Horizontal three-axis stirring water washing tank

A technology for washing tanks and horizontal tanks, which is applied in the field of oil sludge treatment. It can solve the problems of uneven mixing of materials, substandard treatment, inability to perform secondary and multiple washings, etc., and achieve the effect of ensuring stirring and washing and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

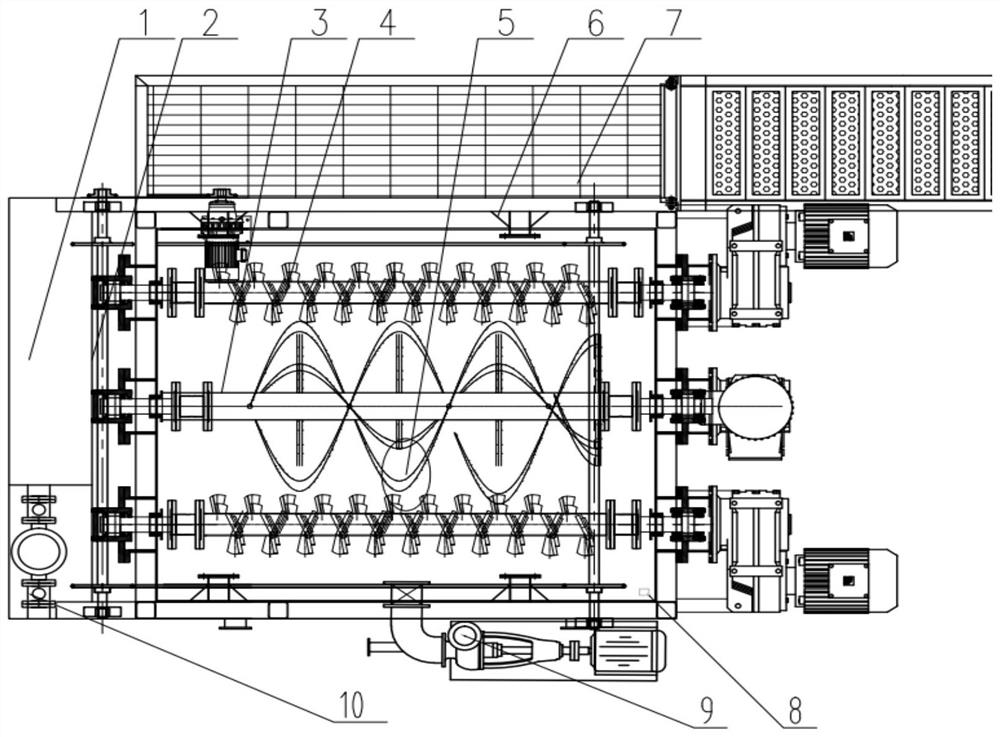

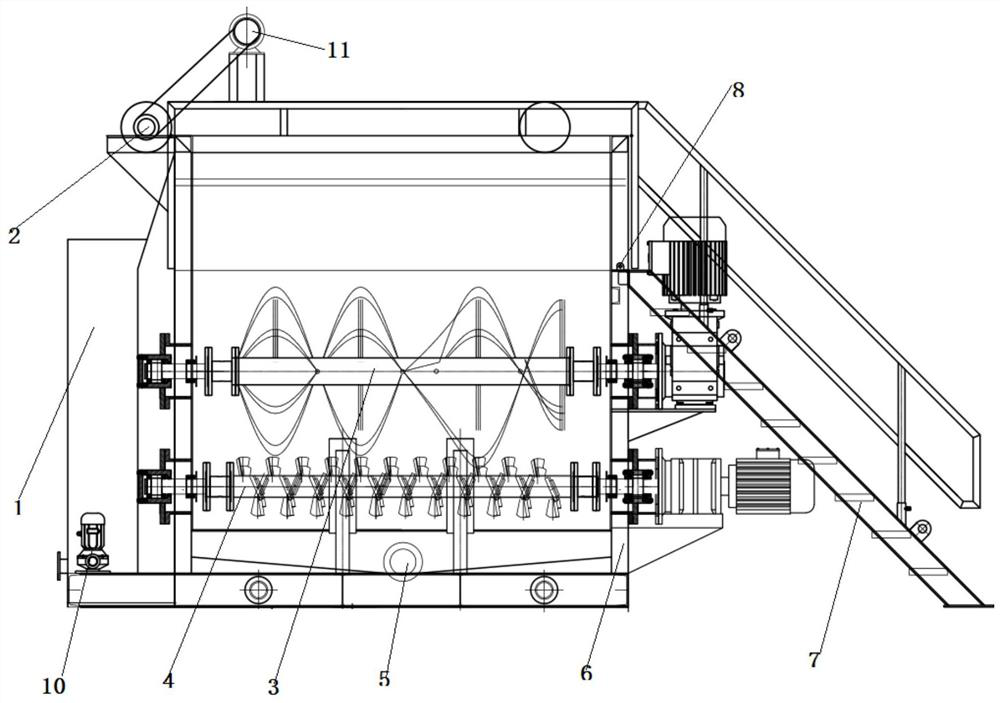

[0021] Such as figure 1 and 2 Shown, a kind of horizontal three-shaft stirring washing tank comprises horizontal tank body 6, length 5m, width 2.4m, height 2.8m; This horizontal tank body 6 is divided into two parts by the dividing plate of height 1.8 meters, One part is used as the oil storage tank 1, and the other part is used as the treatment tank; an oil pump 10 is arranged in the oil storage tank, and three agitators are arranged horizontally in the treatment tank, among which, the spiral agitator 3 is in the middle, and the two sides are The paddle agitator 4, which can be called No. 1 and No. 2, is provided with a discharge port 5 at the bottom of the treatment tank, and the discharge port 5 is connected with a slurry pump 9; an oil scraping system 2 is provided on the top of the treatment tank, so The oil scraping system is a conveyor-belt circulation system, including rotating shafts fixed on two opposite sides of the top of the tank, one of which is powered by a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com