PU curing ring-shaped assembly line for square filter

An assembly line and filter technology, which is applied in the direction of pretreatment surface, coating, device for applying liquid to the surface, etc., can solve the problem that the impact force damages the blocking mechanism and the pushing mechanism, the gears of the unpacking mechanism are easily damaged, and the fixtures are consumed. and energy and other issues, to ensure the service life, improve production efficiency, and reduce the effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

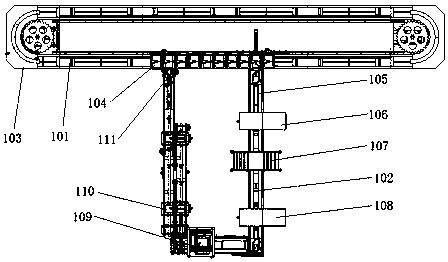

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, objectives and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

[0013] A preferred embodiment of the present invention is to provide a square filter PU curing annular assembly line, the purpose is to use 68 sets of accompanying fixtures to be fixedly connected to the top of the annular curing assembly line, which can ensure the curing time of PU curing. The glue assembly line carries out work such as mold lowering, core removal, mold release agent spraying, gluing and on-line, so that curing and gluing can be carried out at the same time, which can ensure the production rhythm and improve production efficiency; the accompanying fixture moves horizontally throughout the process without collision and low working noise , which can ensure the service life of the accompanying fixture and reduce the cost of production and mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com