TBJ tissue repair film type stent and preparation method thereof

A tissue repair, film-type technology, applied in the field of biomaterials and medical biomaterials, can solve the problems of insufficient mechanical properties, inability to meet the personalized design and repeatable manufacturing of scaffold materials for tendon and bone repair, and poor clinical treatment effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

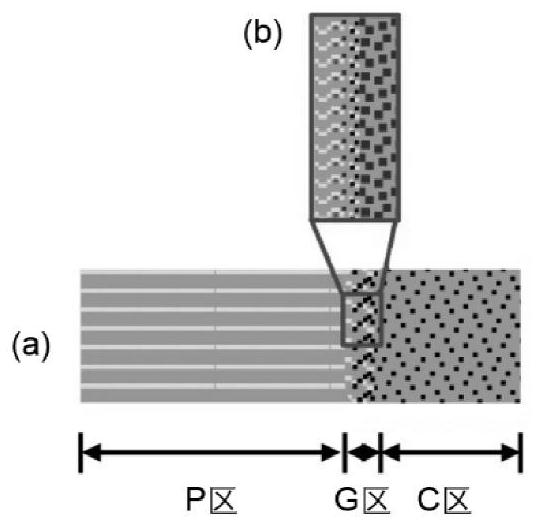

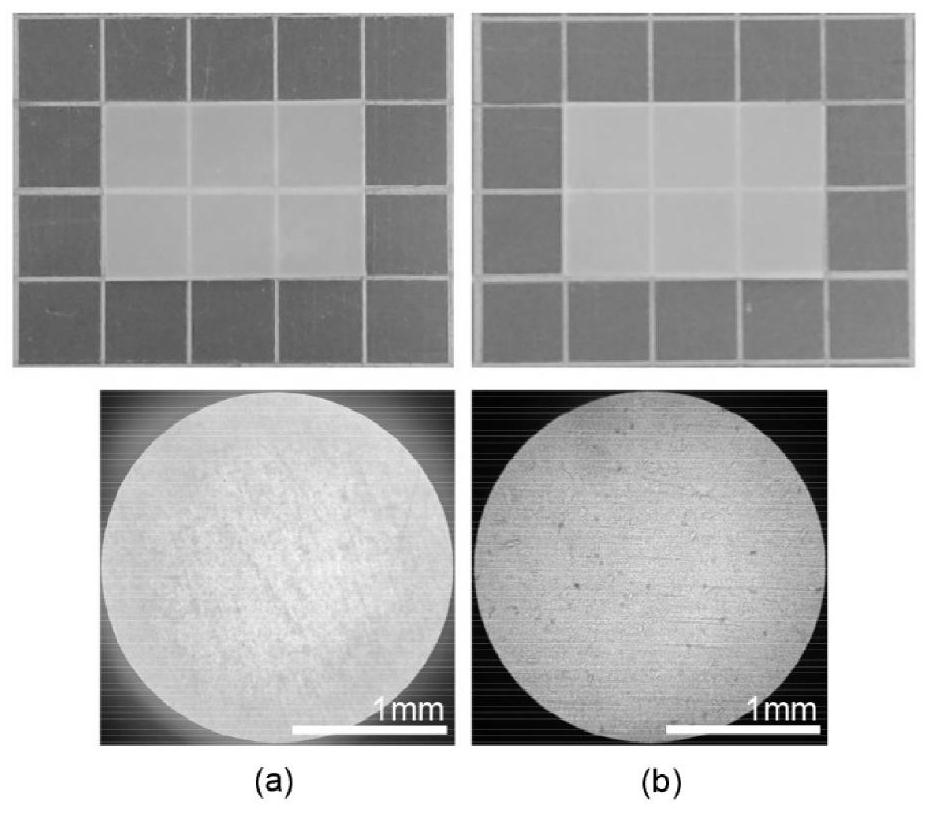

[0057] A biocompatible gradient tendon-bone junction based on synergistic construction of nanodoping and mechanical unidirectional drawing at room temperature (21 °C), strain rate of 10 mm / min, and strain of 600% The scaffold is prepared by the following method:

[0058] Step 1: Preparation of composite bioceramic micro-nanoparticles

[0059] According to the design, 0.6mol / L of Ca(OH) 2 solution and 0.03mol / L AgNO 3 After the solution was mixed, it was added dropwise to 0.40mol / L H 3 PO 4 and 0.06mol / L SiC 8 h 20 o 4 In the mixed solution, the pH value of the solution was adjusted to 10.5 by concentrated ammonia water, and the holding time was 3 hours. Si and Ag doped bioceramic micro-nanoparticles were obtained by heat treatment at 300°C for 4 hours. Si can induce and promote tissue osteogenesis, and Ag has good antibacterial effect in the process of tissue formation.

