Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Good regulation characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

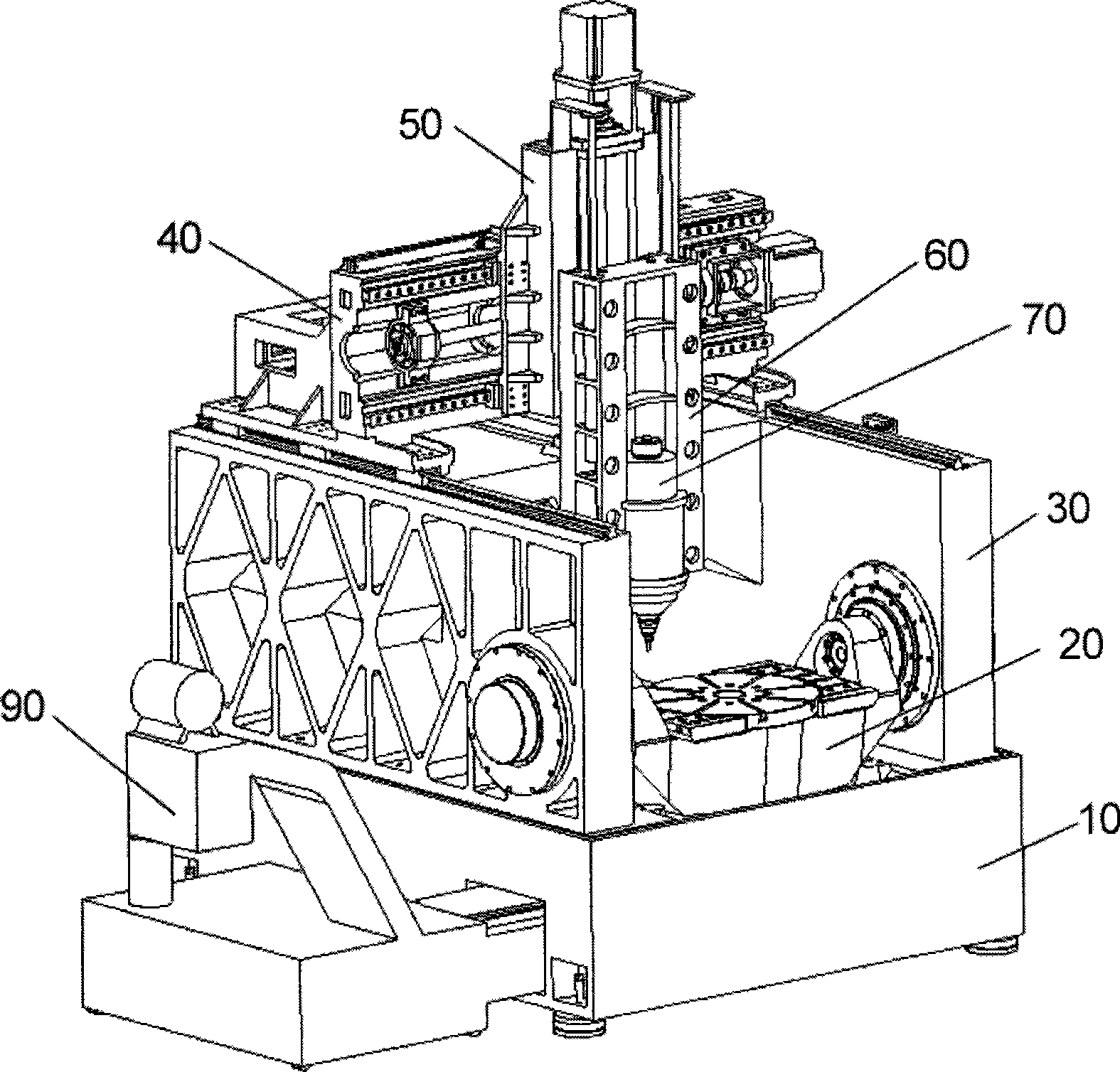

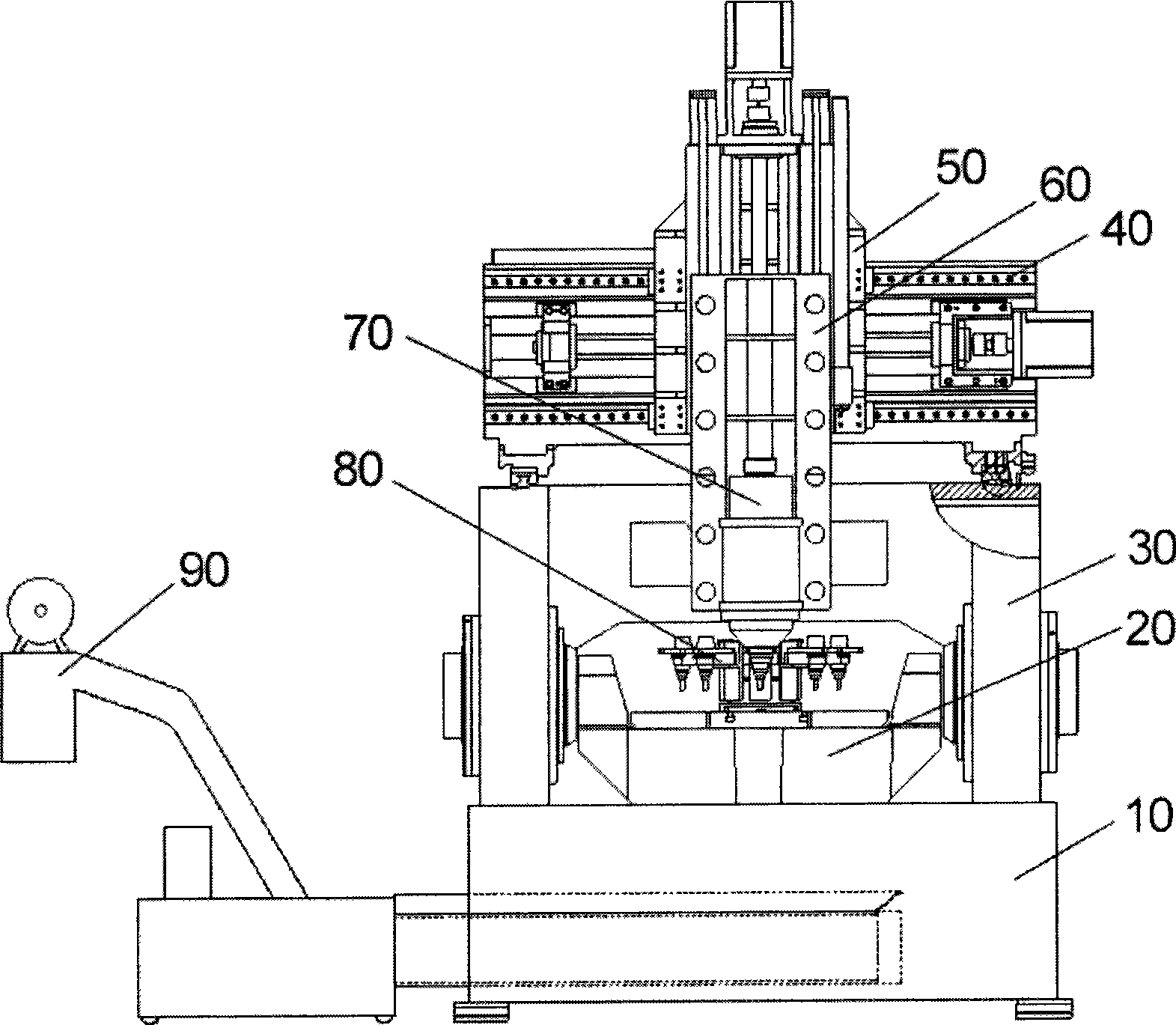

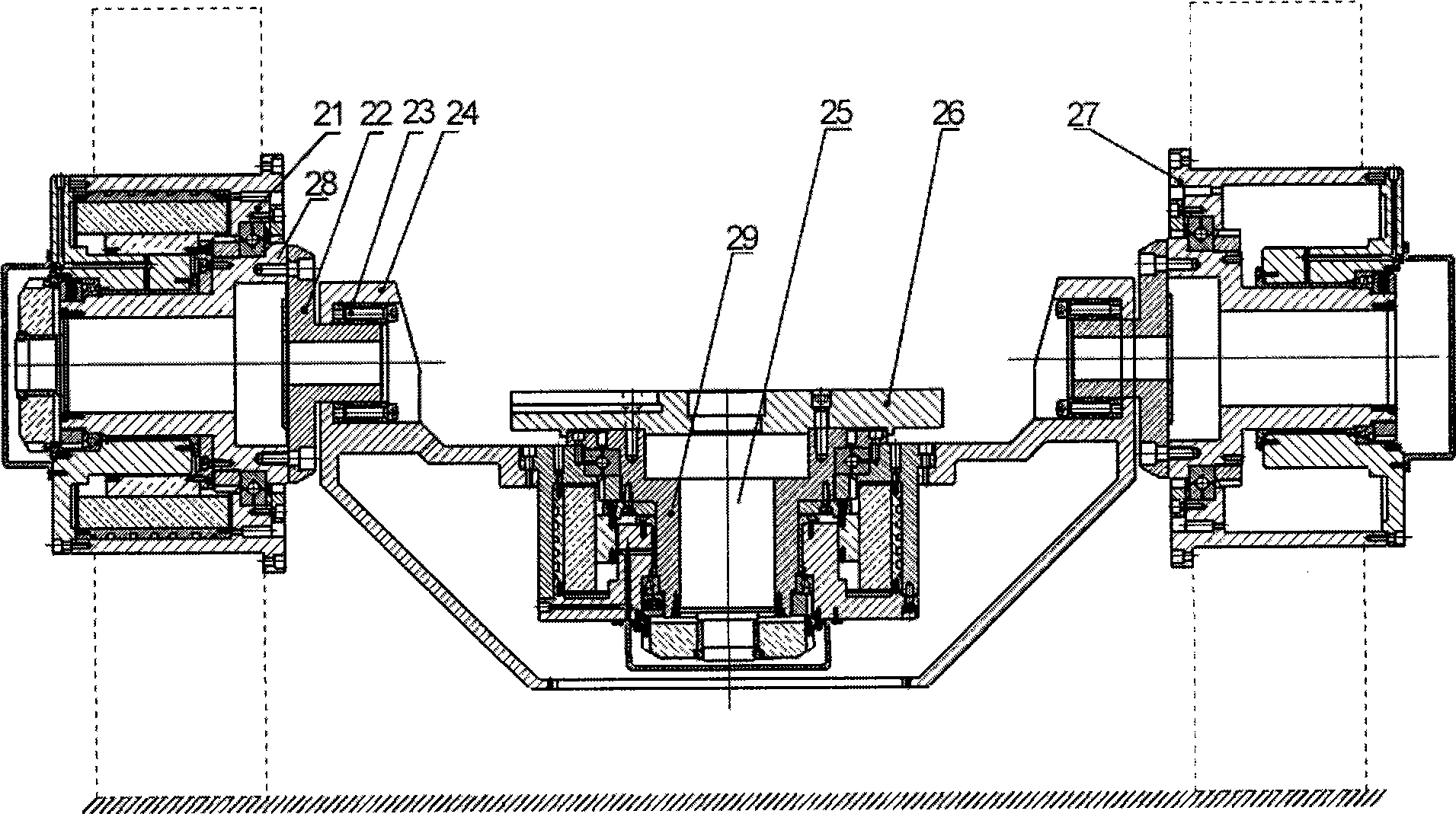

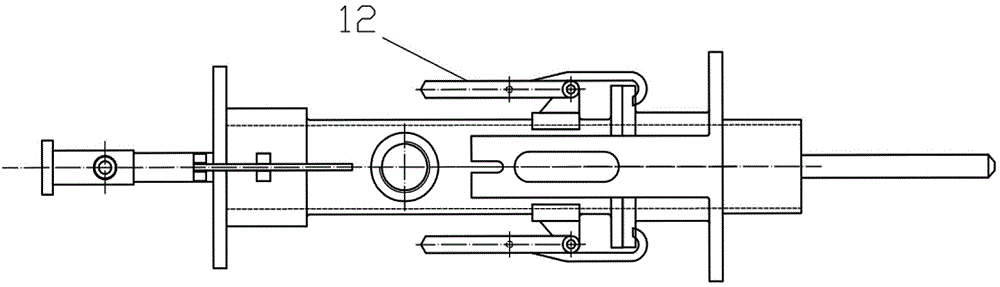

Five-shaft linkage numerical control machining center

InactiveCN101480777ANovel structureSmall footprintLarge fixed membersPositioning apparatusNumerical controlPortal frame

The invention discloses a five-axle linkage digital-control processing centre which comprises a lathe bed (10) and a portal frame (30), wherein the portal frame (30) comprises a left portal upright post (32), a right portal upright post (32) and a fixing portal crossbeam (35), and the front part of each portal upright post (32) is provided with a direct driving type double-shaft precise rotating table (20) which enables a working table (26) to simultaneously rotate round an A shaft and a C shaft. Furthermore, the portal frame (30) is provided with a crossbeam (40) which can move along the Y direction, the front part of the crossbeam (40) is provided with a slide carriage (50) which can move along the X direction, the front part of the slide carriage (50) is provided with a main shaft box (60) which can move along the Z direction, the main shaft box (60) is provided with a main shaft installing hole (66) used for installing a main shaft (70), and a tool magazine (80) is arranged in a cavity positioned between the lathe bed (10) and the portal frame (30). The invention has novel structure, small occupied area, space saving, low cost and stable operation and property. Besides, a motion shaft of a machine tool has high dynamic property, regulating property, positioning precision and repeated positioning precision.

Owner:三六零安全科技股份有限公司 +2

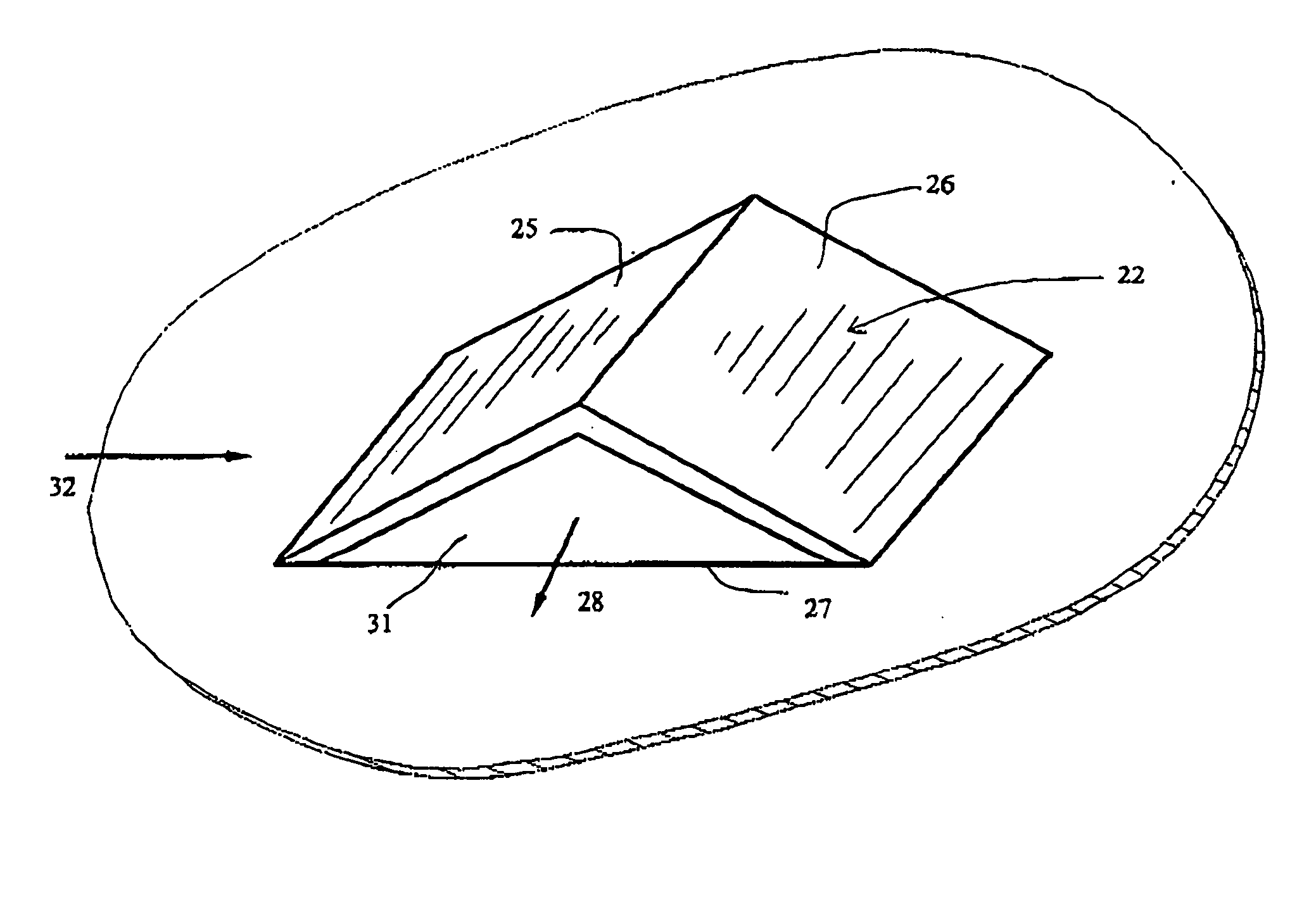

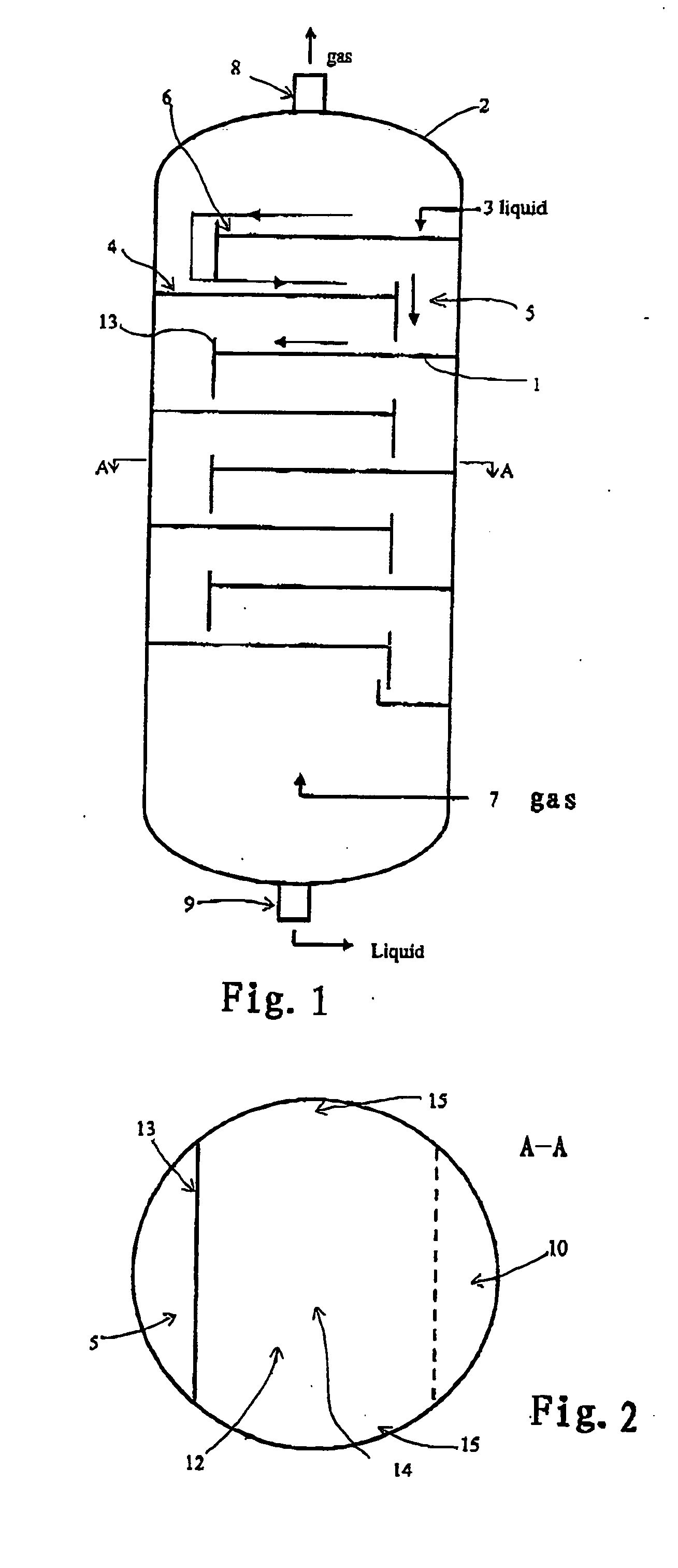

Gas-liquid contact tray with fixed valves for mass transfer

InactiveUS20050280169A1Low liquid entrainmentLow liquid weepingMixing methodsFuel re-atomisation/homogenisationMaterial PerforationVALVE PORT

A gas-liquid contact tray with fixed valves for mass transfer, in which the fixed valve comprising an upstream portion, a midportion and a downstream portion is made by punch from the tray deck so as to form as a deflector, and the upstream portion and the downstream portion are integrated with the tray deck, characterized in that said midportion has a central plane portion and downward inclined margins, and the tray deck is further provided with perforations which are arranged between the fixed valves adjacent in the liquid flow direction. The gas-liquid contact tray with fixed valves for mass transfer according to the present invention has a low liquid entrainment, low liquid weeping, a high mass transfer capacity and good turn-down characteristics.

