Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Guarantee normal production cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

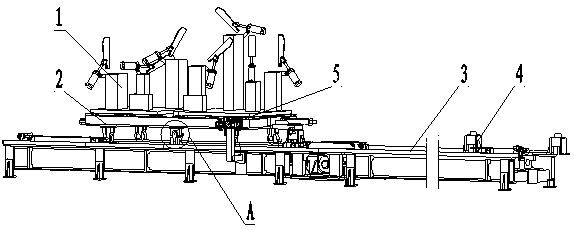

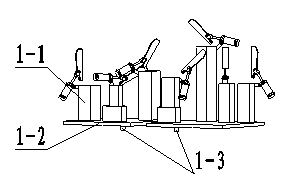

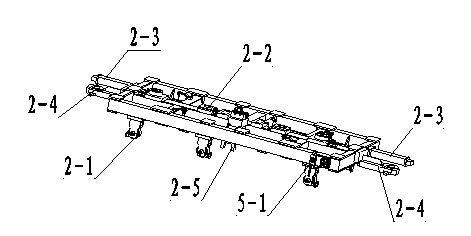

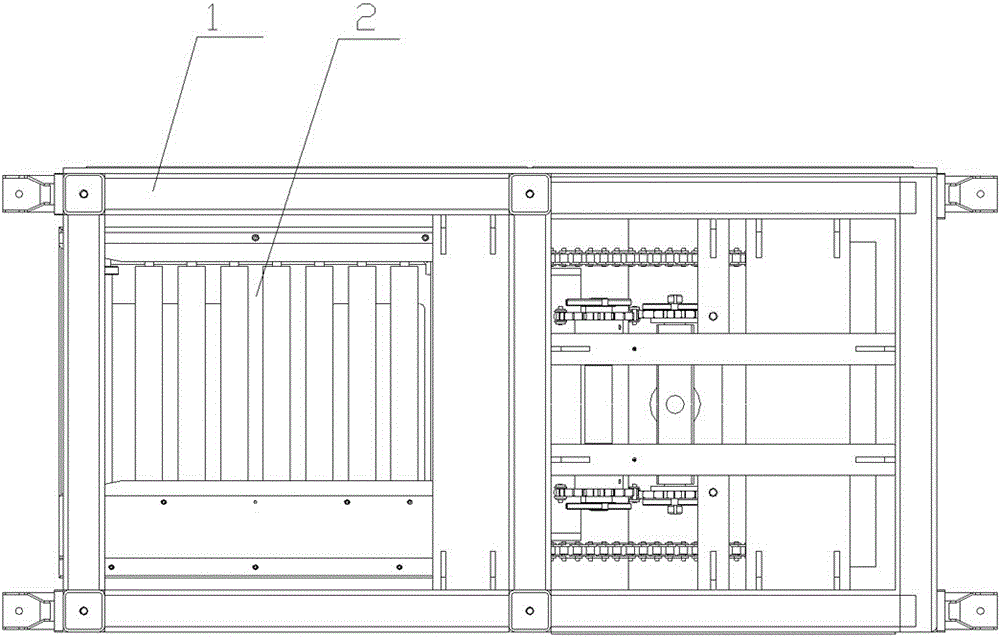

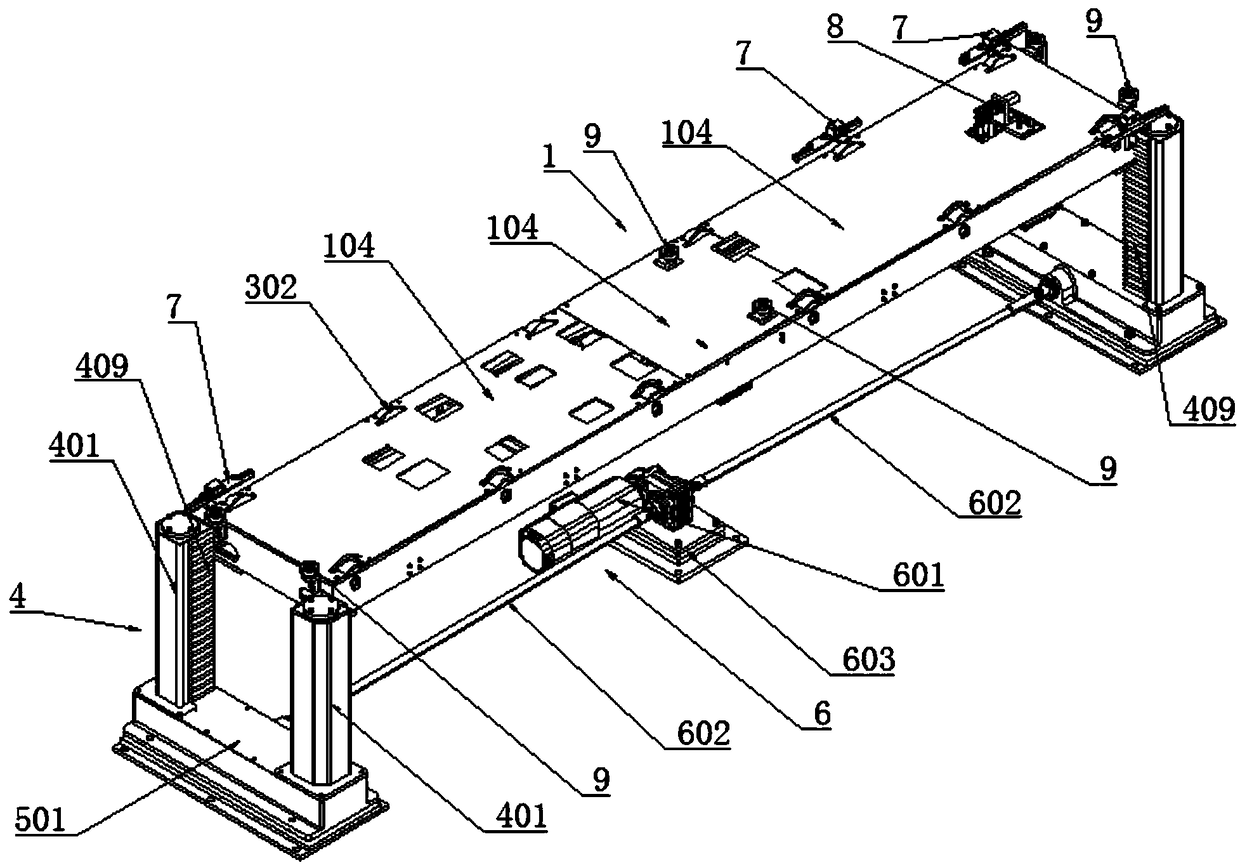

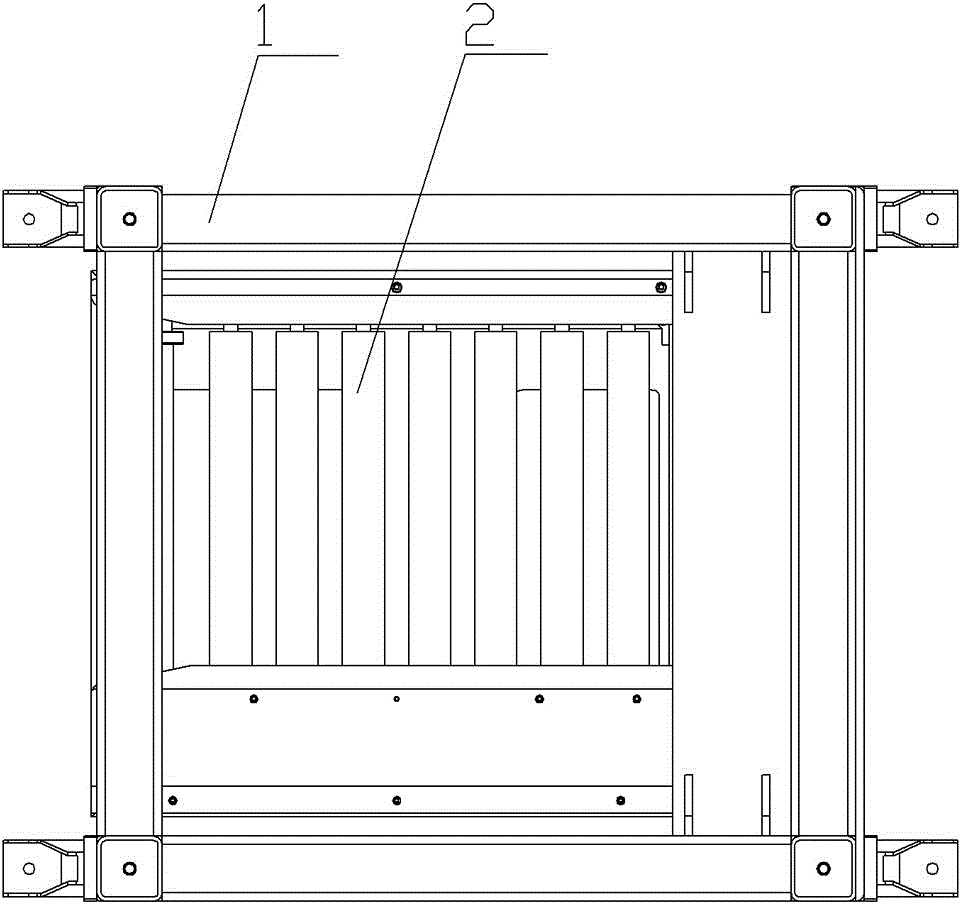

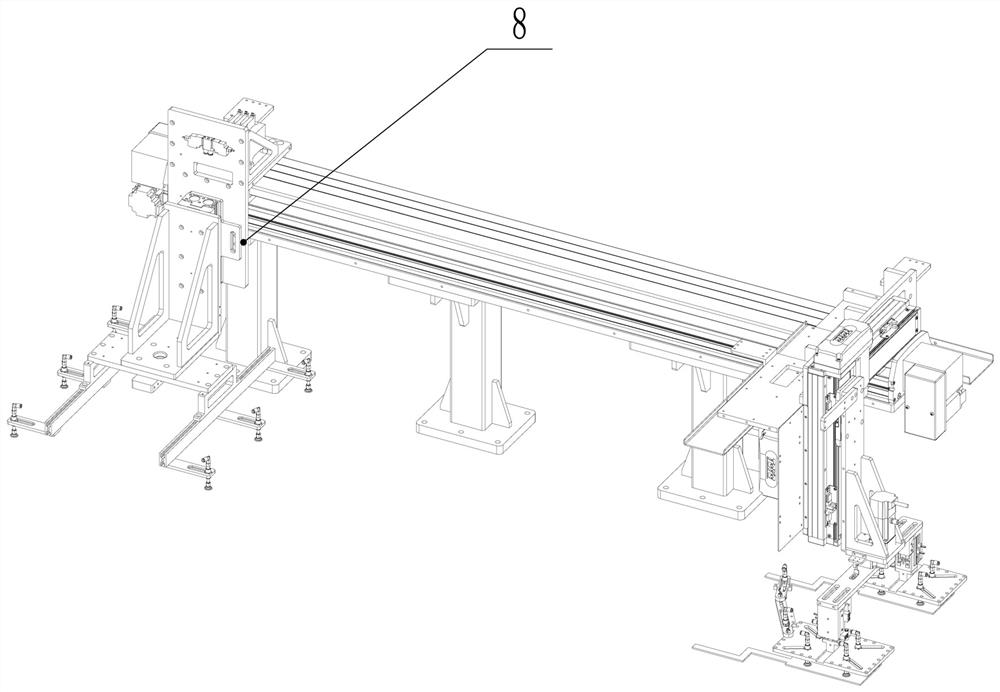

Flexible welding production line for side wall plate of automobile

ActiveCN102699585AImprove flexible production capacityImproved flexible production capacityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineProgrammable logic controller

The invention relates to a flexible welding production line for a side wall plate of an automobile, which is used for improving the flexible production capacity of an autobody welding line body, and comprises a clamp body, a trolley, a frame, a drive mechanism and a PLC (programmable logic controller) control system. The clamp body is installed on the trolley which is connected with the drive mechanism. The trolley is controlled by the PLC control system and dragged by the drive mechanism to reciprocate on a track of the frame to convey the clamp and workpiece of the welding line body. The drive mechanism is arranged on the frame which is fixed on the level ground. The flexible welding production line for the side wall plate of the automobile provided by the invention has the advantages of stable performance, strong universality and high degree of automation, and according to the flexible welding production line, not only is the work efficiency of the welding operation improved remarkably and the production pace of the factory is ensured, but also the flexible production capacity of the welding line body is improved, the capital investment on devices is lowered, the period of new products in batch production is shortened, and large economic benefits is brought for enterprises.

Owner:长城汽车股份有限公司平湖分公司

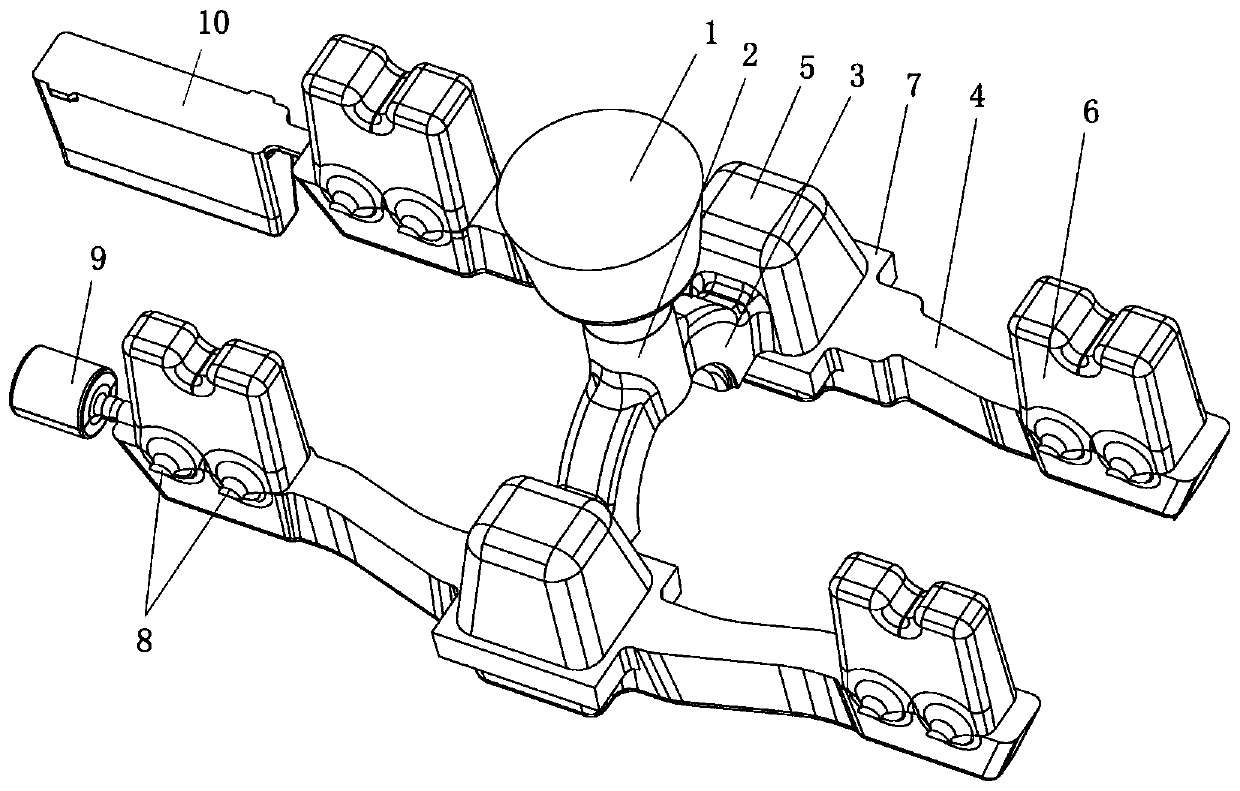

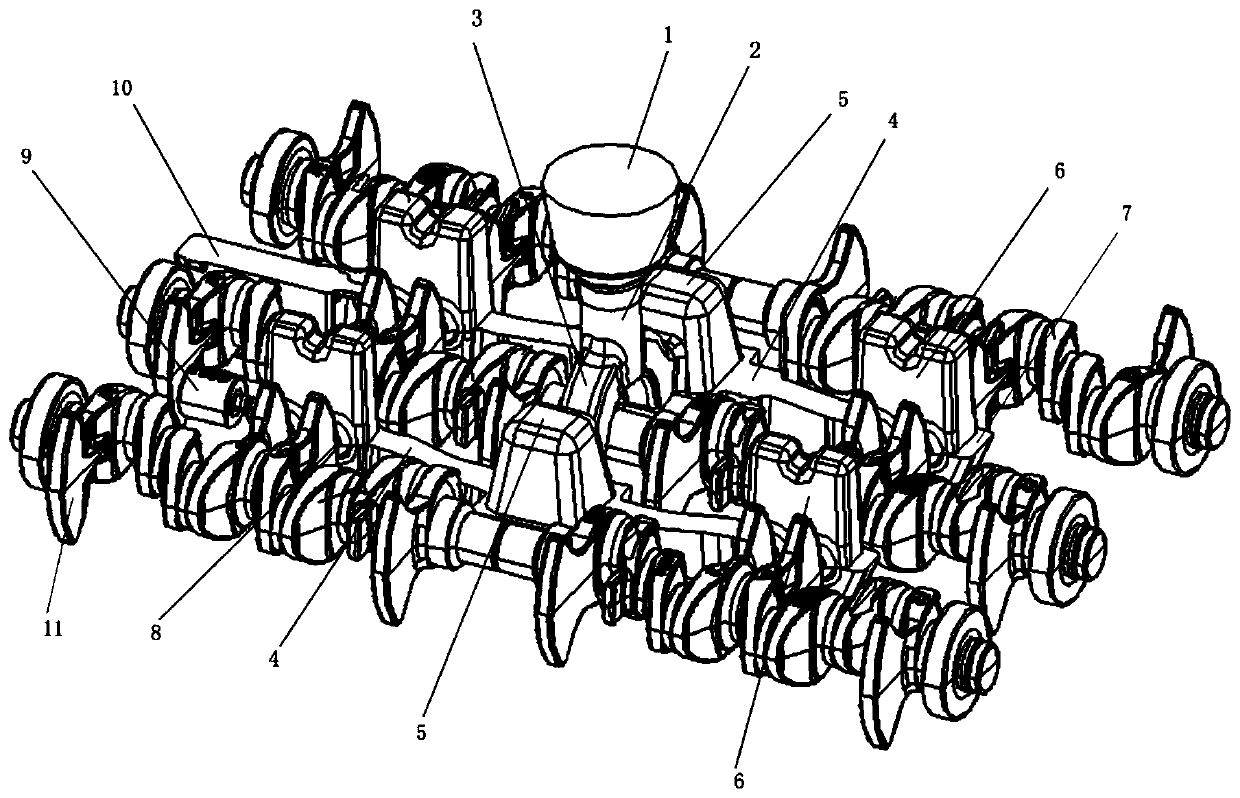

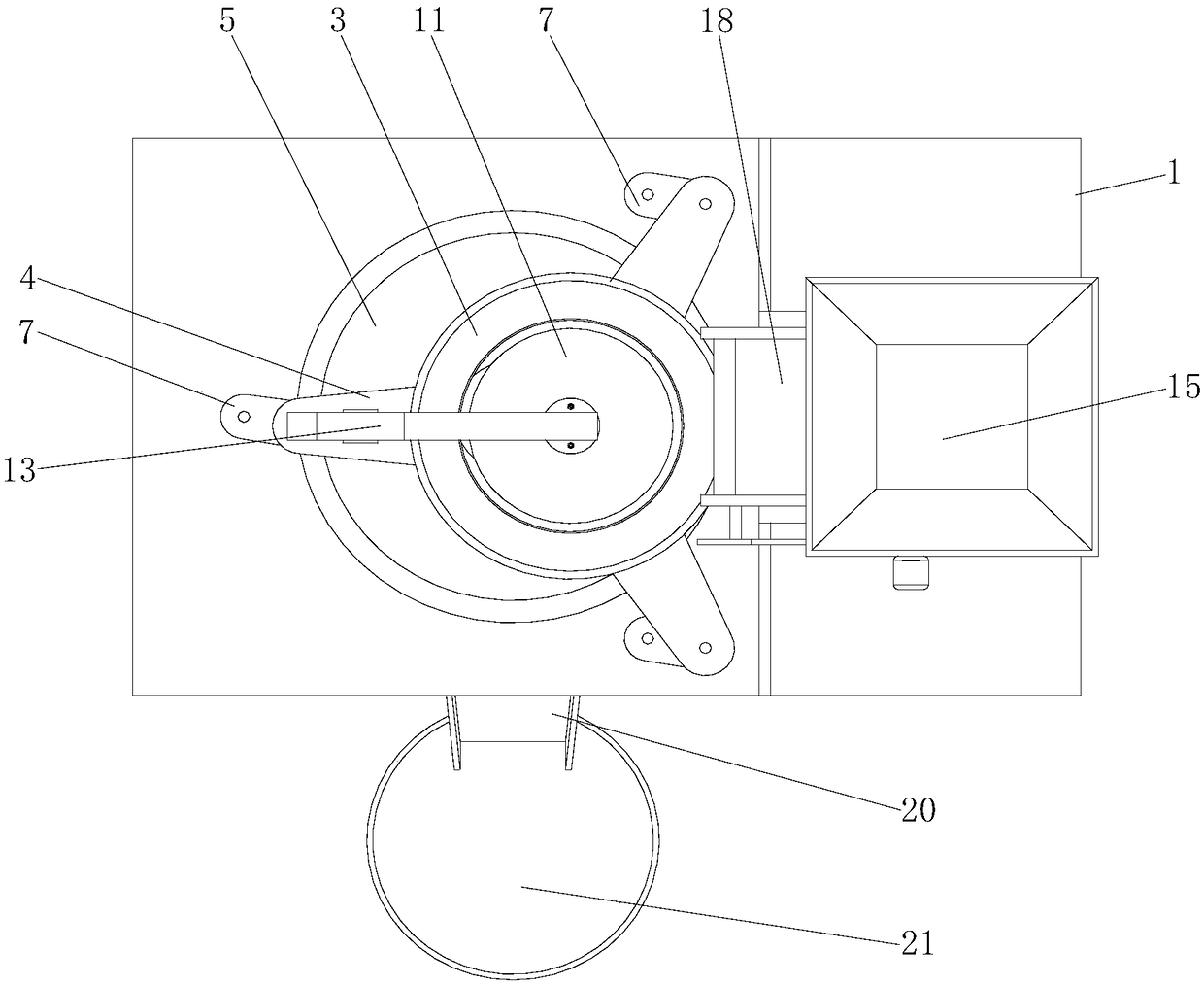

Engine timing system assembling tool

ActiveCN102773818AReduce assembly man-hoursGuarantee normal production cycleWork holdersEngineeringTiming system

The invention discloses an engine timing system assembling tool, which is used for regulating the engine timing position. The engine timing system assembling tool consists of a camshaft timing chain wheel regulation device and a crankshaft timing chain wheel regulation device, wherein the camshaft timing chain wheel regulation device comprises a camshaft timing chain wheel regulation device body, a locking seat, a stop pin and a draw bar; the camshaft timing chain wheel regulation device body is in a disk-shaped structure; the excircle surface of the camshaft timing chain wheel regulation device body is provided with a stop pin avoidance slot; the stop pin is installed on the bottom of the stop pin avoidance slot; the working end surface of the camshaft timing chain wheel regulation device is provided with a ladder groove structure; the ladder groove structure is matched with a hub of a camshaft timing chain wheel; one end of the draw bar is fixedly assembled with the camshaft timing chain wheel regulation device body; and the locking seat is hinged with the camshaft timing chain wheel regulation device body. The engine timing system assembling tool disclosed by the invention has the advantages of simpleness in operation, stable performance and strong popularity and is suitable for assembling protection line bodies for engines of various machine types.

