Unilateral pressing coiling block non-glue tail sealing device

A technology of extrusion device and reel, which is applied in the direction of winding strips, transportation and packaging, and thin material processing, etc., which can solve the problems of fewer lamination layers, unfavorable sealing stability, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

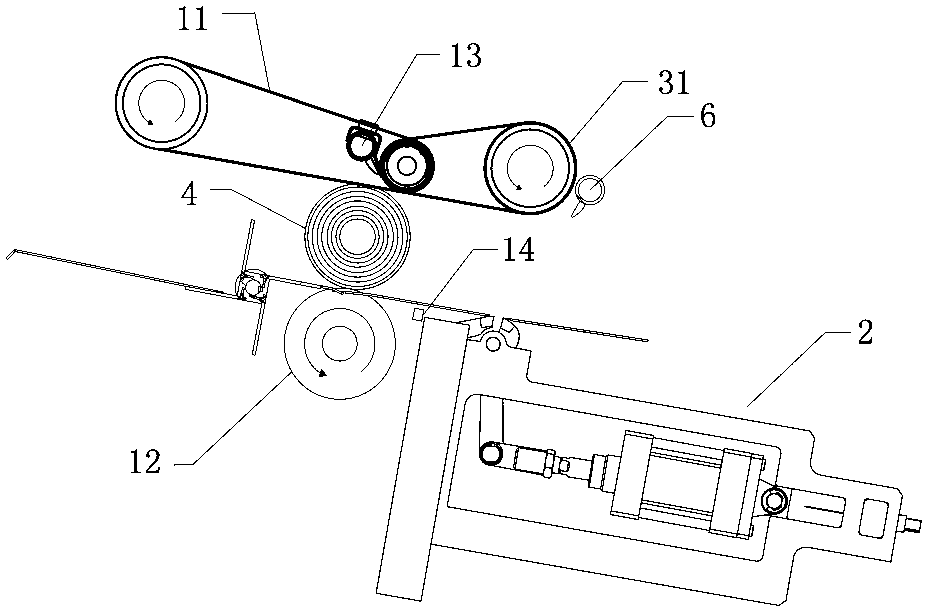

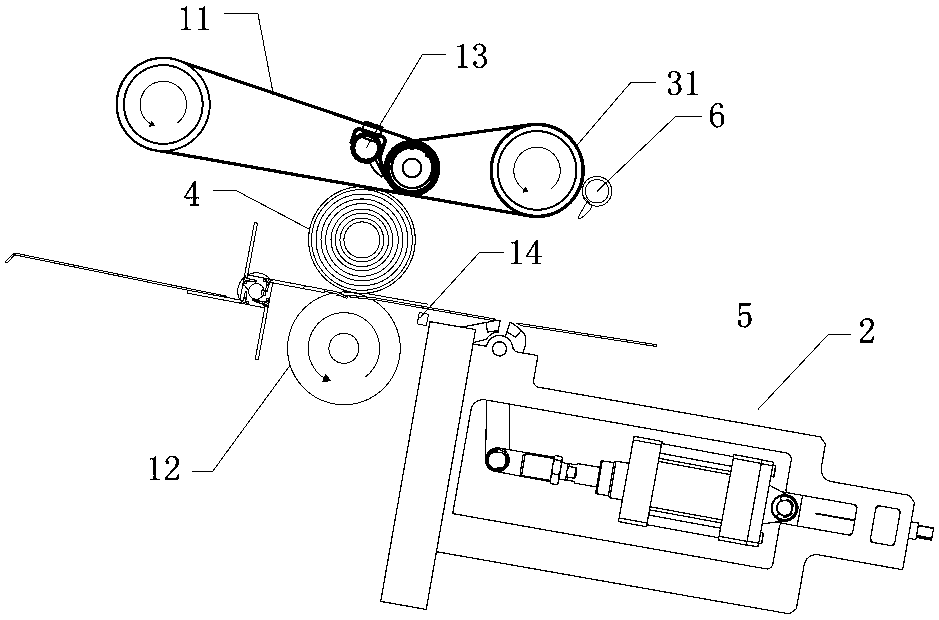

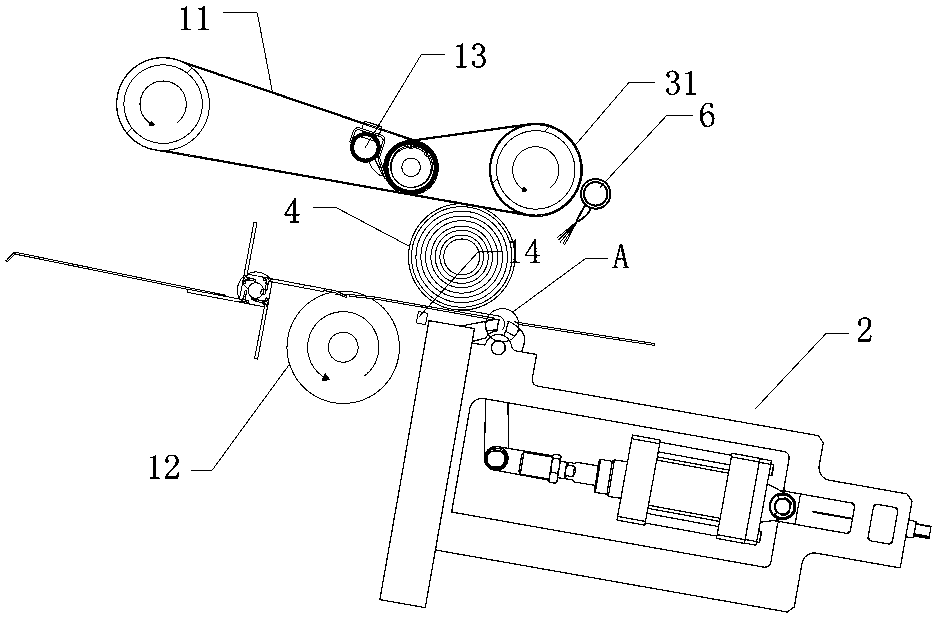

[0037] See attached figure 1 As shown, the unilaterally pressed reel glueless tail-sealing device in this embodiment includes a tail-seeking mechanism for finding the tail end of the reel 4, a tail-sealing mechanism 2 located downstream of the tail-finding mechanism, and a tail-sealing mechanism. The upper and lower pressing devices of the mechanism 2, the finishing mechanism and the air blowing unit 6 located downstream of the sealing mechanism 2.

[0038] In this embodiment, the tail-seeking mechanism includes a conveying belt 11, a roller 12, an air blowing pipe 13 and a detection head 14, wherein the conveying belt 11 and the roller 12 are relatively up and down and rotate in the same direction, so that a gap between the conveying belt 11 and the roller 12 A reel autorotation station is formed to make the reel 4 rotate in situ. Specifically, since the conveying belt 11 and the roller 12 rotate in the same direction with a very small speed difference, the linear speed of th...

Embodiment 2

