Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

162results about How to "Increase the clamping area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

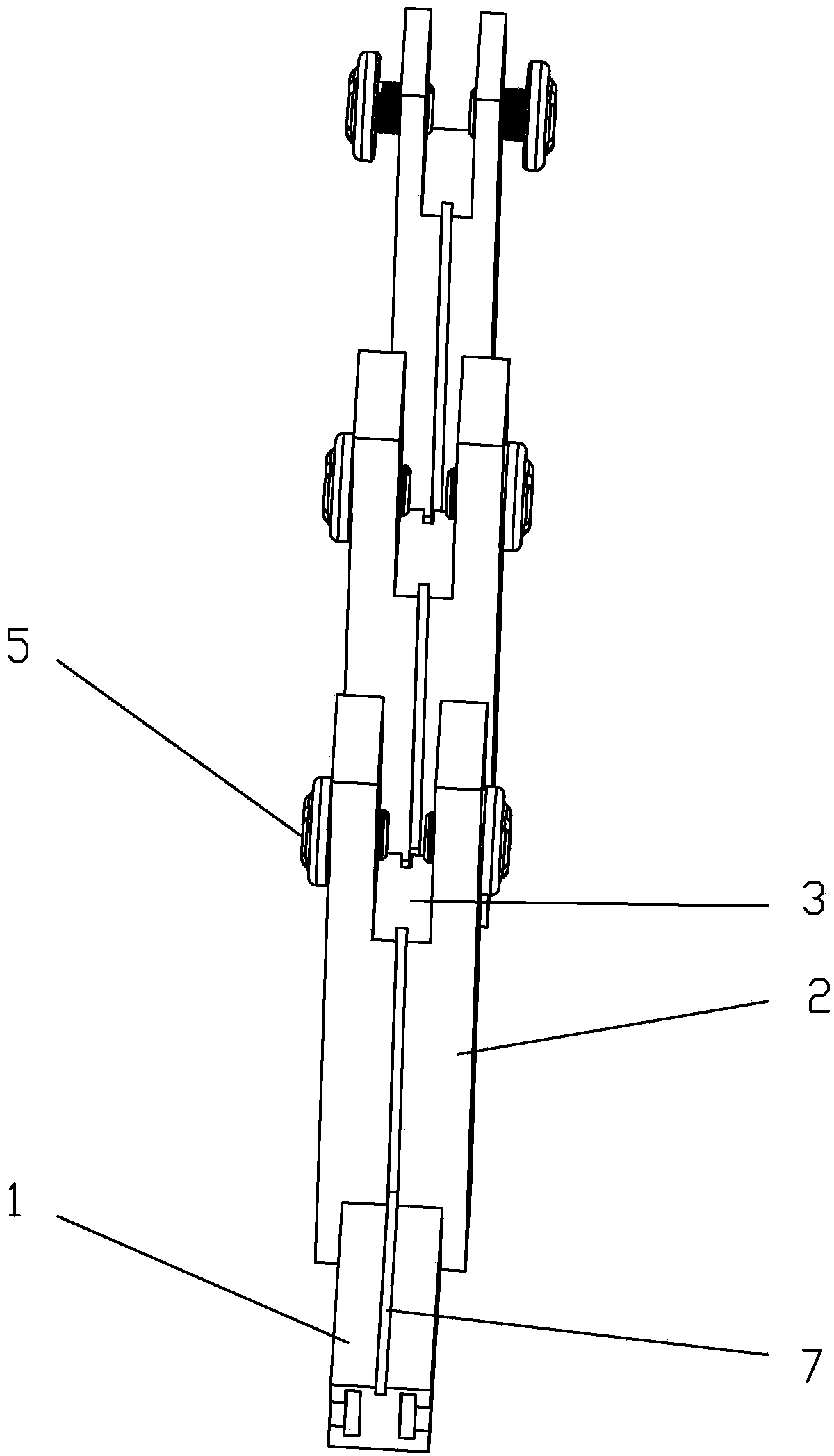

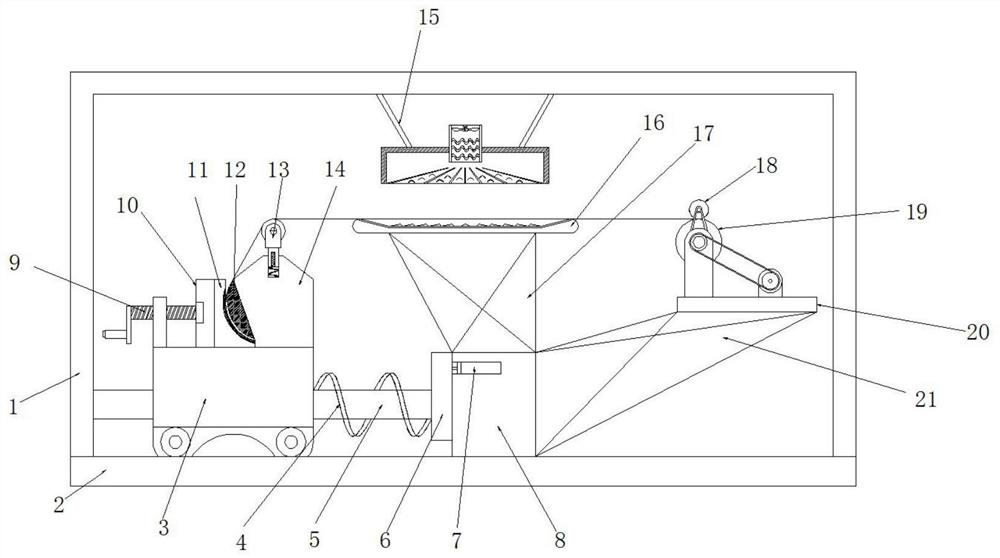

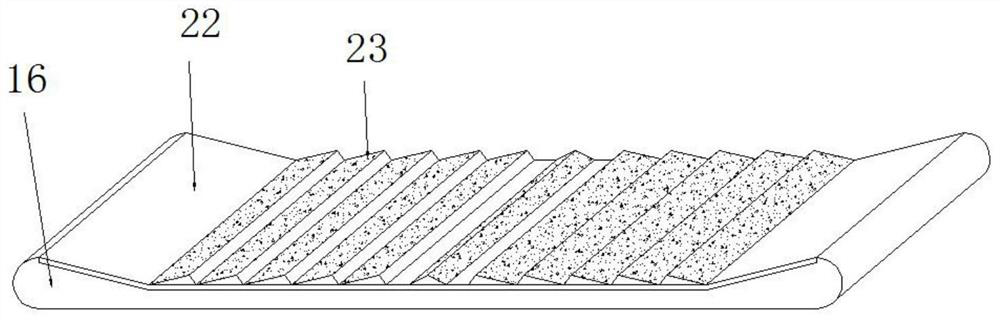

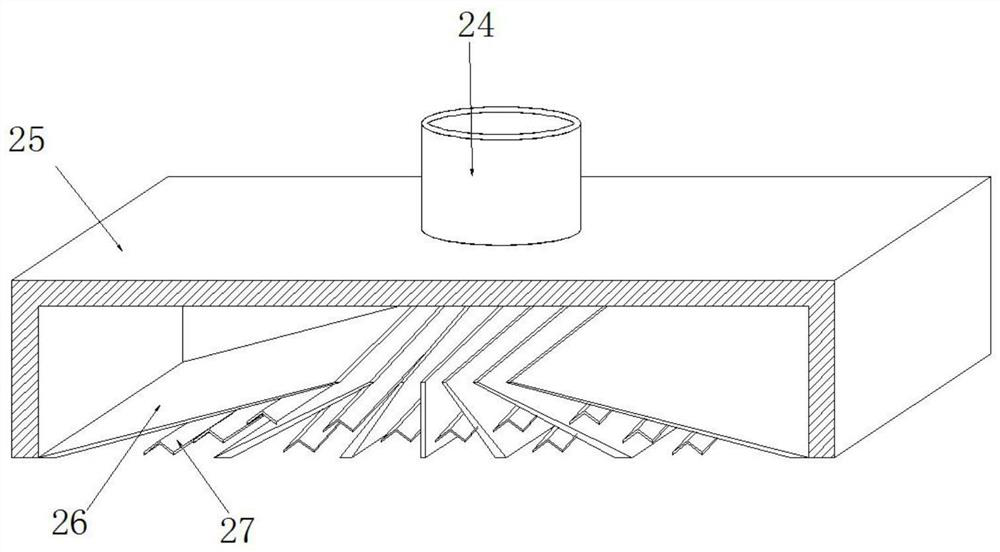

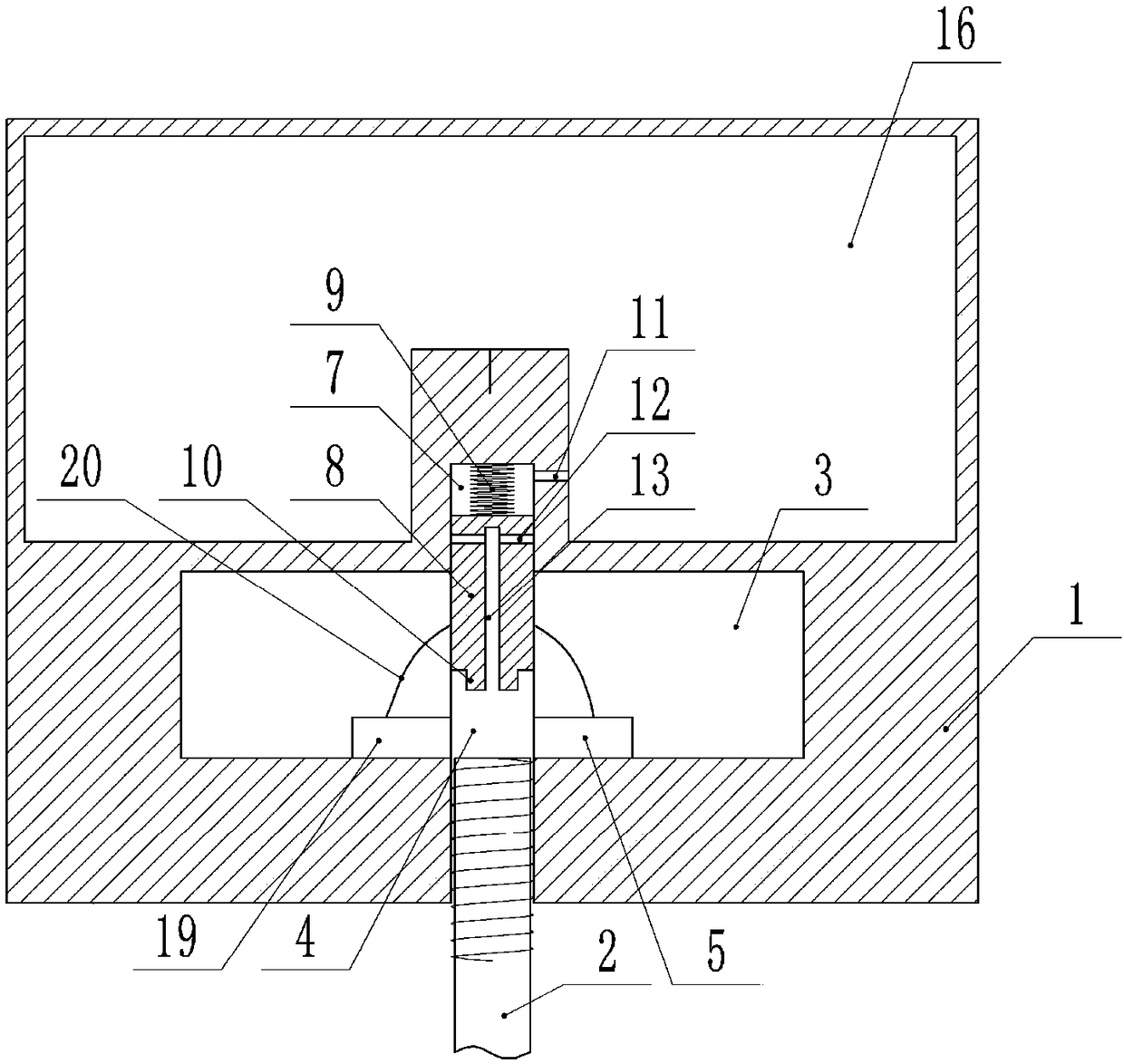

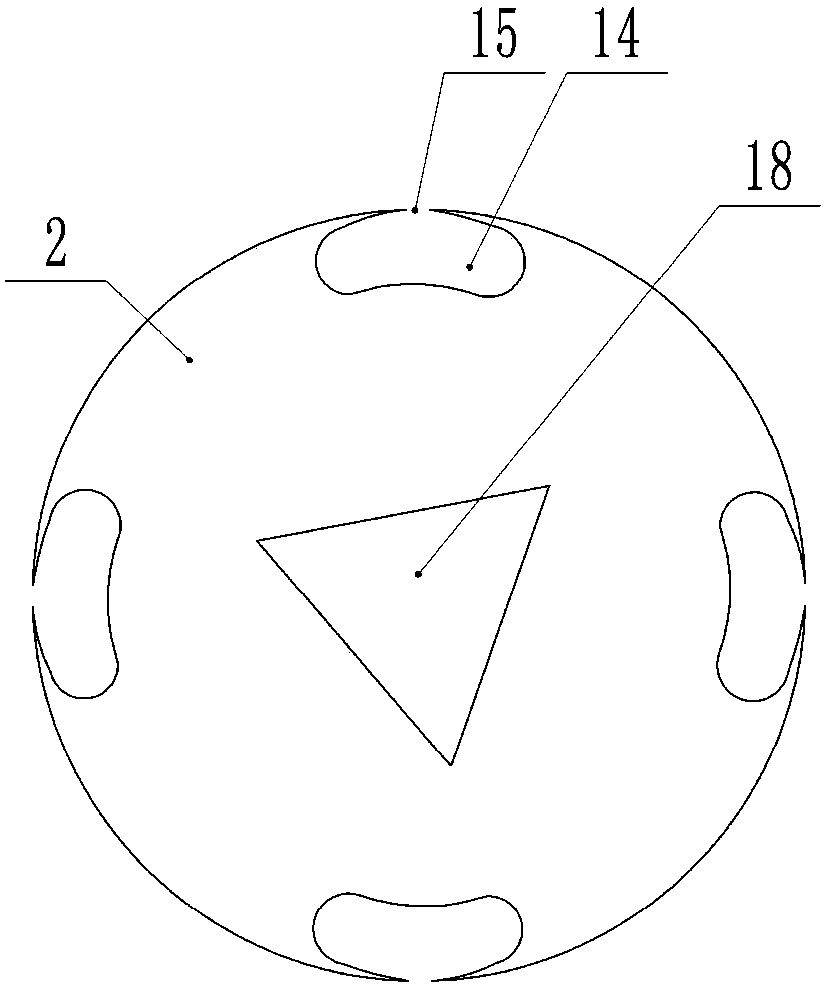

Steel structure drilling device

InactiveCN107824828AAvoid distortionAvoid stickingFeeding apparatusPositioning apparatusDrive wheelArchitectural engineering

The invention discloses a drilling device for a steel structure, which comprises a machine body. Both sides above the inner wall of the machine body are provided with organic casings. One motor, the output shafts of the two first motors are fixedly sleeved with driving wheels, the inner chambers of the two casings are provided with driven wheels, and belts are movably connected between the two driving wheels and the driven wheels, and the two belts Both of them are fixedly connected with fixed blocks, and the two fixed blocks are slidably connected to the inner wall of the through groove, and a support frame is fixedly connected between the two fixed blocks, and the left side of the top of the support frame is provided with a first cylinder. The invention solves the problem that the drill cannot be displaced laterally by adding a device for lateral movement to the drill, and achieves the purpose of the clamp device being able to move forward and backward by setting the turntable and the screw rod, and solves the problem that the existing steel structure drilling cannot be clamped at one time Problem with drilling multiple times.

Owner:余骆杨

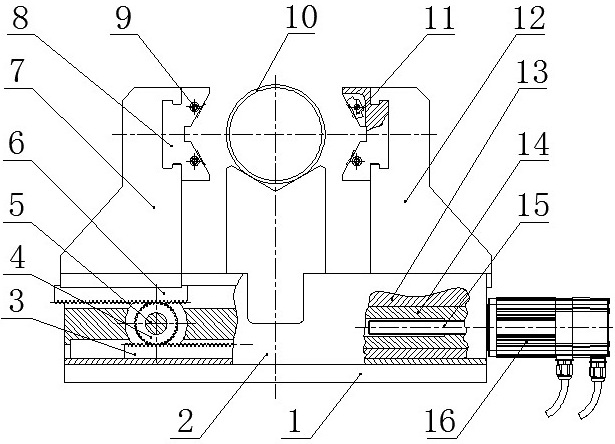

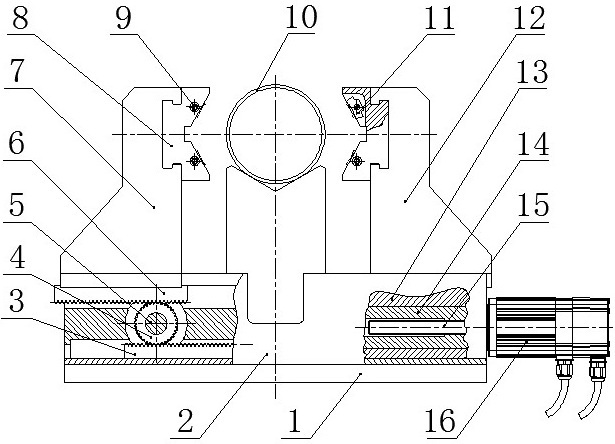

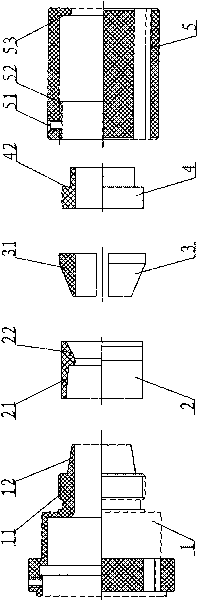

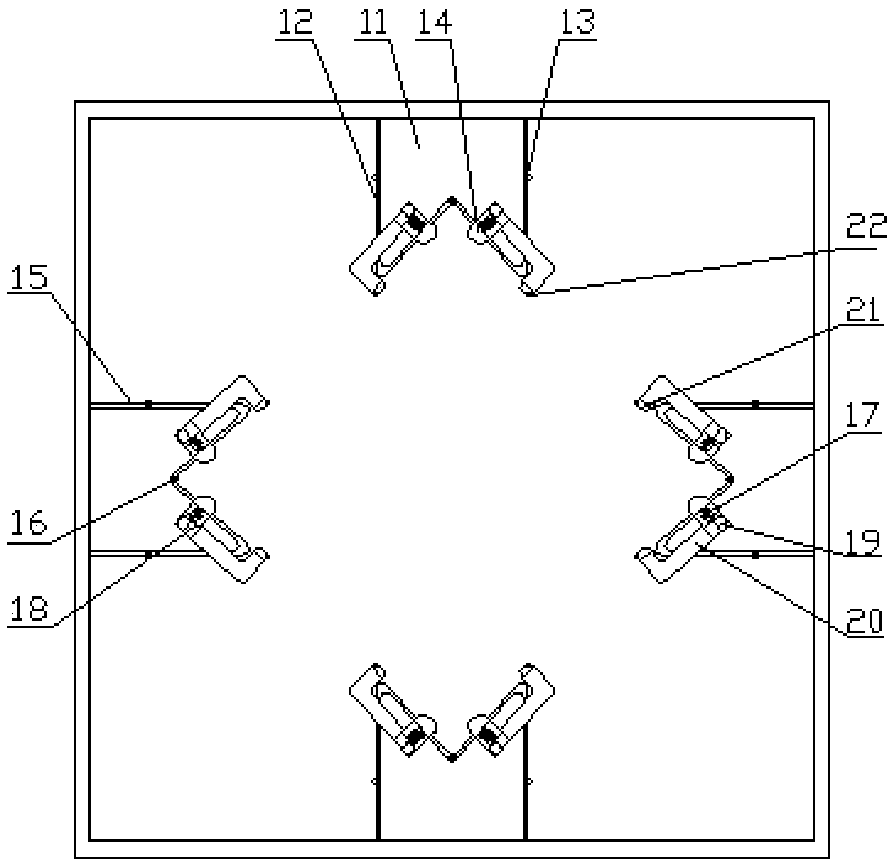

Center-aligning floating clamping fixture

InactiveCN102632404AAvoid deformationDecrease the jump valuePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a center-aligning floating clamping fixture used in a machine tool for two ends of a steel pipe. The structure of the center-aligning floating clamping fixture comprises a fixture supporting frame, a driving mechanism, a transmission mechanism, a clamping mechanism and a floating aligning mechanism, wherein the transmission mechanism and the clamping mechanism are connected with each other, the clamping mechanism is provided with two chuck uprights which are parallel to each other in opposite directions, the uprights are provided with V-shaped jaws and connected with a bracket, a V-shaped clamp is provided with two pairs of floating clamping blocks, clamping surfaces of the clamping blocks are multidentate clamping surfaces, and the multidentate clamping surfaces are positioned on a same cylindrical surface. The center-aligning floating clamping fixture can be used for special machine tool equipment for machining the two ends of the steel pipe of a DT II type roller of a belt conveyor, and the geometric axis center of the steel pipe to be automatically aligned with the axis center of the machine tool so as to control radial deformation of the steel pipe.