Owner:CHINA PETROCHEMICAL CORP +1

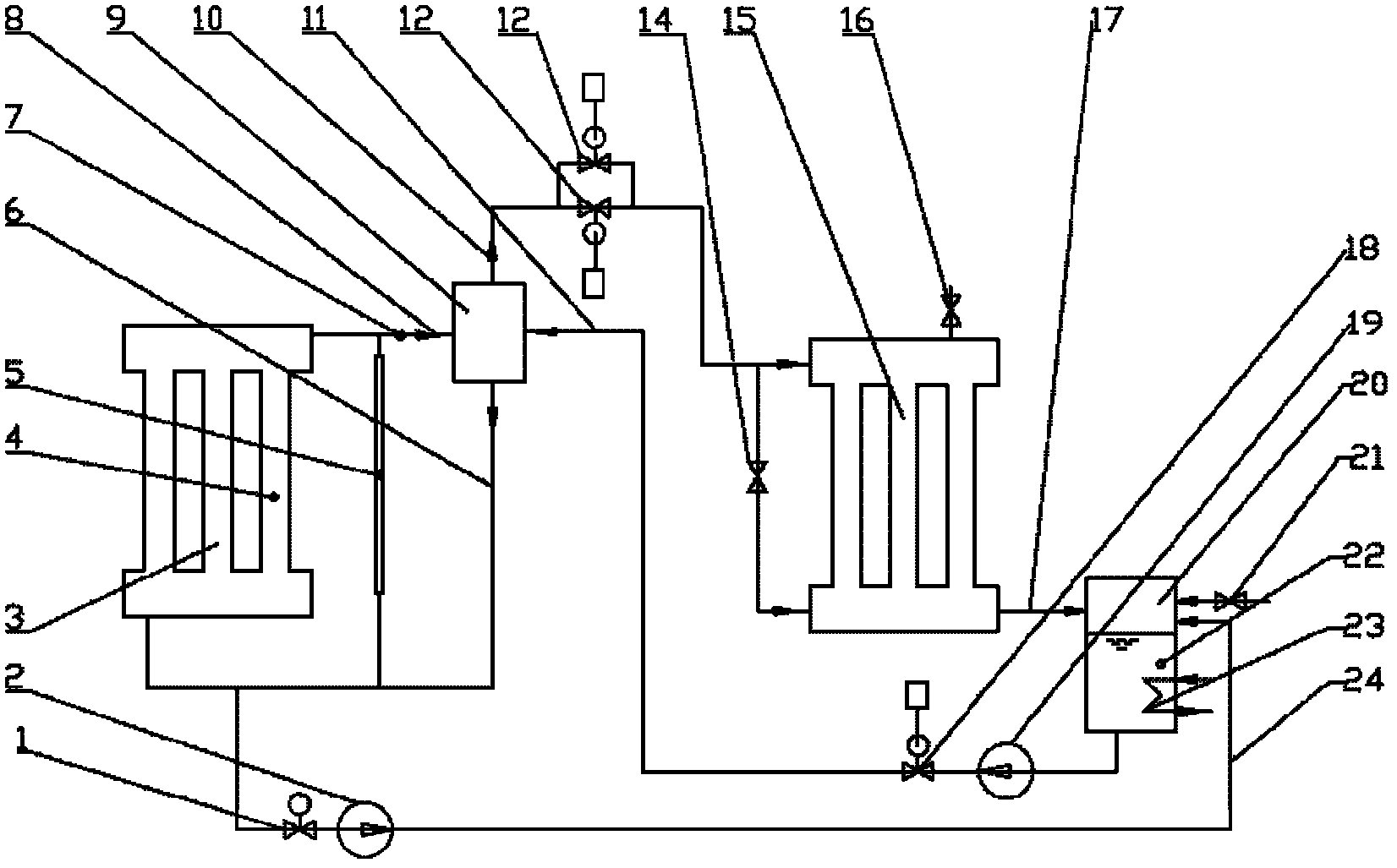

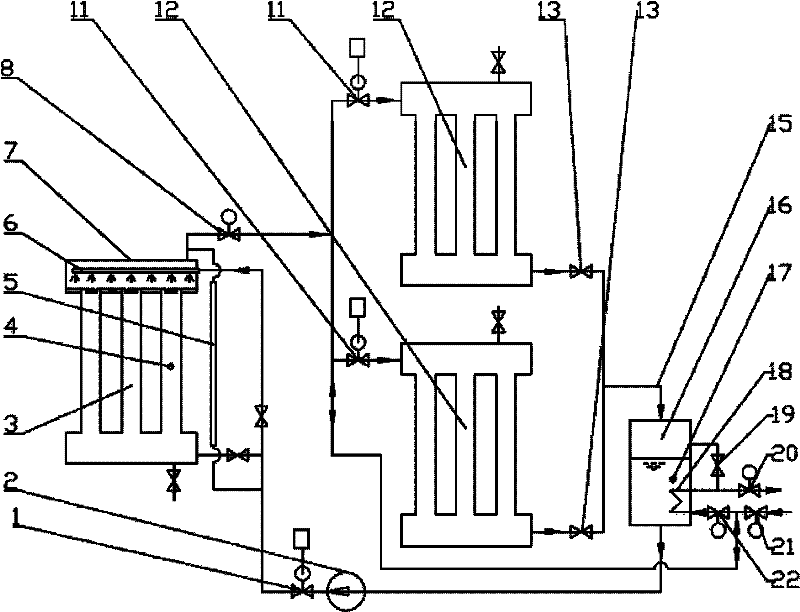

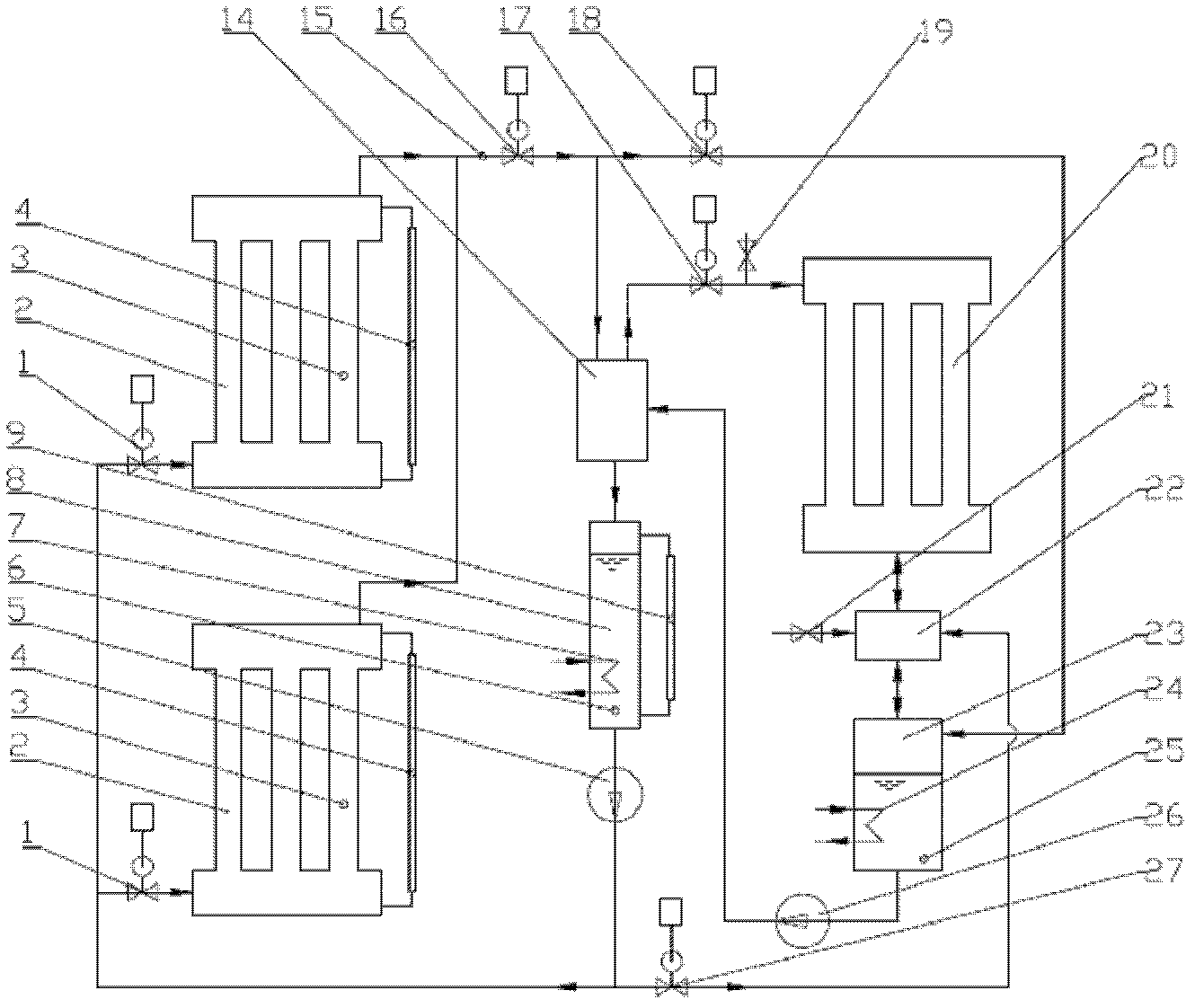

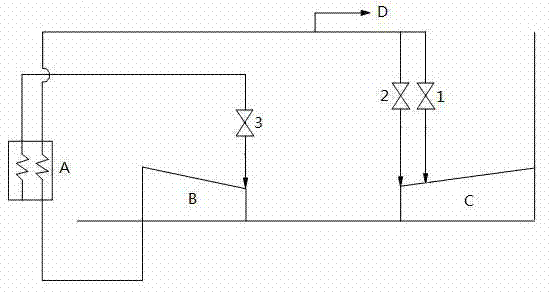

Branch control phase inversion heat exchange system and method based on vapor-liquid heat exchanger

ActiveCN102252543AWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersEngineeringLiquid storage tank

The invention relates to a branch control phase inversion heat exchange system and a branch control phase inversion heat exchange method based on a vapor-liquid heat exchanger. The system comprises a liquid storage tank (20), a heat source heat exchanger (3), a cold source heat exchanger (15) and a vapor-liquid heat exchanger (9); an upper collection tank of the heat source heat exchanger (3) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet steam pipe (8); a vapor-liquid heat exchanger outlet steam pipe (10) which is arranged on the vapor-liquid heat exchanger (9) is divided into two branches which are communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (15); the lower collection tank of the cold source heat exchanger (15) is communicated with the upper part of the liquid storage tank (20) through a cold source heat exchanger liquid outlet pipe (17); the bottom of the liquid storage tank (20) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet condensation liquid pipe (11); and the vapor-liquid heat exchanger (9) is communicated with a lower collection tank of the heat source heat exchanger (3) through a heat exchanger outlet condensation liquid pipe (6). The branch control phase inversion heat exchange system can solve the phenomena of overcooling and overheating and improve heat exchanging efficiency.

Owner:SHANXI SANHESHENG IND TECH

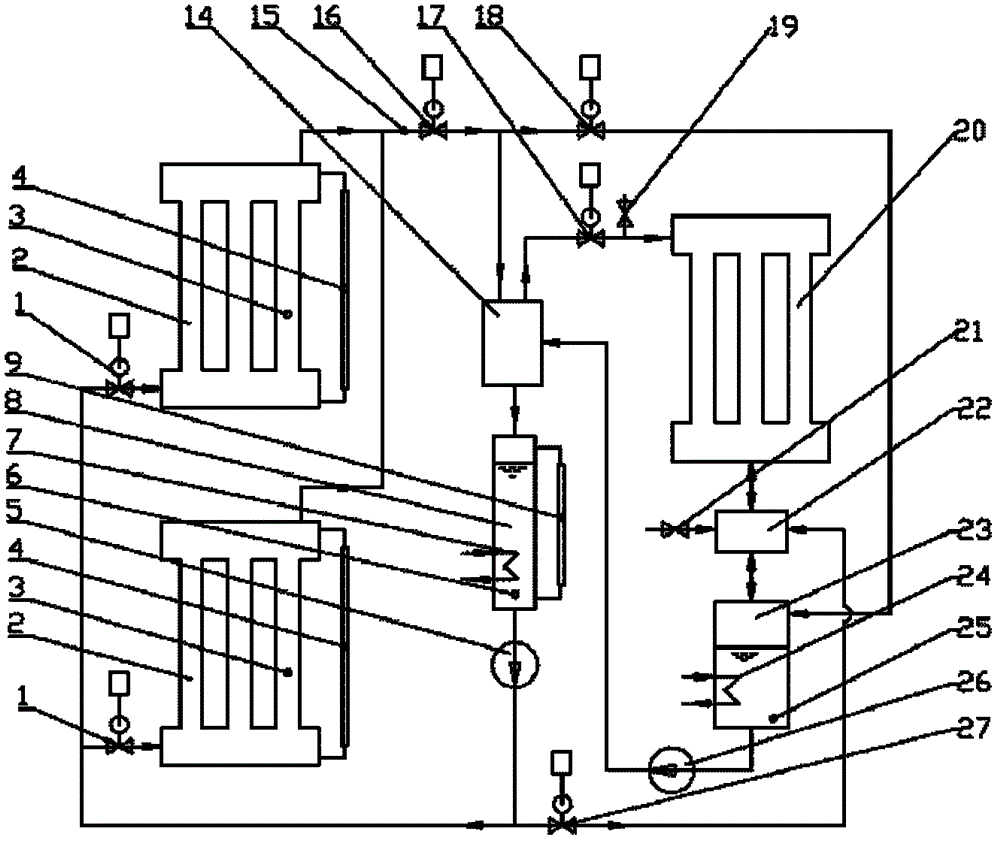

High-efficiency, sub-control and phase-change heat exchange system and method

InactiveCN102230753AWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersHeat exchange apparatusAirflowEngineering

The invention relates to a high-efficiency, sub-control and phase-change heat exchange system. The heat exchange system provided by the invention comprises a heat exchanger of heat source (3) and a heat exchanger of cold source (12) which are mutually communicated through a steam tube and a condensate line to from a sub-control and phase-change heat exchange circuit. The heat exchange circuit is provided with an air flow regulating valve and a liquid flow regulating valve which can control the circuit. A reservoir tank (16) is configured on the condensate line. The header of the steam tube on the top of the heat exchanger of heat source (3) is divided into two steam sub-tubes. A first steam sub-tube is connected with the heat exchanger of heat source (12) and an air flow regulating valve (11) is configured between the first steam sub-tube and the heat exchanger of cold source (12). A second steam tube communicates with the reservoir tank (16) via a condensate heater (18) configured inside the reservoir tank (16). A liquid distribution tube (6) is configured inside the collecting chamber (7) of the heat exchanger of heat source (3), and a plurality of sprayers are configured on the liquid distribution pipe which is used for the mixing heat exchange of steam and condensate. The efficiency of the system provided by the invention is much higher.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

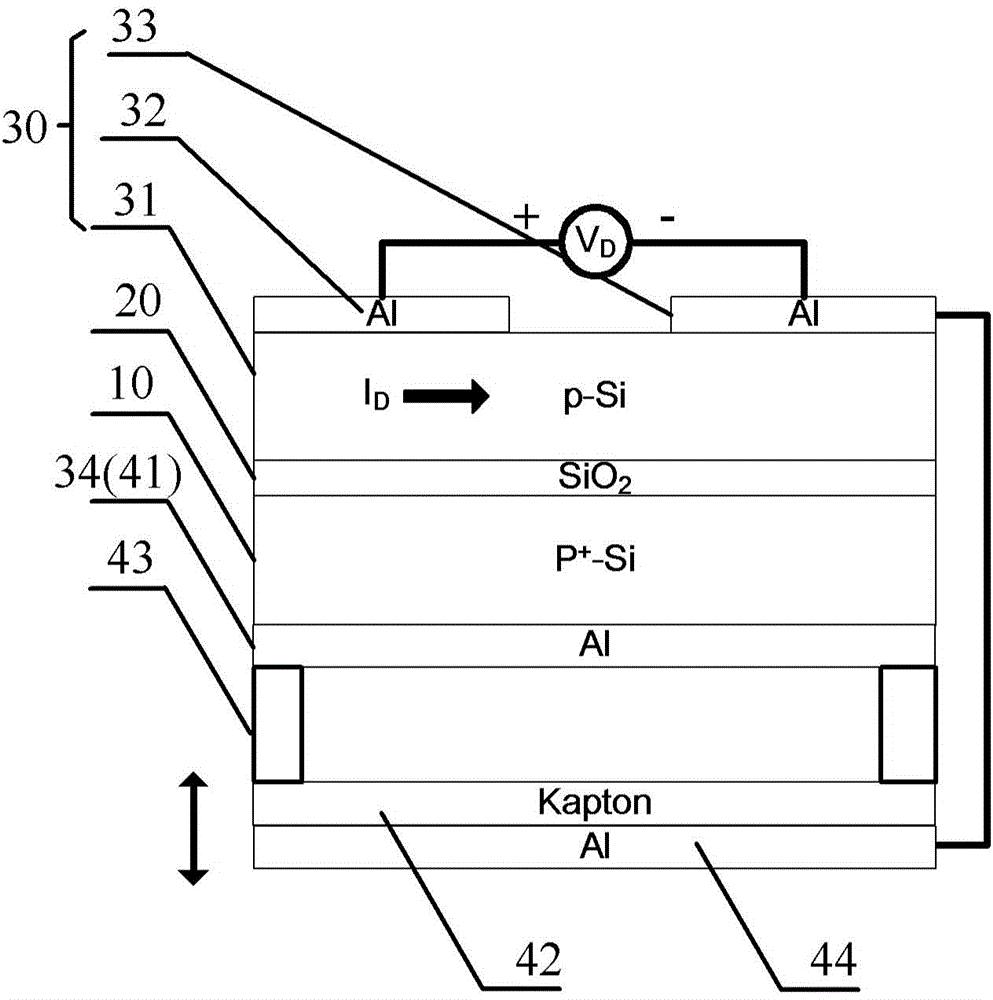

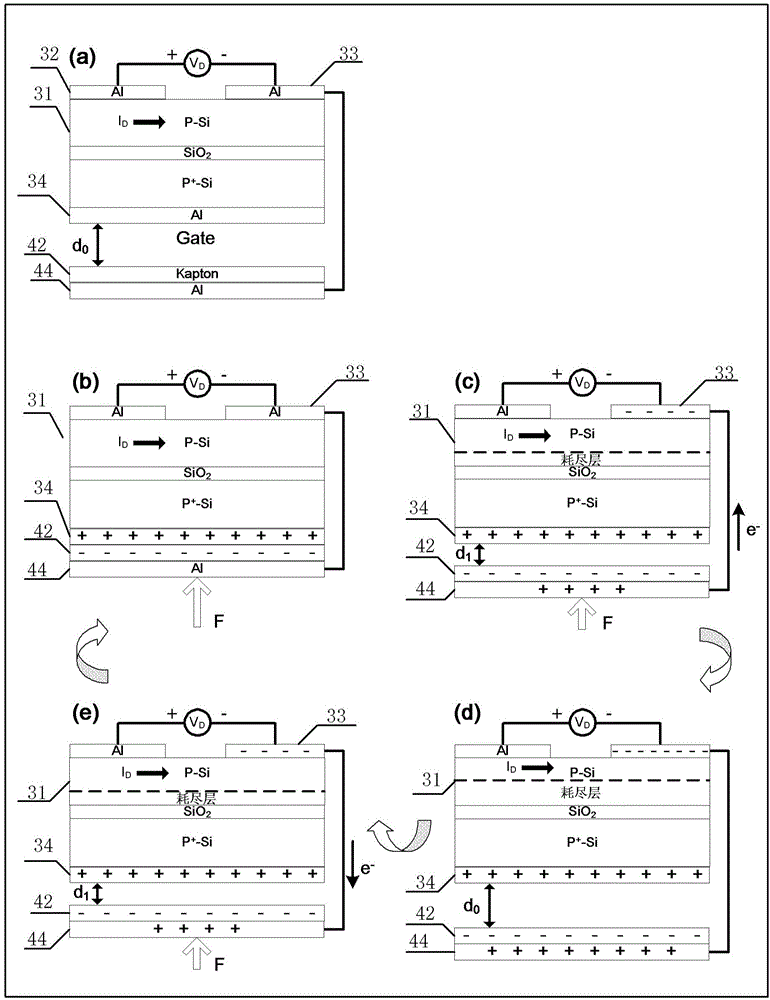

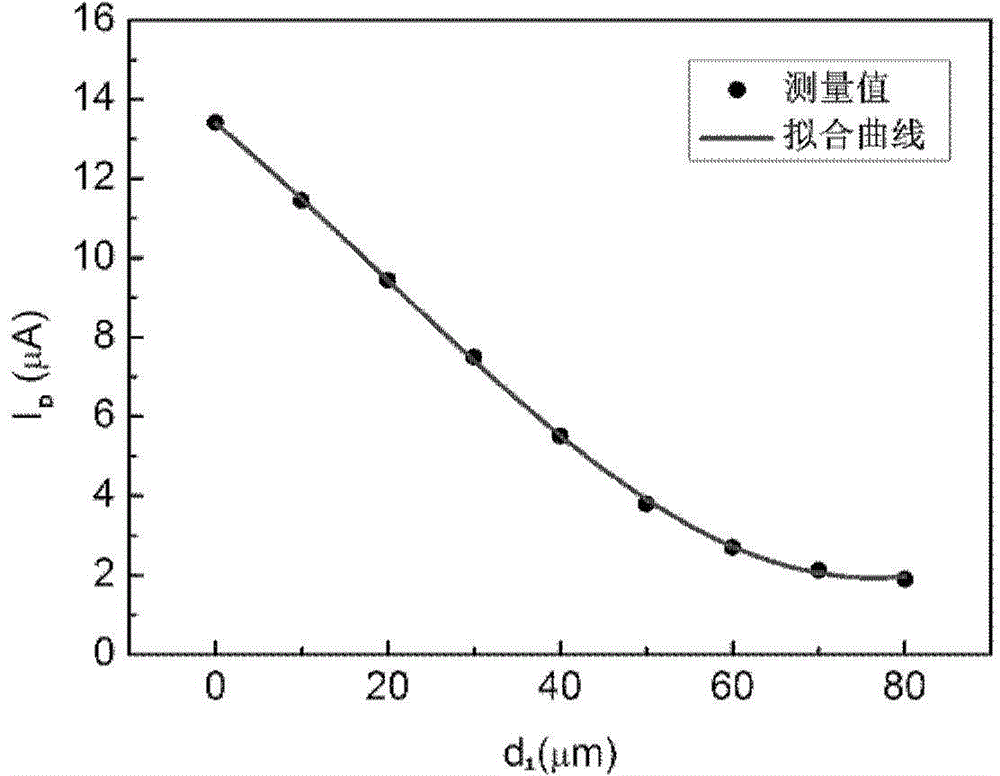

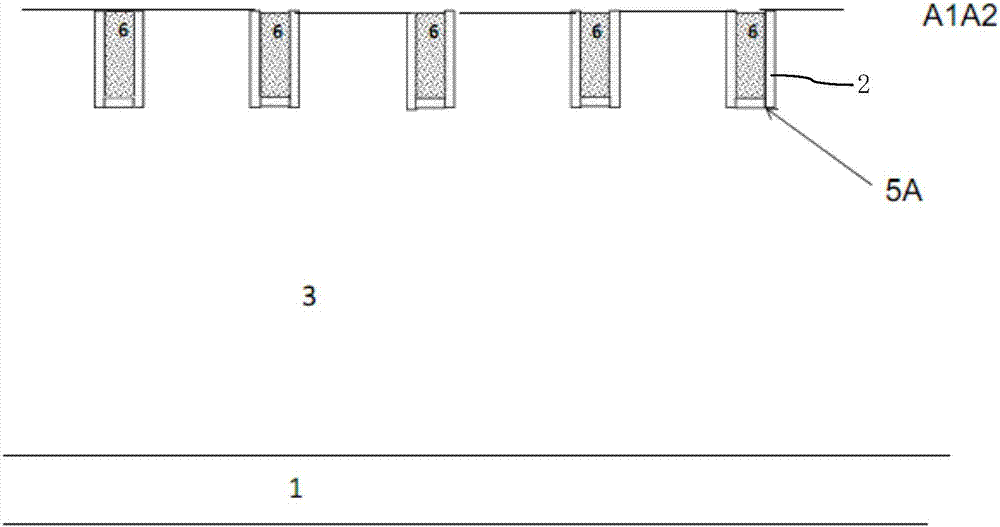

Back-gate field effect transistor based on contact electrification

ActiveCN105470313AGood regulation characteristicsEnable direct interactionSemiconductor/solid-state device detailsSemiconductor devicesElectricityContact electrification

The invention provides a back-gate field effect transistor based on contact electrification. The back-gate field effect transistor comprises the components of a conductive substrate; an insulating layer which is formed on the front surface of the conductive substrate; a field effect transistor assembly which comprises a channel layer, a drain electrode, a source electrode and a gate electrode; and a friction electrification assembly. The friction electrification assembly comprises the components of a static friction layer which is formed on the lower surface of the gate electrode; a movable friction layer which is separated from the static friction layer and is arranged parallelly with the static friction layer; and a second conductive layer which is formed outside the movable friction layer and is electrically connected with the source electrode, wherein the static friction layer and the movable friction layer are arranged at different positions of a friction electrode set. In response to the function of an external force, the static friction layer and the movable friction layer can be repeatedly switched between a separating state and a contacting state. According to the back-gate field effect transistor, an electrostatic potential which is generated by a friction electrification machine is used as a gate electrode gate signal of the back-gate field effect transistor, thereby realizing control for transportation characteristic of carriers in a semiconductor.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