[0053] see Figure 16 with Figure 17 As shown, the difference between the unilaterally pressed reel 4 glueless tail sealing device of this embodiment and the first embodiment is that the fixed clamping die 21a of this embodiment includes a plurality of small fixed clamps arranged in the axial direction of the reel 4 Clamping die 21a unit. The tail sealing mechanism 2 includes a fixed clamping die 21 a arranged axially along the drum 4 , a plurality of movable clamping dies 21 b arranged axially along the drum 4 , a plurality of drive units 23 , and multiple sets of clamps arranged axially along the drum 4 . Arm assembly, wherein, each group of clamping arm assemblies comprises frame 22, mutually hinged movable clamping arm 24b and fixed clamping arm 24a, small fixed clamping die 21a unit and movable clamping die 21b are arranged on fixed clamping arm 24a and movable clamping respectively The head of the arm 24b; the movable clamp arm 24b and the fixed clamp arm 24a are hing...

Embodiment 3

[0055] see Figure 18 As shown, the difference between the unilaterally pressed reel 4 glueless tail sealing device in this embodiment and the first embodiment is that the fixed clamping die 21a and the moving clamping die 21b in this embodiment are arranged oppositely, wherein the fixed clamping die 21a and the moving clamping die 21b The clamping mold 21a can be fixed on the support beam, and the driving unit 23 is connected to one side to push the movable clamping mold 21b. The driving unit 23 expands and contracts to drive the movable clamping mold 21b and the fixed clamping mold 21a to move unilaterally to realize the movable clamping mold 21b opens and closes with fixed clamping mold 21a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com