Owner:SHENZHEN CEMCN

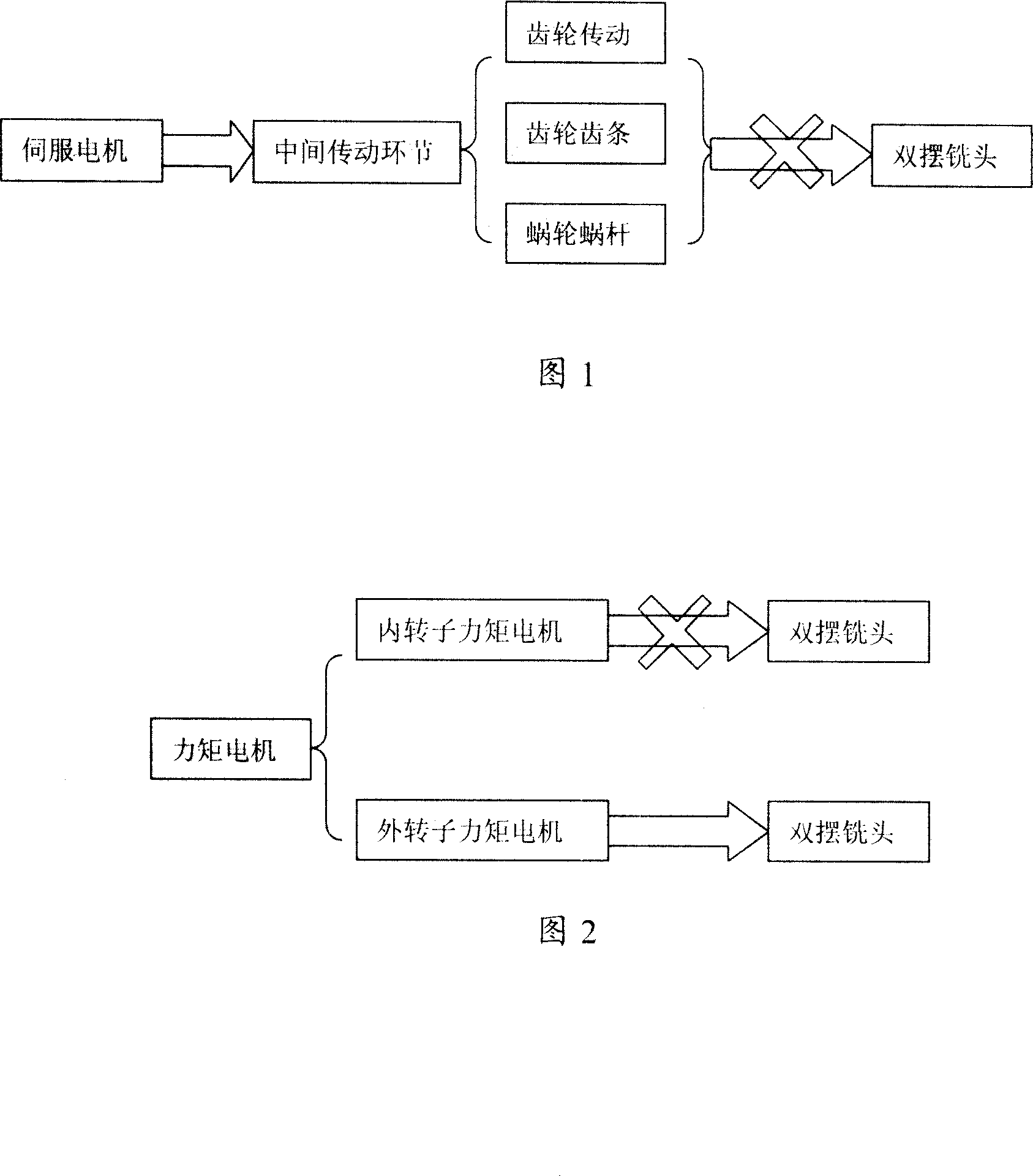

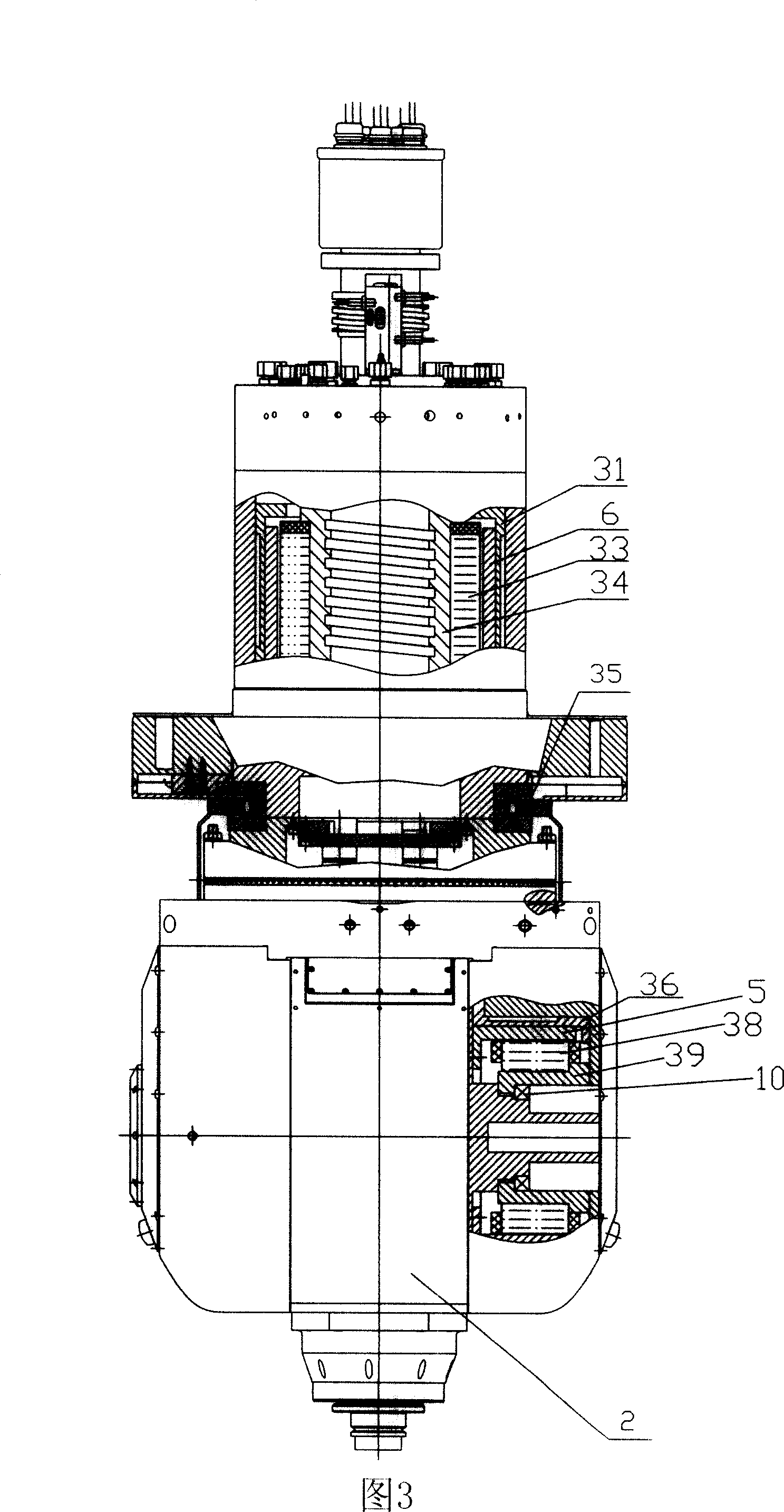

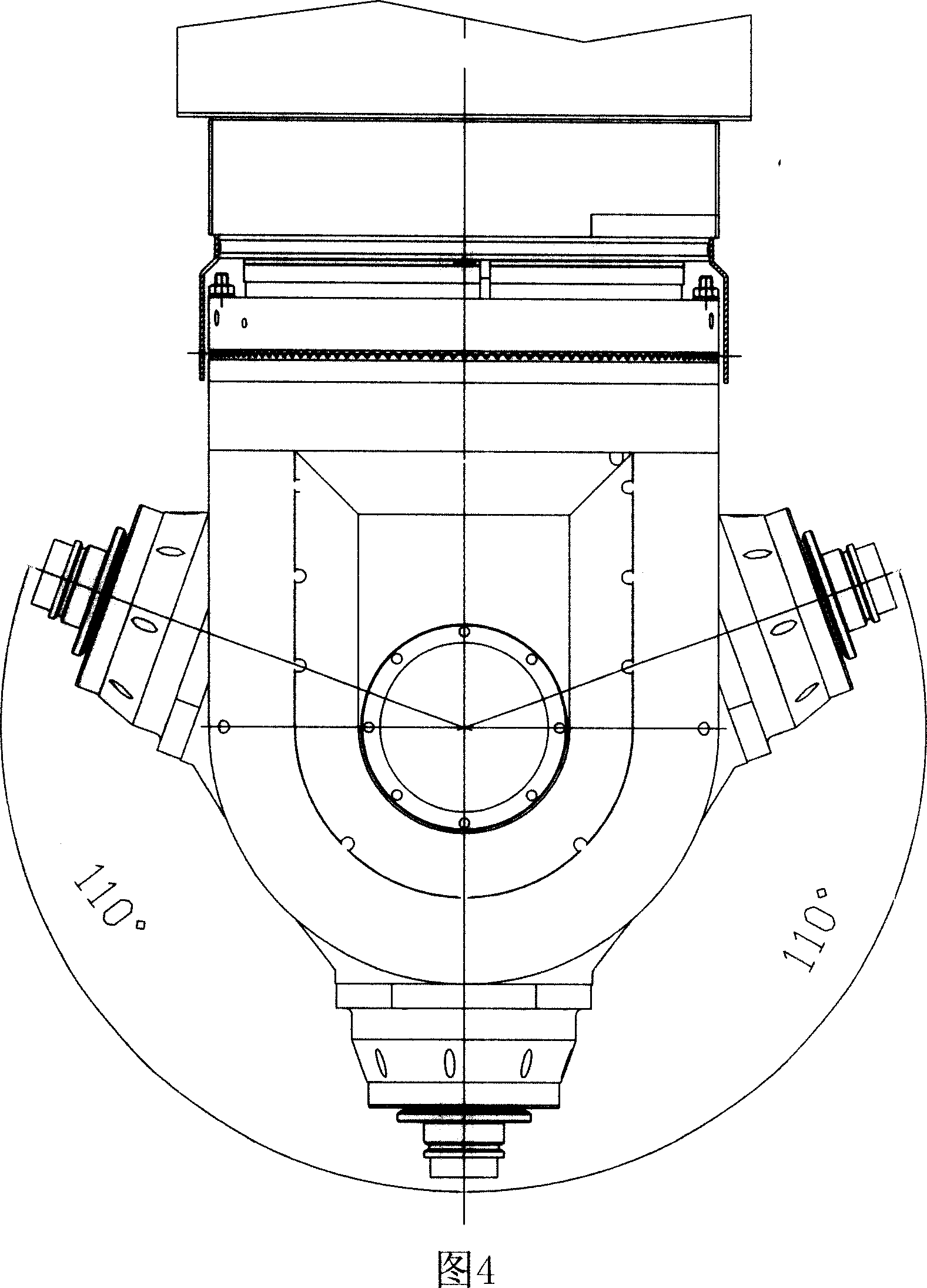

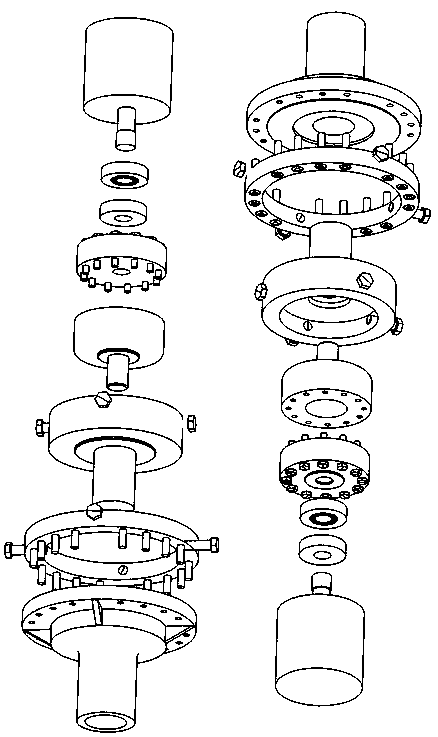

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN101011795AImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

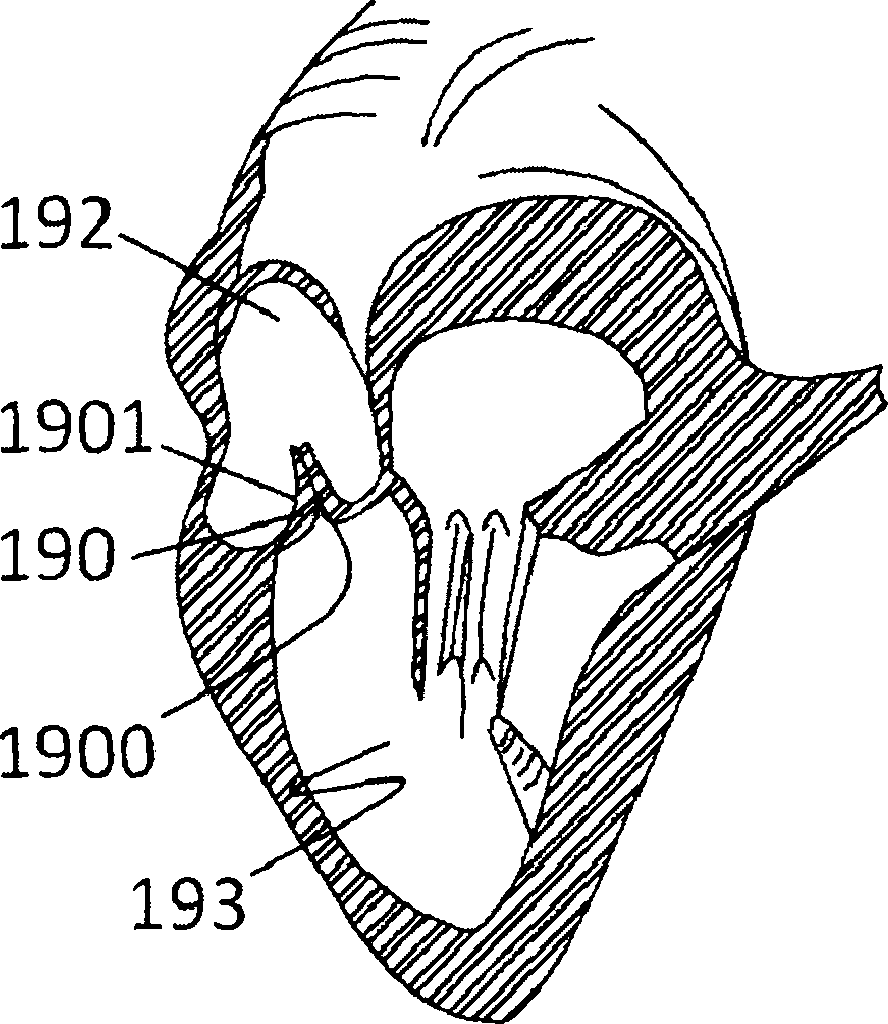

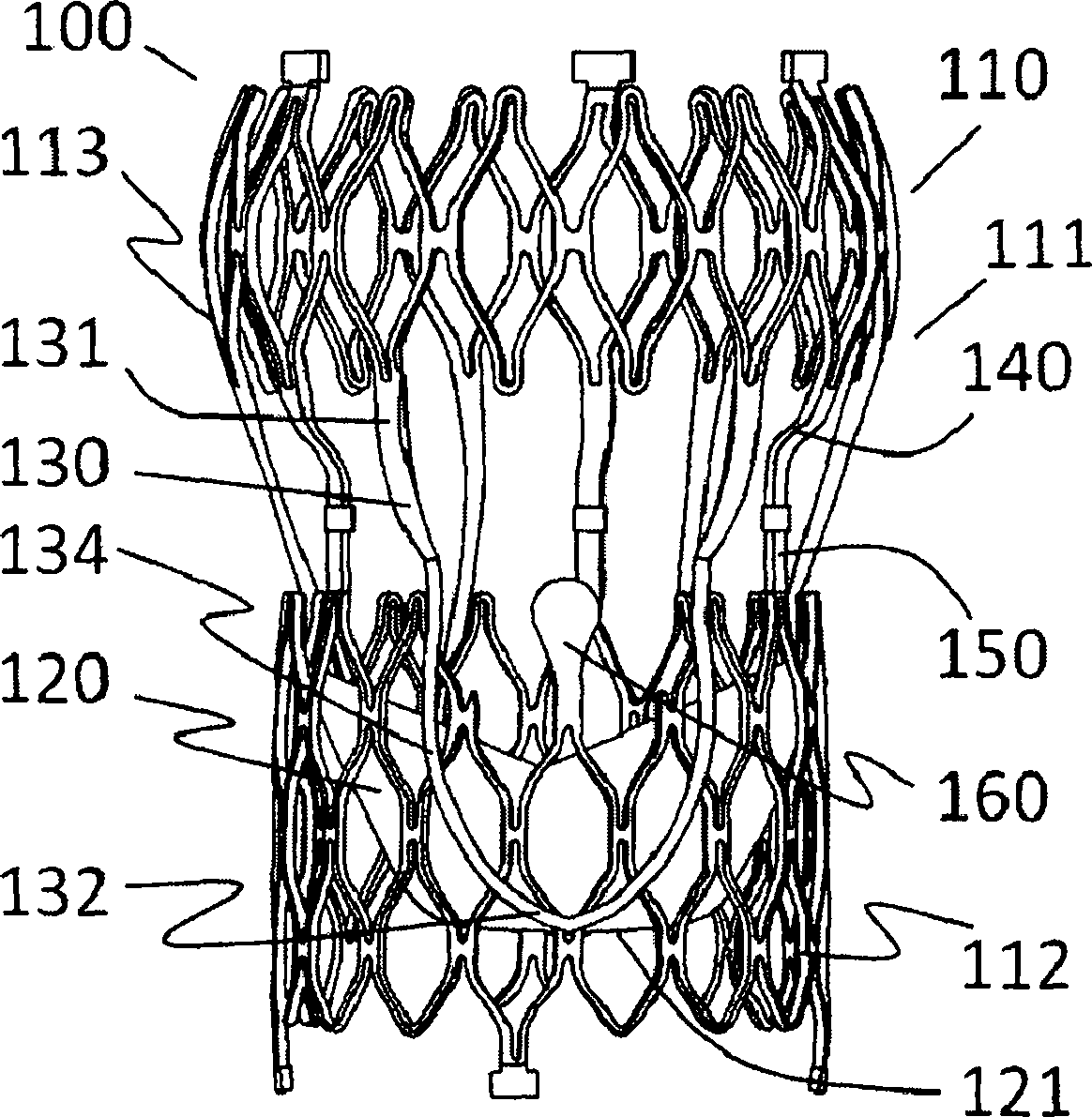

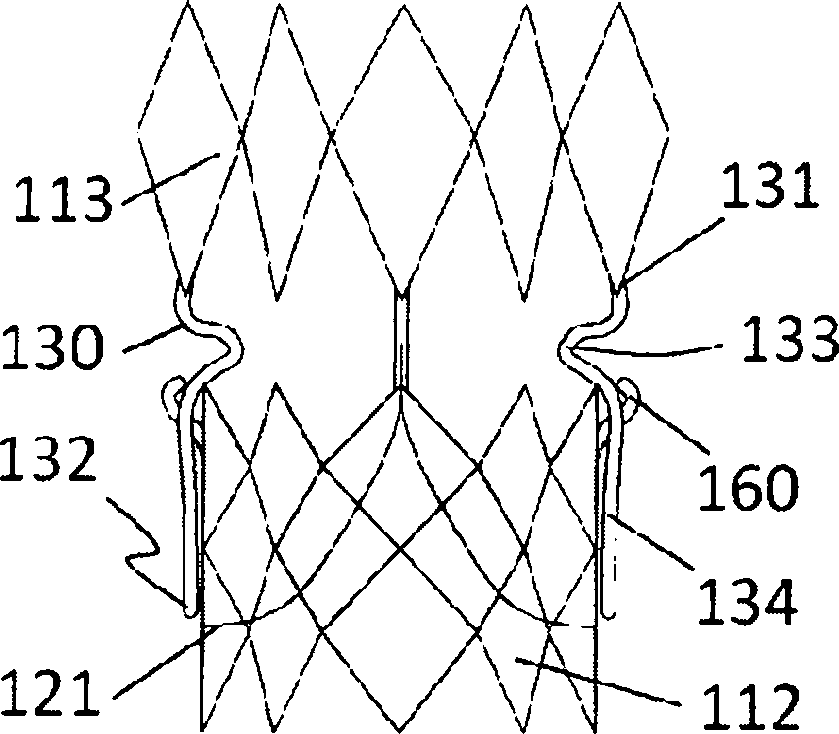

Artificial valve prosthesis with valve leaflet clamping device

The invention relates to artificial valve prosthesis with a valve leaflet clamping device. The manual valve prosthesis comprises a bracket and an artificial valve, wherein the bracket comprises an auxiliary support clamping section and a valve sewing section; the artificial valve is fixedly connected to the valve sewing section; the auxiliary support clamping section is composed of a support bracket, a valve leaflet clamping device and an upper connection fixing section; the leaflet clamping device, the support bracket and the upper connection fixing section are integrally cut; a lower connection fixing section matched with the upper connection fixing section is arranged on the valve sewing section; the bracket is embedded and connected with the lower connection fixing section into a whole through the upper connection fixing section; one part of the valve leaflet clamping device is overlapped with the valve sewing section; the overlapped part is tightly attached to the outer surface of the valve sewing section in a natural state; a bump which protrudes outwards along the radial direction is arranged on a skeleton structure of the valve sewing section in the overlapped region; and a bending section which bends towards the axis direction of the bracket along the radial direction of the bracket is arranged on the valve leaflet clamping device or the support bracket or the upper connection fixing section.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

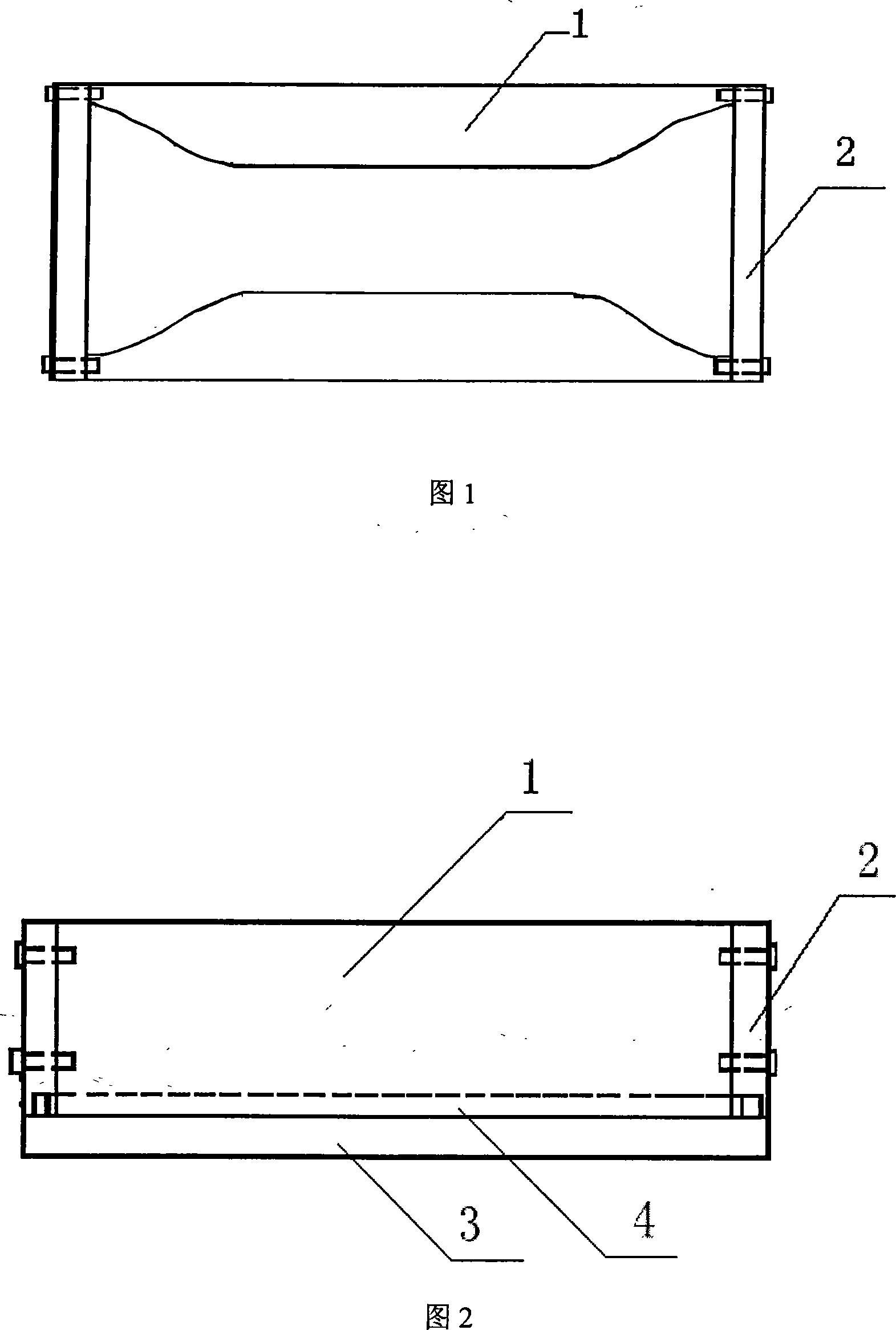

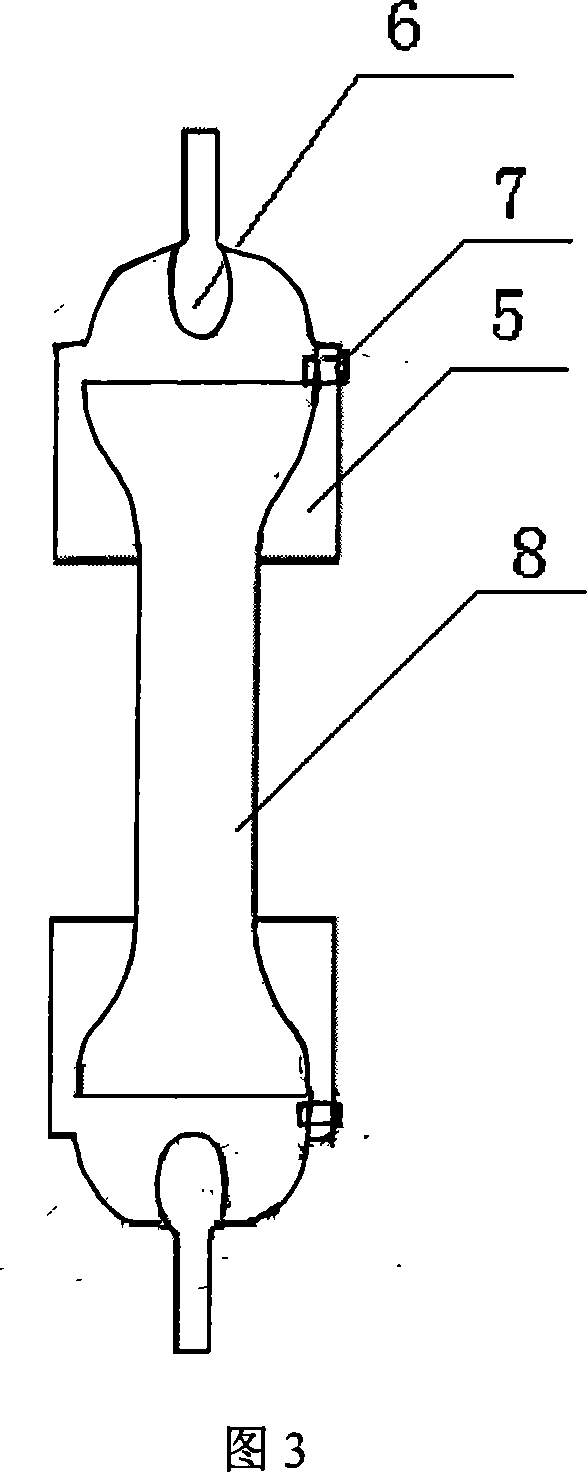

Brittle material test piece moulds and matching tensile test cramping apparatus thereof

The invention relates to a brittle material sample die and a matched tension test fixture and includes a die and a fixture. A conveyer chain is arranged between the die and the fixture. The die includes a side surface plate, an end surface plate and a bottom plate. The side surface plate and the end surface plate are connected by a connecting element. The bottom plate is provided with a waterproof groove. The side surface plate and the end surface plate are connected with the bottom plate through the waterproof groove. The fixture includes a collet which is provided with a collecting spherical hinge. The collet consists of two parts and the two parts are connected through a connecting element. When the die is mounted, after each part is connected, a brittle material can be poured in the die to manufacture a bone-shaped sample. The enlarging end and the uniform section of the bone-shaped sample are transferred by a smooth curved surface. When the sample is stretched, a collet bolt is screwed out firstly and the bolt is screwed tightly after the sample is arranged in the collet. A tension test can be carried through after the connecting spherical hinge and the tension collet of a tension tester are connected. The invention has the advantages of simple structure, convenient dismounting, low cost, good manufacture effect, large holding area and excellent cooperation with the sample shape, etc.

Owner:SHANDONG UNIV

Fastening device

ActiveUS7004695B1Increase frictional resistanceIncrease the clamping areaFlexible elementsItem transportation vehiclesEngineeringMechanical engineering

A fastening device for fastening a rope comprises a main body which includes a base, two spaced-apart legs extending longitudinally from the base and each having one end extending away from the base, and a first cross bar, a second cross bar and a third cross bar spaced from one another and disposed transversely between the two legs in that order from the base to the ends of the legs. The third cross bar is movable to a first position proximate the second cross bar or to second position distal from the second cross bar. First, second and third spaces are defined by the third cross bar with the second cross bar, the second cross bar with the first cross bar, and the first cross bar with the base, respectively, for passage of the rope. A ring member is pivotally mounted in the ends of the legs.

Owner:GOOD SUCCESS CORP

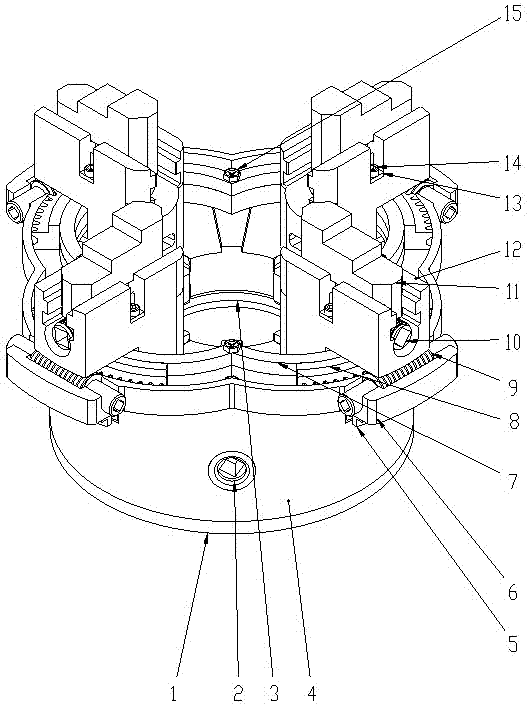

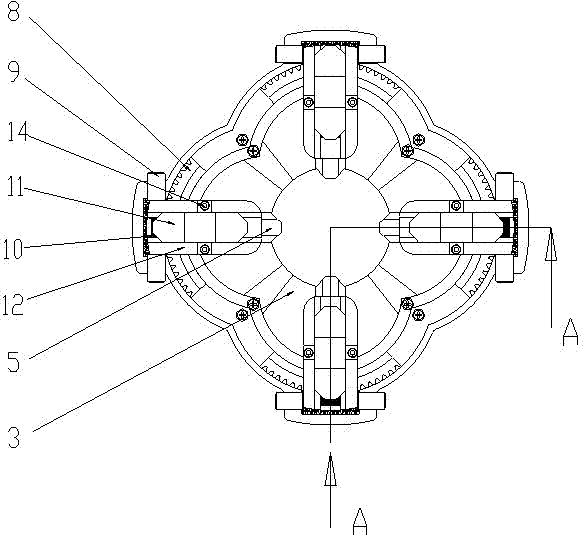

Flexible four-jaw chuck

The invention discloses a flexible four-jaw chuck, and particularly relates to a flexible four-jaw chuck used for clamping irregular workpieces. On the basis of an original self-centering four-jaw chuck, four medium blocks embedded with upper single-acting jaws are added, are connected with lower linkage jaws in a hinged manner, can rotate freely and are independent modules, and a T-shaped worm gear is arranged on each medium block and matched with the same in a sliding pair mode. Each medium block turns to be locked at a constant angle in a mode that a worm drives the T-shaped worm gear, and meanwhile, the upper single-acting jaw embedded on the upper face of each medium block can move frontwards and backwards through rotation of a lead screw and is locked automatically by the aid of a self-locking function of the lead screw. The flexible four-jaw chuck can clamp regular or irregular workpieces by the aid of the rotatable medium blocks, a use range of the chuck is enlarged, and clamping safety, stability and processing accuracy of the workpieces are improved.