Owner:BAODING WEIYI AUTOMOBILE CO LTD

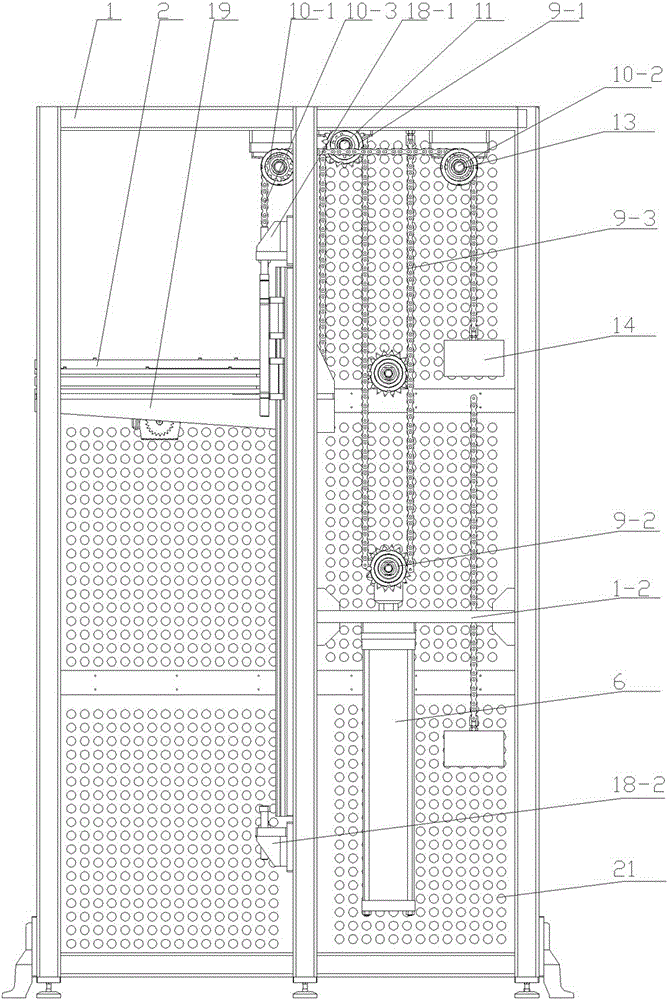

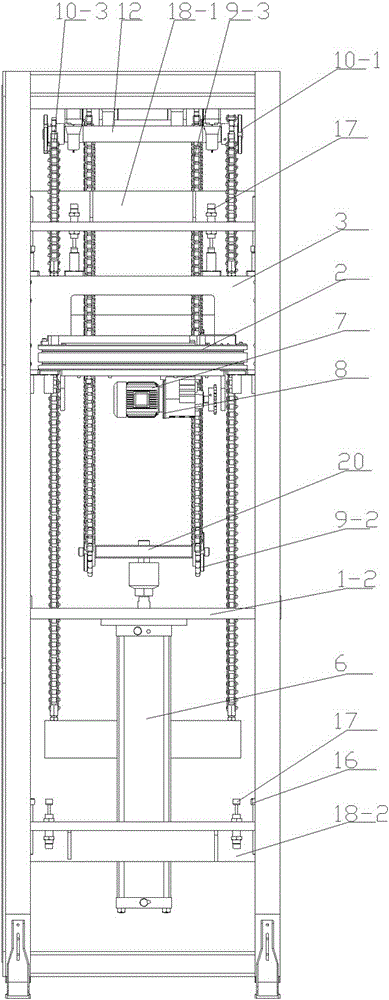

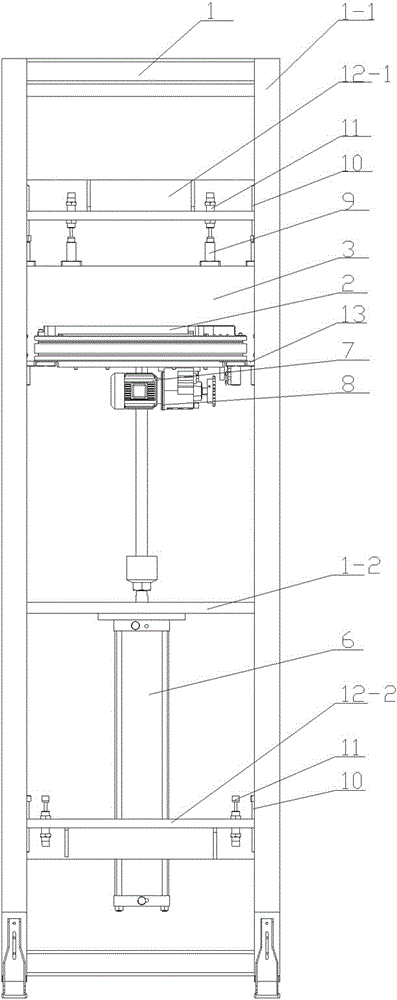

Part tray lifter

InactiveCN106516630ARealize automatic transfer transmissionSupplementary forceMechanical conveyorsRoller-waysChain structureAssembly line

The invention provides a part tray lifer which can be suitable for a part assembly line, can realizably realize automatically transferring part trays from the part assembly line to next tool equipment at working height different from that of the part assembly line. The part tray lifter comprises a rack and a roller conveying base, wherein rollers are arranged on the roller conveying base, are connected through chain wheels, and are driven by a transmission motor. The part tray lifter is characterized by further comprising a lifting base, an air cylinder, a first chain structure, a second chain structure and a limiting structure, wherein the lifting base is mounted on the rack through a guide rail in a sliding mode; the roller conveying base is connected to the lifting base; one end of the first chain structure is connected with the lifting base, and the other end of the first chain structure is connected with the air cylinder, and then is mounted on the top of the rack; one end of the second chain structure is connected with the lifting base, and the other end of the second chain structure is connected with a counterweight block; the limiting structure is equipped with the rack; the limiting structure comprises a limiting post; an induction switch is further mounted on the lifting base; and the induction switch is connected with a transmission motor in an electrically-controlled mode.

Owner:WUXI MINGZHU STEEL BALL

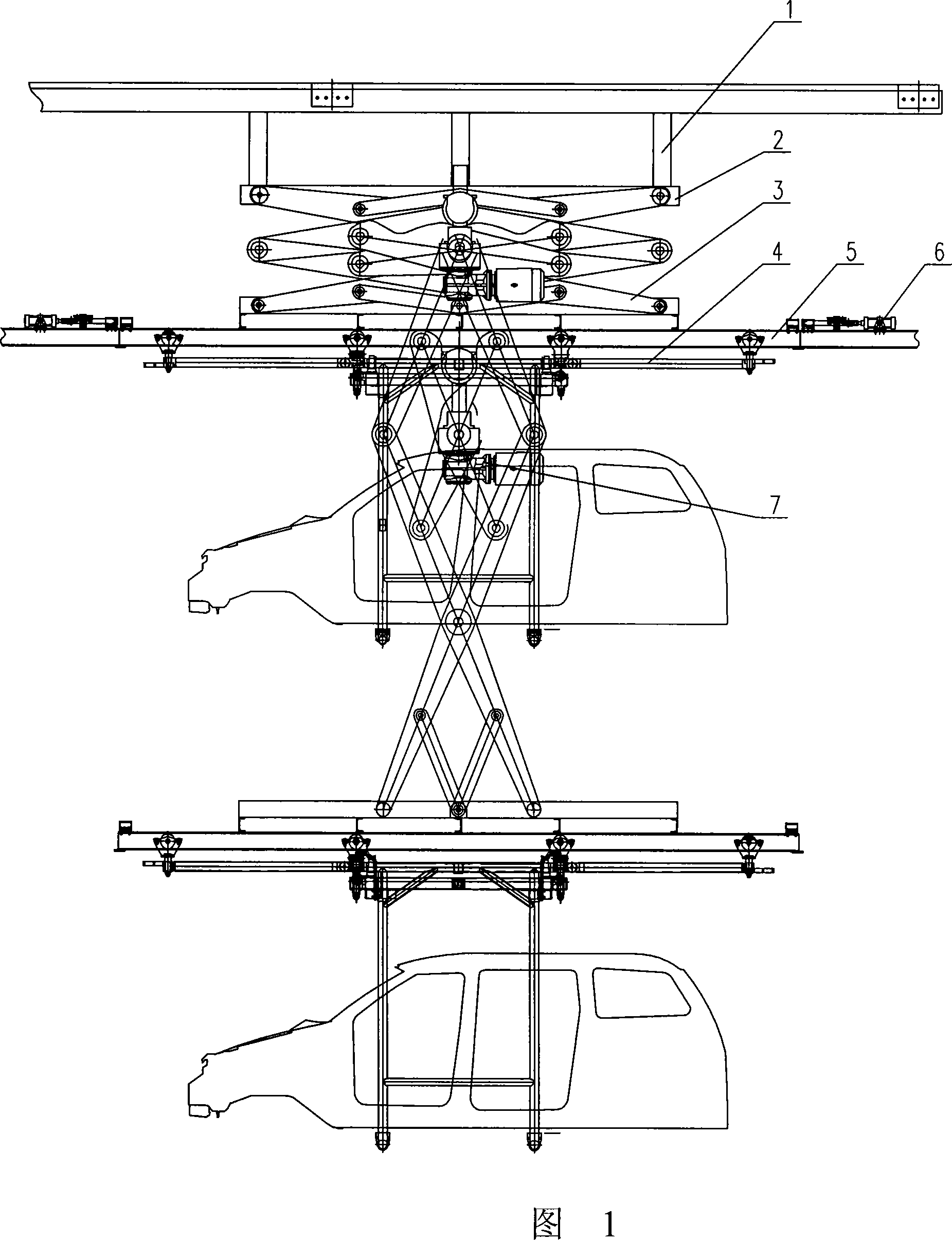

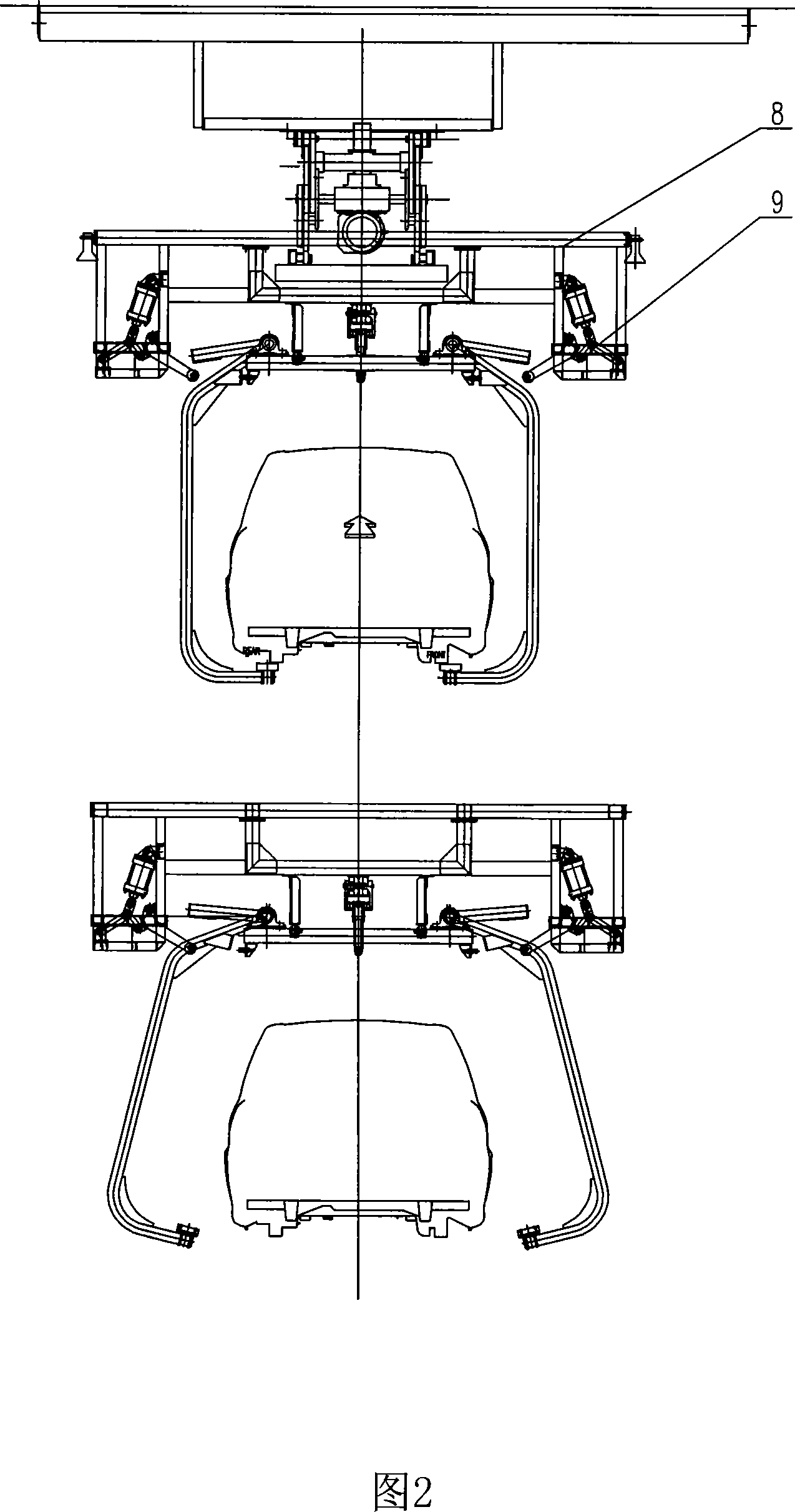

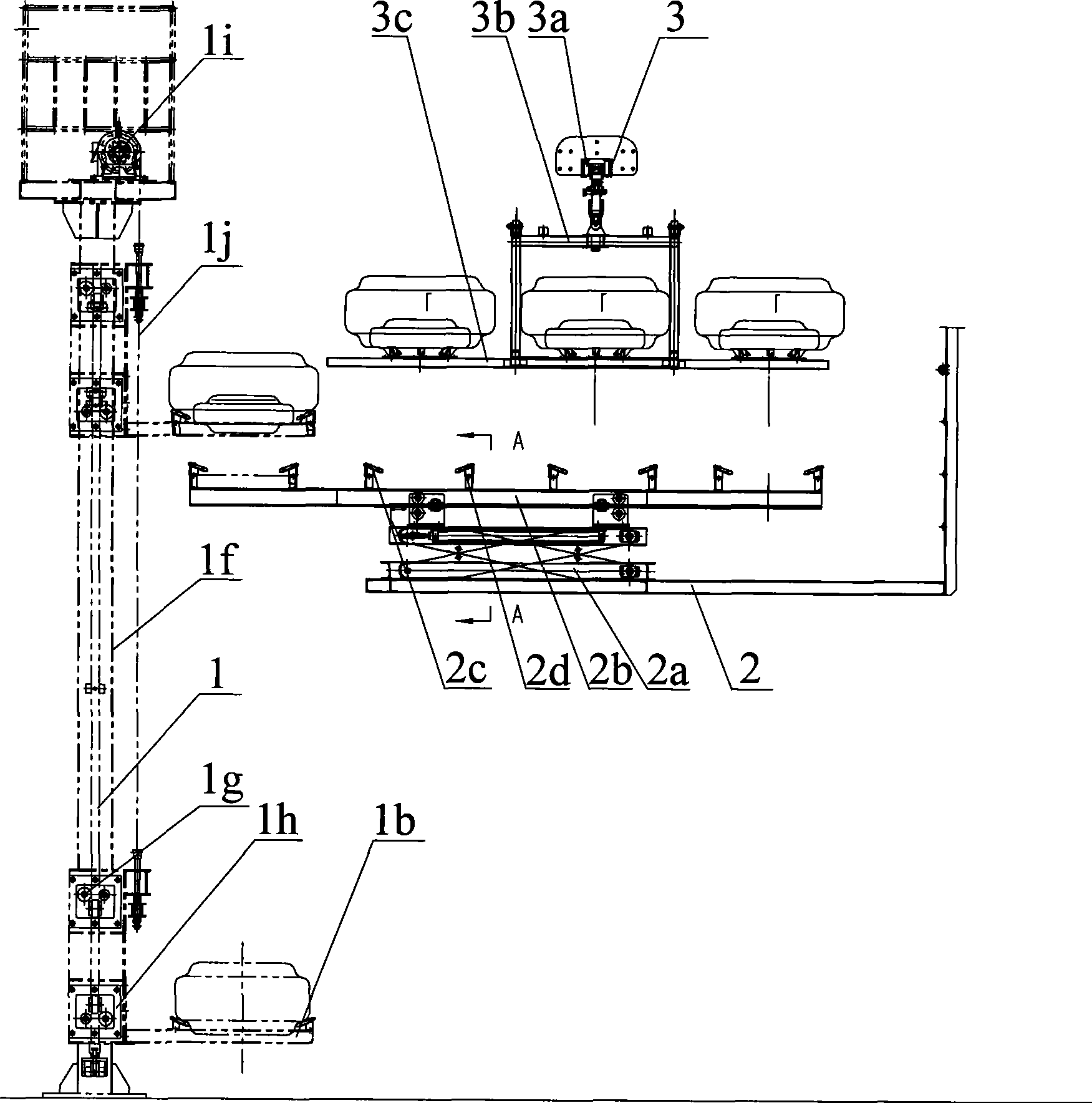

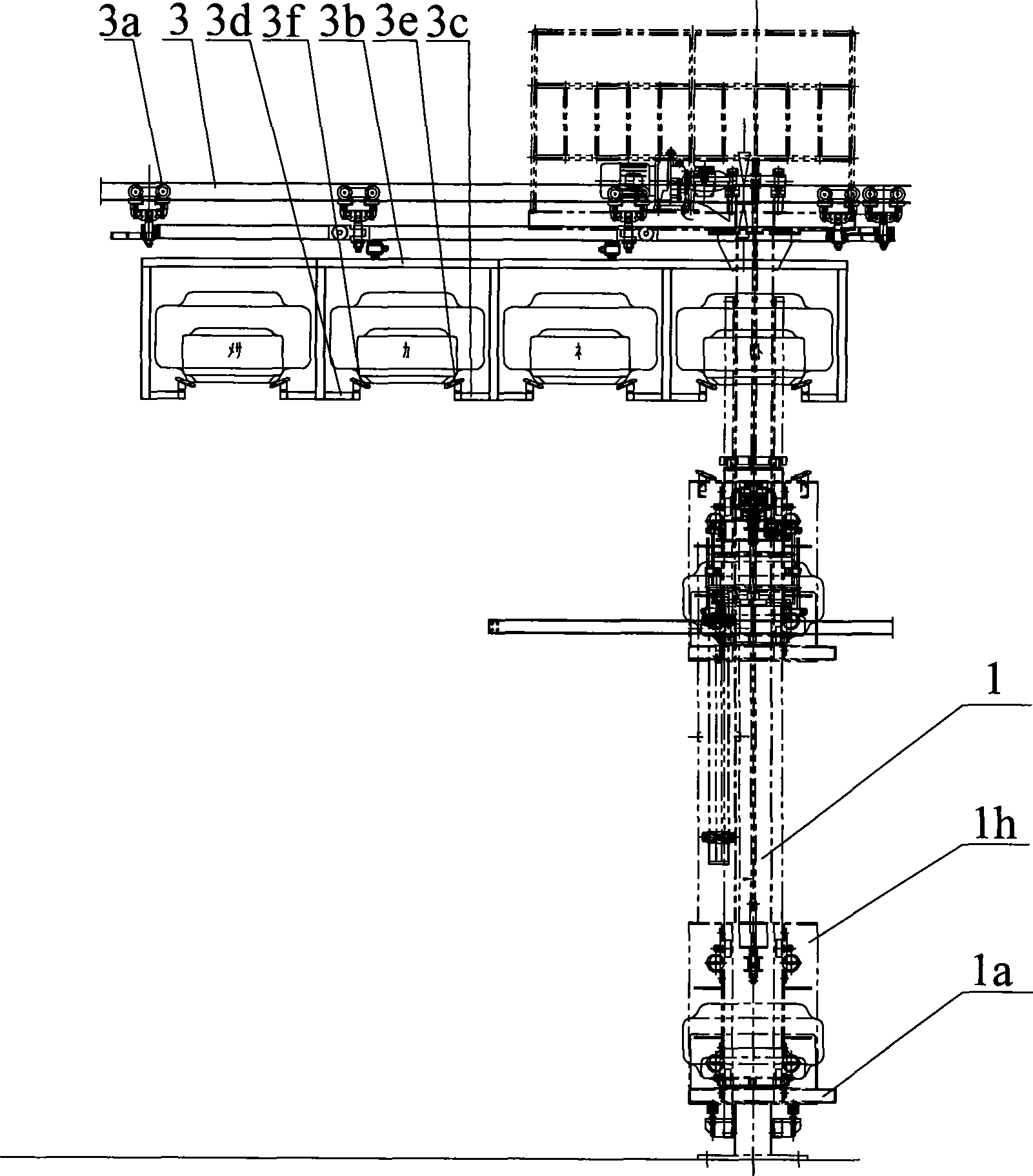

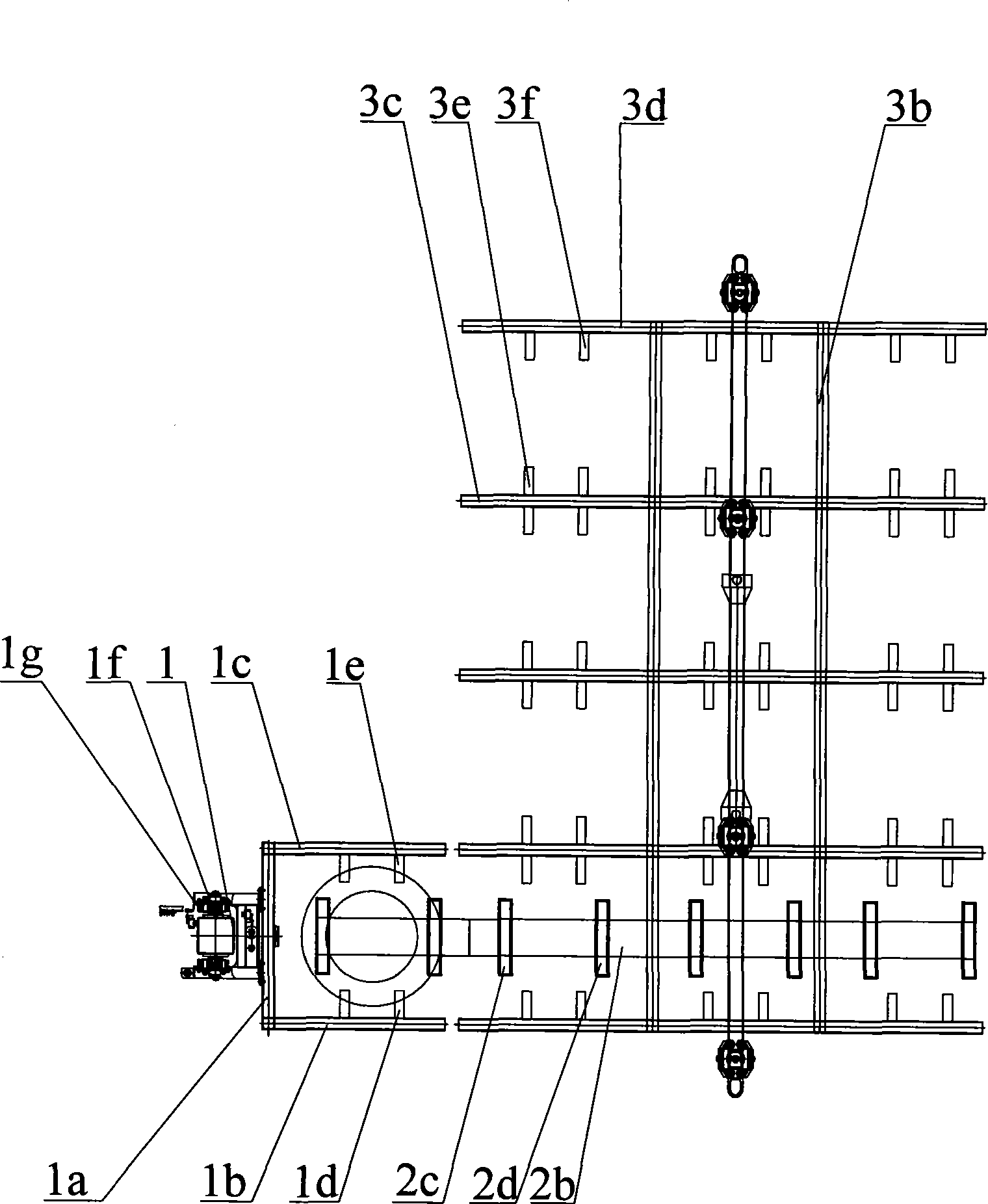

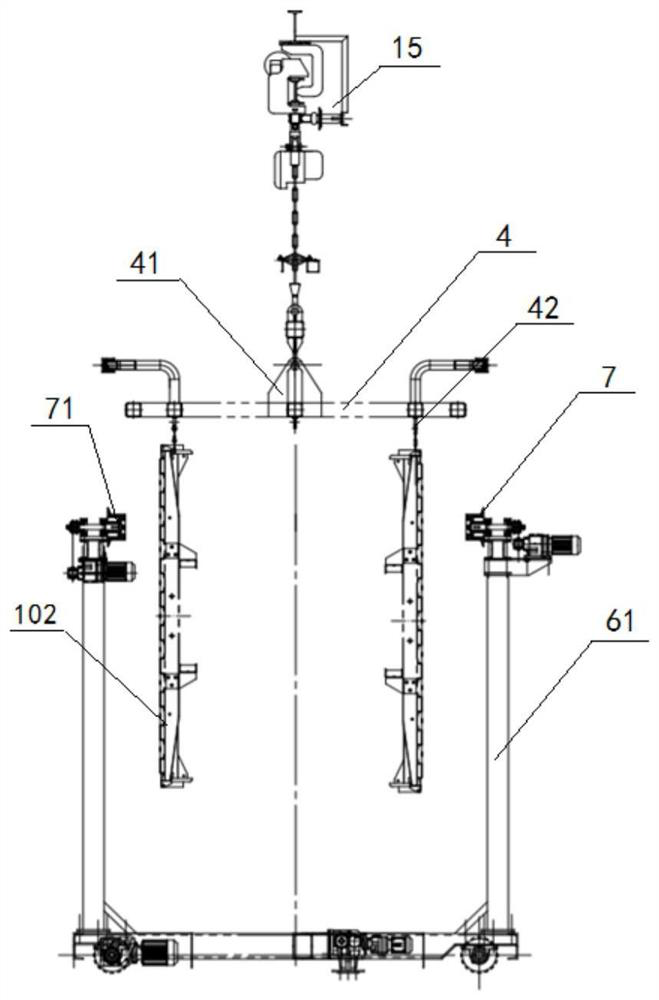

Suspended elevator

The present invention relates to suspended elevator, belongs to the field of conveyor technology, and is especially one kind of car body transferring elevator for car producing line. The suspended elevator has one frame, booms connected to the frame, stabilizing bar assemblies in the frame, electrically driven push rod assemblies connected to the stabilizing bar assemblies, movable rail assemblies mounted to the bottom of the frame, rail aligning mechanisms mounted on the fixed rail, sling opening and closing mechanism supports on the frame, and sling opening and closing mechanisms on the sling opening and closing mechanism supports. The present invention has compact and reasonable structure, relaxed locating requirement, great bearing capacity, low noise and other advantages.

