Method for preparing high-strength and toughness aluminium alloy aviation safety part through modification

A high-strength, high-toughness, aluminum alloy technology, which is applied in the field of modification and preparation of high-strength, high-toughness aluminum alloy aviation safety parts, can solve the problems of not reaching aviation safety parts, and achieve low production costs, cheap equipment costs, and cheap material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

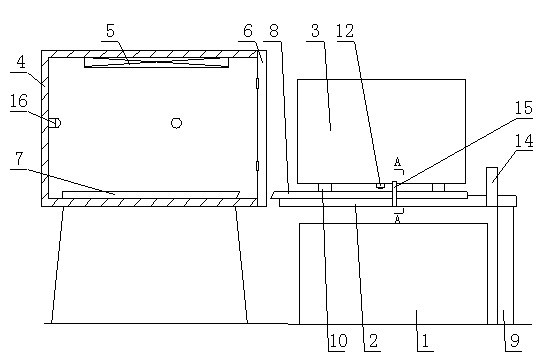

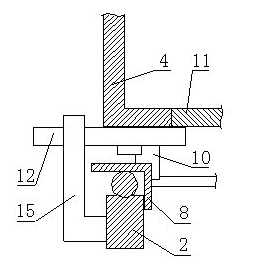

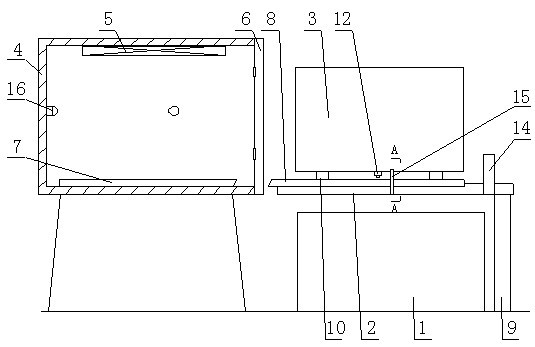

[0013] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] During specific implementation, a modified preparation method of high-strength and high-toughness aluminum alloy aviation safety parts adopts the following methods: figure 1 and figure 2 The modification preparation processing system of the structure shown, the modification preparation processing system includes a heat treatment device, a temperature control module and a computer control center connected in sequence (the structure of the temperature control module and the computer control center is not shown in the figure); the heat treatment device It includes an electric heating furnace, a cold water tank 1, an external guide rail support 2 and a charging trolley; the electric heating furnace includes a furnace body 4 with an inner cavity, and the furnace body 4 has an electric heating device 5 connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com