Intelligent spinning system with full-automatic yarn feeding and tube replacing functions

A fully automatic, textile technology, applied in the direction of thin material handling, conveying filamentous materials, transportation and packaging, etc., can solve the problems of low efficiency of changing cans, and achieve the effect of high degree of automation, labor saving and process saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

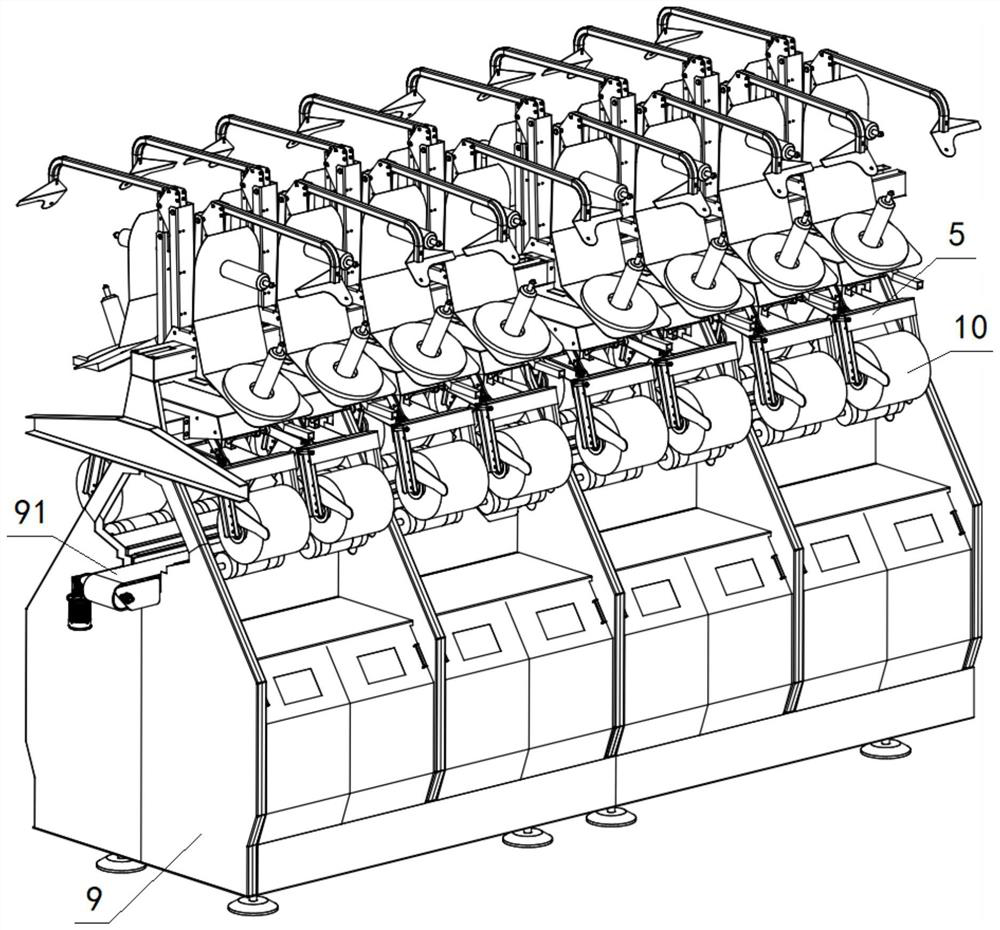

[0088] An intelligent textile system for fully automatic lowering and changing bobbins, comprising a plurality of textile twisting machines 9, the plurality of textile twisting machines 9 are arranged in sequence in the transverse direction, and the textile twisting machines 9 are provided with a winding bobbin clamp 5 to clamp Holding the empty bobbin 1 or the finished yarn spool 10, the intelligent textile system for the automatic lowering and changing of the bobbin further includes an AGV trolley 7, and the movement path of the AGV trolley 7 is arranged with a plurality of the textile twisters 9 The paths are set correspondingly. The top of the AGV trolley 7 is provided with a tube changing device and an automatic yarn bobbin discharging device. The empty yarn bobbin 1 is stored in the yarn bobbin automatic discharging device; The discharge port 21 on the top is butt-fitted, and the pipe changing device is butt-fitted with the winding bobbin clamp 5; each of the top front an...