Owner:MIRACLE AUTOMATION ENG CO LTD

Lead screw lifting high-speed roller bed for conveying

InactiveCN109051515ASolve the problem of collinear productionSmall footprintControl devices for conveyorsRoller-waysStops deviceSmall footprint

The invention discloses a lead screw lifting high-speed roller bed for conveying. The lead screw lifting high-speed roller bed comprises a conveying roller bed and two supporting frames arranged at the two ends of the conveying roller bed, each of the supporting frames is provided with a lead screw lifting mechanism for supporting the conveying roller bed, a lifting drive device capable of drivingthe two lead screw lifting mechanisms is arranged below the conveying roller bed, steering conversion mechanisms for connecting the lead screw lifting mechanisms with the lifting drive device are arranged on the supporting frames, a horizontal conveying mechanism is arranged on the conveying roller bed, a plurality of sensing devices for sensing the positions of workpieces are arranged on the side of the conveying roller bed, and the conveying roller bed is provided with a safety stopping device capable of ascending and descending. The lead screw lifting high-speed roller bed for conveying issmall in floor space and is suitable for cooperating with various peripheral devices such as a multi-axis positioning device and a windmill positioning device.

Owner:广州德恒汽车装备科技有限公司

Wafer cleaning equipment

ActiveCN111463107AReduce maintenance time and costsAvoid secondary corrosionElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma beam

The invention relates to the technical field of wafer cleaning. The invention relates to wafer cleaning equipment. The wafer cleaning equipment comprises a plasma cleaning assembly for removing residues on the surface of a wafer, the plasma cleaning assembly comprises a cleaning chamber and a plasma source, the cleaning chamber is used for placing a wafer, and the plasma source is located in the cleaning chamber and generates plasma beams to clean the wafer. The top end of the cleaning chamber is provided with an installation chamber, the plasma source is located in the installation chamber, the movement direction of a plasma beam generated by the plasma source is obliquely arranged relative to the wafer, and one side of the cleaning chamber is provided with an air extracting piece for extracting the cleaning chamber to be vacuum. The wafer is cleaned by plasma, a large number of pipelines and joints do not need to be installed in the equipment, and the later maintenance time and costof the equipment are reduced. Plasma is used for bombarding and cleaning the surface of the wafer, a rolling brush is prevented from being used and directly contacted with the surface of the wafer forremoving, and green damage-free cleaning is achieved. And as the plasma volume is smaller than that of water molecules, the plasma can go deep into micro holes of the wafer, and ion bombardment cleaning within a certain thickness on the surface of the wafer can be carried out.

Owner:北京晶亦精微科技股份有限公司

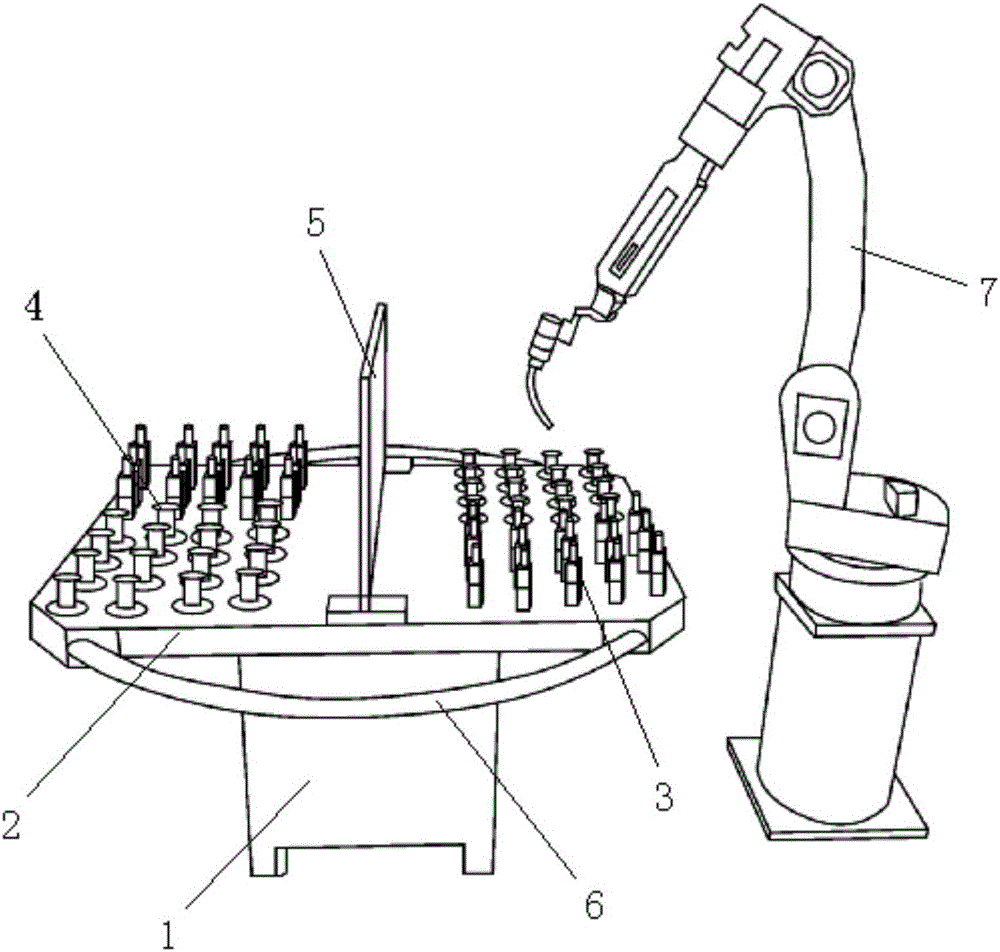

Keel welding production line and welding rotating device thereof

InactiveCN105728999ARealize automatic rotationRealize automatic controlWelding/cutting auxillary devicesAuxillary welding devicesProduction lineRotary stage

The invention discloses a keel welding production line and a welding rotating device thereof. The welding rotating device comprises a base, and a rotating table rotationally connected with the base through a rotating shaft; the rotating table is provided with a first welding spot set and a second welding spot set; the lower end surface of the base is slidingly connected with a line body of the production line through a slide block; and the rotating shaft is arranged in the vertical direction, the top end thereof is fixedly connected with the rotating table, and the outer peripheral direction thereof is rotationally connected with the base through a bearing. The welding rotating device further comprises a power element; and the rotating table rotates by 180 degrees in the horizontal plane around the rotating shaft under the effect of the power element. The welding rotating device can realize automatic rotation of the rotating table, so that the production efficiency is improved, the production takt is guaranteed, and the labor intensity of workers is reduced.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Stamping mold and waste ejection mechanism thereof

The invention discloses a stamping mold and a waste ejection mechanism thereof. The waste ejection mechanism comprises a cylinder of which a fixed end is arranged on a lower die holder, wherein a telescopic end of the cylinder is provided with an ejection plate through a rotating shaft in a rotating manner; the rotating shaft is arranged perpendicular to the axial direction of the cylinder; when the cylinder is at an extension limit position, the ejection plate rotates around the rotating shaft to a state back on to a mold body; one end of the ejection plate is provided with a guide plate which is provided with a guide groove; the fixed end is provided with a guide block which is in slide guide fit with the guide groove; the plane where the guide stroke of the guide groove is positioned is parallel to the axial direction of the cylinder and perpendicular to the axial direction of the rotating shaft; the guide groove comprises an upper guide groove and a lower guide groove which is communicated with the upper guide groove; the slide guide direction of the upper guide groove is parallel to the axial direction of the cylinder; the lower guide groove and the upper guide groove are at a preset angle; the lower guide groove gets away from the mold body gradually in the extension direction away from the upper guide groove. Thus, ejection stroke and discharge direction of waste can be excellently controlled through the arrangement of the guide structure.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Load-transfer machine for tyres

InactiveCN101391701ASimple structureSmall footprintLifting framesConveyor partsLow noiseSmall footprint

The invention relates to a tire transferring conveyor used for transferring tires of different lines. An elevation sliding frame is arranged on a column and a first bearing rod and a second bearing rod are arranged on the elevation sliding frame. A first bracket extending to the second bearing rod is arranged on the side wall of the first bearing rod and a second bracket extending to the first bearing rod is arranged on the side wall of the second bearing rod. A first transferring bracket and a second transferring bracket are arranged on the top end of a flexible transferring rod and the distance between the inner end and the outer end of the first and second transferring brackets is less than the clearance between the ends of the first and second brackets; a conveying frame is provided with a third bearing rod and a fourth bearing rod; a third bracket extending to the fourth bearing rod is arranged on the side wall of the third bearing rod and a fourth bracket extending to the third bearing rod is arranged on the side wall of the fourth bearing rod; the distance between the inner end and the outer end of the first and second transferring brackets is less than the clearance between the corresponding ends of third and fourth brackets. The tire transferring conveyor has the simple structure, small occupied space and high transferring capacity, and can ensure the manufacturing efficiency, low noise and convenient maintenance.

Owner:MIRACLE AUTOMATION ENG CO LTD

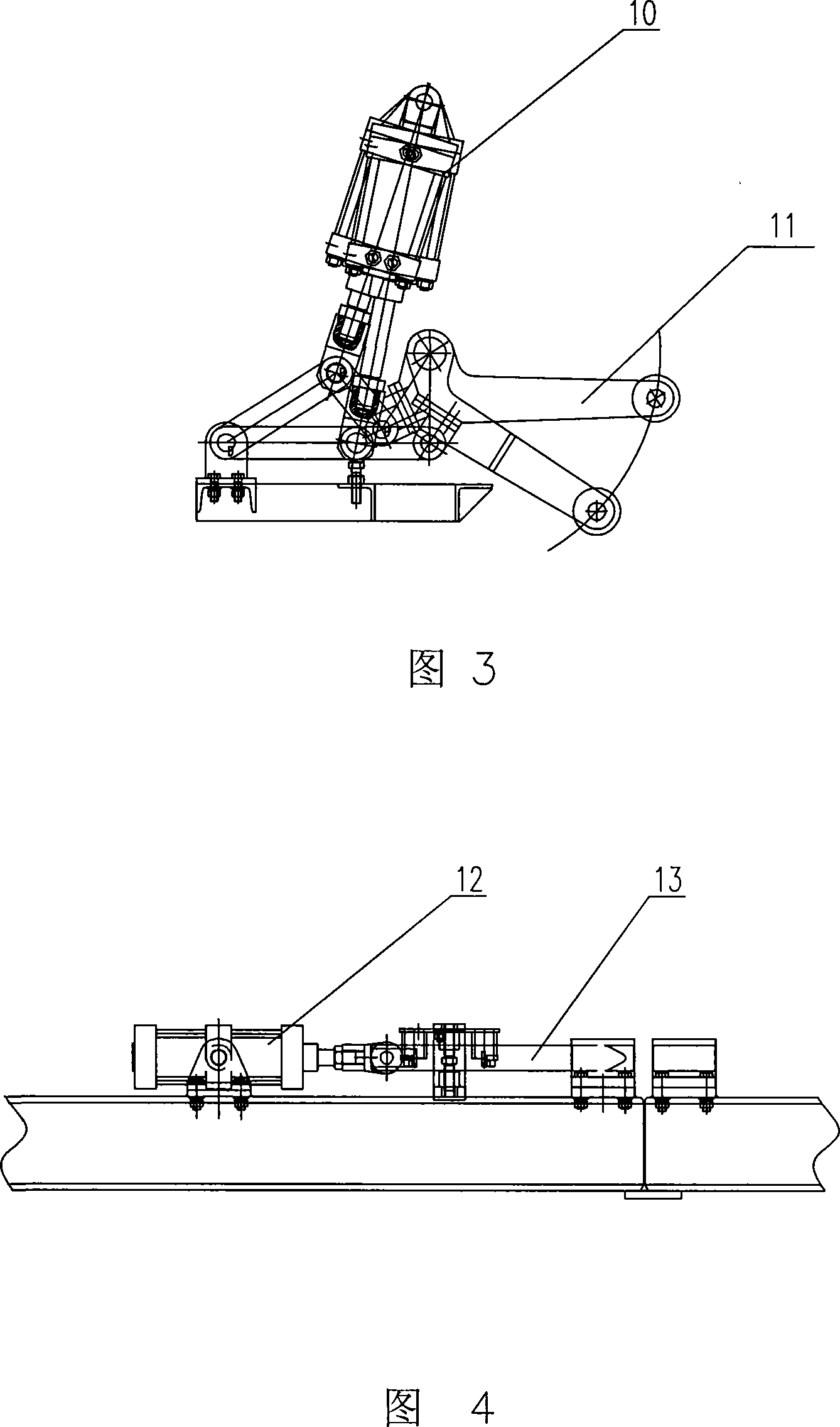

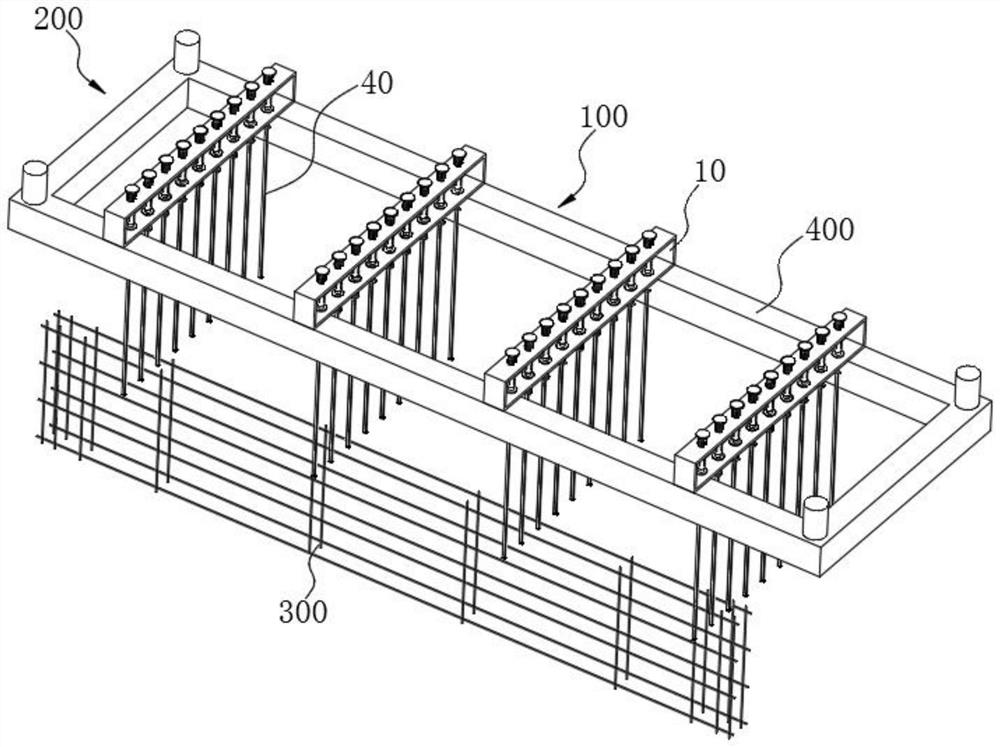

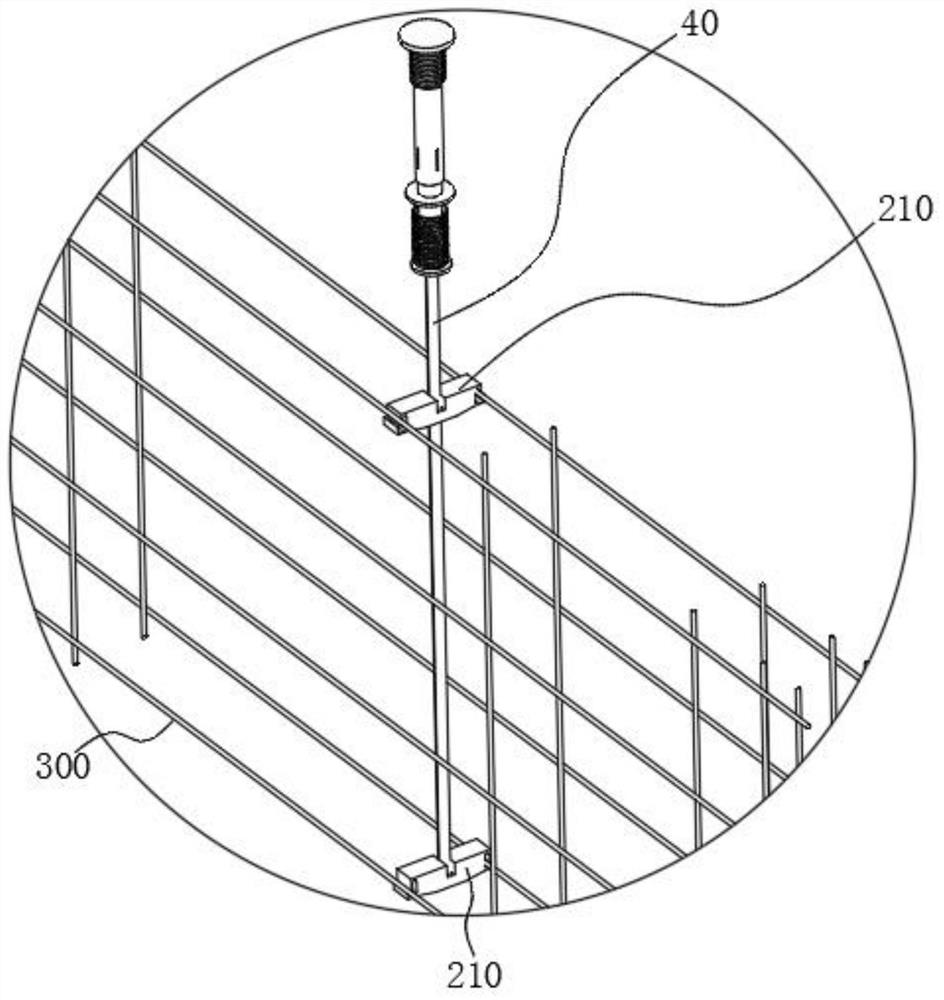

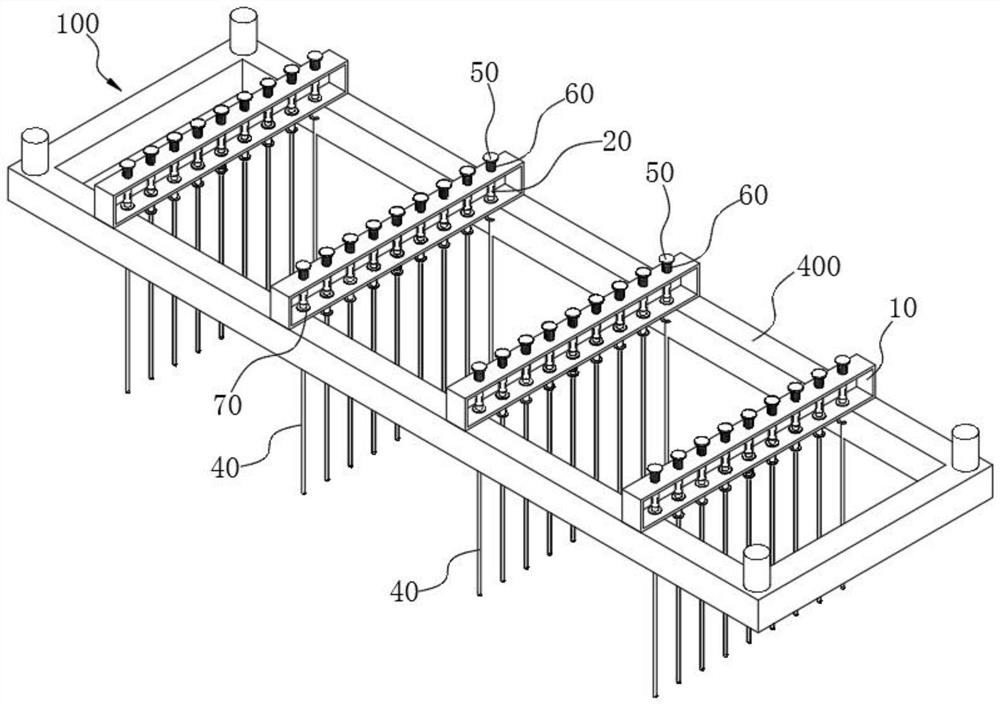

Automatic drill rod rotating mechanism, mesh cage hanging device and wallboard production system

ActiveCN112248218AReduce labor intensityReduce labor costsAuxillary shaping apparatusEngineeringDrill

The invention relates to an automatic drill rod rotating mechanism, a mesh cage hanging device and a wallboard production system. The automatic drill rod rotating mechanism comprises a mounting frame,a first actuating body and a second actuating body. The first actuating body is movably arranged on the mounting frame and is provided with an ejector block. The second actuating body is movably arranged on the mounting frame and is further matched with the first actuating body, the second actuating body is used for being relatively and fixedly connected with a steel drill rod, and the second actuating body is provided with a first slope surface and a second slope surface which are arranged in a spaced mode in the axial direction of the steel drill rod. The first slope surface and the secondslope surface are used for being arranged in a staggered mode in the direction surrounding the periphery of the steel drill rod. The ejector block is arranged between the first slope surface and the second slope surface, can reciprocate between the first slope surface and the second slope surface and further ejects the first slope surface and the second slope surface, so that the second actuatingbody is driven to drive the steel drill rod to rotate. The purpose of replacing manual operation rotating by workers is achieved, the labor intensity of the workers is greatly relieved, and the laborcost of enterprises is reduced; and meanwhile, the working efficiency is higher, the production takt can be better guaranteed, and the production efficiency is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

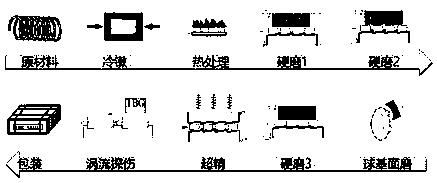

Production process for high-precision bearing roller for rail transit

The invention relates to a production process for a high-precision bearing roller for rail transit. The production process comprises the following steps of step 1, cold heading: after drawing steel byutilizing a four-station high-speed cold header, upsetting the drawn steel into a roller blank; 2, heat treatment which is a full-automatic mesh belt furnace heat treatment flow production line; 3, hard grinding 1; 4, hard grinding 2; 5, ball base surface processing; 6, hard grinding 3; 7, superfinishing, in which 8 oilstones are adopted to perform vibration back and forth to process a raceway surface of a roller; 8, eddy current inspection, in which eddy current inspection equipment produced by German IBG is adopted and is installed on a superfinishing machine to realize unfolding of the roller so as to perform 100 percent eddy current inspection which is mainly used for detecting defects on the surface of the roller and cracks of internal tissues of the roller; and 9, packaging. The production process has the advantages that through four-station multi-formation, the forming precision of a product can be guaranteed, a metal flow direction of a material can tend to be reasonable at the same time, and the service life of the product is prolonged.