Owner:SOUTH CHINA UNIV OF TECH

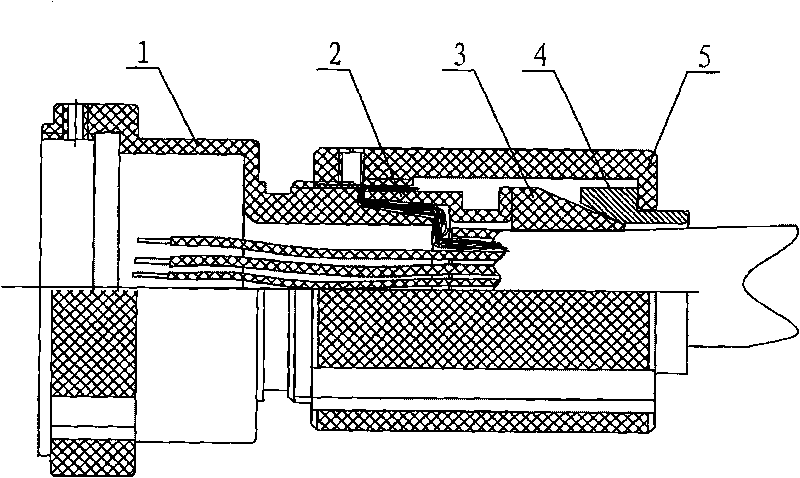

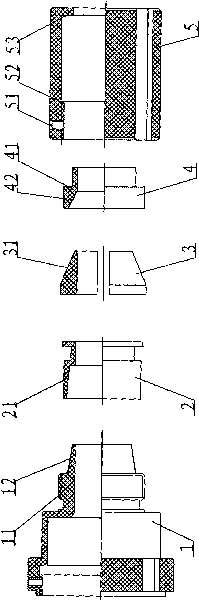

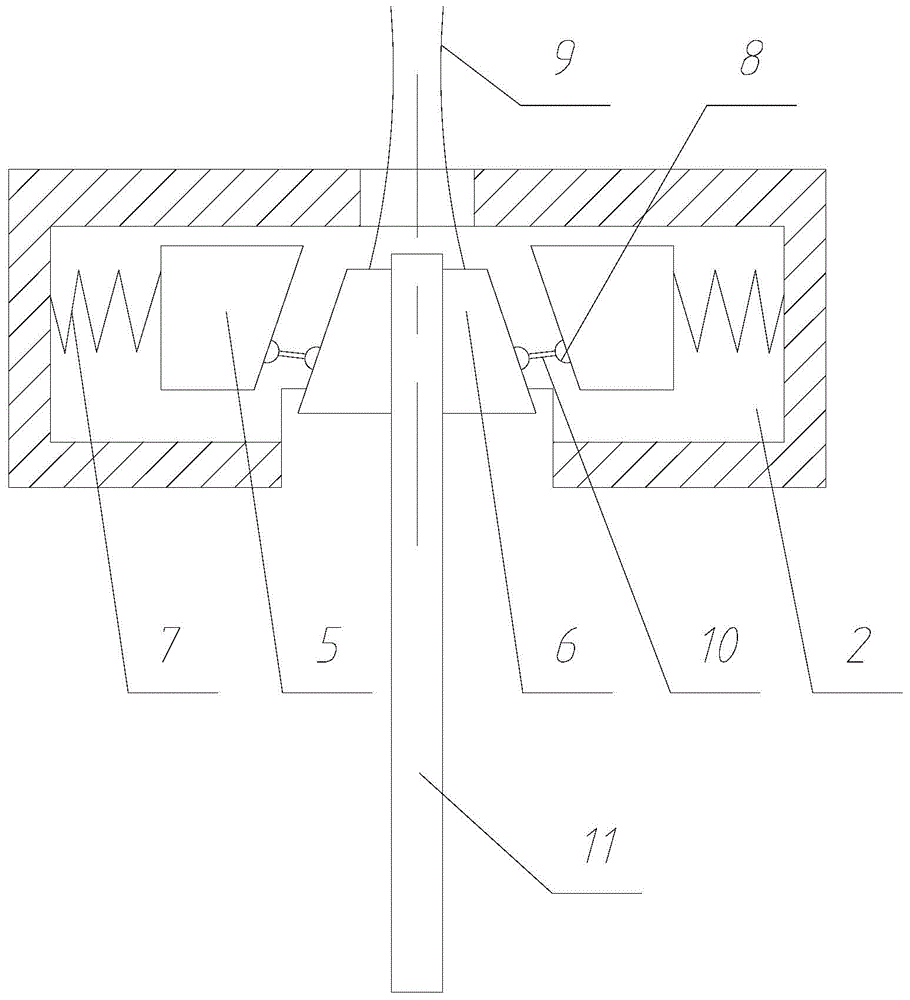

Tail clamping and locking mechanism of low-frequency electric connector

ActiveCN101702477AEasy to disassembleReduced service lifeCoupling device detailsElectricitySurface layer

The invention relates to a tail clamping and locking mechanism of a low-frequency electric connector, comprising a protective line sleeve and a cable cover, wherein the protective line sleeve is connected with a plug or a socket of the electric connector; the cable cover is matched with the protective line sleeve and locks a cable; a contact line of the cable is welded with a pin of the plug or the socket connected with the protective line sleeve; two or more line clamping lamellas with excircle surfaces as conical surfaces are arranged between the protective line sleeve and the cable cover, and the excircle conical surfaces of the two or more line clamping lamellas face to the protective line sleeve or the cable cover and are in a symmetrical or uniformly distributing cable clamping state. The invention has the advantages of large line clamping area, high friction force between the line clamping lamellas and the cable, drag resistance and high twisting resistance; in addition, the line clamping lamellas can meet the requirement for clamping cables with large diameter differences according to the diameter design of the cables without deformation when used for a long time, is difficult to damage cable surface layers and shielding layers and has the advantages of convenient assembly and disassembly, repeated use, low cost and long service life.

Owner:CHINA NORTH IND GRP HANGLIAN TECH CO LTD

Thin-wall sleeve part processing method

The invention discloses a thin-wall sleeve part processing method which comprises the steps of firstly roughly turning an excircle and drilling and boring an inner hole; after roughly turning the excircle and roughly boring the inner hole to the reserved processing allowance, semi-extractive turning an excircle of a thin-wall sleeve part, obtaining a semi-finished product of the thin-wall sleeve part, and cutting off from a bar material; loading the semi-finished product on a digital controlled lathe, precisely turning an incircle and an excircle of the semi-finished product to the set processing allowance, half cutting-off, reserving the set thickness during half cutting-off after chamfering an excircle of a part at the cut-off end, and semi-extractive turning the excircle to the design dimension again; and thoroughly cutting off the processed thin-wall sleeve part from the semi-finished product. The process method provided by the invention is simple and feasible, no working procedureis increased, the deformation in the part processing process is greatly reduced, the excircle dimension tolerance can be ensured to meet the technical requirement of the process design, the product qualification rate is remarkably improved, the method can be completed by adopting a cutting manner, the production period is short, and no auxiliary fixture with high cost is required to be configured.

Owner:AECC AVIATION POWER CO LTD

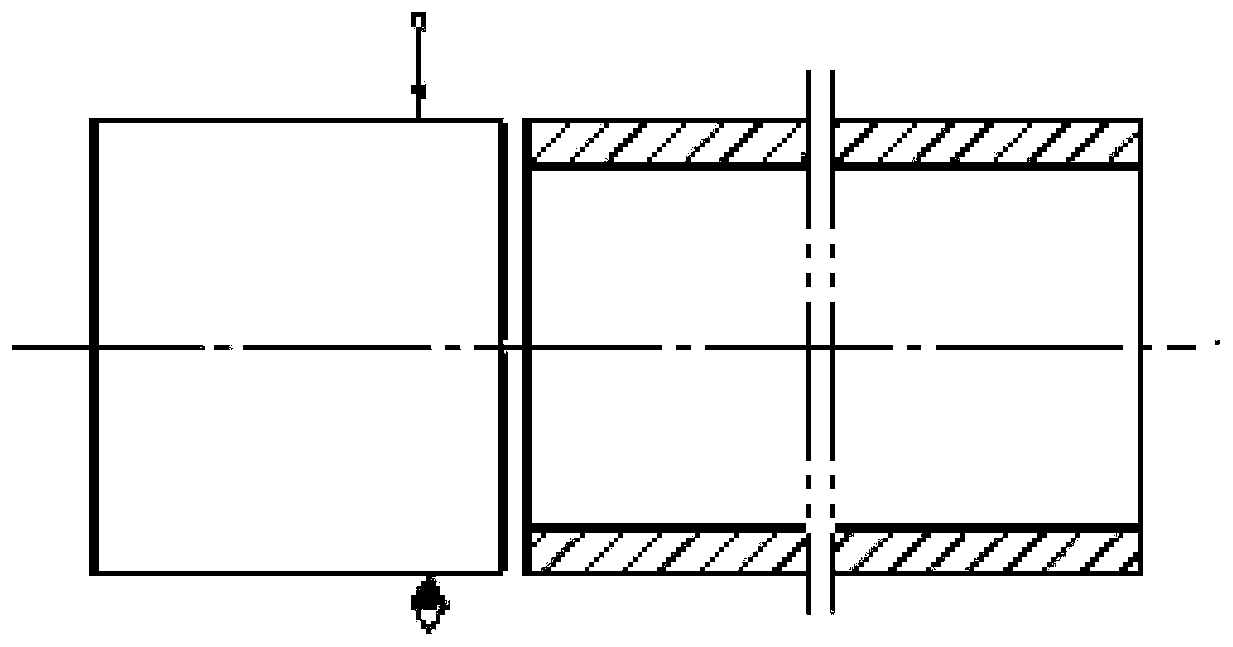

Clamp for plate

The invention relates to a clamp for a plate. The clamp comprises a shell in the shape of a square prism, wherein a cavity in the shape of the square prism is formed in the shell; an upper through hole and a lower through hole are longitudinally formed in the upper end surface and the lower end surface of the shell; a pair of pressure blocks and a pair of clamping blocks of which sections are in the shapes of right trapezoids are arranged in the shell; the plane on which the right-angled waists of the pressure blocks are located and the inner side wall of the shell are connected by virtue of a spring; a plurality of roller slots parallel to the inclined waists are arranged on the planes on which the inclined waists of the pressure blocks and the clamping blocks are located; rollers in pair are arranged in the roller slots; the rollers in pair are connected through roller shafts; the pressure blocks and the roller shafts corresponding to the clamping blocks are connected through connecting rods; lifting ropes capable of extending out from the through holes in the shell are arranged on the upper end surfaces of the clamping blocks. According to the technical scheme of the clamp, the plate is clamped through the clamping blocks, so that the area for clamping the plate is increased, and the stress on the plate is reduced; meanwhile, the stress on the clamping part of the plate is relatively uniform, and damage to the plate due to a fact that the cable ropes are adopted in the prior art, is avoided.

Owner:常州市瑞鸿达工具有限公司

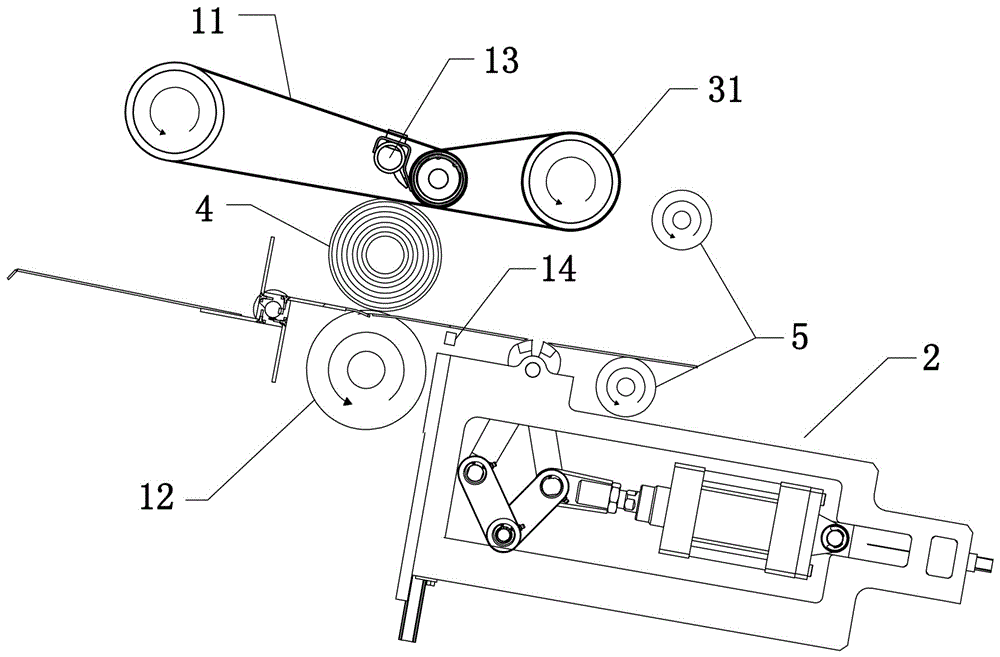

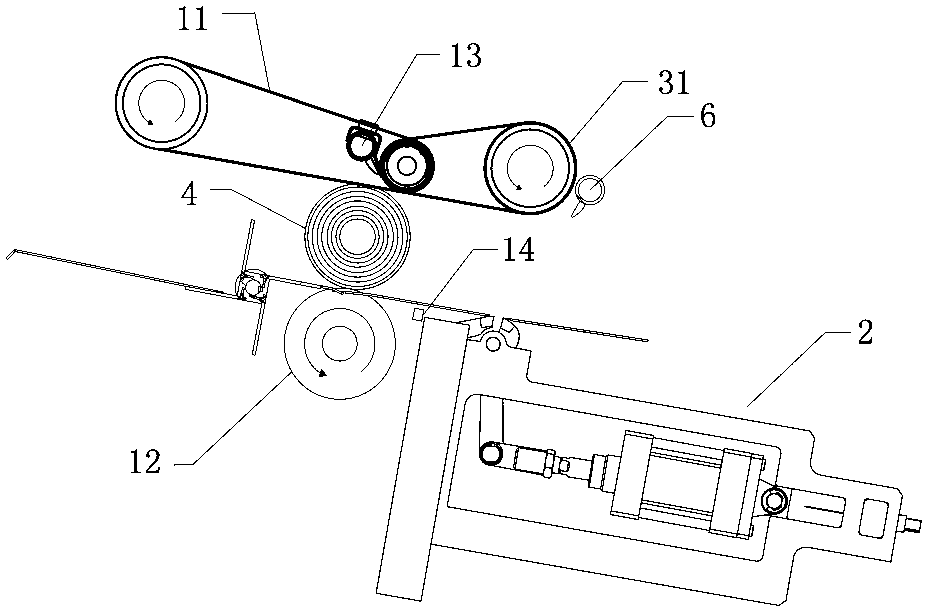

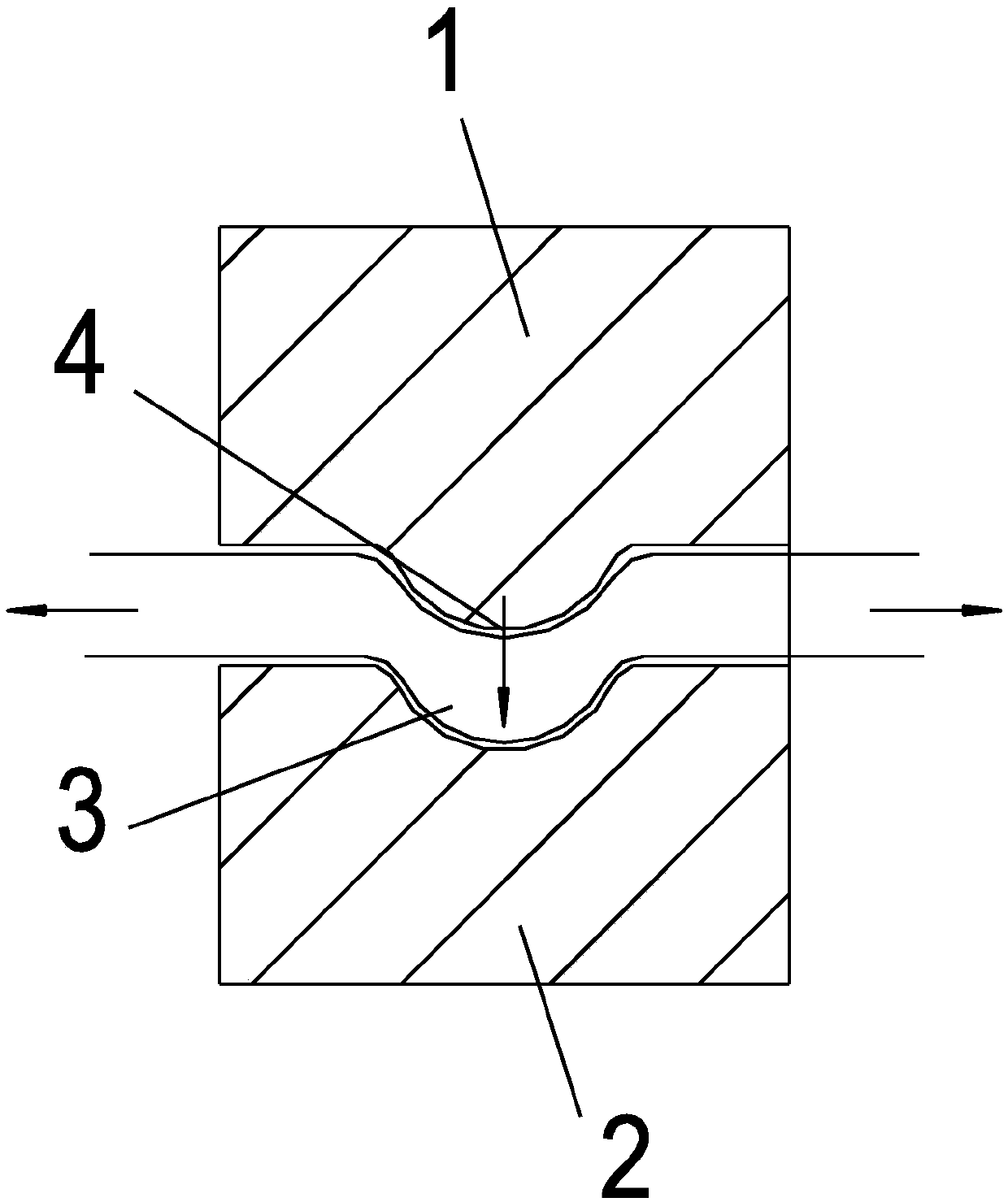

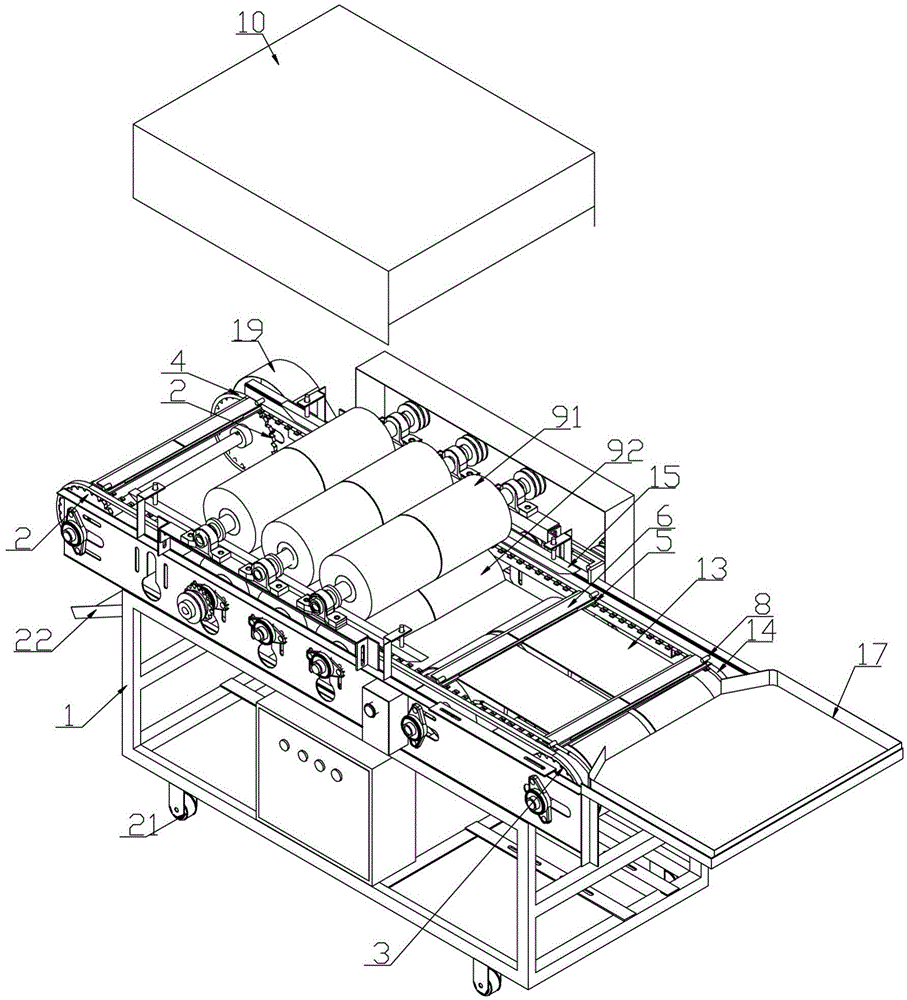

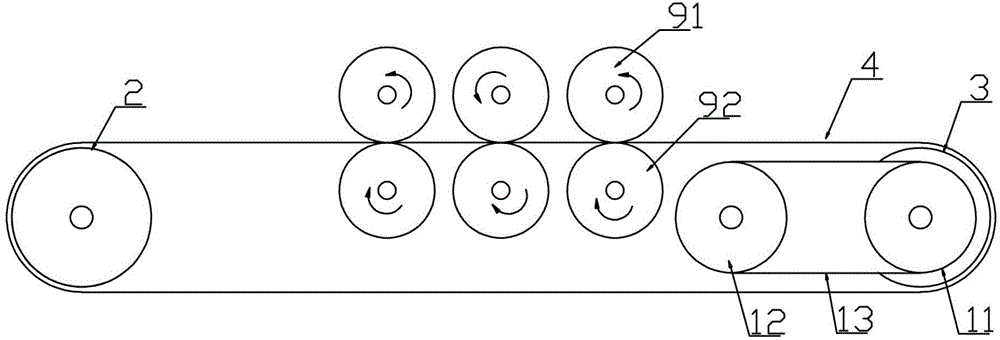

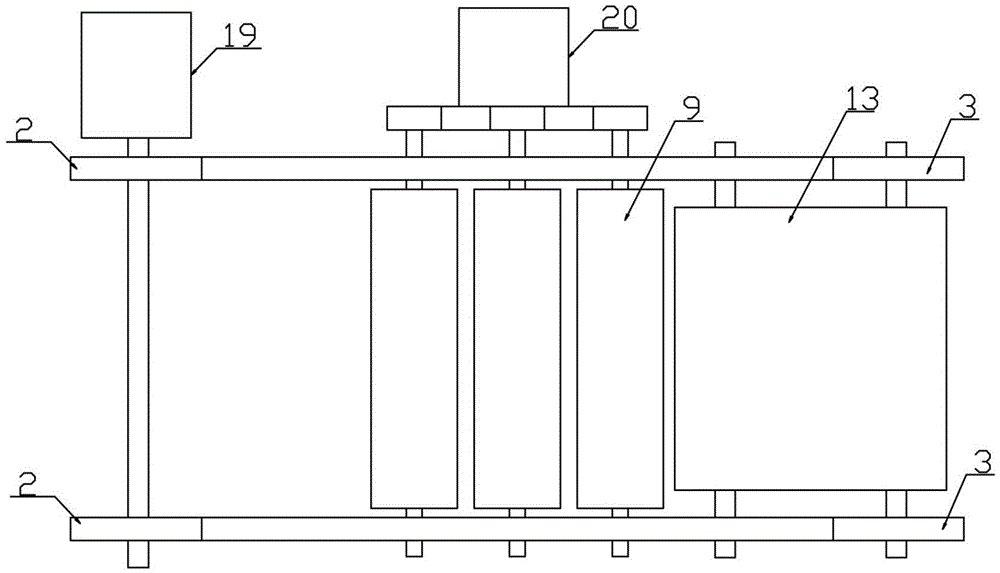

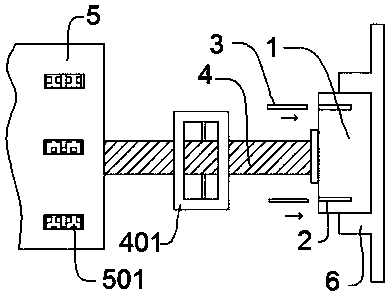

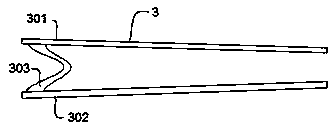

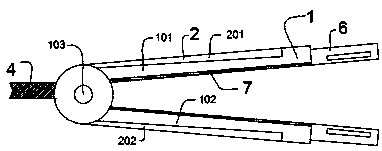

Non-glue tail sealing device for roll

The invention discloses a non-glue tail sealing device for a roll. The non-glue tail sealing device comprises tail sealing mechanisms and extrusion devices, and the tail sealing mechanisms and the extrusion devices are opposite in an up-down mode. The multiple sets of tail sealing mechanisms are axially arranged along the roll. Each set of tail sealing mechanism comprises a first clamping die, a second clamping die and a driving unit. Each driving unit drives the corresponding first clamping die and the corresponding second clamping die to move oppositely so that the first clamping die and the second clamping die can be opened and closed to each other. Each extrusion device is used for extruding the roll between an opening of the corresponding first clamping die and an opening of the corresponding second clamping die, so that a clamping nozzle of the first clamping die and a clamping nozzle of the second clamping die are embedded into the outer circumferential surface of the roll, and a pressing part is formed on the outer circumferential surface of the roll by closing the first clamping die and the second clamping die.

Owner:FOSHAN NANHAI DECHANGYU PAPER MASCH MFG CO LTD

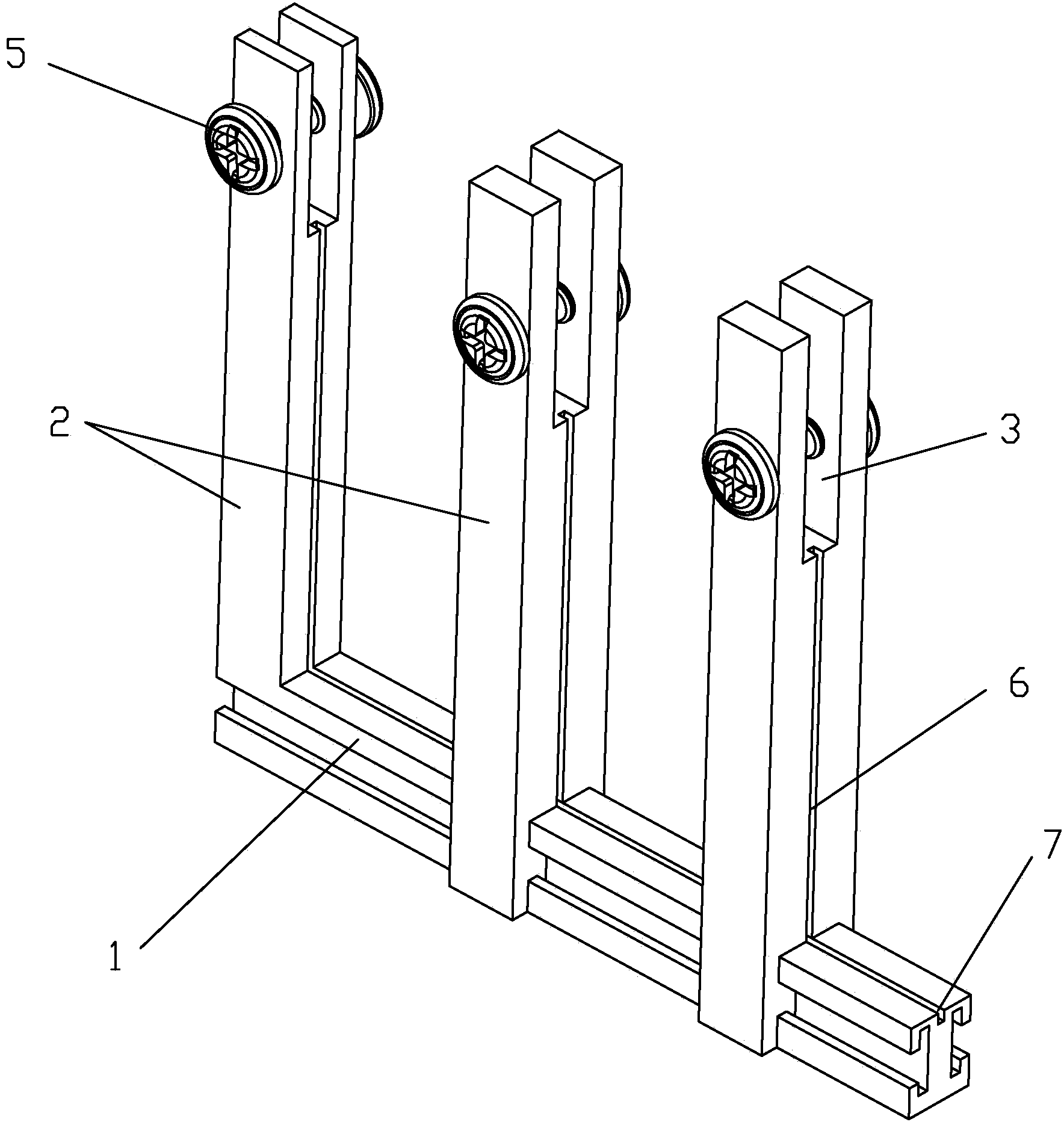

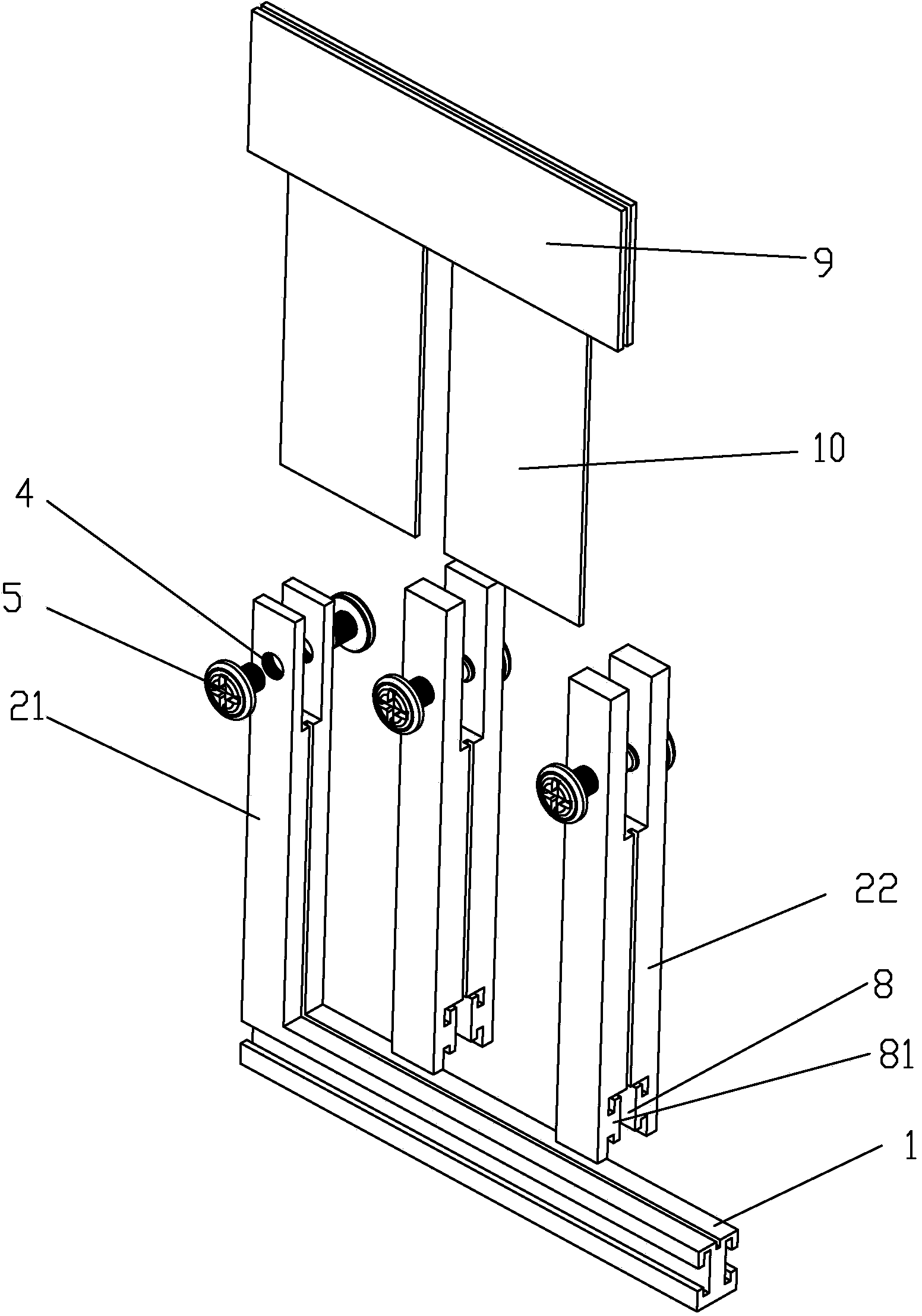

Ceramic circuit board clamp used for electroplating

InactiveCN103757685AAvoid breaking and falling offIncrease the clamping areaElectrolysis componentsProduction lineCeramic

The invention discloses a ceramic circuit board clamp used for electroplating. The key point of the technical scheme is that the ceramic circuit board clamp comprises a baseplate, wherein a plurality of clamp plates are vertically arranged on the baseplate; an edge strip clamping groove used for placing a conductive edge strip is formed in the upper end of each clamp plate; a vertical chuck plate shallow groove communicated with the edge strip clamping groove and used for allowing the side part of a ceramic circuit board to be inserted into is formed in the side surface of the clamp plate; threaded holes are formed in the clamp plates on two sides of edge strip clamping grooves; adjustable screws used for pressing the sides of the conductive edge strips to clamp the ceramic circuit board are arranged in the threaded holes; the clamp plate can be processed into a movable clamp plate moving along the baseplate, so that ceramic circuit boards with different sizes can be clamped; the structure is simple; the operation is convenient. According to the ceramic circuit board clamp, as the adjustable screws are used for pressing the conductive edge strips and the two conductive edge strips are adopted to clamp the ceramic circuit board, the clamping area is increased; the problems in an electroplating process that the ceramic circuit board is damaged by an electroplating clamp or broken and dropped into an electroplate liquid due to vibration of equipment in a product line can be prevented.

