Preparation method of short-peptide/silicon dioxide/hydroxyapatite porous composite material

A porous composite material, hydroxyapatite technology, which is applied in medical science, tissue regeneration, prosthesis, etc. The effect of regulating mechanical properties, facilitating adhesion proliferation, and environment-friendly preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

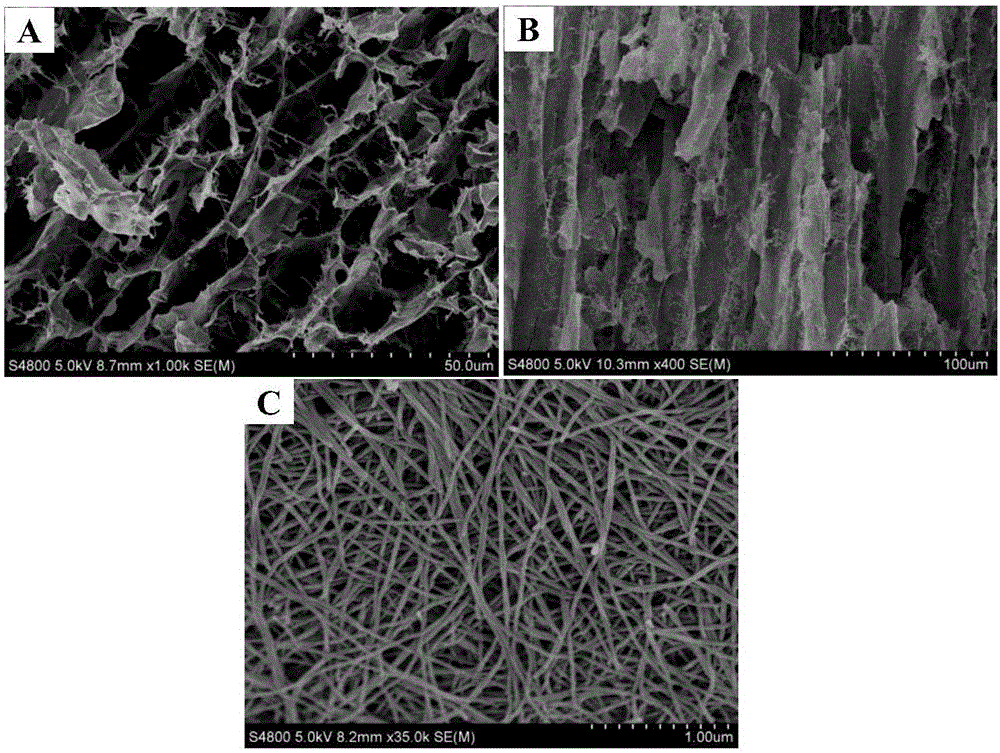

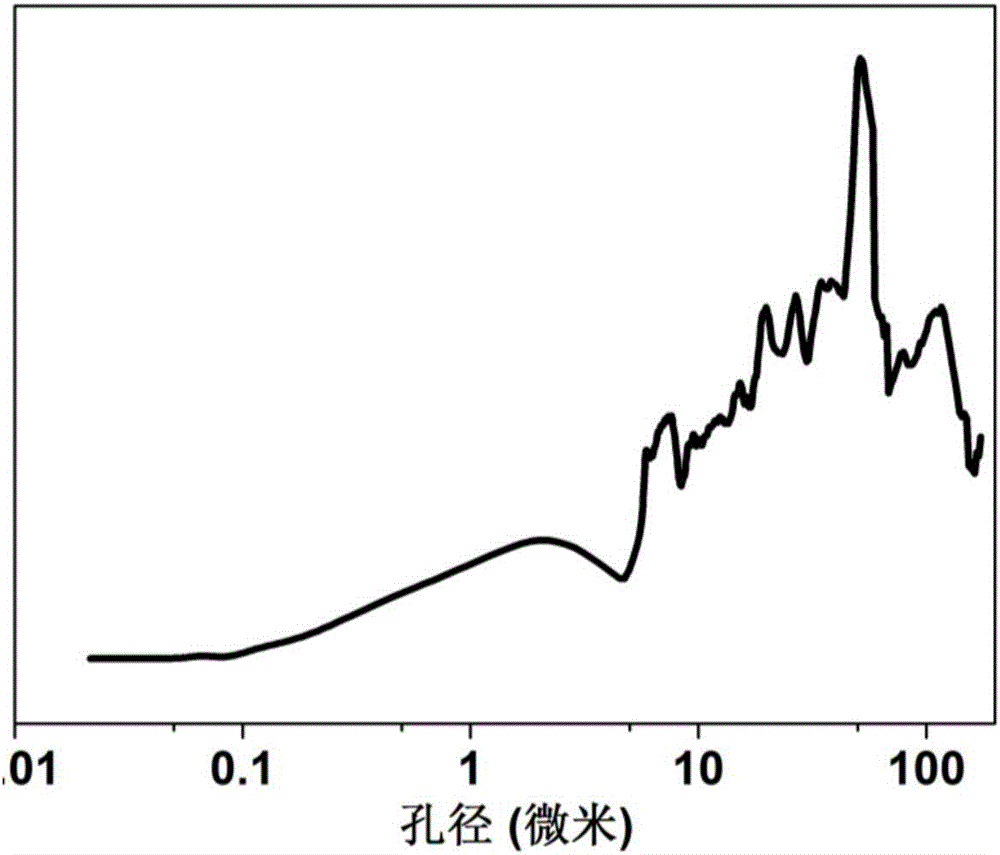

[0029] The embodiment of the present invention provides a preparation method of short peptide / silicon dioxide / hydroxyapatite porous composite material, including:

[0030] S1: Dissolve short peptide molecules in water, ultrasonically disperse them, adjust to a specified pH value, place them at a certain temperature for assembly, and obtain a solution containing short peptide self-assembled bodies, that is, short peptide solutions.

[0031] In this step, the non-covalent interaction between amphiphilic short peptide molecules is used to construct a short peptide self-assembly with mineralization activity. Specifically, dissolve the weighed short peptide powder in ultrapure water, disperse it with ultrasound, adjust it to a specified pH value and let it stand for assembly. Before using it in the next step, ensure that it is fully assembled. You can use an atomic force microscope or The assembly was observed by transmission electron microscopy. Through this step, a short peptide...

Embodiment 1

[0049] First prepare a 4mM amphiphilic short peptide solution, and place it at room temperature until it self-assembles; add 40 μL tetraethyl orthosilicate and 1wt% polyvinyl alcohol to 1 mL of the assembled amphiphilic short peptide solution, shake evenly Then react at 25°C for 3 days to obtain a short peptide / silica gel; replace the obtained gel with ultrapure water for 6 times, then conduct freezing induction treatment with a -80°C refrigerator, lyophilize and soak in simulated body fluid After 3 days, the short peptide / silica / hydroxyapatite porous composite material 1 was obtained.

Embodiment 2

[0051] First prepare a 10mM amphiphilic short peptide solution, and place it at room temperature until it self-assembles; add 200 μL tetraethyl orthosilicate and 2wt% sodium alginate to 1 mL of the assembled amphiphilic short peptide solution, shake evenly Then react at 25°C to obtain a short peptide / silica hydrogel; replace the obtained gel with ultrapure water for 6 times, and then conduct freezing induction treatment with liquid nitrogen at -196°C, freeze-dry it and place it in simulated body fluid After soaking for 5 days, the short peptide / silicon dioxide / hydroxyapatite porous composite material 2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com