Owner:JIANGSU LIXING GENERAL STEEL BALL +1

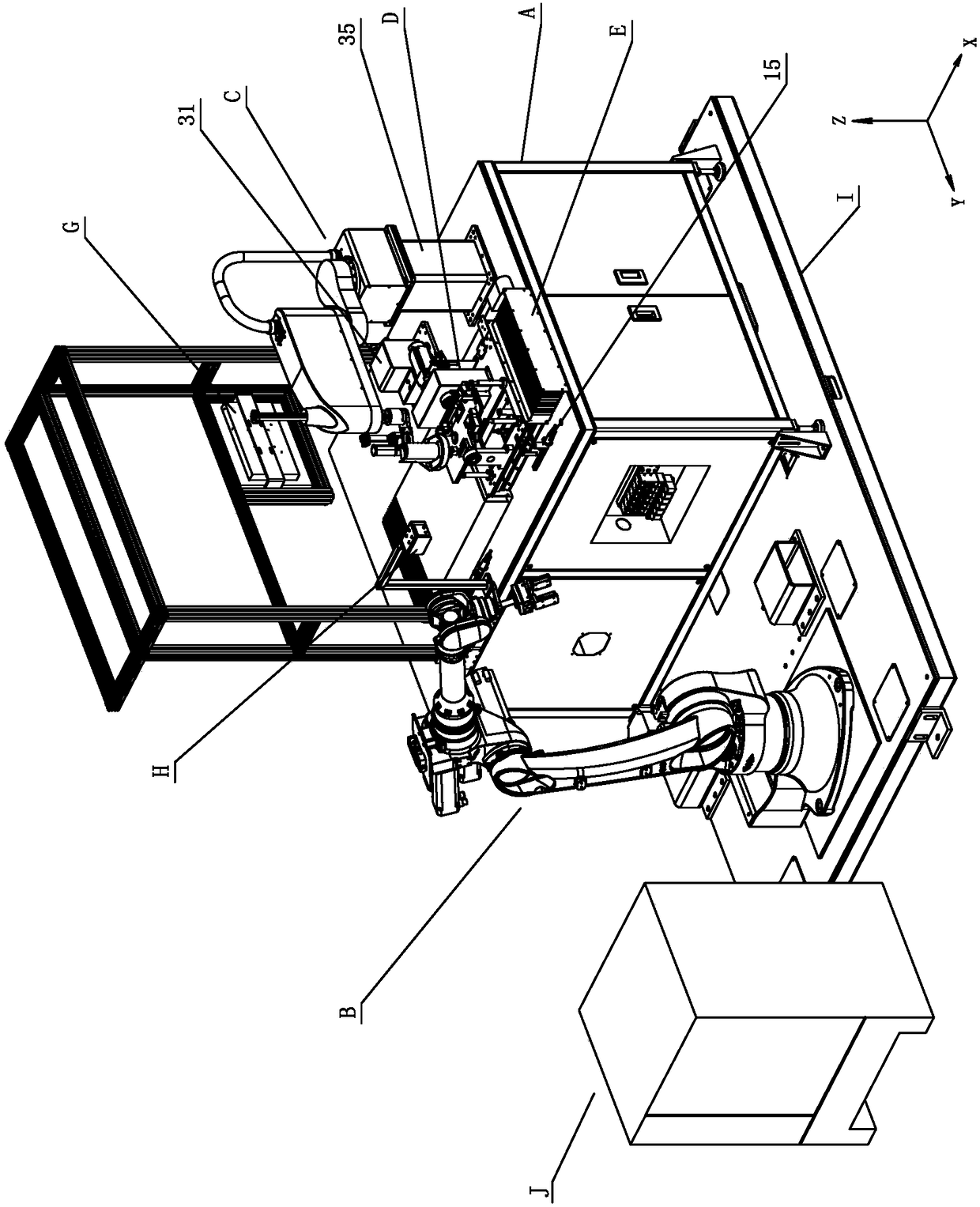

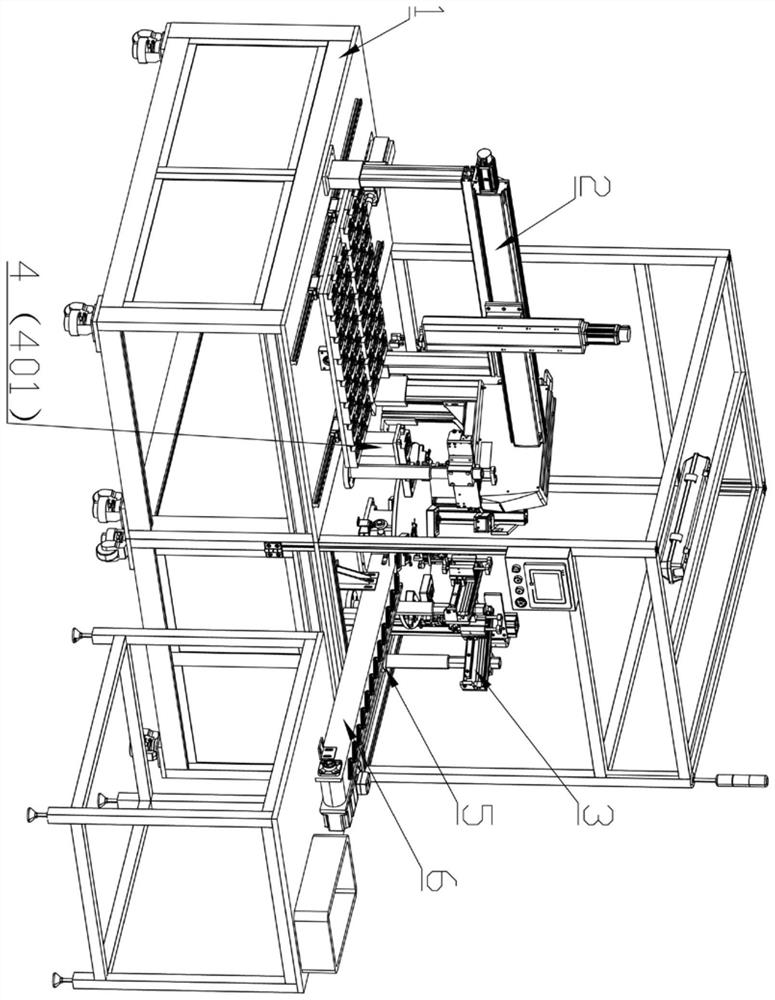

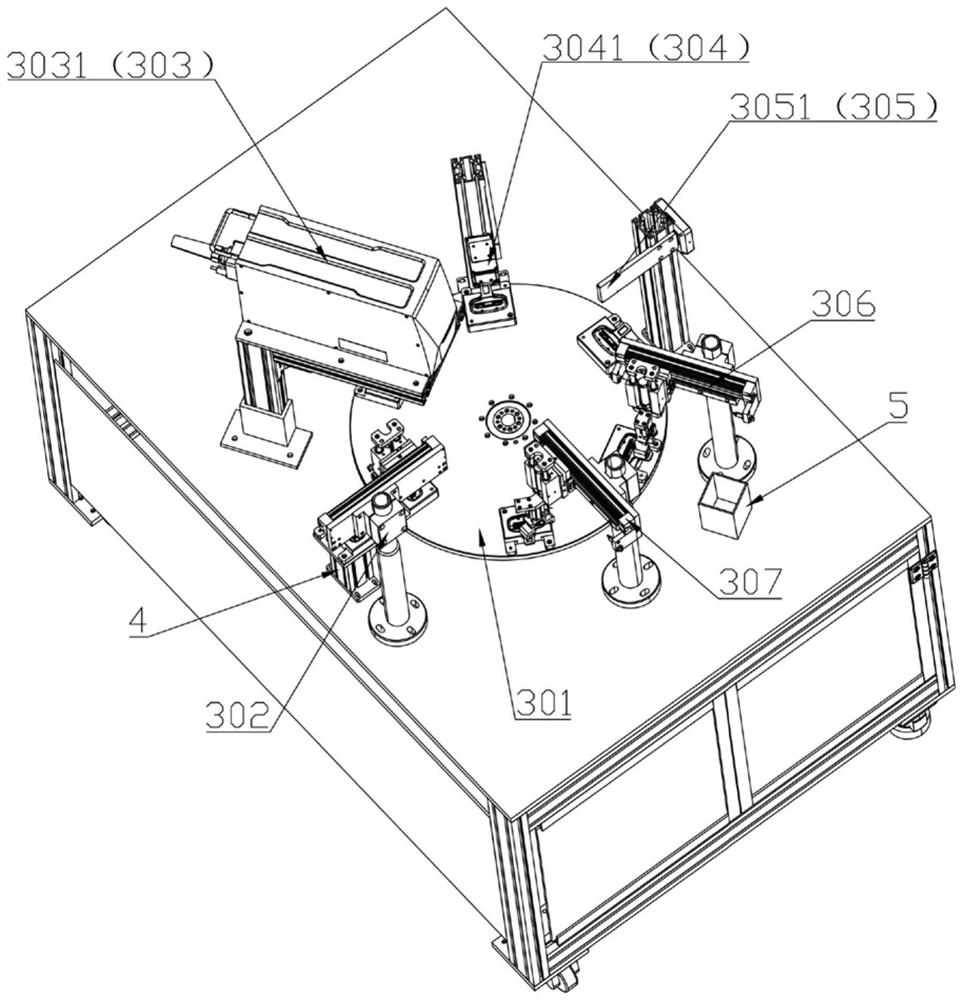

Automatic assembling equipment of driver control panel

ActiveCN108356508AImprove assembly efficiencyGuaranteed assembly qualityMetal working apparatusMotor driveEngineering

The invention discloses automatic assembling equipment of a driver control panel. The automatic assembling equipment comprises an equipment cabinet, a robot carrying mechanism, a screw screwing mechanism, a turnover mechanism and a transplanting mechanism, wherein the turnover mechanism is used for turning over the control panel and comprises a turnover motor and a tool plate; the control panel isat least positioned and assembled on the tool plate when the screw screwing operation is carried out; the turnover motor drives the tool plate to position and turn over to turn over the control panelon the tool plate, so that the screw screwing mechanism can conveniently carry out screw screwing operation on the obverse side / or reverse side of the control panel; the turnover mechanism is arranged on the equipment cabinet; and the transplanting mechanism is used for driving the turnover mechanism to move in the X-axis and / or Y-axis and / or Z-axis direction and is arranged on the equipment cabinet. The automatic assembling equipment can carry out automatic screw screwing assemble on the obverse side / or reverse side of the driver control panel to further effectively improve the assembling efficiency, lower the labor cost, lower the labor intensity of a worker and improve the assembling quality.

Owner:GUANGDONG LXD ROBOTICS CO LTD

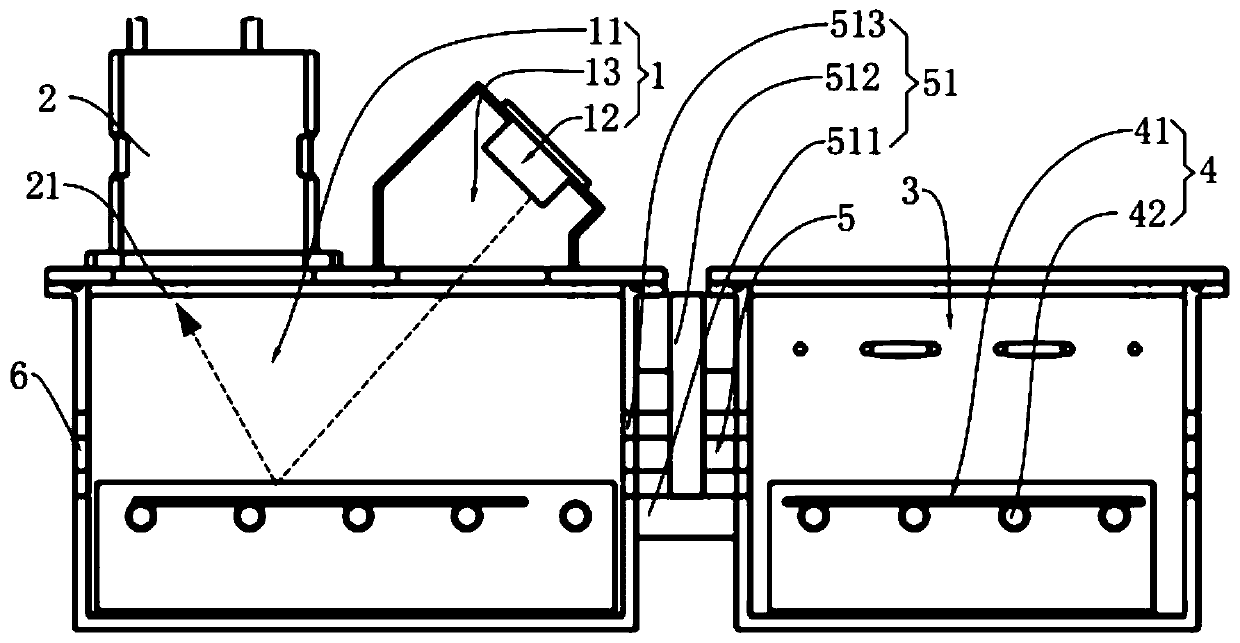

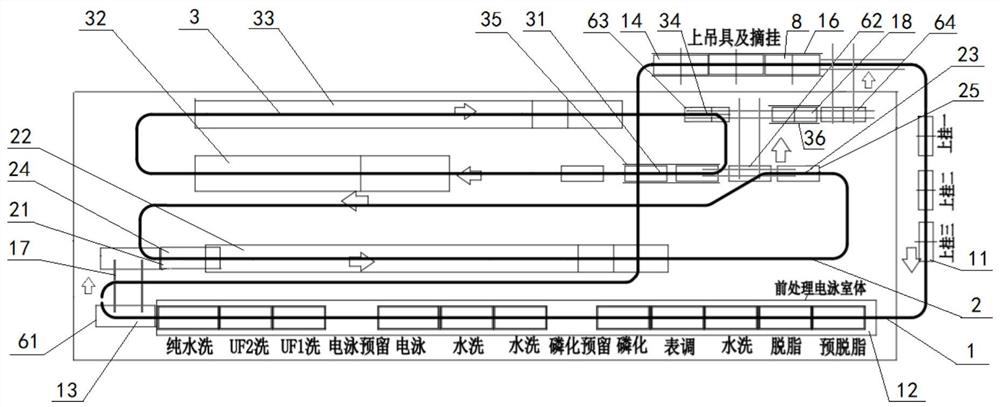

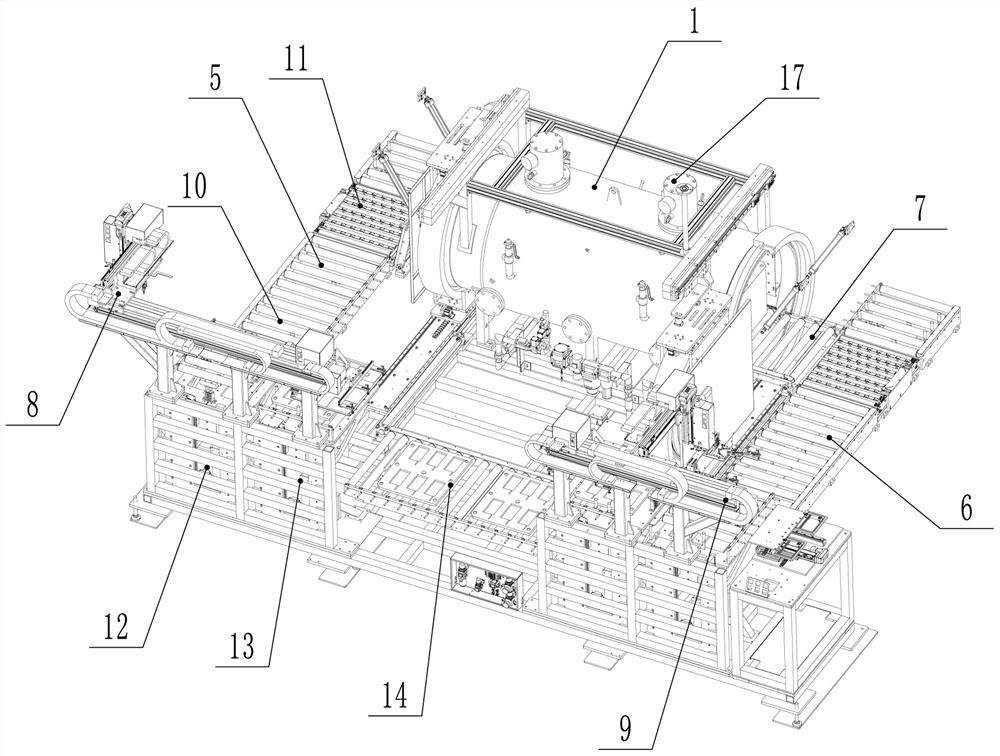

Mixed flow coating line and mixed flow coating method for standard compartment and van vehicles

The invention relates to a mixed flow coating line and a mixed flow coating method for standard compartment and van vehicles. The mixed flow coating line comprises an annular pretreatment track, a primer treatment suspension chain and a finish treatment suspension chain, wherein a hanging station, a pretreatment electrophoresis chamber, a pretreatment discharging station and a picking and hangingstation are sequentially arranged below the pretreatment track in the running direction of an electric hoist; a primer feeding station, a primer drying furnace and a primer discharging station are sequentially arranged below the primer drying suspension chain in the rotating direction of a suspension chain track; a finish feeding station, a paint spraying chamber, a finish drying furnace and a finish discharging station are sequentially arranged below the finish treatment suspension chain in the rotating direction of the suspension chain track; and to-be-coated parts are suspended on a movablehanging bracket for conveying and a high-position roller way and a transverse moving trolley are matched through a descending track, a low track and an ascending track which are arranged on the suspension chains for rotary hanging and feeding and discharging. According to the design, mixed flow production of the standard compartment and van vehicles is realized through unique coating line arrangement and suspension conveying and rotary hanging modes.

Owner:DONGFENG AUTOMOBILE COMPANY

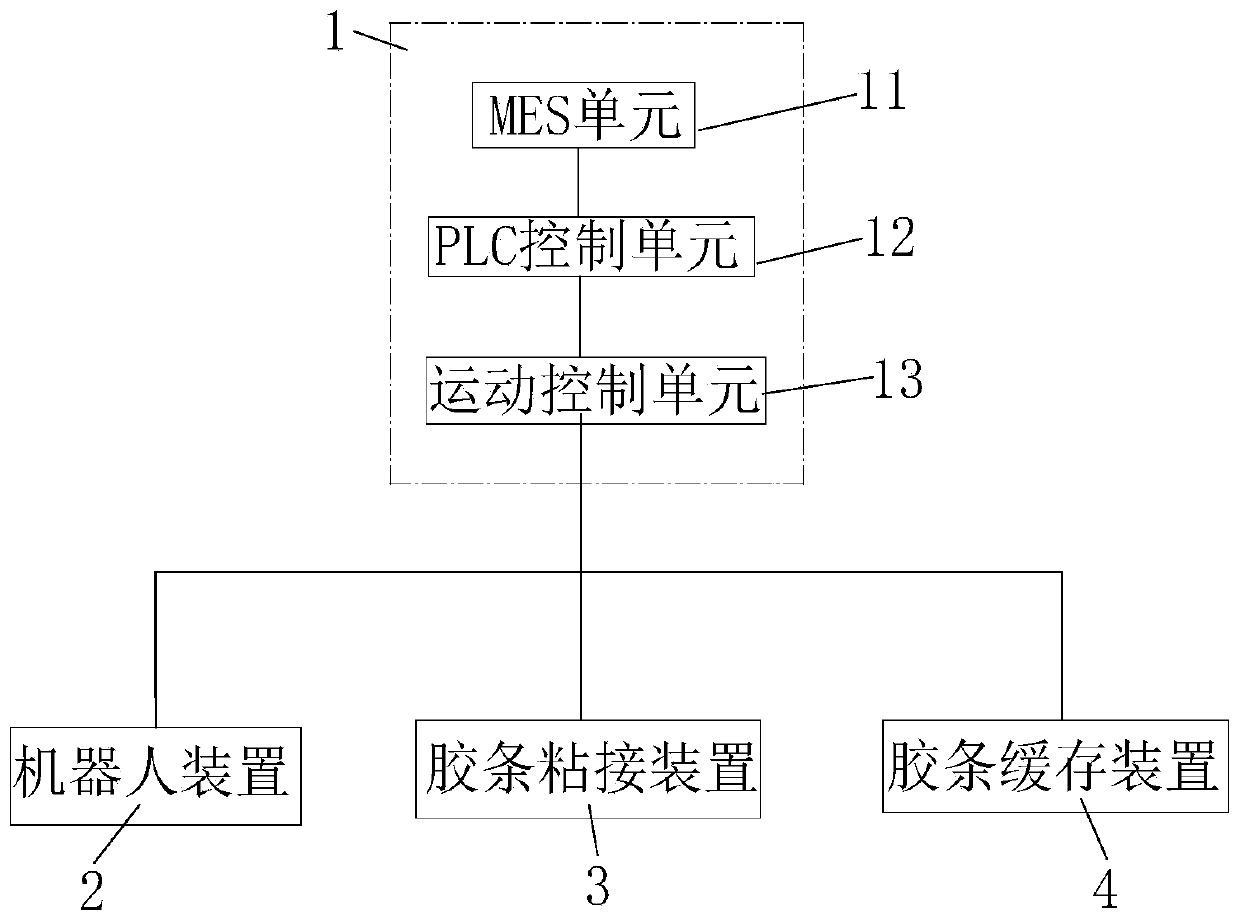

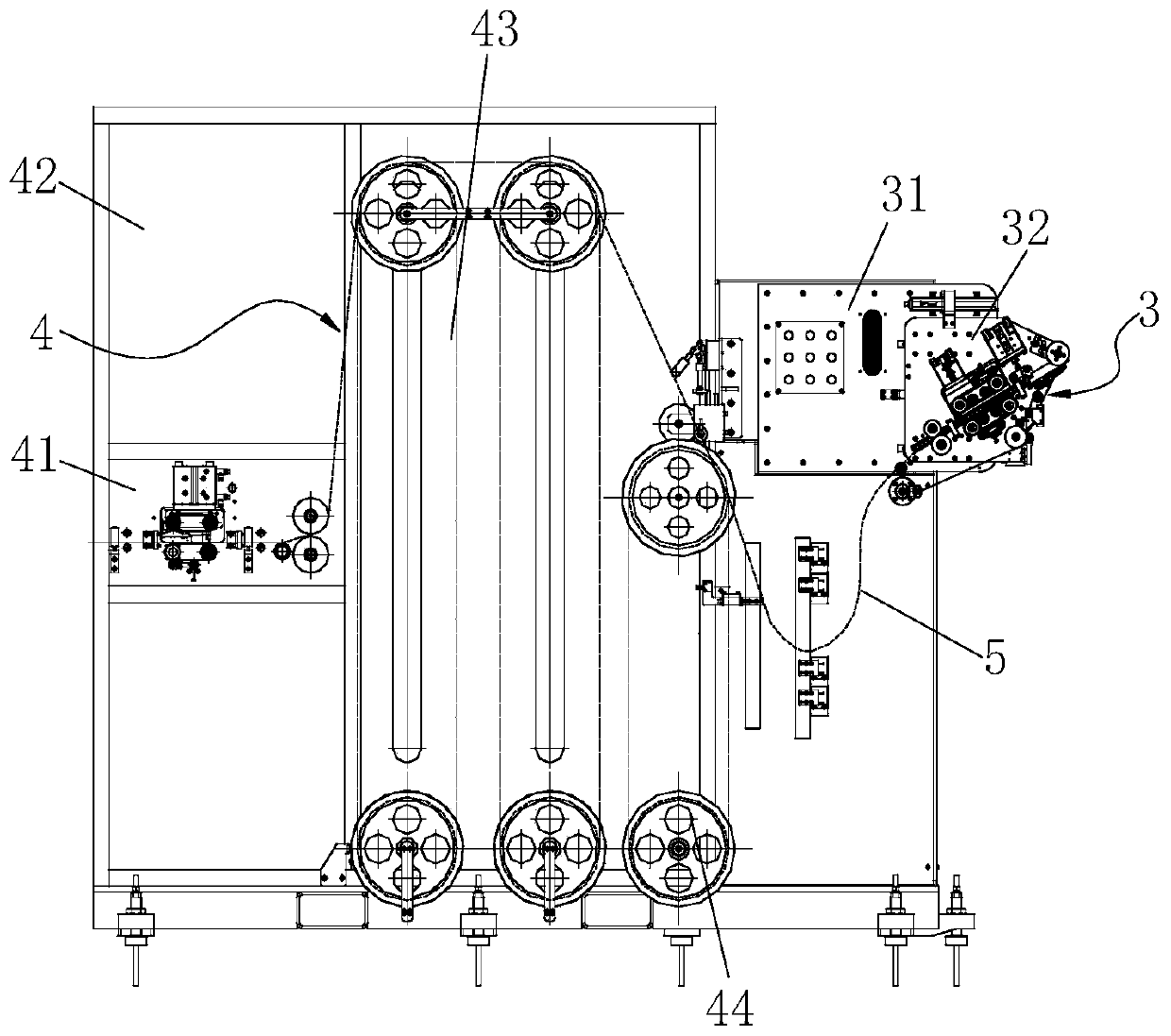

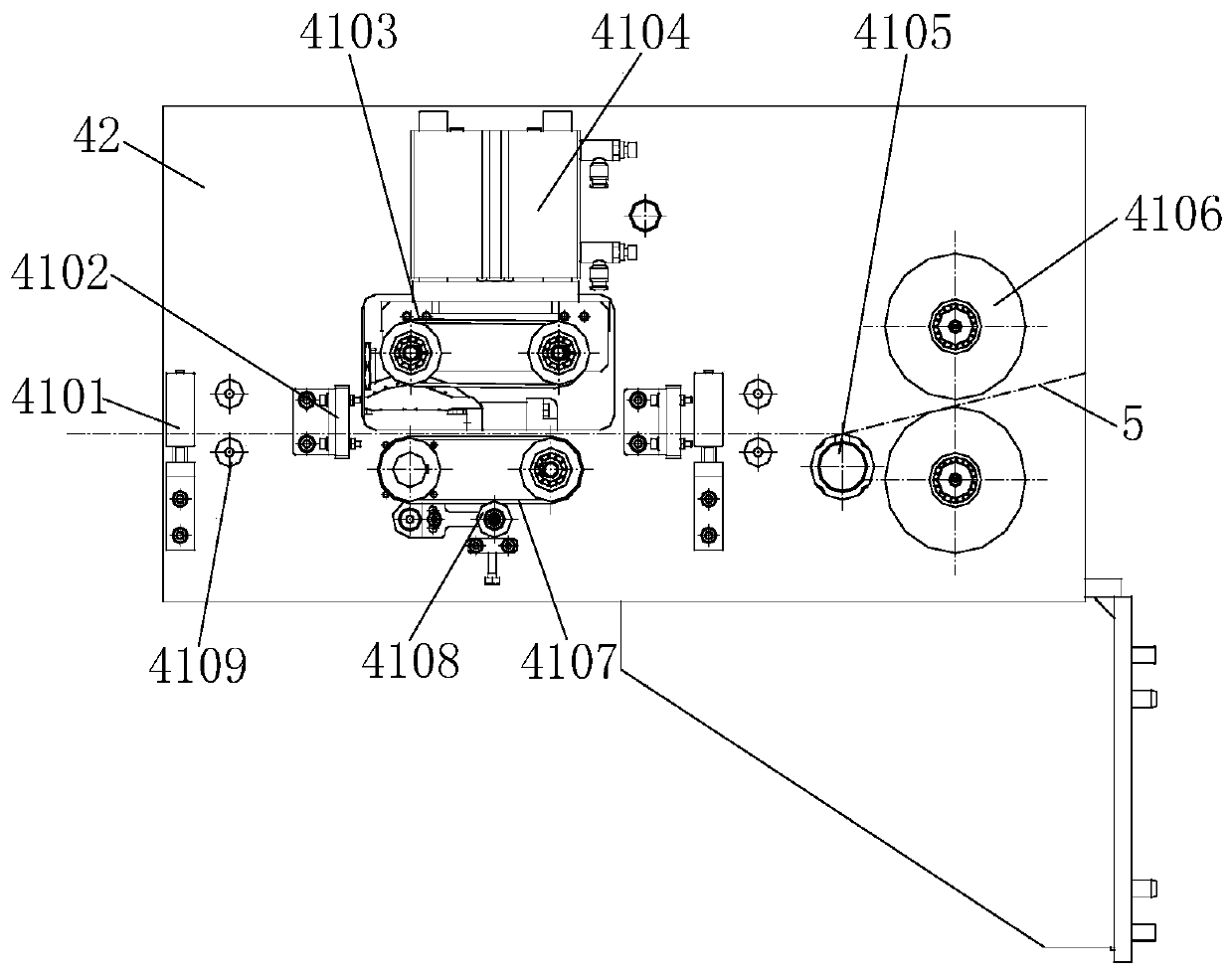

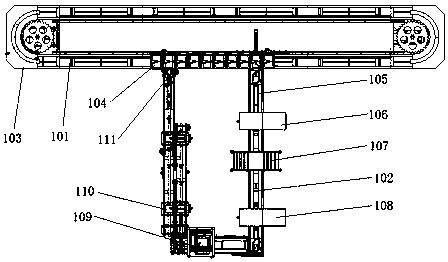

Automatic adhesive tape bonding system and method

ActiveCN109958690AReduce mistakesImprove controllabilityMaterial gluingControllabilityTemporary storage

The invention provides an automatic adhesive tape bonding system and method. The automatic adhesive tape bonding system comprises a control device, a robot device used for grabbing parts to drive theparts to move, an adhesive tape temporary storage device used for temporarily storing and conveying adhesive tapes and an adhesive tape bonding device used for bonding the adhesive tapes to the parts,wherein the control device is used for storing and checking production information of vehicle door bonding, and controls the operating state of the robot device, the adhesive tape temporary storage device and the adhesive tape bonding device according to a checking result. According to the automatic adhesive tape bonding system, the robot device, the adhesive tape temporary storage device and theadhesive tape bonding device are controlled to operate through the control device, automatic bonding of the adhesive tapes on the parts to be bonded can be realized, fault of personnel can be reduced, the controllability in the production process and the production flexibility are increased, and thus, improvement of the production efficiency is facilitated.