Owner:广东达进电子科技有限公司

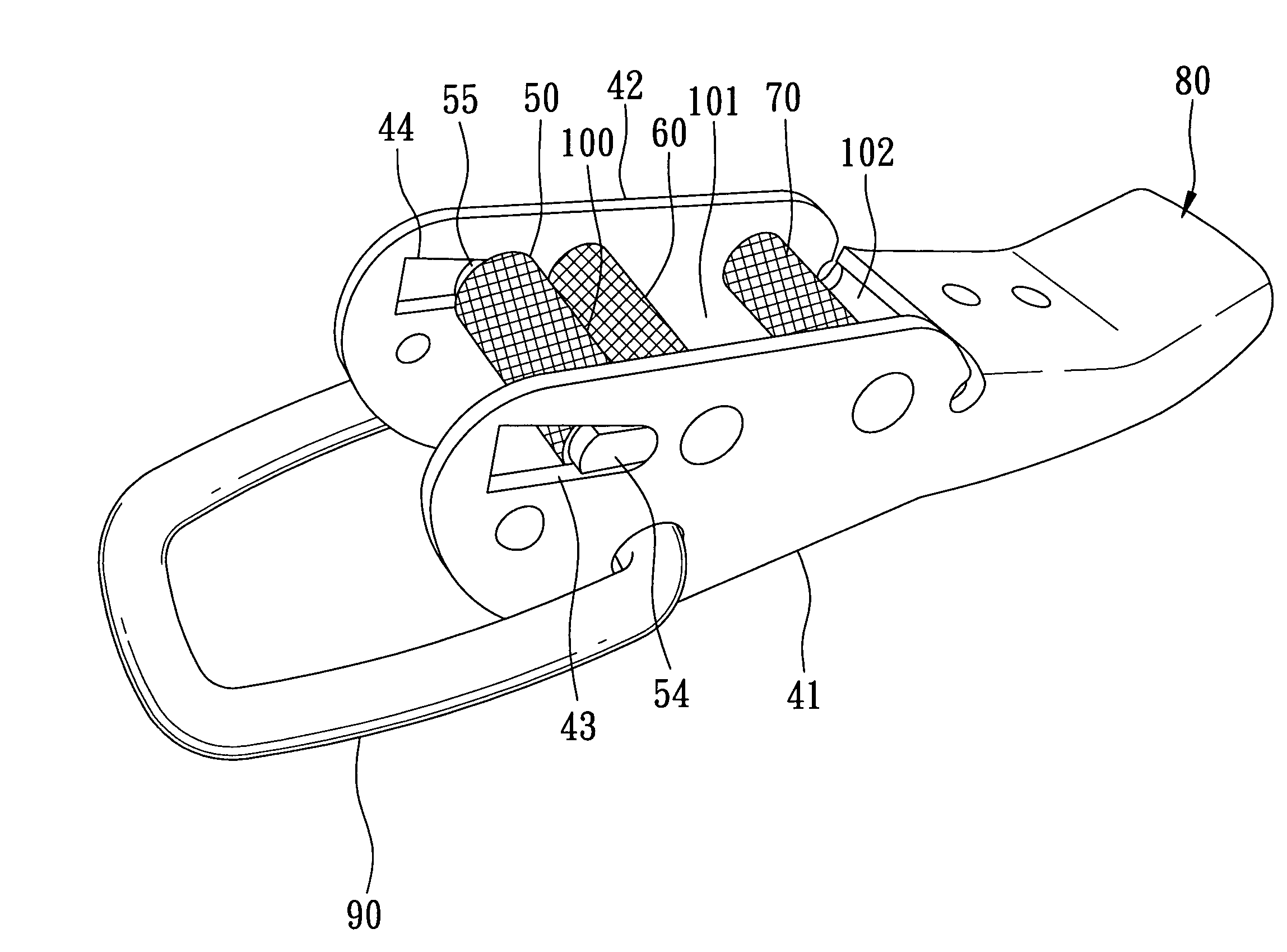

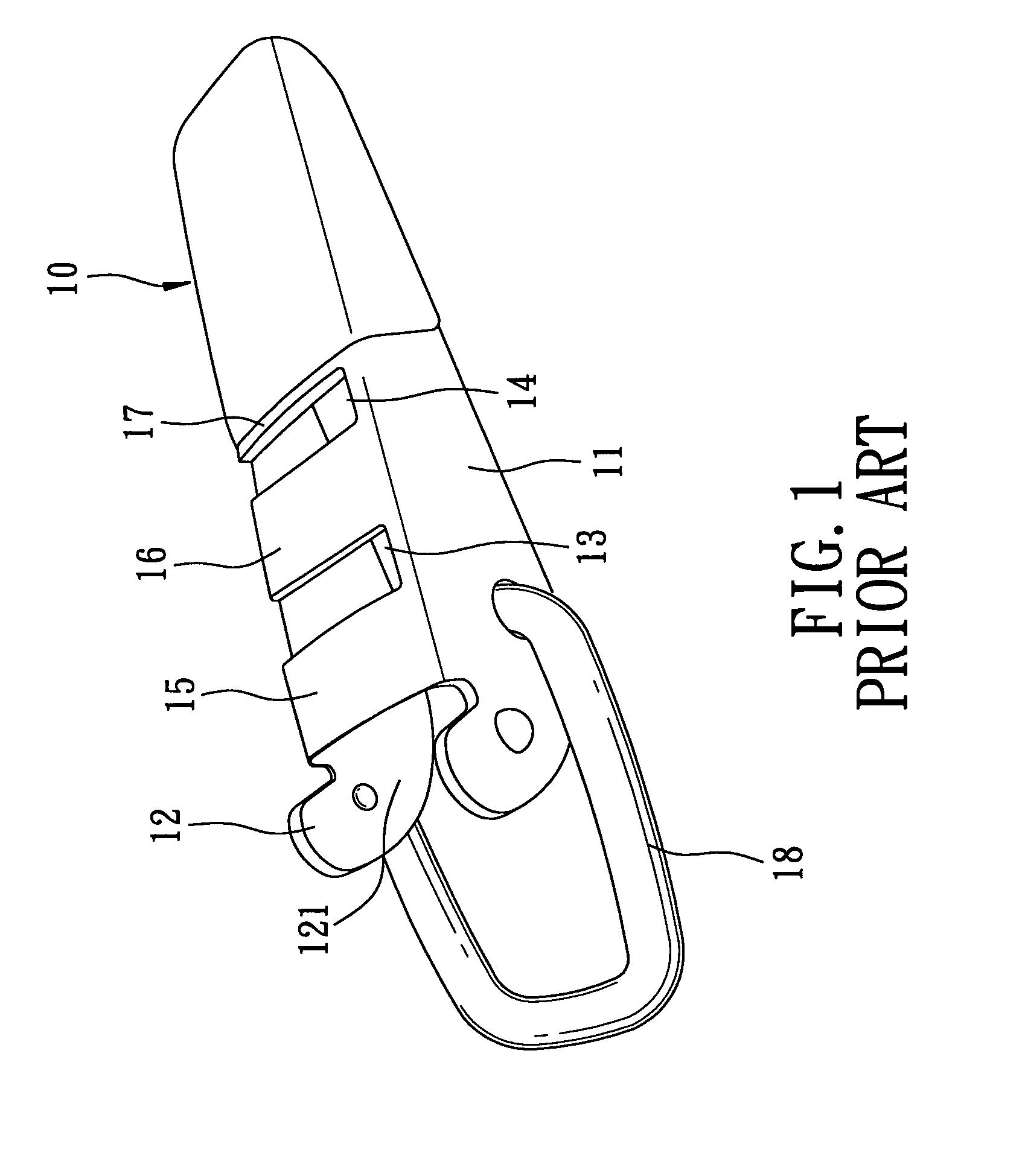

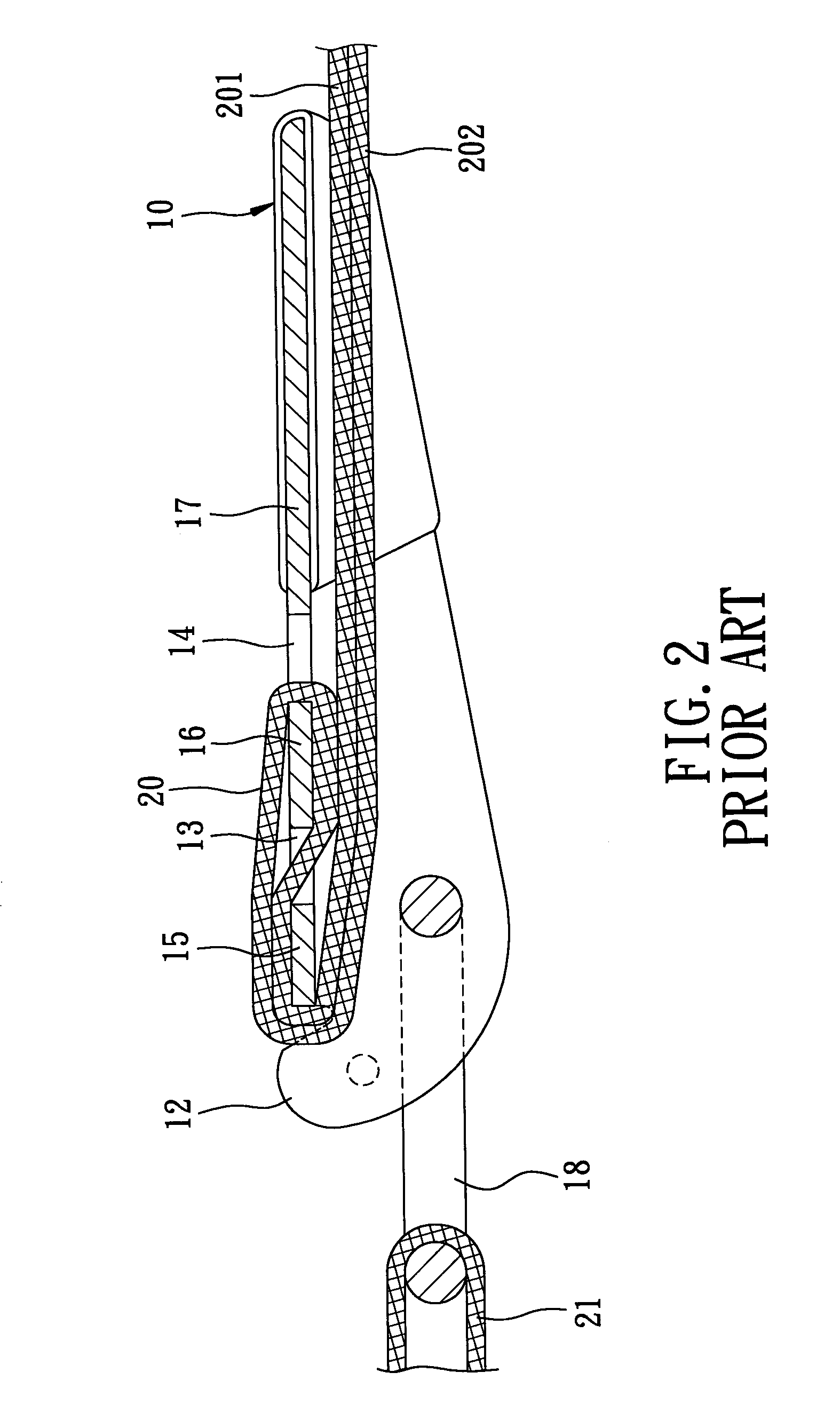

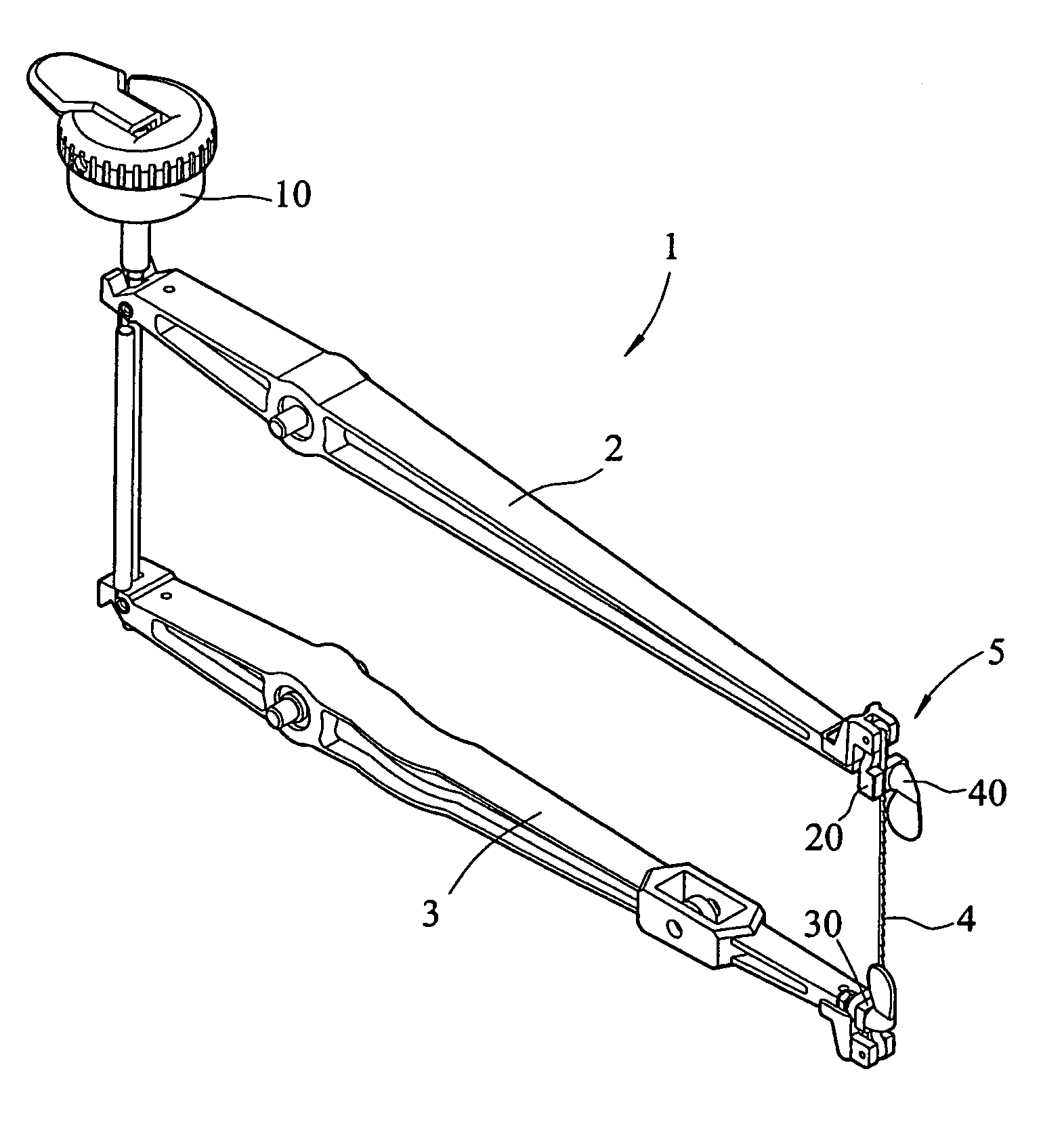

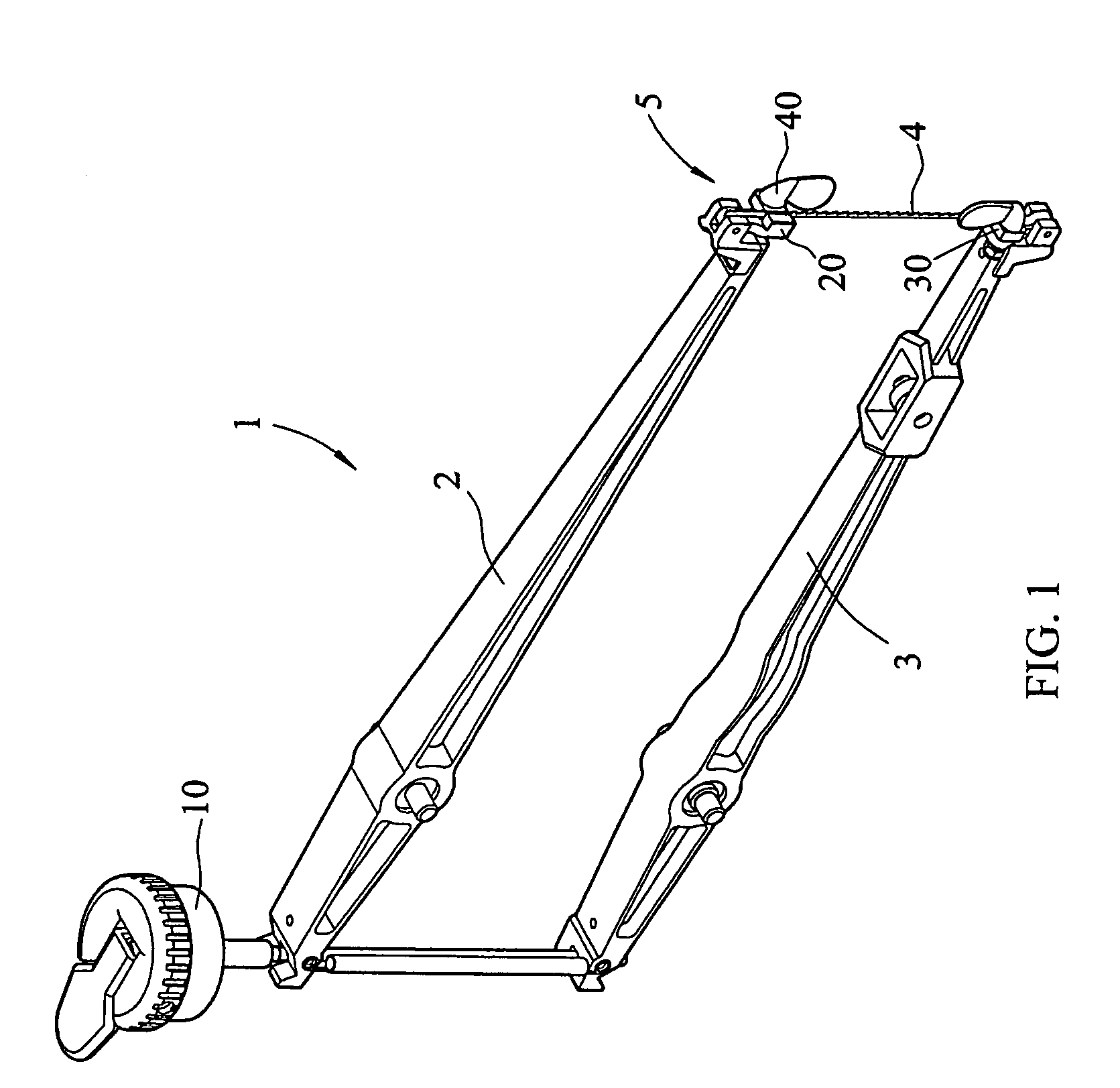

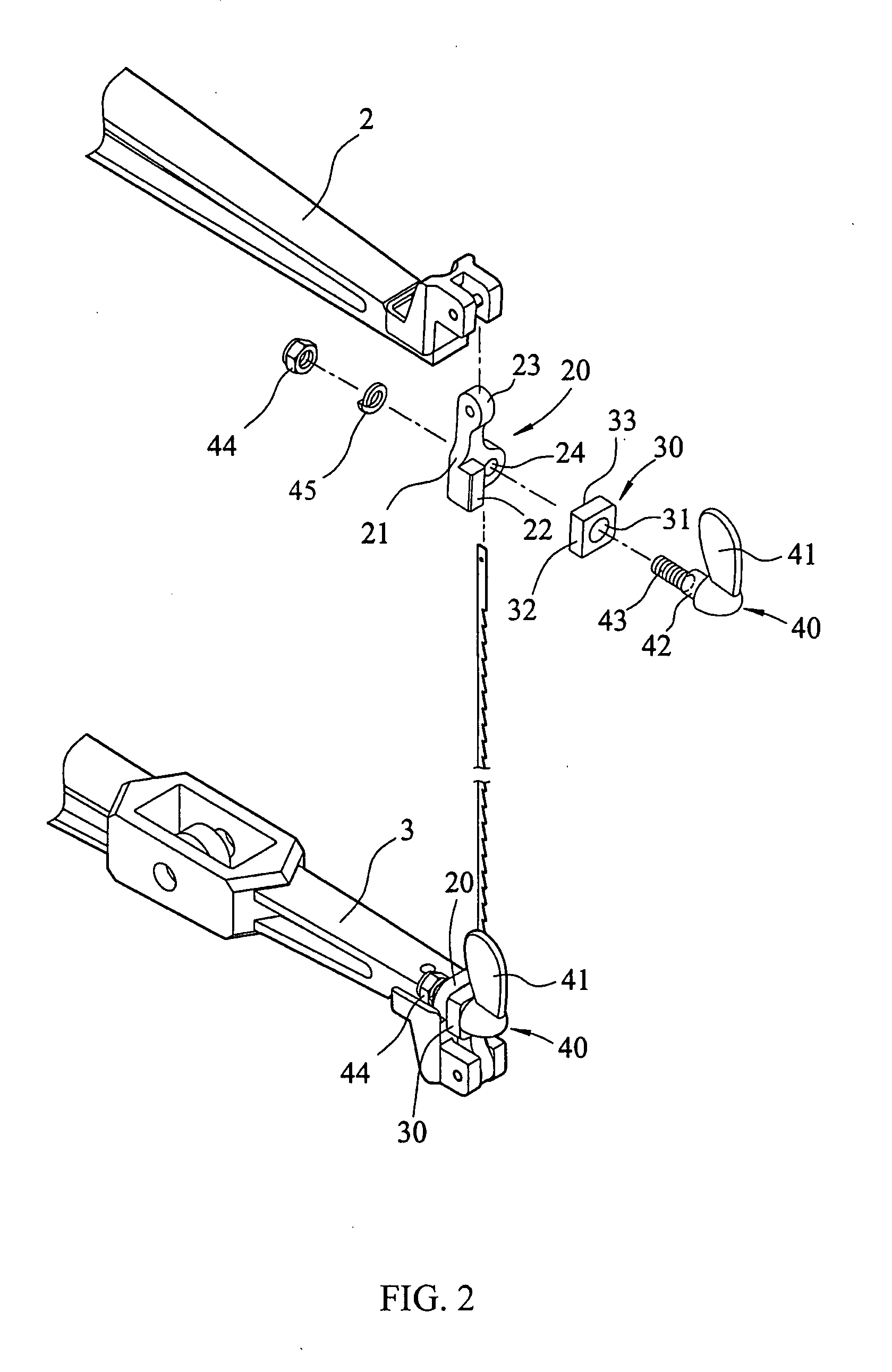

Saw blade mounting structure of a scroll saw

InactiveUS20070266838A1Easy to replaceIncrease the clamping areaMetal sawing devicesCross-cut reciprocating sawsEngineeringCantilever

A saw blade mounting structure formed of two saw blade clamps and used in a scroll saw to hold a saw blade between two suspension arms in which each saw blade clamp comprises a mounting block pivotally connected to one suspension arm and provided with a through hole and a stop flange, a clamping block with a through hole, an operating member, a first rod member fixedly connected to the operating member and inserted through the through hole of the clamping block, a second rod member eccentrically extending from one end of the first rod member and inserted through the through hole of the mounting block and screwed into a check nut for enabling the first rod member to move the clamping block relative to the stop flange of the mounting block so as to lock / release the saw blade upon forward / backward rotation of the operating member.

Owner:REXON IND CORP LTD

Device for detecting tensile strength of lithium battery diaphragm

PendingCN114659901AReduce initial stretch speedImprove protection workMaterial strength using tensile/compressive forcesStructural engineeringStress sensors

The invention discloses a lithium battery diaphragm tensile strength detection device which comprises a bottom plate, a box body is fixed to the top of the bottom plate, a boss is fixed to the center of the outer wall of the top of the bottom plate, a guide rod is fixed between the outer wall of the left side of the boss and the inner wall of the box body, the guide rod is slidably sleeved with a sliding block, and an extrusion mechanism is fixed to the right side of the sliding block. A clamping mechanism is fixed to the left side of the top of the sliding block, a limiting strip is fixed to the right side of the top of the sliding block, a buffering groove is formed in the top of the limiting strip, and a buffering mechanism is arranged in the buffering groove. The stretching acting force can be buffered through the elasticity of the supporting springs and the guiding effect of the guiding wheels, so that the guiding wheels can apply downward acting force to the supporting springs, and the situation that the speed is too high in the initial stretching process, the pulling strength is too large, and consequently tearing is caused is avoided.

