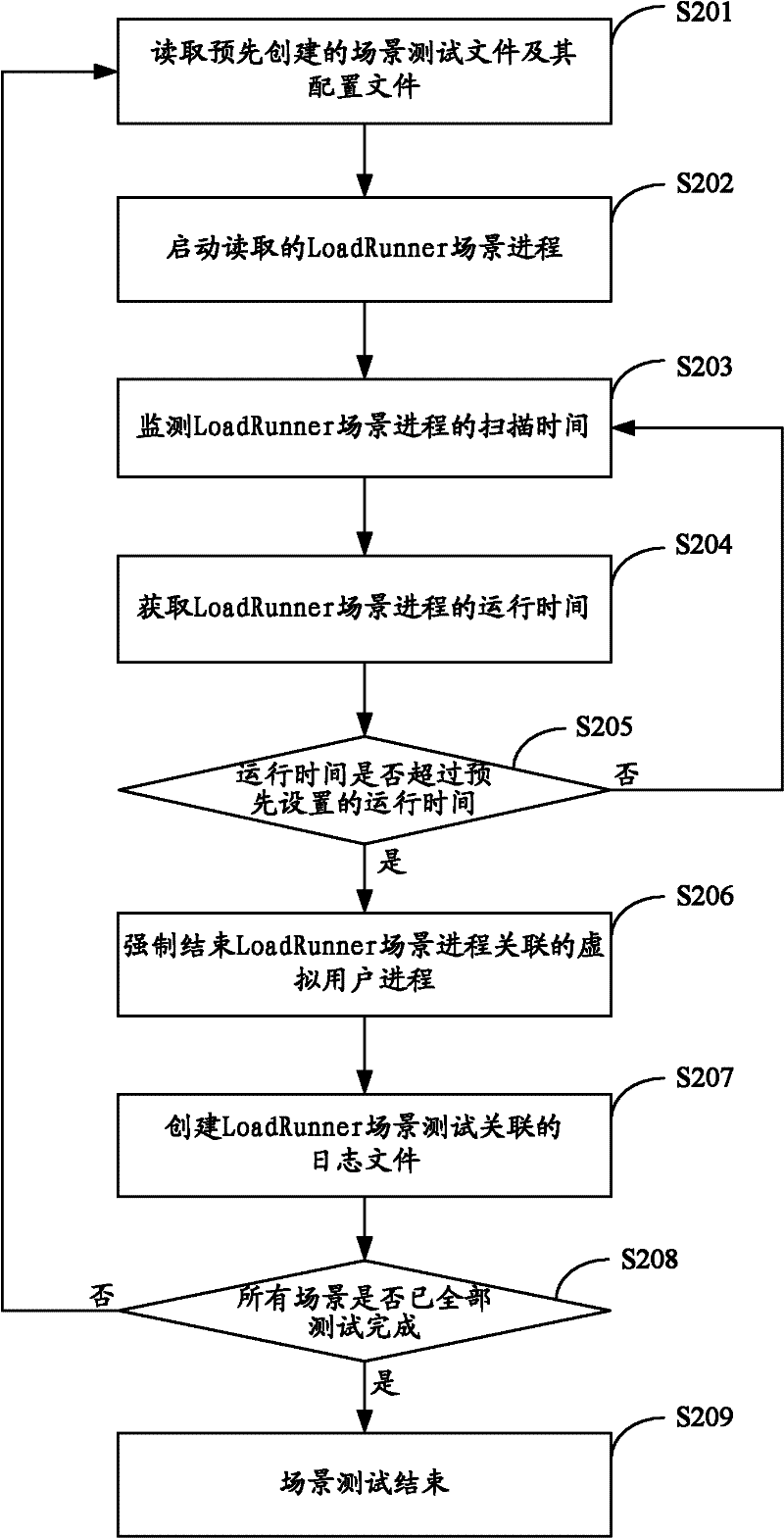

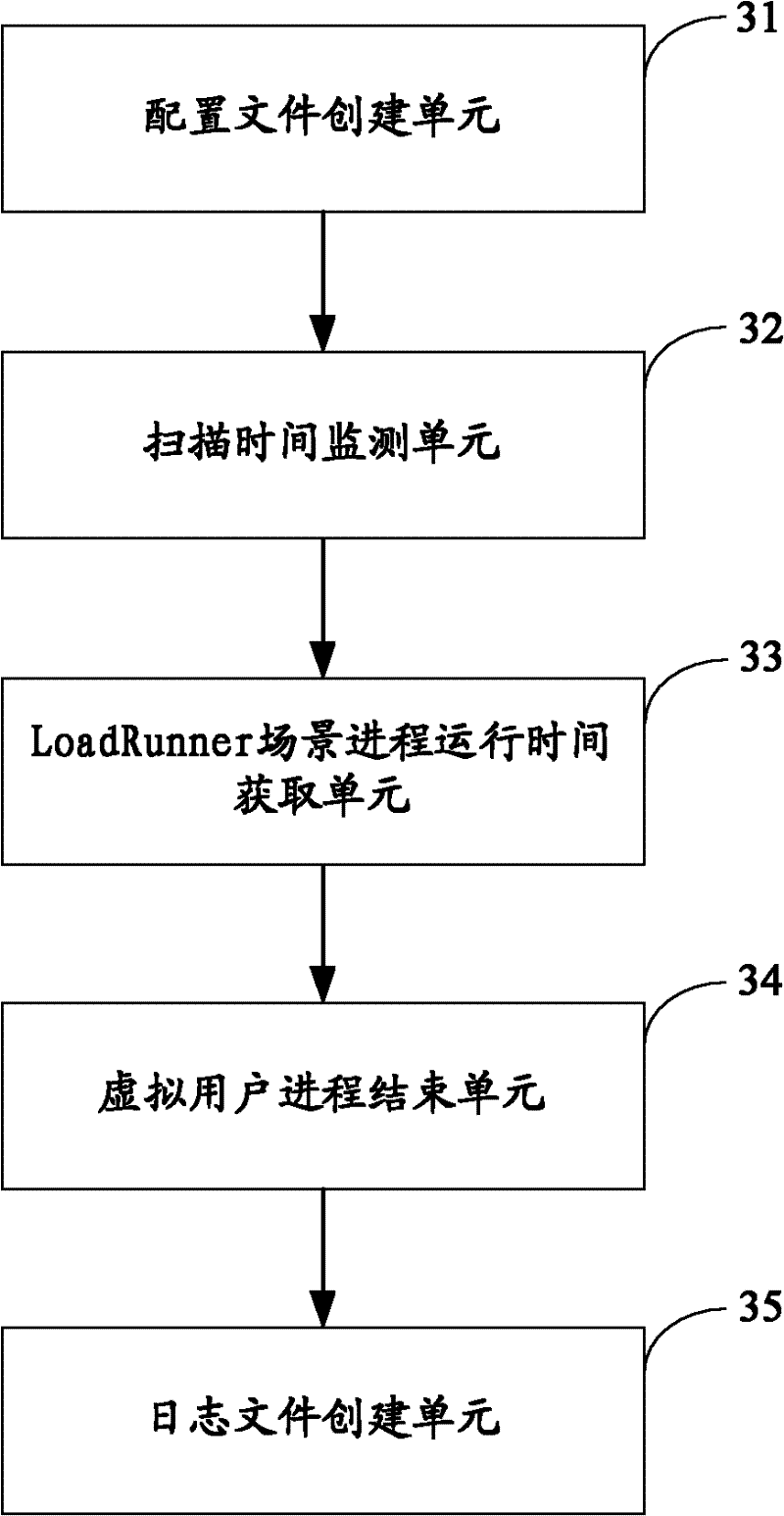

Scenario testing monitoring method, device and system

InactiveCN102479146AReduce workloadGuaranteed to run automaticallyHardware monitoringVirtual userWorkload

The invention is applicable to the field of computer technology and provides a scenario testing monitoring method, device and system, wherein the method comprises the following steps: monitoring the scanning time of LoadRunner scenario process according to a scanning period of the LoadRunner scenario process set in advance; acquiring the running time of the LoadRunner scenario process when the scanning time of the LoadRunner scenario process is reached; and forcibly ending a virtual user process related to the LoadRunner scenario process when the running time of the LoadRunner scenario process exceeds the running time of the LoadRunner scenario process set in advance. According to the invention, the virtual user process related to the LoadRunner scenario process can be forcibly ended when the monitored running time of the LoadRunner scenario process exceeds the running time of the LoadRunner scenario process set in advance, so that automatic running of the scenario testing can be ensured under the unattended condition, the scenario testing can be executed in batch, the scenario testing efficiency can be improved, the user workload can be reduced and then the LoadRunner scenario testing can be more humanized.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

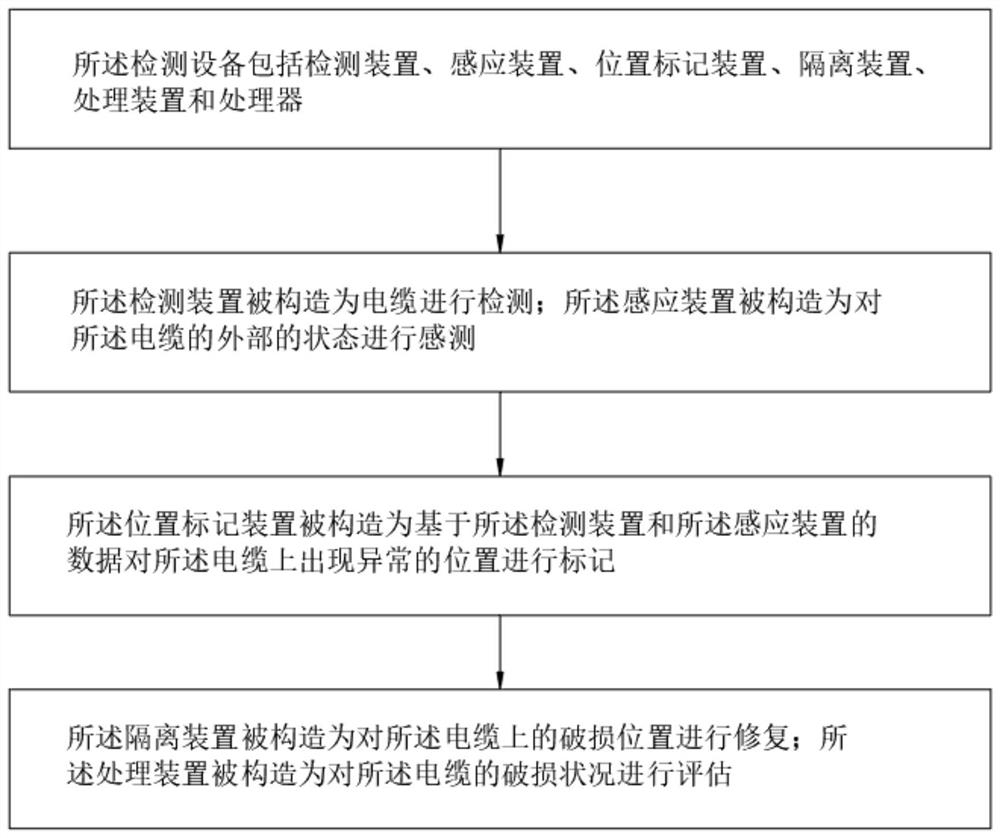

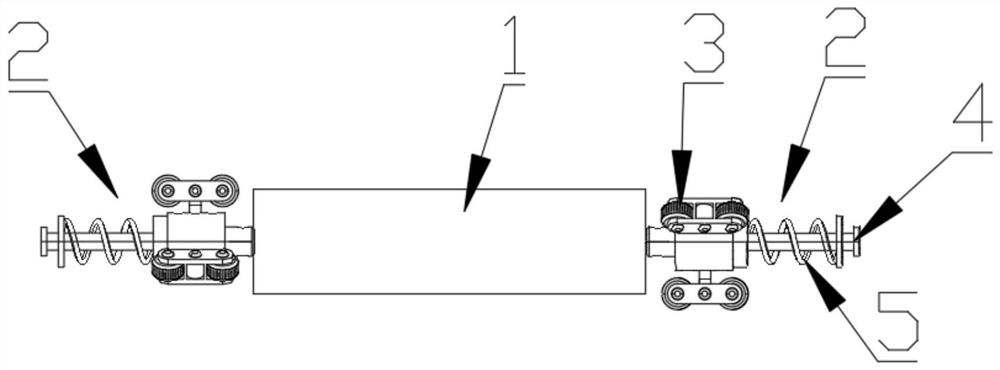

High-stability intelligent unmanned aerial vehicle inspection and detection equipment for cable tunnel

ActiveCN112683911AImprove maintenance efficiencyGuaranteed to run automaticallyOptically investigating flaws/contaminationShort-circuit testingAbnormal positionsUncrewed vehicle

The invention provides high-stability intelligent unmanned aerial vehicle inspection and detection equipment for cable tunnel, the equipment comprises a detection device, a sensing device, a position marking device, an isolation device, a processing device and a processor; the detection device is configured to detect a cable; the sensing device is configured to sense the state of the exterior of the cable; the position marking device is configured to mark an abnormal position on the cable based on the data of the detection device and the sensing device; the isolation device is configured to repair a damaged position on the cable; the processing device is configured to evaluate a damage condition of the cable. According to the invention, the processing device is adopted to evaluate the condition of the cable, accurate evaluation is carried out based on the abnormal image of the abnormal position, the operation of priority processing is triggered, the whole equipment can be ensured to operate automatically, and the maintenance efficiency of the cable is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

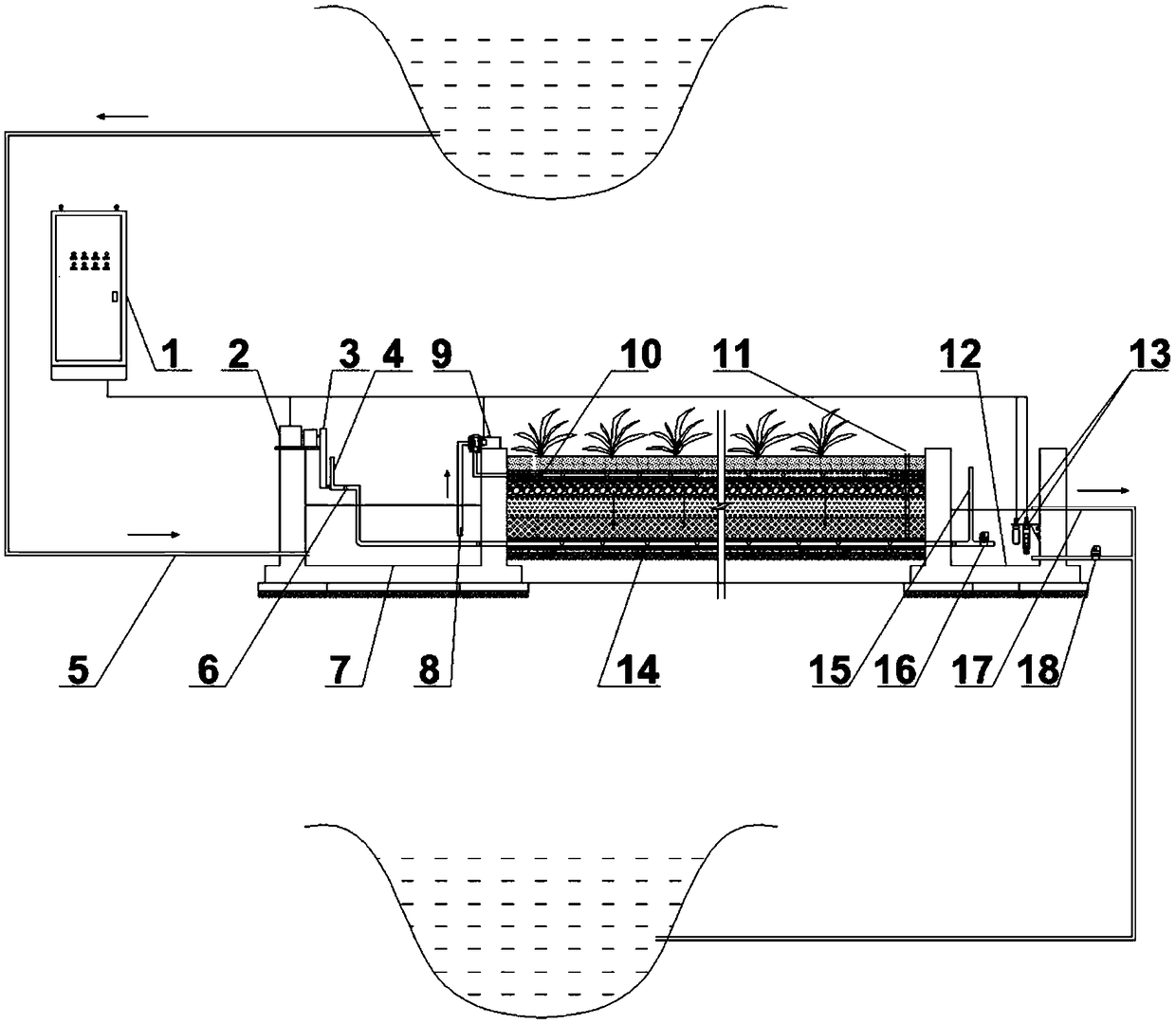

Automatic water level adjustment system and method for artificial wetland

PendingCN109437405AImprove physical and chemical propertiesImprove distributionWater treatment parameter controlBiological treatment apparatusConstructed wetlandWater quality

The invention relates to an automatic water level adjustment system and method for an artificial wetland. The automatic water level adjustment system comprises a wetland water inlet pipe, an adjustingtank, an adjusting tank water inlet pipe, a water distribution pipe, a water collection pipe, a water collection tank, a water outlet pipe of the water collection tank and a control unit, wherein thewater collection pipe extends into the water collection tank and the other end of the water collection pipe extends into the adjusting tank; after the other end of the water collection pipe enters the adjusting tank, the water collection pipe extends upwards to a position above a water level of the adjusting tank; a tail section above the water level extends in a bending manner and is communicated with one end of an L-shaped water level adjusting pipe through a rotary connector; the water level adjusting pipe rotates by taking the rotary connector as a shaft under the control of the control unit, so as to adjust the height of an opening end of the water level adjusting pipe; water flow in the artificial wetland flows into the adjusting tank along the water collection pipe and the water level adjusting pipe. According to the automatic water level adjustment system provided by the invention, the water level is dynamically changed, and physical and chemical properties of a wetland environment are improved by utilizing a water level flexible adjusting strategy, so that plants and microorganisms grow better, the water treatment efficiency of the artificial wetland is improved and the water quality of output water of the artificial wetland is ensured.