Owner:精诚工科汽车系统有限公司

PU curing ring-shaped assembly line for square filter

PendingCN110538771AGuaranteed curing timeGuaranteed service lifePretreated surfacesCoatingsOverlineAssembly line

The invention discloses a PU curing ring-shaped assembly line for a square filter. The PU curing ring-shaped assembly line comprises a control device, a ring-shaped curing assembly line and a glue applying assembly line. A ring-shaped rack is connected to the bottom of the ring-shaped curing assembly line, and multiple follow clamps are connected to the top of the ring-shaped curing assembly line.A U-shaped support is connected to the bottom of the glue applying assembly line, and a first connecting part and a second connecting part connected with the ring-shaped rack are arranged at the twoends of the U-shaped support correspondingly. The two ends of the glue applying assembly line are connected with the ring-shaped curing assembly line, and an upper die taking machine, an overline ladder, a paper core taking machine, a release agent spraying machine, a glue applying machine and a line feeding mechanism are sequentially arranged on the glue applying assembly line in the direction from the first connecting part to the second connecting part. The control device is in control connection with the ring-shaped curing assembly line, the glue applying assembly line, the upper die takingmachine, the paper core taking machine, the release die spraying machine, the glue applying machine and the line feeding mechanism respectively.

Owner:益齐威自动化设备(上海)有限公司

Part tray lifting mechanism

InactiveCN106516690AAutomatic transfer transferImprove work efficiencyConveyorsConveyor partsElectric machinerySprocket

The invention provides a part tray lifting mechanism. The part tray lifting mechanism can be adapted to a part assembly line and can automatically transfer part trays on the part assembly line to next tool equipment at a work height different from that of the part assembly line. The part tray lifting mechanism comprises a rack and a roller conveying seat, rollers are distributed on the roller conveying seat, the multiple rollers arranged side by side are connected together through a chain wheel, and the chain wheel is connected with a transmission motor. The part tray lifting mechanism is characterized in that the part tray lifting mechanism furthermore comprises a lifting seat, an air cylinder and a limiting structure; the lifting seat is slidably installed on the rack through guide rails, the side of the lifting seat is connected with the roller conveying seat, and the bottom of the lifting seat is connected with the air cylinder; the limiting structure is installed on the rack and comprises limiting pillars; and the lifting seat is furthermore provided with an inductive switch, and the inductive switch is in electric control connection with the transmission motor.

Owner:WUXI MINGZHU STEEL BALL

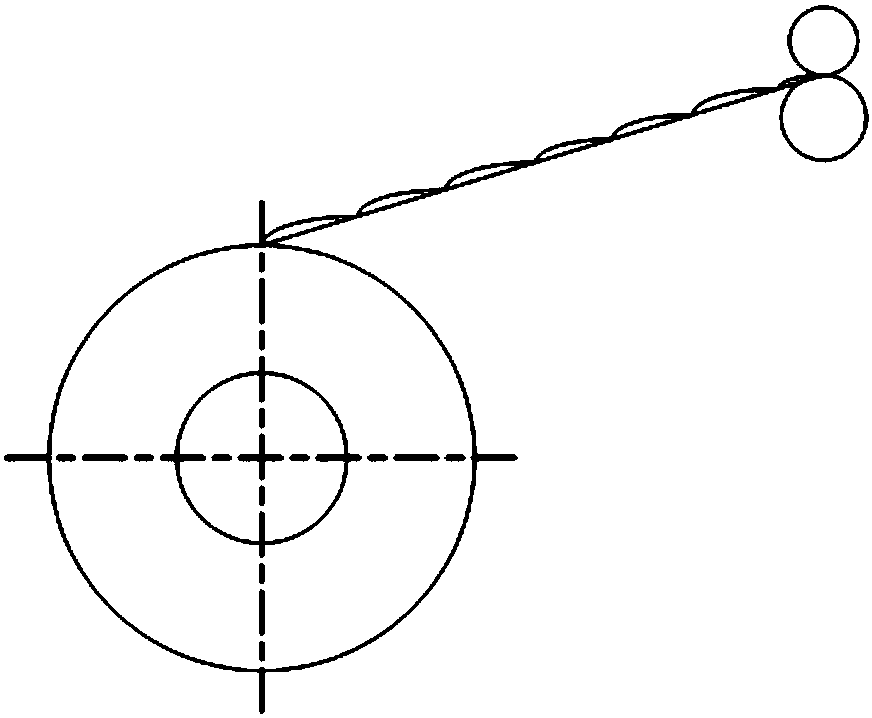

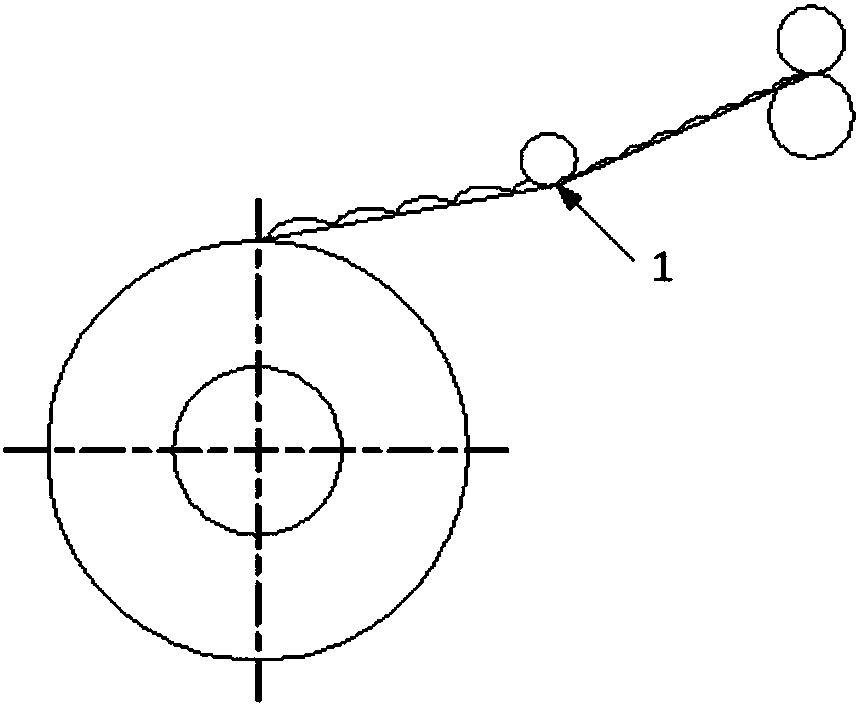

Control method for hot rolled low carbon steel uncoiling cross creases

ActiveCN108160715AImprove product qualityReduce the chance of cross-foldingRoll mill control devicesMetal rolling arrangementsStrip steelCarbon steel

The invention discloses a control method for hot rolled low carbon steel uncoiling cross creases. The control method for the hot rolled low carbon steel uncoiling cross creases includes the followingsteps that firstly, the diameter of a to-be-uncoiled hot rolled low carbon steel coil is detected; secondly, according to the diameter, measured in the first step, of the hot rolled low carbon steel coil, the downward pressing amount of a deep bending roller is calculated; and thirdly, according to the downward pressing amount value calculated in the second step, the deep bending roller is presseddownwards, and uncoiling production is performed on the hot rolled low carbon steel coil. According to the control method for the hot rolled low carbon steel uncoiling cross creases, the occurring possibility of the cross creases on the surface of strip steel is reduced, and the product quality after uncoiling of the hot rolled low carbon steel is effectively improved; and the production efficiency is improved, the product qualification rate is increased, and good popularization value is achieved.

Owner:内蒙古包钢稀土钢板材有限责任公司

Space spanning pouring system for iron mold sand coating process

PendingCN111318649AIncrease productivityReduce energy consumptionFoundry mouldsFoundry coresSlagChemistry

The invention discloses a space spanning pouring system for an iron mold sand coating process. The pouring system comprises a sprue cup, a sprue and a bridging sprue, wherein the bridging sprue comprises semi-arch bridge channels, runners and risers, the bottom of the sprue cup is connected with the top of the sprue, the two ends of the bottom of the sprue are respectively connected with one endsof the semi-arch bridge channels, the two semi-arch bridge channels form an arch bridge channel, the other ends of the two semi-arch bridge channels are respectively connected with one ends of the runners, the two ends of each runner are respectively connected with the risers, and one side or two sides of each riser is connected with inner sprues. Molten iron is introduced into the arch bridge channel through the sprue cup and the sprue, sequentially flows through slag collection bags, filter screens, the runners and the risers, and is injected into product casting molds through the inner sprues. According to the pouring system, space placement channels of the product casting molds can be increased, so that the product casting amount produced by a single box is increased by 1.5-2 times, the production efficiency is high, the yield is high, the quality is stable, the operation is convenient, and the pouring system is suitable for popularization.

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

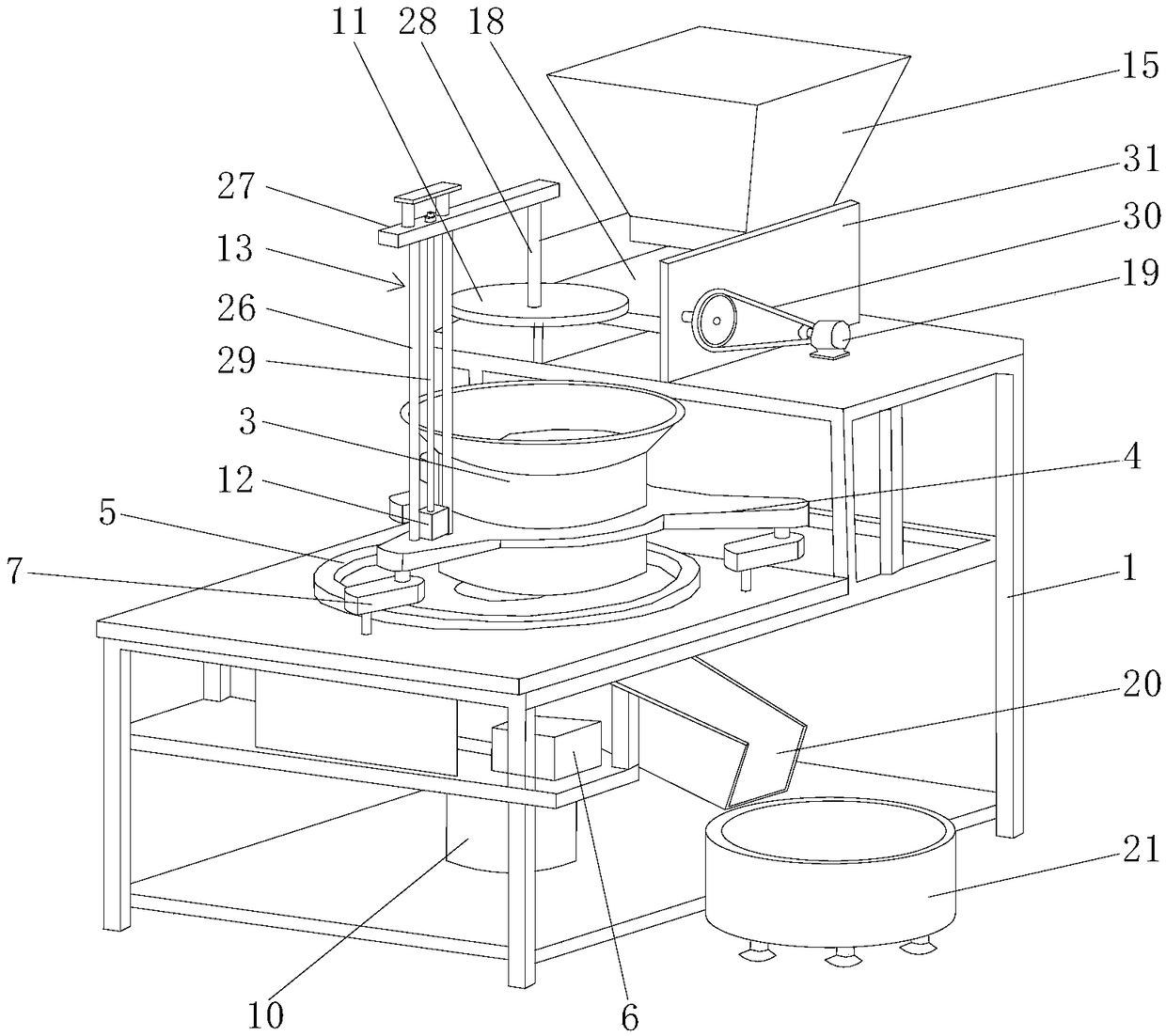

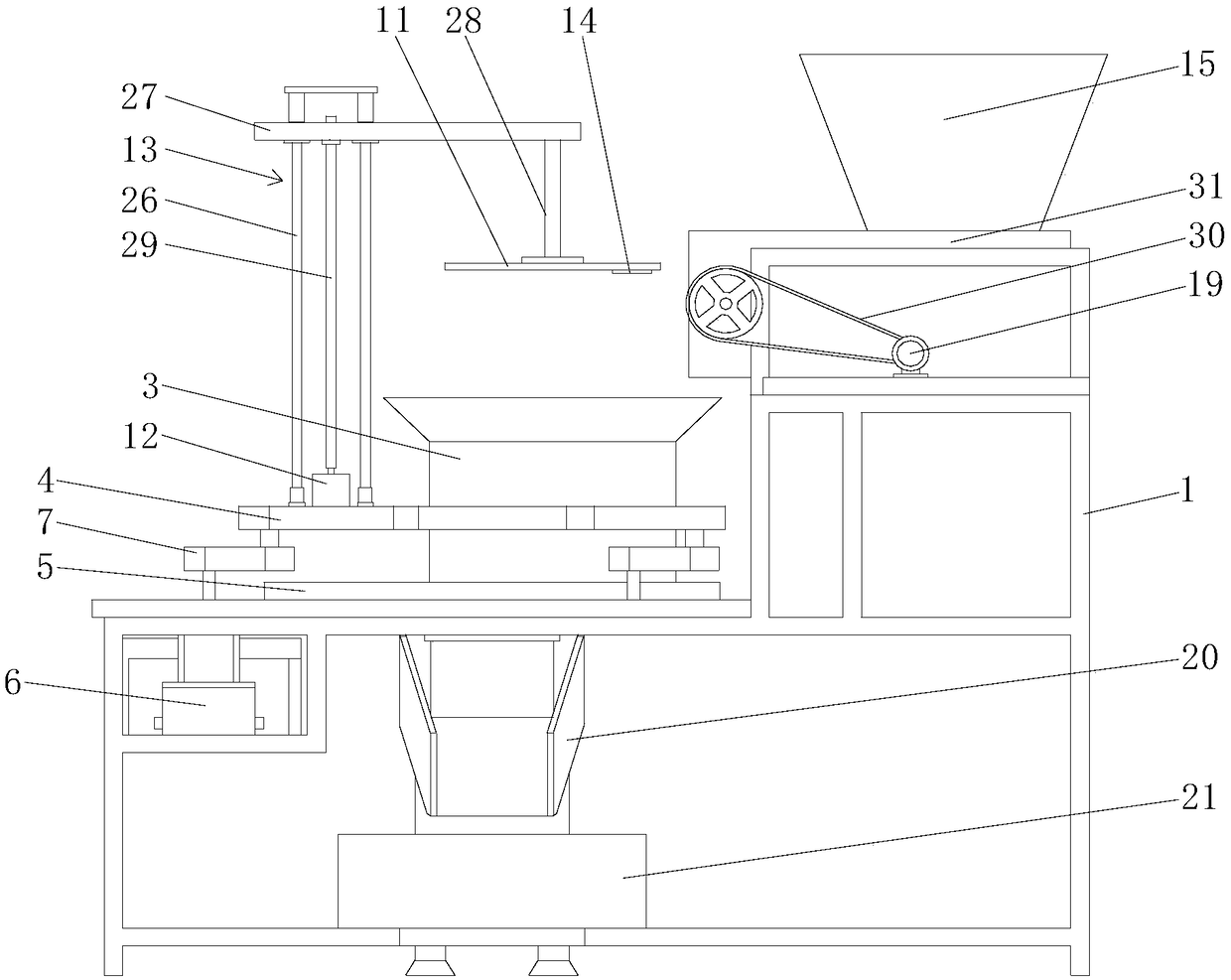

Tea leaf twisting machine

PendingCN108887423AReduce manufacturing costImprove product qualityPre-extraction tea treatmentProduction rateEngineering

The invention discloses a tea leaf twisting machine. The tea leaf twisting machine comprises a stander and a controller, wherein a material storage mechanism, a feeding mechanism, a pressurizing mechanism, a twisting mechanism and an unloading mechanism are respectively arranged on the stander, one end of the feeding mechanism is linked with an input hole of the storage mechanism, the other end ofthe twisting mechanism linked with the twisting mechanism, the pressurizing mechanism is mounted on the twisting mechanism, and the unloading mechanism is linked with the output hole of the twistingmechanism; and the controller is connected with the material storage mechanism, the feeding mechanism, the pressurizing mechanism and the twisting mechanism respectively so as to be used for controlling the mechanisms to work. The tea leaf twisting machine has the beneficial effects that the pressure in the twisting process of tea leaves can be changed, automatic loading and unloading can be realized, the operation is simple, the production rate is high, and the production quality of tea is good.