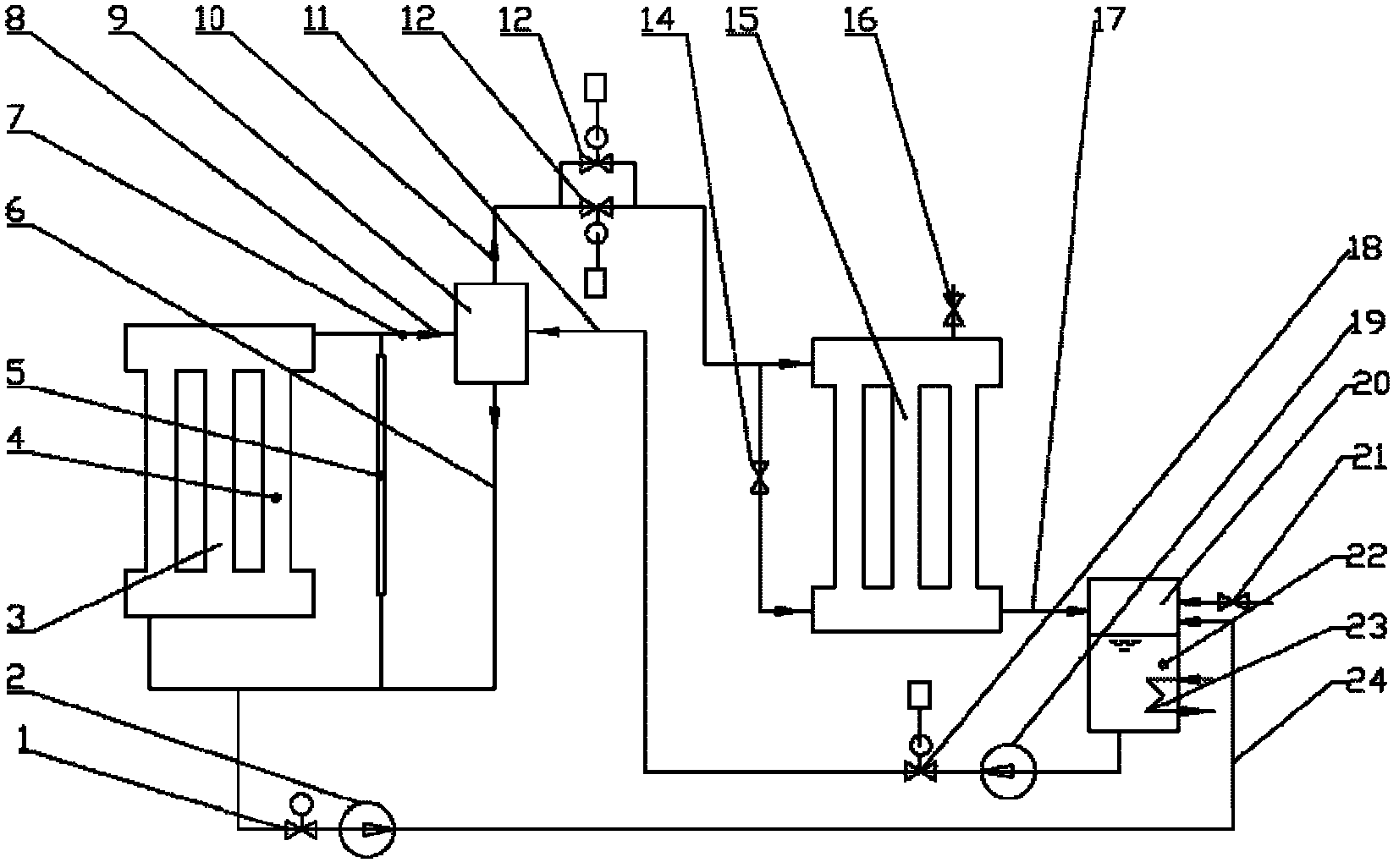

Branch-control and phase-change heat exchange system and method based on two-stage steam-liquid heat exchanger

ActiveCN102200403ANo disturbance effectReliable sub-control performanceIndirect heat exchangersHeat exchange apparatusControl systemEngineering

The invention relates to a branch-control and phase-change heat exchange system and method based on a two-stage steam-liquid heat exchanger. The system comprises a heat source heat exchanger (2), a cold source heat exchanger (20) and a low temperature liquid tank (23), and the system further comprises a high temperature heat exchanger (14), a low temperature heat exchanger (22) and a high temperature liquid tank (8); a main heat source steam pipe at the top part of the heat source heat exchanger (2) is divided into two branch pipes after passing through a heat source steam exhaust adjusting valve (16), the two branches are respectively communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (20), and control systems are respectively arranged on the branches; the low temperature liquid tank (23) is communicated with the high temperature heat exchanger (14) through a condensate pipeline, the bottom of the high temperature heat exchanger (14) is communicated with the high temperature liquid tank (8) through a condensate pipeline, and the condensate pipeline at the bottom of the high temperature liquid tank (8) is respectively communicated with the low temperature heat exchanger (22) and the heat source heat exchanger (2). According to the branch-control and phase-change heat exchange system disclosed by the invention, overheat and over-cold phenomenon of steam and condensate are solved, and the heat exchange efficiency is further improved.

Owner:SHANXI SANHESHENG IND TECH

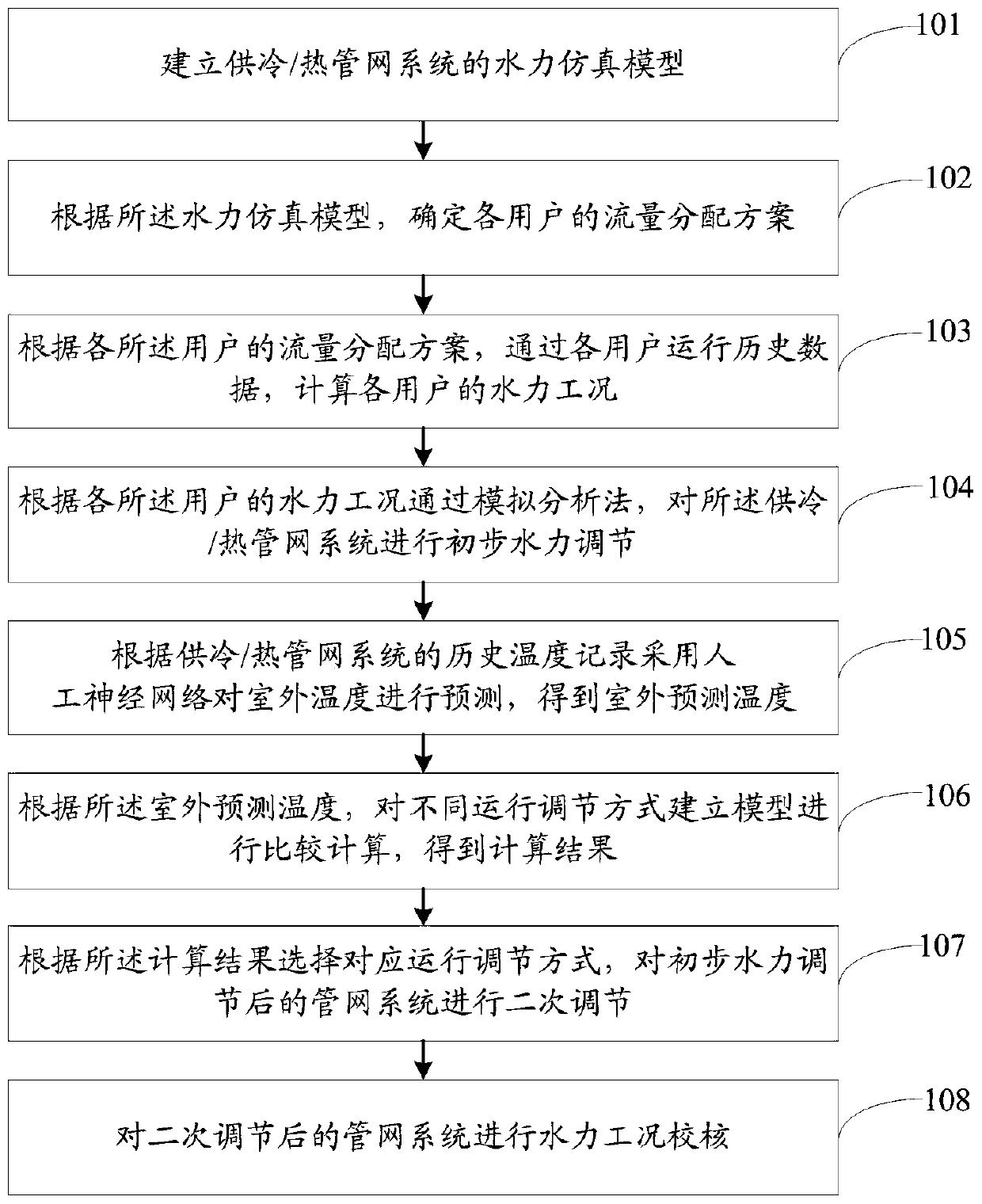

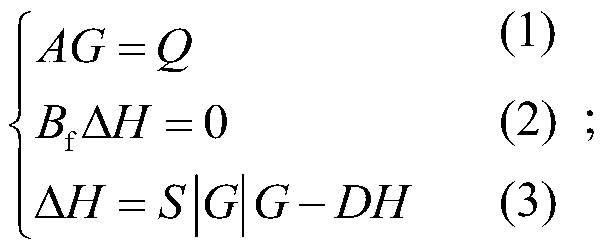

Control method and system for hydraulic disorders of cold/heat supply pipe network

InactiveCN111023224AIncreased operating energy consumptionNo need to change the structureMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsEngineering

The invention relates to a control method and system for hydraulic disorders of a cold / heat supply pipe network. The method comprises the steps that a hydraulic simulation model of a cold / heat supplypipe network system is set up; the flow distribution scheme of users is confirmed; according to the flow distribution scheme of the users, the hydraulic conditions of the users are calculated throughthe running historical data of the users; according to the hydraulic conditions of the users, primary hydraulic adjustment is carried out on the pipe network through the model analysis method; according to the historical temperature records of the old / heat supply pipe network system, the artificial neural network is adopted for predicating outdoor temperature; according to the outdoor predicated temperature, models are set up for different running adjusting manners to be compared and calculated; according to the calculation result, the corresponding running adjusting manners are selected, andthe pipe network system obtained after primary hydraulic adjustment is adjusted secondarily; and hydraulic condition inspection is carried out on the pipe network system obtained after secondary adjustment. According to the method, on the premise of achieving hydraulic balance of the cold / heat supply pipe network, hydraulic balance adjustment can be completed within a short time after the cold / heat supply system is put into operation.

Owner:珠海横琴能源发展有限公司 +1

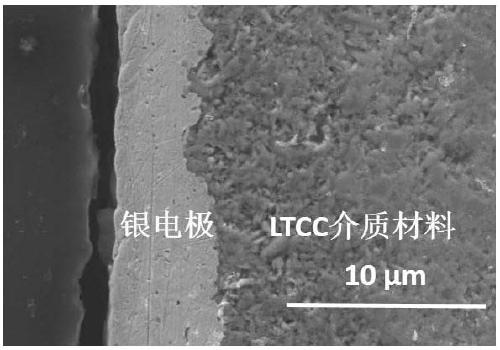

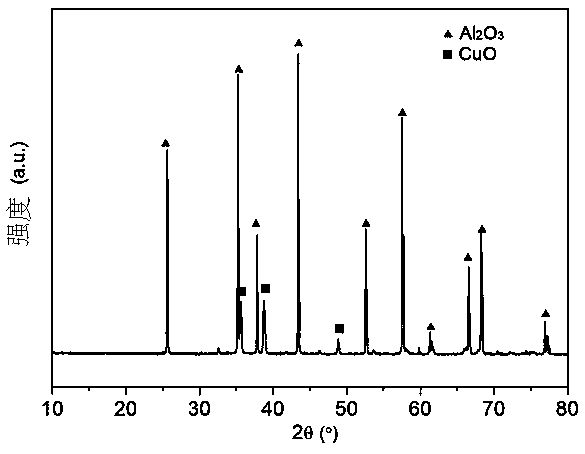

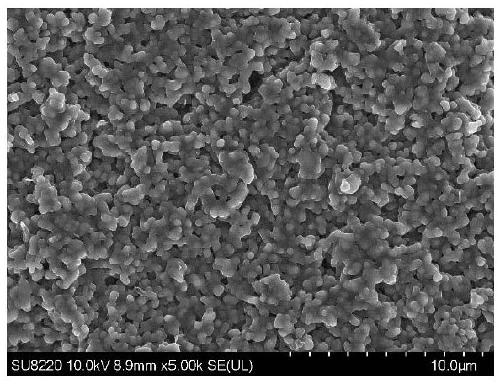

Low-temperature co-fired ceramic dielectric material and preparation method thereof

The invention relates to a low-temperature co-fired ceramic dielectric material and a preparation method thereof. The LTCC dielectric material comprises an oxide dielectric material having a high sintering temperature and an oxide activator, and the LTCC dielectric material concretely comprises 1-20 wt% of the oxide activator, and the balance of the oxide dielectric material having the high sintering temperature; the oxide dielectric material with the high sintering temperature is an oxide of M, wherein M is at least one of Mg, Al, Ti, Ca, Zr, Nd, MgTi, MgAl, CaTi and NdAl; and the oxide activator comprises an oxide of A and an oxide of B, A is at least one of Zn, Cu, Mn, Sn, Fe, Co and Ni, B is at least one of V, Nb, Ta, Ti and Si, and the mass of the oxide of A is 10-100% of the total mass of the oxide activator.

Owner:ZHEJIANG SIRAMIC TECH CO LTD

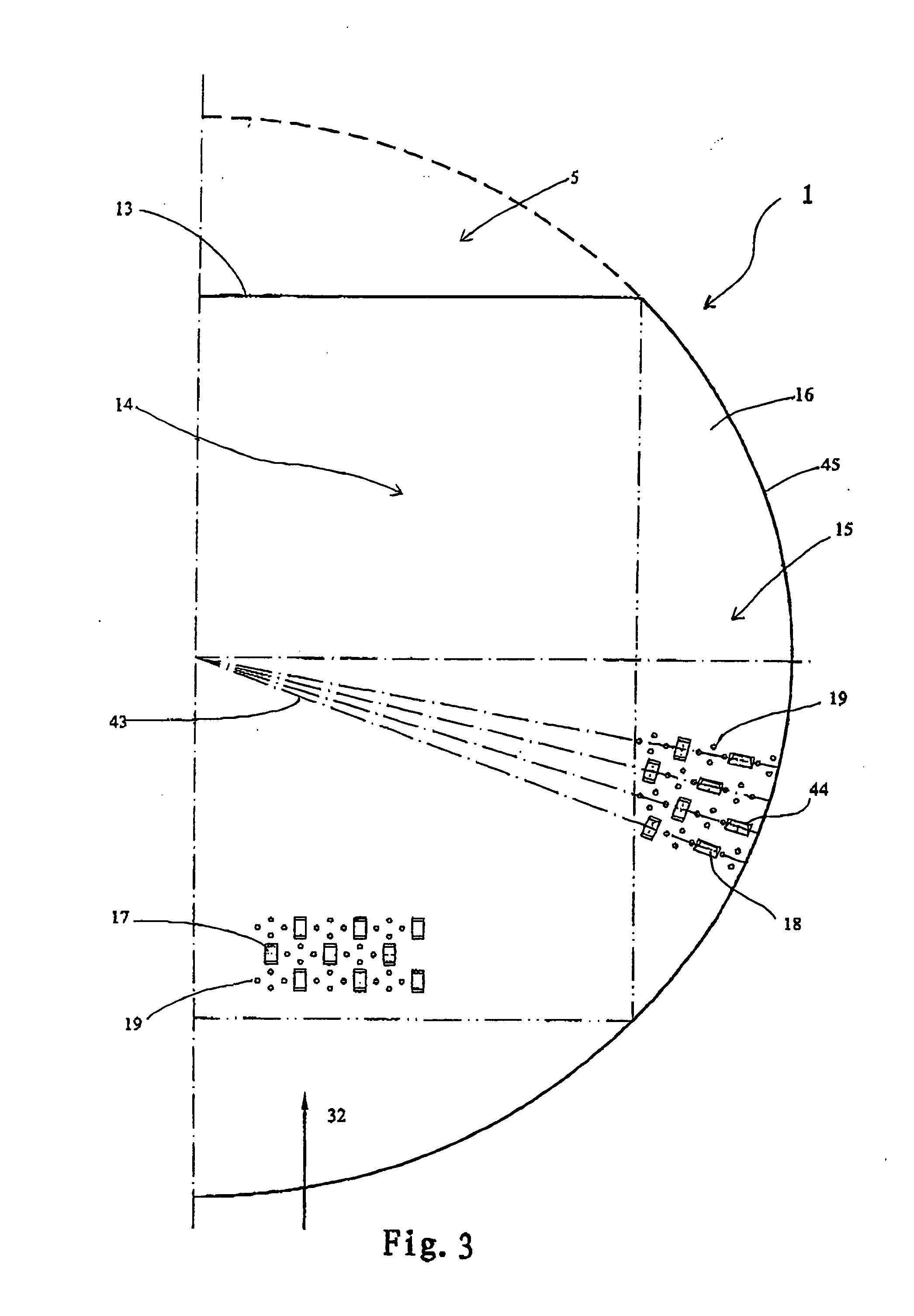

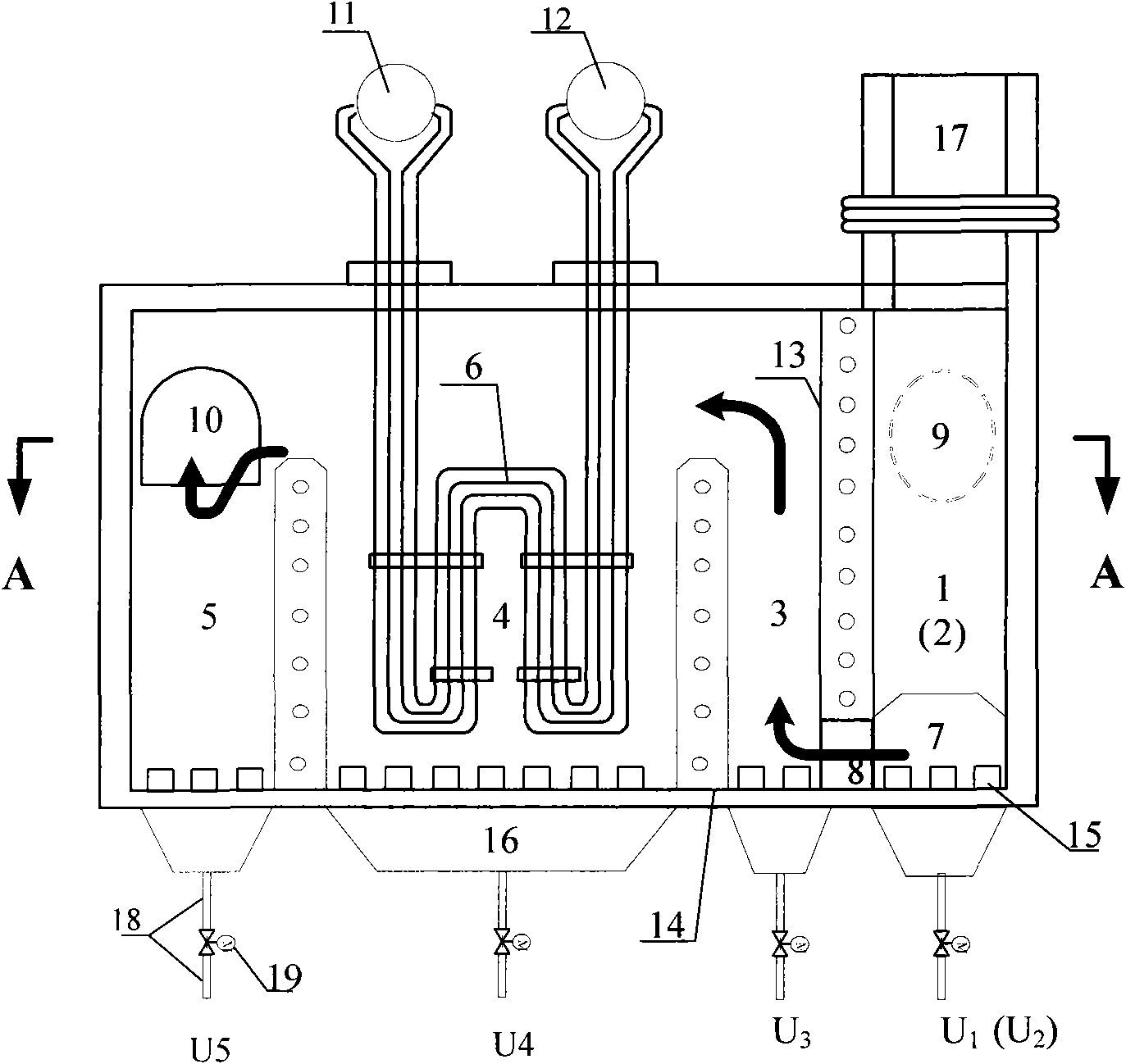

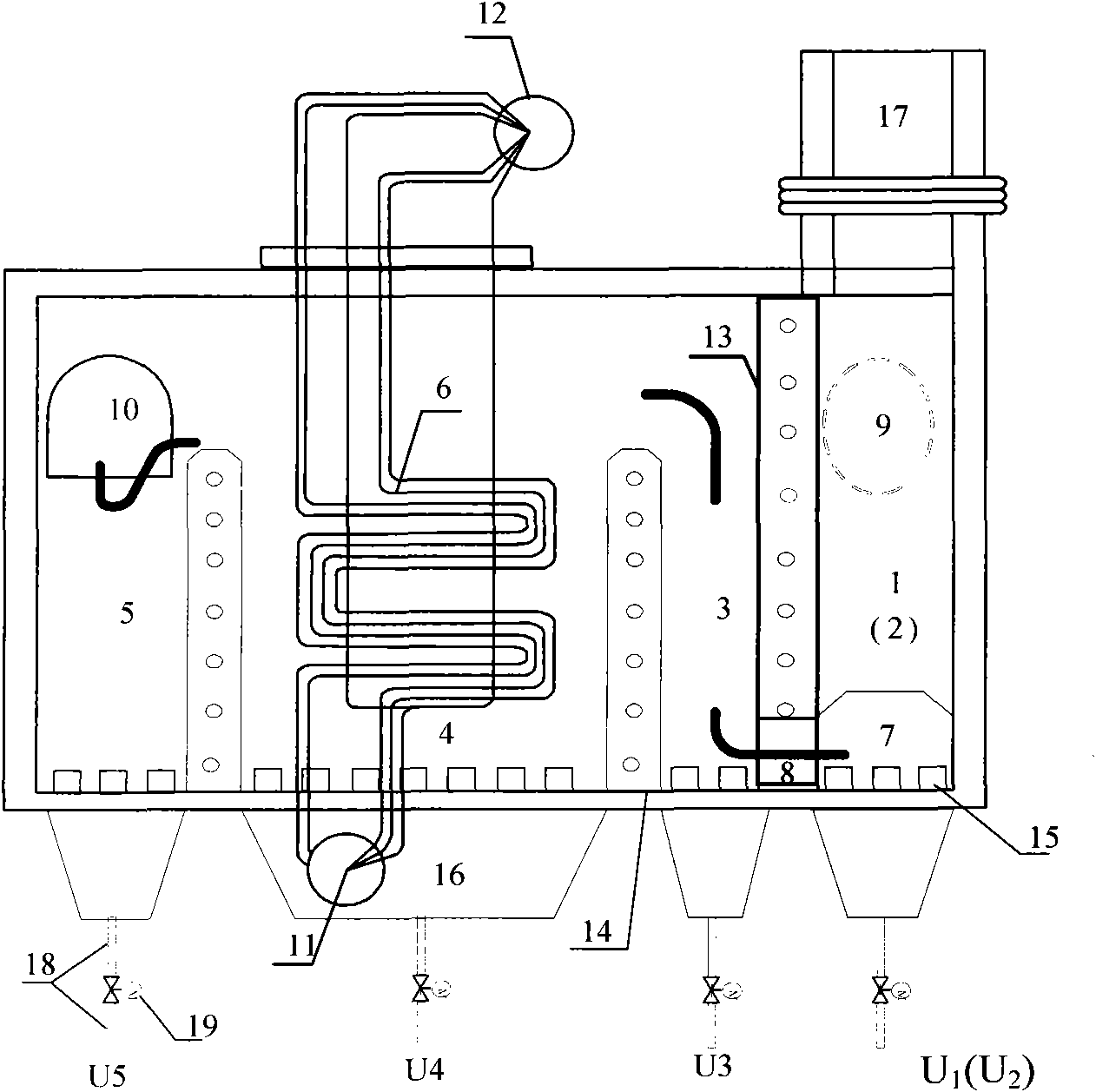

Current-equalizing pneumatic heat exchanging bed

ActiveCN101629717AFlexible and reliable controlNo mechanical failureFluidized bed combustionApparatus for fluidised bed combustionEngineeringDistributor

The invention is a current-equalizing pneumatic heat exchanging bed for a circulating fluidized bed boiler (CFBB), comprising a feed bin 1, a high-temperature bin 2, a current-equalizing bin 3, a heat exchanging bin 4, a low-temperature bin 5, a wind box 16 of each bin and the bottom part thereof, an air distributor 15, a hood 14, an air duct 18 and a wind speed control device 19 to form an independent and operable integral. The shunting ratio of circulating ash can be controlled by adjusting wind speed of each bin, part of circulating ash directly goes back to a furnace 20, and the other part thereof goes back to the furnace 20 after being cooled by a heating surface 6. The invention uses a pneumatic method for realizing shunting and controlling of the circulating ash, has the advantages of wide adjusting range, evenly heat exchanging, no abrasion and tube explosion and mechanical fault, and is applicable to large-scale circulating fluidized bed boiler (CFBB).