Owner:BEIJING ORIENT LANDSCAPE

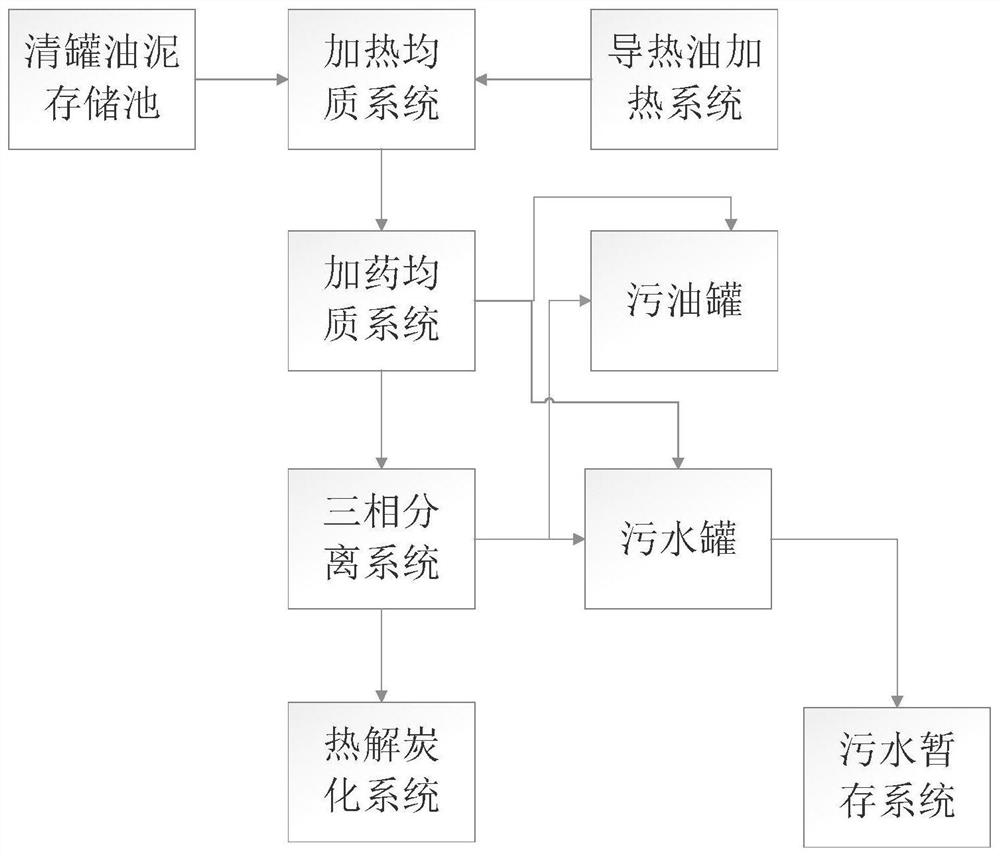

Harmless treatment system and process for tank cleaning oil sludge

PendingCN112723698AGuaranteed normal processingGuaranteed to run automaticallyWaste water treatment from quariesSludge treatment by pyrolysisAfter treatmentCarbonization

A harmless treatment system for tank cleaning oil sludge comprises a tank cleaning oil sludge storage pool, a heating homogenizing system, a heat conduction oil heating system, a dosing homogenizing system, a three-phase separation system, a pyrolysis carbonization system, a sewage temporary storage system, a waste oil tank and a sewage tank. An outlet of the tank cleaning oil sludge storage pool is sequentially connected with the heating homogenizing system, the dosing homogenizing system, the three-phase separation system and the pyrolysis carbonization system through pipelines. An outlet of the dosing homogenization system is connected with the three-phase separation system and is also connected with the waste oil tank and the sewage tank. Similarly, the outlet of the three-phase separation system is connected with the pyrolysis carbonization system and is also connected with the waste oil tank and the sewage tank. According to the invention, manpower and material resources are saved in the tank cleaning oil sludge treatment process. Not only can crude oil in the tank cleaning oil sludge be recycled, but also it can be ensured that the treated solid residues cannot cause harm to the environment. The problems that existing tank cleaning oil sludge is difficult to treat and does not reach the standard after treatment are solved.

Owner:陕西欧菲德环保科技有限公司

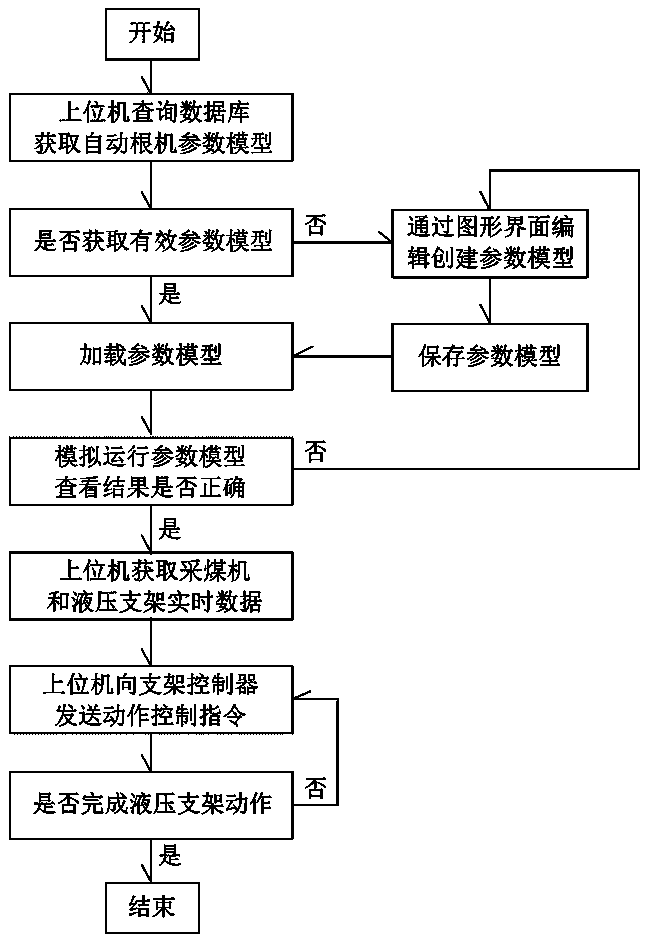

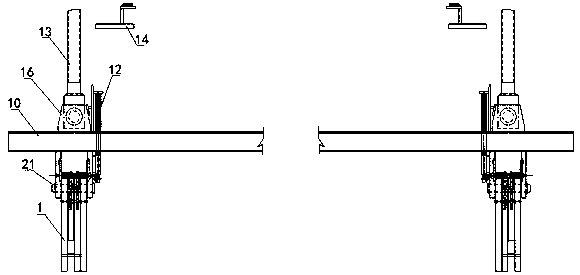

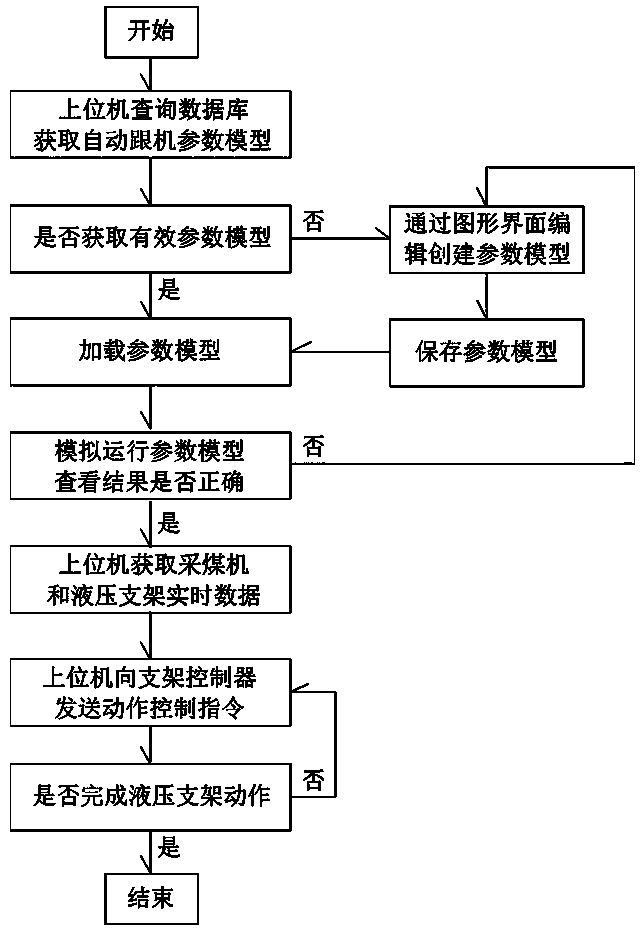

Programmable upper computer automatic follow-up method

ActiveCN109209504AImprove control efficiencyImprove human-computer interaction experienceMining devicesSlitting machinesReal-time dataSoftware engineering

The invention discloses a programmable upper computer automatic follow-up method. 1, an upper computer queries the database to obtain an effective automatic follow-up parameter model; 2, judging whether the obtained automatic follow-up parameter model is valid or not, and if it is an effective automatic follow-up parameter model, carrying out the third step; if the parameter model is invalid, theparameter model is edited and created through the graphical interface, and then saved to the database for the third step; 3, the parameter model of the automatic follow-up machine is load by the uppercomputer; 4, the automatic follow-up parameter model is simulated and operated, and whether the running result is correct is checked; if the result is correct, step 5 is carried out and otherwise, the second step is repeated; 5, real-time data of that shearer, the conveyor and the hydraulic support is obtained by the upper computer; 6, the upper computer sends an action control instruction to thebracket controller; 7, whether the action of the hydraulic support is complete is judged; if completed, end; otherwise step 6 is repeated. The invention has the advantages of achieving continuous, safe and efficient mining of the fully mechanized mining face.