Owner:WUZHOU UNIV

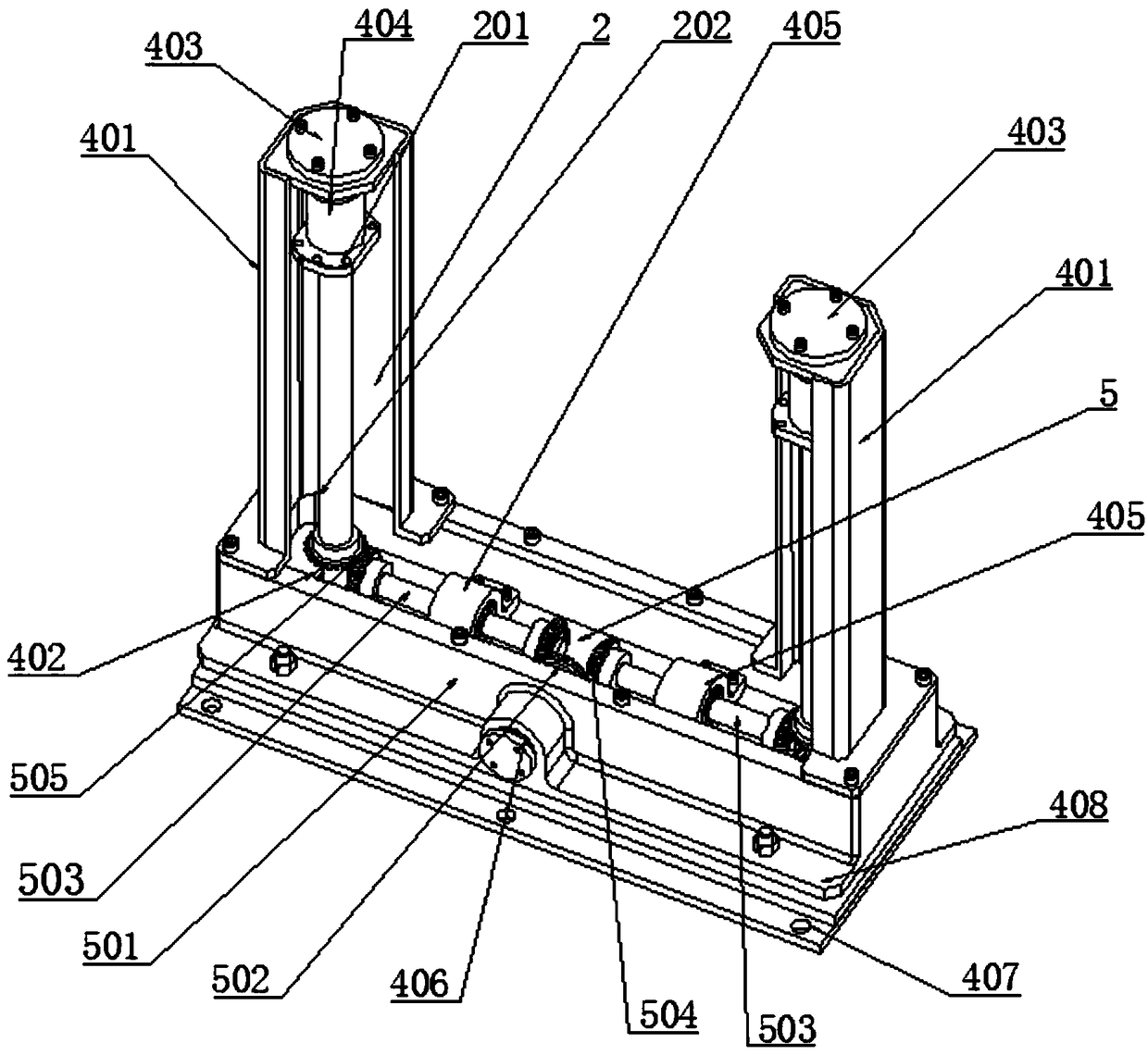

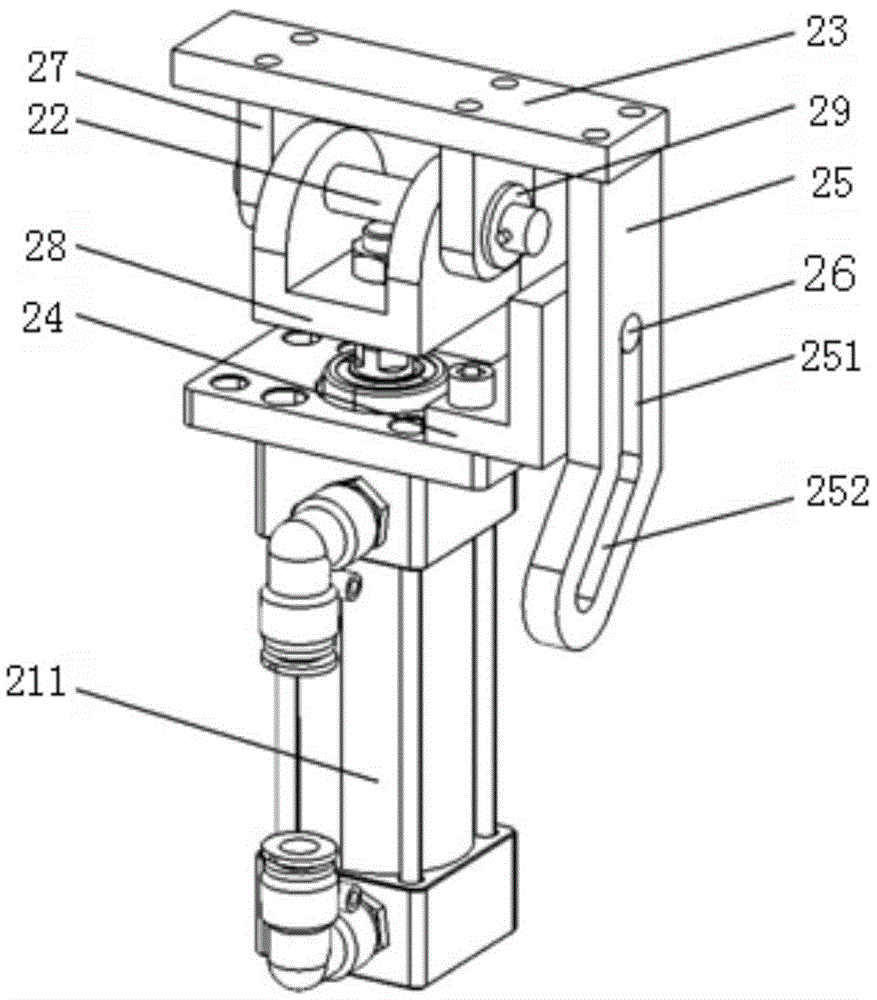

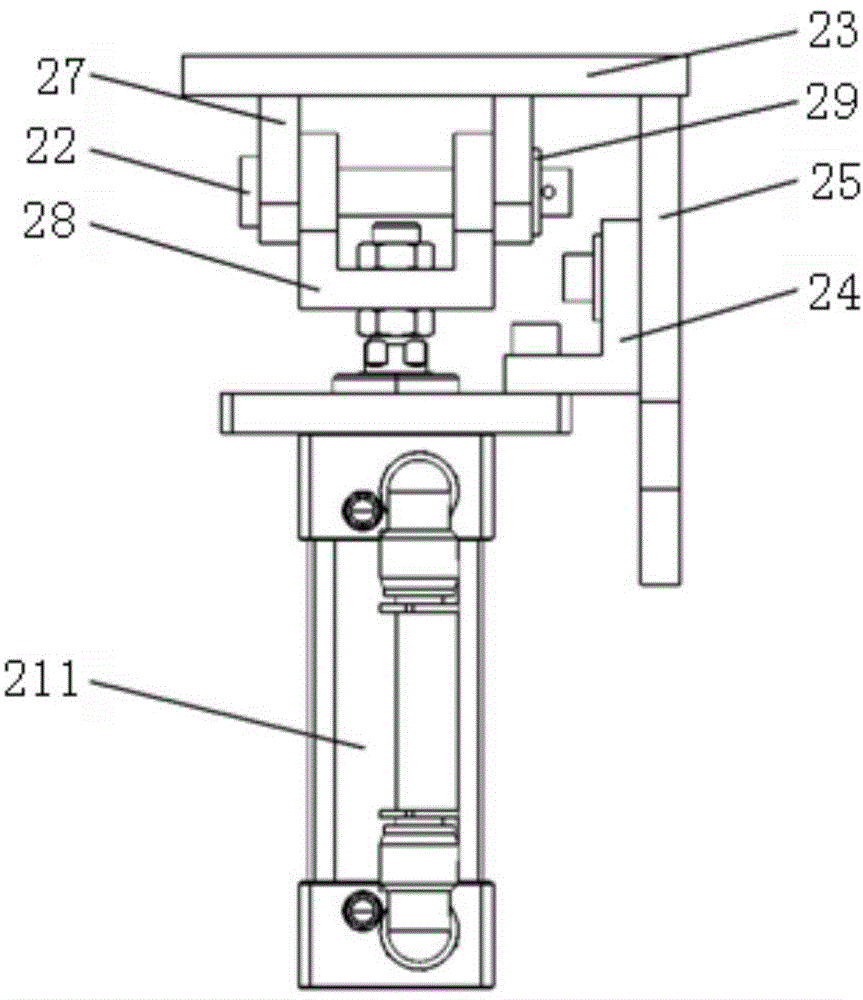

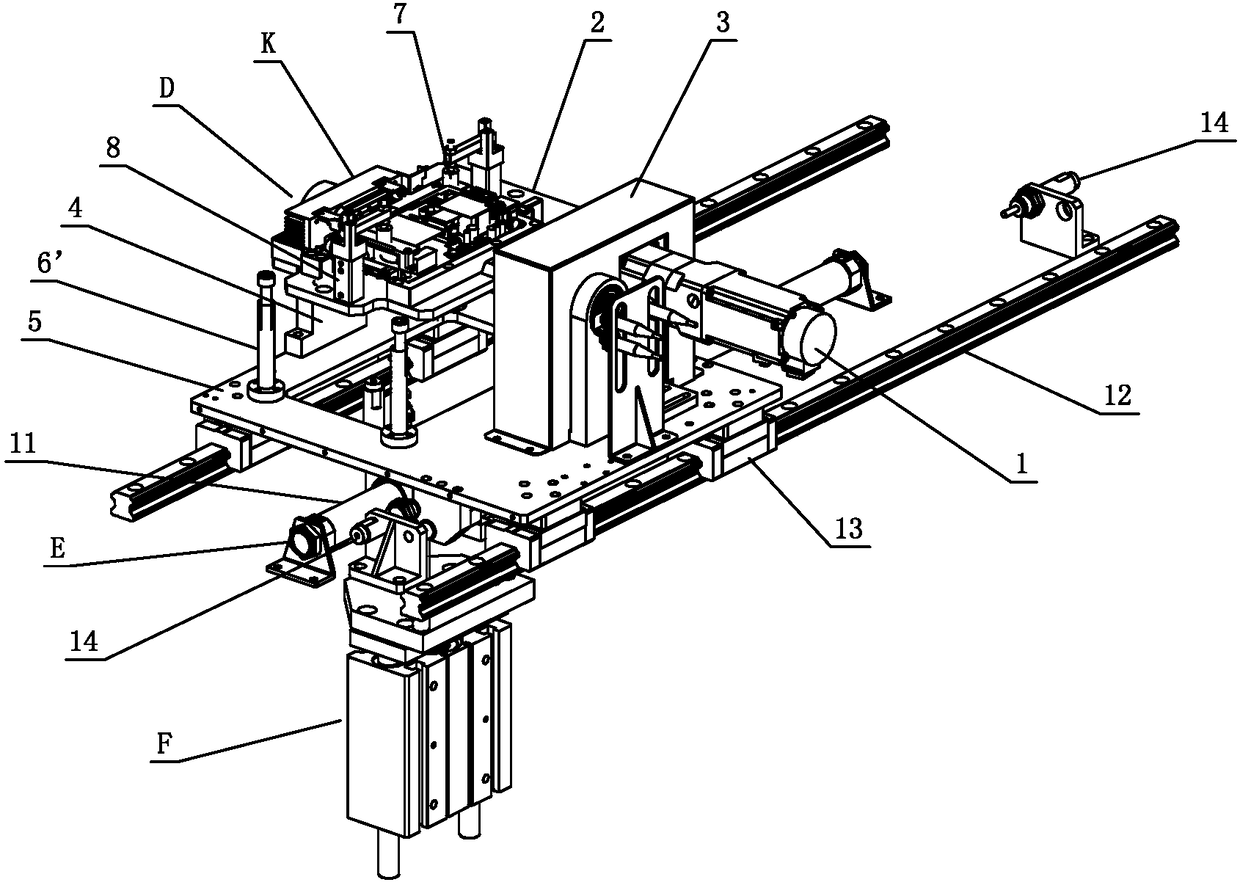

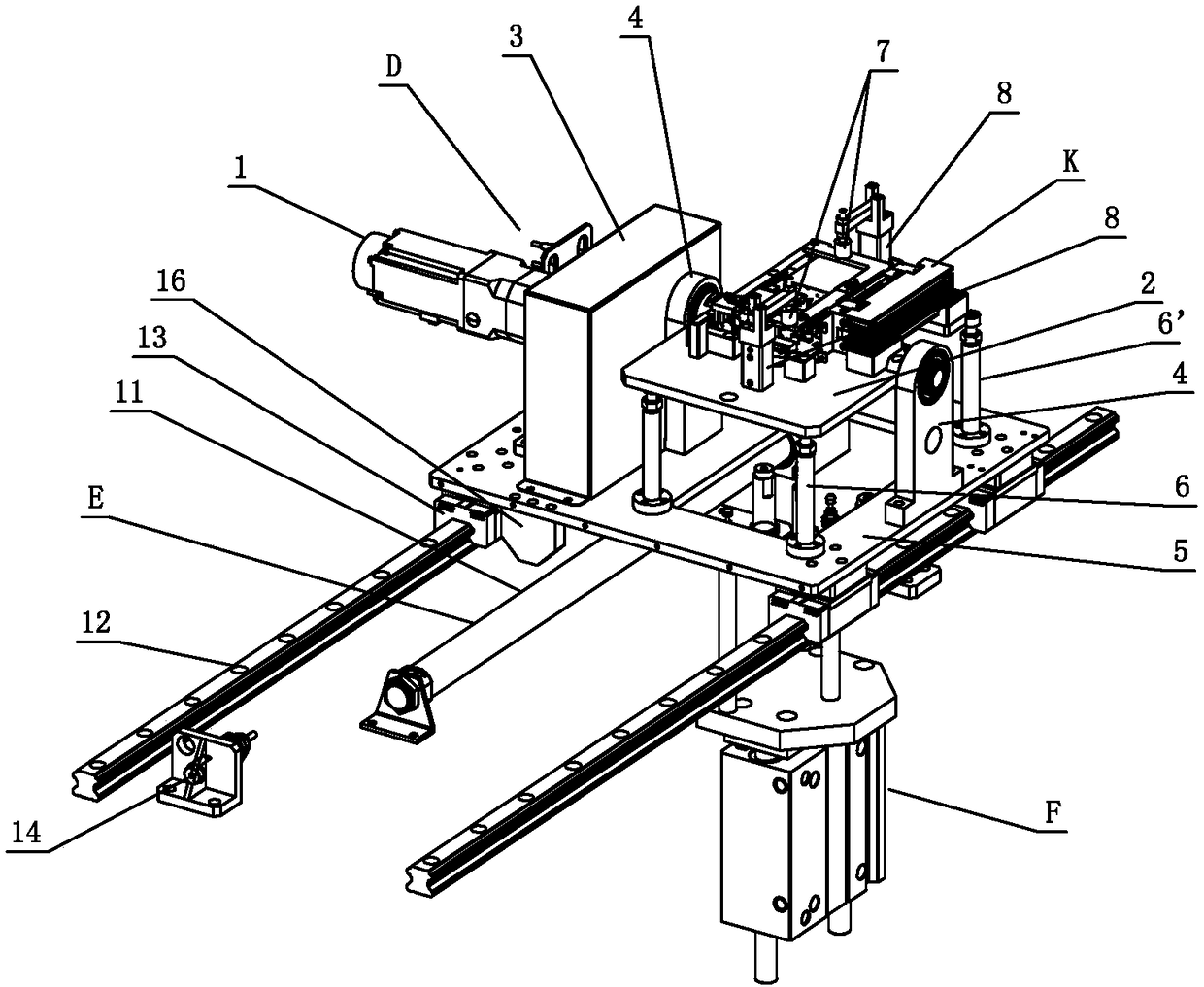

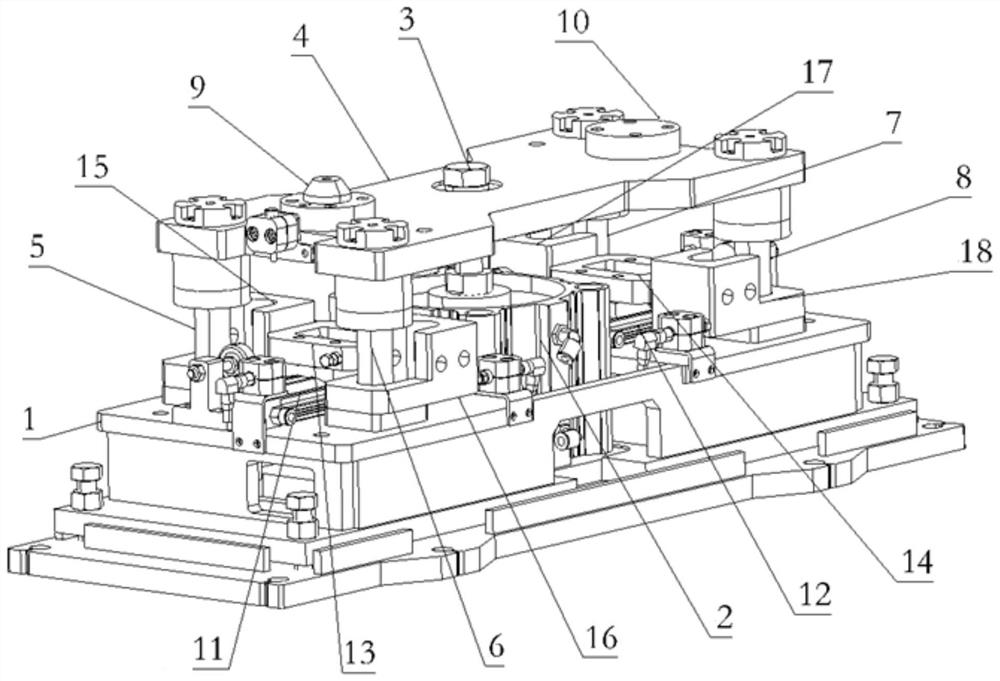

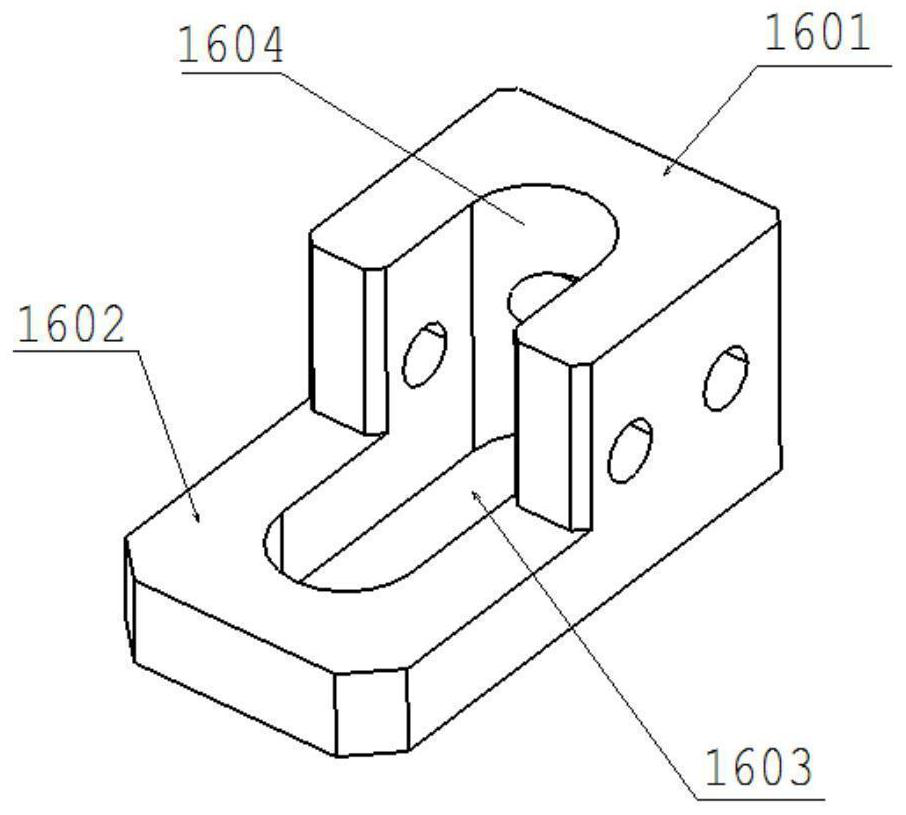

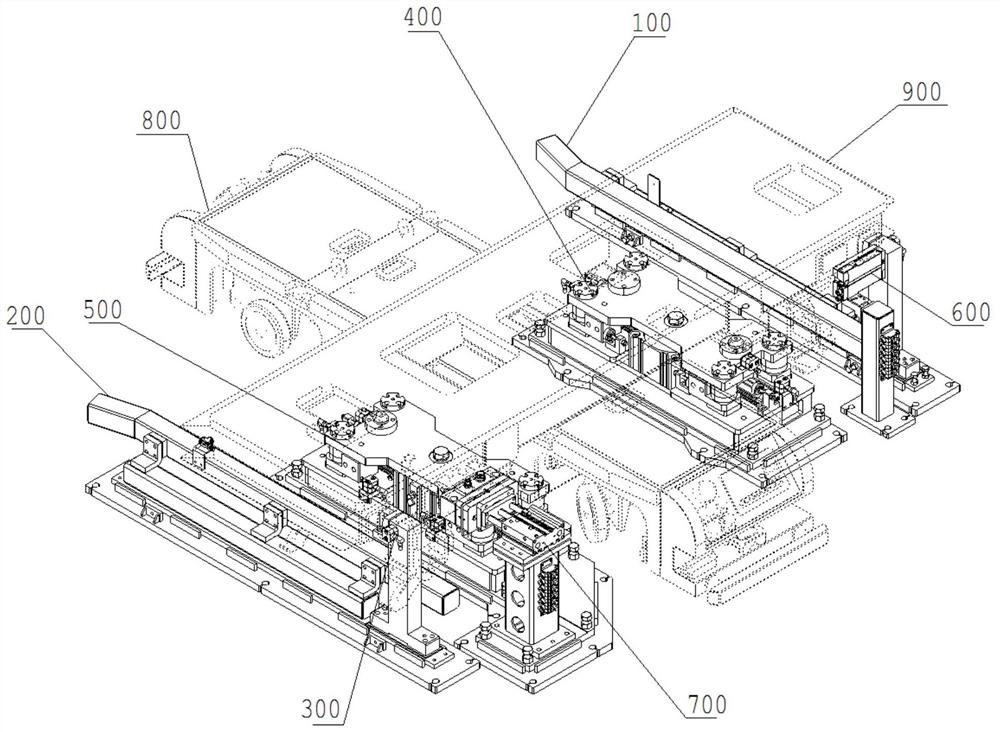

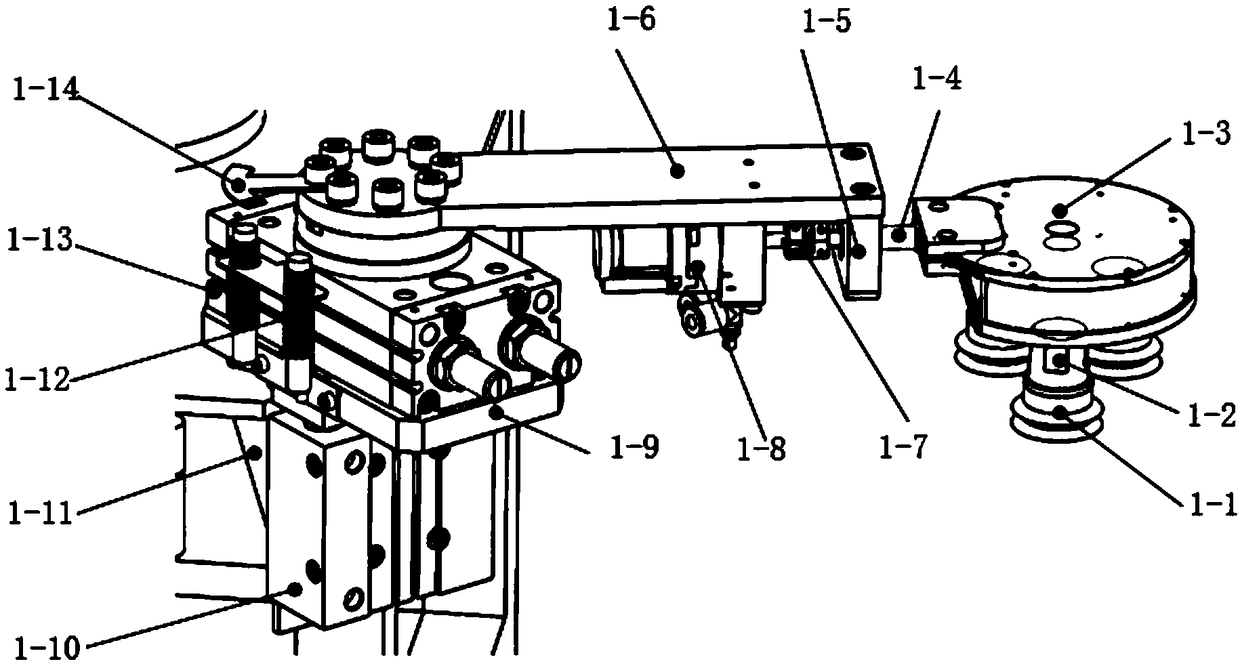

Flexible welding island clamp positioning lifting mechanism, automatic switching device and switching method

ActiveCN111822918ARealize automatic positioningReduce usageWelding/cutting auxillary devicesAuxillary welding devicesPilot holeControl engineering

The invention discloses a flexible welding island clamp positioning lifting mechanism, an automatic switching device and a switching method. In the positioning lifting mechanism, a lifting air cylinder is installed in the middle of a base; the push-pull end is connected with a top plate above; the bottom of the top plate is provided with a guide column matched with a guide hole in the base; a positioning assembly is fixed to the upper surface of the top plate; a pneumatic sliding rail is horizontally fixed to the upper surface of the base; the sliding end of the pneumatic sliding rail is connected with a limiting block; the limiting block is provided with two limiting faces with different heights; and under driving of the pneumatic sliding rail, the limiting block moves and switches the limiting faces with different heights to abut against the limiting contact face at the bottom of the top plate, limiting of the top plate at different height positions is achieved, and then a clamp is controlled to be positioned at different heights. The automatic switching device of the clamp is composed of a guide mechanism, a lifting positioning mechanism, a clamp detection unit, a clamp recognition unit and a medium unit. Automatic switching of the clamp can be achieved, the equipment purchasing and using cost is reduced, and the switching time is shortened.