Owner:XIAN THERMAL POWER RES INST CO LTD

Airbag type ventilation and drainage positive and negative pressure water hammer control valve group

ActiveCN103542138APrecise control of water flowRealize quick opening and slow closingValve members for absorbing fluid energyPipe elementsExhaust valvePositive pressure

The invention discloses an airbag type ventilation and drainage positive and negative pressure water hammer control valve group. The airbag type ventilation and drainage positive and negative pressure water hammer control valve group is arranged on an infusion pipeline or a container system and comprises a water hammer relief valve, a trace exhaust valve, a high-speed exhaust valve, a rear regulating valve, a negative pressure air suction valve, a manual venting and draining valve and a monitoring pressure gauge; the rear regulating valve is arranged at the outlet end of the high-speed exhaust valve; the water hammer relief valve is directly connected with the top or the lateral side of the negative pressure air suction valve through threads or a flange; the trace exhaust valve is connected with a hole which is formed in the front of the water hammer relief valve; the high-speed exhaust valve is directly connected with the top or the lateral side of the negative pressure air suction valve through threads or a flange; the negative pressure air suction valve is connected with the external infusion pipeline. According to the airbag type ventilation and drainage positive and negative pressure water hammer control valve group which is integrated and omni-directional, the structure is compact and firm, the conveying and the installation are convenient, the reliability is strong, the positive pressure water hammer can be relieved, the relief speed is high, and the water hammer of cavities collapsing due to the negative pressure can be inhibited.

Owner:ANHUI REDSTAR VALVE

Flow-volume regulator

ActiveCN102788178ACompact structureLess prone to failureCheck valvesValve members for absorbing fluid energyEngineeringPressure difference

The invention relates to a flow-volume regulator having a regulator housing which has at least one regulator ring channel which contains an annular flow restrictor made of elastic material which bounds, between itself and a channel wall that bears a regulatory profiling, a control gap for which it is possible to alter the passage cross section by means of the flow restrictor, which deforms under the pressure difference that forms during the flow, and also having at least one valve which has a valve body which moves under the pressure of the flowing medium from an open position counter to a restoring force into a closed position, in which closed position the valve body closes off at least one valve opening. In order to be able to make the flow-volume regulator according to the invention compact and also to mount it in space-saving fashion under confined circumstances, the invention provides for the valve body to be provided in a valve ring channel in the regulator housing which valve ring channel has at least one valve opening in the region of its channel base, for the valve body to be of annular design and to made from elastic material, and for the annular valve body to deform under the pressure of the flowing medium such that the valve body moves from the open position counter to the restoring force of the inherent elasticity of the elastic material used for the valve body into the closed position.

Owner:NEOPERL

Manufacturing method of trench-gate superjunction device

InactiveCN107994076AReduce leakageImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringPolycrystalline silicon

The invention discloses a manufacturing method of a trench-gate superjunction device. The manufacturing method comprises the steps of 1, forming a trench gate, wherein the step 1 comprises the steps of 11, forming a gate groove in a first epitaxial layer in which a superjunction structure is not formed; 12, forming a gate oxide layer, and rounding a bottom angle and a top angle of the gate grooveby a thermal oxidization process of the gate oxide layer; and 13, forming a poly-silicon gate; and 2, forming the superjunction structure, wherein the step 2 comprises the steps of 21, forming a superjunction post groove; and 22, filling a second epitaxial layer in the superjunction post groove to form a second conductive type of post of the superjunction structure, wherein the first conductive type of post of the superjunction structure comprises the first epitaxial layer between the superjunction grooves. By the manufacturing method, the electric leakage of the device can be reduced, the reliability of the device is improved, and meanwhile, the specific conduction resistance of the device also can be reduced.

Owner:SHENZHEN SANRISE TECH CO LTD

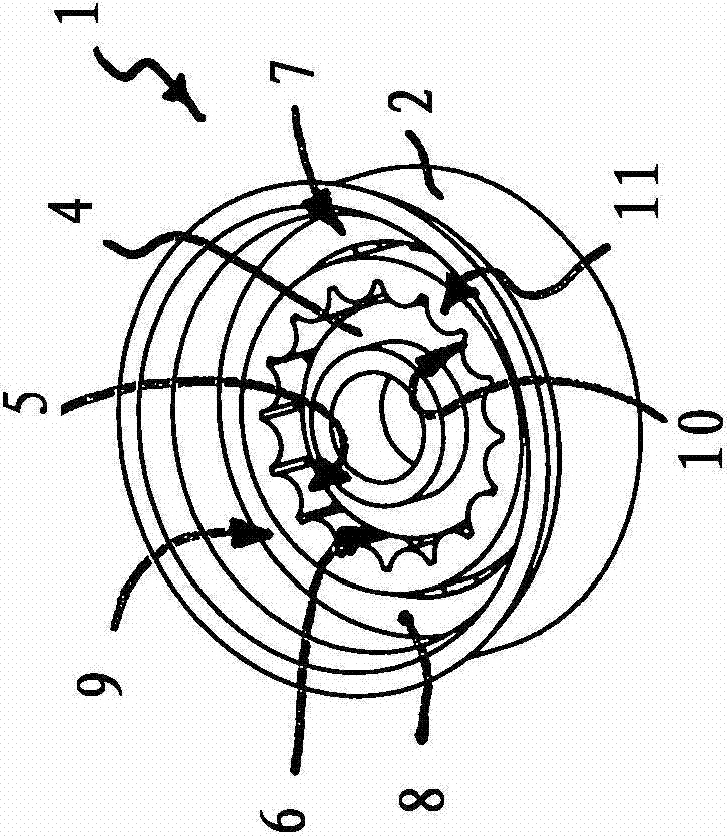

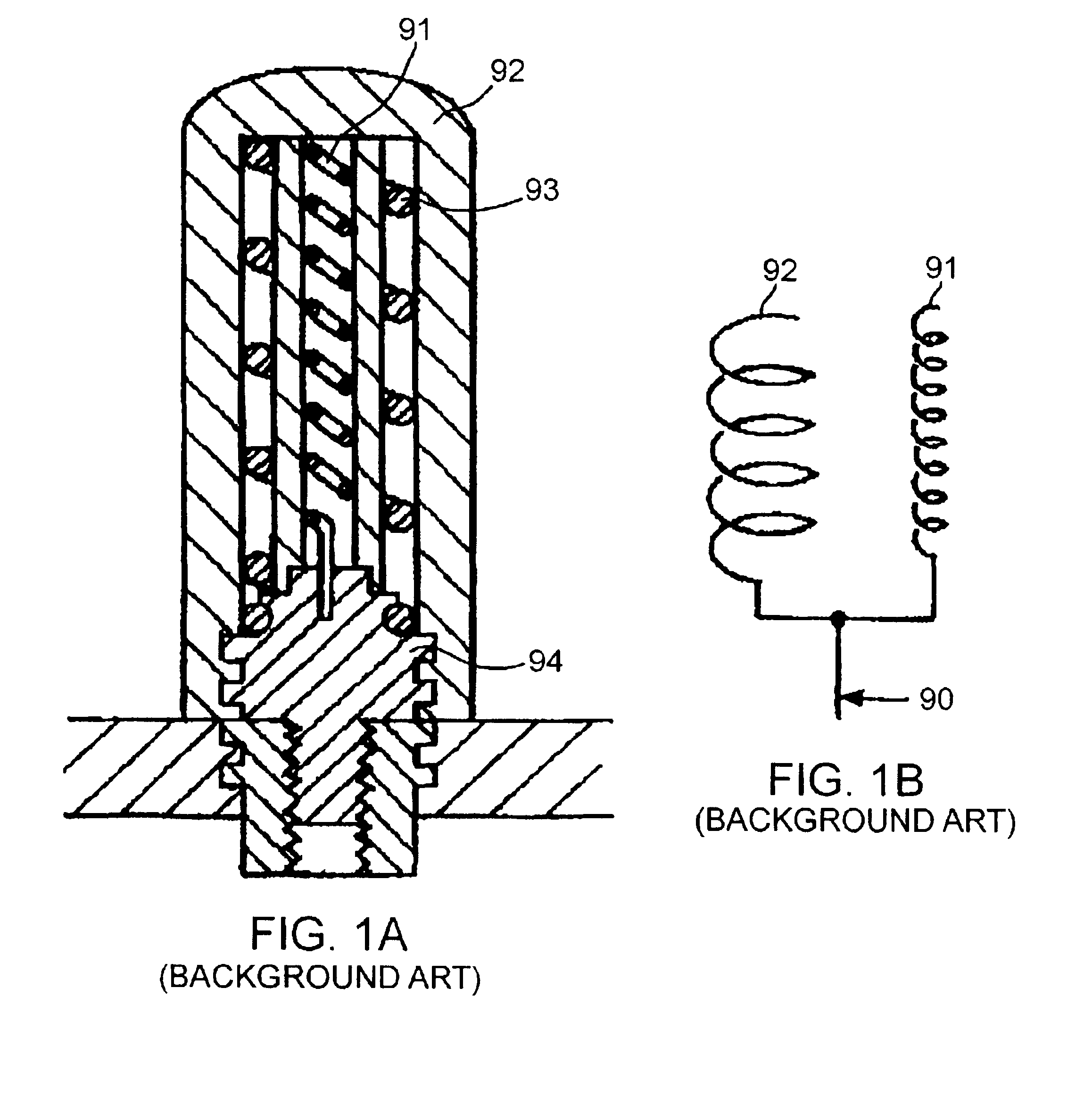

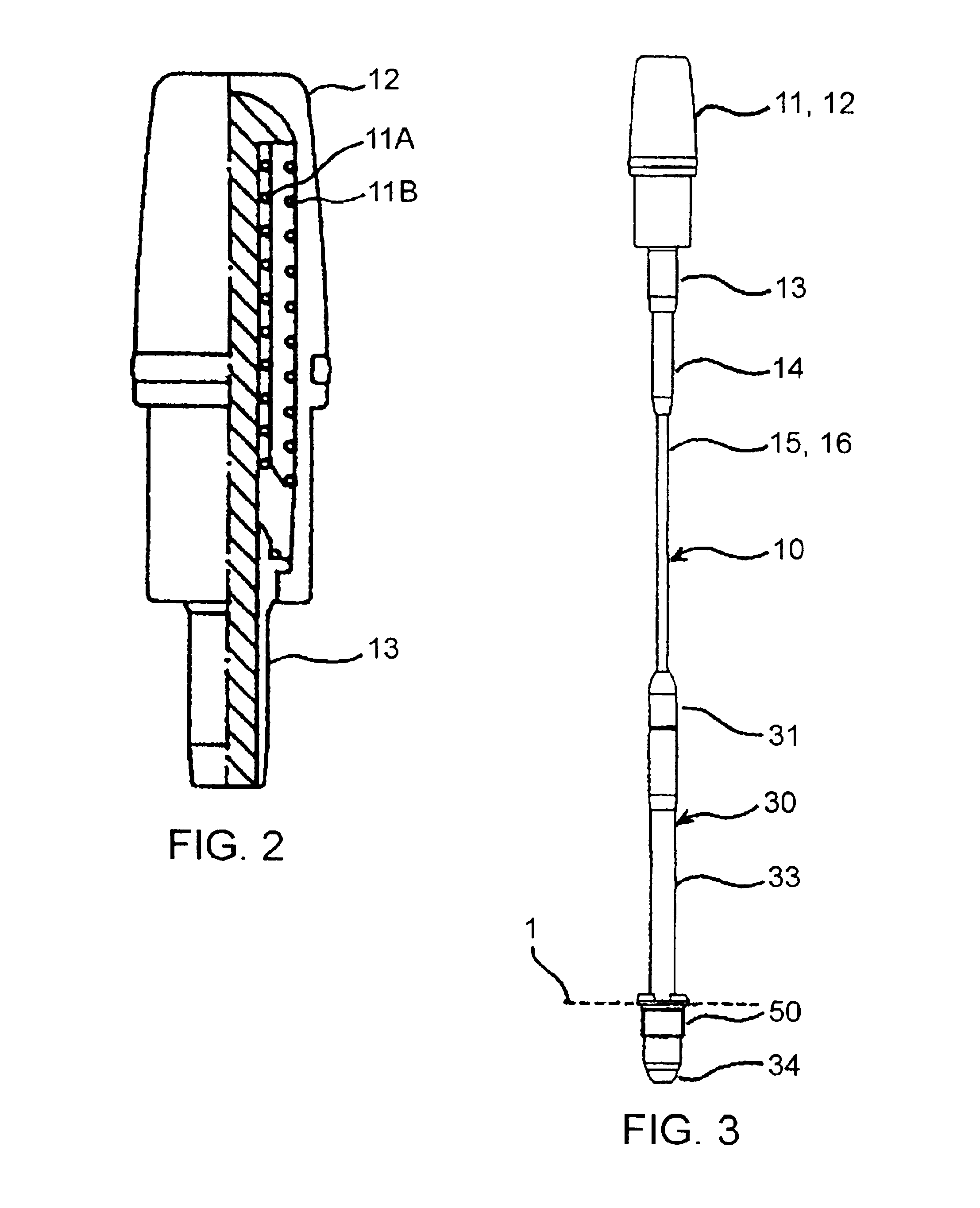

Antenna

InactiveUS6952186B2Improve antenna characteristicGood antenna characteristicsLogperiodic antennasSimultaneous aerial operationsCapacitive couplingCapacitance

A helical antenna capable of operating at a plurality of different resonant frequencies. The helical antenna has a first helical antenna element, a second helical antenna element arranged coaxially with the first helical antenna element and coupled to the first helical antenna element through capacitive coupling, and a metal connection directly connected only to the first helical antenna element to fed the helical antenna. The first helical antenna element is fed through one end thereof to function as a quarter-wave antenna. The second helical antenna element is fed through capacitive coupling to function as a half-wave antenna.

Owner:NEC CORP

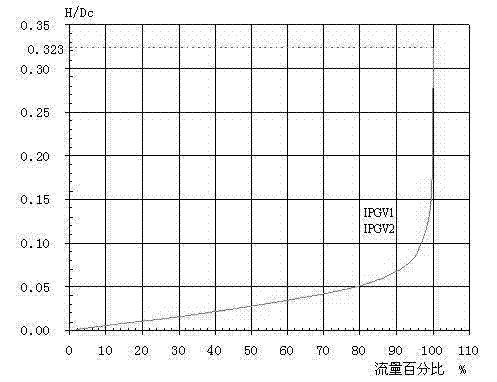

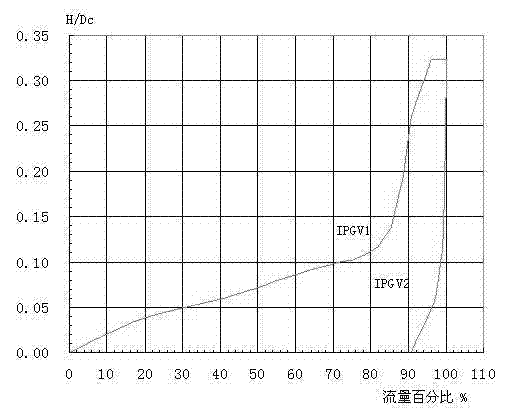

Adjustment method for steam extraction and heat supply of large steam turbine

ActiveCN102410051AEasy to adjustGuaranteed stabilityMachines/enginesEngine componentsEconomic benefitsEngineering

The invention relates to an adjustment method for the steam extraction and the heat supply of a large steam turbine; the steam turbine is provided with two working conditions, i.e. straight condensation and steam extraction and heat supply; a steam extraction and heat supply end of the steam turbine is arranged on a reheating section pipeline between the outlet of a boiler re-heater and a medium-pressure main steam valve; two medium-pressure regulating valves are respectively arranged on two parallel reheating section pipelines; when the steam turbine is switched from a straight condensation working condition to the steam extraction and heat supply working condition, the two medium-pressure regulating valves are sequentially and gradually turned off in a steam distribution way through sequential valves, so that the steam extraction and heat supply pressure of the steam turbine is regulated. Consequently, the regulating performance of the medium-pressure regulating valves is improved, so that the pressure of the reheating section of the steam turbine is stabilized in the heat supply and steam extraction pressure scope, the stability and the safety are ensured, energy is saved and emission is reduced, and huge social and economic benefits are created.

Owner:DONGFANG TURBINE CO LTD

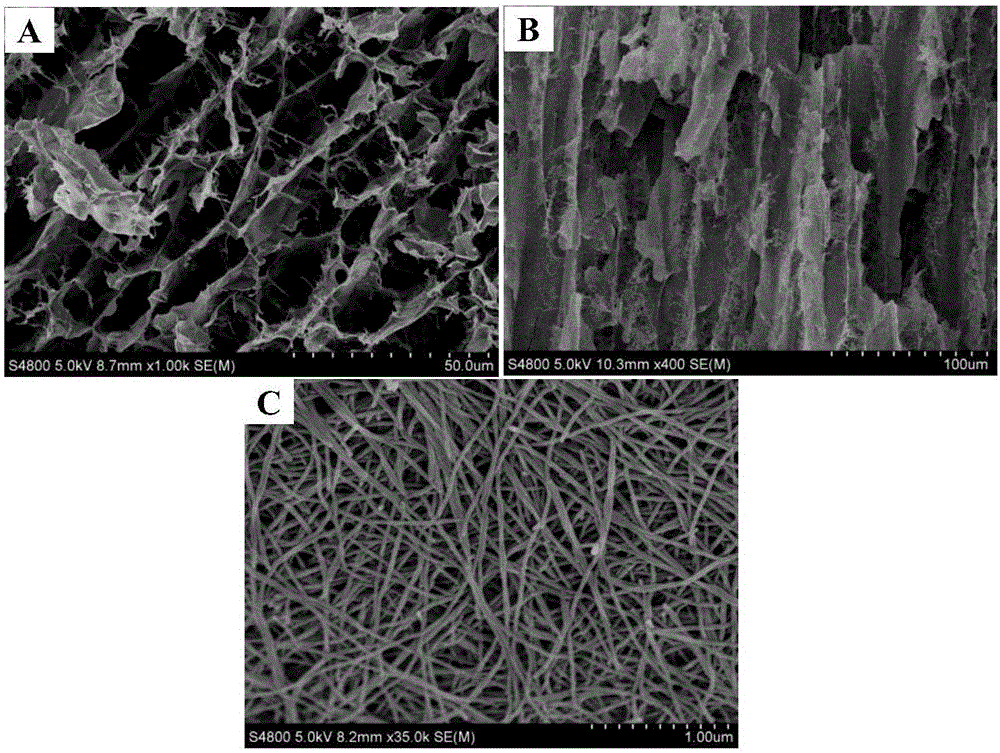

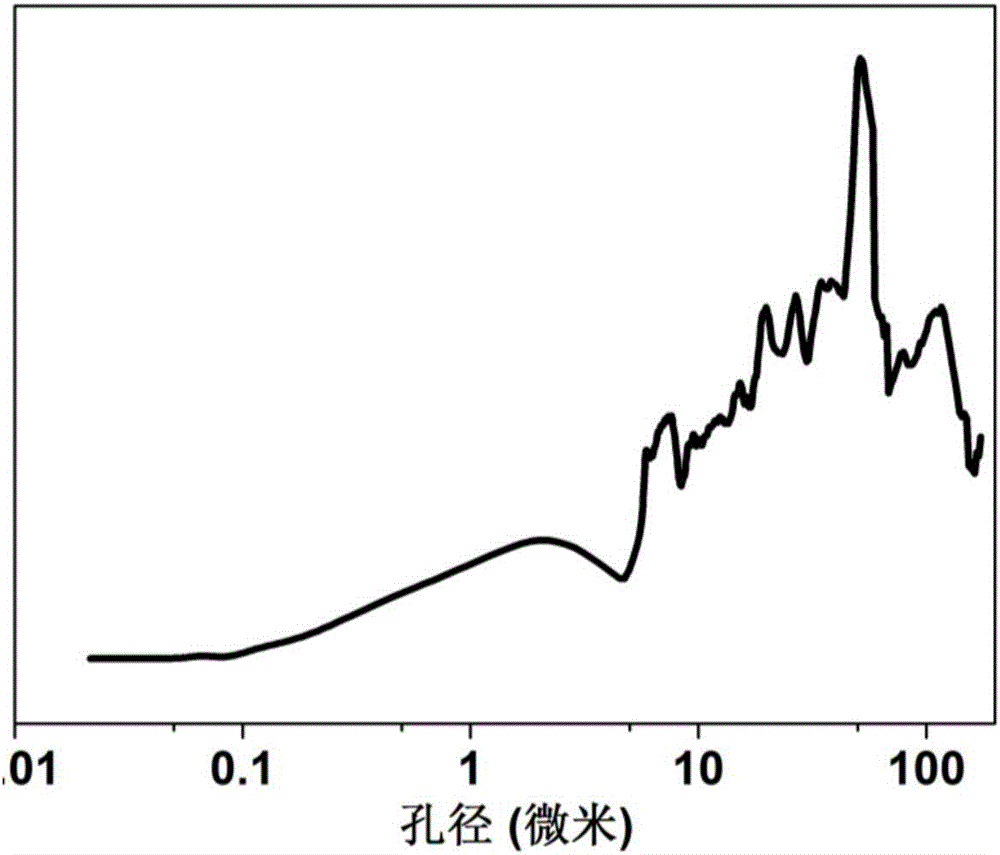

Preparation method of short-peptide/silicon dioxide/hydroxyapatite porous composite material

ActiveCN106668941AAdjustable mechanical propertiesFacilitates adhesion and proliferationTissue regenerationProsthesisAdhesiveFreeze dry

The invention relates to a preparation method of a short-peptide / silicon dioxide / hydroxyapatite porous composite material, belonging to the technical field of preparation of biological composite materials. The short-peptide / silicon dioxide / hydroxyapatite porous composite material can be used as a bone-repairing three-dimensional scaffold material, has good biological activity, mechanical property and degradation characteristic, and is beneficial to improvement of the bone repairing effect. The preparation method comprises the steps of dissolving short-peptide molecules into water for assembly; mixing the assembled short-peptide solution, a silicon precursor and an adhesive, and reacting to form short-peptide / silicon dioxide gel; replacing the gel by using ultra-pure water and then freezing a sample by using a condensation induction method and carrying out freeze-drying to obtain a short-peptide / silicon dioxide porous material; soaking the material by using simulated body fluid, and carrying out freeze-drying to obtain the short-peptide / silicon dioxide / hydroxyapatite porous composite material. The short-peptide / silicon dioxide / hydroxyapatite porous composite material is used for preparing an organic / inorganic porous composite material, has a hierarchical porous structure which is easy to regulate and control, and can be applied to the field of bone repairing as a three-dimensional scaffold of an artificial bone material.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Roll stand provided with a displacement device