Owner:郑州恒达智控科技股份有限公司

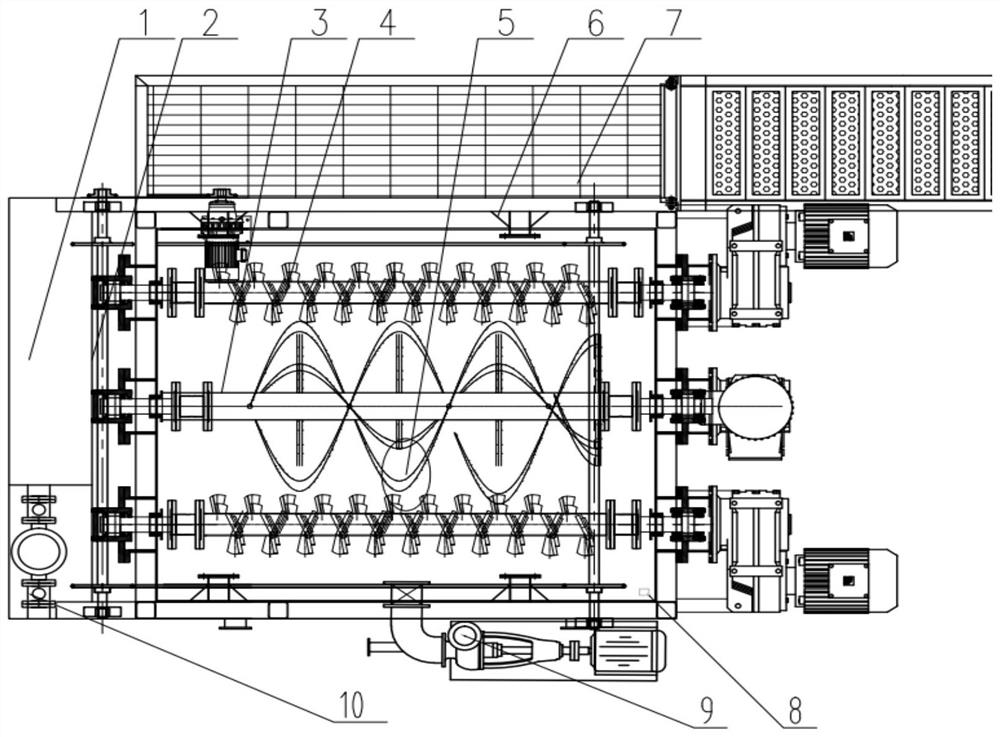

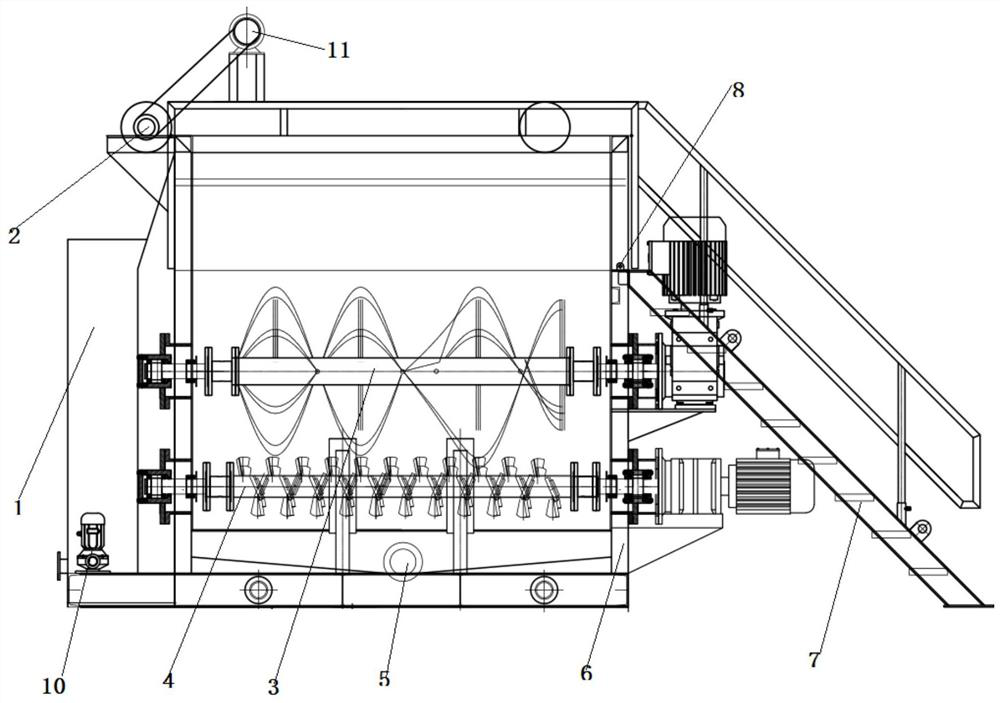

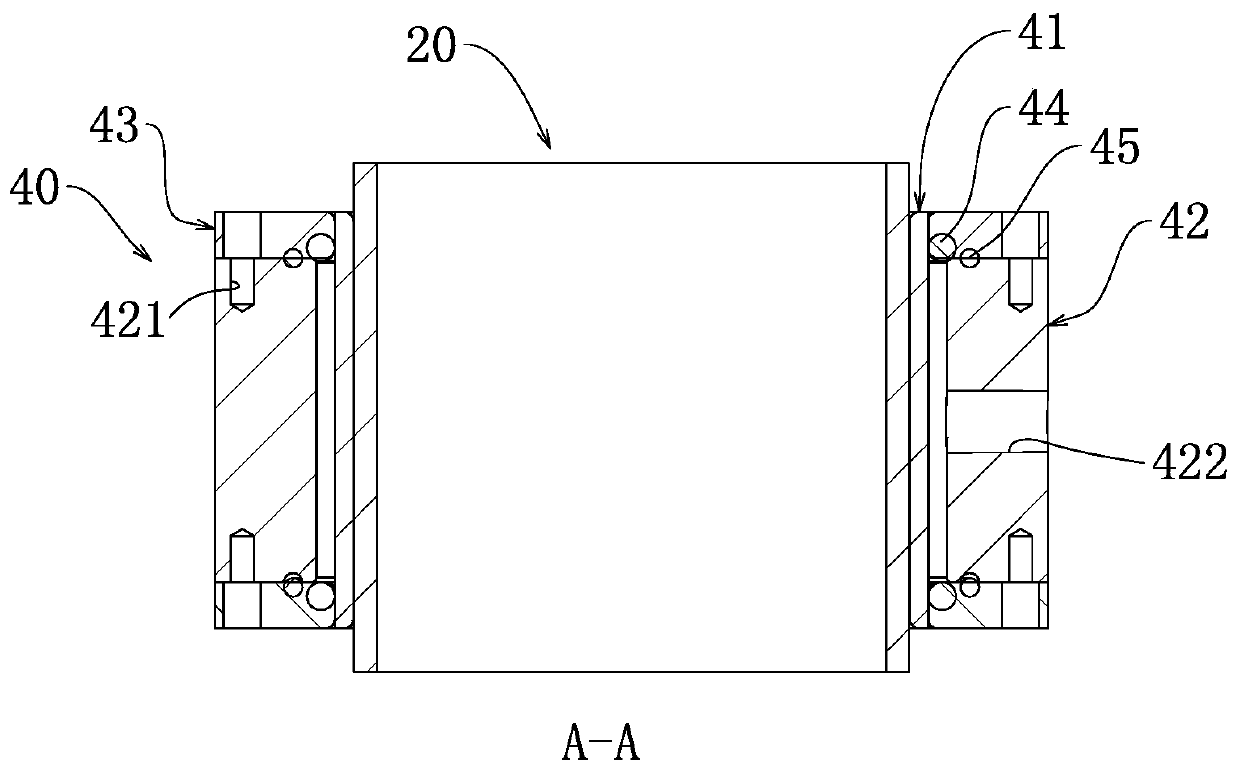

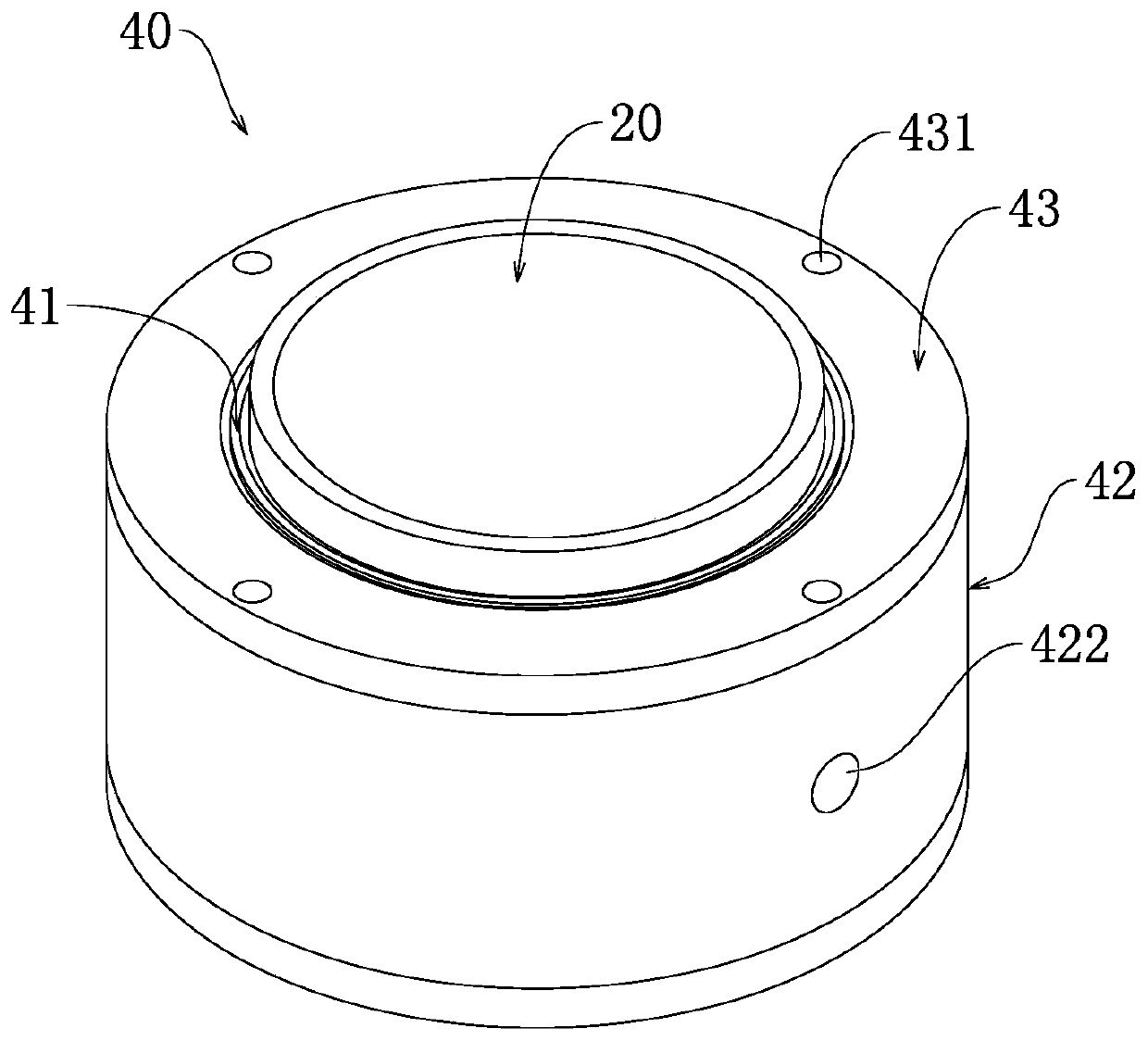

Horizontal three-axis stirring water washing tank

PendingCN111922006AReduce work intensityGuaranteed normal operationRotary stirring mixersTransportation and packagingAgitatorOil well

A horizontal three-axis stirring water washing tank comprises a horizontal tank body. The horizontal tank body is divided into two parts through a partition, wherein one part of the horizontal tank body is used as an oil storage tank, and the other part of the horizontal tank body is used as a treatment tank. An oil well pump is arranged in the oil storage tank. Three stirring devices are transversely arranged in the treatment tank, wherein the spiral stirring device is located in the middle, and slurry stirring machines are arranged on the two sides. A discharge opening is formed in the tankbottom of the treatment tank. The discharge opening is connected with a slurry pump. An oil scraping system is arranged on the top of the treatment tank. According to the horizontal three-axis stirring water washing tank, the high self-control performance of the device is utilized, so that the materials in the tank are uniformly stirred, the reaction is complete, and it is guaranteed that the material treatment can reach the expected target.

Owner:陕西欧菲德环保科技有限公司

Unmanned logistics vehicle control system with optimized walking path and control method thereof

PendingCN110626737ACompact structureIntelligent handlingControl devices for conveyorsMechanical conveyorsProduction lineLogistics management

The invention relates to an unmanned logistics vehicle control system with the optimized walking path and a control method of the unmanned logistics vehicle control system and belongs to the technicalfield of industrial automatic carrying control. The unmanned logistics vehicle control system comprises a running track. A plurality of transverse tracks which are in arc connection with the runningtrack are arranged in the running track. A plurality of unmanned logistics vehicles are arranged on the running track and the transverse tracks. An unloading station is arranged on one side of the running track, and a to-be-loaded station is arranged on the other side of the running track. A plurality of loading stations which are equally spaced from and parallel to the transverse tracks are arranged between the to-be-loaded station and the unloading station. The unmanned logistics vehicle control system has the beneficial effects of being compact in structure, automatic in vehicle distribution, intelligent in carrying operation and capable of achieving automatic control and carrying production lines, greatly improving production efficiency, reducing operation cost and saving time and labor. A plurality of carrying modes are adopted to replace single carrying, and the automatic operation of the whole system is ensured according to the automatic signal output prompting, the conveying and conveying completion.

Owner:MEIDEN HANGZHOU DRIVE SYSTEMS CO LTD

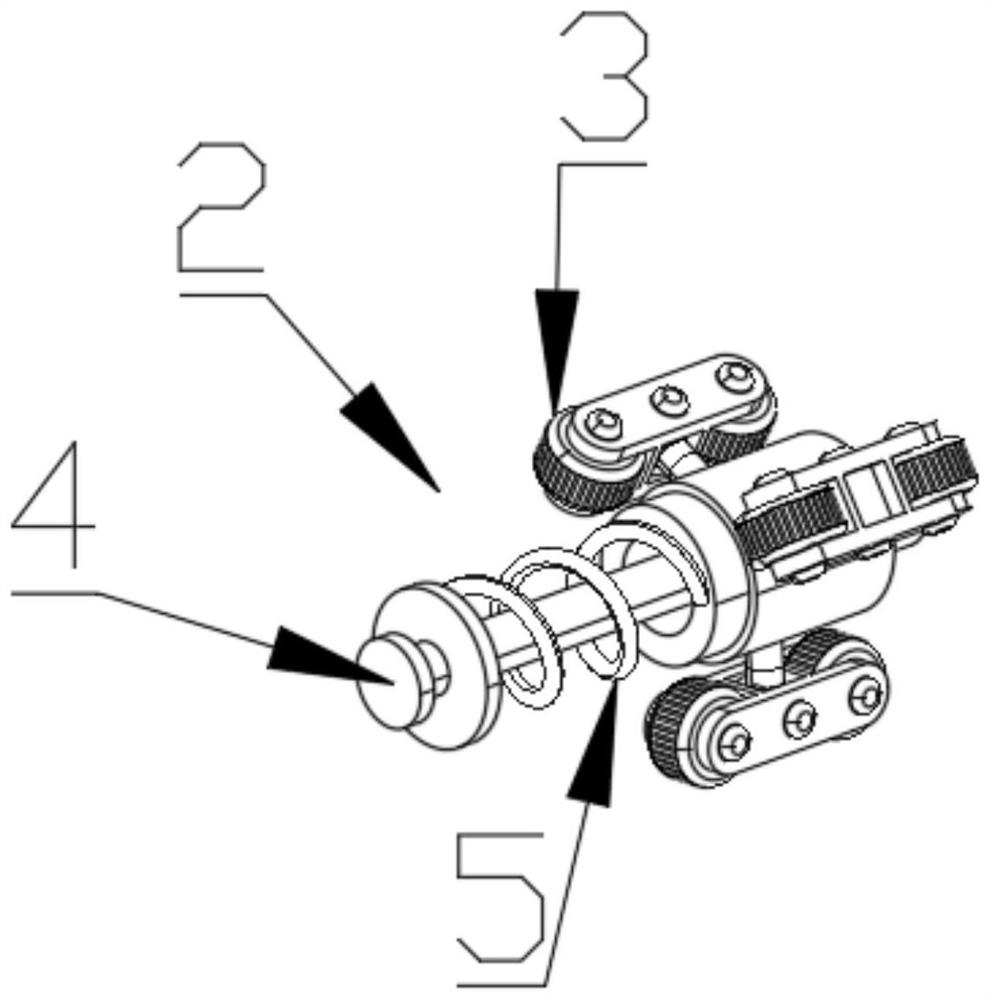

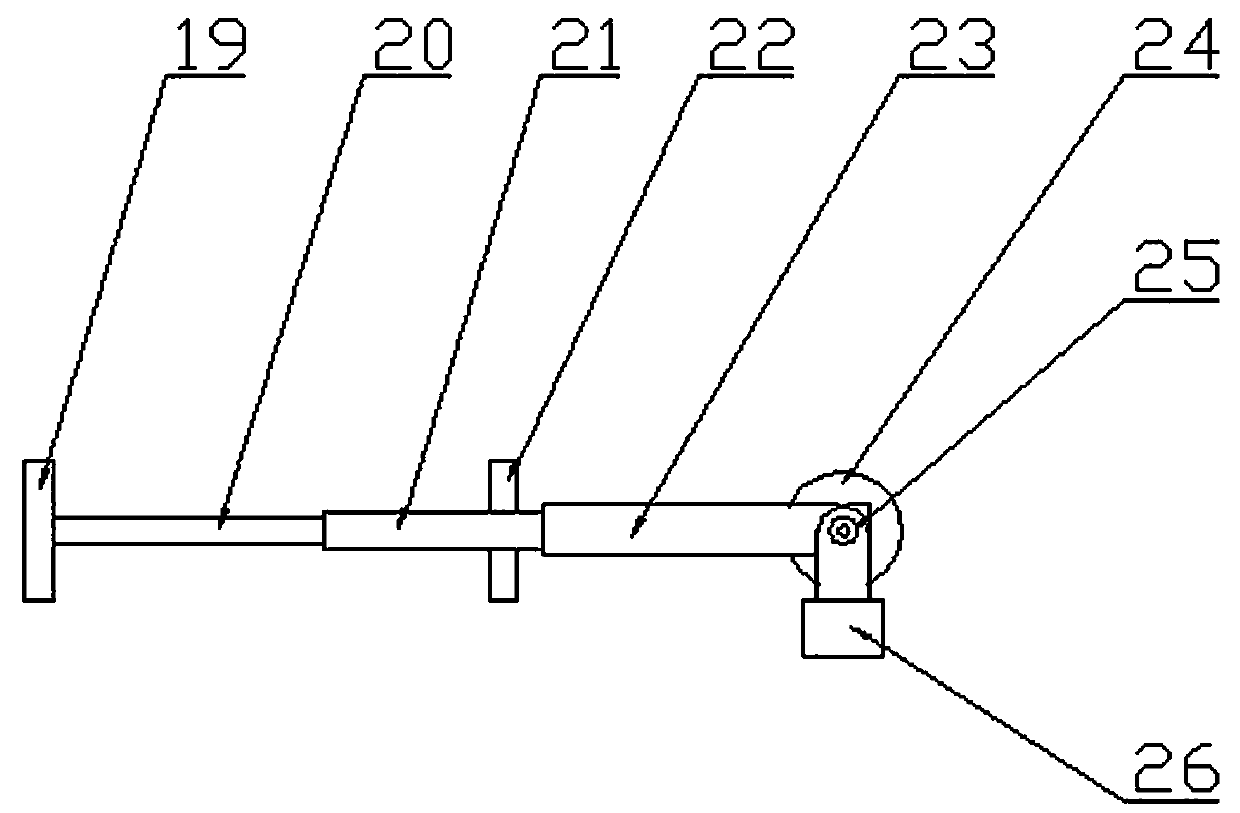

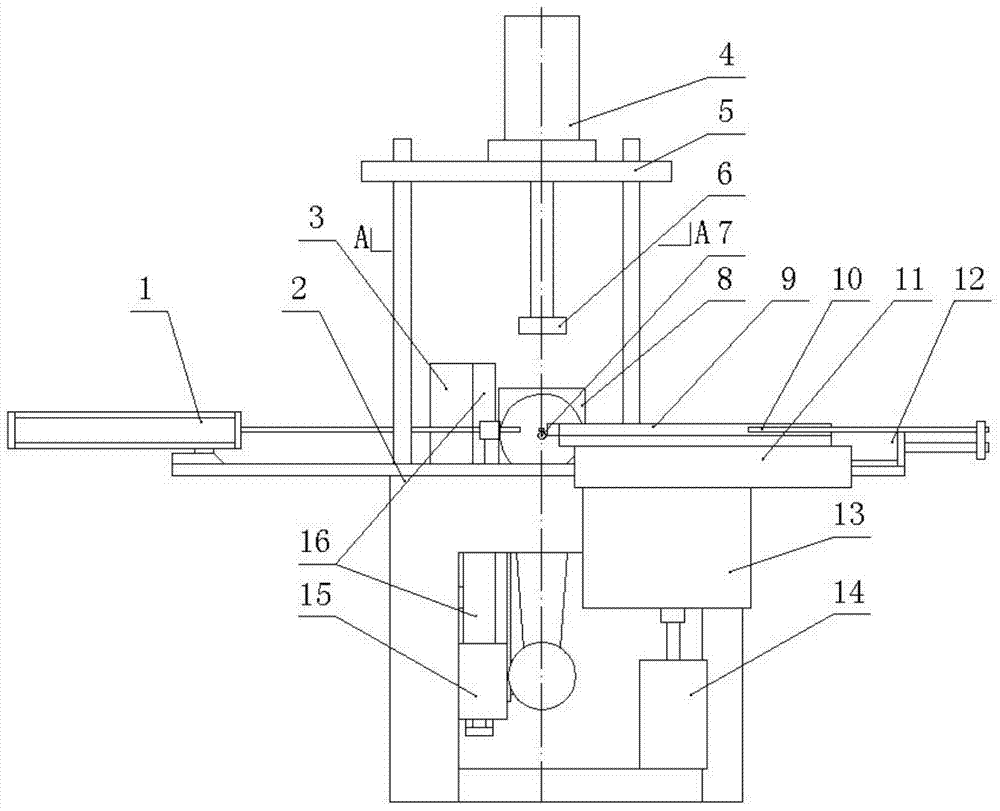

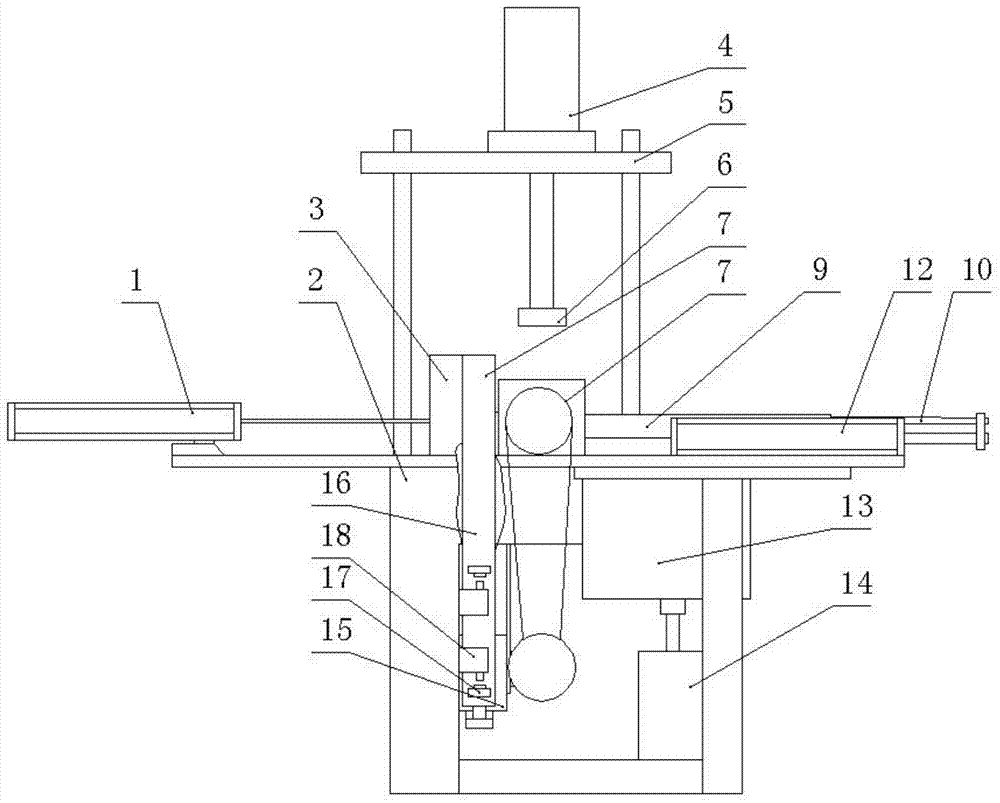

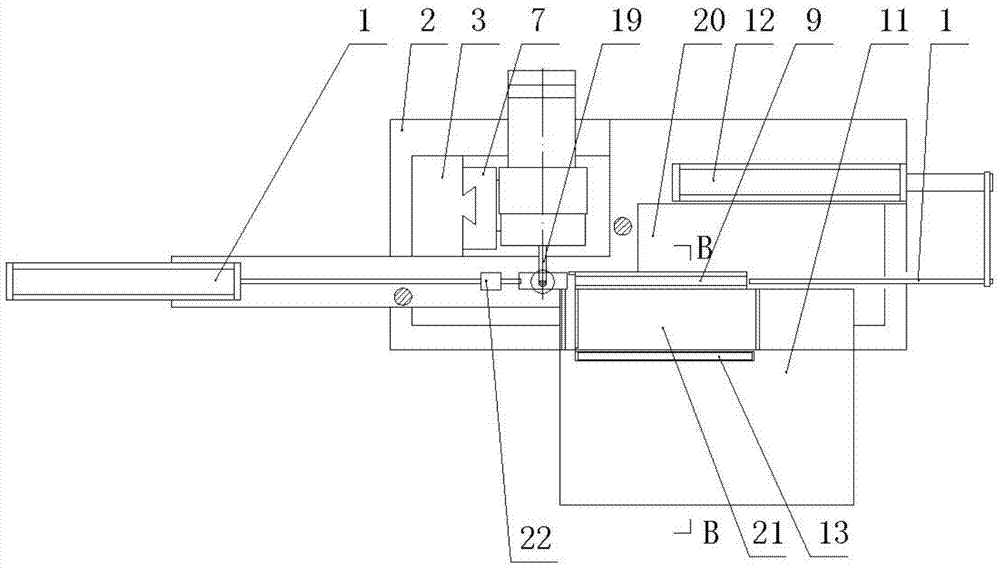

An automatic continuous feeding valve stem keyway processing equipment

ActiveCN104588753BRealize automatic feedingRealize automatic loading and unloadingWork clamping meansFeeding apparatusHigh rateMilling cutter

The invention relates to an automatic continuous-feeding valve rod keyway processing device. The device comprises a support, a material feeding assembly, a compaction assembly, an ejector rob cylinder, a discharging cylinder and a milling cutter assembly. A piston of a cylinder of the compaction assembly presses a valve rod down. The lower part of an ejector rob of the ejector rob cylinder is provided with a valve rod positioning groove. The ejector rod can axially slide in the positioning groove. The front side of the support corresponding to the valve rod positioning groove is provided with the material feeding assembly. The material feeding assembly makes an inclined feeding plate of the material feeding assembly slide into the positioning groove. The lower end of the support between the ejector rod and the end of the positioning groove is provided with the milling cutter assembly. When the milling cutter moves upward, the milling cutter rotating at a high rate can mill a keyway on the lower surface of the valve rod. The automatic continuous-feeding valve rod keyway processing device realizes automatic feeding of the valve rod, an ejector plate can push all the valve rods into a fixing groove one by one, after positioning, the valve rod is processed, and then the valve rod is automatically removed so that automatic loading and unloading of the valve rod are realized and production efficiency is improved.

