OLED (organic light-emitting diode) coating machine with dual-rotation mechanism

A dual-rotor, coater technology used in the manufacture of OLEDs with larger dimensions. It can solve the problems that the coating uniformity of the sample substrate fails to meet the device requirements, is not suitable for OLED coating, and the thickness of the evaporated layer is uneven, and achieves the effect of improving the probability, increasing kinetic energy and improving the pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

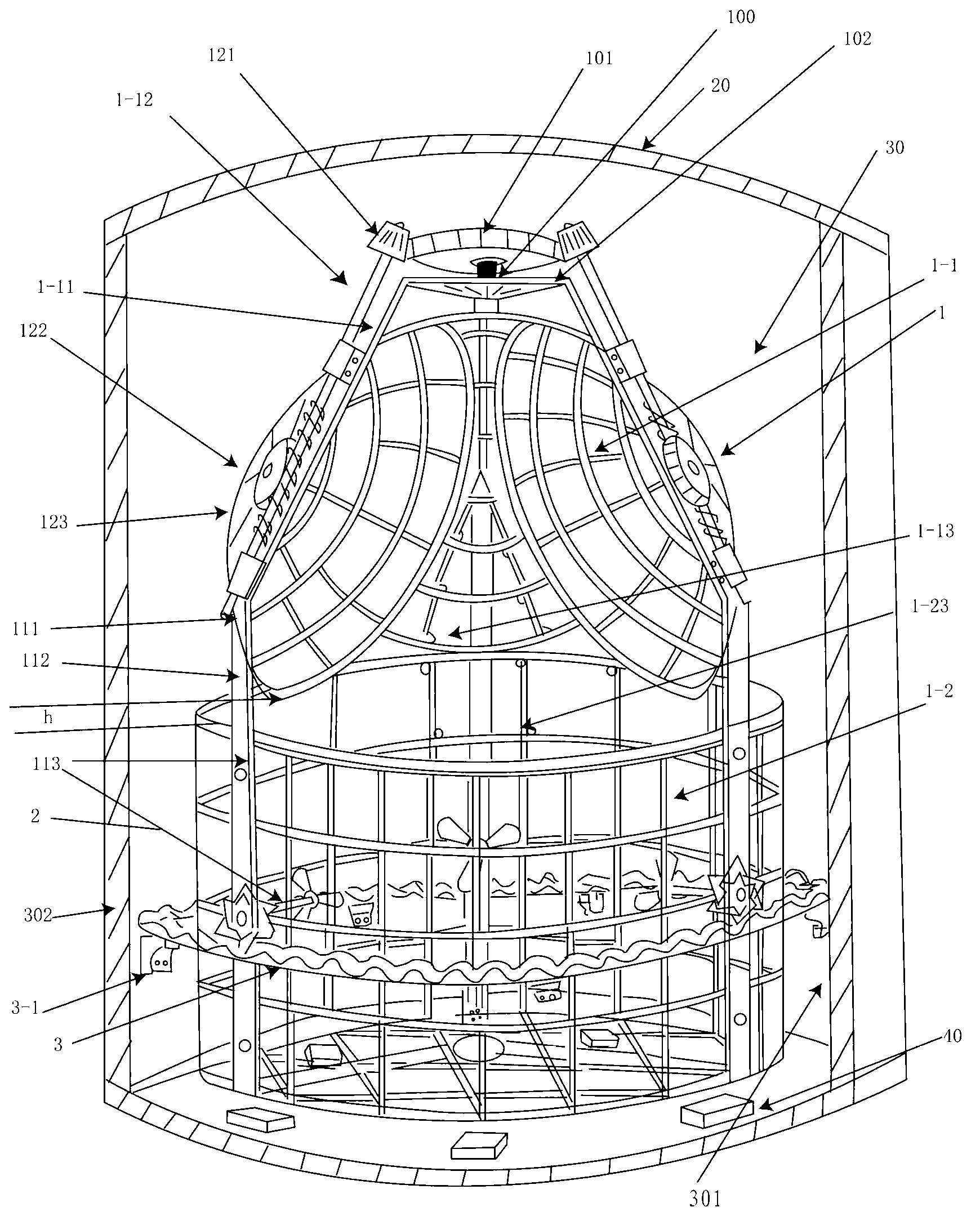

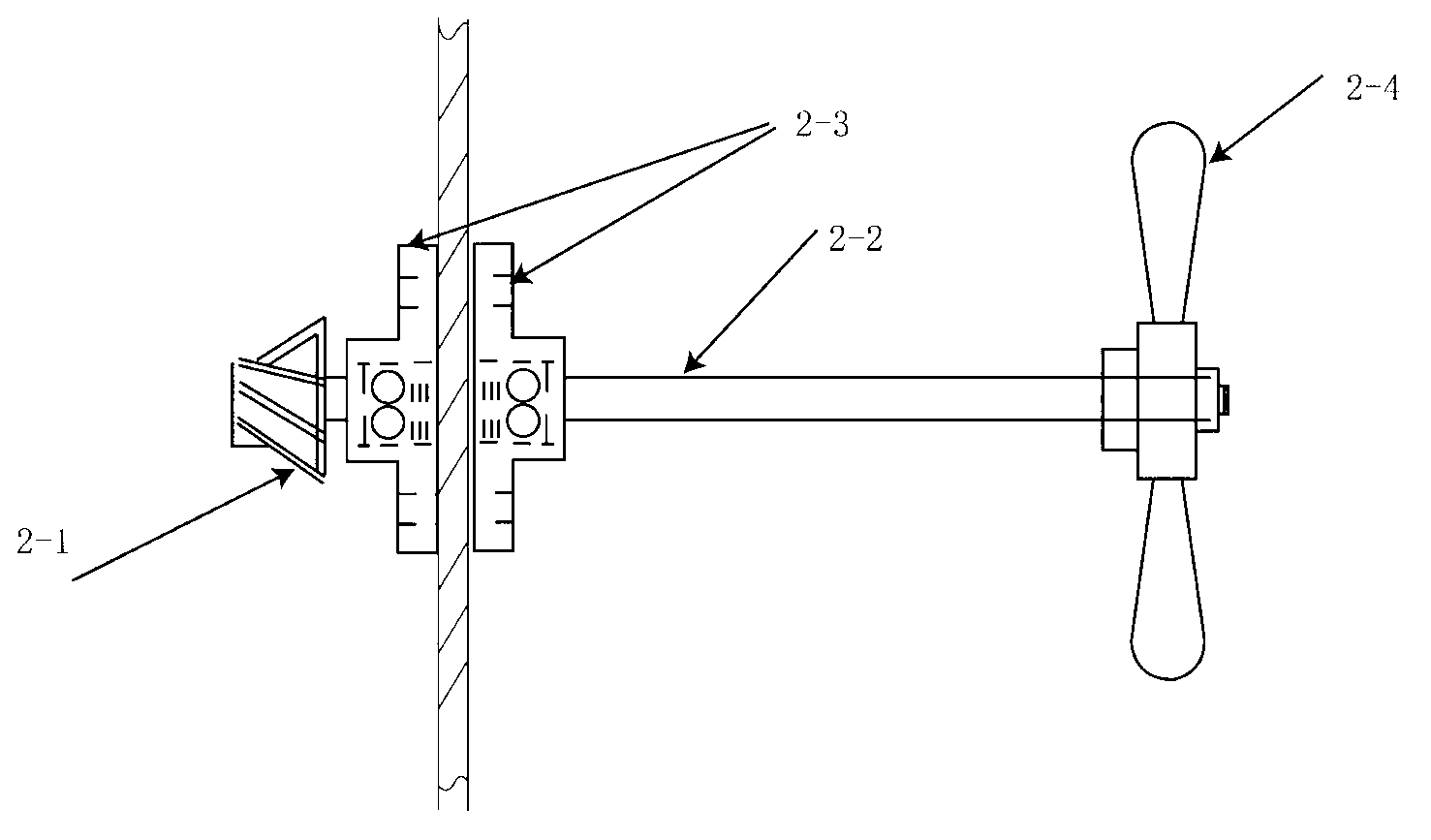

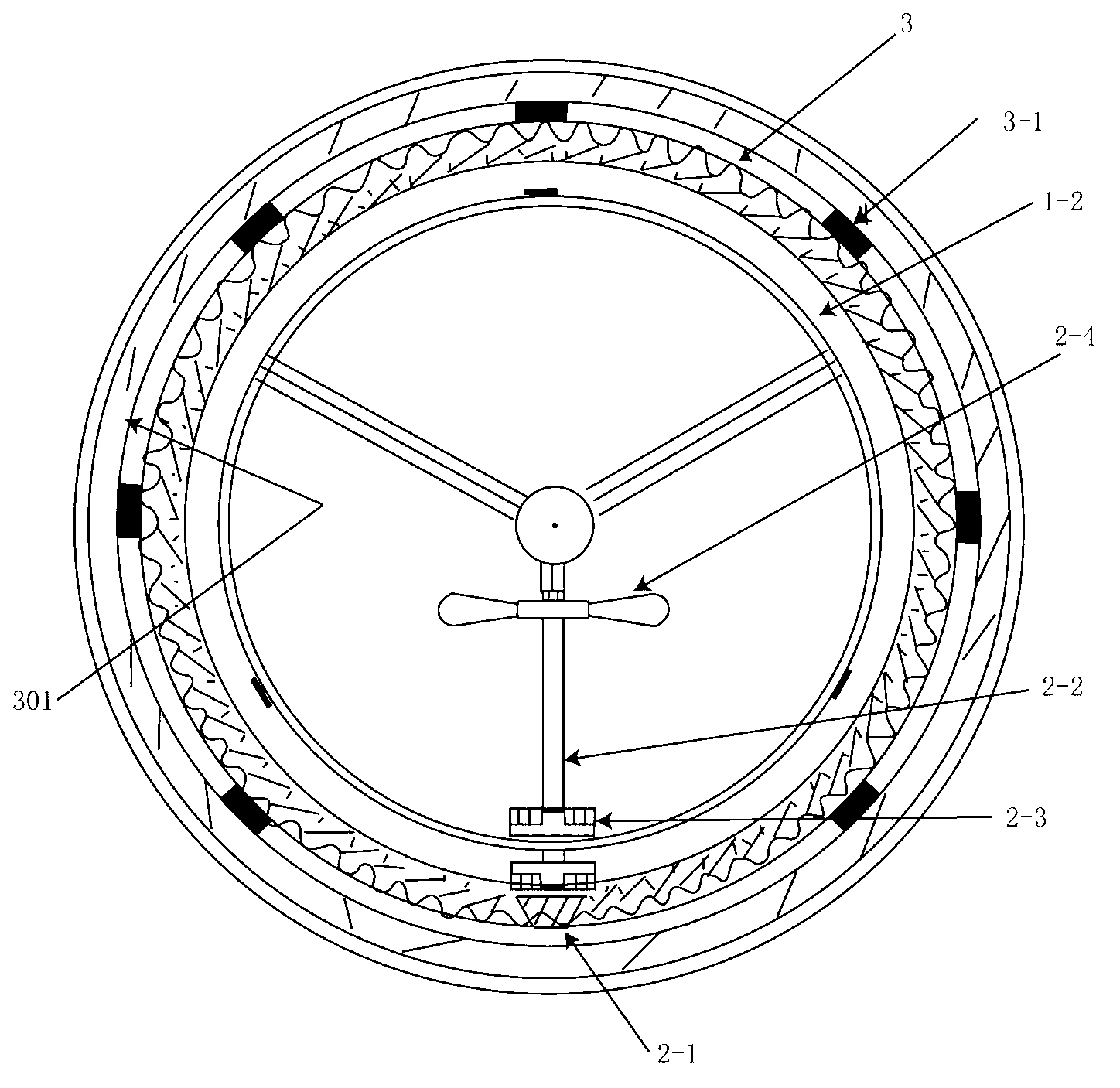

[0022] figure 1 It is a schematic diagram of the arrangement of the double rotary mechanism 1 in the vacuum chamber according to the present invention. This embodiment adopts an OLED coating machine composed of a double rotating mechanism 1 . This OLED coating machine includes a frame, a vacuum chamber 30 and a double rotating mechanism 1 configured inside the vacuum chamber 30, a plurality of molybdenum boats 40 and a power system for driving the double rotating mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com