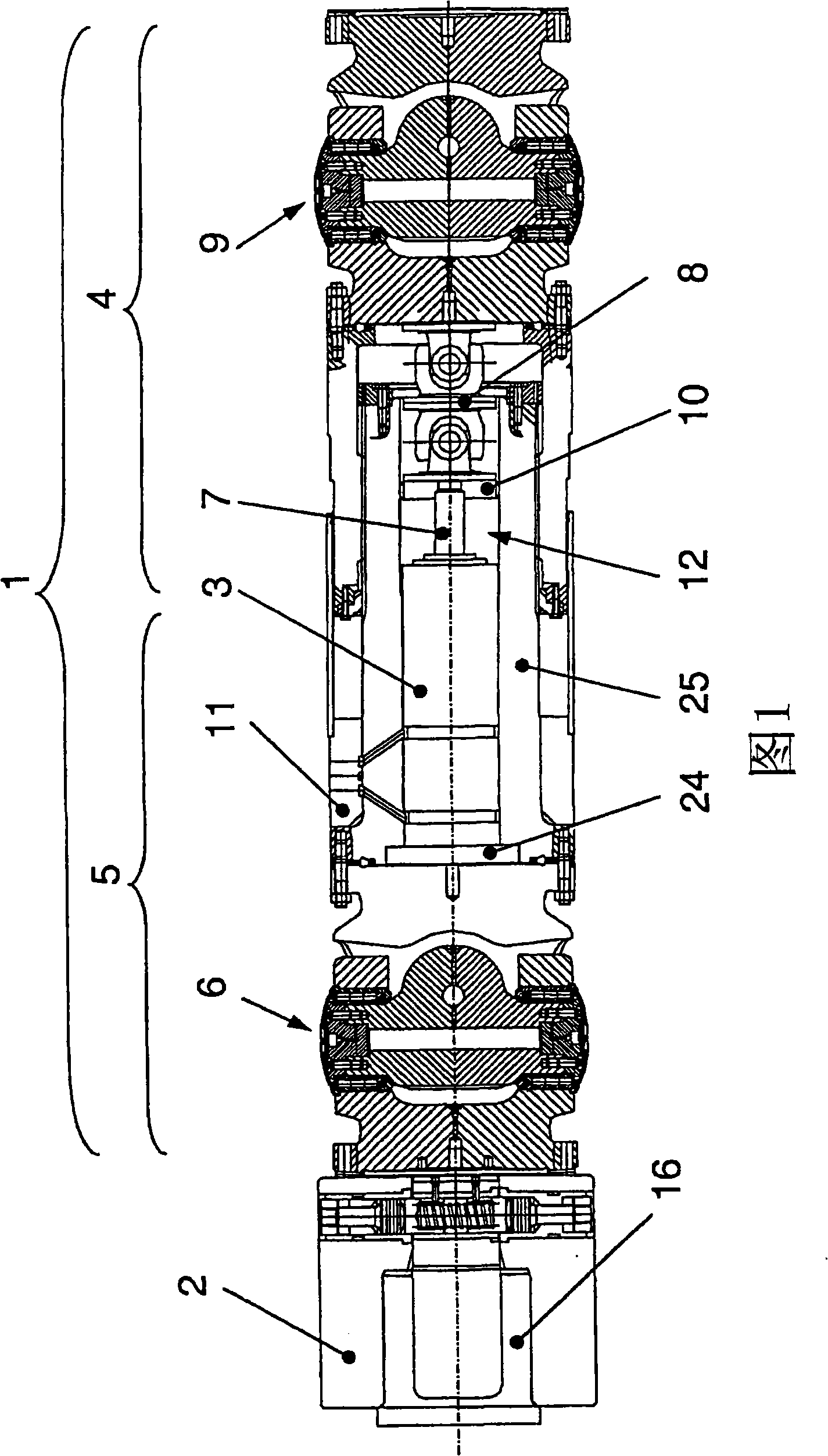

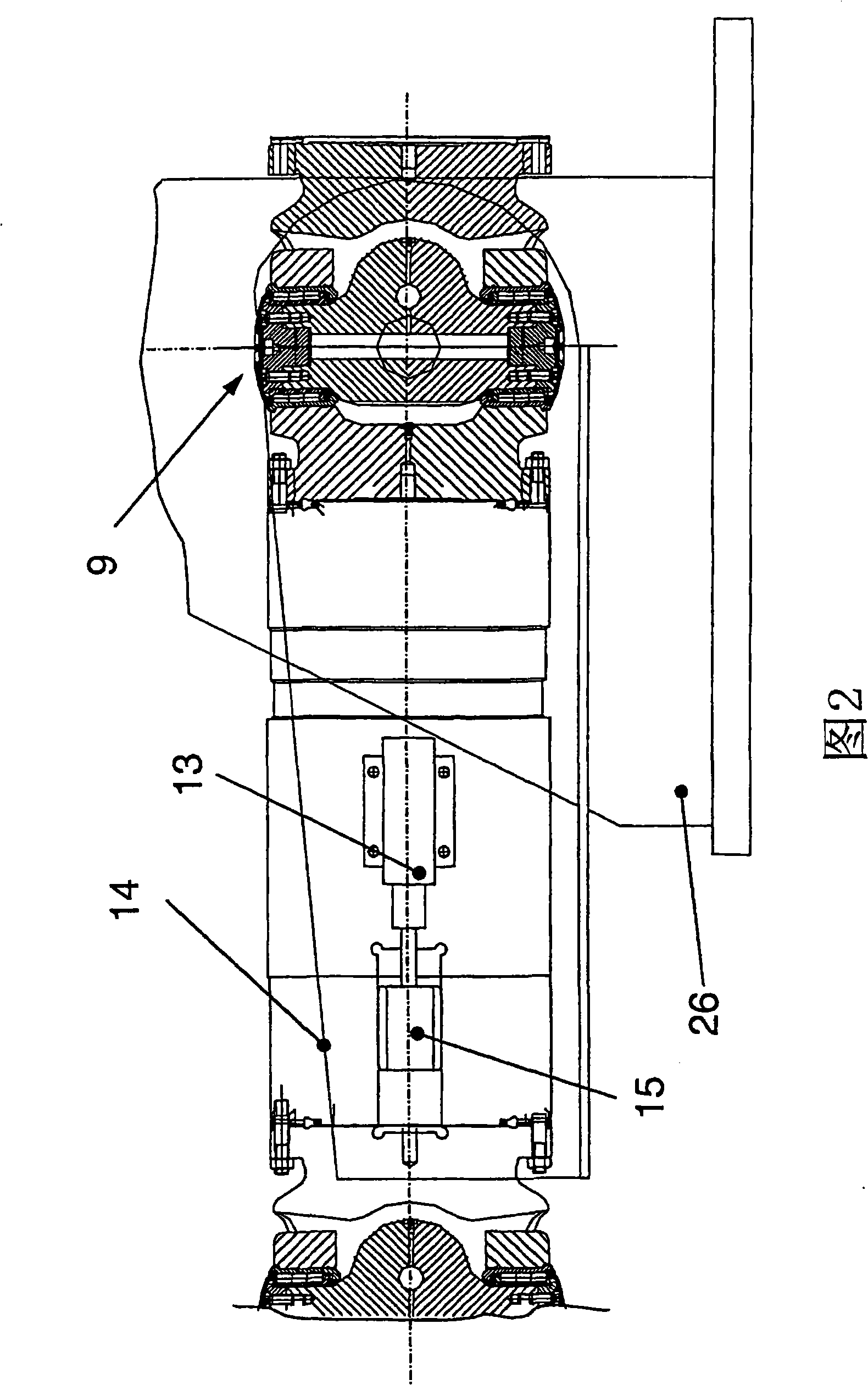

InactiveCN101277771AReliable supplySimple structureMetal rolling stand detailsShaftsStanding frameDrive shaft

