Harmless treatment system and treatment process for ground oily sludge

A technology of harmless treatment and landing of oily sludge, applied in sludge treatment, water/sludge/sewage treatment, pyrolysis treatment of sludge, etc., can solve problems such as environmental pollution, resource loss, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

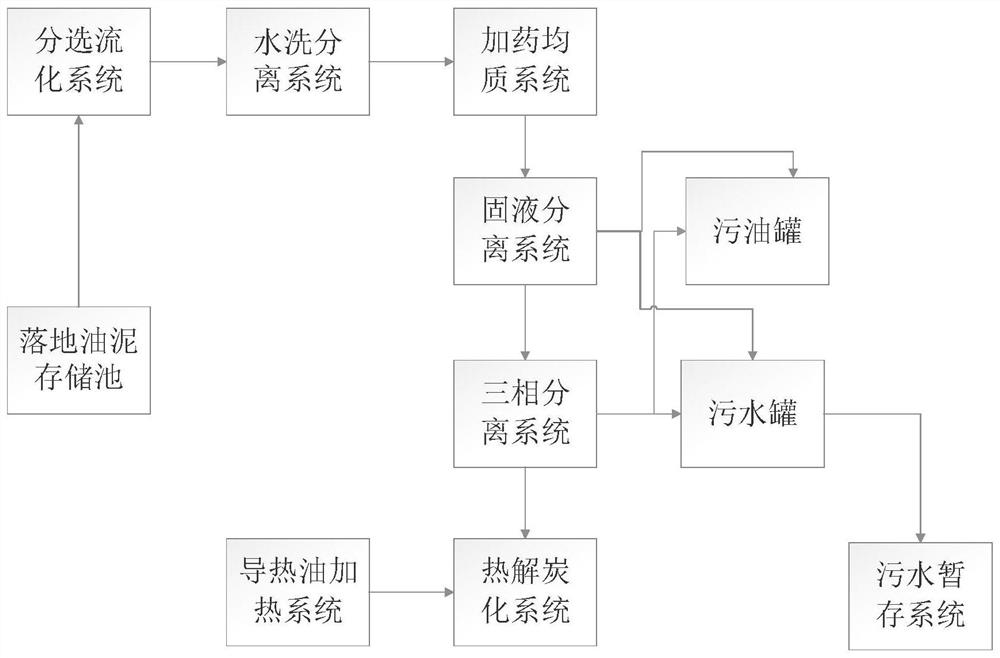

[0030]Such asfigure 1As shown, a landing cream harmless treatment system includes a landing shelter storage pool, a vibrating screen, a distribution system (screening of the collected flooring soil is sieved by vibrating screen, and the debris is transported to the pyrolytic carbonization system Nearby debris stacks. Small particulate matter and oil mud mixtures are fluidized by adding water), water washing separation system (oil, water, water, water, mud, water, mud, water, water, and mud), dosing Substance system (dosing to the treatment system, adjusting solid-liquid ratio in the pharmaceutical homogeneous system, satisfying the subsequent centrochemical processing requirements), solid-liquid separation system (separating the mud water mixture in the dosing homogeneous can, Oil into the sewage oil tank, sewage into the sewage tank), sewage tank, three-phase separation system (the oil, water, mud in the sewell tank is separated, the separated oil into the crude oil tank, sewage in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com