Owner:襄阳惠强新能源材料科技有限公司

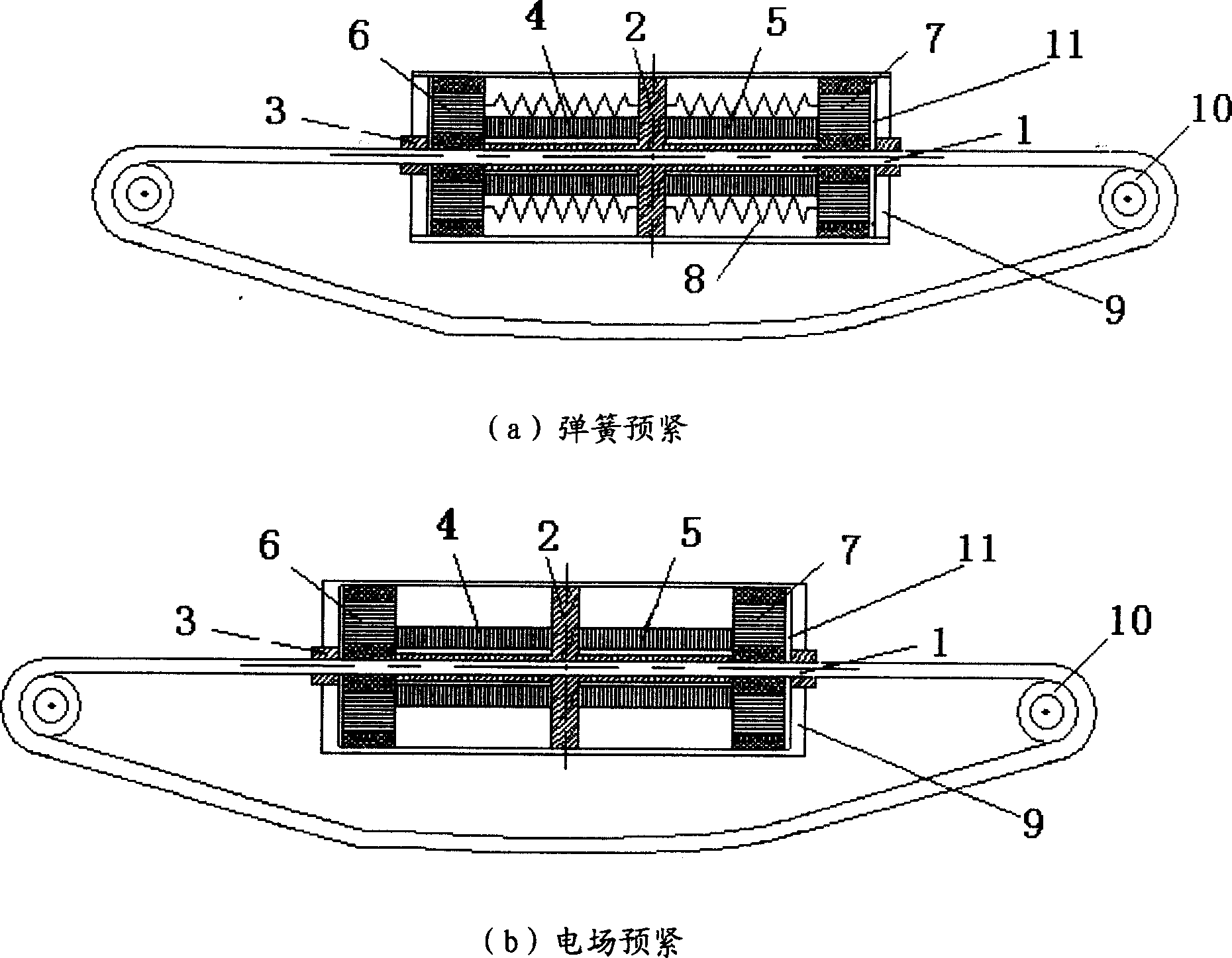

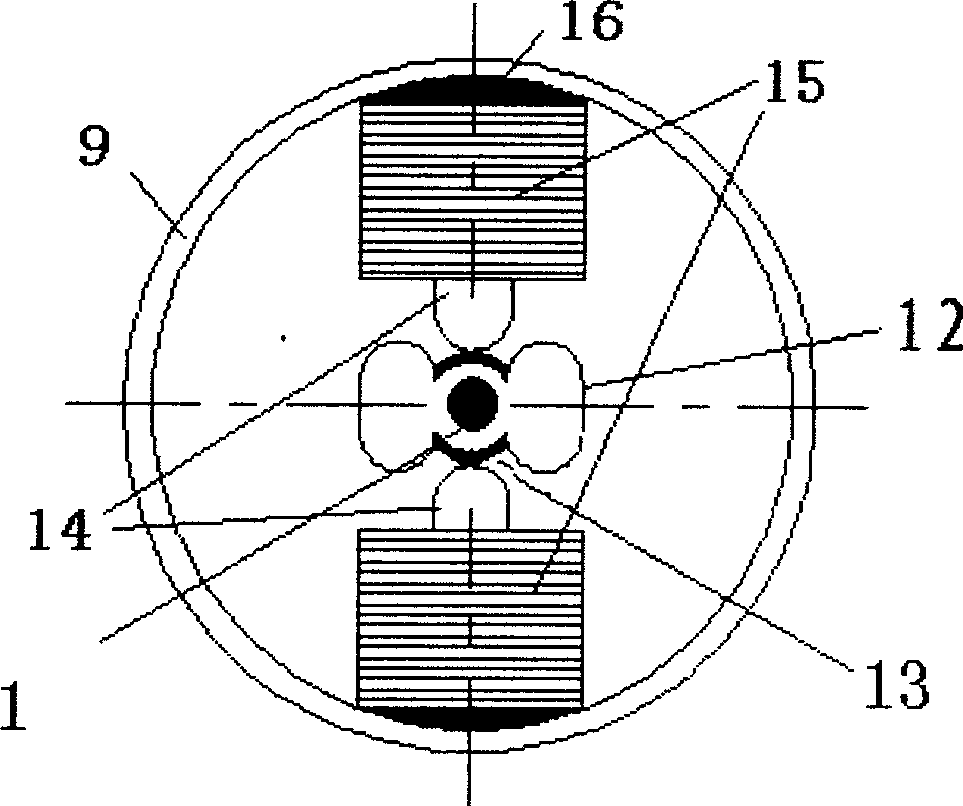

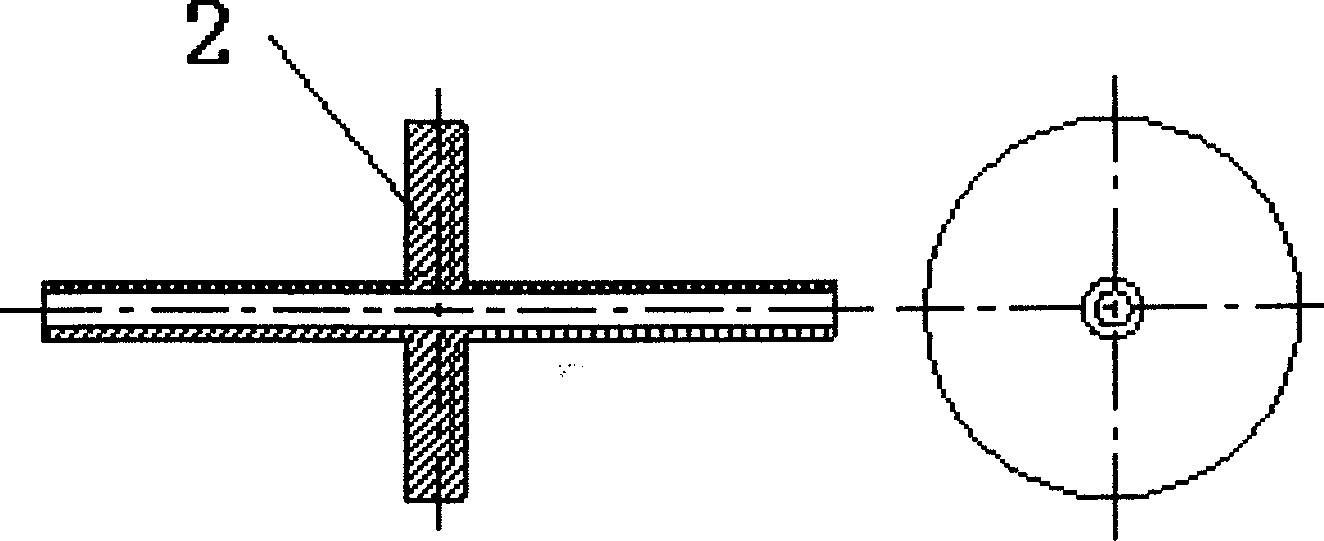

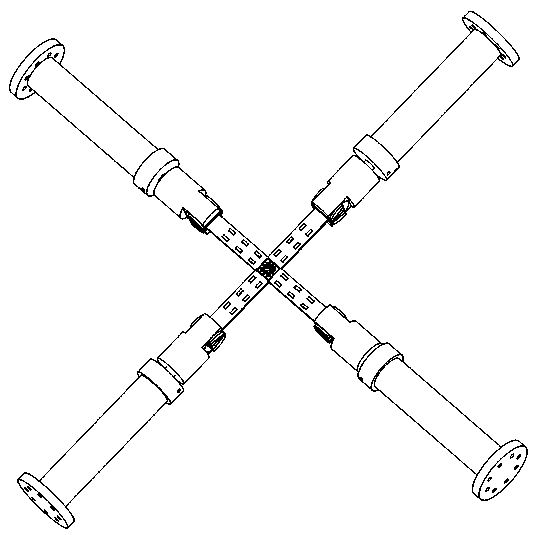

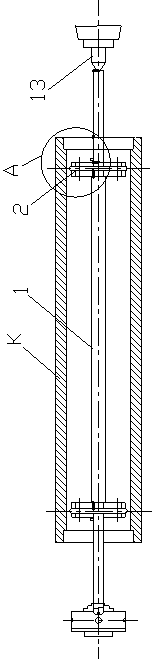

High-precision linear driver with arbitrary distance of run

InactiveCN1845443AStay clampedQuick responsePiezoelectric/electrostriction/magnetostriction machinesRoboticsHigh intensity

The provided arbitrary-travel high-precise direct driver comprises: based on bionic motion principle, applying piezoelectric ceramic as basic motion executive element, high-tension high-toughness mono-strand or multi-strand ring rope as output element, lateral / vertical shrinking unit as drive element. Wherein, the control precision can achieve up to 50nm, output force up to 50-100N or more. This invention has wide application, special to anthropomorphic robotic.

Owner:UNIV OF SCI & TECH OF CHINA

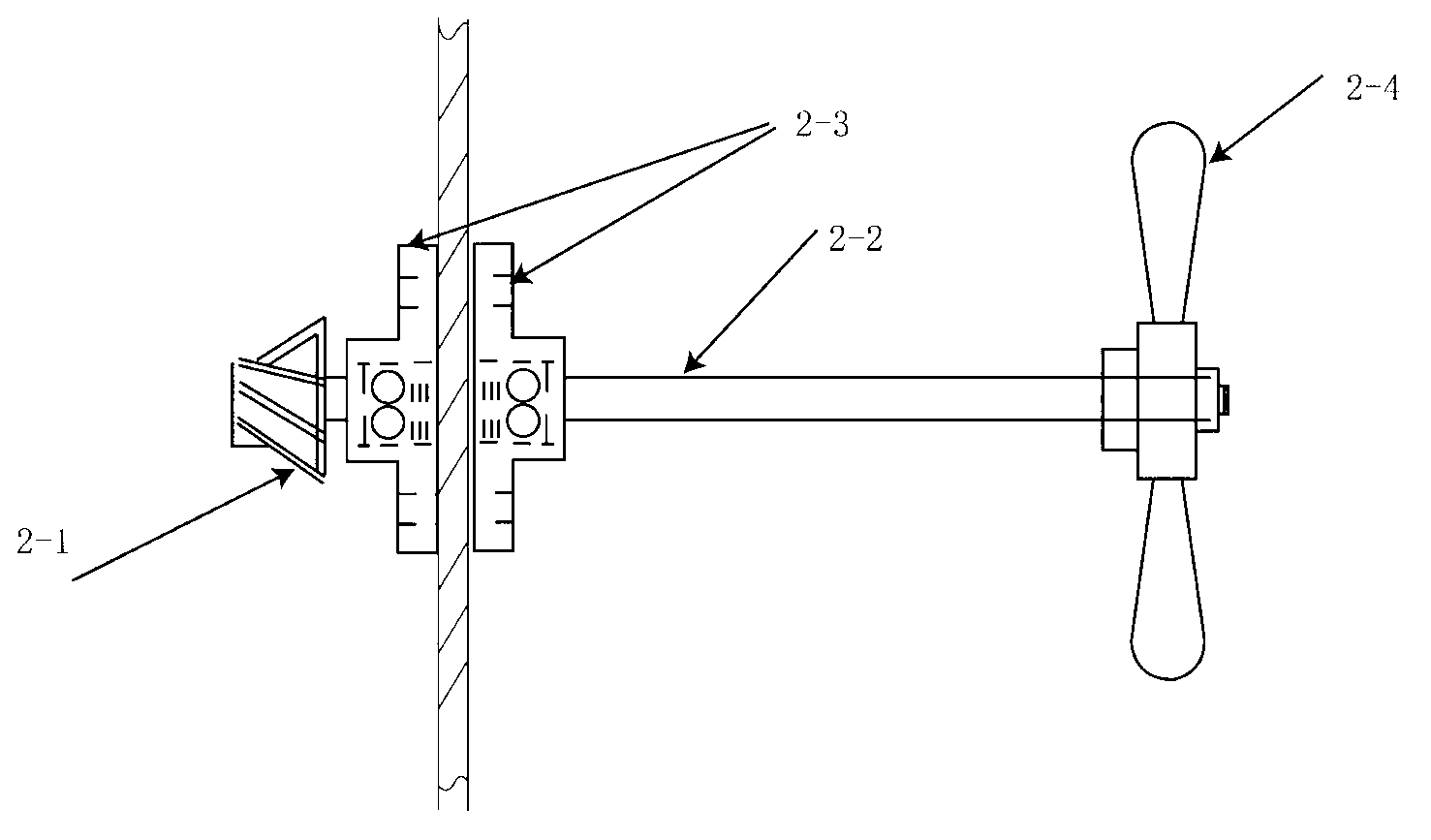

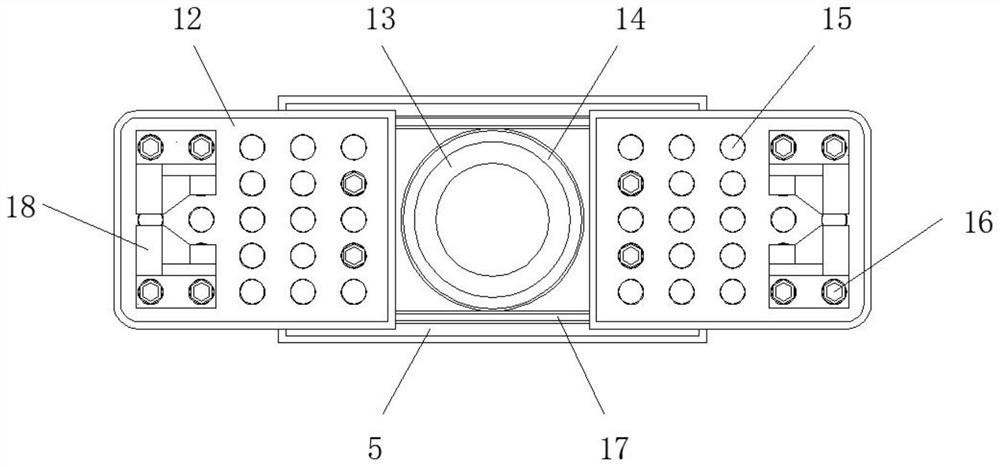

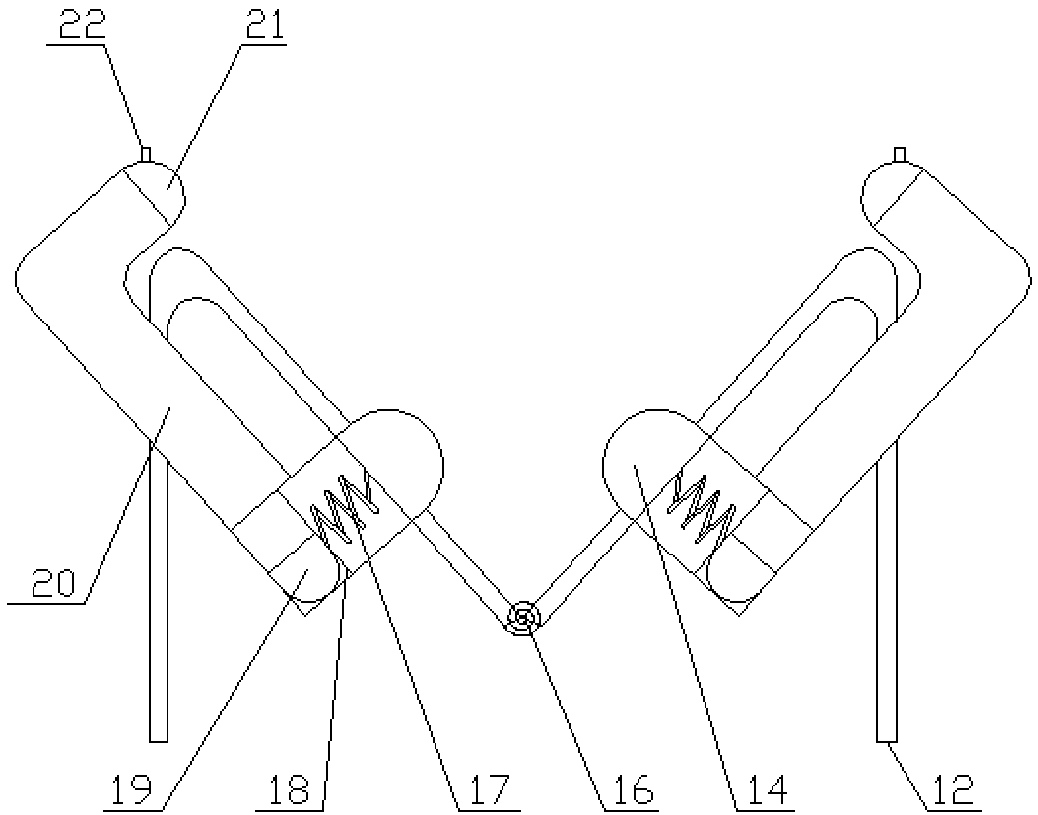

Four-axis centering adjustment system and method for biaxial tensile testing machine

ActiveCN110726636ASolve problems that cannot be adjusted in real timeSolve the uncontrollable accuracy of manual assembly adjustmentMechanical measuring arrangementsStrength propertiesControl engineeringMachine

The invention relates to a four-axis centering adjustment system and method for a biaxial tensile testing machine and belongs to the field of testing machine technologies. The system comprises a spindle loading chain, a centering adjustment device, a centering sensor, a feedback device and a rack, wherein the centering adjustment device is installed on the spindle loading chain, the spindle loading chain is installed on the rack, and a detection and feedback mechanism is installed on the rack and is used for detecting and controlling the adjustment amount. The system has the advantages that adjustment at five degrees of freedom can be realized, and precision is correspondingly matched with a detection device; the system is connected with a complete machine loading chain, the strength of the whole device is improved, and damage to a loading shaft is reduced; and the system is high in adaptability, can match loading chains in different forms and multiple types of fixtures, occupies a small space, is easy to operate and high in repeated adjustment precision, improves experimental precision and makes measured data more precise.

Owner:JILIN UNIV

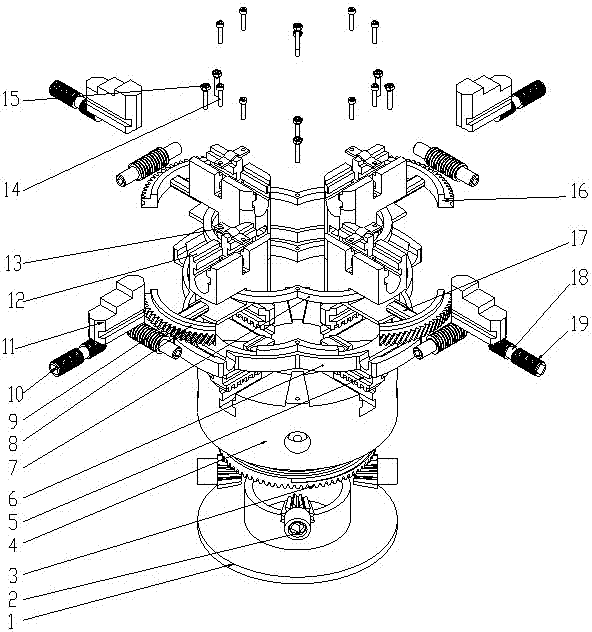

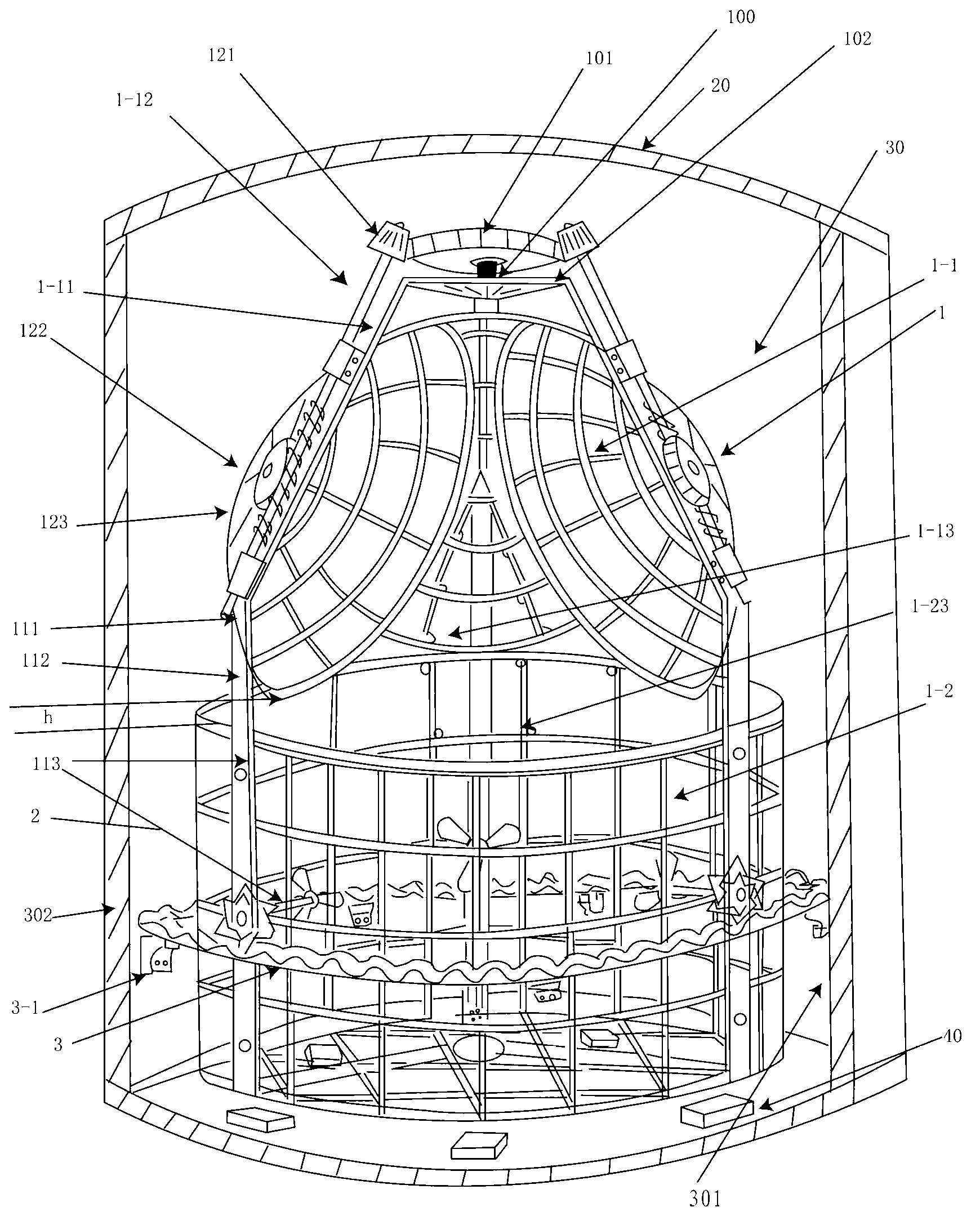

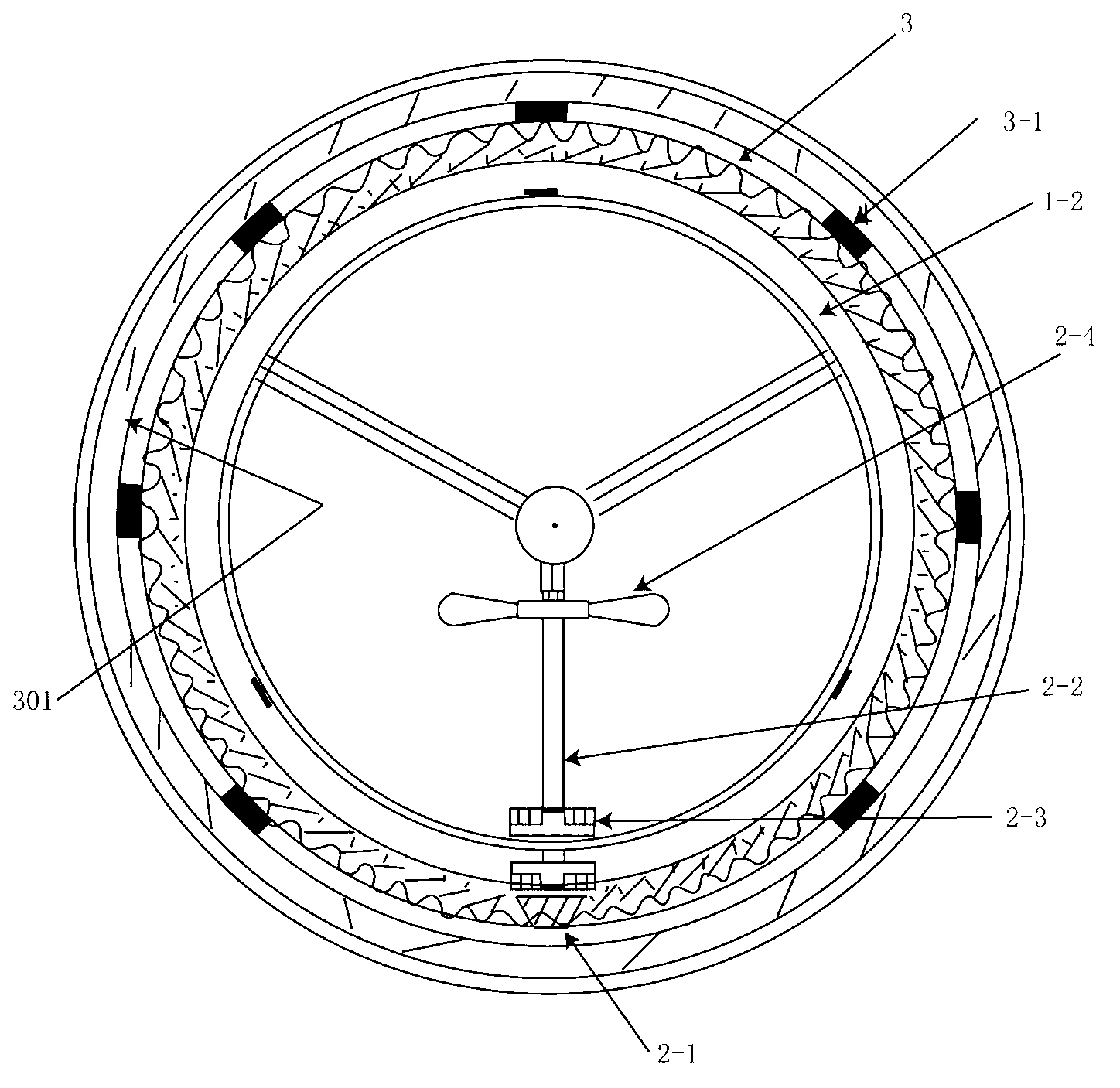

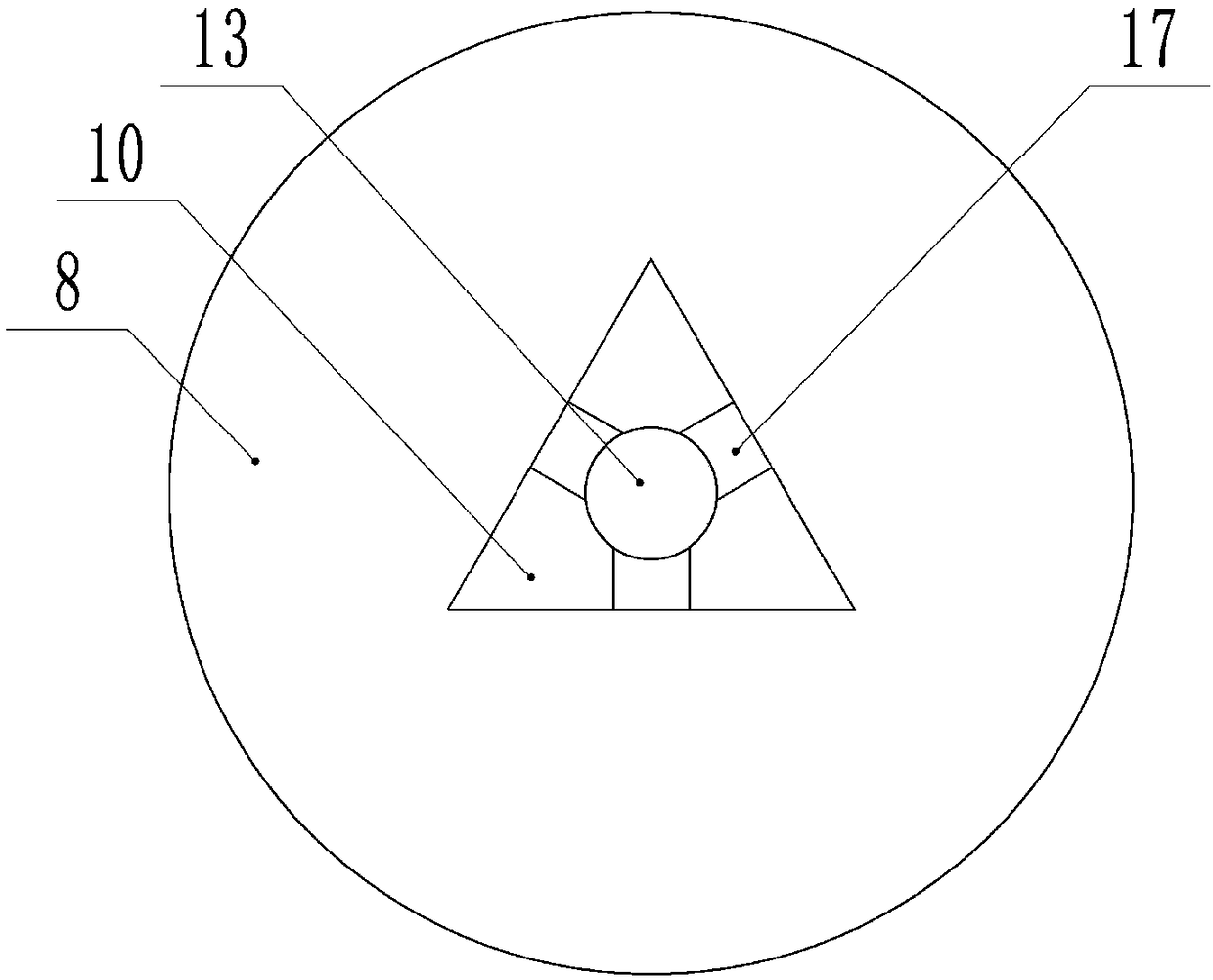

OLED (organic light-emitting diode) coating machine with dual-rotation mechanism

InactiveCN103243307AIncrease the clamping areaIncrease the number ofVacuum evaporation coatingSputtering coatingVacuum pumpingVaporization