[0060] Step 2: Preparation of Precursor Polymer Membranes in the Tendon Region

[0061] According...

Embodiment 2

[0069] A biocompatible gradient tendon-bone junction based on synergistic construction of nanodoping and mechanical unidirectional drawing at a temperature close to the melting point of PCL (55 °C), a strain rate of 10 mm / min, and a strain of 600%. The dot scaffolds were prepared as follows.

[0070] Step 1: Preparation of composite bioceramic micro-nanoparticles

[0071] According to the design, 0.6mol / L of Ca(OH) 2 solution and 0.03mol / L AgNO 3 After the solution was mixed, it was added dropwise to 0.40mol / L H 3 PO 4 and 0.06mol / L SiC 8 h 20 o 4 In the mixed solution, the pH value of the solution was adjusted to 10.5 by concentrated ammonia water, and the holding time was 3 hours. Si and Ag doped bioceramic micro-nanoparticles were obtained by heat treatment at 300°C for 4 hours. Si can induce and promote tissue osteogenesis, and Ag has good antibacterial effect in the process of tissue formation.

[0072] Step 2: Preparation of Precursor Polymer Membranes in the Ten...

Embodiment 3

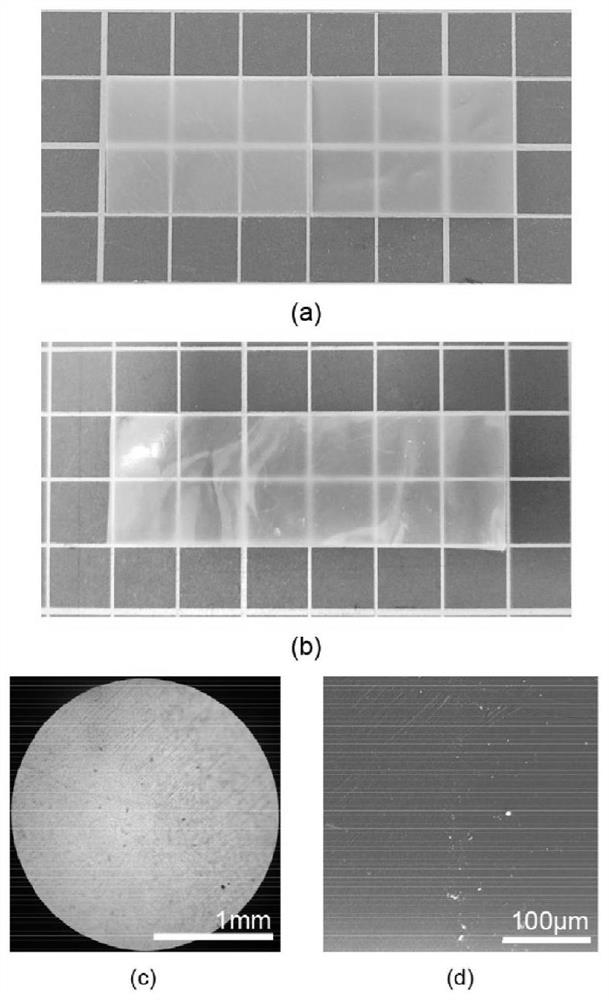

[0081]A biocompatible gradient tendon-bone junction based on synergistic construction of nanodoping and mechanical unidirectional drawing at room temperature (21 °C), strain rate of 10 mm / min, and strain of 1000% The scaffold is prepared by the following method:

[0082] Step 1: Preparation of bioceramic micro-nanoparticles

[0083] According to the design, 0.6mol / L of Ca(OH) 2 solution and 0.03mol / L AgNO 3 After the solution was mixed, it was added dropwise to 0.40mol / L H 3 PO 4 and 0.06mol / L SiC 8 h 20 o 4 In the mixed solution, the pH value of the solution was adjusted to 10.5 by concentrated ammonia water, and the holding time was 3 hours. Si and Ag doped bioceramic micro-nanoparticles were obtained by heat treatment at 300°C for 4 hours. Si can induce and promote tissue osteogenesis, and Ag has good antibacterial effect in the process of tissue formation.

[0084] Step 2: Preparation of Precursor Polymer Membranes in the Tendon Region

[0085] According to the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com