Owner:西门子VAI金属技术有限责任公司

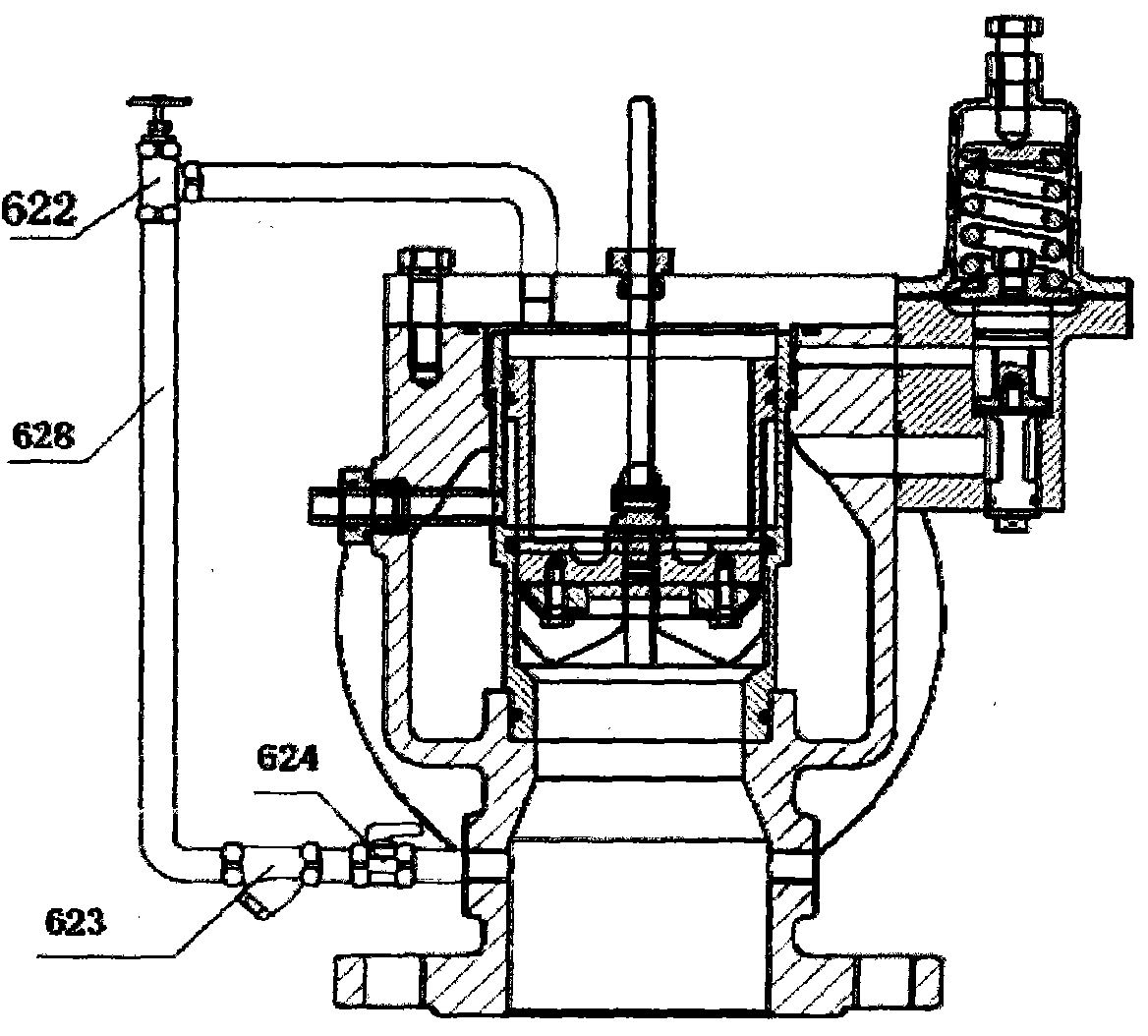

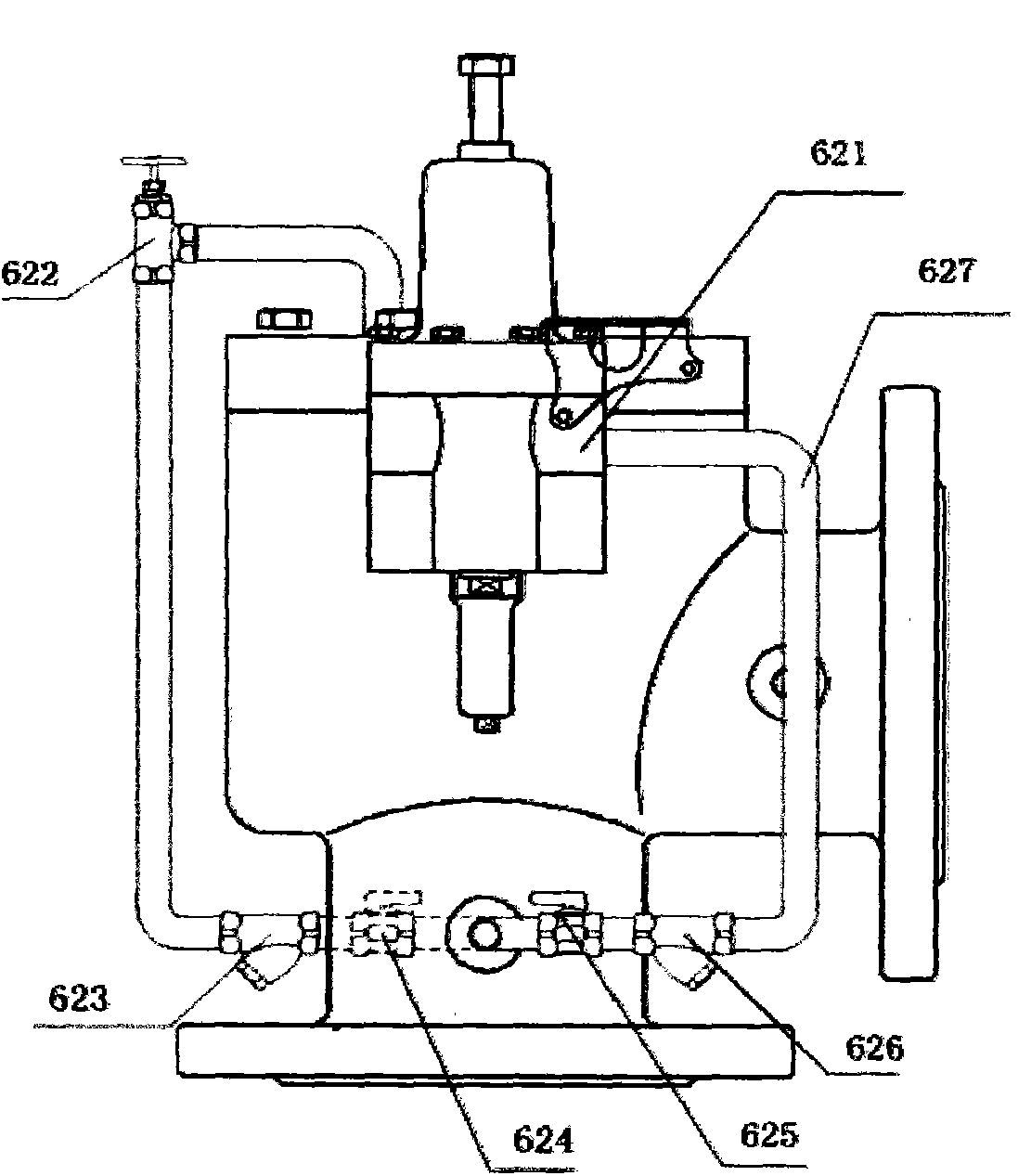

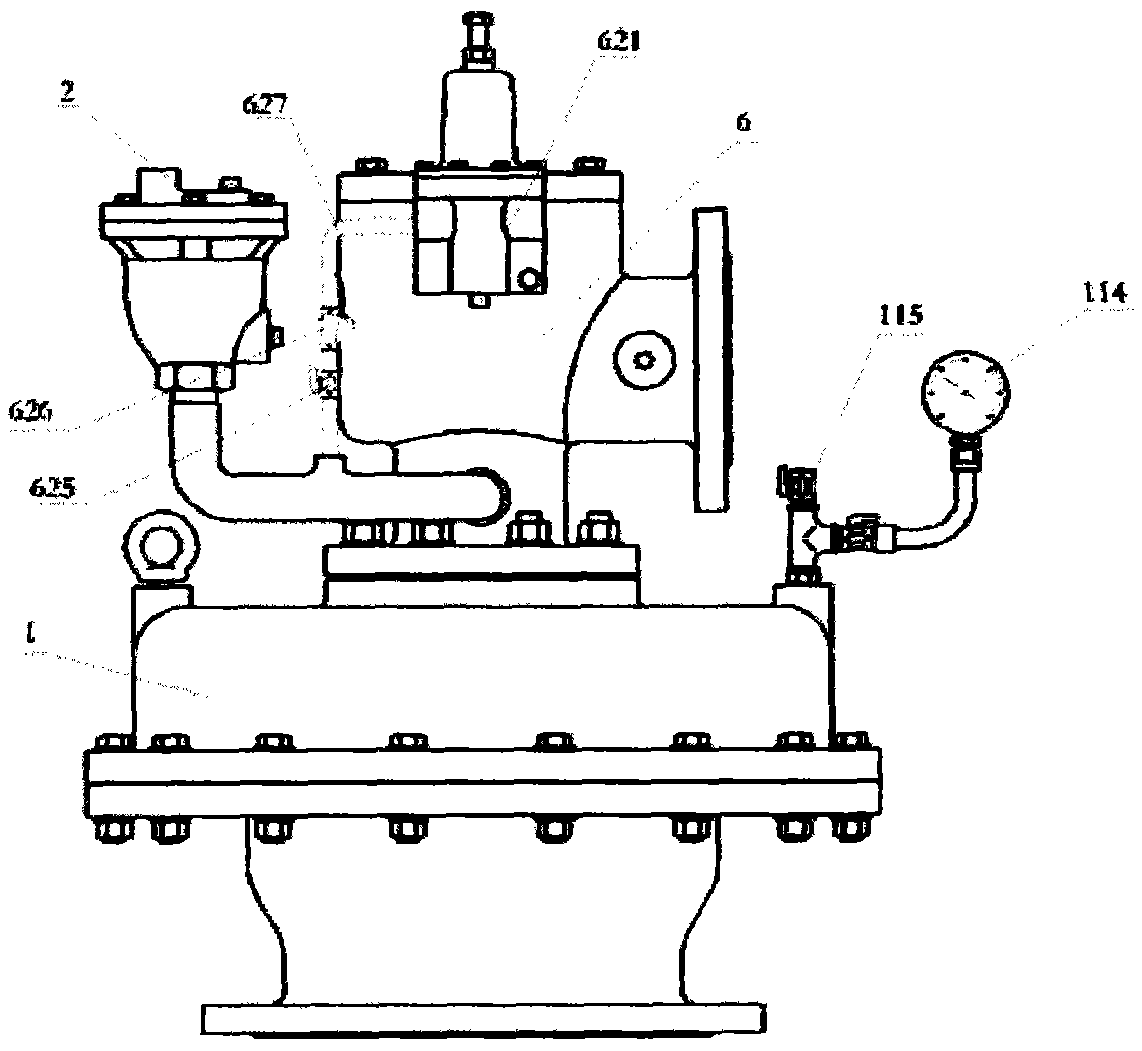

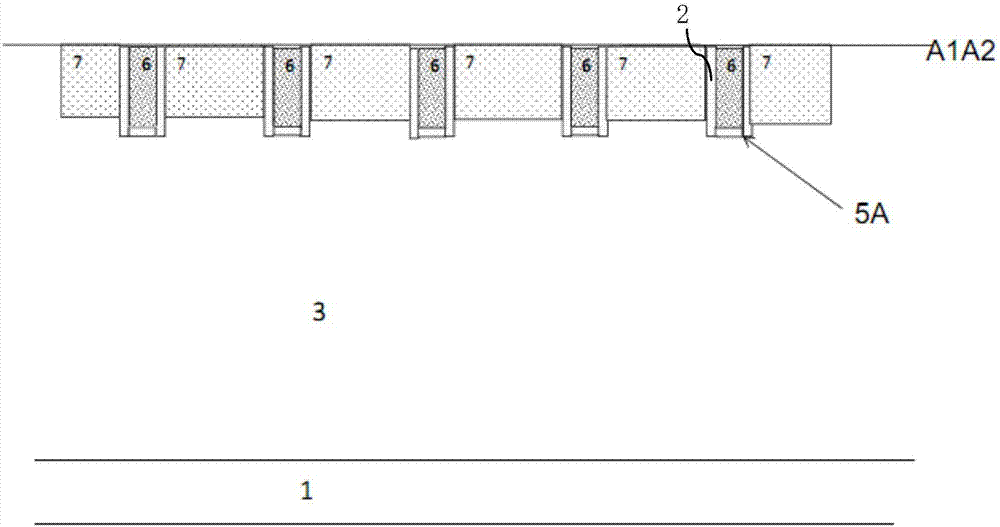

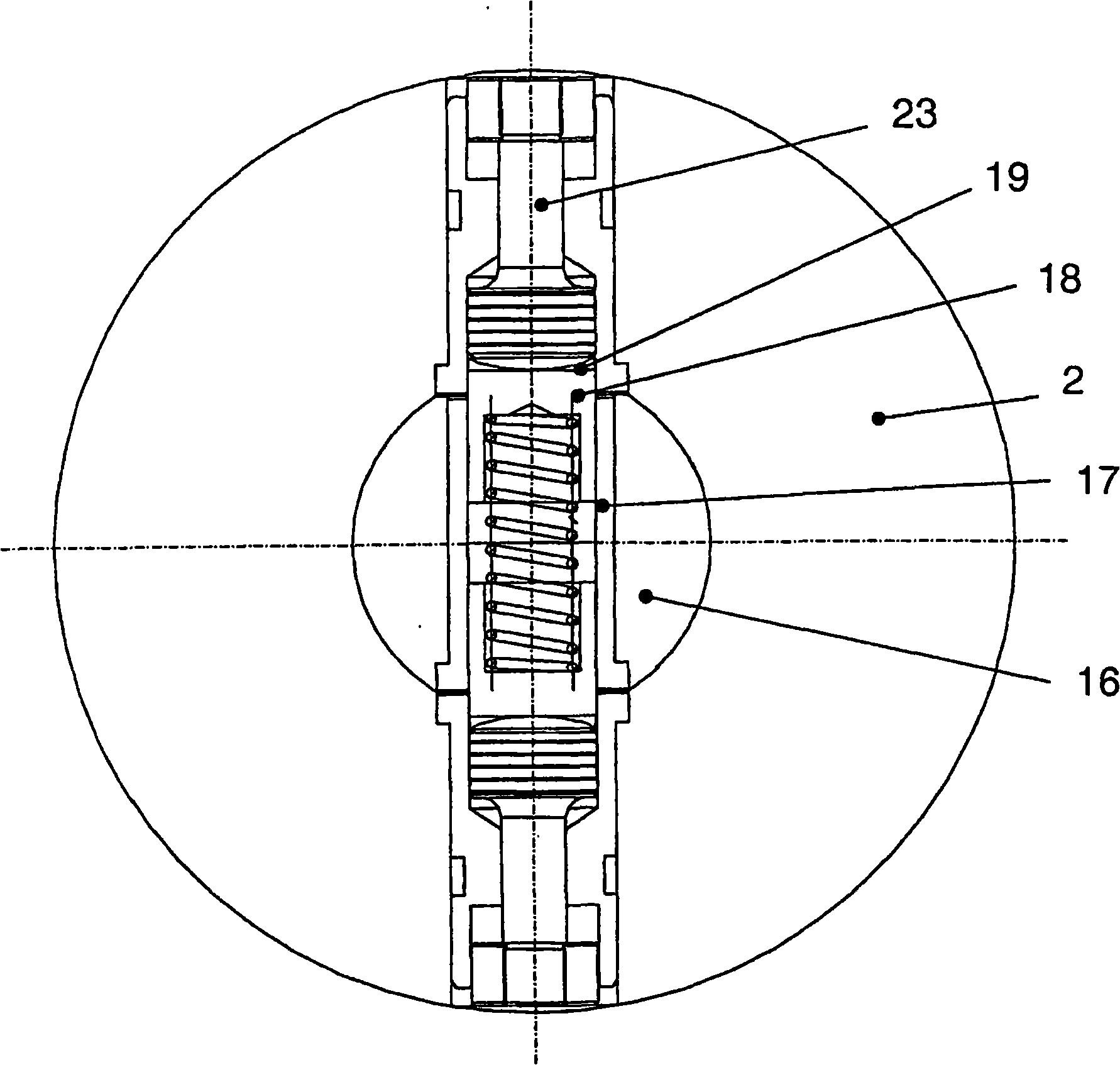

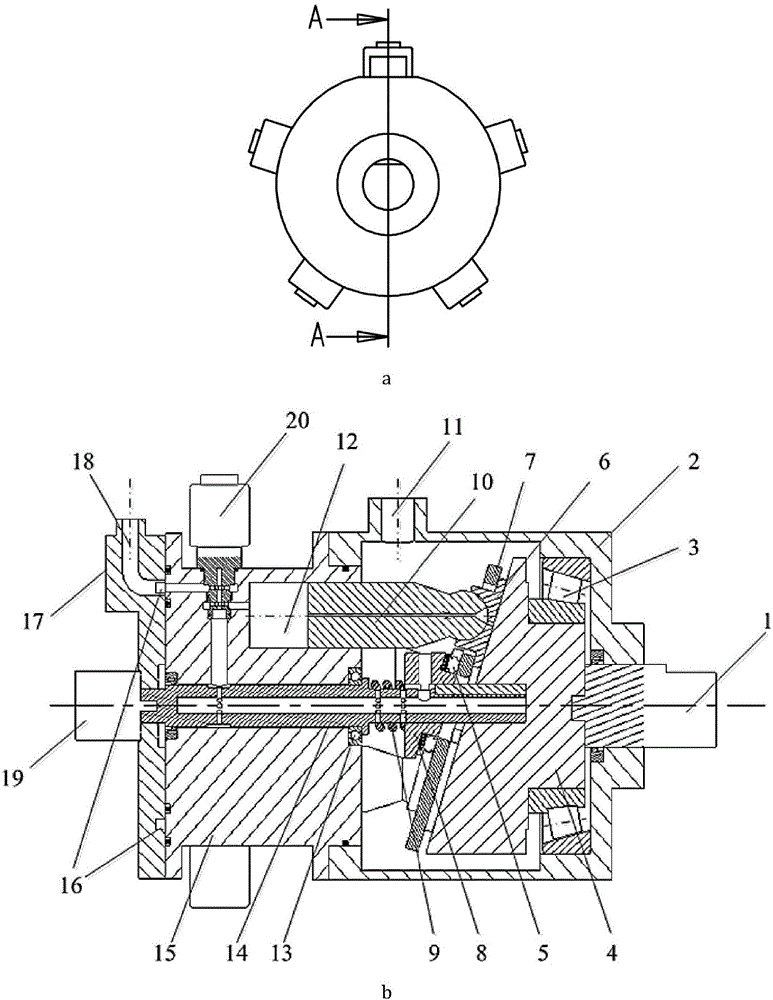

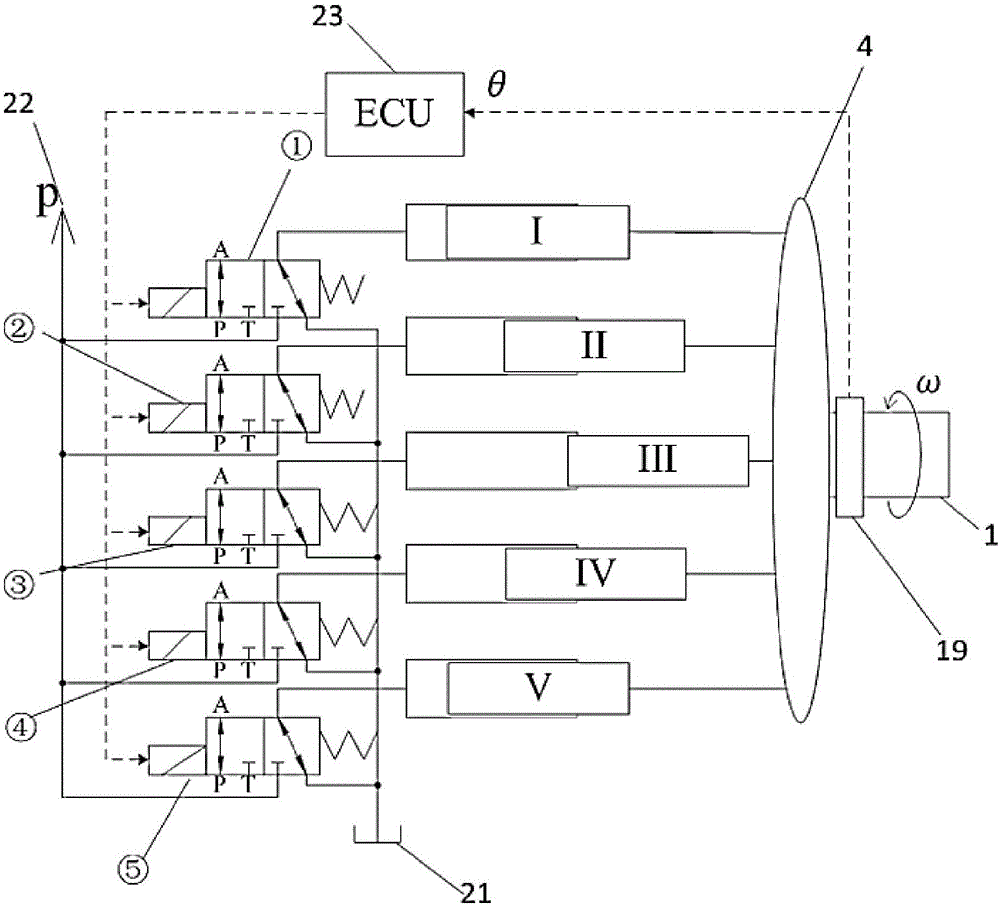

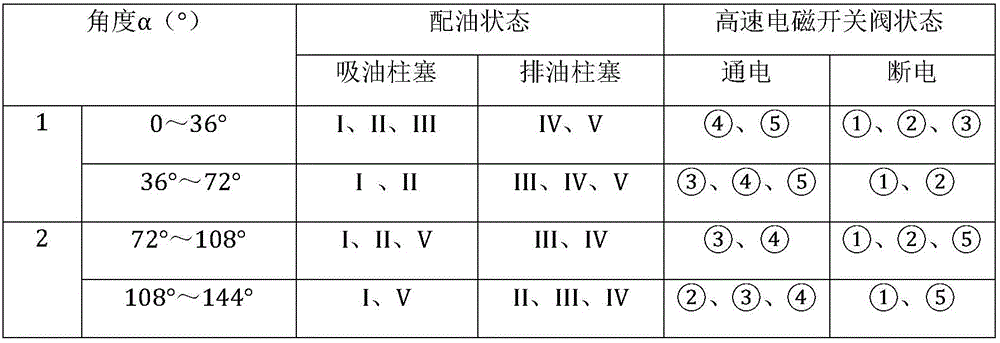

Digital flow distribution and speed adjustment type low-speed axial plunger pump

InactiveCN106762503AExtended service lifeGood regulation characteristicsPositive displacement pump componentsPump parameterLow speedLow voltage

A digital flow distribution and speed adjustment type low-speed axial plunger pump comprises a shell, an input shaft mechanism arranged in the shell, a return mechanism, five sets of plungers each provided with a high-speed electromagnetic switch valve, and corresponding flow pass structures, wherein the tail end of the input shaft mechanism is provided with an angle encoder connected with an electronic control unit, the five high-speed electromagnetic switch valves are controlled respectively through the electronic control unit, the input end of each high-speed electromagnetic switch valve is connected with a corresponding plunger cavity, and two output ends of each are connected with a low-voltage cavity and a high-voltage cavity respectively. By modifying the whole flow pass structure of the axial plunger pump, all friction pairs are lubricated with cold oil; a pump block is simple and compact in structure, energy conversion efficiency is high, and the service life is extended; in addition, the high-speed electromagnetic switch valves distributed at the plunger cavities are used herein to replace traditional flow distribution plates or flow distribution one-way valves, and easy-to-control digital flow distribution and speed adjustment mode under random low-speed input is formed.

Owner:SHANGHAI JIAO TONG UNIV

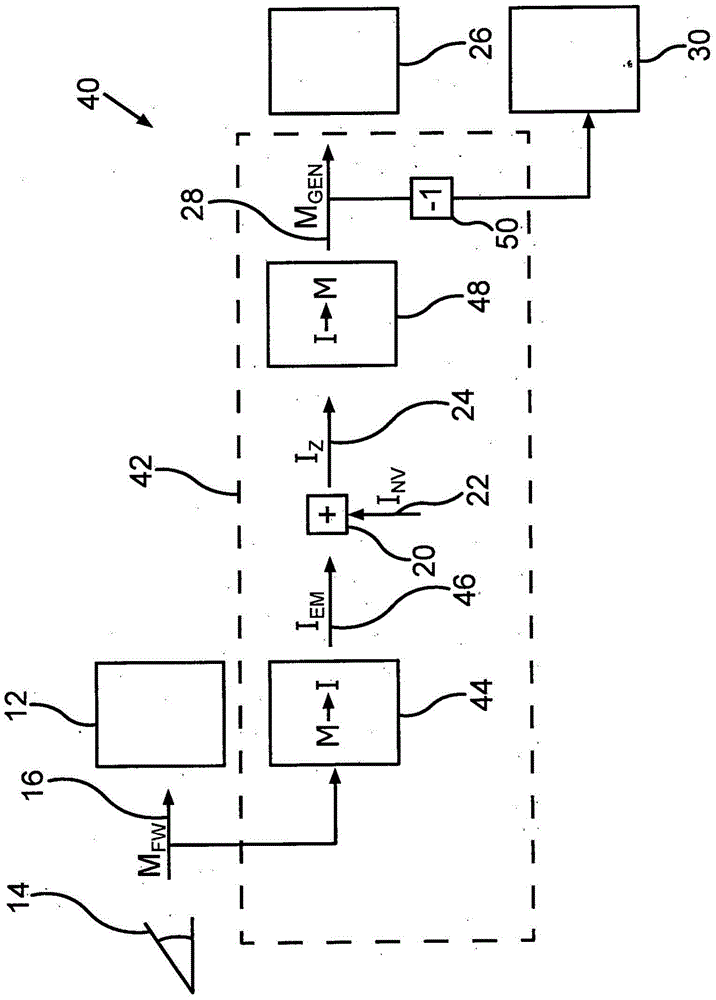

Vehicle drive control

ActiveCN105473399AShorten adjustment speedAvoid oscillationHybrid vehiclesSpeed controllerDriver/operatorExternal combustion engine

The invention relates to a method for controlling a drive (40) of a vehicle with at least one first axle which is occupied by at least one wheel. A drive torque (16) is specified by a driver of the vehicle, and the first axle is driven by means of a first electric machine (12) dependent on the drive torque (16). A second electric machine (26) which is coupled to at least one internal combustion engine (30) provides electric energy for the purpose of driving the first axle by means of the first electric machine (12). A respective control or target torque (28) assigned to the second electric machine (26) and the internal combustion engine (30) is calculated while taking into consideration the drive torque (16) and machine parameters of at least the second electric machine (26), and the second electric machine (26) and the internal combustion engine (30) are each regulated with respect to the assigned control torque or with respect to the assigned target torque (28).

Owner:AUDI AG

Impact-resistant reverse unloading distribution type high-precision gas pressure reduction device

ActiveCN110260005AReduce outlet pressure deviationHigh sensitivityValve members for absorbing fluid energyEqualizing valvesProduct gasInlet pressure

The invention provides an impact-resistant reverse unloading distribution type high-precision gas pressure reduction device. The device is designed by adopting a distribution pressure guide structure, outlet low-pressure gas at different positions is guided to the upper cavity of the valve core through feedback holes located in different sections of the valve core, the pressure deviation of the upper cavity and the lower cavity of the valve core is reduced, the upper cavity of the pressure reducing device is rapidly and accurately modeled in the adjusting process, and the sensitivity and the stability are improved. Meanwhile, the influence of inlet pressure is eliminated by adopting a reverse unloading structure design, the valve core has the unloading rod function, the high-pressure stress part of the valve element is isolated from the low-pressure stress part through the sealing assembly, pressure unloading design is realized, the upper sealing surface and the lower sealing surface of the valve body are subjected to equal-section design, so that the acting force of the inlet pressure acting on the upper end surface and the lower end surface of the valve core moving part is counteracted, the complete unloading of the inlet pressure is realized, so that the valve element is not influenced by the change of the inlet pressure in the adjusting process, so that the opening degree of the valve element is only influenced by the pressure change of the outlet.

Owner:XIAN AEROSPACE PROPULSION INST

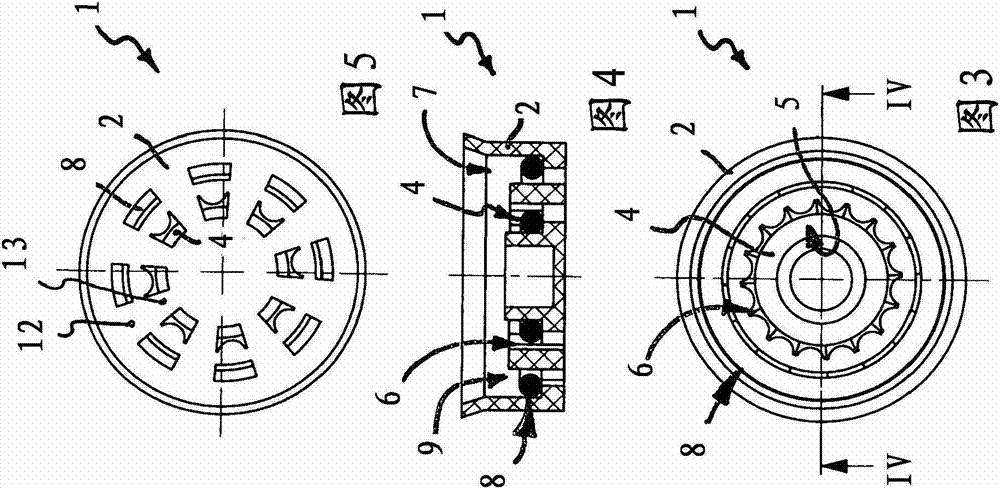

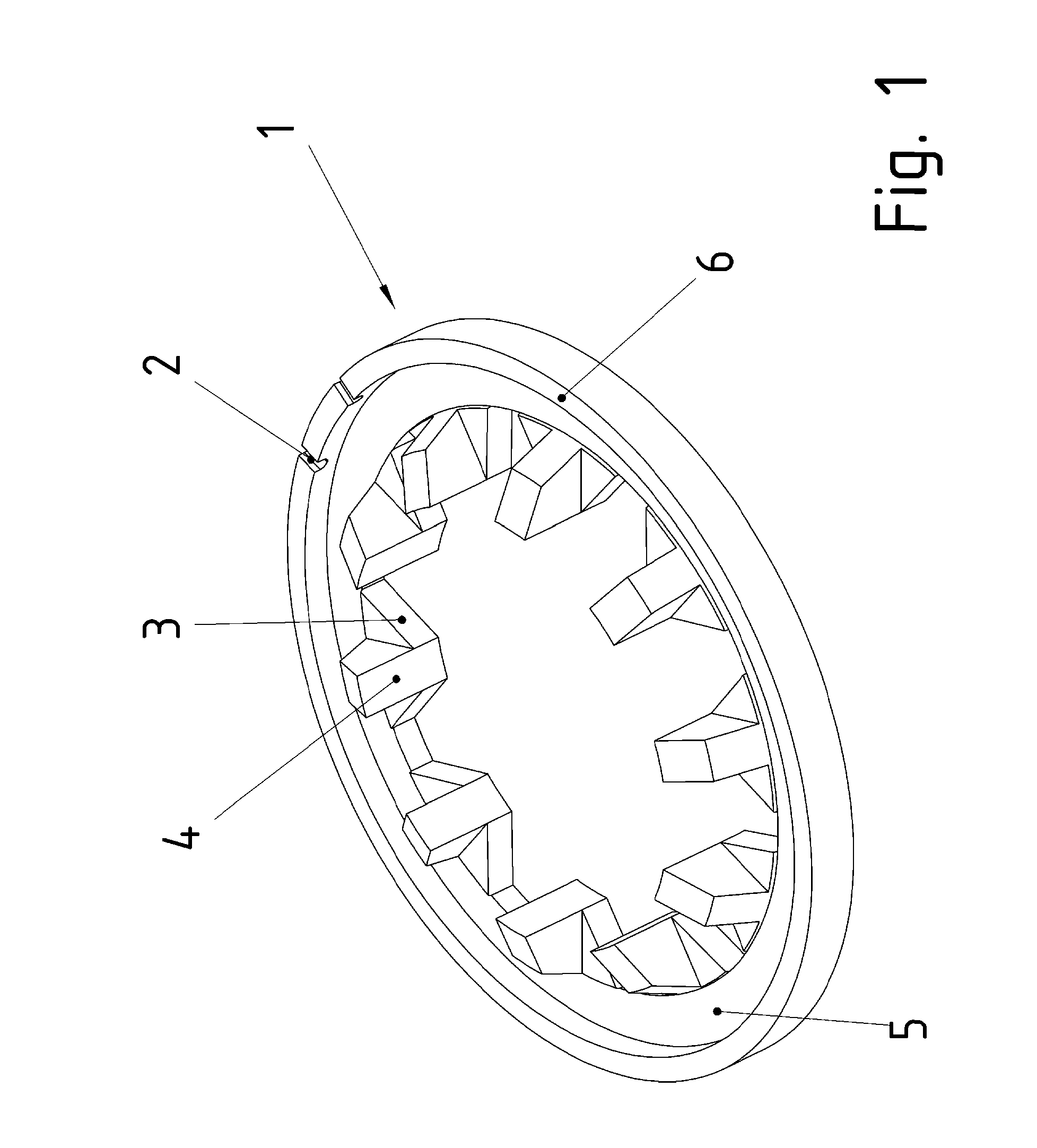

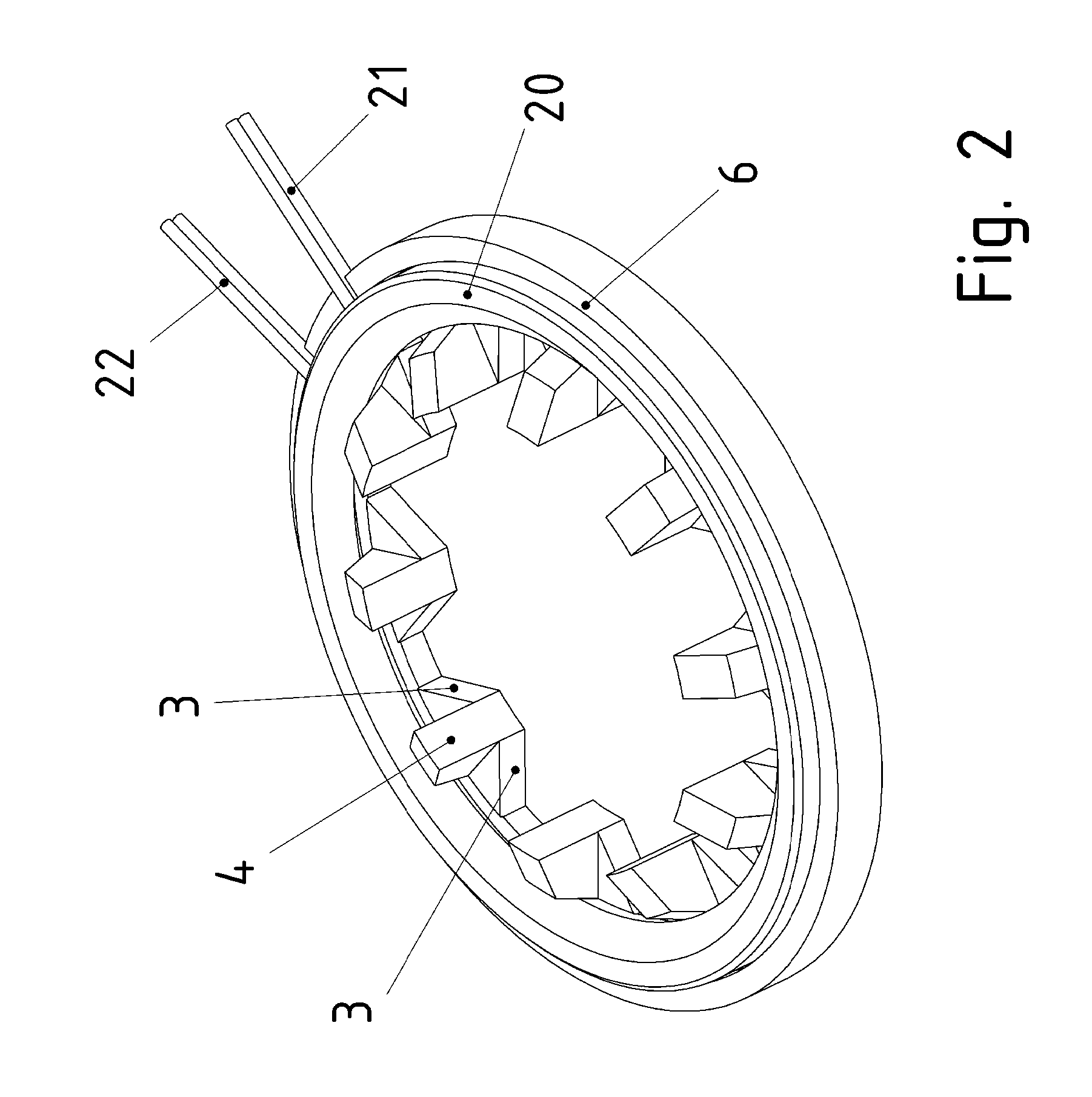

Electric Machine

ActiveUS20140346920A1Good regulation characteristicsIncrease torqueWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machineEngineering

An electric machine, especially a transversal flux machine, the stator being composed of a stack of phase segments, each phase segment having at least one stator segment and one stator winding, especially a single winding, each stator segment having an annular stator bridge, on which pole shoes are premolded, which in particular extend in the radially inward direction, and / or which extend in the direction of the rotor and / or which are situated between the rotor and the annular stator bridge, the pole shoes having the same shape, in particular, the axial width of the pole shoe decreasing with increasing radial clearance, the associated profile being disposed between a first and a second profile, the first profile being a linear function of the radial clearance, the pole back associated with the first profile being a planar area, in particular, the second profile being a circular function, in particular a circular segment function, the pole back associated with the second profile being a cylindrical section area, in particular.