Owner:TIANJIN KAIYUAN THIRD VALVE

Method for preparing high-strength and toughness aluminium alloy aviation safety part through modification

The invention discloses a method for preparing a high-strength and toughness aluminium alloy aviation safety part through modification. The method is characterized in that a modification preparation system comprising a heat treatment device, a temperature control module and a computer control center which are connected in sequence is adopted; and the heat treatment device comprises an electric heating furnace, a cold water tank, an external guide rail bracket and a charging carriage. The method comprises the steps of charging, heating, heat preserving, cooling and the like. Through inspection, the mechanical property of the product obtained through treatment of the method can meet the requirement of aviation. Meanwhile, as the product is prepared by carrying out secondary modification on the workpiece processed with the common 2Al2-O aluminium alloy through heat treatment, the cost of the material is low. In addition, the treatment system used in the method is also obtained through combination of many existing conventional tools, so the equipment cost is low and the treatment system has the advantage of low production cost.

Owner:CHONGQING YUYI MACHINE

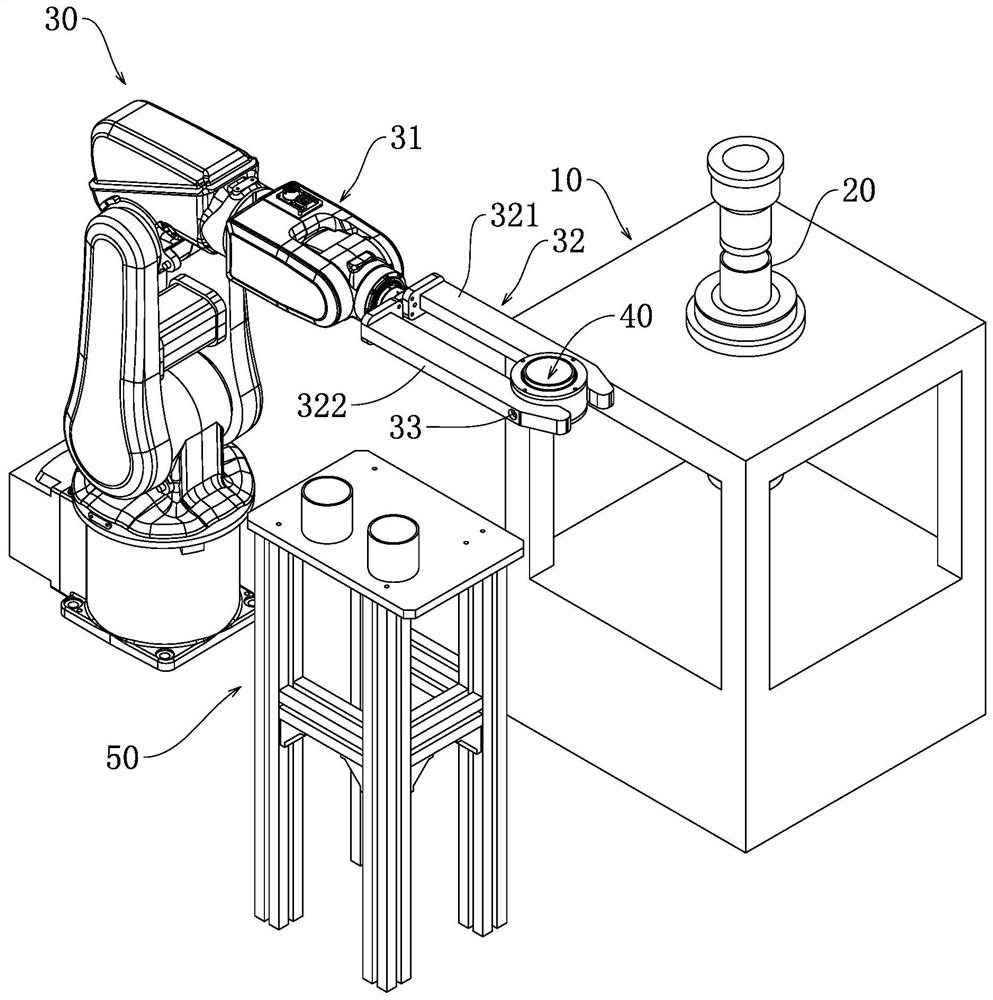

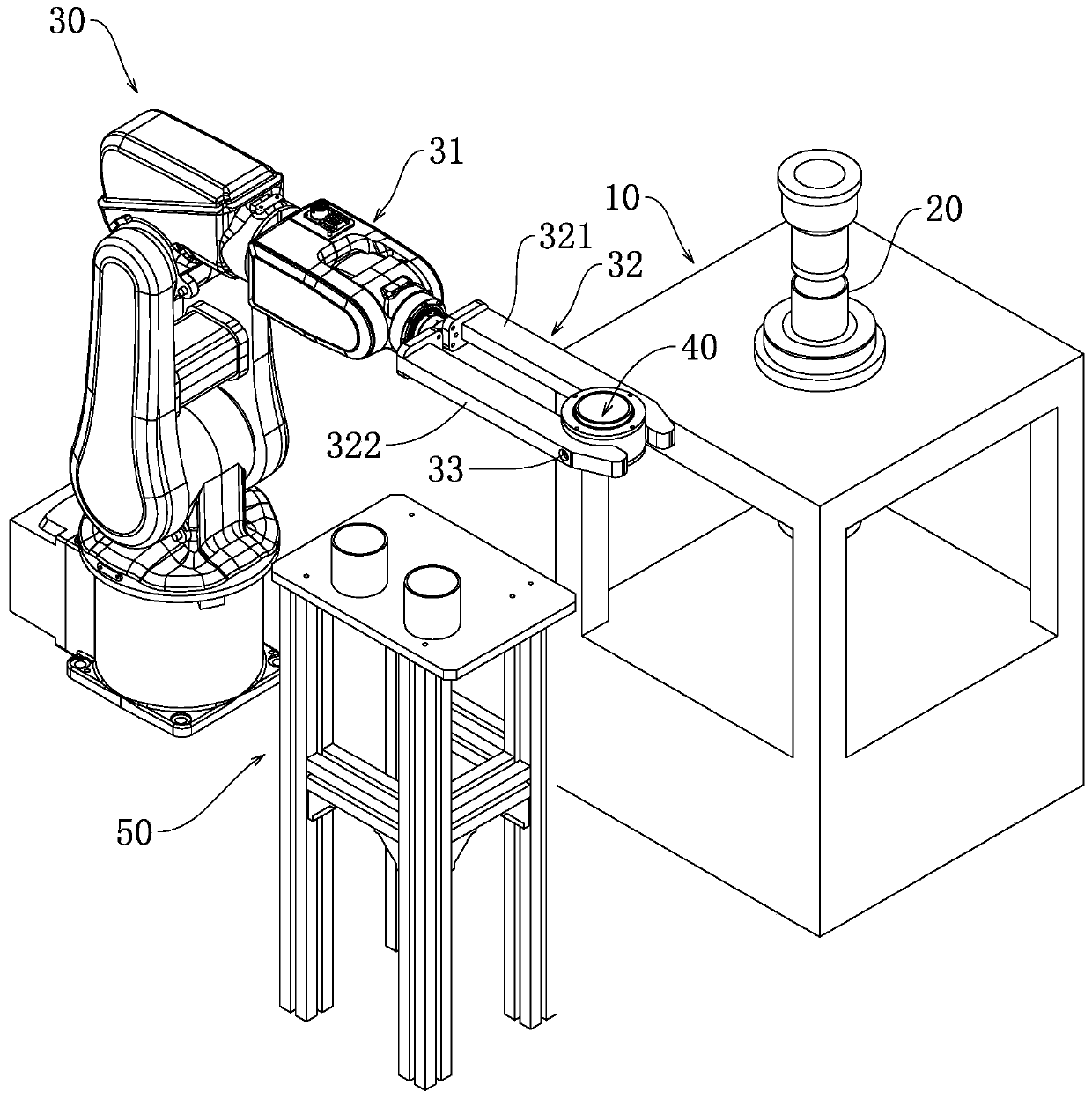

Method and device for grasping and moving low-density magnet blanks formed by pressing

A method and device for grabbing and moving low-density magnet blanks formed by pressing, the method comprising: a. molding a low-density magnet blank by a press; Jacket, the vacuum jacket is moved from the outside of the press to the top of the magnet blank on the press; c, the manipulator clamps the magnet blank through the vacuum jacket; d, the manipulator moves the clamped vacuum jacket and the magnet blank to The magnet blank is placed on the table, the pressure is relieved and released, and the magnet blank is grasped once. The device includes a manipulator and a vacuum jacket. The manipulator is equipped with or connected with a negative pressure device. The vacuum jacket is a sleeve-like body with the same shape as the magnet blank and a diameter larger than the upper and lower openings of the magnet blank. The invention can grasp and move the low-density magnet blank, without collision and extrusion to the magnet blank during the grasping and moving process, and can ensure that the magnet blank is moved from one point to another intact.

Owner:安徽粤海磁业有限公司

An ice cream vending machine

ActiveCN105166309BPrecise control outputGuaranteed to run automaticallyFrozen sweetsApparatus for dispensing fluids/granular materialsEngineeringIce cream

The invention provides an ice cream vending machine. The ice cream vending machine comprises a machine body and an ice cream making unit, a cone supply unit, a material receiving and goods delivery unit and an operating unit, which are installed on the machine body and are connected with a control unit, wherein the material receiving and goods delivery unit is arranged between the ice cream making unit and the cone supply unit and comprises a lifting support mechanism, a horizontal transport mechanism and a material receiving and goods delivery mechanism; the lifting support mechanism is installed in the machine body; the horizontal transport mechanism is installed on the lifting support mechanism and is driven by the lifting support mechanism to move up and down; the material receiving and goods delivery mechanism is installed on the horizontal transport mechanism and is driven by the horizontal transport mechanism to move left and right; when receiving materials, the material receiving and goods delivery mechanism can vertically place cones below discharge holes; and when delivering goods, the material receiving and goods delivery mechanism can obliquely place the cones toward the inside of the machine body and extend out of a goods delivery hole. The problem that traditional ice cream vending machines need to depend on manpower to hold the cones with hands to receive ice cream can be solved by adopting the ice cream vending machine.

Owner:GUANGZHOU GUANGSHEN ELECTRIC PROD CO LTD

Control system based on intelligent campus management

PendingCN113098921AEfficient transmissionGuaranteed maintenanceTelevision system detailsData processing applicationsInformation transmissionSystems engineering

The invention relates to the technical field of intelligent campuses, in particular to a control system based on intelligent campus management, which comprises a control module, and a safety module, a course module, a payment module, an environment module and a positioning module which are electrically connected with the control module respectively. According to the invention, the problems that the school operation cost is relatively high due to the fact that different quantities of manpower need to be distributed for each post in the existing campus management, and the information transmission between the posts is lagged due to the fact that the information transmission between the personnel is not timely are solved.

Owner:云荟科(惠州)智能控制技术有限公司

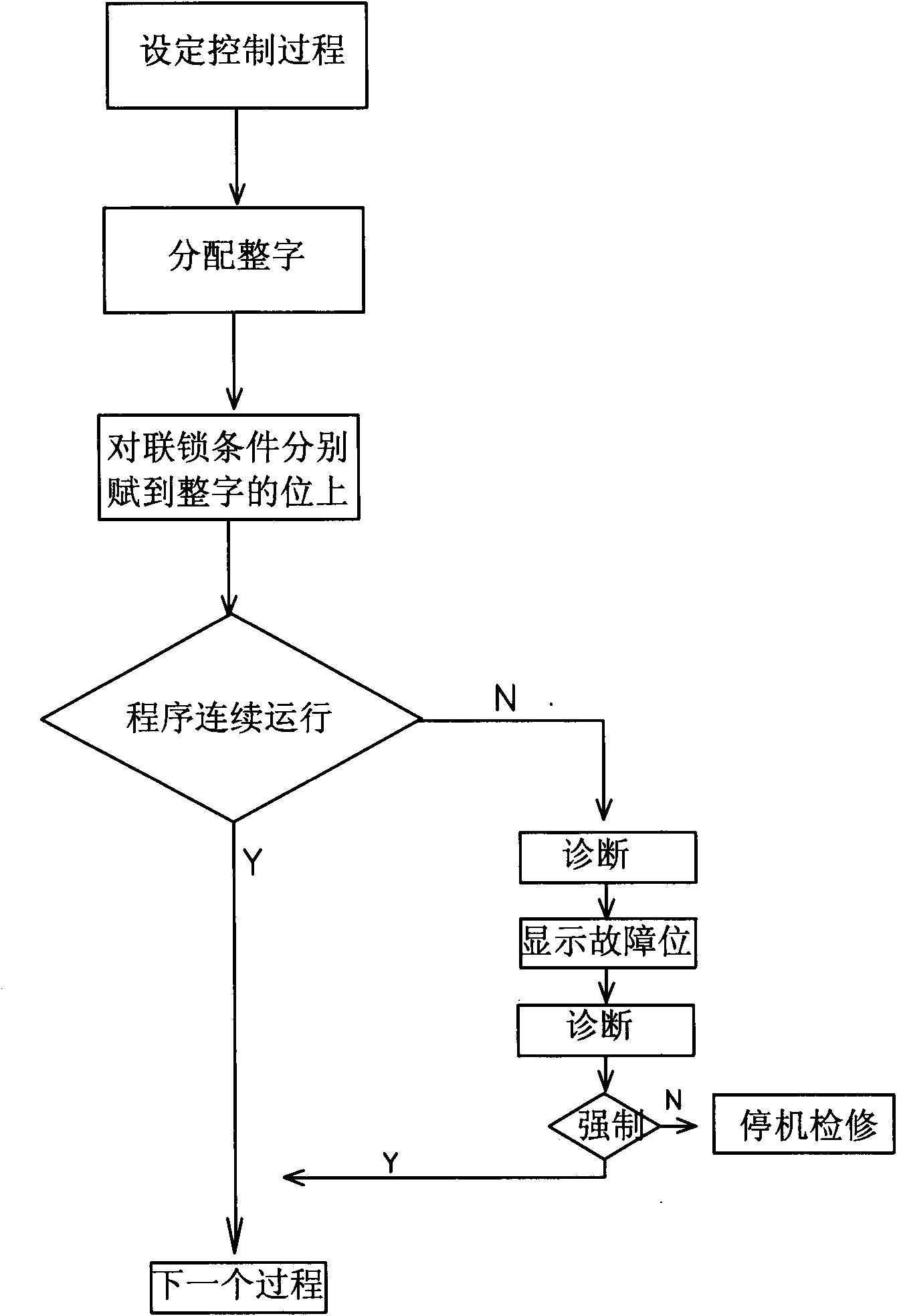

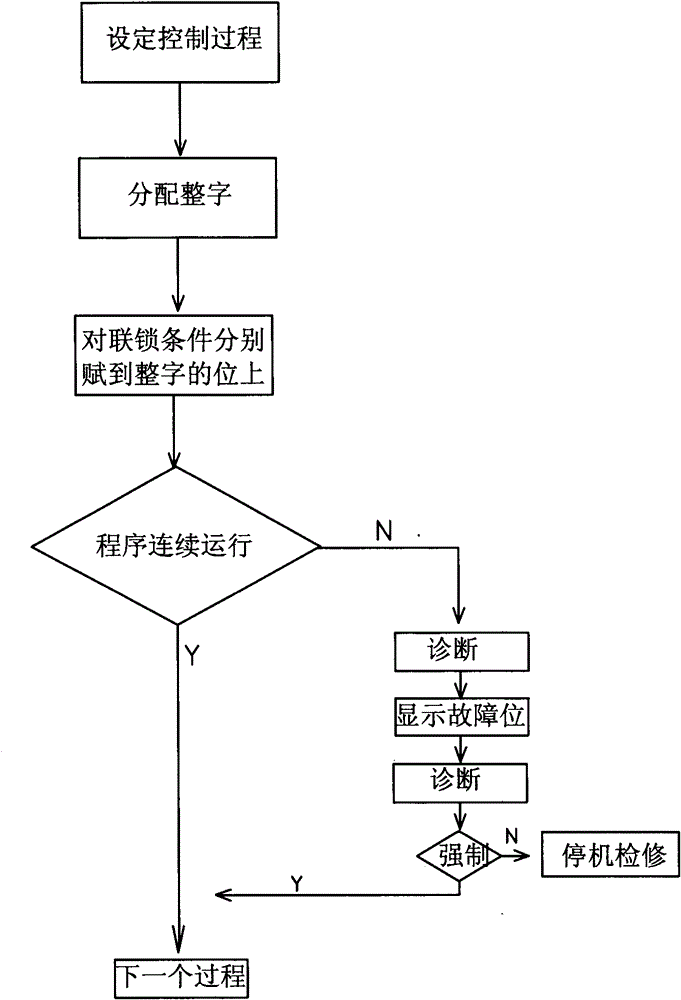

Automatic running programmable logic controller (PLC) program interlocking fault quick recognition method of coke oven locomotive