Owner:CHINA FIRST AUTOMOBILE +1

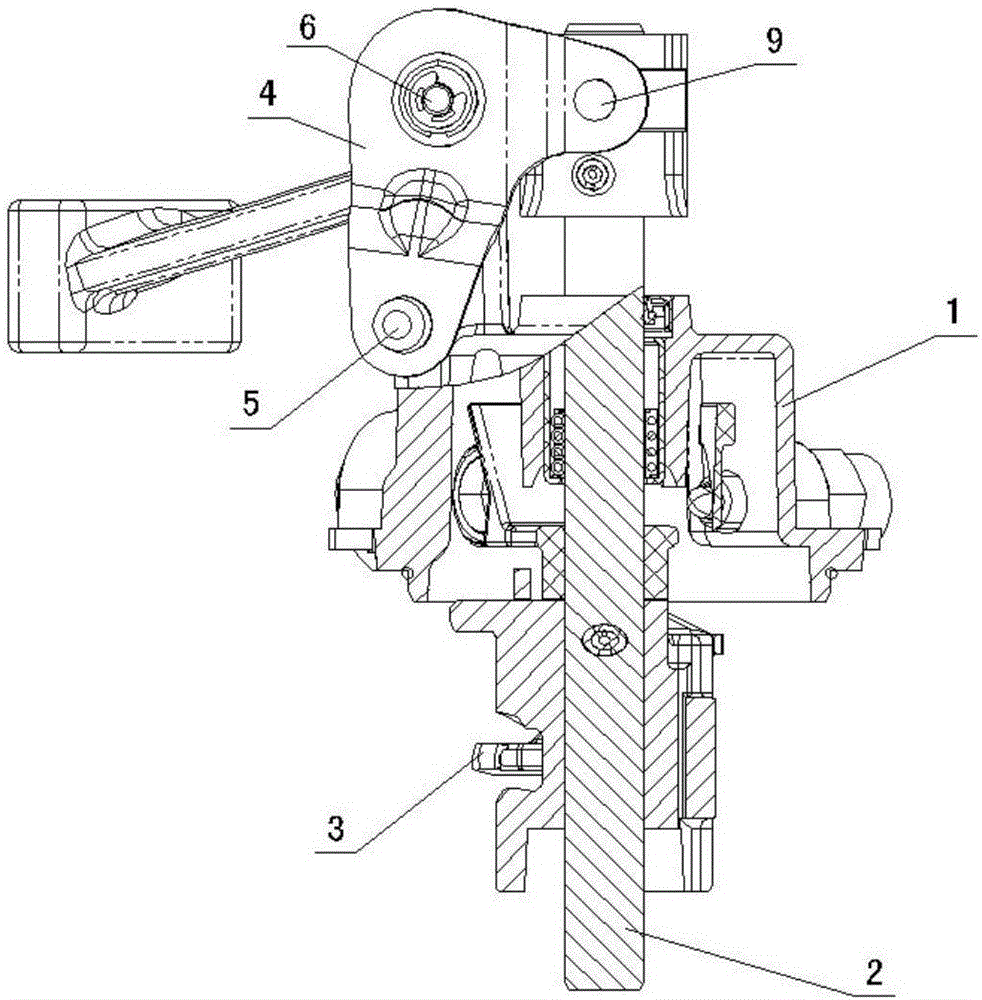

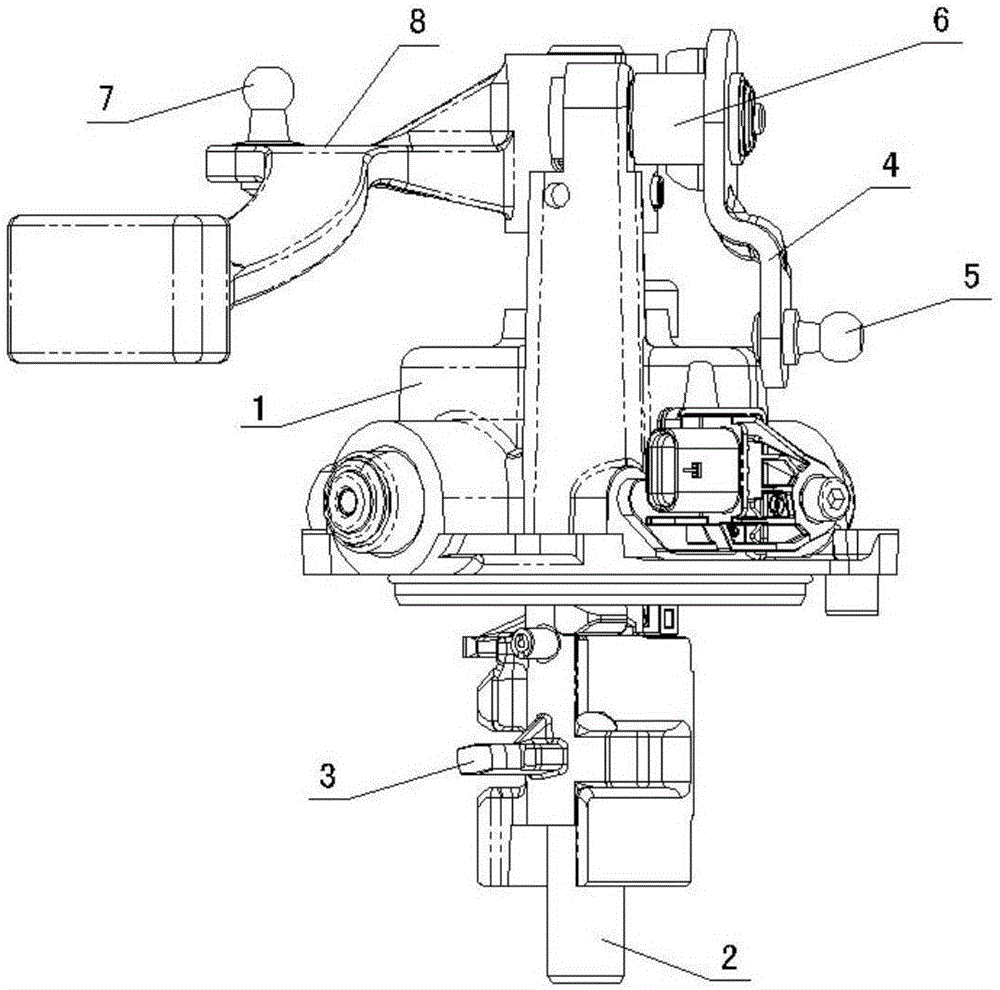

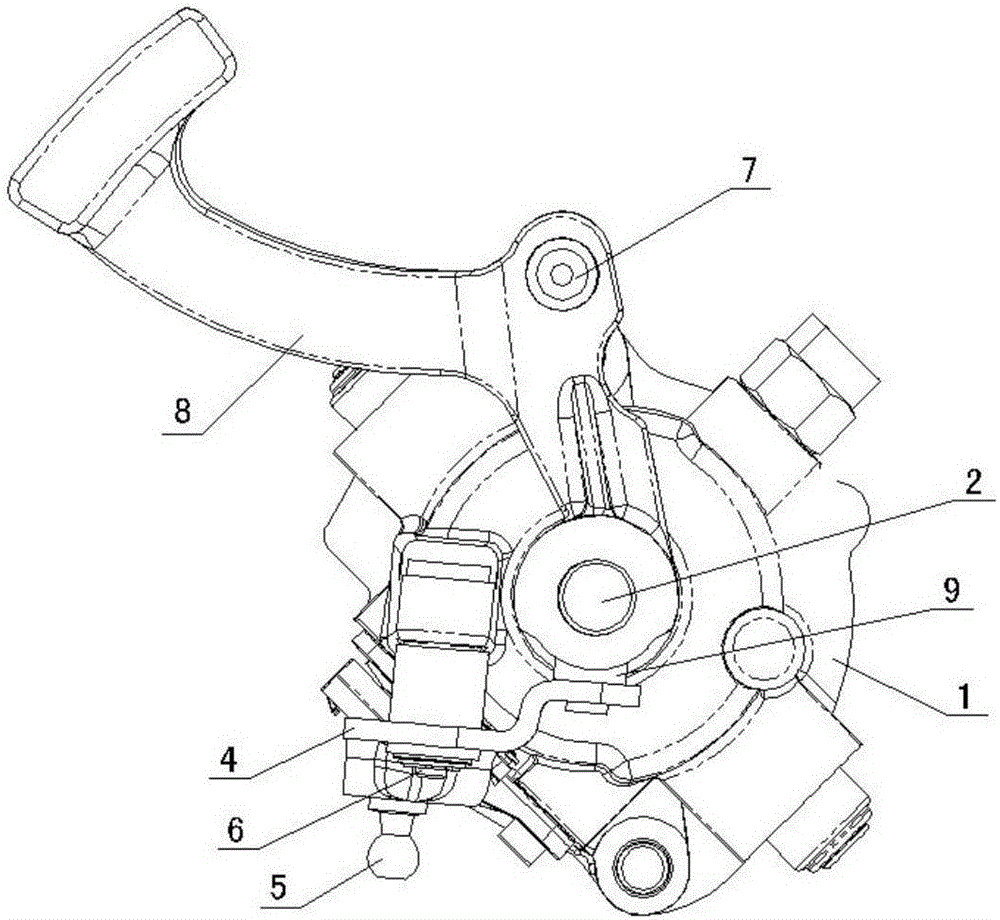

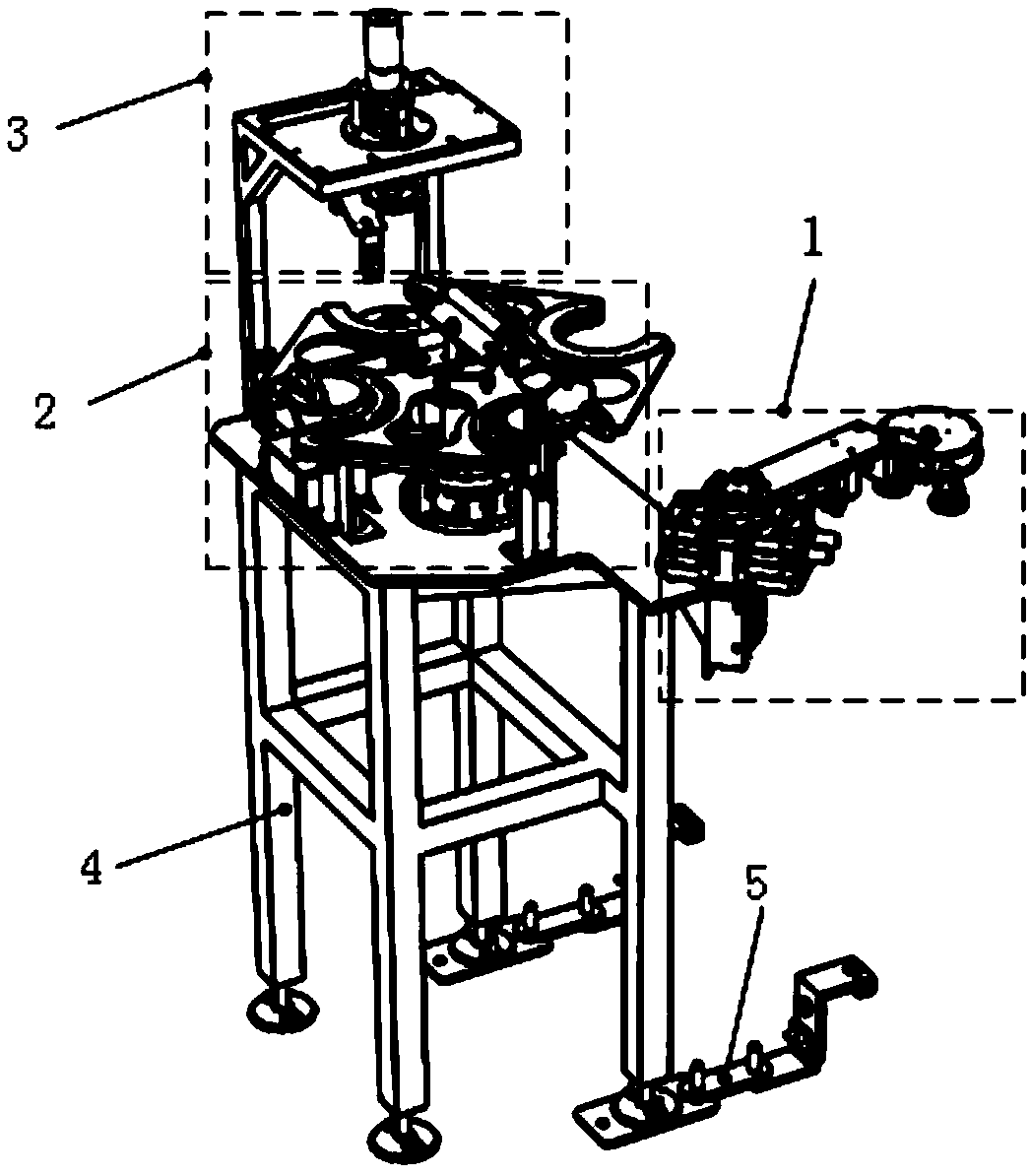

Gear selecting and shifting switching mechanism of manual transmission and application of gear selecting and shifting switching mechanism in gear selecting and shifting detection

InactiveCN106286819AImprove assembly pass rateGuarantee normal production cycleMachine gearing/transmission testingGearing controlEngineeringCantilever

The invention discloses a gear selecting and shifting switching mechanism of a manual transmission and application of the gear selecting and shifting switching mechanism in gear selecting and shifting detection. The gear selecting and shifting switching mechanism is characterized in that a gear selecting and shifting shaft capable of rotating and axially moving relative to a cylindrical shell is arranged in the cylindrical shell in a sleeved mode, and a puller for gear selecting and shifting is fixedly connected to the shaft end of the gear selecting and shifting shaft; one end of a gear selecting rotary arm is a gear selecting driving end, and the other end of the gear selecting rotary arm is connected with the gear selecting and shifting shaft through a pushing block; the gear selecting rotary arm can drive the gear selecting and shifting shaft to move axially in the cylindrical shell through the pushing block; one end of a gear shifting cantilever is fixedly connected with the gear selecting and shifting shaft, the other end of the gear shifting cantilever is an overhanging gear shifting driving end, and the gear selecting and shifting shaft can rotate in the cylindrical shell under driving of the gear shifting cantilever. The gear selecting and shifting switching mechanism is used in cooperation with gear selecting and shifting driving equipment and is correspondingly provided with a force sensor and a displacement sensor; the characteristic quantities of gear selecting and shifting mechanisms are obtained through detection in the gear selecting or shifting process, then the qualified ear selecting and shifting mechanism is screened out, the product assembly percent of pass can be effectively increased, the production takt can be guaranteed, and the production efficiency can be improved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

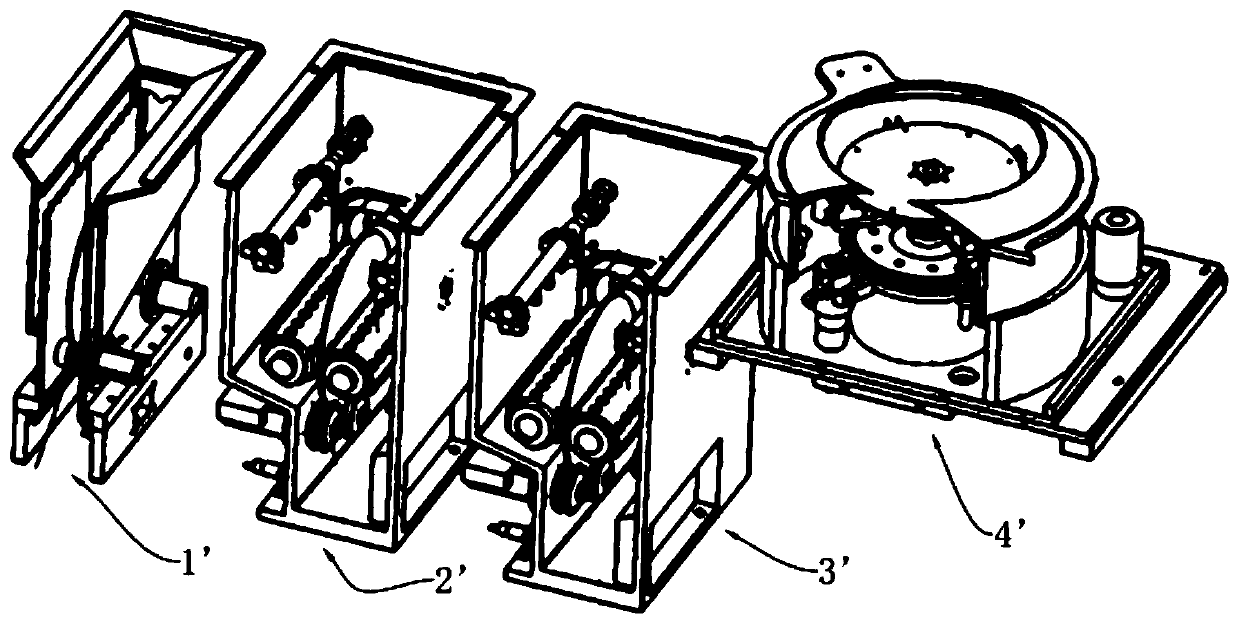

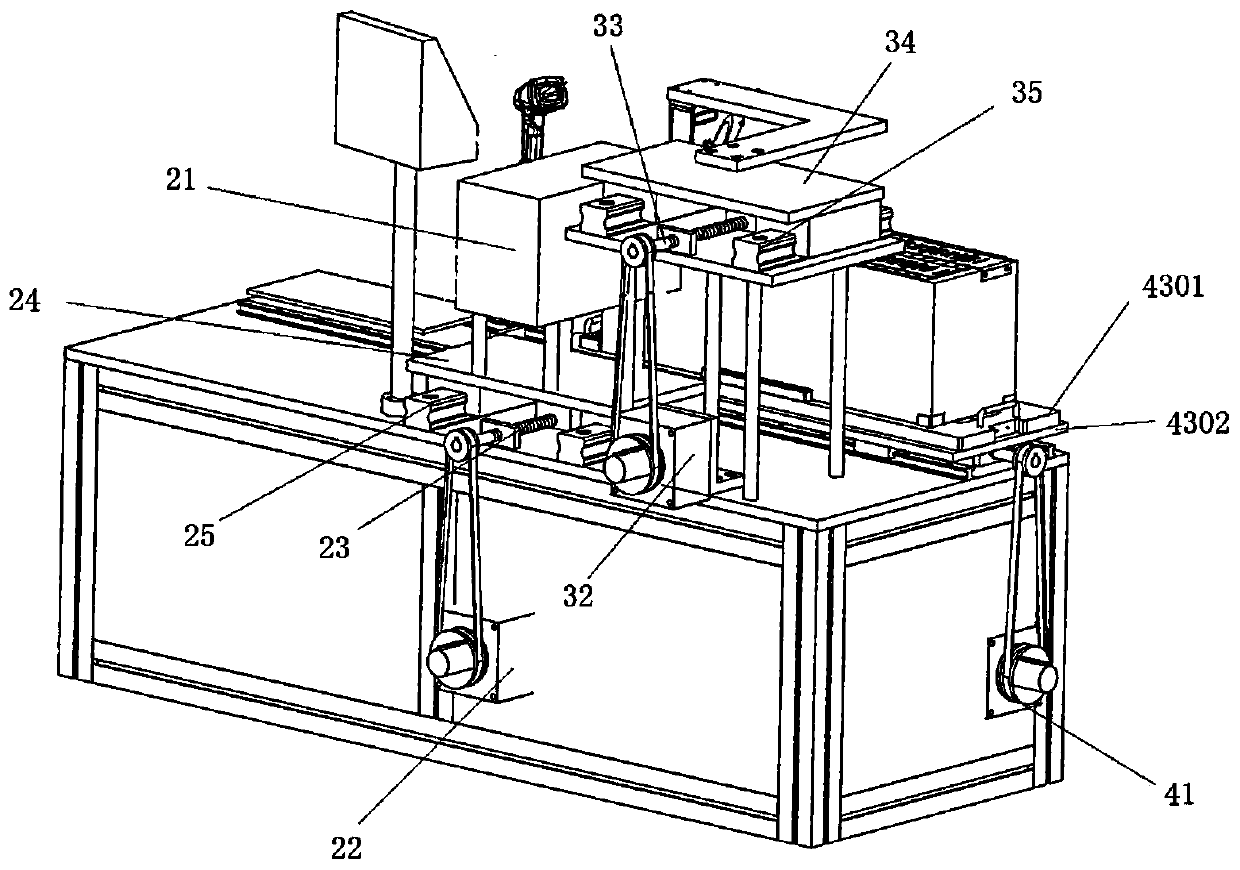

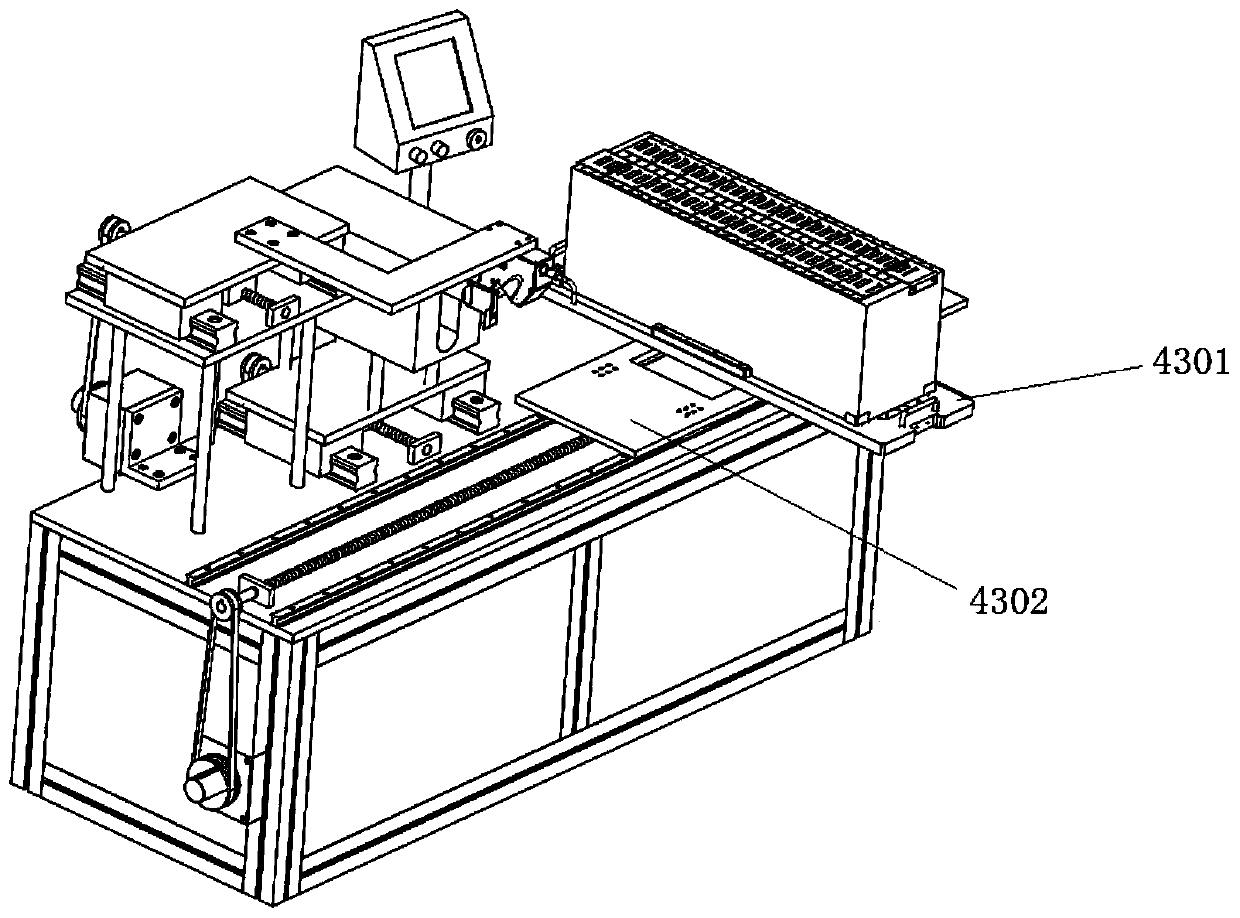

Discharging, detecting and sorting device of grinding wheel sheets and method

ActiveCN109317421AAutomate operationsAvoid personal injurySortingGrinding wheelMechanical engineering

The invention belongs to a discharging, detecting and sorting device of grinding wheel sheets. The device comprises a discharging and grabbing mechanism, a sorting mechanism and a detection mechanism,wherein the discharging and grabbing mechanism is fixed on one side of a main machine frame, the sorting mechanism is fixed above a main frame, and the detection mechanism is fixed above the main frame; the discharging and grabbing mechanism is used for overturning a to-be-measured grinding wheel sheets along the horizontal plane and transferring the grinding wheel sheets to the next working procedure; and the sorting mechanism comprises a rotary table which is provided with four stations and can rotate under the driving of a driving device, the rotary table is provided with at least one moldcavity, the mold cavities of the rotary tables are used for bearing the to-be-measured grinding wheel sheets from the discharging and grabbing mechanism at a first station, carried out detecting of the detection mechanism at a second station, and carried out sorting of a removal mechanism at other stations. According to the device and the method, the sorting efficiency and precision of the discharging, detecting and sorting device of the grinding wheel sheets can be improved.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