Owner:SEW-EURODRIVE GMBH & CO KG

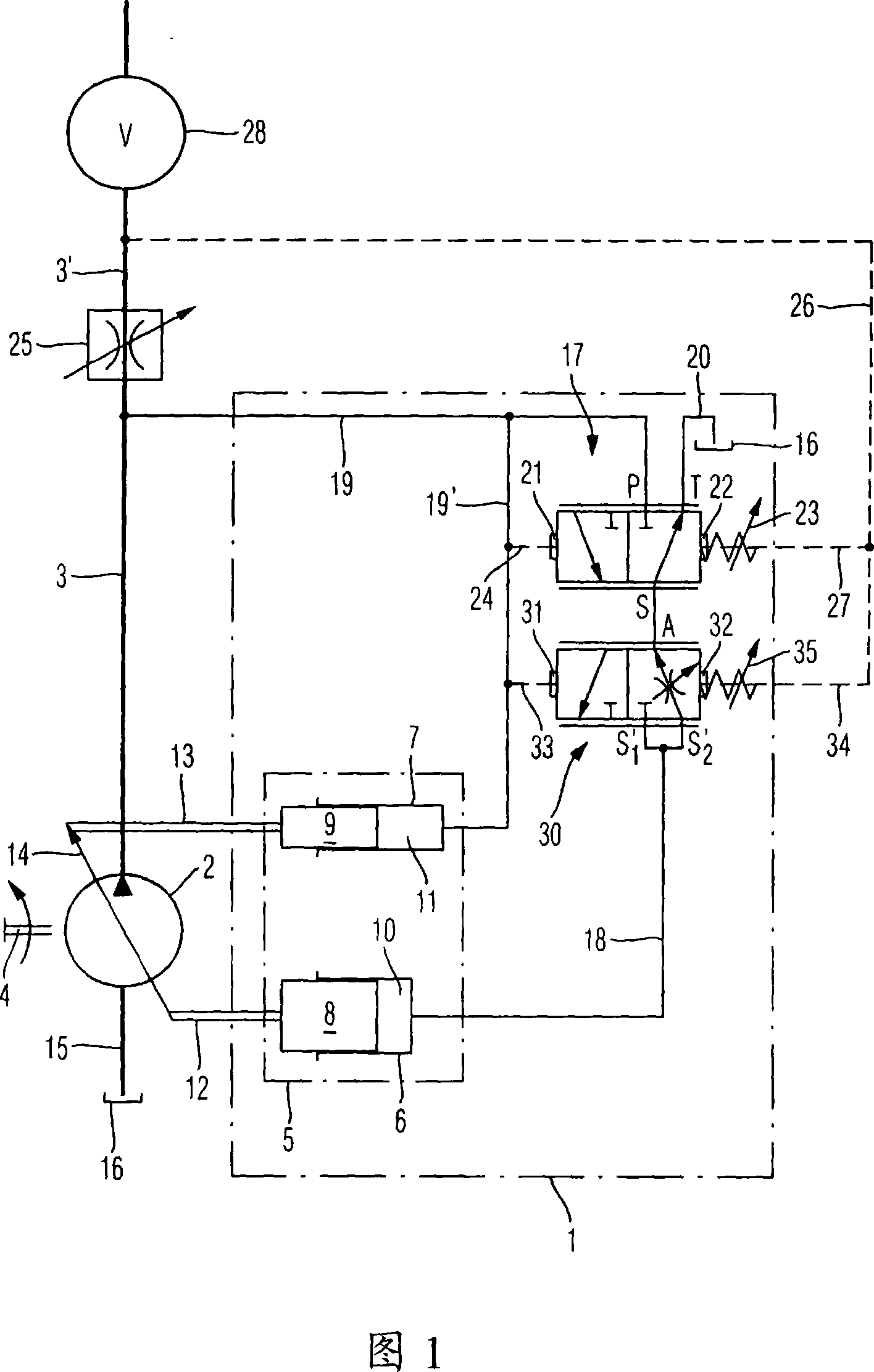

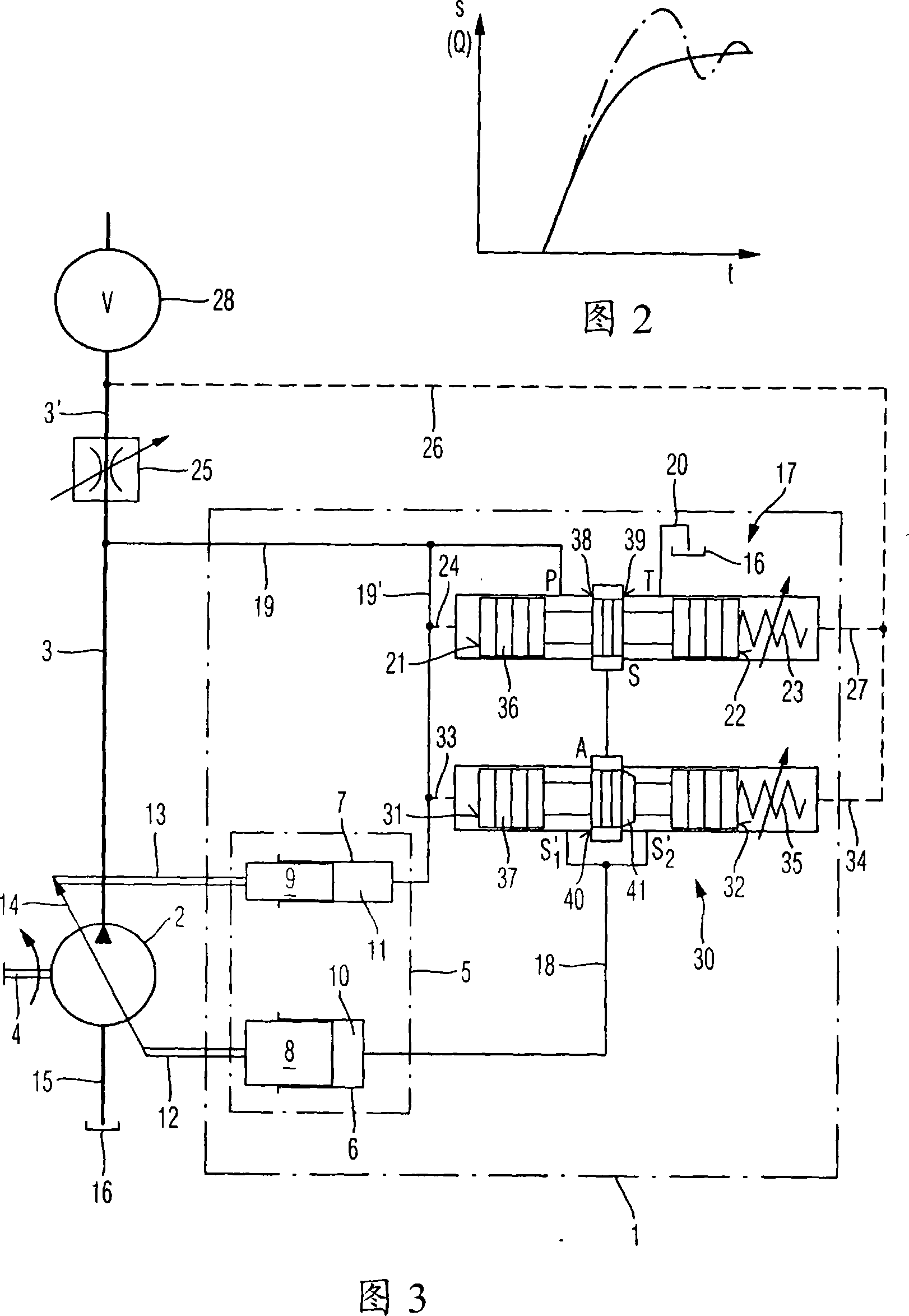

Load-pressure-controlled feed flow regulator with vibration damping

InactiveCN101175921AAvoid excessive vibrationExcessive vibration does not occurFluid parameterServomotorsHydraulic pumpEngineering

The invention relates to a load-pressure-controlled fees flow regulator ( 1 ) for adjusting the feed volume of an adjustable hydraulic pump ( 2 ) which feeds in a working line ( 3 ). The load-pressure-controlled feed flow regulator ( 1 ) has an adjusting device ( 5 ) for adjusting the feed volume of the hydraulic pump ( 2 ). The adjusting device ( 5 ) is acted on with an adjusting pressure in order to adjust the feed volume of the hydraulic pump ( 2 ). The level of the adjusting pressure is generated by an adjusting pressure regulating device ( 17 ). In addition to the adjusting pressure regulating device ( 17 ), the fees flow regulator ( 1 ) has a damping device ( 30 ).

Owner:HYDROMATIK GMBH

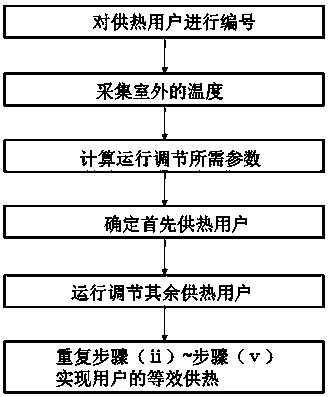

Adjustment method for solving hydraulic imbalance problem of heat supply system

ActiveCN109253492AElimination of horizontal thermodynamic imbalanceGood regulation characteristicsLighting and heating apparatusSpace heating and ventilation detailsProcess engineeringOutdoor temperature

The invention discloses an adjustment method for solving the hydraulic imbalance problem of a heat supply system. The method comprises the following steps of 1, numbering heat supply users, 2, collecting an outdoor temperature, 3, calculating parameters required for running adjustment, 4, determining the first heat supply users, 5, conducting running adjustment on the remaining heat supply users,and 6, repeating steps 2 to 5 to achieve the equivalent heat supply for the users. At intervals, user valves are switched on from the far-end users to the near-end users one by one, the power supply flow of a circulating water pump is adjusted while the switches are switched on, and it is ensured that the heat supply effects on the n users are consistent within an adjustment time period. Accordingto the method, the influence of the heat supply distance on the users is considered, the horizontal thermal imbalance of the heat supply system is fundamentally eliminated so that the near-end usersand the far-end users can all have the same heat supply effect, the adjustment characteristics of a pipe network are improved, the situation that the increase of the running energy consumption is caused by a large-flow running mode is avoided, and the pipe diameter of a main heat supply pipeline does not need to be increased.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

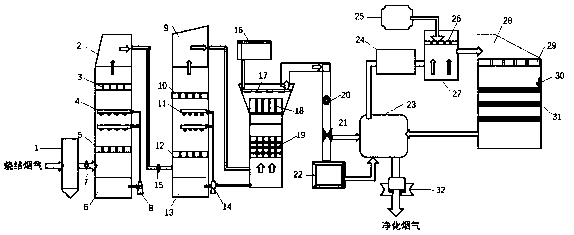

Desulfurization, denitrification and white smoke elimination device for ultralow emission of sintering machine flue gas and process thereof

InactiveCN111589288AConcentration real-time detectionReduce concentrationCombination devicesGas treatmentPtru catalystDust control

The invention provides a desulfurization, denitrification and white smoke elimination device for ultralow emission of flue gas of a sintering machine and a process thereof. The device and the processare high in desulfurization, denitrification and dust removal efficiency and stable in long-term operation, reduce energy consumption and satisfy ultra-low emission requirements of sintering machinesand sintering agglomerates in the iron and steel industry. A double-tower device in a desulfurization system is subjected to desulfurization efficiency improvement and transformation, so that the ultra-low emission index of SO2 is achieved; a spiral-flow type efficient dust-removing demister and a wet type electric dust remover are arranged at the upper part of the secondary absorption tower, so that pollutants such as smoke dust, slurry fog drops, SO3 and heavy metals in the flue gas are effectively removed, and the ultralow emission index of the smoke dust is achieved; the denitration systemadopts a medium-low temperature SCR (Selective Catalytic Reduction) process, ammonia gas and NOx are subjected to a redox reaction under the action of a catalyst, NOx is reduced into N2 and H2O, andthe ultralow emission index of NOx is achieved.

Owner:YANGCHUN NEW STEEL CO LTD

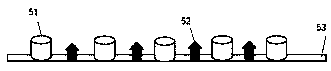

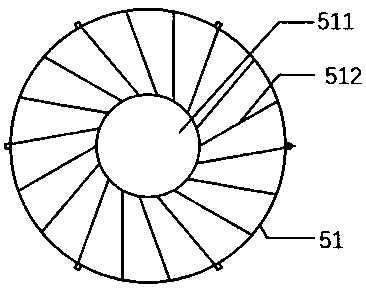

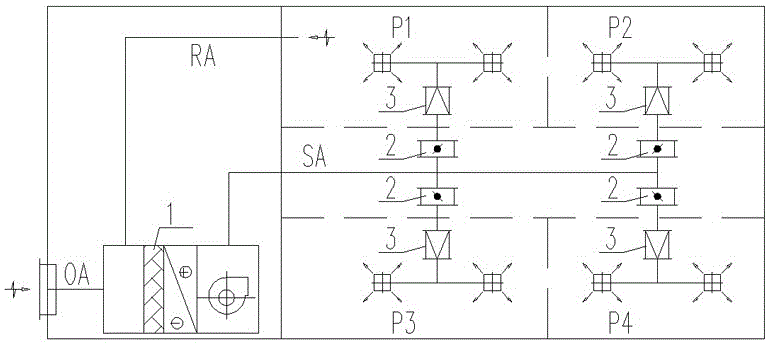

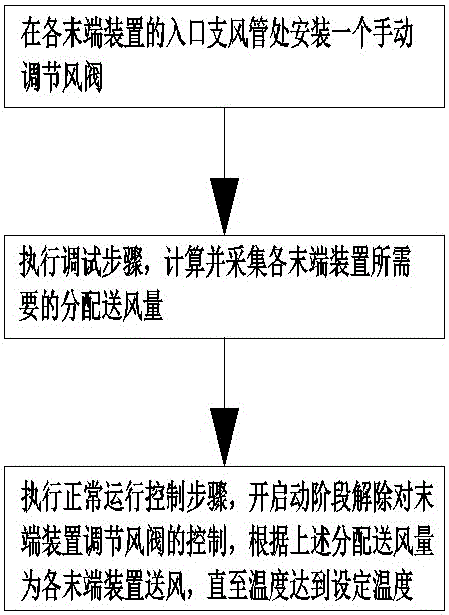

VAV system start up air flow balancing method and system

ActiveCN106679019AGood regulation characteristicsSolve the noiseMechanical apparatusSpace heating and ventilation safety systemsAir volumeTerminal equipment

The invention discloses a VAV system start up air flow balancing method. The method comprises the following steps: mounting a manual adjusting air valve at the position of a branch air duct of an inlet of each VAV terminal device; carrying out a debugging step before use, operating an air conditioning unit at industrial frequency, opening all the adjusting air valves of the VAV terminal devices on the premise of not receiving related instructions of temperature adjustment control, adjusting the manual adjusting air valves, and enabling the supply air volume of each VAV terminal device to be close to but not less than a design value; and carrying out a normal operating control step, running the air conditioning unit at the industrial frequency at first, opening all the adjusting air valves of the VAV terminal devices on the premise of not receiving the related instructions of temperature adjustment control, supplying air for the VAV terminal devices according to the supply air volume which is required to be distributed and obtained from the debugging step, when temperatures, which are detected by temperature sensors, of rooms corresponding to the VAV terminal devices reach the set temperature, receiving the related instructions of temperature adjustment control by using the adjusting air valves of the VAV terminal devices, adjusting the open degree values of the adjusting air valves, and meanwhile, receiving a frequency converting control instruction by using the air conditioning unit. By the VAV system start up air flow balancing method, a number of problems which exist in an existing VAV system can be solved, and the VAV system is easy to maintain in the later period.

Owner:奥意建筑工程设计有限公司

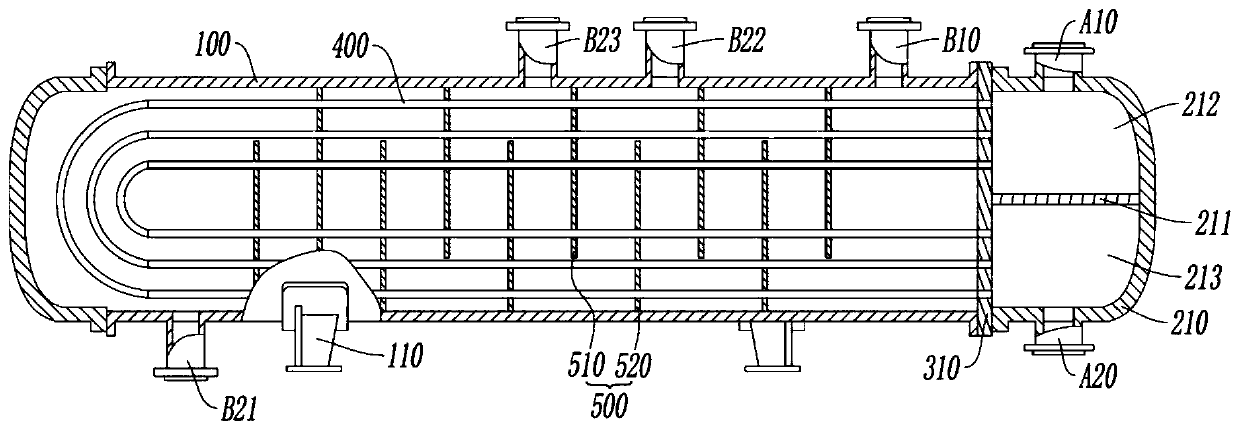

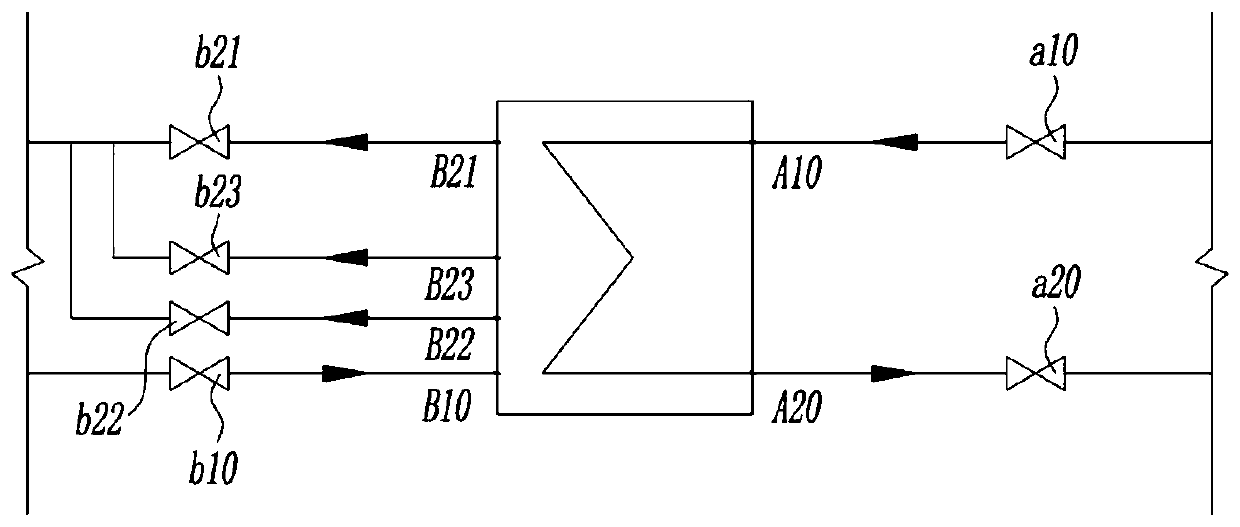

Shell and tube type heat exchanger and control method thereof

ActiveCN110579120AOutlet temperature stabilizationReduce shell lengthHeat exchanger casingsStationary tubular conduit assembliesEngineeringTubes types

The invention discloses a shell and tube type heat exchanger and a control method thereof. The shell and tube heat exchanger comprises a shell, a pipe box, a pipe plate and a heat exchange pipe, wherein the shell is provided with an inner cavity, the shell is provided with a shell pass inlet, a shell pass first outlet and a shell pass second outlet; the shell pass inlet and the shell pass first outlet are located at the two ends of the shell correspondingly, the pipe box is at least arranged at one end of the shell, the pipe box is provided with an inner cavity, a pipe pass inlet and a pipe pass outlet are formed in the pipe box, the pipe plate is located between the shell and the pipe box, the heat exchange pipe is arranged in the inner cavity of the shell, the heat exchange pipe penetrates through the pipe plate to communicate with the inner cavity of the pipe box, and the ratio of the shell pass length between the shell pass second outlet and the shell pass inlet accounts for the shell pass length between the shell pass first outlet and the shell pass inlet is 1 / 5-1 / 3. According to the scheme, the problems that when the pipe shell and tube heat exchanger is operated under the variable working condition, a cooling medium adjusting valve cannot be in the interval with excellent adjusting characteristics and accurate control of the outlet temperature of a cooled medium is difficult to be realized according to the working conditions are solved.

Owner:国能神皖池州发电有限责任公司

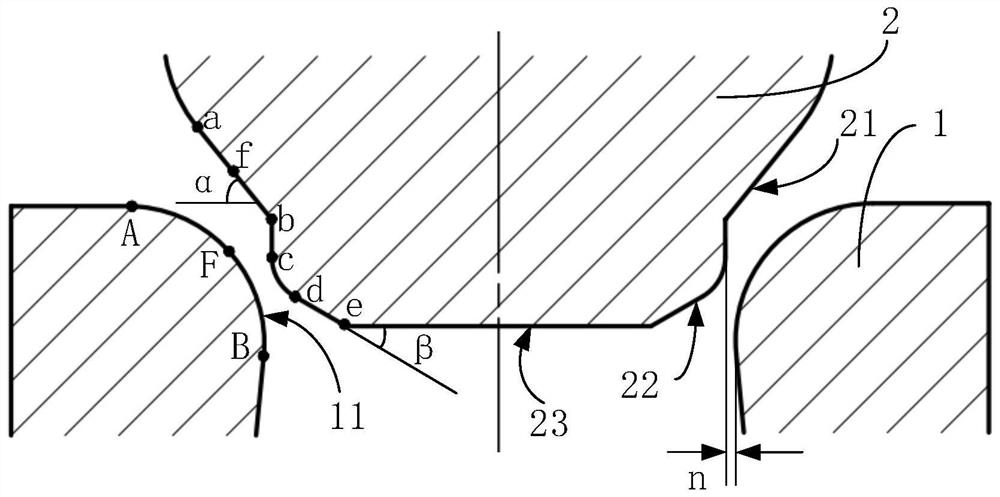

Regulating valve molded line structure and regulating valve

ActiveCN112032327AHigh adjustment accuracyImprove flow capacityLift valveValve housingsEngineeringValve seat

The invention provides a regulating valve molded line structure and a regulating valve adopting the same. The regulating valve molded line structure comprises a valve disc molded line and a valve seatmolded line, wherein the valve disc molded line is arranged on a valve disc, the valve disc molded line comprises a sealing section molded line, a flow control section molded line and a valve disc head molded line which are connected in sequence, The valve seat molded line is arranged on a valve seat, the flow control section molded line comprises a first tangent section molded line, an arc-shaped section molded line and a second tangent section molded line which are connected in sequence, the arc-shaped section molded line is provided with a first end point and a second end point, the firsttangent section molded line and the arc-shaped section molded line are tangent at the first end point, the second tangent section molded line and the arc-shaped section molded line are tangent at thesecond end point, the first tangent section molded line is connected with the sealing section molded line, and the second tangent section molded line is connected with the valve disc head molded line.The molded line structure has high flow adjusting precision under the working condition of small opening, and meanwhile it can be guaranteed that the molded line structure has high through-flow capacity under the working condition of full opening.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Branch-control and phase-change heat exchange system and method based on two-stage steam-liquid heat exchanger

ActiveCN102200403BNo disturbance effectReliable sub-control performanceIndirect heat exchangersHeat exchange apparatusControl systemEngineering

The invention relates to a branch-control and phase-change heat exchange system and method based on a two-stage steam-liquid heat exchanger. The system comprises a heat source heat exchanger (2), a cold source heat exchanger (20) and a low temperature liquid tank (23), and the system further comprises a high temperature heat exchanger (14), a low temperature heat exchanger (22) and a high temperature liquid tank (8); a main heat source steam pipe at the top part of the heat source heat exchanger (2) is divided into two branch pipes after passing through a heat source steam exhaust adjusting valve (16), the two branches are respectively communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (20), and control systems are respectively arranged on the branches; the low temperature liquid tank (23) is communicated with the high temperature heat exchanger (14) through a condensate pipeline, the bottom of the high temperature heat exchanger (14) is communicated with the high temperature liquid tank (8) through a condensate pipeline, and the condensate pipeline at the bottom of the high temperature liquid tank (8) is respectively communicated with the low temperature heat exchanger (22) and the heat source heat exchanger (2). According to the branch-control and phase-change heat exchange system disclosed by the invention, overheat and over-cold phenomenon of steam and condensate are solved, and the heat exchange efficiency is further improved.