ActiveCN103034157AGuaranteed to run automaticallyGuaranteed automatic continuous operationComputer controlSimulator controlAutomatic controlProgrammable logic controller

The invention relates to an automatic running programmable logic controller (PLC) interlocking fault quick recognition method of a coke oven locomotive and belongs to the technical field of electric automatic control. The method includes the following steps: setting a binary integral character for each running process of each running step, enumerating the interlocking condition of each process according to the sequence in process control, assigning each interlocking condition on the corresponding bit of the binary integral character, setting assignment of the bit of each interlocking condition under the non-fault state to be '0' and to be '1' when the condition is not satisfied or in the fault state, utilizing a programmable logic controller (PLC) to detect the running process that the integral character is not '0', finding the running process of fault points, utilizing the PLC to detect the integral character condition of the process, finding a first bit with assigned value as '1', finding the interlocking condition of the bit, finding the fault point and enabling the coke oven locomotive to run continuously after the fault is resolved. The automatic running PLC interlocking fault quick recognition method is capable of quickly and accurately checking all interlocking conditions and finding faults.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

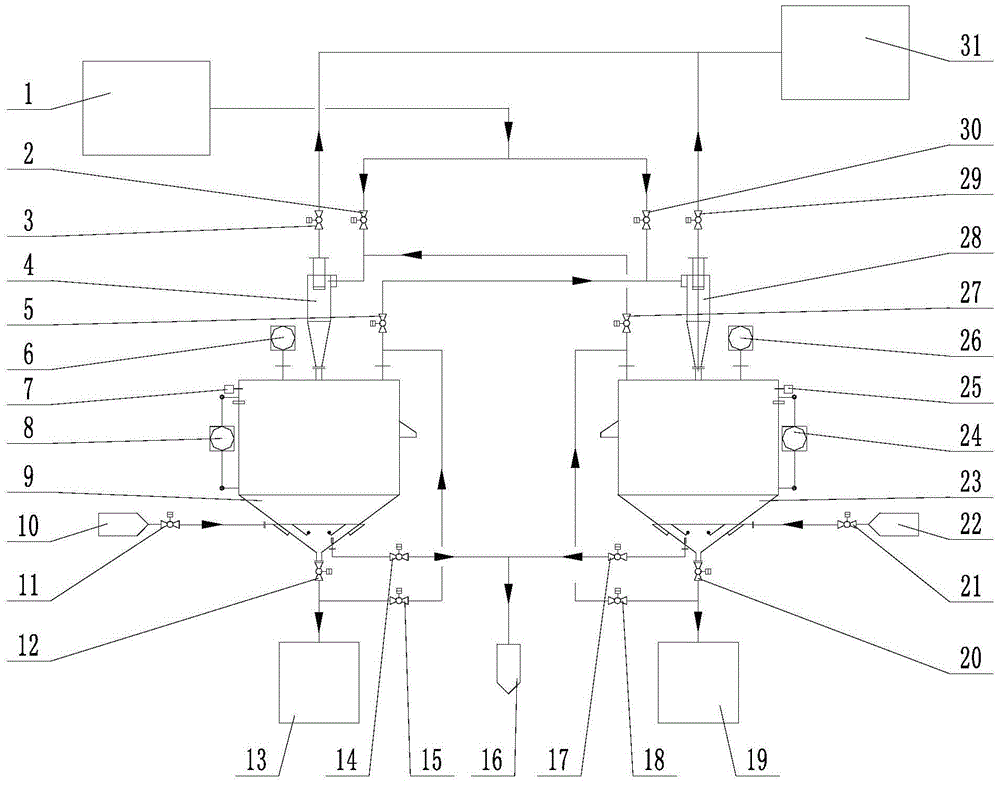

A method and device for automatic dedusting of pyrolysis gas in the production of hexafluoropropylene

ActiveCN104707405BIncrease profitImprove dust removal efficiencyDispersed particle separationHexafluoropropyleneDust control

The invention provides an automatic dust collection method and a device for cracked gas in production of hexafluoropropylene. An automatic dust collection system in the automatic dust collection method comprises an automatic dust collection device, am automatic liquid drainage device, an automatic powder discharge device and a steam washing device of the cracked gas; two high-efficiency cyclone separators and a powder bin carry out automatic dust collection operation alternately; and the automatic dust collection device comprises a left dust collection system and a right dust collection system. An outlet of an external cracked gas quenching system is divided into two branches to be connected with inlets of the left dust collection system and the dust collection system respectively; outlets of the left dust collection system and the right dust collection system are connected to an inlet of an external cracked gas neutralizing system; and the bottoms of the left dust collection system and the right dust collection system are further connected with an external sewage tank. According to the automatic dust collection method and the device, the cracked gas entering the device is discharged after automatic dust collection, and pollution discharge is carried out automatically; the left dust collection system and the right dust collection system are used in turn to ensure normal operation of equipment; manual intervention is not required; and the method and the device are safe, stable and higher in dust collection efficiency.

Owner:福建三农新材料有限责任公司

Pressed low-density magnet blank grabbing and moving method and device

The invention provides a pressed low-density magnet blank grabbing and moving method and device. The method comprises the steps that a, mould pressing is conducted by a pressing machine to obtain a low-density magnet blank; b, a vacuum clamping sleeve for fixing the magnet blank is clamped by a mechanical arm with a negative pressure device, and the vacuum clamping sleeve is moved to the upper side of the magnet blank on the pressing machine from the exterior of the pressing machine; c, the magnet blank is clamped by the mechanical arm through the vacuum clamping sleeve; d, the mechanical armmakes the clamped vacuum clamping sleeve and the magnet blank move to a magnet blank placement table, pressure is released, and the magnet blank is released, so that the process of grabbing the magnetblank one time is completed. The device comprises the mechanical arm and the vacuum clamping sleeve, the mechanical arm is provided with or connected with the negative pressure device, the vacuum clamping sleeve is a sleeve body in a shape identical to that of the magnet blank, and the diameter of the vacuum clamping sleeve is larger than the diameters of upper and lower openings of the magnet blank. By means of the device, the low-density magnet blank can be grabbed and moved, in the grabbing and moving processes, the magnet blank cannot be collided or squeezed, and it can be ensured that the magnet blank is moved to another point from one point without damage.

Owner:安徽粤海磁业有限公司

A quick identification method for PLC program interlock faults in automatic operation of coke oven locomotives

ActiveCN103034157BGuaranteed to run automaticallyGuaranteed automatic continuous operationComputer controlSimulator controlAutomatic controlProgrammable logic controller

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

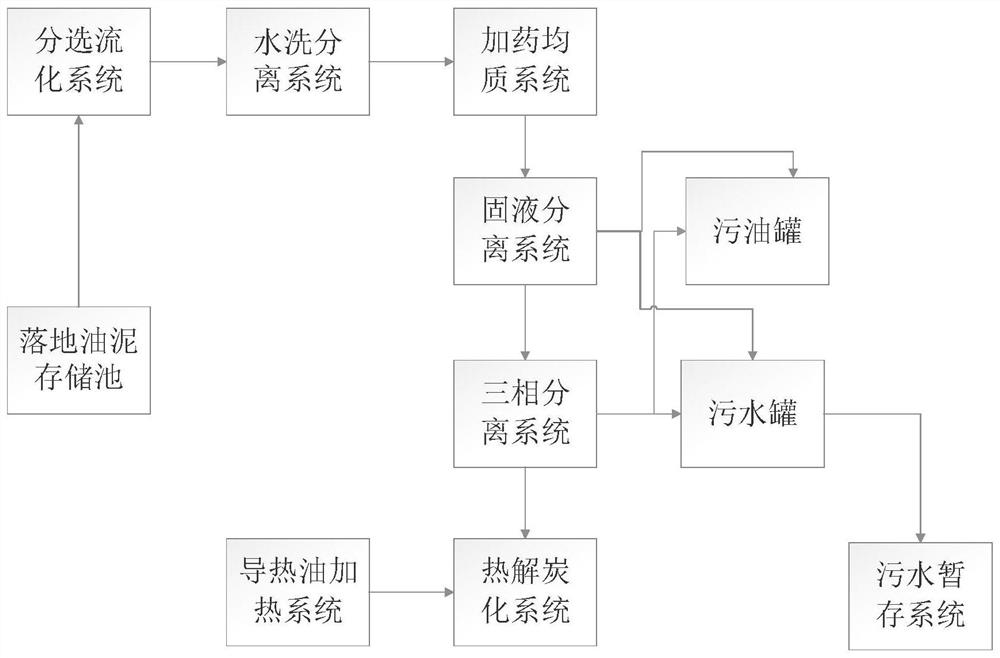

Harmless treatment system and treatment process for ground oily sludge

PendingCN112744990AAchieve the desired effectGuaranteed to run automaticallyWaste water treatment from quariesSludge treatment by pyrolysisCarbonizationOil sludge

A harmless treatment system for ground oily sludge comprises a ground oily sludge storage pool, a vibrating screen, a separation fluidization system, a washing separation system, a dosing homogenization system, a solid-liquid separation system, a sewage tank, a three-phase separation system, a heating system and a pyrolysis carbonization system, an outlet of the ground oily sludge storage pool is sequentially connected with the vibrating screen, the separation fluidization system, the washing separation system, the dosing homogenization system, the solid-liquid separation system, the three-phase separation system and the pyrolysis carbonization system through pipelines; the solid-liquid separation system is provided with two outlets, wherein one outlet leads to the three-phase separation system, and the other outlet is divided into two sub-paths which are respectively connected to a dirty oil tank and a sewage tank; one outlet of the three-phase separation system leads to the pyrolysis carbonization system, and the other outlet of the three-phase separation system is also divided into two sub-paths which are respectively connected to the dirty oil tank and the sewage tank; the sewage tank is connected to the sewage temporary storage system; and the heating system is communicated with the pyrolysis carbonization system. According to the invention, recycling and harmlessness of treatment of the ground oily sludge are realized.

Owner:陕西欧菲德环保科技有限公司

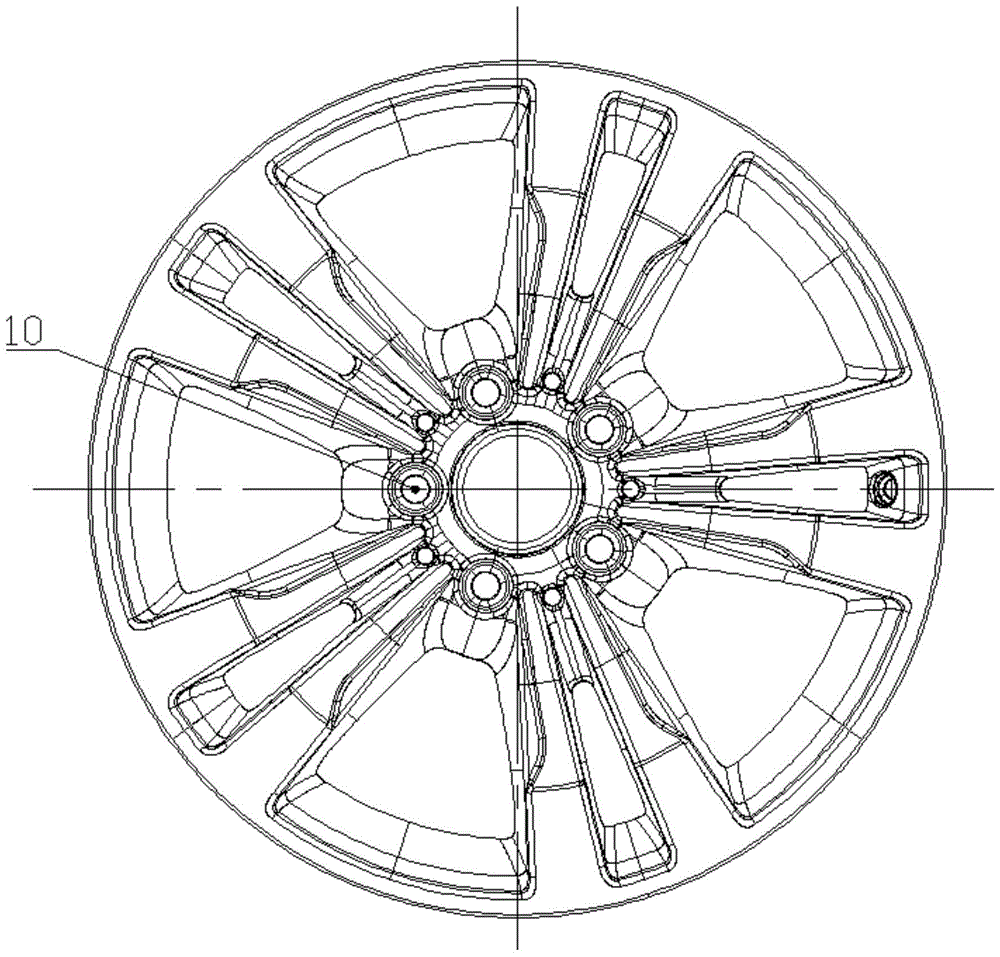

A method for detecting the center depth of aluminum wheel billet

ActiveCN105526870BImprove processing yieldReduce labor intensityUsing optical meansWheel manufactureLaser rangingEngineering

The invention relates to a device and method for detecting the depth of the wheel center of an aluminum wheel slab. The device includes a roller tray (1), a position sensor (3), a frame (4), a CCD camera (5), a programmable control Device (6) and laser ranging sensor (7), upper servo cylinder (8), motor support (11), servo motor (12), lower servo cylinder (13). The benefits of the present invention are that, using the method of automatic detection and identification of wheel core depth of wheel billets to identify and classify wheel billets, reduce the influence of large casting size tolerances on machining size tolerances, improve the machining yield of automatic machining units, and ensure The production line runs automatically with quality and quantity guaranteed, while reducing the labor intensity of the operator.

Owner:CITIC DICASTAL

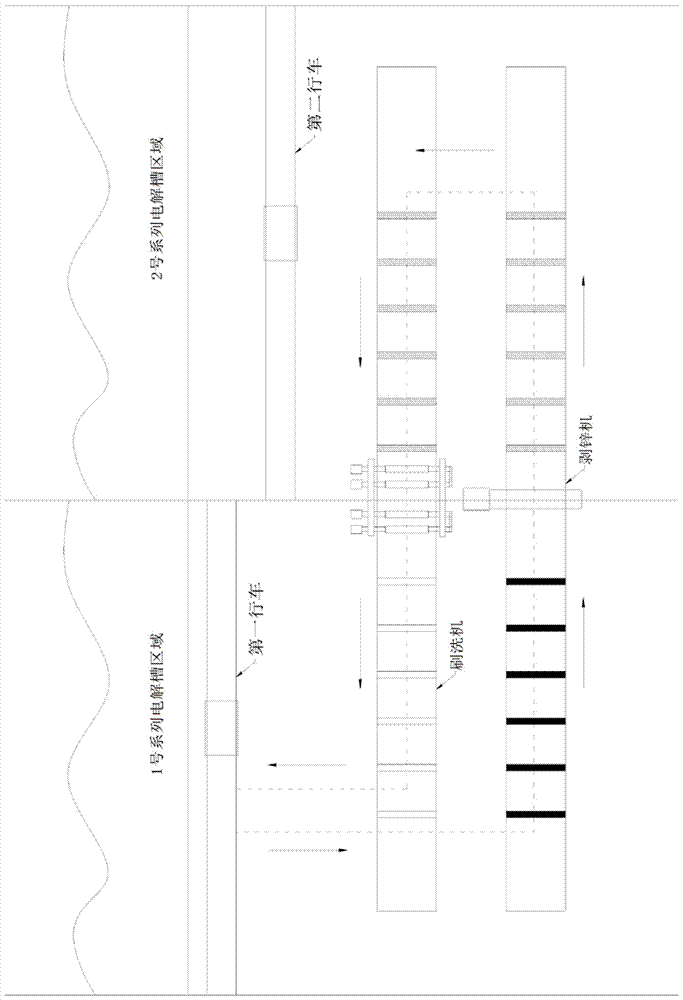

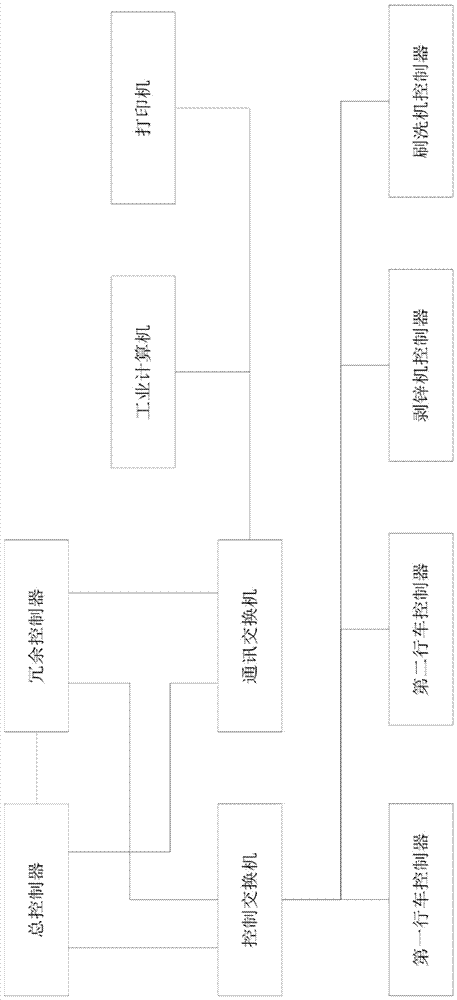

Centralized control system and control method for zinc stripping production line

ActiveCN105204479BGuaranteed to run automaticallyIncrease the level of automationTotal factory controlProgramme total factory controlProduction lineControl system

