Automatic charging device, automatic charging device control method and display device

A technology of automatic charging device and equipment, which is applied in the directions of transportation and packaging, thin material handling, and conveying filamentous materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

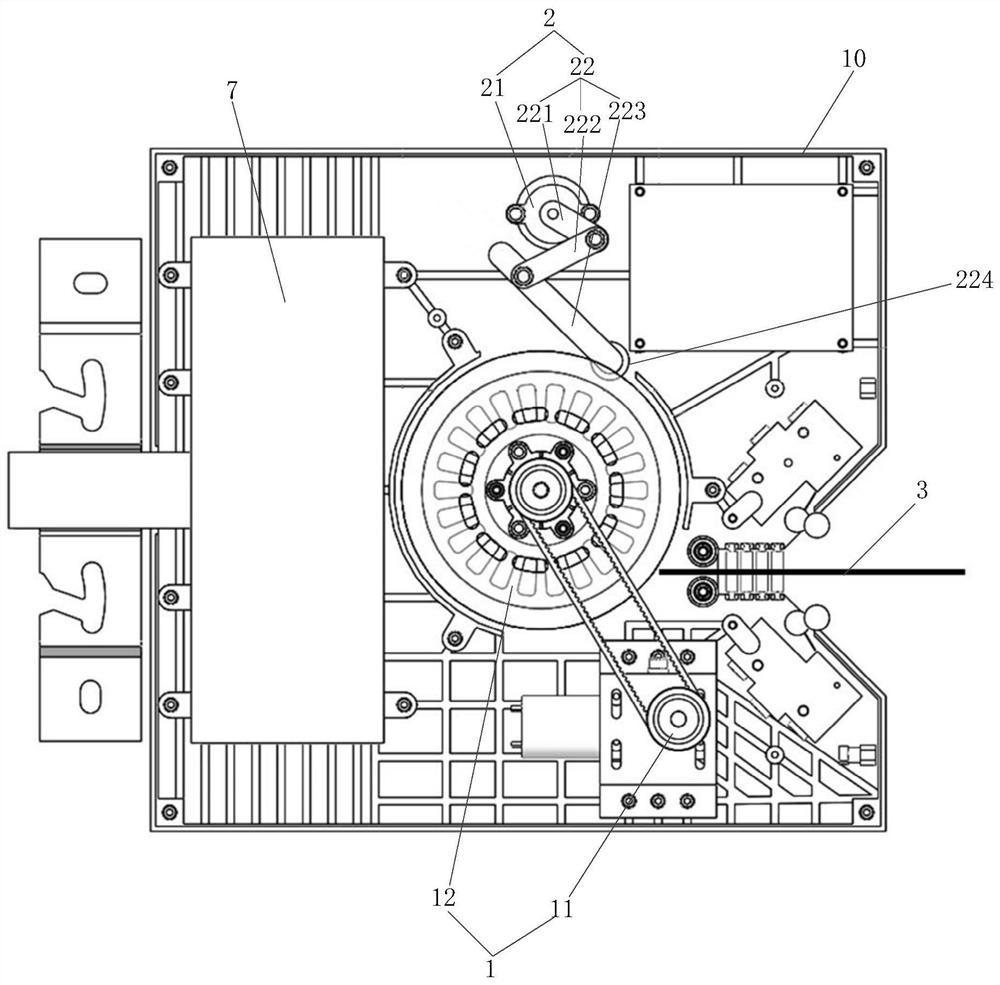

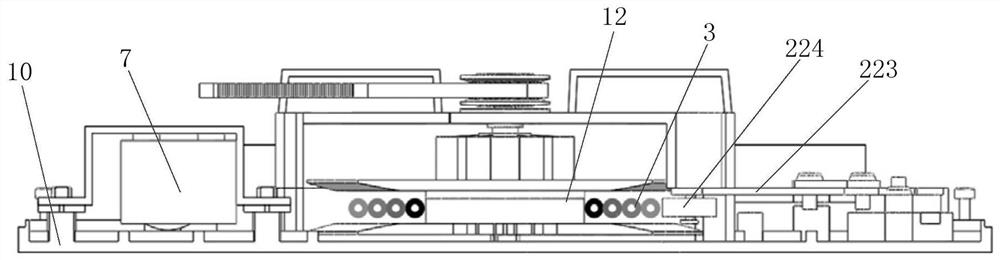

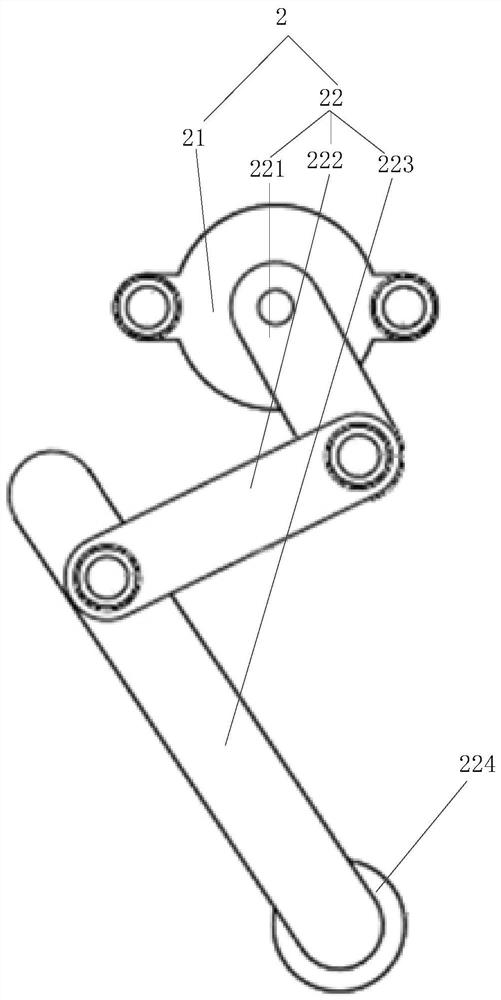

[0037] Such as Figure 1-3 As shown, the first embodiment of the present invention proposes an automatic charging device, which includes: a take-up and pay-off device 1, a limit device 2 and a controller 4, and the take-up and pay-off device 1 includes a first drive motor 11 and a reel 12. The first drive motor 11 drives the reel 12 to rotate reciprocally, and the reel 12 is used to wind the discharge connecting wire 3; the limit device 2 includes a second drive motor 21 and a pressing structure 22, the The second driving motor 21 drives the pressing structure 22 to press on the surface of the outermost circle of the electrical connection wire 3 wound by the reel 12; the controller 4 communicates with the first driving motor 11 and the second The two driving motors 21 are connected to control the reciprocating rotation of the first driving motor 11 to drive the reel 12, and to control the pressing force of the second driving motor 21 on the electrical connection wire 3 through...

Embodiment 2

[0057] An automatic charging device control method proposed in Embodiment 2 of the present invention is used for the above-mentioned automatic charging device, which includes: the controller controls the first driving motor and the second driving motor to rotate simultaneously, and controls the