Embodiment 2

[0090] Example 2 is basically the same as Example 1, except that:

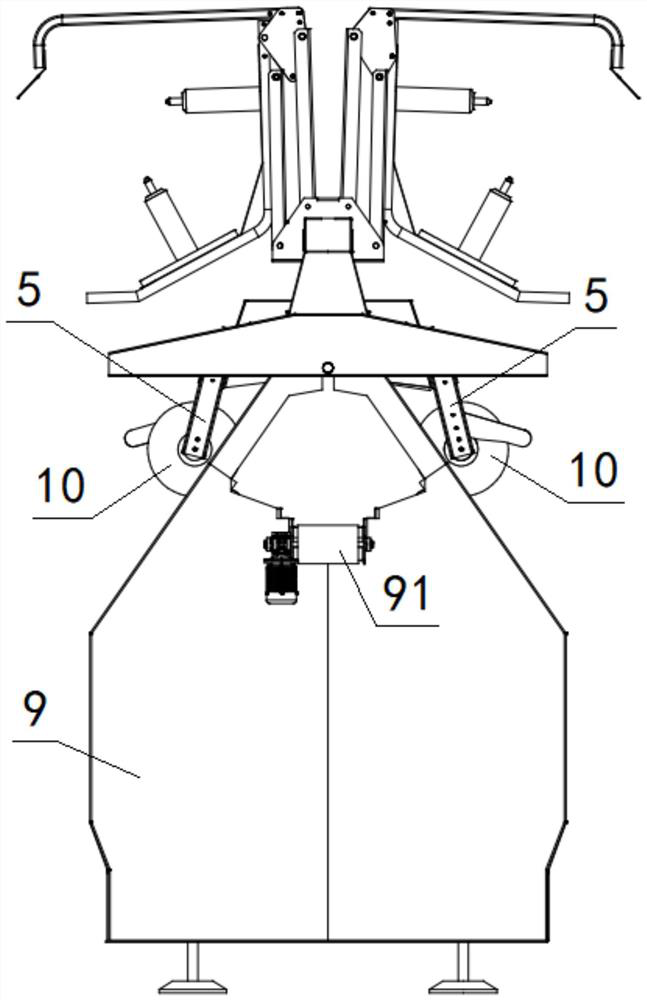

[0091] The winding creel clip 5 includes a top clamping beam 51, a movable side arm 52 and a fixed side arm 53. One end of the top clamping beam 51 is hinged to the top of the movable side arm 52, and the other end of the top clamping beam 51 is connected to the fixed side arm. The top end of 53 is fixedly connected, and the bottom ends of the movable side arm 52 and the fixed side arm 53 are respectively provided with a movable insert plate 55 and a fixed insert plate 56. The inner ends are connected, and the outer end of the inclined handle 54 extends in the direction away from the movable side arm 52; the yarn lowering device 6 includes an outer gripper 61, a yarn lowering base plate 62, an electric push rod 63 and a concave push plate 64, so The outer gripper 61 is clamped and matched with the outer end of the inclined handle 54, the outer gripper 61 is connected with one end of the yarn lowering base plat...

Embodiment 3

[0093] Example 3 is basically the same as Example 2, except that:

[0094]The yarn bobbin automatic discharging device includes a feeding box 2 and a storage box 3 , one side of the feeding box 2 is provided with a discharge port 21 , and the other side of the feeding box 2 is connected with the side of the storage box 3 , a feeding port 31 is provided at the connection between the feeding box 2 and the storage box 3, and the interior of the feeding box 2 is communicated with the interior of the storage box 3 through the feeding port 31; the feeding box 2 is provided with a yarn spool transfer device 4 , the yarn spool transfer device 4 is located between the feeding port 31 and the material outlet 21; the yarn spool transfer device 4 includes a corresponding upper sprocket 41 and a lower sprocket 42, the upper sprocket 41 passes through the chain 43 In cooperation with the lower sprocket 42, the outer circumference of the chain 43 is provided with a plurality of bobbin convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com