Owner:CINF ENG CO LTD

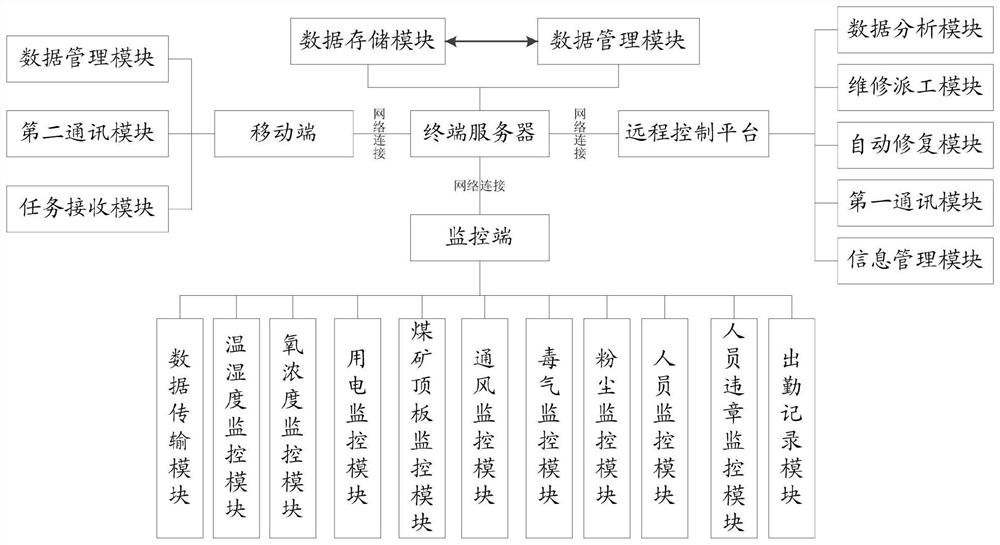

Coal mine production safety intelligent management system

PendingCN114137925AGuarantee the production progressEnsure personal safetyTechnology managementTotal factory controlTerminal serverMobile end

The invention, which relates to the technical field of coal mine management, discloses a coal mine production safety intelligent management system comprising a terminal server, a remote control platform, a mobile terminal and a monitoring terminal. The terminal server comprises a data storage module and a GIS model module; the monitoring end comprises a data transmission module, a temperature and humidity monitoring module, an oxygen concentration monitoring module, an electricity utilization monitoring module, a coal mine roof monitoring module, a ventilation monitoring module, a poison gas monitoring module, a dust monitoring module, a personnel monitoring module, a personnel violation monitoring module and an attendance recording module; the remote control platform comprises a data analysis module and an automatic repair module; the number of the mobile terminals is multiple. The invention aims to provide the intelligent management system for coal mine production safety, which can automatically operate, reduce human input and further ensure the production progress of a coal mine and the personal safety of workers.

Owner:山东省邱集煤矿有限公司

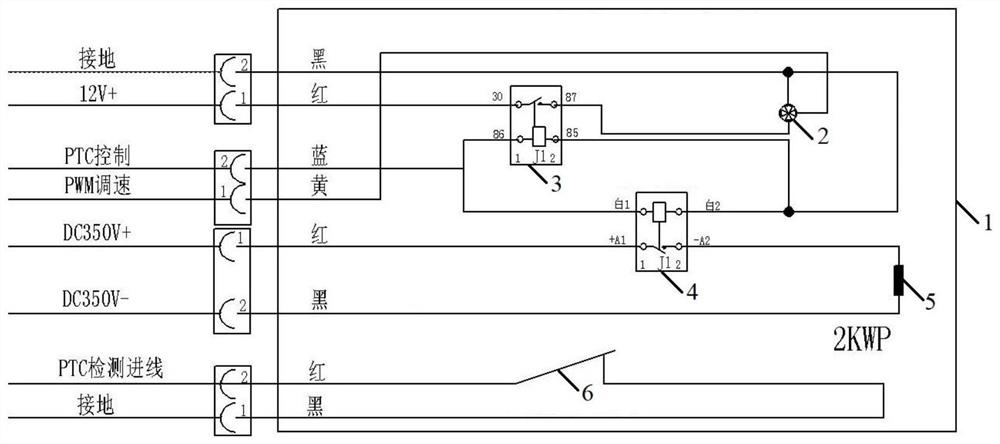

PTC assembly with alarming and automatic air volume adjusting functions

PendingCN112440669ARealize free adjustment functionReasonable size controlAir-treating devicesVehicle heating/cooling devicesTemperature controlAir volume

The invention provides a PTC assembly with alarming and automatic air volume adjusting functions. The PTC assembly is characterized in that a PTC core body, a fan, a direct-current contactor, a direct-current relay and a temperature control switch are arranged in a shell, the contacts of the direct-current relay are respectively connected with a first power supply and the fan, the PTC control signal output end of an air conditioner controller is connected with the coil input ends of the direct-current relay and the direct-current contactor, the coil output ends of the direct-current relay andthe direct-current contactor are jointly connected to the negative electrode of the fan, the PWM speed regulation signal output end of an automobile air conditioner is connected with the PWM signal receiving end of the fan, the contact of the direct-current contactor is connected with the positive electrode of a second power supply and one end of the PTC core body, the other end of the PTC core body is connected with the negative electrode of the second power supply, one end of the temperature control switch is connected with the PTC detection wire inlet end of the air conditioner controller,and the other end of the temperature control switch is grounded. The PTC assembly has the alarm and air volume automatic regulation functions, and PTC air volume stepless speed regulation and over-temperature alarm are achieved.

Owner:YUXIN MACHINRY

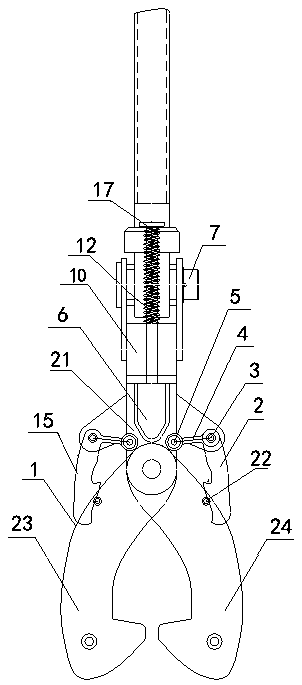

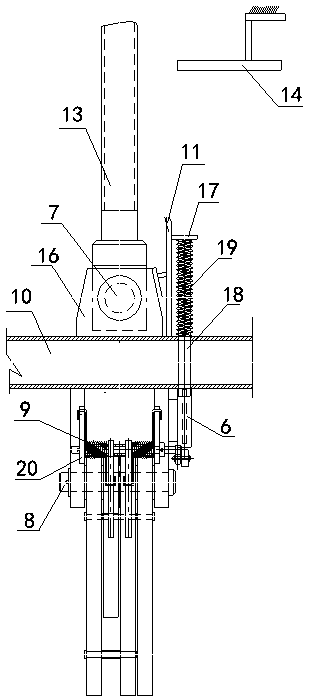

Automatic grab hook lifting appliance for I-shaped steel

PendingCN111320070AReduce maintenance costsAvoid collisionLoad-engaging elementsIdler-wheelRocker arm

The invention provides an automatic grab hook lifting appliance for I-shaped steel. The automatic grab hook lifting appliance comprises a grab hook body, and the grab hook body comprises a connectingpart, a grab hook arranged on the lower part of the connecting part in a hinged mode, and locking pieces arranged on the two sides of the connecting part in a mirroring mode; and the locking pieces each comprise an idler wheel arranged on the connecting part, a positioning piece arranged on the side face of the connecting part, a pin shaft arranged on the positioning piece, a locking hook arrangedon the pin shaft, and a rocker arm arranged between the idler wheel and the pin shaft, torsional springs are arranged on the pin shafts, one ends of the torsional springs abut against the positioningpieces, the other ends of the torsional springs abut against the locking hooks, locking shafts are arranged on the two sides of the grab hook correspondingly, the locking hooks are movably arranged on the locking shafts, and the inner edge and the outer edge of the grab hook are each in an arc shape. Compared with the prior art, the locking structure is simple, the locking state is firm, the security risk of hoisting of the I-shaped steel is reduced or avoided, and the functions of stable moving, efficient working, automatic hooking and automatic locking are achieved; and during constructionoperation, manual hooking for fixing is not needed, manual intervention is reduced, and the construction efficiency is improved.

Owner:中电建(洛阳)装配式建筑科技有限公司 +1

Programmable upper computer automatic follow-up method

ActiveCN109209504BImprove control efficiencyImprove work efficiencyMining devicesSlitting machinesReal-time dataAlgorithm

The invention discloses a programmable upper computer automatic follow-up method. 1, an upper computer queries the database to obtain an effective automatic follow-up parameter model; 2, judging whether the obtained automatic follow-up parameter model is valid or not, and if it is an effective automatic follow-up parameter model, carrying out the third step; if the parameter model is invalid, theparameter model is edited and created through the graphical interface, and then saved to the database for the third step; 3, the parameter model of the automatic follow-up machine is load by the uppercomputer; 4, the automatic follow-up parameter model is simulated and operated, and whether the running result is correct is checked; if the result is correct, step 5 is carried out and otherwise, the second step is repeated; 5, real-time data of that shearer, the conveyor and the hydraulic support is obtained by the upper computer; 6, the upper computer sends an action control instruction to thebracket controller; 7, whether the action of the hydraulic support is complete is judged; if completed, end; otherwise step 6 is repeated. The invention has the advantages of achieving continuous, safe and efficient mining of the fully mechanized mining face.

Owner:郑州恒达智控科技股份有限公司

Method for preparing high-strength and high-toughness aluminium alloy aviation safety part through modification

InactiveCN102108476BMeet the standard requirementsSimple structureTemperature controlComputer module

The invention discloses a method for preparing a high-strength and toughness aluminium alloy aviation safety part through modification. The method is characterized in that a modification preparation system comprising a heat treatment device, a temperature control module and a computer control center which are connected in sequence is adopted; and the heat treatment device comprises an electric heating furnace, a cold water tank, an external guide rail bracket and a charging carriage. The method comprises the steps of charging, heating, heat preserving, cooling and the like. Through inspection, the mechanical property of the product obtained through treatment of the method can meet the requirement of aviation. Meanwhile, as the product is prepared by carrying out secondary modification on the workpiece processed with the common 2Al2-O aluminium alloy through heat treatment, the cost of the material is low. In addition, the treatment system used in the method is also obtained through combination of many existing conventional tools, so the equipment cost is low and the treatment system has the advantage of low production cost.

Owner:CHONGQING YUYI MACHINE

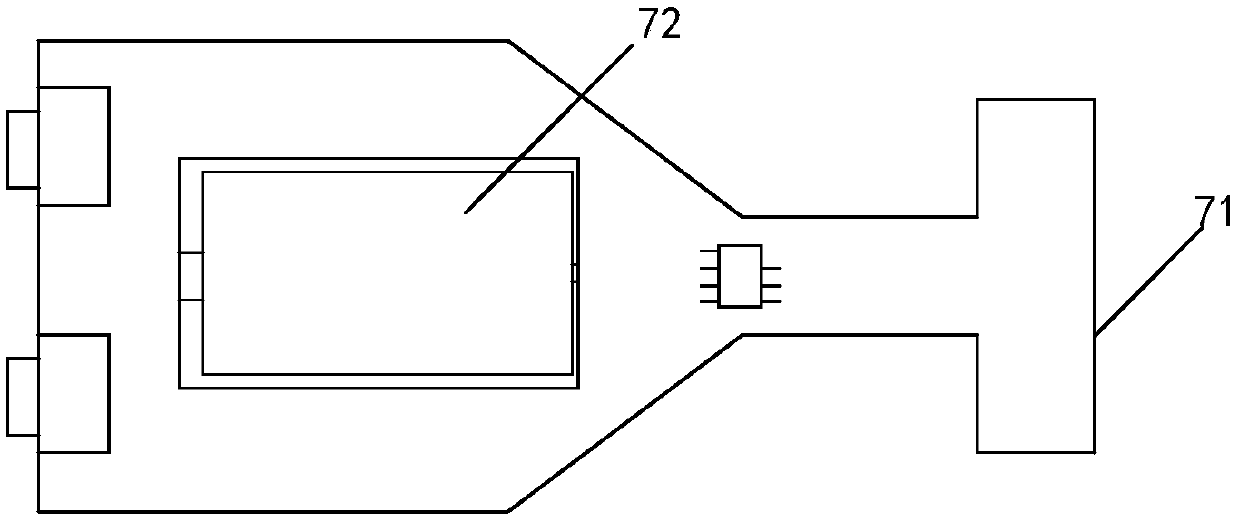

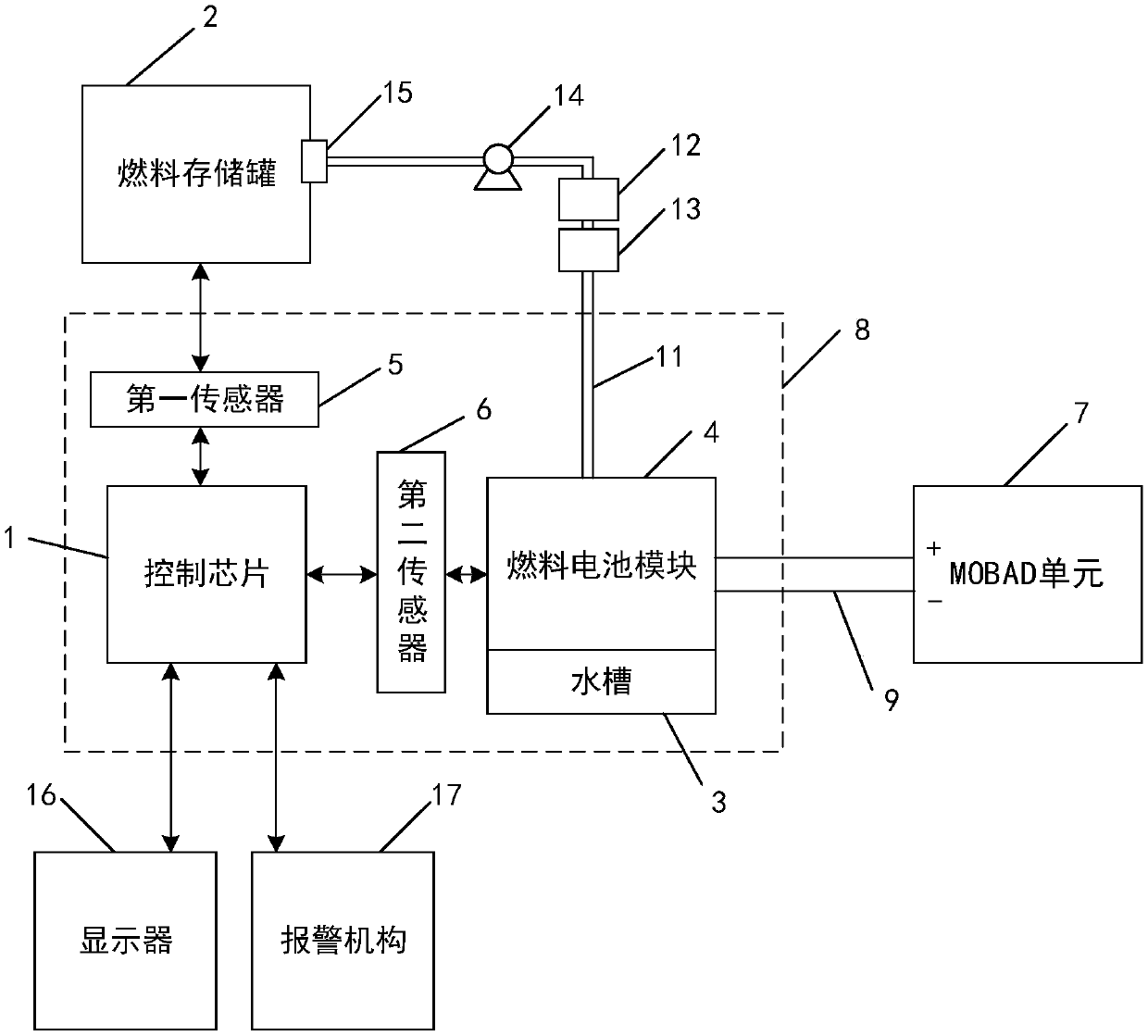

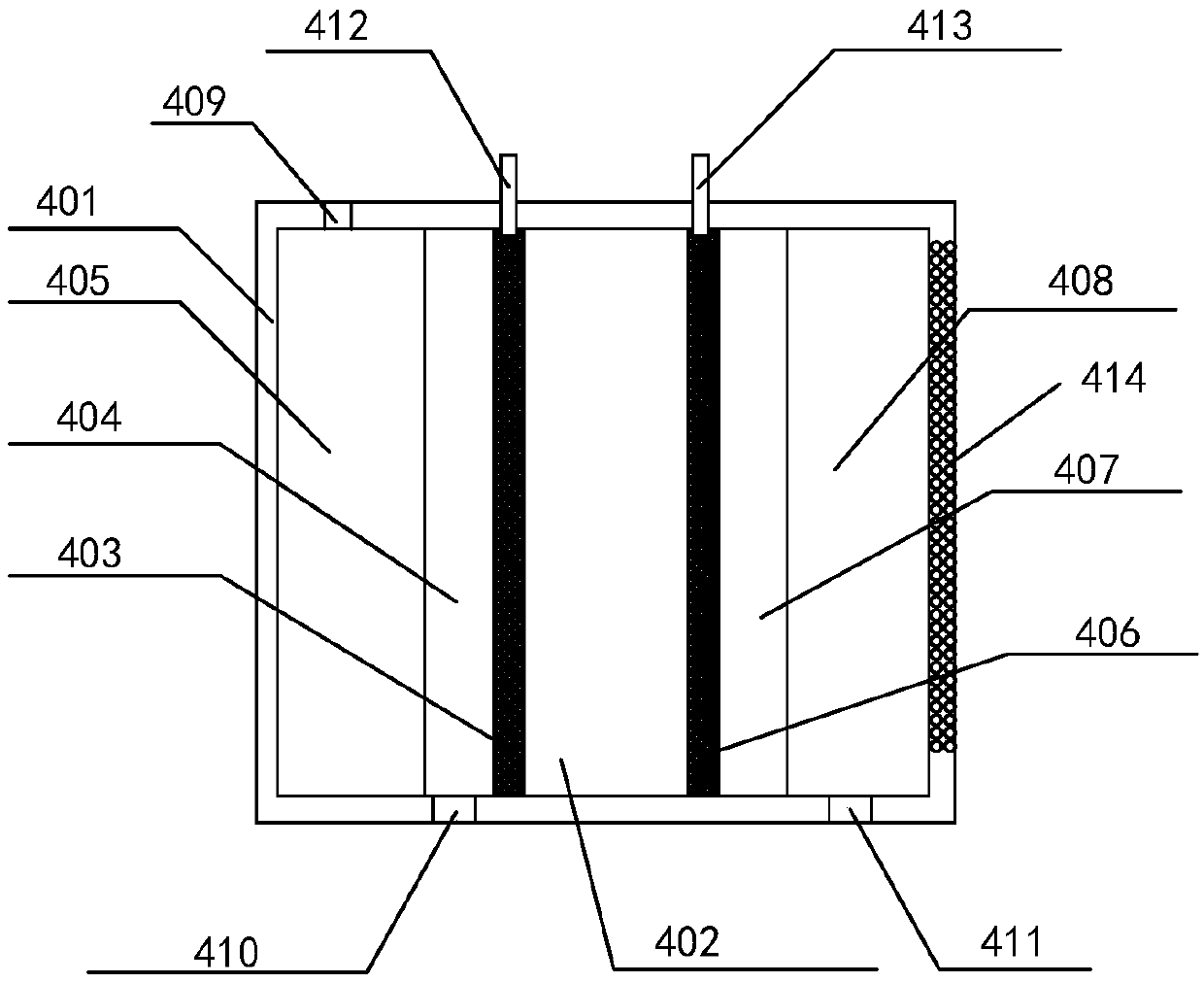

Fuel cell device for train ATP system

PendingCN110858656AImprove reliabilityGuaranteed to run automaticallyFuel cell controlFuel cellsControl theory

