Space spanning pouring system for iron mold sand coating process

A sand-covering and pouring system technology for iron molds, which is applied in the direction of molds, cores, mold components, etc., can solve the problems that the temperature of iron molds cannot meet the process requirements, the use of iron molds is small, and increase the production cycle, etc., to achieve High yield, high production efficiency, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

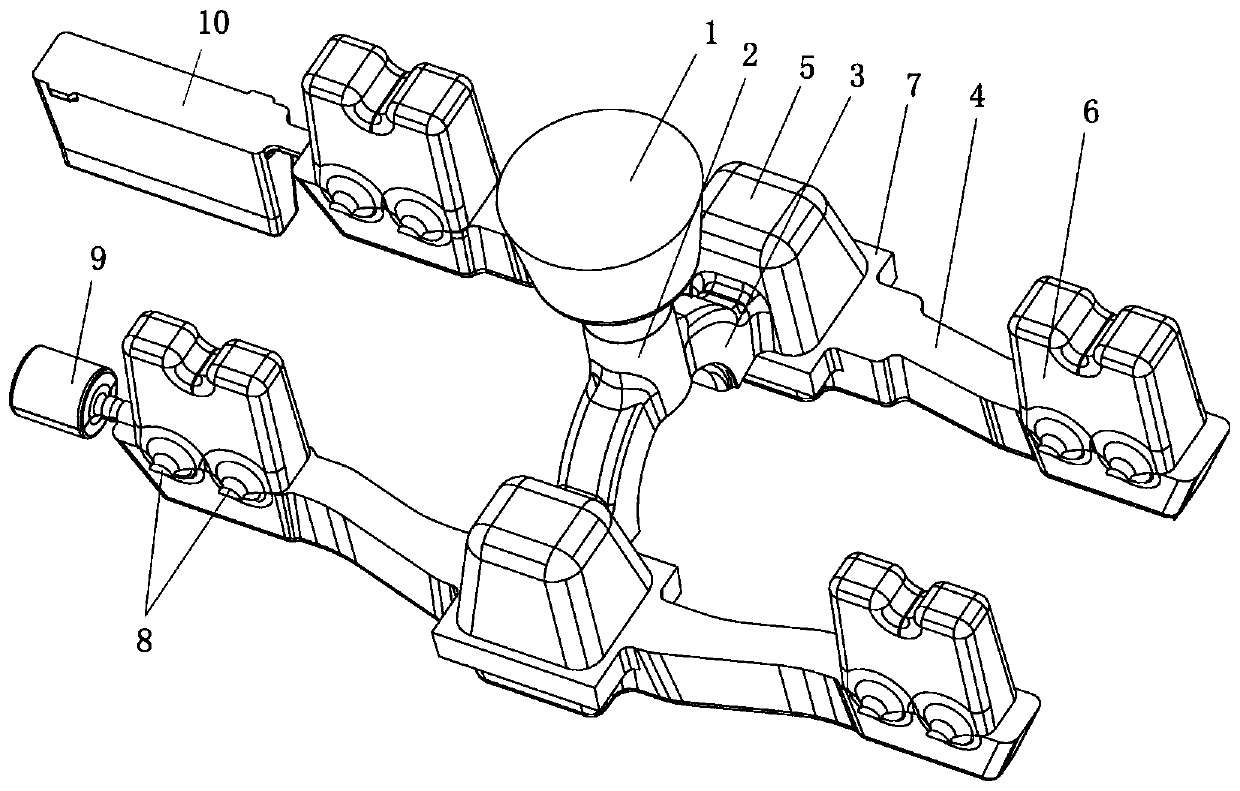

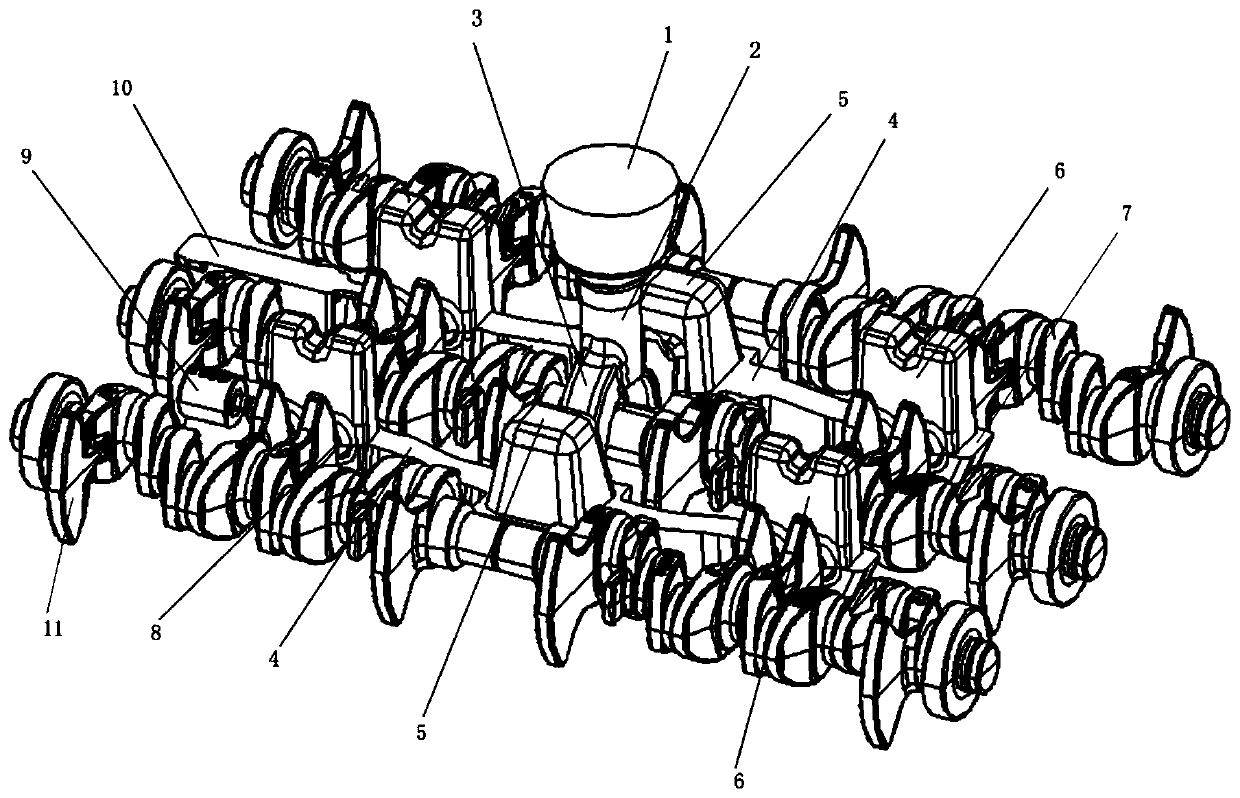

[0028] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be noted that this specific embodiment is not intended to limit the scope of rights of the present invention. Such as figure 1 and figure 2 As shown, taking the production of single-box small crankshafts as an example, this embodiment provides an iron mold sand-covered process space spanning pouring system suitable for the production of single-box small crankshafts, including sprue cup 1, sprue 2, bridge pouring Road, metallographic sample container 9, attached casting test block container 10 and small crankshaft mold 11, the bridge runner includes half-arch bridge channel 3, slag collection bag 5, runner 4 and riser 6, two half-arch The bridge channel 3 forms an arch bridge channel, the bottom of the sprue cup 1 is connected to the top of the sprue 2, the two ends of the bottom of the sprue 2 are respectively connected to one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com