The invention provides an OLED (organic light-emitting diode) coating machine with a dual-rotation mechanism. The OLED coating machine composed of a dual-rotation mechanism comprises a machine frame, a vacuum chamber, a dual-rotation mechanism, a plurality of molybdenum boats, a power system for driving the dual-rotation mechanism, a molybdenum boat electrifying heating system, a vacuum-pumping system, a vacuum chamber heating system and an instrument cabinet, wherein the dual-rotation mechanism, the molybdenum boats and the power system are arranged in the vacuum chamber; the instrument cabinet is composed of a dual-rotation mechanism speed indication and control subsystem, a vacuum-pumping system indication and control subsystem, a molybdenum boat electrifying heating indication and control subsystem, a film thickness indication and control subsystem, a vacuum chamber temperature indication and control subsystem, a general supply indication and control subsystem and other subsystems; the dual-rotation mechanism is composed of a rotation pot-shaped bracket positioned on the upper part in the vacuum chamber, a rotation cylindrical bracket positioned on the middle lower part of the vacuum chamber, and a gas disturbance homogenizing mechanism; and the rotation pot-shaped bracket and the rotation cylindrical bracket are respectively provided with a mechanism for fixing a workpiece subjected to vaporization coating, thereby facilitating the charging and discharging of the workpiece.

Owner:SOUTHEAST UNIV +1

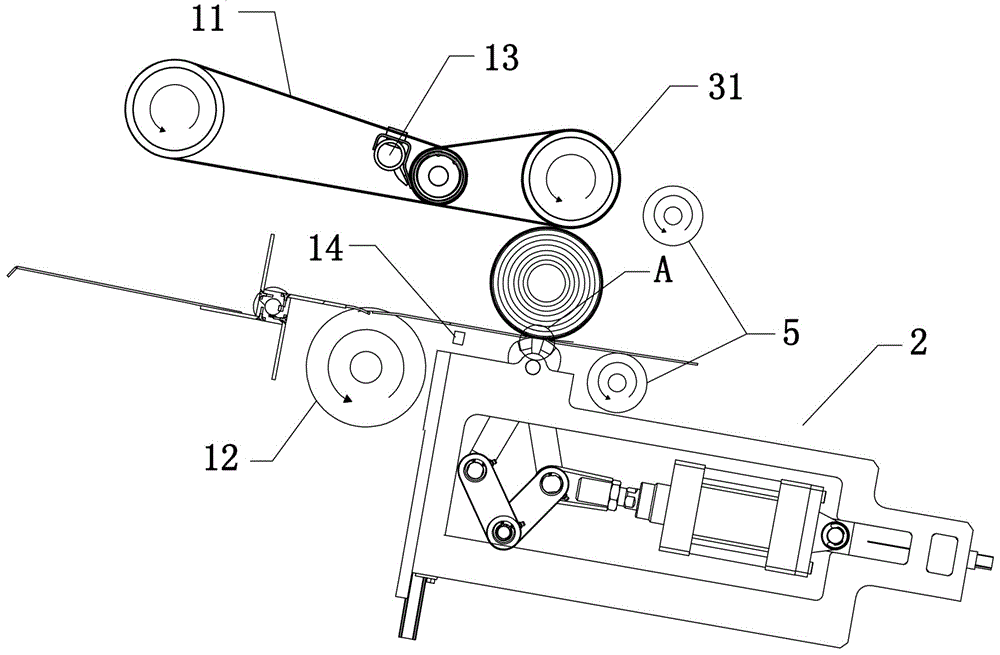

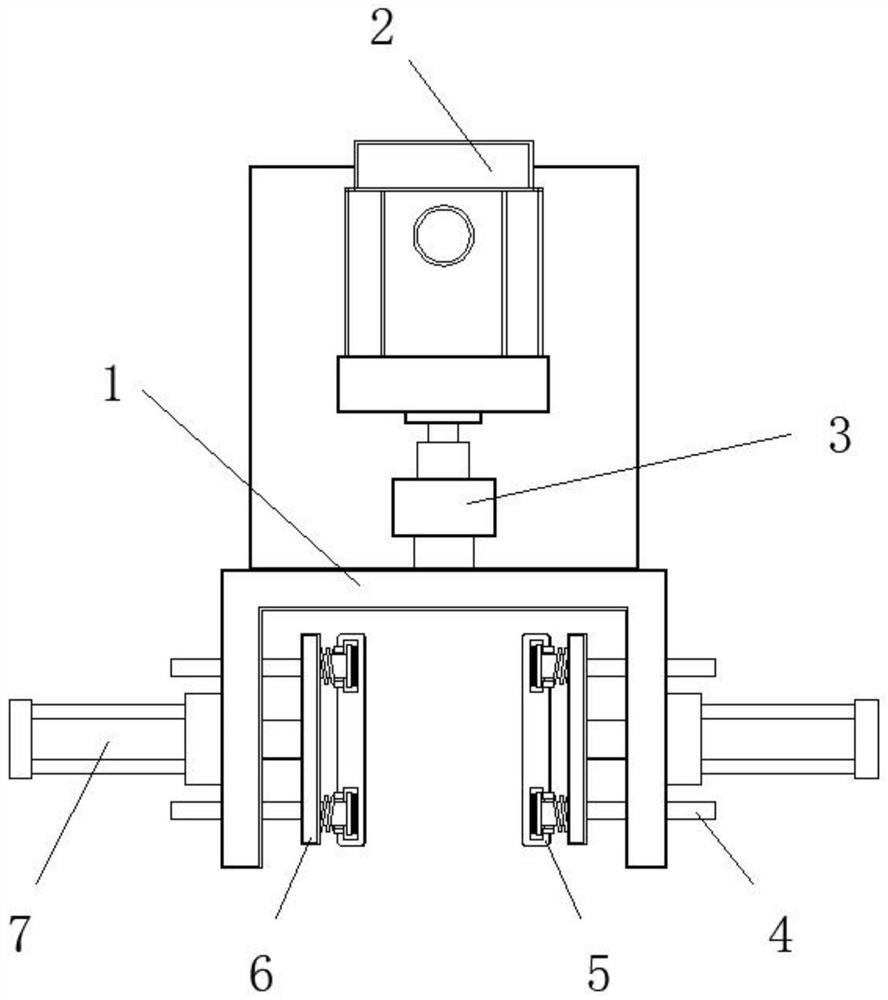

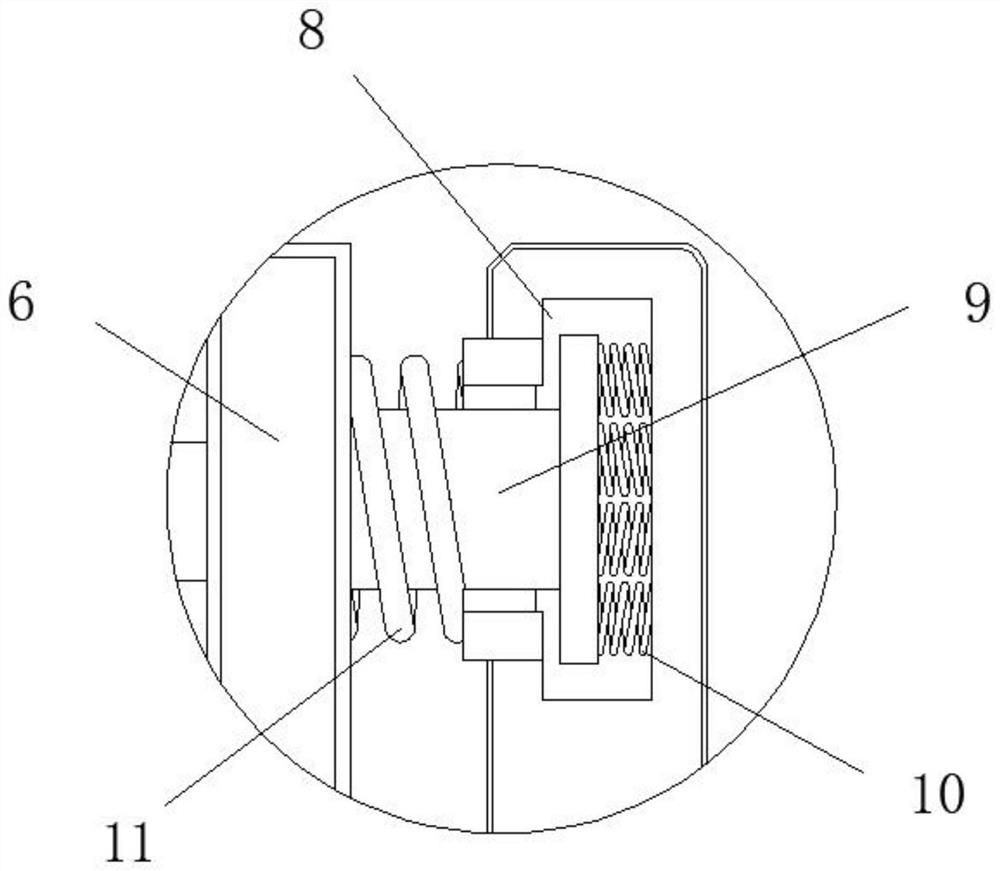

Bearing turnover mechanism of fully automatic rotor assembly equipment

InactiveCN111823186ASolve the problem of easy damage to the bearing surfaceFix damageWork holdersManufacturing dynamo-electric machinesClassical mechanicsHydraulic pump

The invention discloses a bearing turnover mechanism of fully automatic rotor assembly equipment. The mechanism comprises a fixing frame, a motor, a bearing seat, a hydraulic pump, a base plate and apositioning column, wherein the outer surface of the base plate is provided with a fixing clamping plate, a fixing groove is provided on the end surface of the fixing clamping plate adjacent to the base plate, the end surface of the base plate adjacent to the fixing clamping plate is fixedly connected with a fixing column, the end of the fixing column is fixed inside the fixing groove, the end surface of the fixing column and the inner wall of the fixing groove are fixedly connected with an inner spring, an outer spring is provided on the outside of the fixing column, one end of the outer spring is fixed on the inner surface of the fixing clamping plate, and the other end of the outer spring is fixed on the outer surface of the base plate. Through the designed fixing column, the inner spring and the outer spring, the fixing clamping plate produces a buffer for the certain deformation of the inner spring and the outer spring during the bearing clamping process, and the resilient force of the springs ensures the clamping of the bearing by the clamping part.