The invention relates to a fuel cell device for a train ATP system, which comprises a control chip, a fuel storage tank, a water tank, a fuel cell module, a first liquid level sensor and a second liquid level sensor, wherein the first liquid level sensor is connected with the fuel storage tank; the second liquid level sensor is connected with the fuel cell module; a valve is arranged at an outletof the fuel storage tank; the first liquid level sensor, the second liquid level sensor and the valve are all connected with the control chip; the fuel storage tank is connected with the fuel cell module; the water tank is installed below the fuel cell module; and the fuel cell module is connected with an MOBAD unit in the train ATP system. Compared with the prior art, a user only needs to supplement fuel to ensure normal operation of the train ATP system, the operation is simple, a complex battery replacement process is omitted, and the working efficiency is improved. Moreover, the stabilityof the system is improved by using the fuel cell, and the whole process is environment-friendly and efficient.

Owner:SHANGHAI RAILWAY COMM

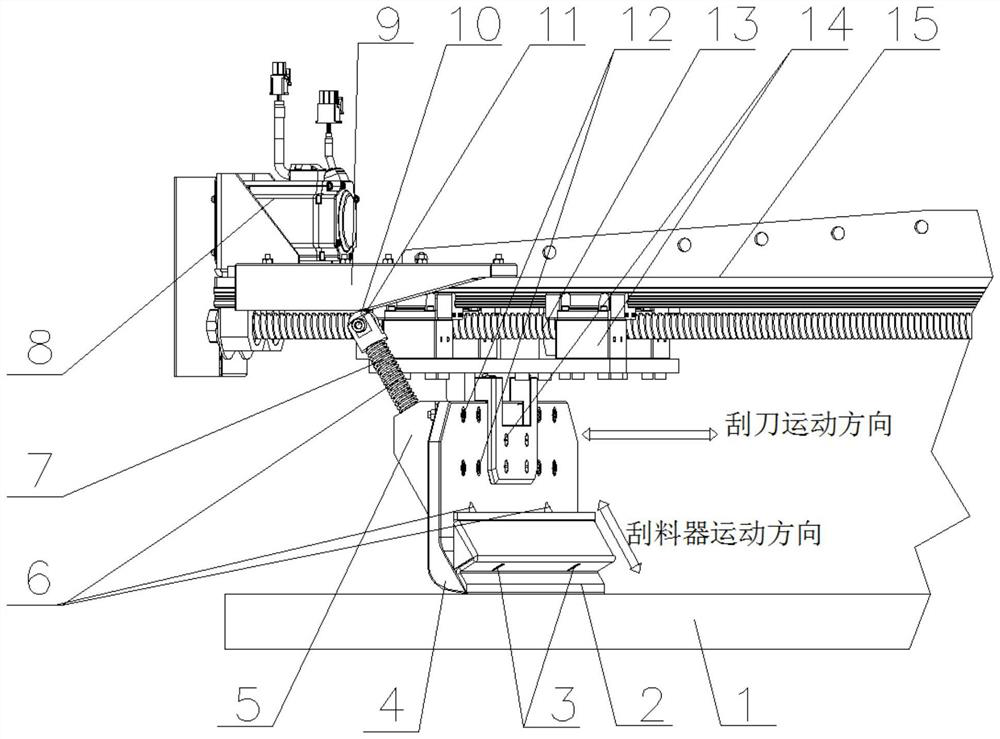

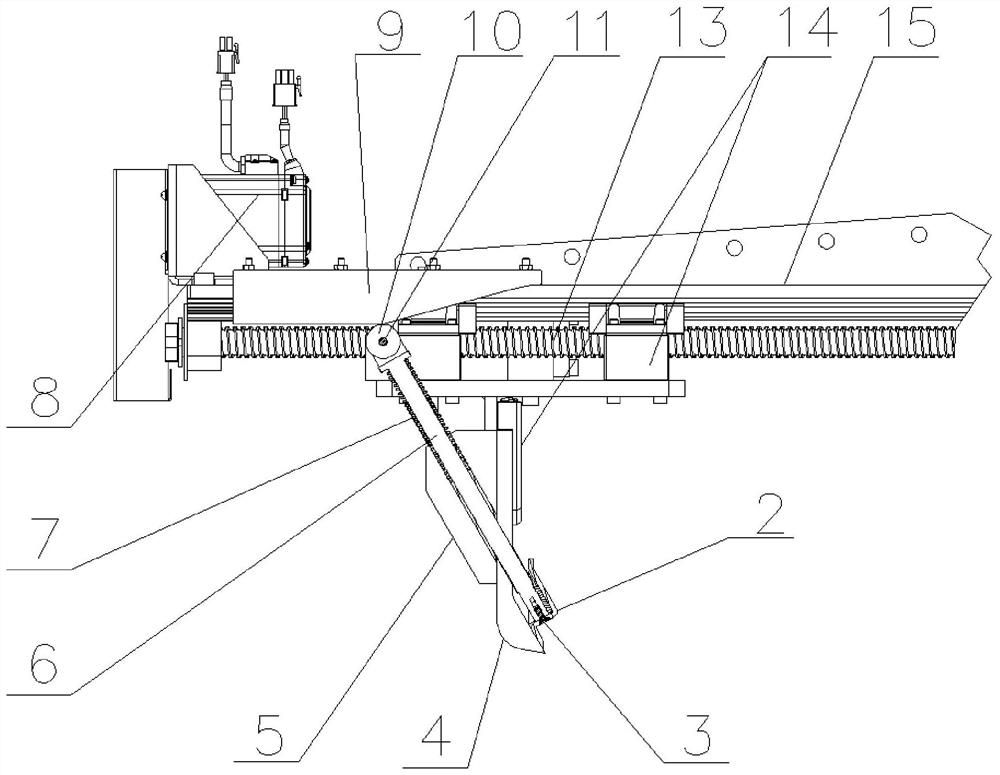

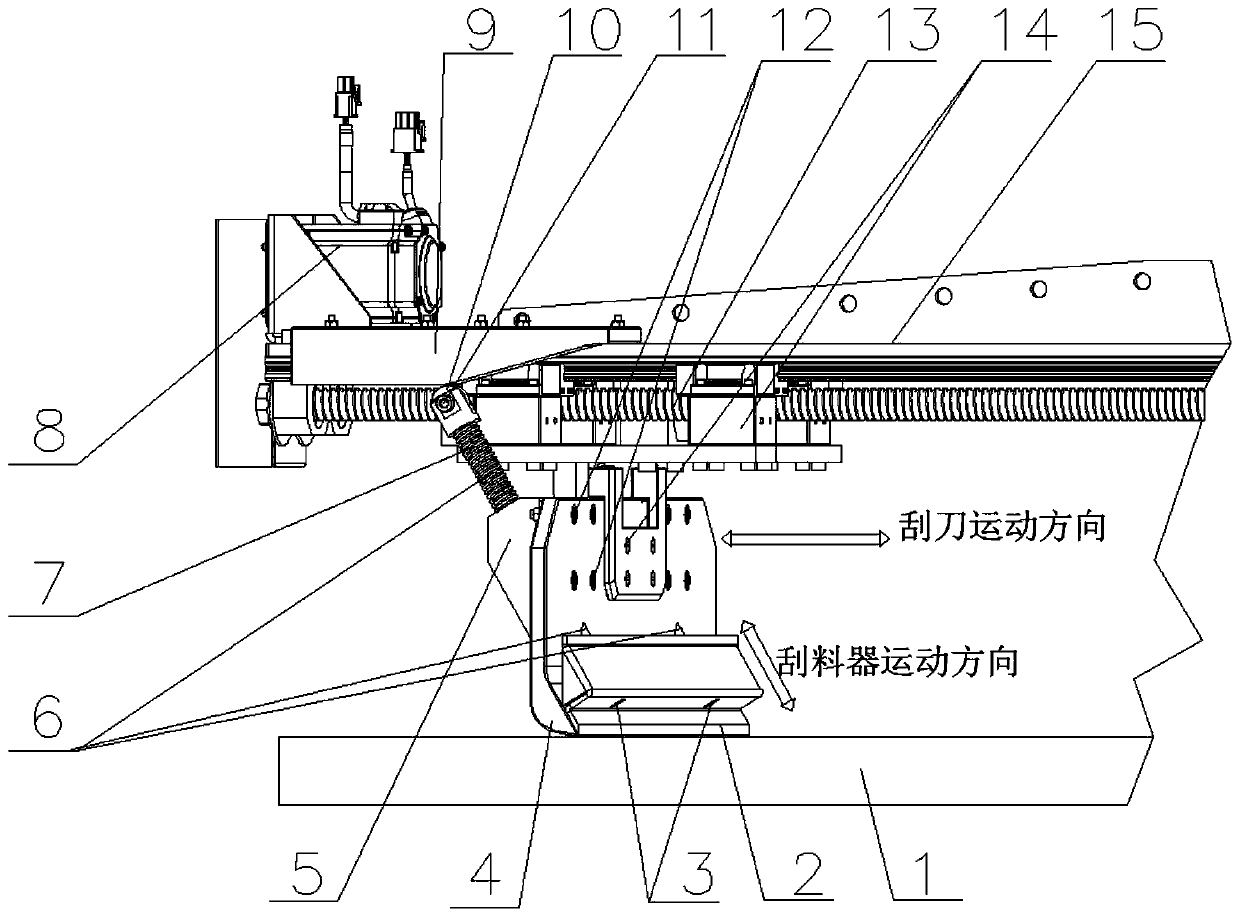

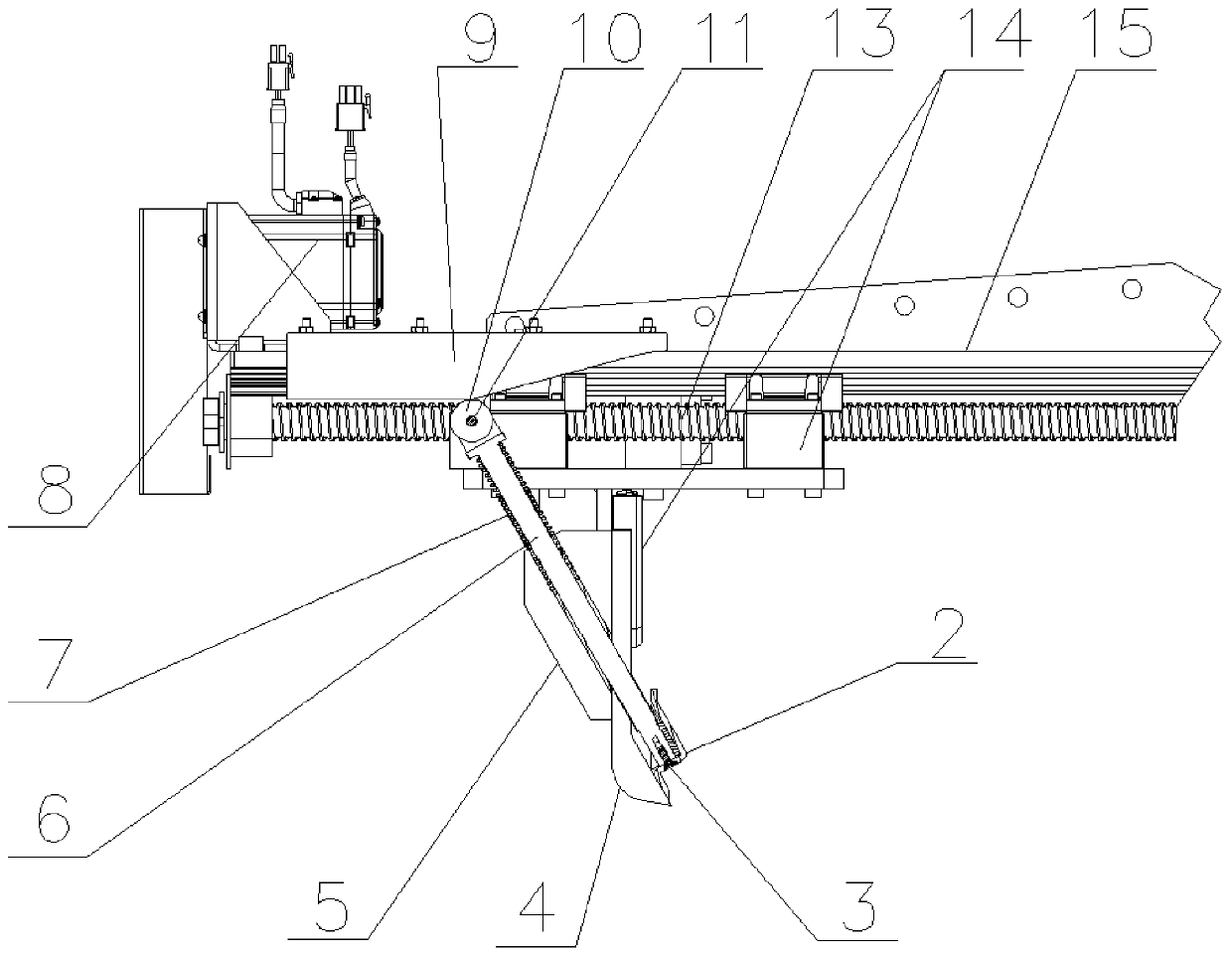

A scraper device with a scraper on the scraper

ActiveCN111185412BGuaranteed scraping effectGuaranteed to run automaticallyCleaning using toolsPressesStructural engineeringMechanical engineering

The invention discloses a scraping device with a scraper on a scraper, which includes a cross beam, an inclined wedge, a driving assembly, a scraper seat, a scraper, a scraper, a sliding rod, a sliding sleeve, and a spring; the inclined wedge and the driving assembly are provided separately. On the beam, the top of the scraper seat is connected to the driving component, the bottom of the scraper seat is connected to the scraper, the scraper is in contact with the inclined surface at the bottom of the scraper, the scraper is connected to the bottom of the sliding rod, and the top of the sliding rod passes through the scraper, sliding sleeve and inclined surface in sequence. The bottom surface of the wedge is in contact with each other, the spring is sleeved on the sliding rod, and the spring is located between the sliding sleeve and the inclined wedge. The scraper in the device of the invention can scrape off the adhering composite material on the scraper, thereby ensuring the scraping effect of the scraper, ensuring the automatic operation of the machine, and avoiding pausing the machine during production to clean the adhering material on the scraper. After the scraper device with a scraper on the scraper of the present invention is used on the machine, the problem of sticky materials on the scraper affecting production can be solved, the production efficiency can be improved, and the labor intensity of workers can be reduced at the same time.