Owner:SHANXI SANHESHENG IND TECH

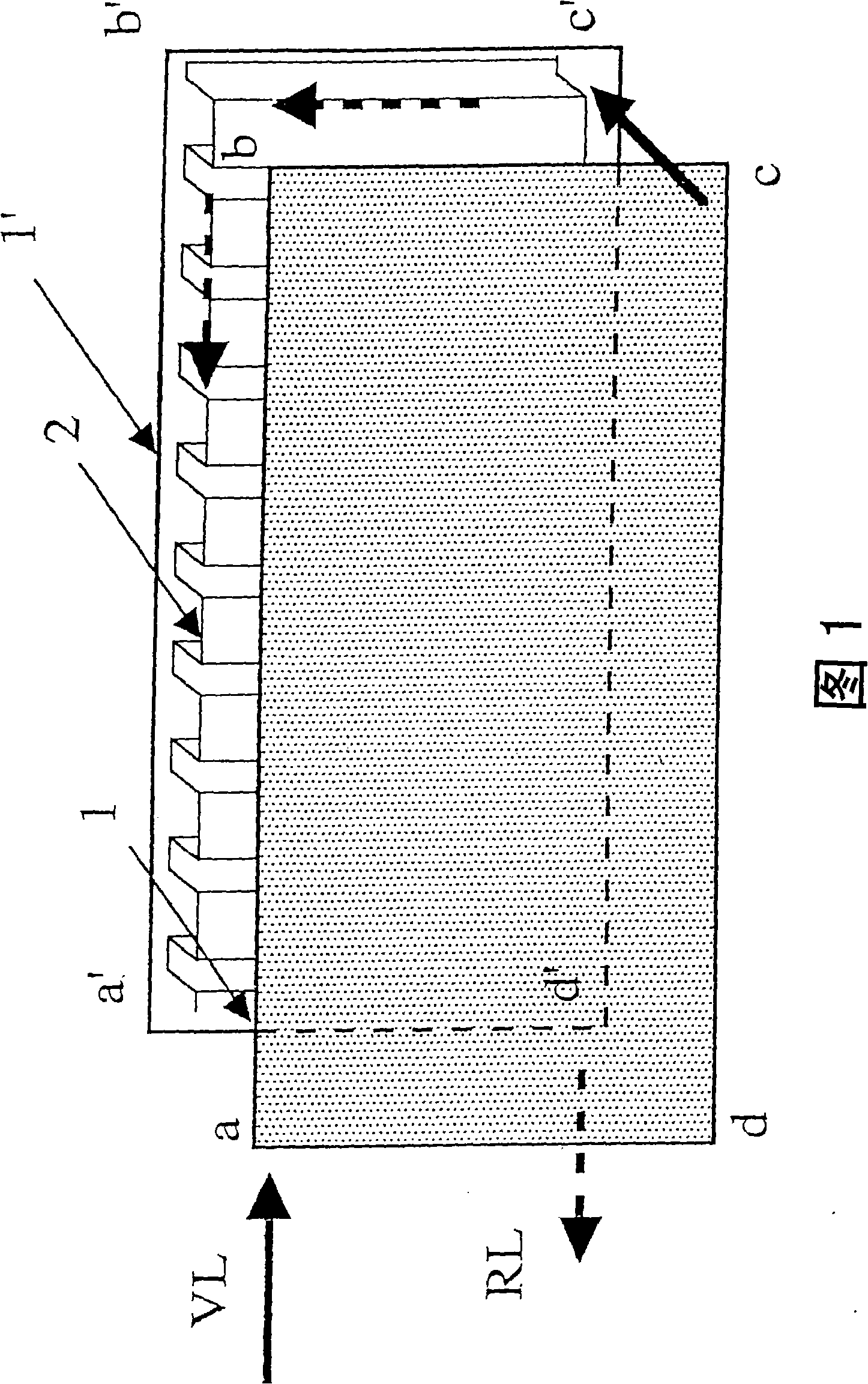

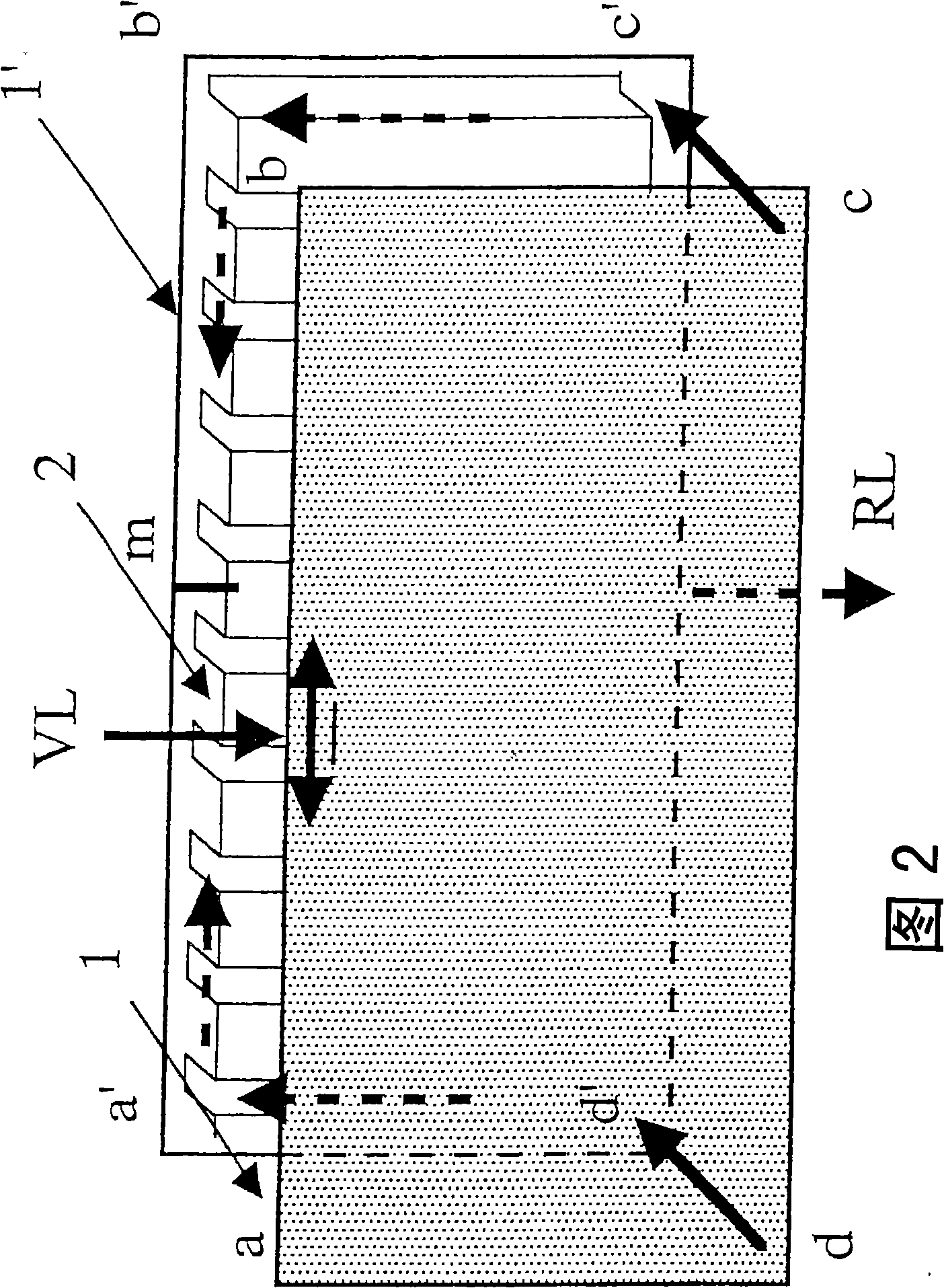

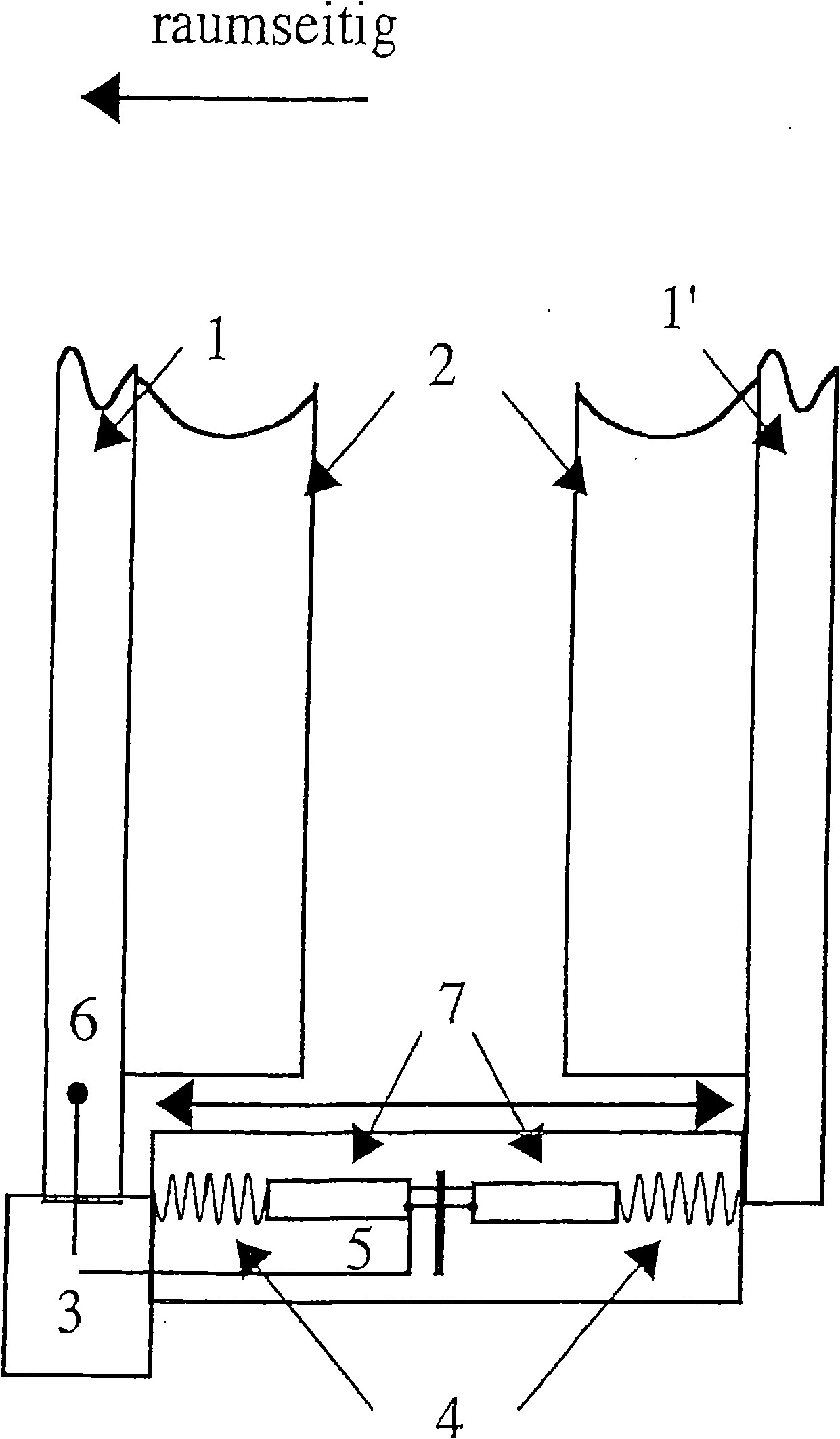

Single-row or multi-row heating body containing at least two different sections

InactiveCN101358751AIncrease heating powerGood regulation characteristicsLighting and heating apparatusSpace heating and ventilation detailsEngineeringElectrical and Electronics engineering

The invention relates to a single-row or multi-row heating member including at least two differently designed sections, in particular a flat heating member. The invention includes: an inflow linker (VL), a reflex linker (RL), a first section (1) that is flown over and is preferably toward to a chamber to be heated, and an another section (1') that is at least flown over and is preferably mounted in the back of the first section, wherein the first section is substantially and evenly flown before other sections, wherein at least one linker flowing to at least another section (1') is arranged in the lower end portion region of the first section (1).

Owner:KERMI GMBH

Burning lance for coal tar oxy-fuel control system

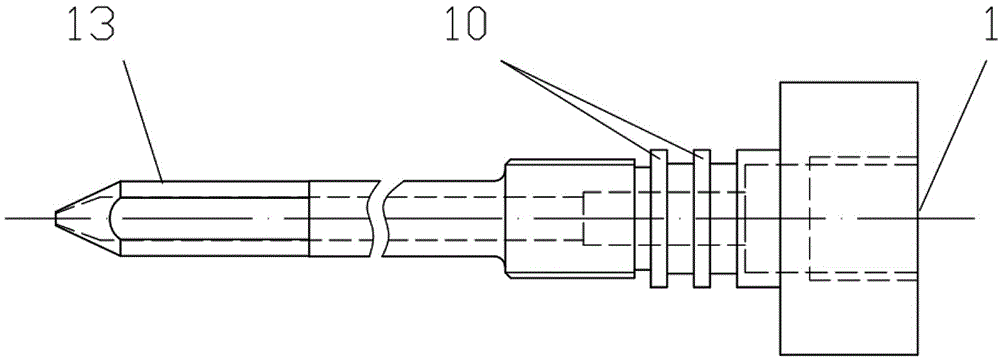

InactiveCN105485677AAtomized particle size is finer and more uniformGood regulation characteristicsBurnersIndirect carbon-dioxide mitigationControl systemEngineering

The invention discloses a burning lance for a coal tar oxy-fuel control system. The burning lance comprises a lance core, a lance body, a lance shell and a connector which are sequentially arranged from inside to outside in a sleeving manner. Gaps are formed between every two of the lance core, the lance body and the lance shell. The lance body and the lance core extend out of the lance shell together. The lance core is provided with an axial through hole. By the adoption of the gas atomization technology, the atomization parameter matching is reasonable, so that the atomization grain size of coal tar is more fine and even, the good adjustment feature is achieved, and the atomization quality of the coal tar is improved; and oxy-fuel is adopted, the content of oxygen is increased greatly relative to that of air burning, dust in the coal tar is more fully burned, the problems that smoke is generated due to incomplete combustion of the coal tar is eliminated, and the phenomena that the coal tar is coked and blocks the gun are reduced remarkably.

Owner:WUXI SUNDIATEC TECH

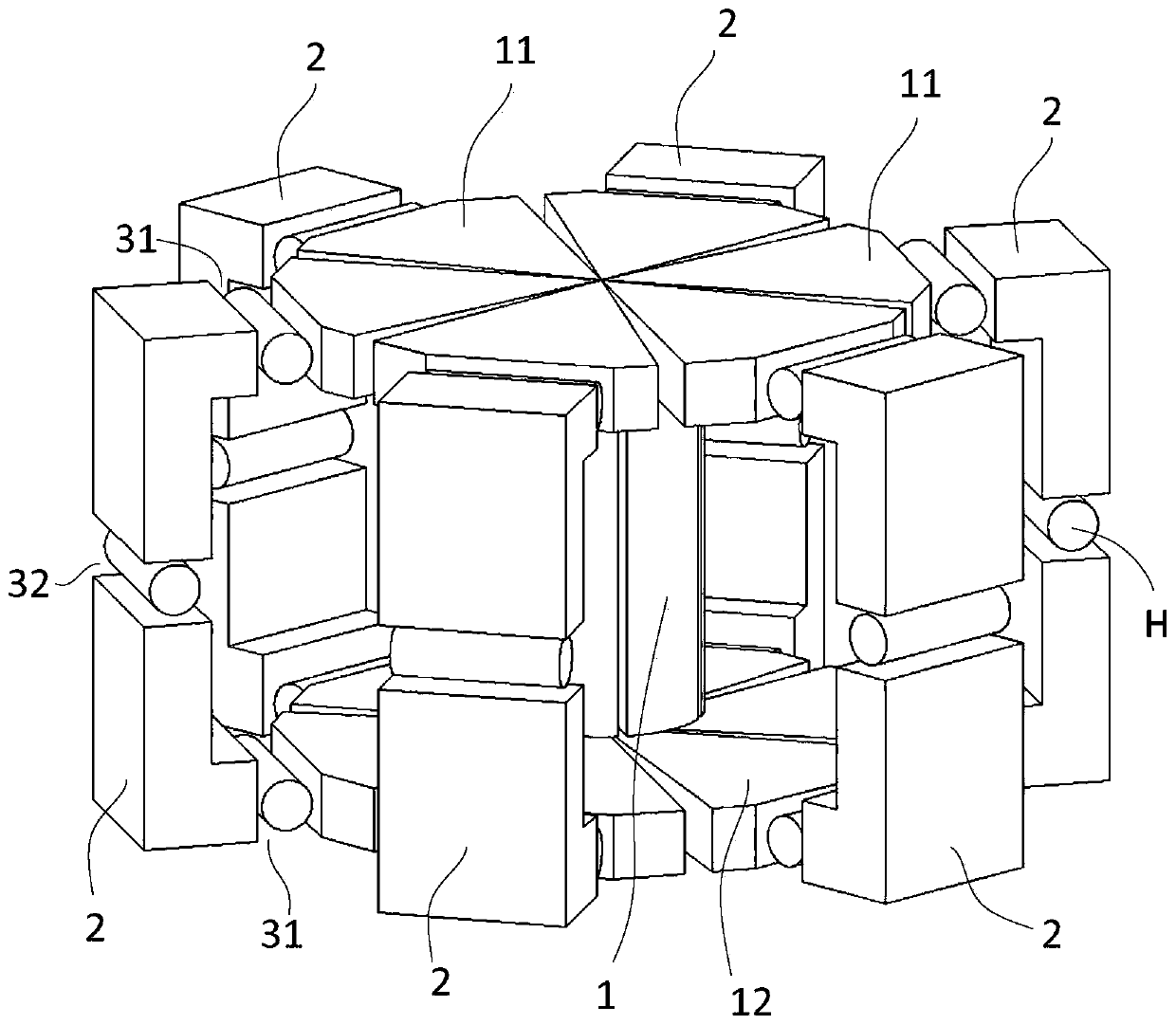

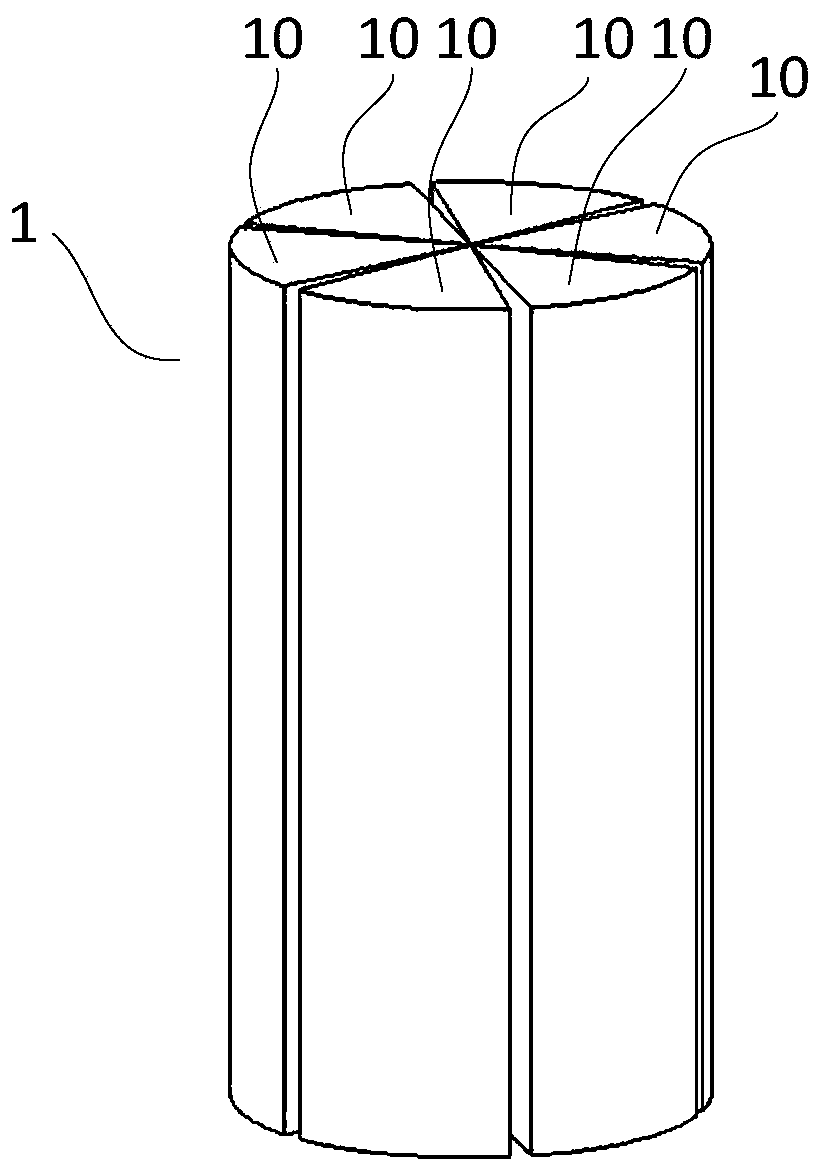

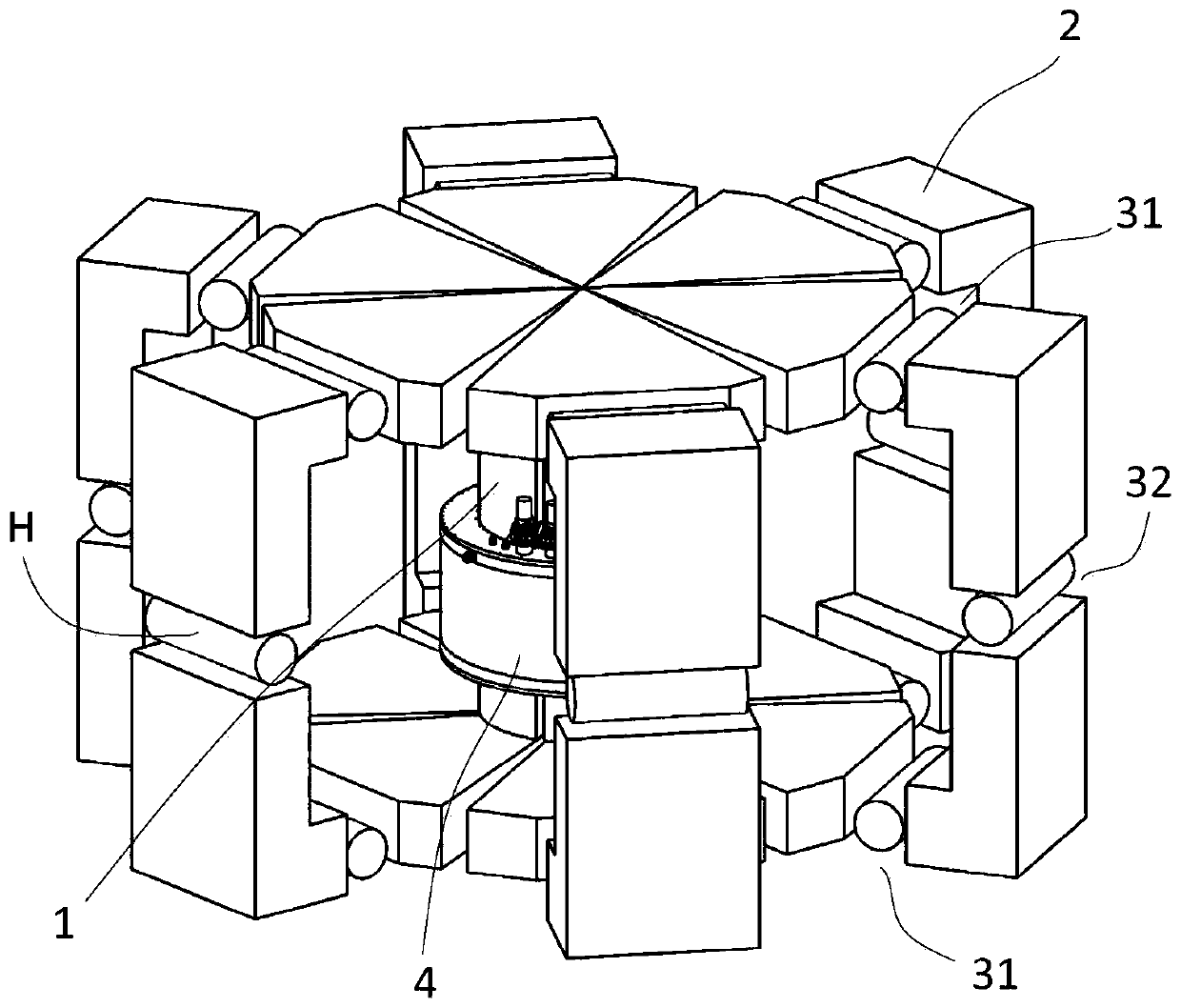

Hybrid magnetic circuit superconducting induction heating device based on split iron core

ActiveCN111315055AImprove heating efficiencyReduce lossesCoil arrangementsSuperconducting CoilsEngineering

The invention discloses a hybrid magnetic circuit superconducting induction heating device based on a split iron core. The device comprises a magnetic conductive iron core, a superconducting coil arranged around the magnetic conductive iron core and a plurality of parallel iron yokes circumferentially distributed around the magnetic conductive iron core. The magnetic conductive iron core is composed of a plurality of sub iron cores formed by longitudinally cutting a columnar iron core; an upper concentrating flux plate is correspondingly arranged at an upper end of each sub iron core, and a lower concentrating flux plate is correspondingly arranged at a lower end of each sub iron core; the number of the iron yokes is equal to that of the sub iron cores, each iron yoke corresponds to one sub iron core, a first air gap is formed between an upper end face / lower end face of each iron yoke and a side wall of the upper concentrating flux plate of the upper end or a lower concentrating flux plate of the lower end of the corresponding sub iron core, and the first air gaps are used for containing workpieces to be machined. A to-be-heated workpiece can rotate under the action of external force to generate induced current to heat the to-be-machined workpiece. The hybrid magnetic circuit superconducting induction heating device based on the split type iron core is provided with the independent anti-interference magnetic circuit, and therefore, the better heating adjusting characteristic is achieved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com