Owner:上海斐奥自动化科技有限公司

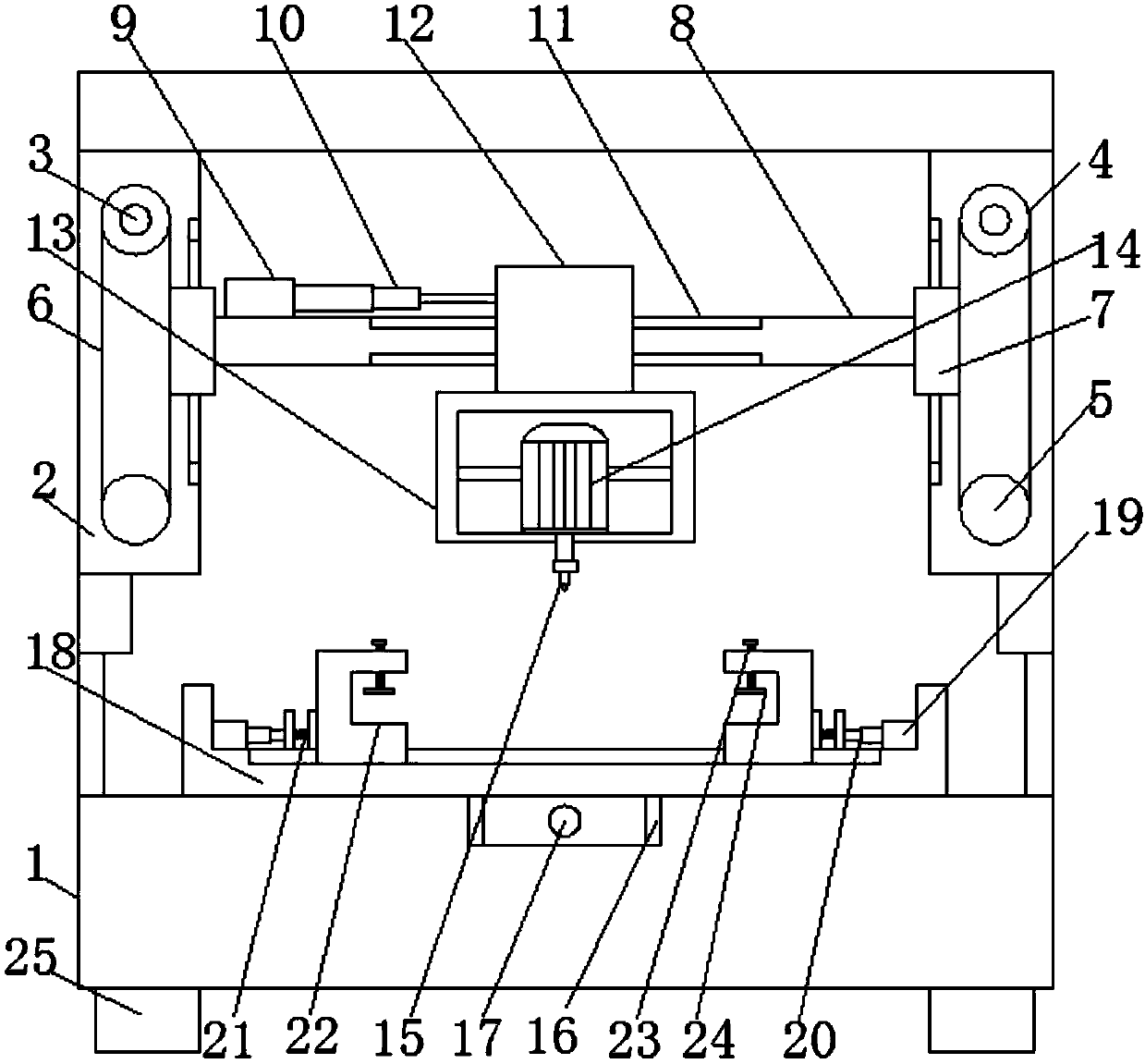

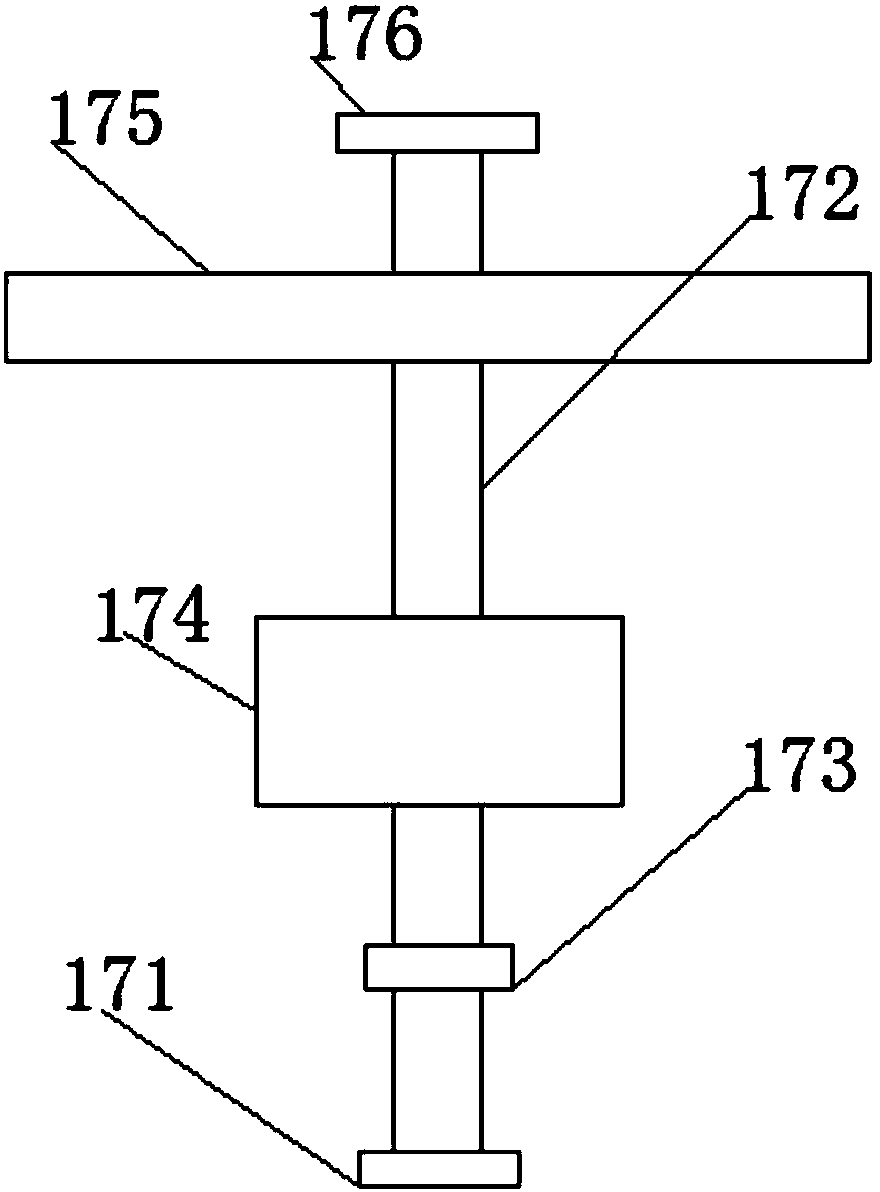

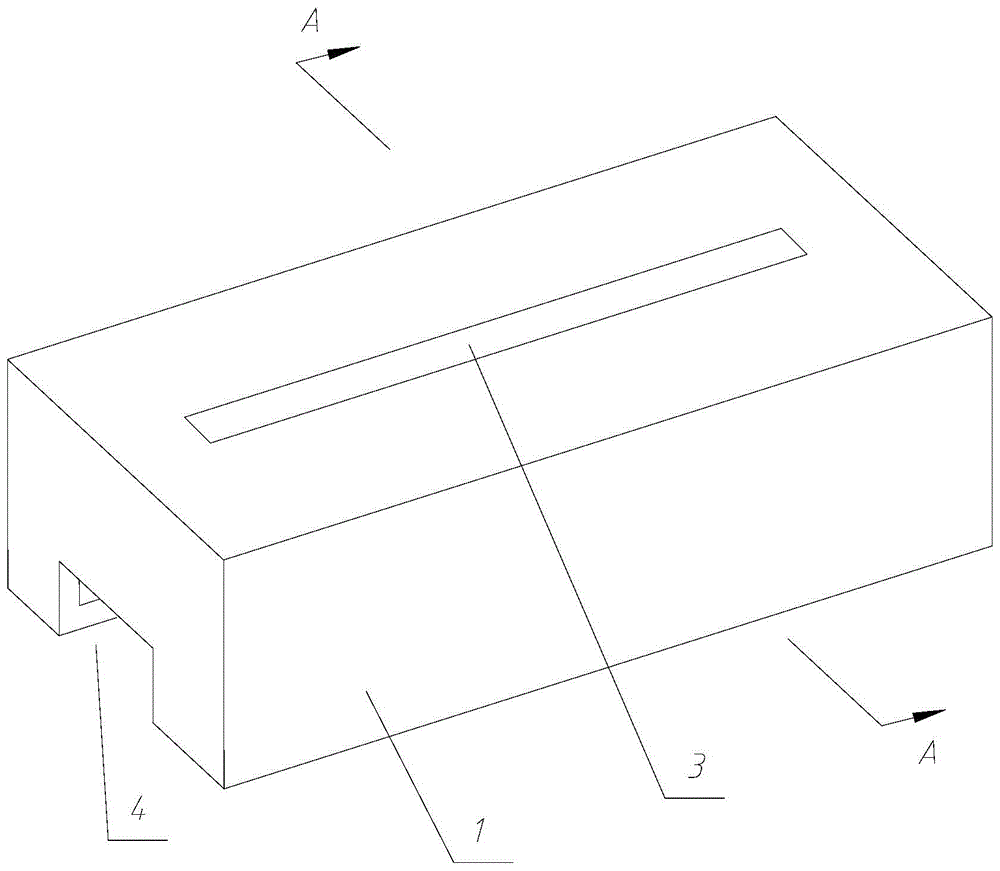

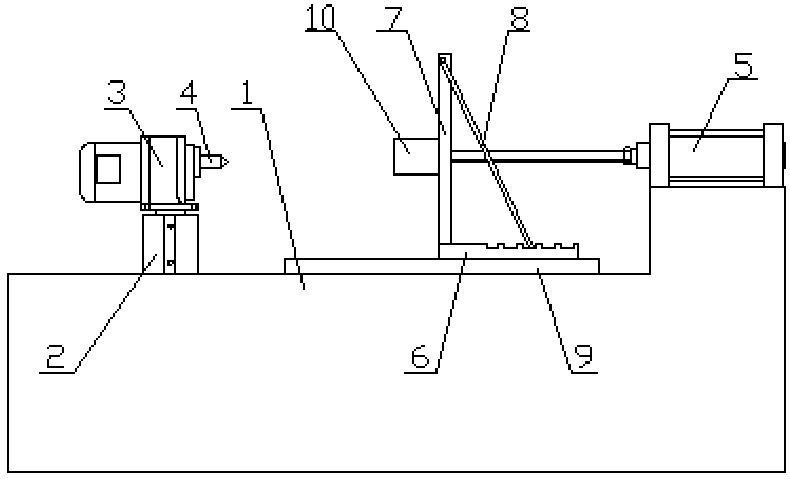

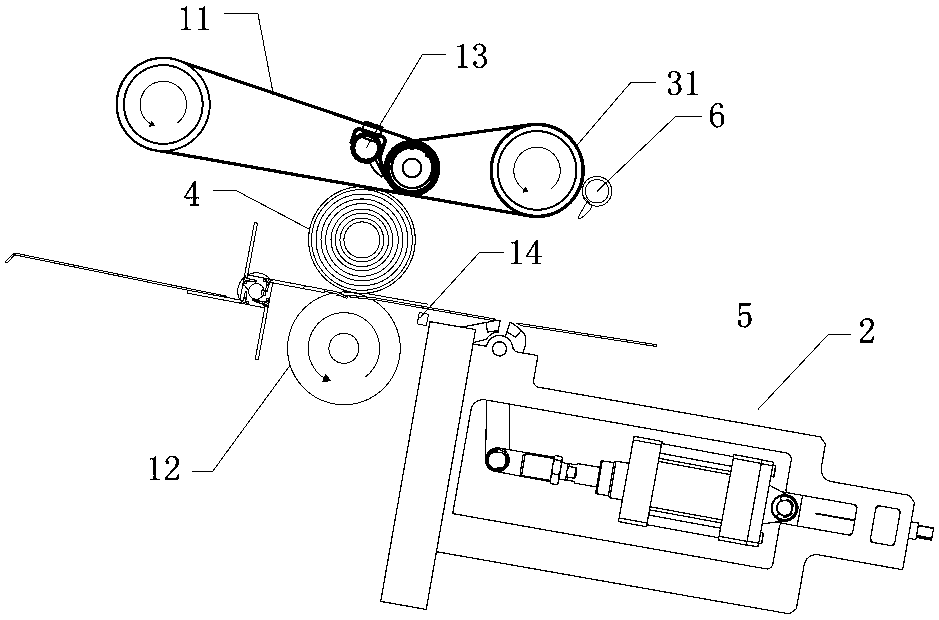

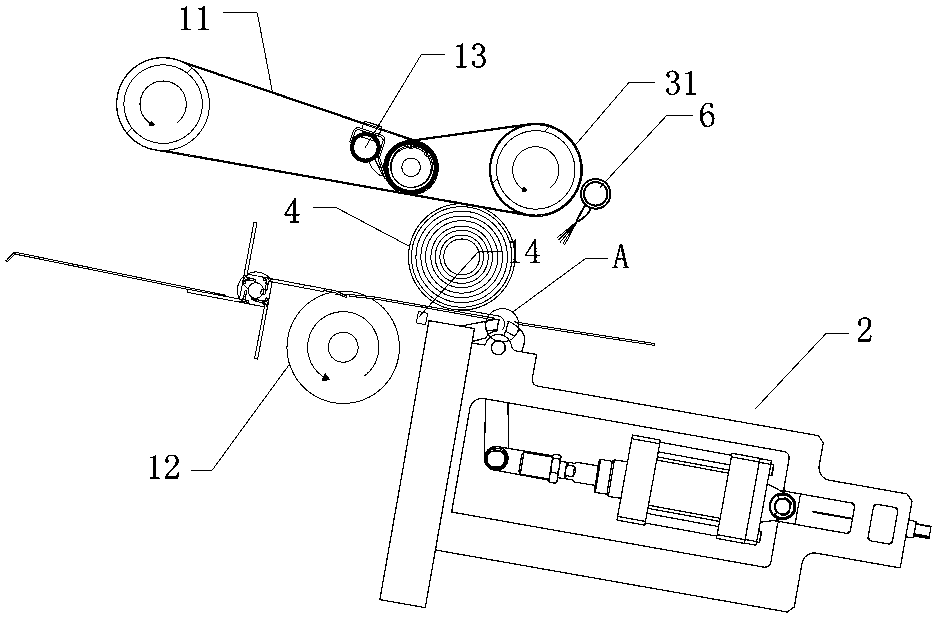

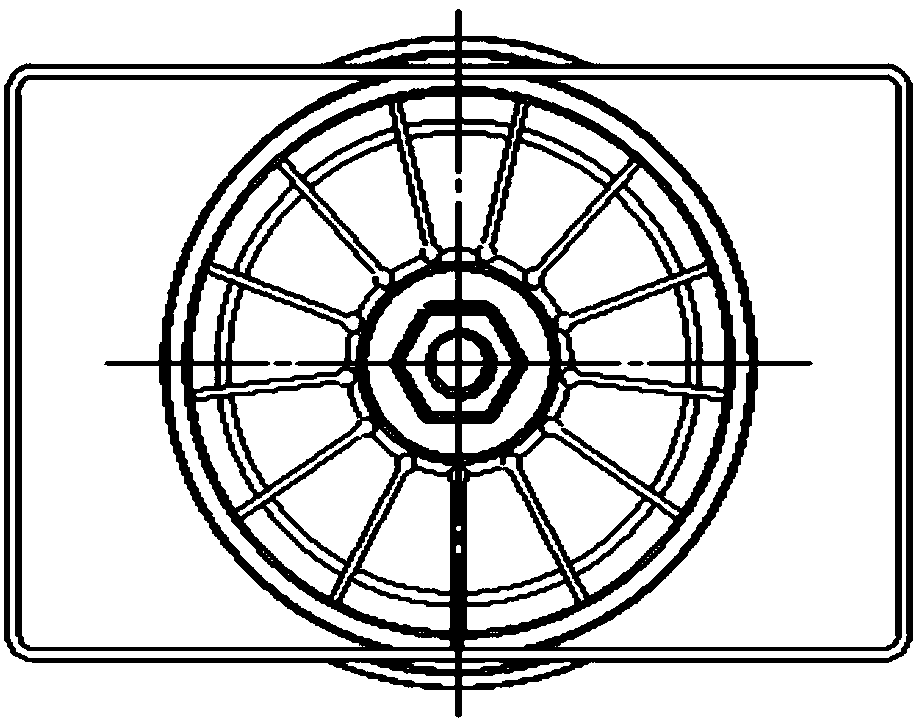

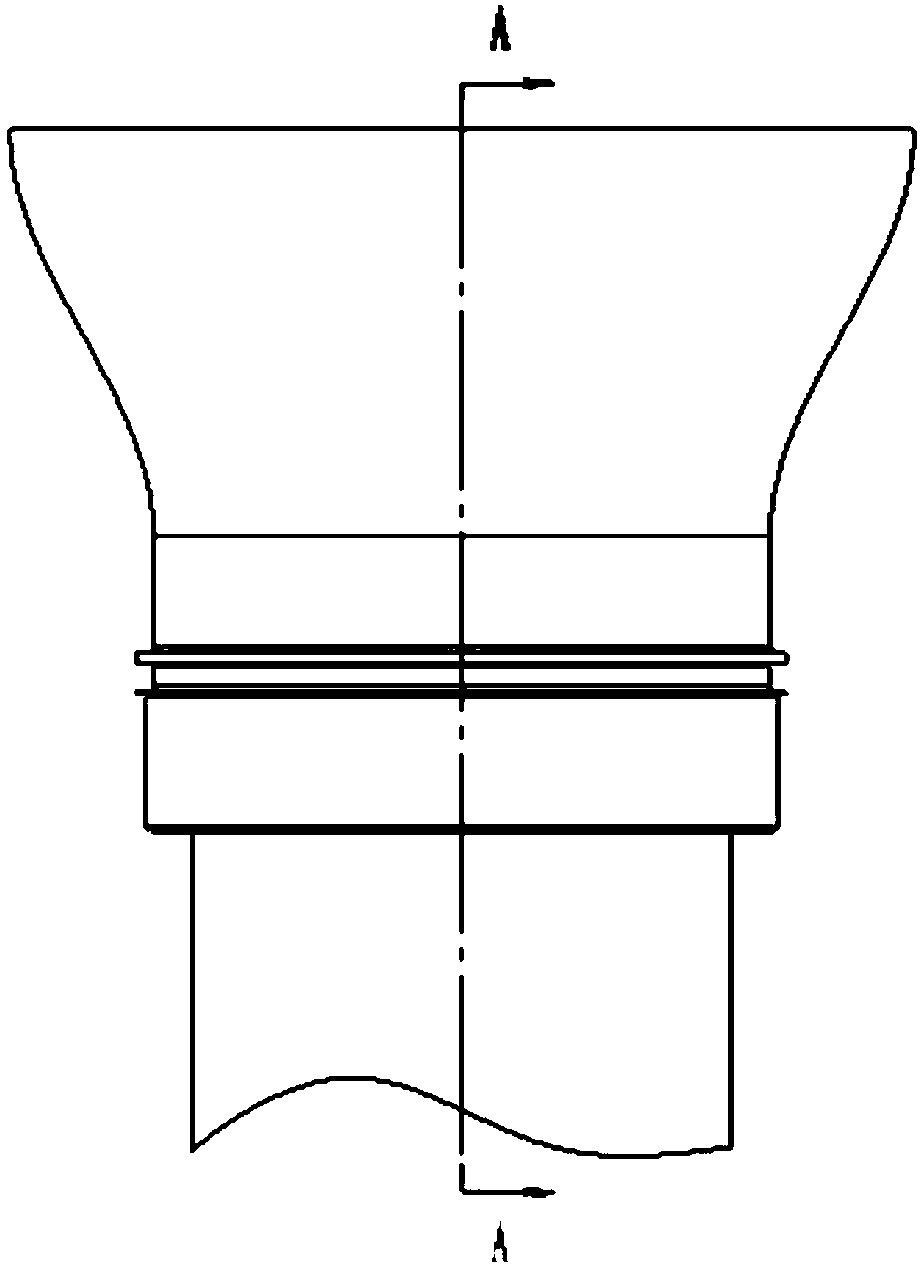

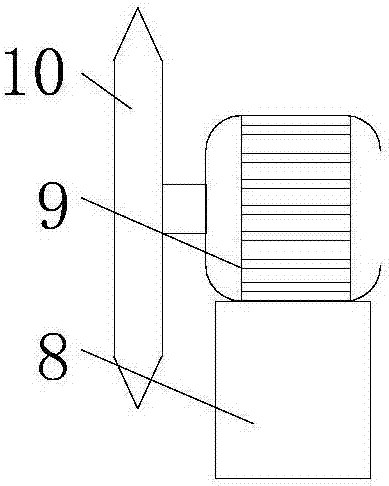

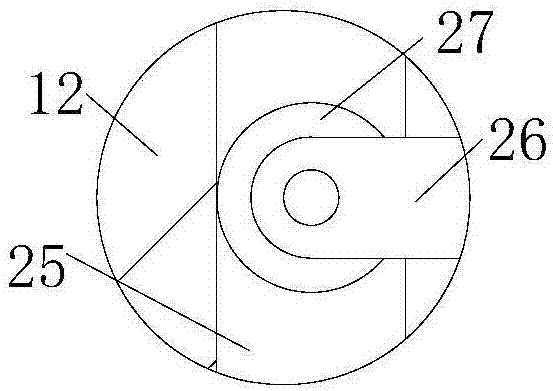

Drilling machining device

ActiveCN107671323AClamp fasteningIncrease the clamping areaPositioning apparatusMetal-working holdersManufacturing technologyFixed frame

The invention discloses a drilling machining device and relates to the technical field of motor part machining and manufacturing. The drilling machining device comprises a worktable. A motor and a thrust air cylinder are arranged on the worktable. A drill bit is arranged on the motor. A driving device is arranged on the thrust air cylinder. The driving device comprises a rotating plate, a base anda supporting frame. The rotating plate is rotationally connected with the base. A groove is formed in the base. The supporting frame and the rotating plate are rotationally connected. The rotating plate is provided with a clamping box, and the clamping box is provided with clamping devices. Each clamping device comprises a fixing frame and a clamping head, wherein the clamping head is provided with a connecting spring, a protrusion, a sliding groove and a pipeline hole, the protrusion is provided with a compression spring, the compression spring is connected with a compression plate, the compression plate is provided with a first air bag which is connected with a connecting pipeline, the connecting pipeline is provided with a second air bag, the second air bag is provided with an air inlet hole, and the air inlet hole is provided with an air inlet stopper. By the adoption of the technical scheme, the problem that an existing drilling device cannot conduct drilling on workpieces with irregular shapes, and the drilling machining device can be used for drilling machining of workpieces with all shapes.

Owner:NANTONG GUANFENG CASTING

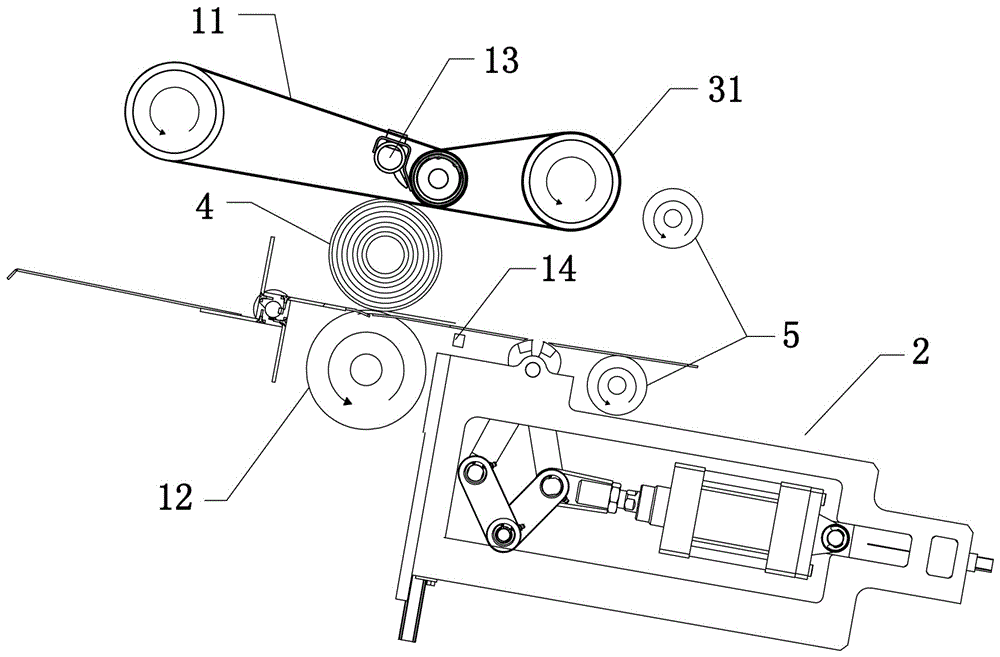

Unilateral pressing coiling block non-glue tail sealing device

The invention discloses a unilateral pressing coiling block non-glue tail sealing device. The unilateral pressing coiling block non-glue tail sealing device comprises a tail sealing mechanism and an extruding device which are vertically opposite; the tail sealing mechanism comprises a fixed clamp mold arranged in the axial direction of a coiling block, a plurality of movable clamp molds arranged in the axial direction of the coiling block, and a plurality of driving units, wherein each driving unit correspondingly drives at least one movable clamp mold; the driving units drive the movable clamp molds to move towards the fixed clamp mold so that the movable clamp molds and the fixed clamp mold can be mutually opened and closed; the extruding device is used for extruding the coiling block toan opening between the fixed clamp mold and the movable clamp molds so that clamp openings of the fixed clamp mold and the movable clamp molds can be embedded into the peripheral face of the coilingblock; and the movable clamp molds are closed towards the fixed clamp mold so that the peripheral face of the coiling block can be extruded to form a press-fitting part.

Owner:FOSHAN NANHAI DECHANGYU PAPER MASCH MFG CO LTD

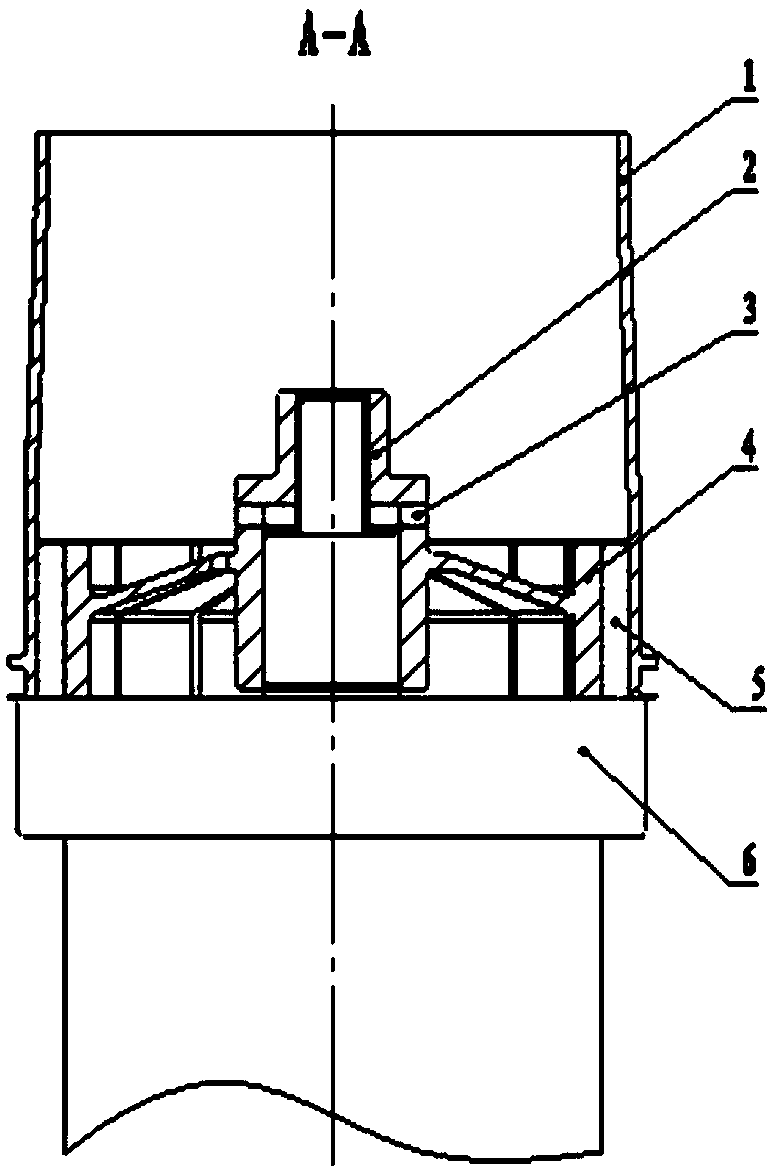

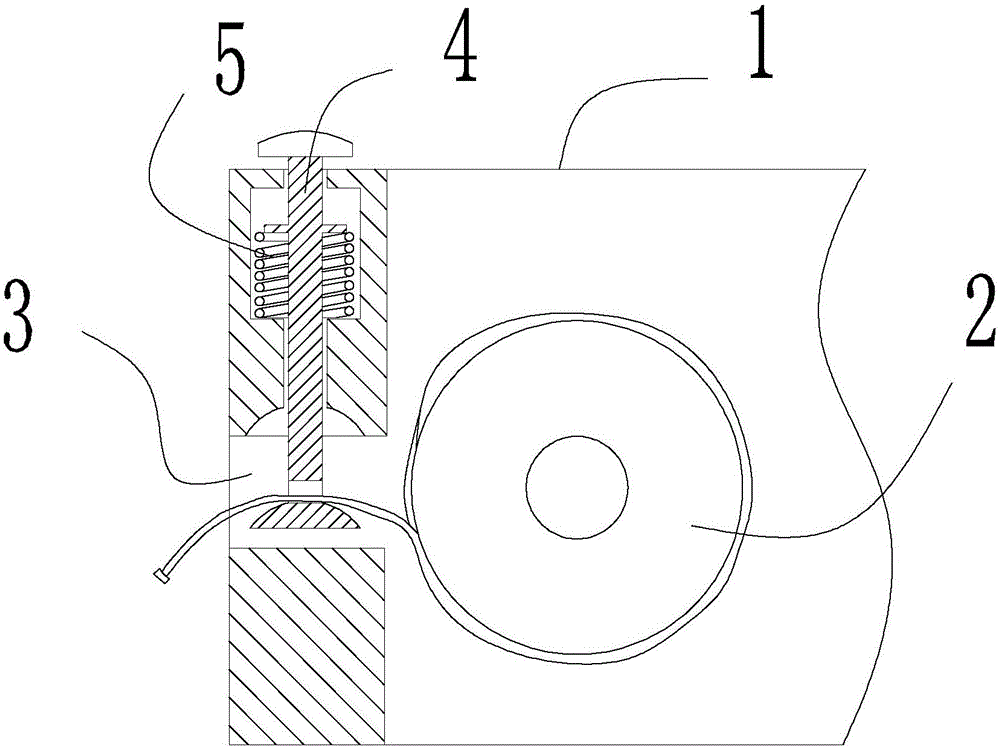

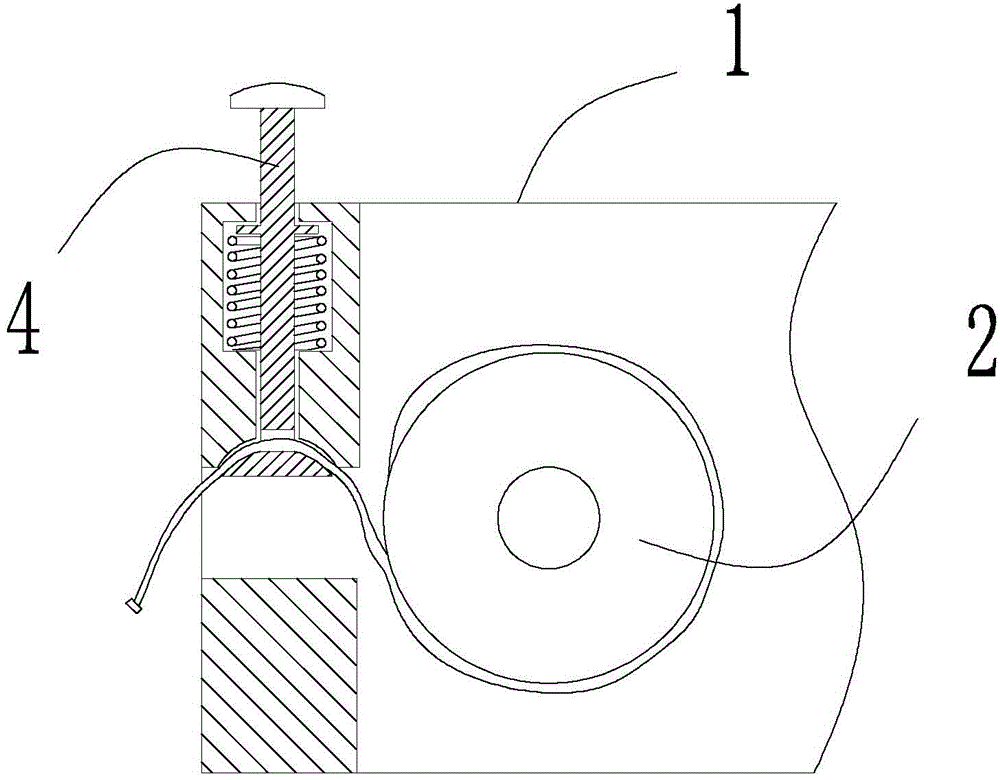

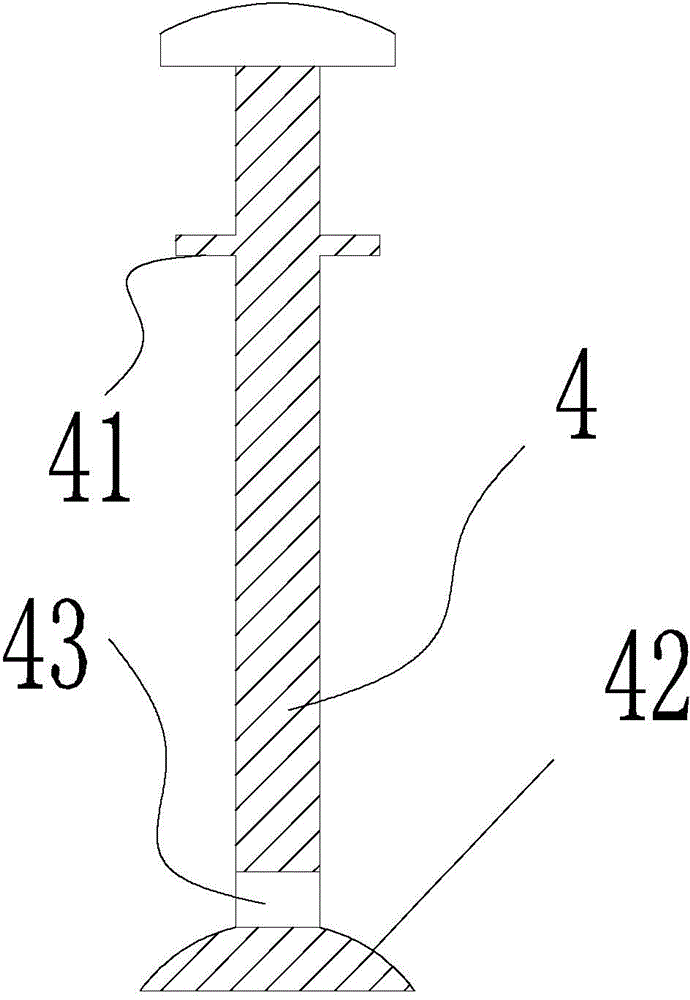

Method and fixture for controlling turning deformation of ultra-thin wall aluminum alloy high-precision nozzle sealing groove

InactiveCN109622990AAvoid clamping deformationReduce vibrationWork clamping meansTurning machinesEngineeringMachining process

The invention discloses a method and fixture for controlling a turning deformation of an ultra-thin wall aluminum alloy high-precision nozzle sealing groove. The fixture comprises an elastic expansionsleeve support body (4) with a continuously variable outer diameter, an opening expansion ring (5) and a fixture body (6); the elastic expansion sleeve support body (4) and the fixture body (6) are detachably connected; and the opening expansion ring (5) is arranged on the outer peripheral surface of the elastic expansion sleeve support body (4); and the fixture body (6) is connected to a machinetool. According to the method and the fixture, the inner hole positioning of the nozzle of a special-shaped sealing groove is utilized, and the evenly distributed clamping force in the circumferential direction when the fixture is positioned and clamped is ensured by relying on a fixture profile and the arc inner surface of the nozzle is fitly close to 360 DEG, so that the clamping deformation and turning deformation of an ultra-thin wall aluminum alloy part are avoided; and meanwhile, the direction of clamping force is symmetrically stressed with a contact point of a tool and a part during the machining process, so that the deformation of the part is effectively controlled.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

Network cable socket

InactiveCN103915734AAvoid being clamped badlyIncrease the clamping areaFlexible lead accommodationEngineeringCavity wall

The invention discloses a network cable socket. The network cable socket comprises a shell fixed to a cavity wall, and a network cable output hole formed in the shell, wherein a rotating shaft is arranged in the shell, a coiling shaft is connected to the rotating shaft through a disk-type spring, a certain length of network cable is coiled on the coiling shaft, the network cable stretches out through the network cable output hole, and a clamping rod for limiting movement of the network cable is installed in the position, of the network cable output hole, of the shell. Under the action of a reset spring, the network cable can be clamped in a cavity along with a chuck when being static, the clamping area is increased, and the network cable can be effectively protected and prevented from being clamped to damage.