Owner:深圳市华阳通达精密机械有限公司

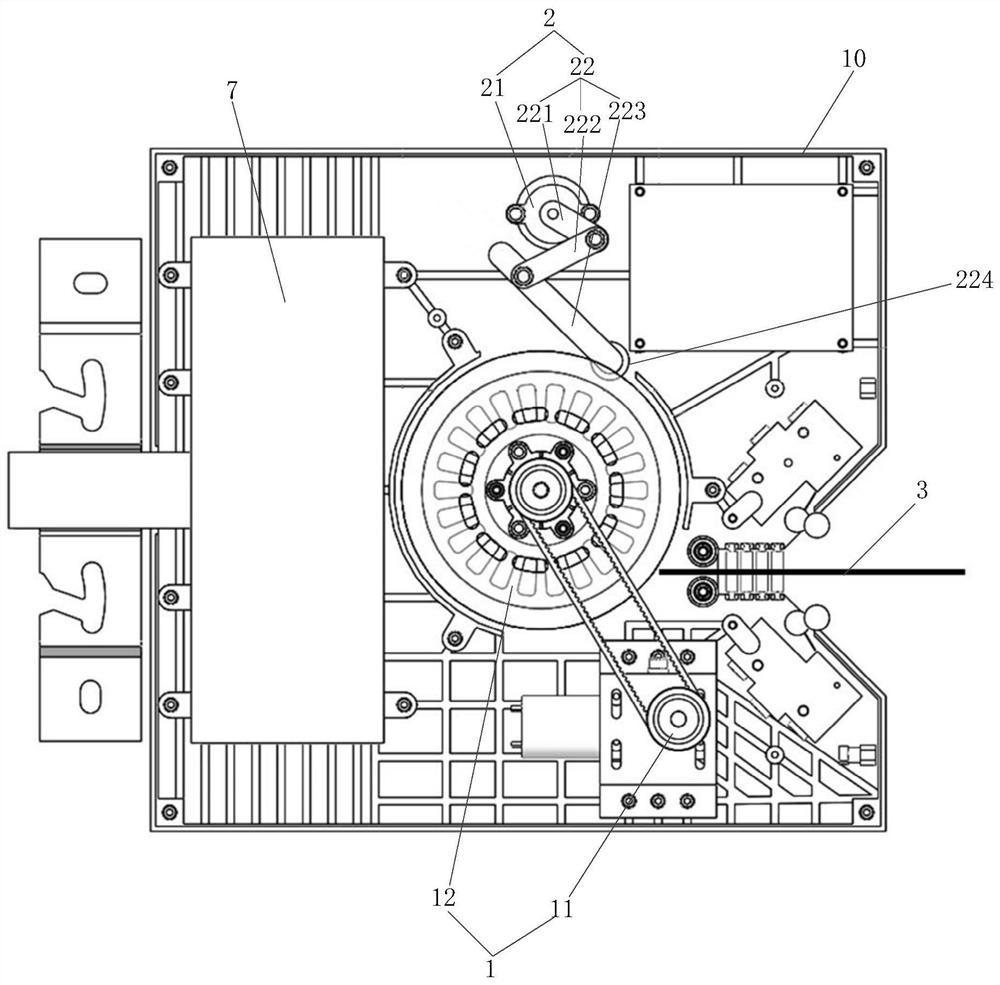

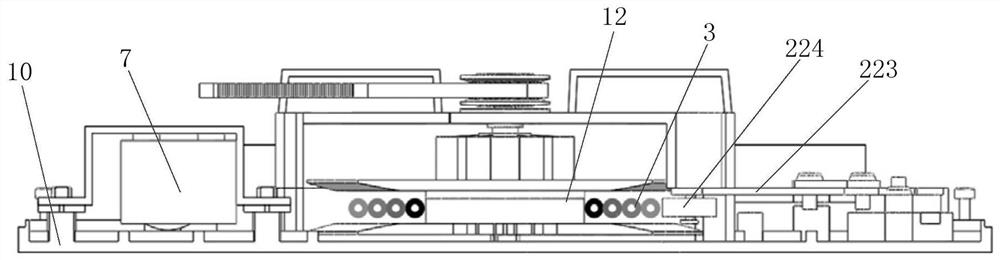

Automatic charging device, automatic charging device control method and display device

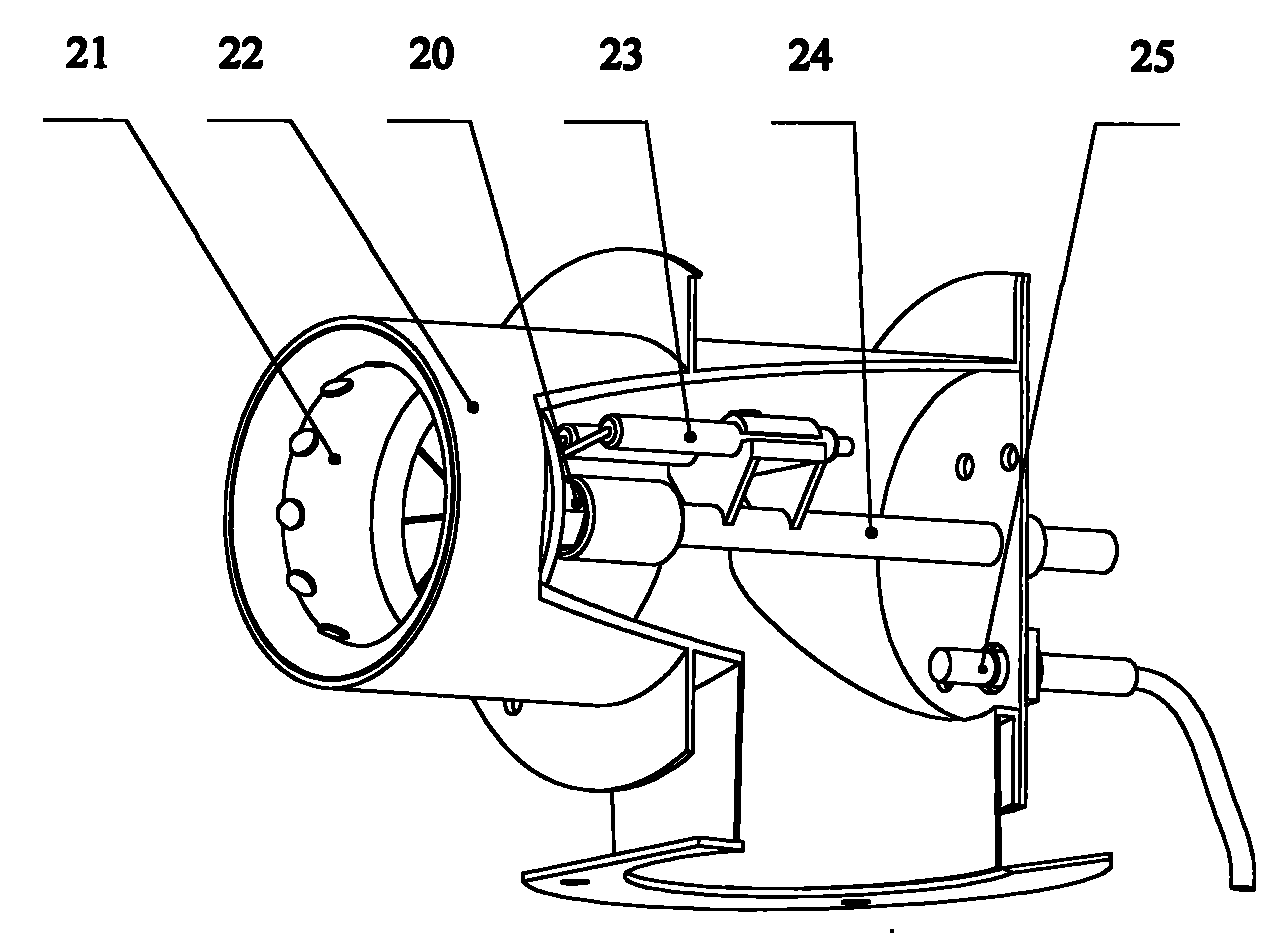

ActiveCN110054034BAchieve windingAvoid messy entanglement situationsFilament handlingWire rodElectric machine

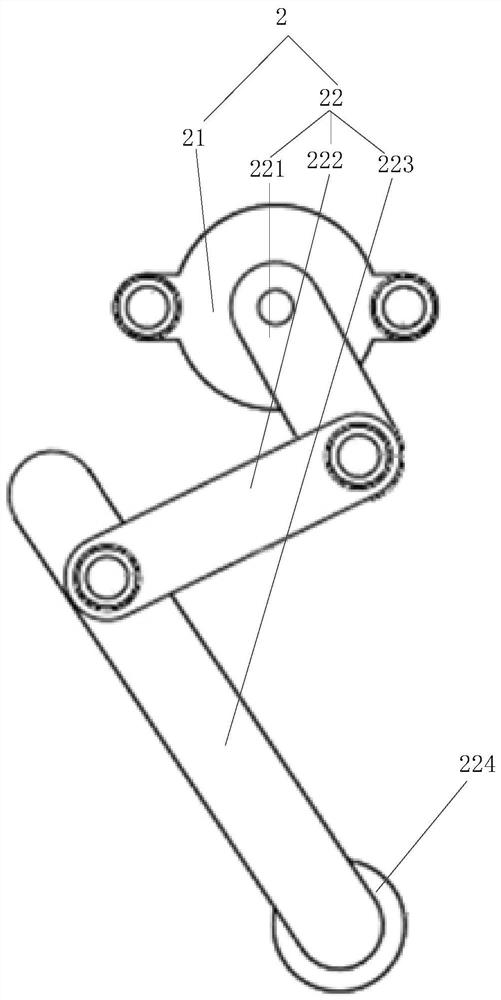

A wire collection device, comprising: a wire winding and unwinding device (1), a limiting device (2) and a controller (4). The wire winding and unwinding device (1) comprises a first drive motor (11) and a reel (12), wherein the first drive motor (11) drives the reel (12) to reciprocate. The reel (12) is configured to wind up a winding and unwinding electrical connection wire (3) in use. The limiting device (2) comprises a second drive motor (21) and a pressing structure (22), wherein the second drive motor (21) is configured to drive the pressing structure (22) to press on the surface of the outermost circle of the electrical connection wire (3) wound by the reel (12) in use. The controller (4) is in signal connection with the first drive motor (11) and the second drive motor (21), and is configured to control the first drive motor (11) to drive the reel (12) to reciprocate, and to control the second drive motor (21) to apply a pressing force to the electrical connection wire (3) in use through the pressing structure (22). The wire collection device solves the problem of disordered winding of electrical connection wires. The present invention further relates to a charging device, a charging device control method, and an electronic device.

Owner:BOE TECH GRP CO LTD

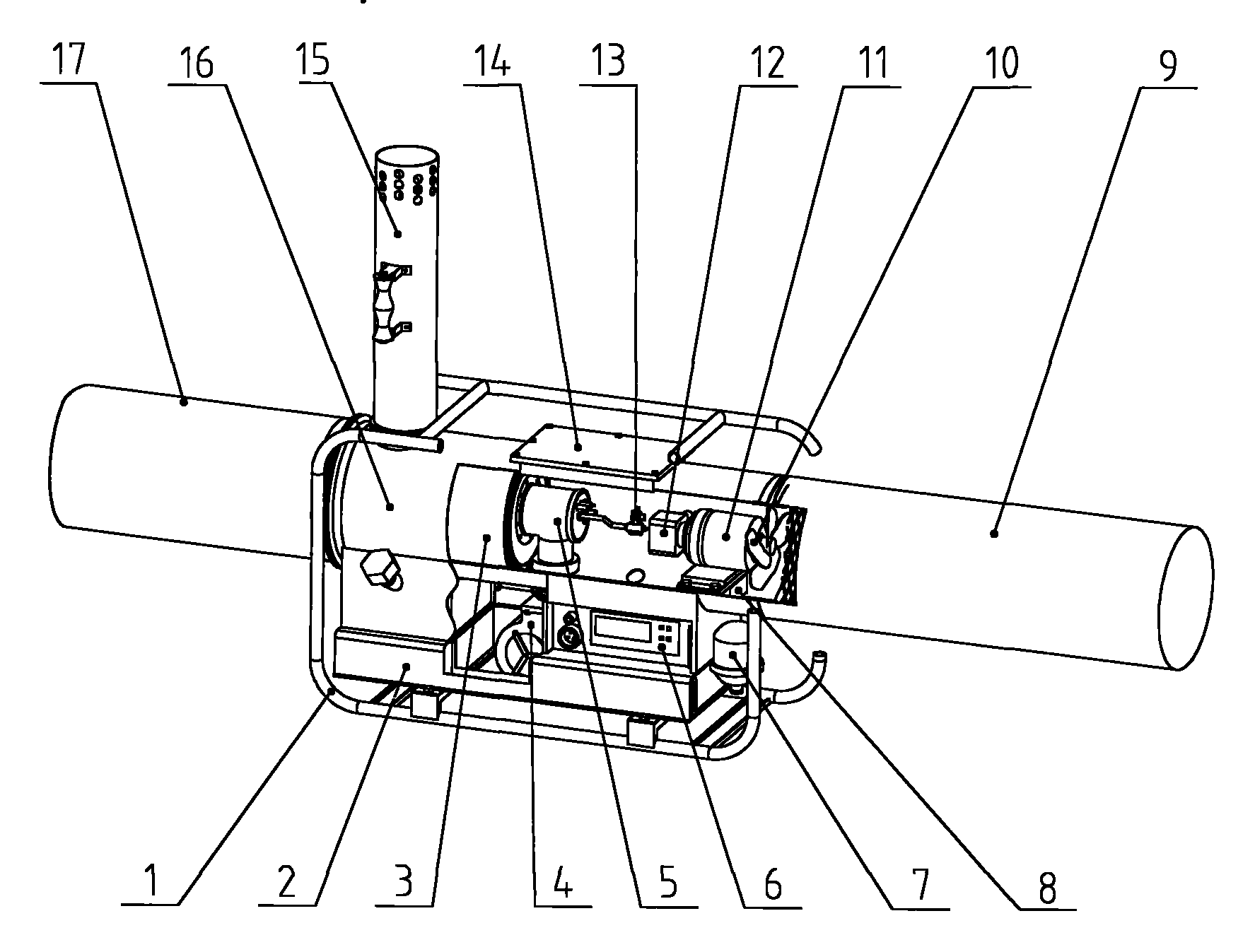

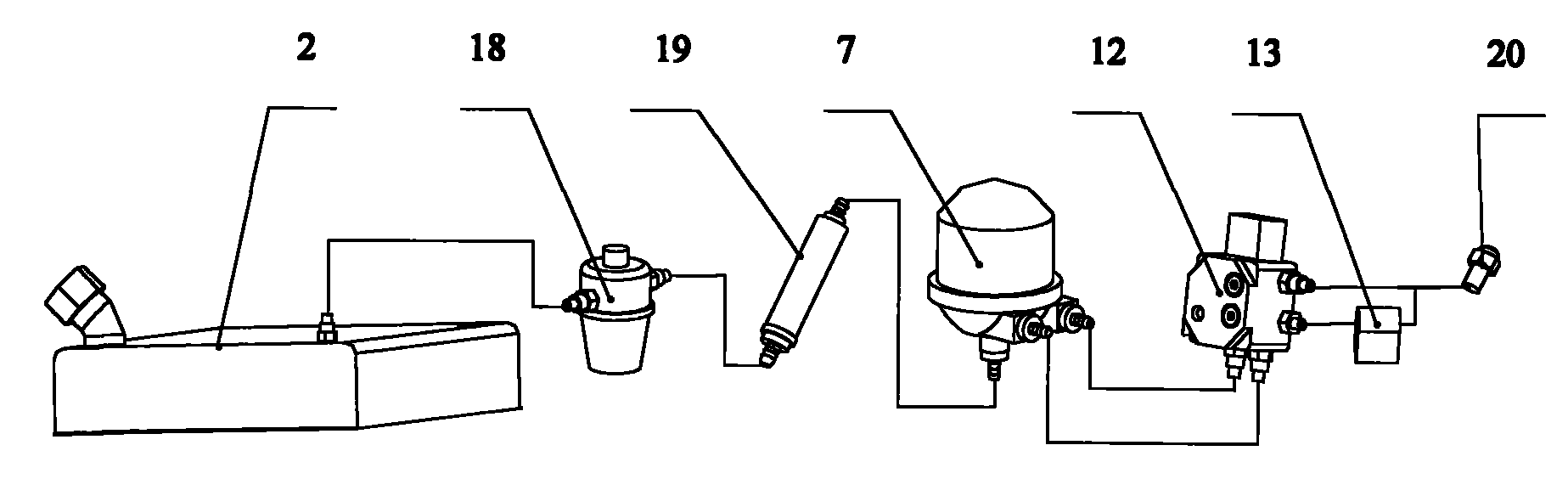

Portable fuel heater unit

InactiveCN101539329BReduce volumeSolve the problem of black smokeAir heatersCombustion systemCombustion chamber

The invention discloses a portable fuel heater unit. The bottom of a frame is fixed with a fuel tank, the middle of the fuel tank is fixed with a combustion fan, the frame is provided with a controller, the side is provided with a flow control valve, the heater unit is fixed with a cylinder body close to the upper part, the inner part of the cylinder is axially sequentially provided with a combustion chamber and a heat exchanger which are connected with a combustion system, the combustion is connected with a normally open solenoid valve of a fuel supply system through a fuel pipe and is connected with a fuel pump through a fuel pipe, one end of a motor is connected with the fuel pump, the other end of the motor is connected with a heat exchange fan, the motor is fixed in the cylinder body, the controller is connected with an ignition transformer, and flue pipes are inserted into outlets of the combustion chamber and the heat exchanger.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

Scraping device with scrapers on scraping blades

ActiveCN111185412AGuaranteed scraping effectGuaranteed to run automaticallyCleaning using toolsPressesStructural engineeringMechanical engineering

The invention discloses a scraping device with scrapers on scraping blades. The scraping device comprises a cross beam, inclined wedges, driving assemblies, scraping blade bases, the scraping blades,the scrapers, sliding rods, sliding sleeves and springs, wherein the inclined wedges and the driving assemblies are arranged on the cross beam, the tops of the scraping blade bases are connected withthe driving assemblies, the bottoms of the scraping bases are connected with the scraping blades, the scrapers abut against the slopes of the bottoms of the scraping blades, the scrapers are connectedwith the bottoms of the sliding rods, the tops of the sliding rods sequentially penetrate through the scraping blades and the sliding sleeves to abut against the bottom faces of the inclined wedges,and the springs sleeve the sliding rods and are located between the sliding sleeves and the inclined wedges. According to the scraping device, the scrapers in the device can scrape off composite materials adhering to the scraping blades, so that the scraping effect of the scraping blades is ensured, the automatic operation of a machine is ensured, and the situation that the machine is paused to clear materials adhering to scraping blades in the production process is avoided. After the scraping device with the scrapers on the scraping blades is adopted on the machine, the problem that production is affected due to the fact that the materials adhere to the scraping blades can be solved, the production efficiency is improved, and meanwhile the labor intensity of workers is relieved.

Owner:深圳市华阳通达精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com