first driving motor to rotate clockwise Or every turn counterclockwise, the second drive motor is controlled to drive the holding structure to hold one end of the electrical connection wire, and approach or leave the axis of the reel at a distance equal to the diameter of the electrical connection wire.

[0058] Specifically, when the controller receives a charging signal, such as a charging signal from the battery management unit, the controller can control the first driving motor and the second driving motor to work simultaneously, and since the first driving motor controls the The electrical connection wire is wound around the reel, and the second drive motor controls the swing of the...

Embodiment 3

[0061] A display device proposed in Embodiment 3 of the present invention, which includes: an automatic charging device; Figure 1-Figure 3 As shown, the automatic charging device includes: a take-up and pay-off device 1, a limit device 2 and a controller 4, and the take-up and pay-off device 1 includes a first drive motor 11 and a reel 12, and the first drive motor 11 drives The spool 12 rotates reciprocatingly, and the spool 12 is used for winding the discharge connecting wire 3; the limiting device 2 includes a second driving motor 21 and a pressing structure 22, and the second driving motor 21 drives the pressing and holding The structure 22 is pressed on the surface of the outermost circle of the electrical connection wire 3 wound by the reel 12; the controller 4 is connected with the first drive motor 11 and the second drive motor 21 for controlling the The first driving motor 11 drives the reciprocating rotation of the reel 12, and controls the pressing force of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com