Owner:ZHEJIANG OCEAN UNIV

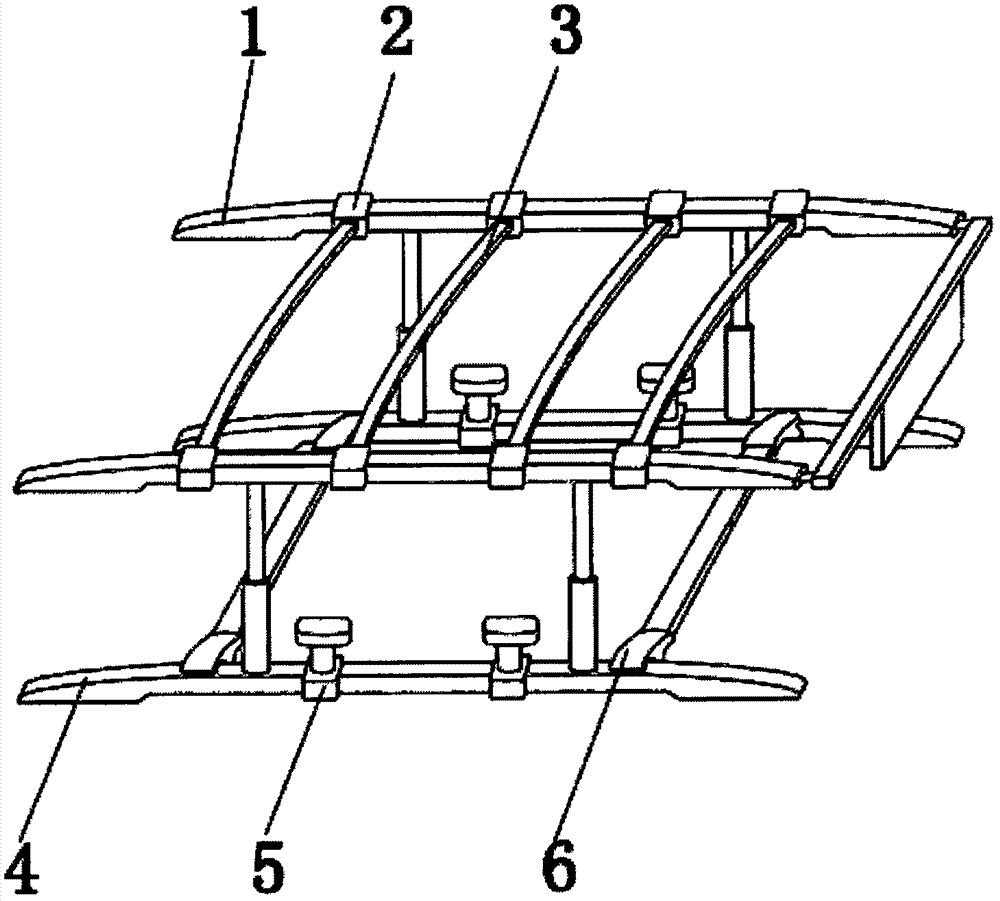

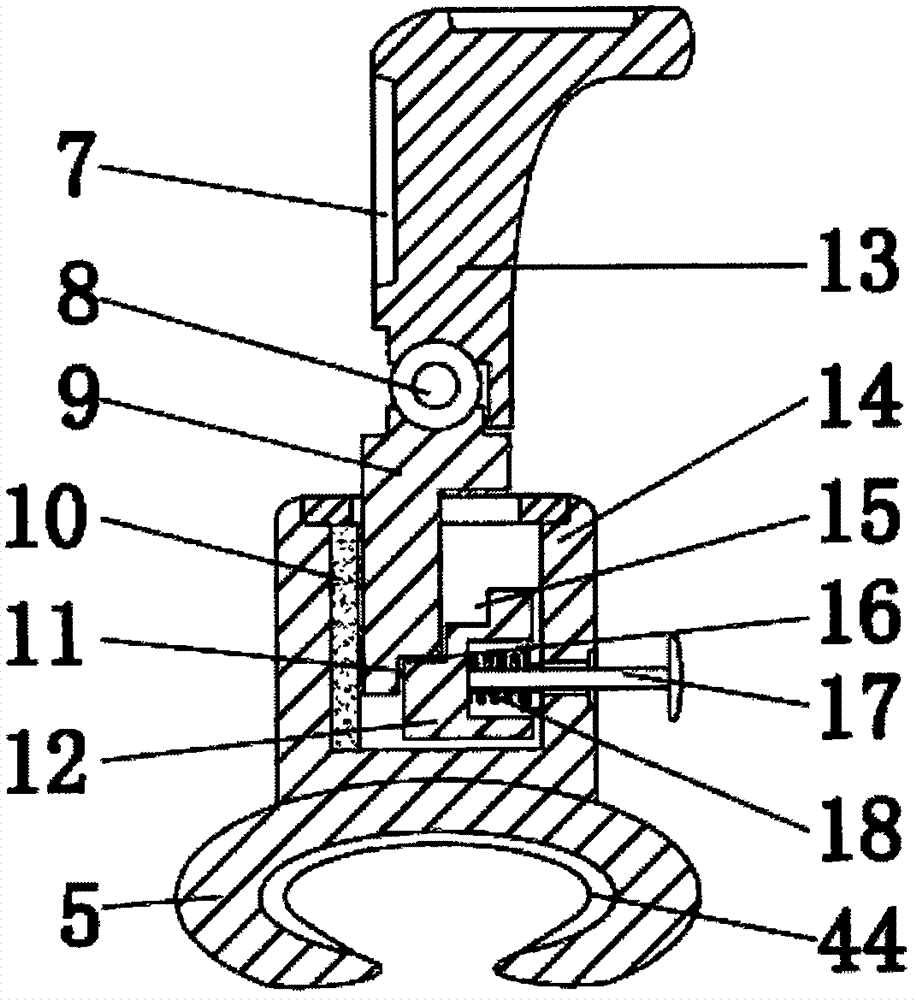

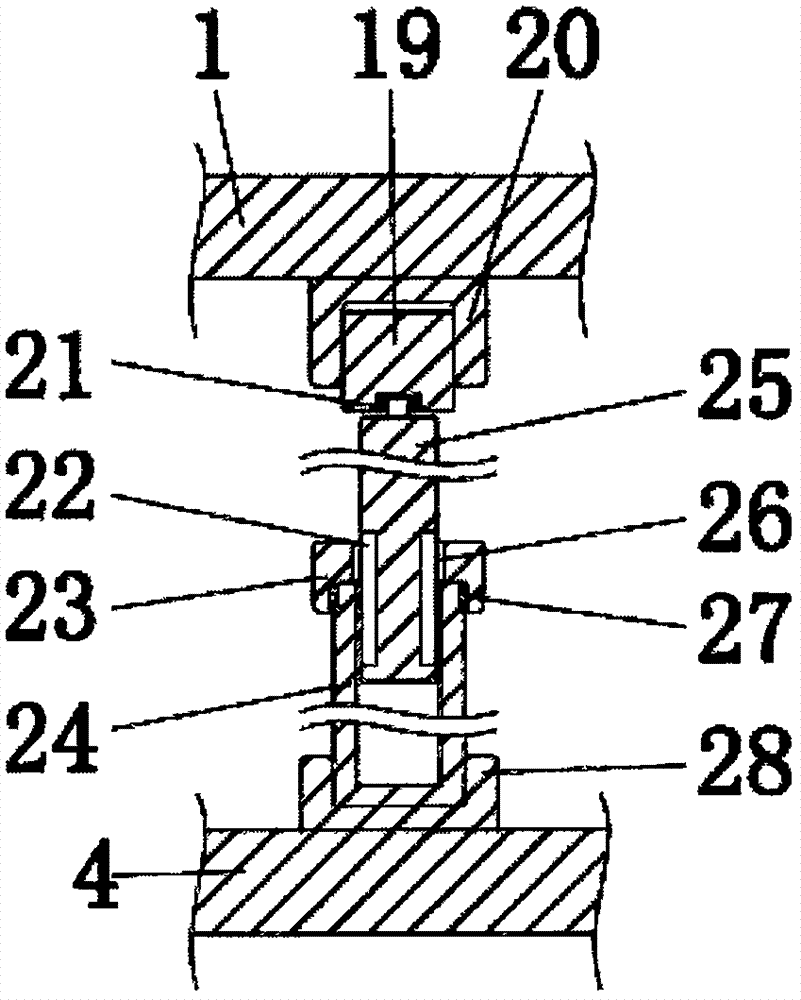

Automobile luggage rack

The invention discloses an automobile luggage rack, comprising bottom frames; cross beams are mounted at the inner sides of the bottom frames, each bottom frame is sleeved with second ferrules, top clamp plates are arranged at the top end of each inner bottom plate, the top end of each bottom barrel is provided with a cap outside, each top barrel penetrates the corresponding cap, and a rubber belt is mounted at the inner side of each first ferrule. Under cooperation of the top frames, the bottom frames and the top clamp plates in the automobile luggage rack, when the top clamp plates are fastened in through moving parts, a case is squeezed and fixed; when a large case is placed, the top clamp plates are fastened up through moving parts, inner gaps are enlarged, clamping area is increased, and enhanced clamping and fixing effects are provided for the bottom end of the case; the top frames are arranged at the front end of the case, first bearings rotate in top seats when top barrels are in rotation, the top barrels pull the top frames to move down to press and fix the case when the top barrels are rotated at reduced speed, enhanced fixing effect is provided for the case; therefore, the service effect is good.

Owner:张志通

Special fixture for turning of thin cylindrical parts and operation method thereof

InactiveCN108480672AEliminate clamping deformationIncrease the clamping areaExpansion mandrelsCircular discEngineering

The invention relates to a special fixture for turning of thin cylindrical parts and an operation method thereof. The special fixture for turning of the thin cylindrical parts is characterized by comprising a mandrel clamped onto a three-jaw fixture and expandable supporting disks fixedly arranged at the two ends of the mandrel in a sleeving mode; each supporting disk comprises an inner disk arranged at the stepped shaft end of the mandrel in a sleeving mode and an annular drag plate arranged on the periphery of the inner disk in a sleeving mode; the peripheral surface of each annular drag plate is provided with an annular groove, and a steel ring abutting against the inner wall surface of a workpiece is arranged in each annular groove in a sleeving mode; the inner peripheral surface of each inner disk is provided with a plurality of countersink groove; cuphead pins are embedded in the countersink grooves; the sidewall surface of each inner disk is provided with screw holes communicating with the corresponding countersink grooves; fastening screws are arranged in the screw holes; the ends of the fastening screws abut against the inner ends of the cuphead pins, and the outer ends ofthe cuphead pins abut against the inner peripheral wall of the corresponding annular drag plates.

Owner:FUZHOU UNIV

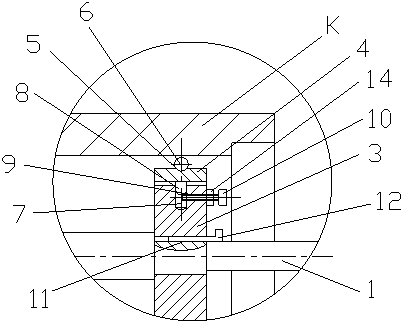

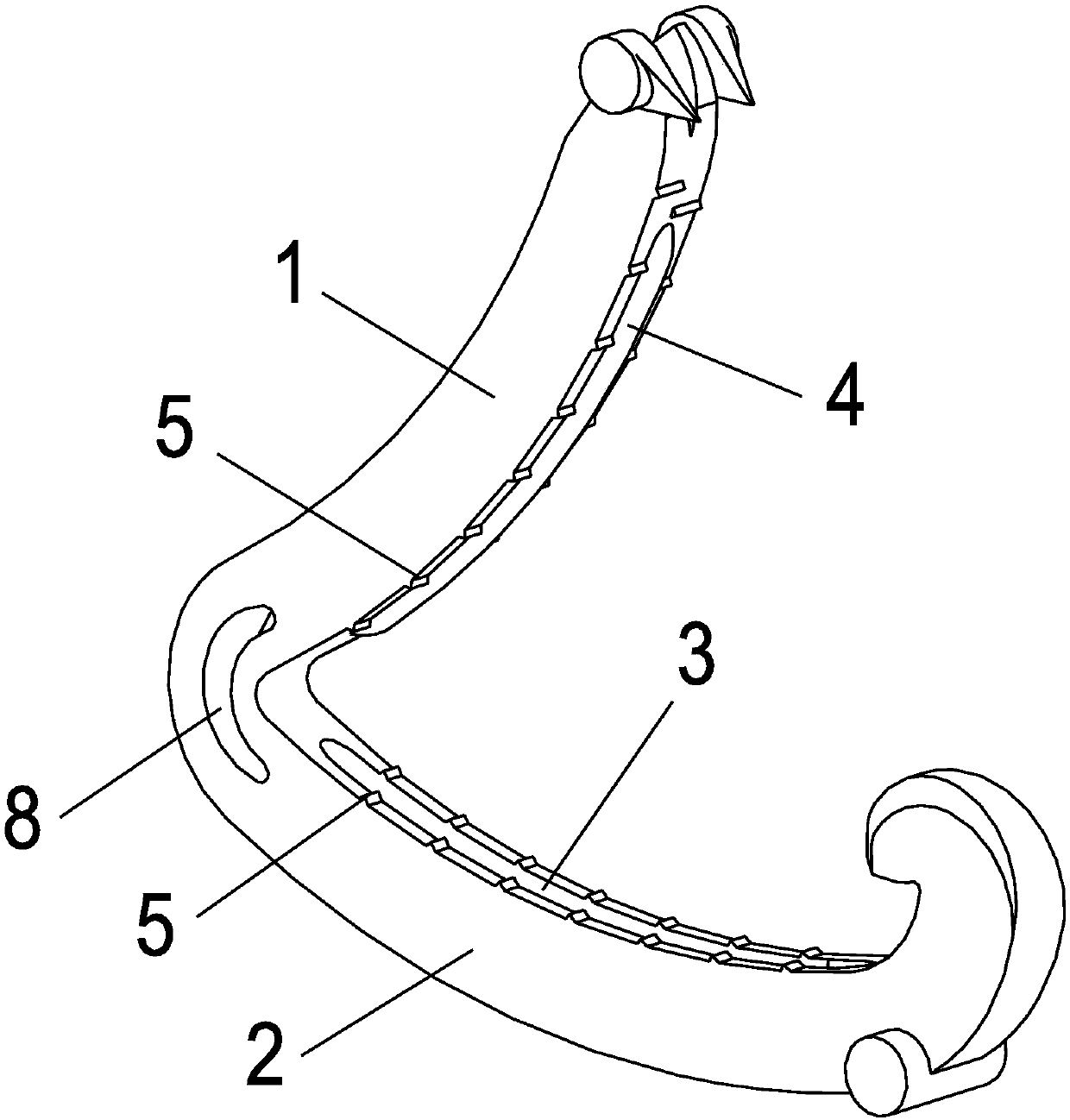

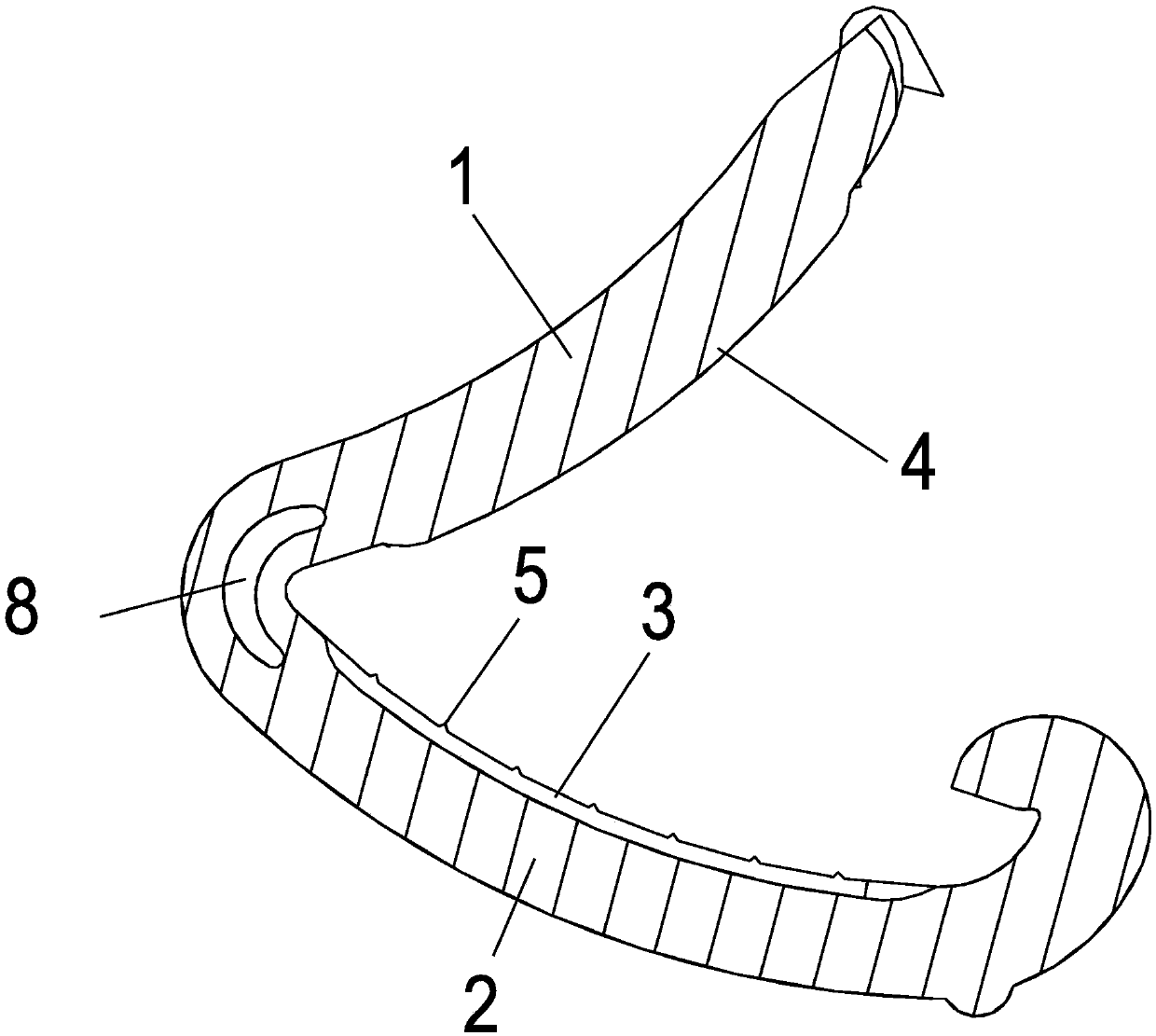

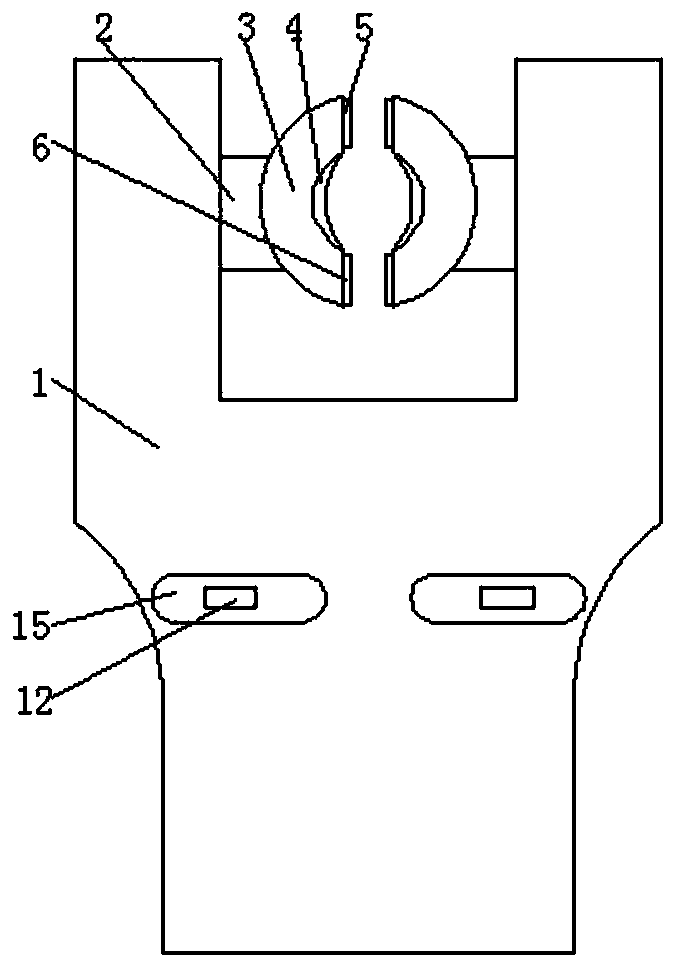

Separating-preventing ligating clip

PendingCN107714129APrevent lateral slippageIncrease the clamping areaWound clampsPhysical medicine and rehabilitationLigation clip

The invention relates a separating-preventing ligating clip. The separating-preventing ligating clip comprises an upper clip arm and a lower clip arm, wherein the tail ends of the upper clip arm and the lower clip arm are fixedly connected, and the front ends of the upper clip arm and the lower clip arm are fixed through a locking structure; for the upper clip arm and the lower clip arm, one clamping face is provided with an anti-skid elongated slot extending along the length direction of the clip arms, the other clamping face is provided with an anti-skid bulge extending along the length direction of the clip arm, and the anti-skid elongated slot and the anti-skid bulge are arranged in a corresponding manner. The invention aims at providing the separating-preventing ligating clip which can prevent the tissue from separating horizontally and is firm and reliable in ligating. The separating-preventing ligating clip has the advantages that the clamping faces of the upper clip arm and thelower clip arm are provided with the anti-skid elongated slot and the anti-skid bulge which are matched with each other, when the upper clip arm and the lower clip arm are in clamping, the anti-skidelongated slot and the anti-skid bulge are buckled, thus the clamping area is increased, meanwhile, the clamped issue is positioned on different faces, so that the horizontal sliding of the blood vessel can be prevented.

Owner:SURGAID MEDICAL XIAMEN CO LTD

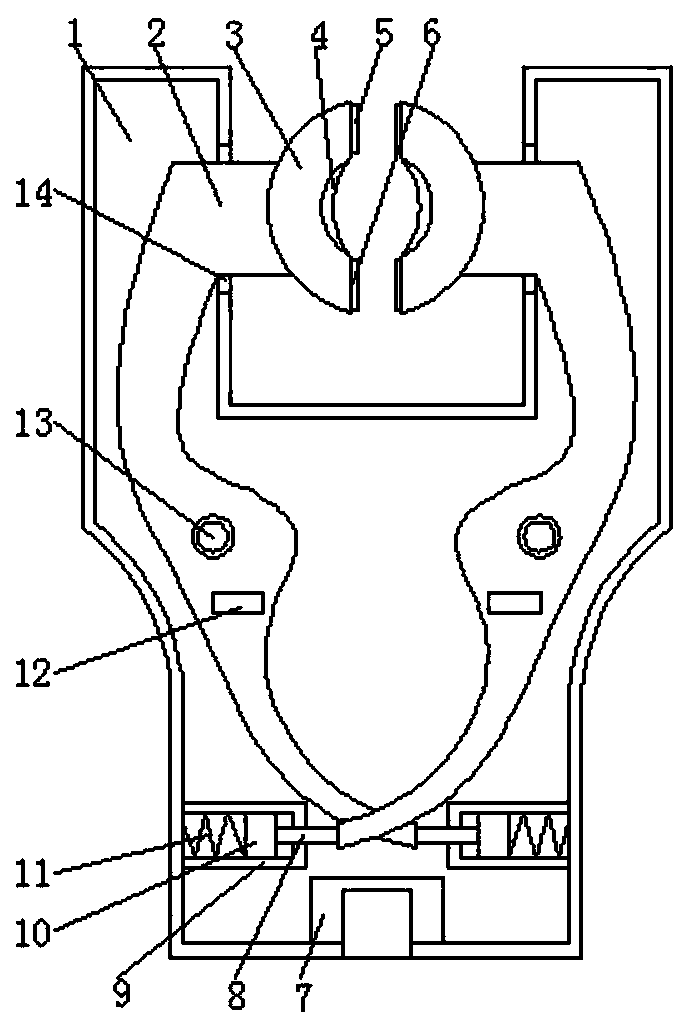

Dialysis tube fixing device for nephrology department

InactiveCN111588933AIncrease the clamping areaAvoid entangled situationsDialysis systemsCatheterApparatus instrumentsMedical treatment

The invention provides a dialysis tube fixing device for the nephrology department, and relates to the technical field of medical instruments for the nephrology department. The dialysis tube fixing device for the nephrology department comprises a Y-shaped shell, wherein a side opening is formed in the position, located on the inner side, of the upper end of the Y-shaped shell; a fixing column is fixedly connected to the inner surface of the Y-shaped shell; a special-shaped plate is fixedly connected to the outer surface of the fixing column; and a chuck is fixedly connected to the end, penetrating through the side opening outwards, of the upper end of the special-shaped plate; a silica gel pad is fixedly connected to the inner side of the chuck; and an upper magnet is arranged on the side,away from the special-shaped plate, of the chuck and located on the upper portion of the silica gel pad. The dialysis tube is fixed through elastic force of a spring, attraction force of the magnet and negative pressure generated by the dialysis tube, the contact area is relatively large, the chuck of the device can be separated through an adjusting handle or similar tools, the situation that thedevice is opened by mistake through external force can be effectively prevented, a relatively wide installation range is provided, and the health workers is convenient to use.

Owner:袁玉飞

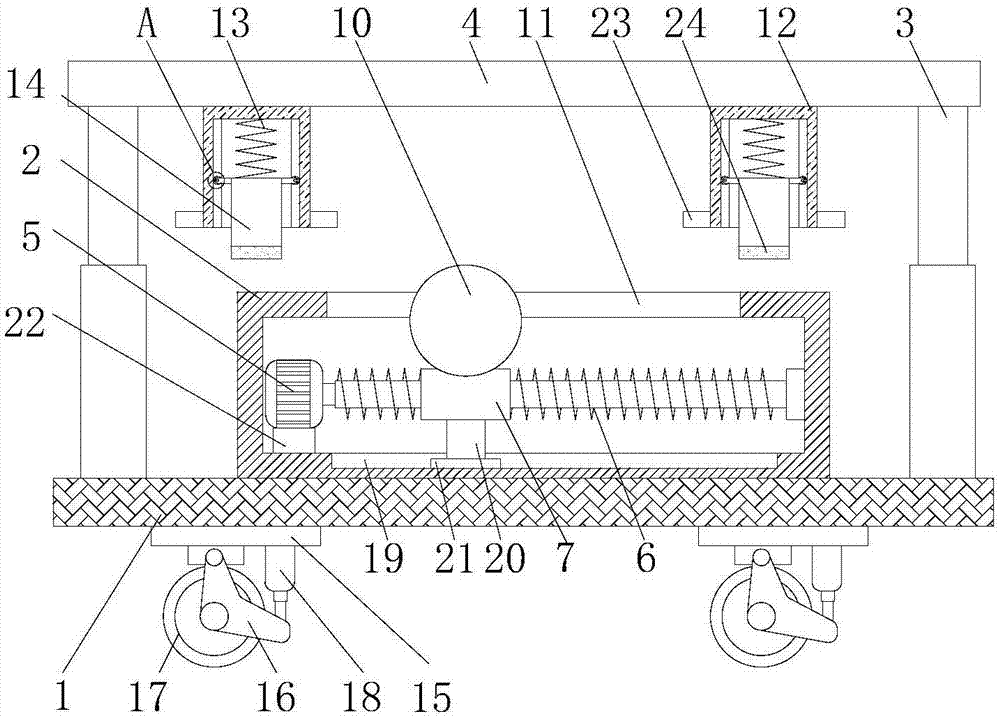

Fish scale removing device

ActiveCN104542883AImprove processing productivityReduce labor intensityFish washing/descalingEngineeringAssembly line

The invention discloses a fish scale removing device and belongs to the technical field of fish product processing. The device comprises a rack, a chain conveyer, an input conveyer, a scale removing assembly and a power mechanism, wherein the chain conveyer comprises a driving chain wheel, a driven chain wheel, an annular chain and clamping mechanisms, each clamping mechanism comprises a fish clamping bottom board and a cutting board which are movably connected, short rods are arranged on the fish clamping bottom boards, the scale removing assembly comprises at least one pair of scale removing roller brushes and a shield, the input conveyer comprises a driving roller, a driven roller and an input conveying belt, inlet and outlet guide rods are arranged at an inlet and an outlet of the rack respectively, the short rods correspondingly extend out of upper parts of the inlet guide rods and extend into lower parts of the outlet guide rods, and pressing boards are also arranged on the rack. The device can remove scales continuously, realizes assembly line processing, is particularly applicable to types of fishes with flat fish bodies, and is high in scale removing efficiency and good in scale removing effect.

Owner:PENGLAI JINGLU FISHERY

Cutting device for plastic processing

InactiveCN107877562AHeight adjustableEasy to moveMetal working apparatusArchitectural engineeringEngineering

The invention discloses a cutting device for plastic processing, comprising a base, the top of the base is fixedly connected with a box body, both sides of the top of the base are fixedly connected with a first electric lift-and-retract rod, and the first electric lift-and-retract rod The top of the box is fixedly connected with a horizontal plate, the inner cavity of the box body is provided with a first motor, the output end of the first motor is fixedly connected with a threaded rod, and the right end of the threaded rod is movably connected with the right side of the box inner cavity through a bearing. In the present invention, the height of the cutting device can be adjusted by opening the box body to lift, and the cutting object can be clamped through the cooperation of the casing, the spring and the fixing plate, which is convenient for cutting the cutting object. Through the first motor, The cooperative use of the threaded rod, the threaded sleeve and the support plate can move the second motor and the cutting blade, so the cutting object can be cut automatically, and the cutting device can be moved conveniently through the setting of the support plate and the bracket.

Owner:叶青

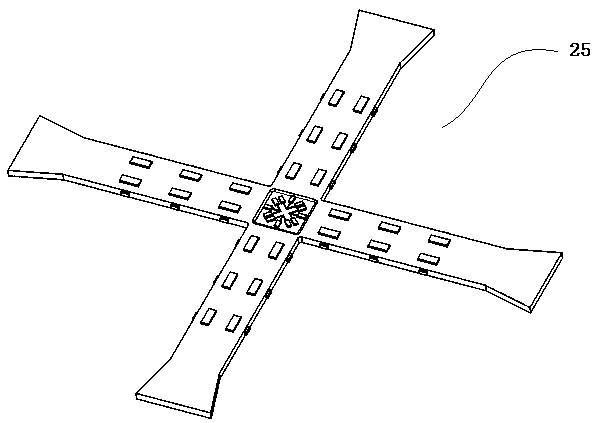

Milling cutter clamping device

InactiveCN108515373AQuick clampingRealize automatic clampingPositioning apparatusMaintainance and safety accessoriesMechanical engineeringEngineering

The invention belongs to the technical field of clamping equipment, and particularly discloses a milling cutter clamping device. The milling cutter clamping device comprises a clamping head and a cutting head, a crossed-shaped mounting groove is formed in the lower part of the clamping head, and the mounting head comprises a transverse groove and a vertical groove. Sleeves which are rotatably connected with the transverse groove are arranged at the positions, on both sides of the vertical groove, of the transverse groove, threads are arranged on the outer sides of the sleeves, and convex teethare arranged on the inner walls of the sleeves in the circumferential direction. Ratchets are hinged to the positions, on the inner sides of the sleeves, of the transverse groove, and the ratchets abut against the convex teeth. The cutting head is provided with threads which are matched with the threads on the outer sides of the sleeves. The milling cutter clamping device is mainly used for clamping the cutter head of a milling machine, and solves the problem that the machining efficiency of parts is reduced due to the low speed of changing the milling cutter.

Owner:重庆市耀植机械有限责任公司

Fixing device for sofa cushion and bed sheet

PendingCN110074591AAvoid insufficient clamping forceReduce occupancySofasCouchesEngineeringMechanical engineering

The invention discloses a fixing device for a sofa cushion and a bed sheet. The fixing device comprises a hinge, wherein at least two assembly grooves are formed in the hinge; a fixing pin is arrangedin each of the assembly grooves; the hinge comprises a first clamping plate, a second clamping plate and a rotating shaft part; the rotating part is respectively connected with the tail end of the first clamping plate and the tail end of the second clamping plate; the first clamping plate and the second clamping plate are in opposite arrangement, and are used for enabling the sofa cushion and thebed sheet to be in contact with the first clamping plate and the second clamping plate. A flat belt is arranged on the rotating shaft part of the hinge; the tail end of the flat belt is provided witha fixing pad, and is used for enabling the fixing pad to abut against the bottom of a sofa seat or a bed mattress, so that the problems that the sofa cushion and the bed sheet can easily move, and aconventional sofa / bed sheet fixing device can easily damage the sofa seat or the bed mattress are expected to be solved.

Owner:方涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com