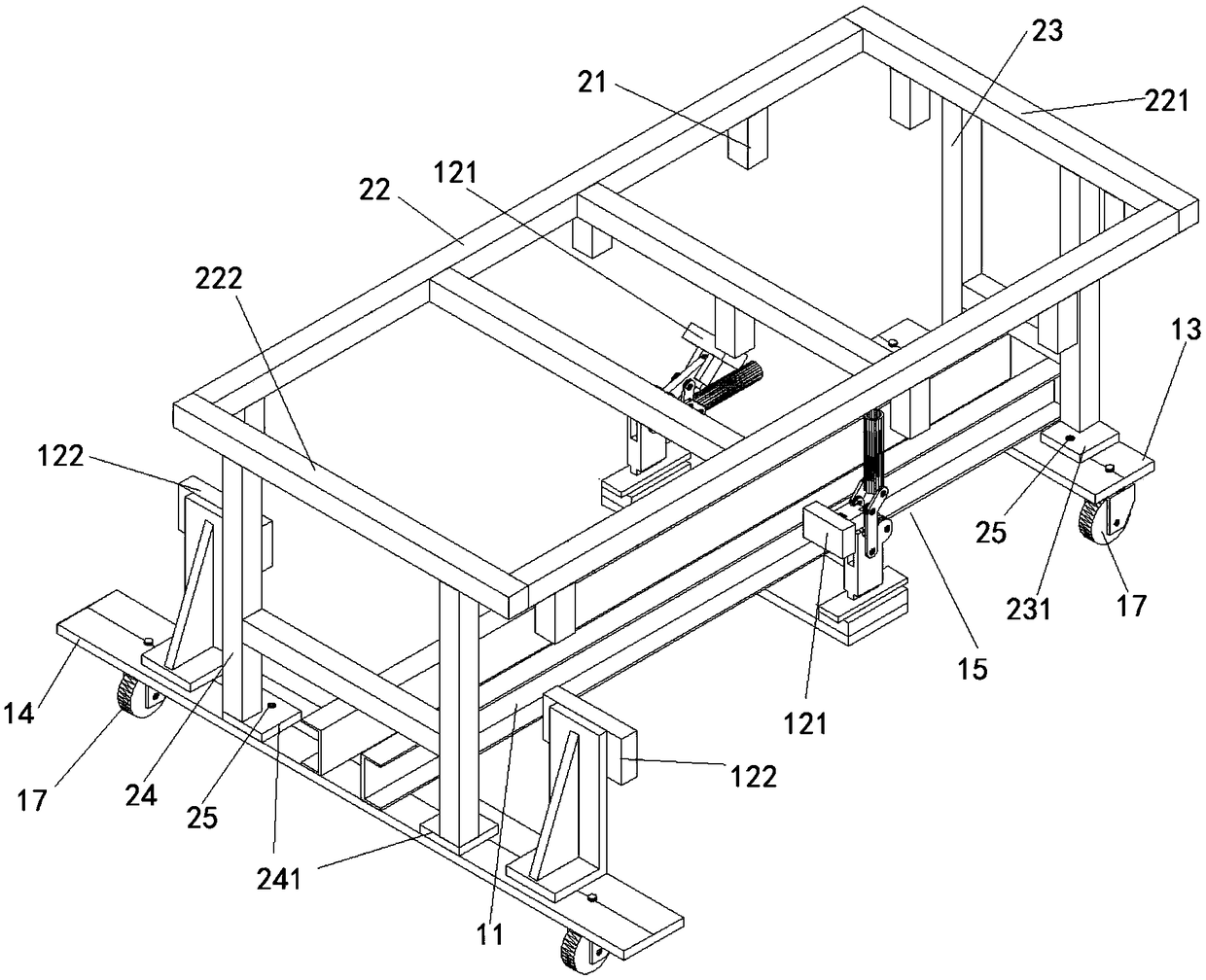

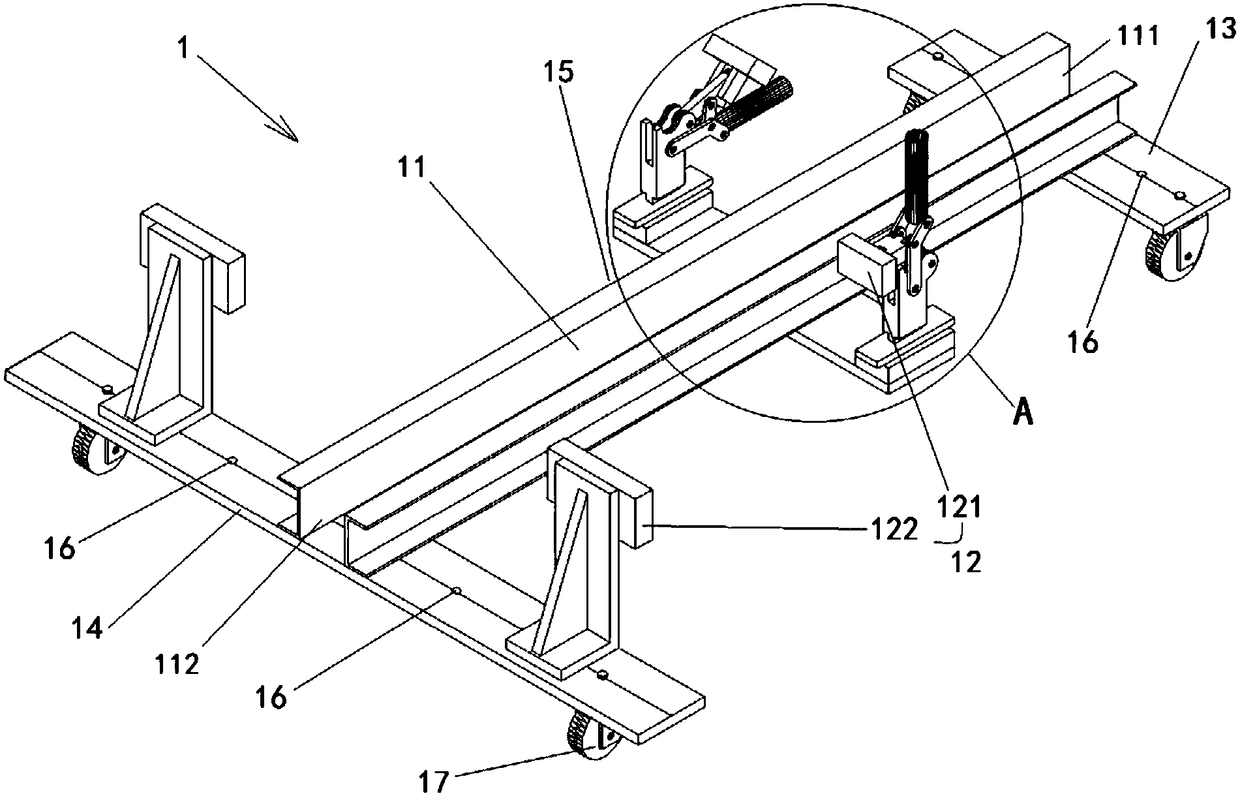

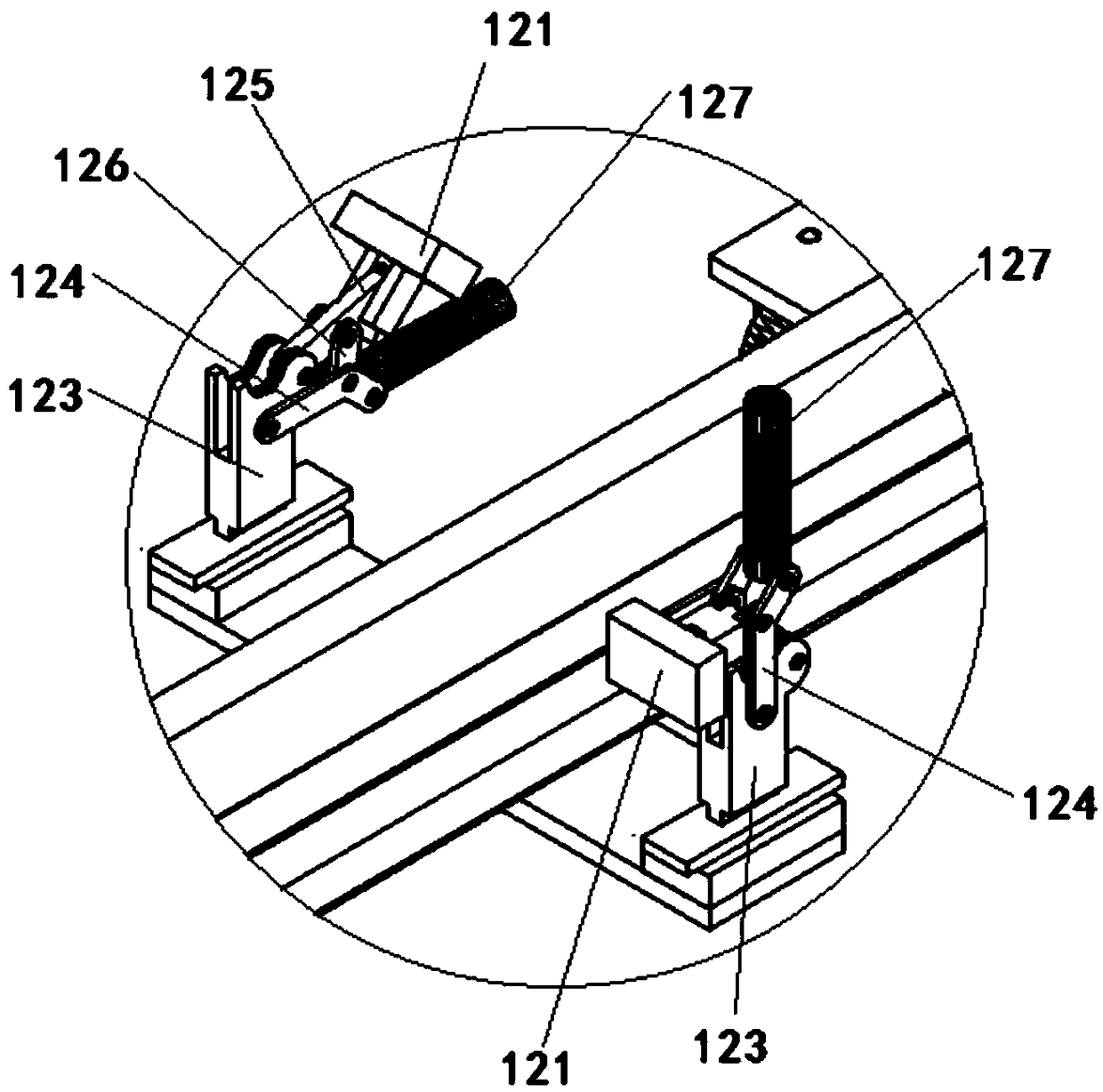

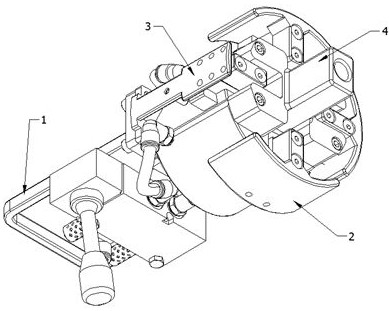

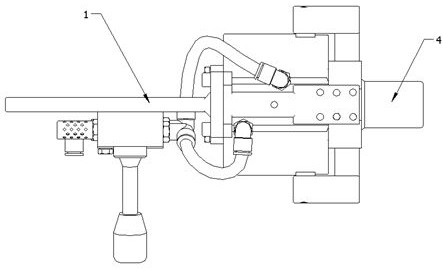

Positioning fixture detection mechanism and method of white body transfer vehicle

PendingCN108444422AGuaranteed accuracyGuarantee normal production cycleMeasurement devicesProduction lineEngineering

The invention relates to a positioning fixture detection mechanism and method of a white body transfer vehicle. The positioning fixture detection mechanism comprises a simulation positioning tyre (1)for fixing the white body transfer vehicle and a detection tool (2) with multiple reference detection positions (21), wherein both the white body transfer vehicle and the detection tool (2) are fixedly connected with the simulation positioning tyre (1) in a detachable manner; and the detection mechanism further comprises a measurement tool that is used for measuring a distance between each reference detection point (21) and a position of a corresponding positioning fixture of the white body transfer vehicle fixedly connected with the simulation positioning tyre (1). In production, malpositionof the positioning fixture may cause deviation of the white body, resulting in alarming, production stagnation and production line congestion. The positioning fixture detection mechanism solves the above technical problem. The positioning fixture detection method saves time and effort for regulating the positioning fixture and guarantees regulation precision.

Owner:BEIJING HYUNDAI

Process for assembling driving cab of heavy truck

The invention provides a process for assembling a driving cab of a heavy truck. The process comprises the following steps: a) fixing a driving cab mounting bottom plate to a partial-assembling device; b) forming a front wall module; c) hoisting the front wall module to a mounting station at an assembly line; d) daubing a primer coating to the driving cab in the assembly line; e) injecting adhesive to the air-dried primer coating by the adhesive injecting method; f) moving the front wall module to the driving cab direction with an assistant manipulator, adhering and fixing the front wall module to the driving cab, and then fastening with bolts. According to the process for assembling the driving cab of the heavy truck, a combined pedal assembly, an electrical junction box assembly, a driving cab wire harness assembly and a driving cab instrument desk assembly are respectively mounted on the driving cab mounting bottom plate off line, the front wall module is conveniently and quickly fixed to the driving cab through the assistant manipulator, and thus the works of assembling the front well module on line are decreased by the mode of partial assembling first and mounting of the partial-assembling assembly second, and the pressure on the assembly line is also relieved; simultaneously, an assistant assembling tool provided for mounting enables the mounting reliability and the stability of the adhesive to be ensured.

Owner:SINO TRUK JINAN POWER

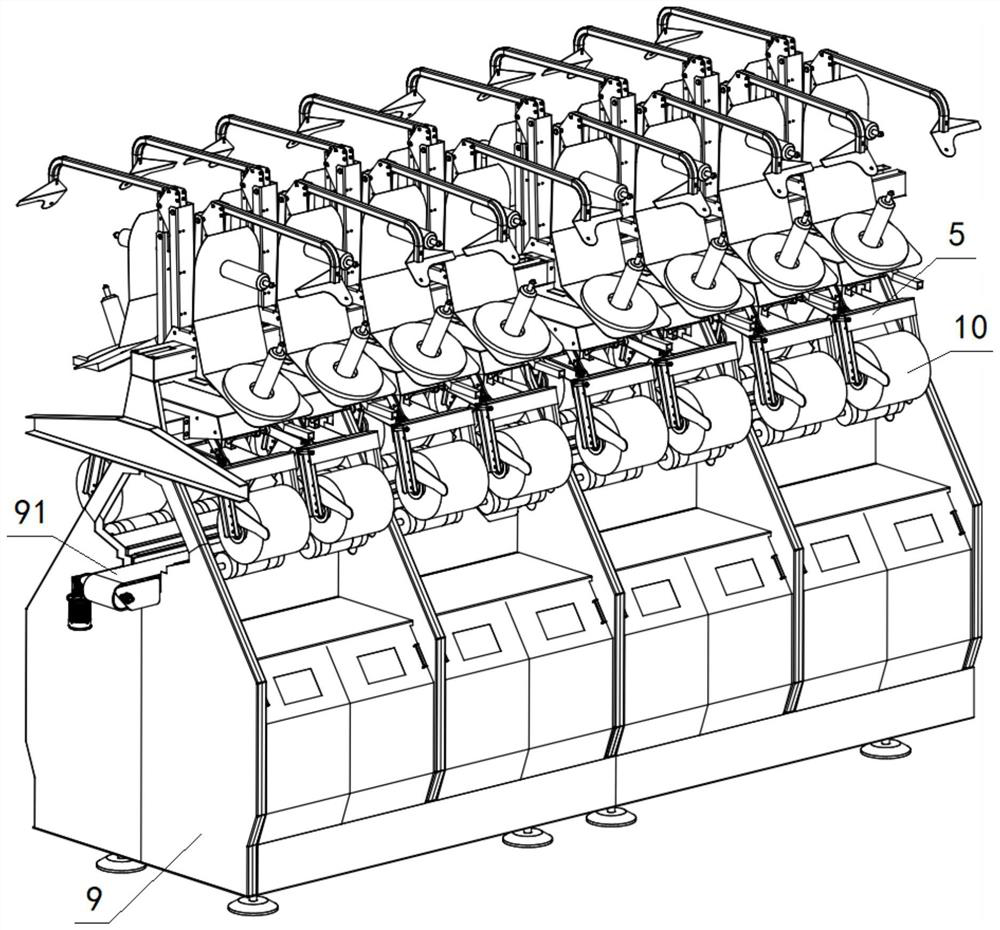

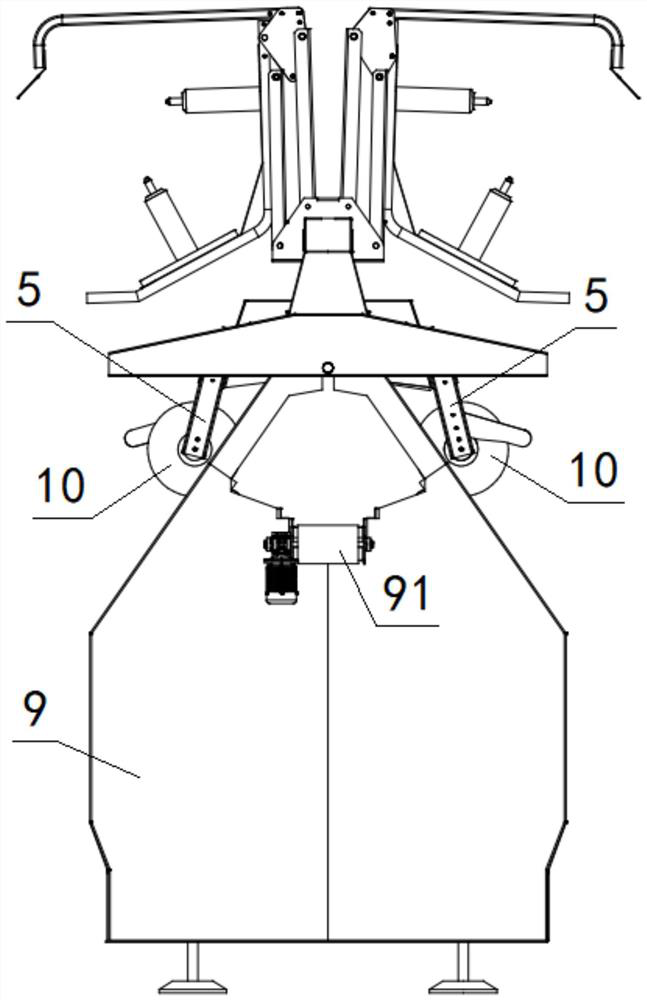

Intelligent spinning system with full-automatic yarn feeding and tube replacing functions

PendingCN114671303ASave human effortHigh degree of automationFilament handlingYarnManufacturing line

An intelligent spinning system capable of achieving full-automatic yarn feeding and bobbin replacing comprises a plurality of spinning twisting machines which are sequentially arranged in the transverse direction, and winding bobbin clamps are arranged on the spinning twisting machines to clamp empty yarn bobbins or resultant yarn rolls. The textile system with the automatic yarn discharging and bobbin replacing functions further comprises an AGV, the movement path of the AGV corresponds to the arrangement path of the multiple textile twisting machines, and a mechanical arm, a bobbin replacing device installed on the mechanical arm and an automatic yarn bobbin discharging device are arranged at the top of the AGV. The bobbin replacing device is matched with a discharging port in the automatic yarn drum discharging device in a butt joint mode, and the bobbin replacing device is matched with the winding bobbin clamp in a butt joint mode. By means of the design, automatic yarn discharging of rolled yarn and automatic replacement of yarn drums on the whole production line in a production area can be achieved, the frequency of manually supplementing empty yarn drums can be reduced, the working procedures are reduced, and the production takt is guaranteed.

Owner:WUHAN TEXTILE UNIV

Novel polyurethane flat steel belt winding and clamping device

PendingCN112607465AIncrease the clamping areaSimplify the operation processWebs handlingPistonSteel belt

The invention discloses a novel polyurethane flat steel belt winding and clamping device which comprises a four-claw air cylinder, a clamping sector piece and a clamping fixing block are installed on the outer side of the four-claw air cylinder, an air valve and an air valve installation plate are installed at one end of the four-claw air cylinder, and a clamp rotating connecting block is installed at the other end of the four-claw air cylinder. According to the novel polyurethane flat steel belt winding and clamping device, the piston area of the four-jaw air cylinder is 6.25 times that of an original finger air cylinder, the problem that a steel belt stub bar is pulled off in the winding process is solved, the clamping area of the steel belt stub bar is increased, and the risk of potential clamping marks of the steel belt stub bar is effectively avoided; after material winding is finished, a pneumatic clamping jaw retracts, the outer diameter of the clamping sector piece is reduced from 120 mm during opening to 108 mm during retracting and loosening, and the outer diameter of the clamping and winding device is completely separated from the inner diameter of a coiled material to generate a gap; and the problem that the winding and clamping device is difficult to separate from the core part of the coiled material is solved.

Owner:依合斯电梯配件(上海)有限公司

Safety belt lock catch marking and detecting all-in-one machine

PendingCN114082671AImprove processing efficiencyReduce processing timeTypewritersSortingProcess engineeringIdentification device

The invention relates to a safety belt lock catch marking and detecting all-in-one machine which comprises a workbench; the workbench is sequentially provided with a feeding mechanism and a rotary table processing and detecting mechanism; a transition material table is arranged between the feeding mechanism and the rotary table processing and detecting mechanism, and the rotary table processing and detecting mechanism is provided with a multi-station rotary table; a feeding station, a marking station, a two-dimensional code recognition station, a pattern recognition station, an unqualified product grabbing station and a discharging station are arranged on the multi-station rotary table, and a feeding device, a marking device, a two-dimensional code recognition device, a pattern recognition device, an unqualified product grabbing device and a discharging device are correspondingly arranged on the workbench; and the unqualified product grabbing device, the discharging device and the feeding device are equally arranged. According to the safety belt lock catch marking and detecting all-in-one machine, a multi-station processing mode is adopted, the two working procedures of marking and detecting are completed on the same equipment, the processing efficiency is improved, the processing time is shortened, and thus the production cost is reduced.

Owner:YANCHENG JIAANLE AUTOMATION TECH CO LTD

System and method for detecting tab welding quality of flexibly-packaged battery cell module

PendingCN111398296ANo fatigueShorten the timeOptically investigating flaws/contaminationCell component detailsUltrasonic weldingNew energy

The invention discloses a system and a method for detecting the tab welding quality of a flexibly packaged battery cell module, and belongs to the field of new energy vehicles. A battery module walking assembly is installed on a first guide rail on the machine table, the vibration leveling assembly and the detection assembly are installed on the same side of the first guide rail, an ultrasonic welding machine welding head in the vibration leveling assembly and a line laser measuring instrument sensing head in the detection assembly are both located above the first guide rail, and the sensing head is arranged at the downstream position of the welding head in the working procedure. According to the system, related control programs can be flexibly set according to different weld joint positions and numbers of different battery modules, the welding head vibrates on the busbar near the weld joint by setting the downward pressure of the welding head and the like; according to the method, thewelding seam with poor welding is loosened and tilted, whether the welding seam is welded or not is judged by photographing and scanning, and whether the welding is qualified is judged by measuring the relative height difference between the tab and the busbar, so that the tab welding seam subjected to laser welding meets the requirements of the welding position and reliably fits the busbar.

Owner:浙江尚特新能源科技有限公司

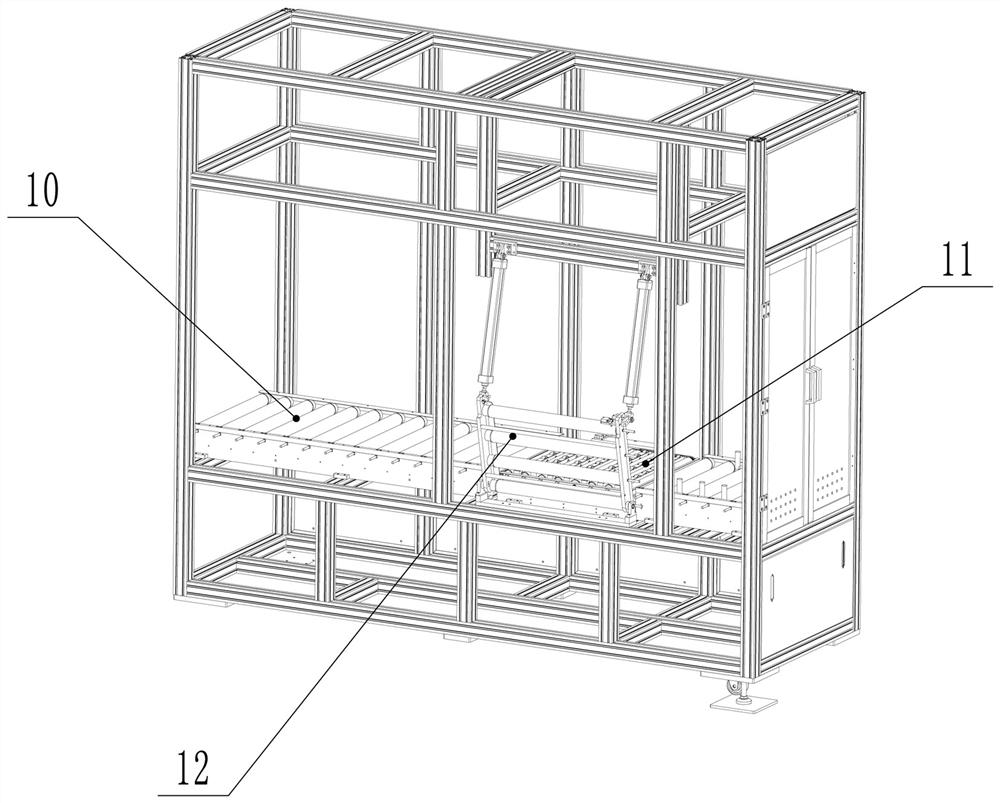

De-foaming machine with double-side door opening function

PendingCN111717640ASimple designLow failure rateConveyor partsIdentification meansEngineeringMachine

The invention relates to the technical field of de-foaming machines, in particular to a de-foaming machine with a double-side door opening function. The technical problem that an existing cavity typede-foaming machine is high in failure rate and low in production efficiency is solved. According to the following technology, door bodies are mounted on two ends of a de-foaming cavity body in a sealmanner, a de-foaming conveying mechanism is arranged on the lower portion in the cavity, a loading conveying mechanism and a discharging conveying mechanism are arranged on the outer sides of the twoends of the de-foaming cavity in a spaced manner, a suspension bridge conveying mechanism is arranged between the loading conveying mechanism and the de-foaming cavity, a suspension bridge conveying mechanism is arranged between the discharging conveying mechanism and the de-foaming cavity, the sides, away from the de-foaming cavity, of the suspension bridge conveying mechanisms are hinged to theloading conveying mechanism or the discharging conveying mechanism, opposite sides are driven to rotate around the side away from the de-foaming cavity, when the suspension bridge conveying mechanismsare in the horizontal state, the suspension bridge conveying mechanisms are connected with the de-foaming conveying mechanism, the loading conveying mechanism, the discharging conveying mechanism, the de-foaming conveying mechanism and the two suspension bridge conveying mechanisms form a conveying channel, the loading conveying mechanism is correspondingly provided with a loading mechanical arm,and the discharging conveying mechanism is correspondingly provided with a discharging mechanical arm.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

Forming device of ultrahigh-pressure static liquid extrusion magnesium alloy pipe and forming process thereof

ActiveCN106311783AAchieve expansion moldingAchieve shrink moldingExtrusion diesHydraulic pumpHigh pressure

The invention discloses a forming device of an ultrahigh-pressure static liquid extrusion magnesium alloy pipe and a forming process thereof. The forming device totally adopts a horizontal structure, and comprises a supercharging cylinder, an extruding cylinder, a first pressing medium exchange disc, a second pressing medium exchange disc, a third pressing medium exchange disc, an extruding mold, a first heating sleeve, a second heating sleeve and a high-pressure hydraulic pump with an extruding shaft. The supercharging cylinder, the extruding cylinder, the pressing medium exchange discs, the mold and the high-pressure hydraulic pump are all fixed between a movable beam and a fixed beam; and the movable beam and the fixed beam are connected through a tension column. The supercharging cylinder and the extruding cylinder are arranged in parallel, and are positioned in the same one horizontal plane. The extruding shaft is positioned in the supercharging cylinder; a blank is positioned in the extruding cylinder; the travel of the extruding cylinder and the size of the blank both can be increased; the magnesium alloy pipe with a longer length can be obtained by static liquid extrusion machining through the forming process on the forming device; and the production efficiency can be improved.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com