Automatic grab hook lifting appliance for I-shaped steel

An I-beam and automatic technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of large amount of manual intervention, weak hooks, low efficiency, etc., achieve safe and reliable operation, and reduce the overall maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

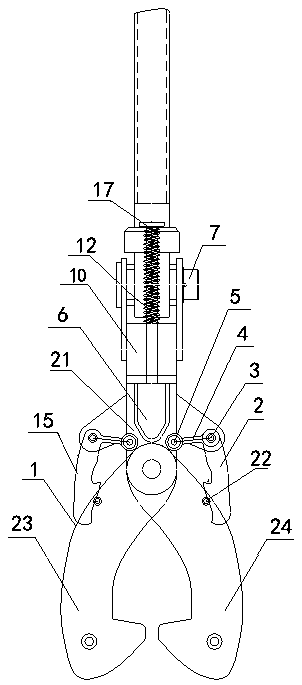

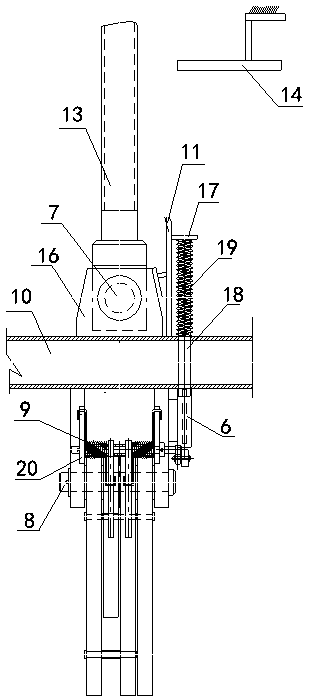

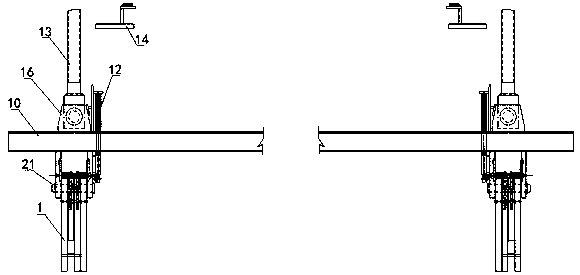

[0027] First embodiment, as shown in Fig. 1 to Figure 6 Shown: an automatic grapple hanger for I-beams, which includes: a grapple body 1, the grapple body 1 includes a connecting portion 21, a grapple hingedly arranged under the connecting portion 21 and the locking piece 15 that is mirror imaged on both sides of the connecting portion 21; the connecting portion 21 includes two sets of steel plates arranged at intervals; the grapple includes a left hook 23 and a right hook 24, and the left hook 23 and the right hook 24 are provided with a hinged portion, the hinged portion is arranged between two groups of steel plates, the hinged portion and the steel plates are provided with hinged holes correspondingly, and the grapple body 1 Hinged with the connecting part 21 through the main pin 8 arranged in the hinged hole;

[0028] The locking member 15 includes a roller 5 arranged on the connecting portion 21, a positioning member 20 arranged on the side of the connecting portion 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com