Flexible welding island clamp positioning lifting mechanism, automatic switching device and switching method

A lifting mechanism and automatic switching technology, which is applied to welding/cutting auxiliary equipment, welding equipment, auxiliary devices, etc., can solve the problems of large power consumption, slow lifting process, and slow down of the station beat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0049] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0050] In the present invention, unless otherwise clearly specified and limited, terms such as "installation", "connection", "connection" and "fixation" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection , or integrated; it may be mechanically connected or electrically connected; it may be directly connected or indirectly connected through an intermediary, and it may be the internal communication of two components or the interaction relationship between two components, unless otherwise specified limit. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention according to specific situations.

[0051] In the present i...

Embodiment 1

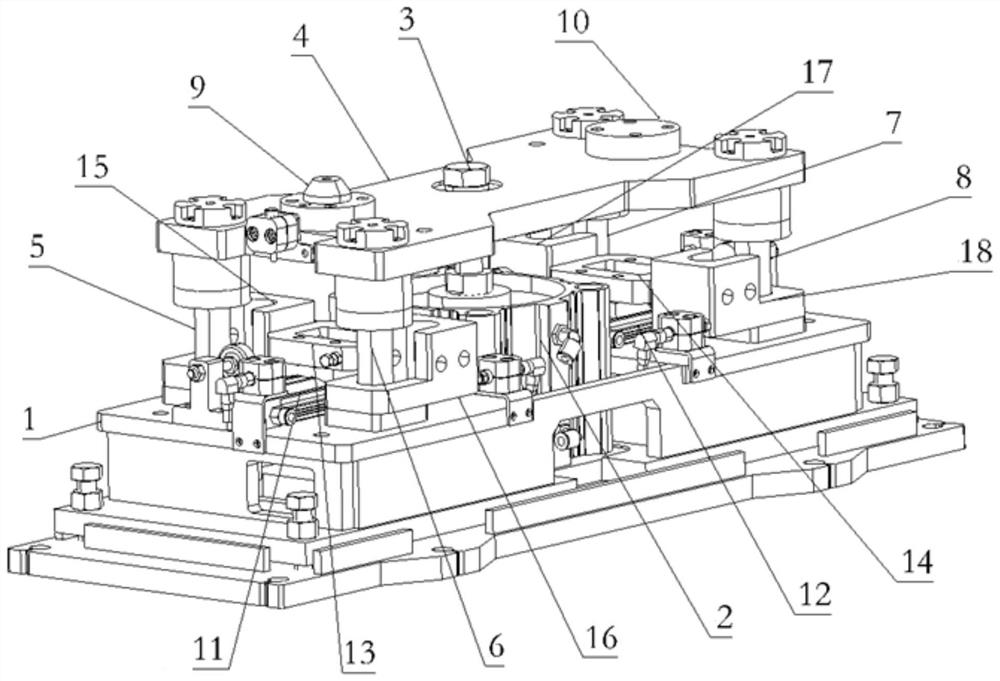

[0054] Such as figure 1 As shown, the first embodiment discloses a lifting and positioning mechanism for a flexible welding island fixture, including: a base, a lifting cylinder, a hinged head, a top plate, a guide post, a positioning assembly, a pneumatic slide rail, a connecting plate and a limit block.

[0055] The base 1 is fixedly installed on the ground as the base body of the entire lifting mechanism;

[0056] The lifting cylinder 2 is vertically arranged in the middle of the base 1, the cylinder end of the lifting cylinder 2 is fixed on the base 1, and the push-pull end of the lifting cylinder 2 is connected with the top plate 4 above by a hinged joint 3.

[0057] The top plate 4 is horizontally arranged directly above the base 1, and the middle part of the top plate 4 is connected with the lifting cylinder 2 through the hinge joint 3. The four corners of the top plate 4 are symmetrically fixed downwards and respectively fixed with four guide columns arranged in the ve...

Embodiment 2

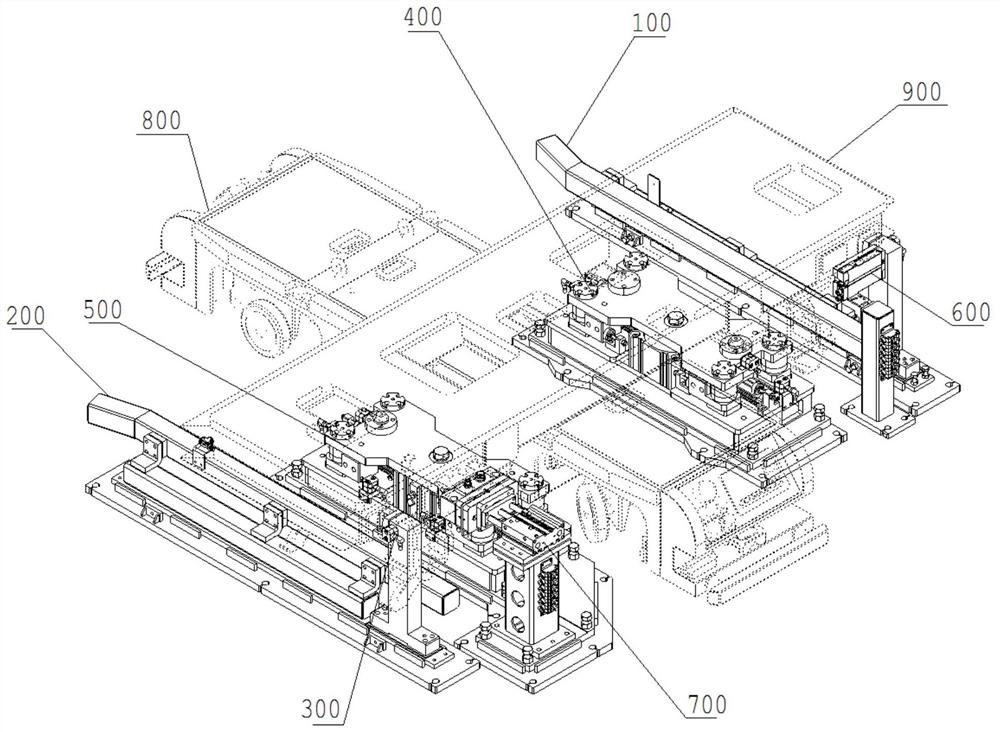

[0083] Such as image 3 As shown, the second embodiment discloses an automatic switching device for flexible welding island clamps, including: a guide mechanism, a lift positioning mechanism, a clamp detection unit, a clamp identification unit and a medium unit.

[0084] There are two groups of the guide mechanism, respectively the first guide mechanism 100 and the second guide mechanism 200. The first guide mechanism 100 and the second guide mechanism 200 are arranged symmetrically in the left and right along the guide direction at the empty material opening, and fixed Installed on the ground, when the welding island needs a certain fixture 900, the AGV800 drags the fixture 900 to the designated empty material opening, and the guide wheels on the left and right sides of the fixture 900 first cooperate with the first guide mechanism 100 and the second guide mechanism on both sides 200 inside the guide surface contact, the first guide mechanism 100 and the second guide mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com