Back-gate field effect transistor based on contact electrification

A field-effect transistor and contact electrification technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of selection and application restrictions, and achieve the effects of simple structure, easy fabrication and integration, and wide external force sensing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

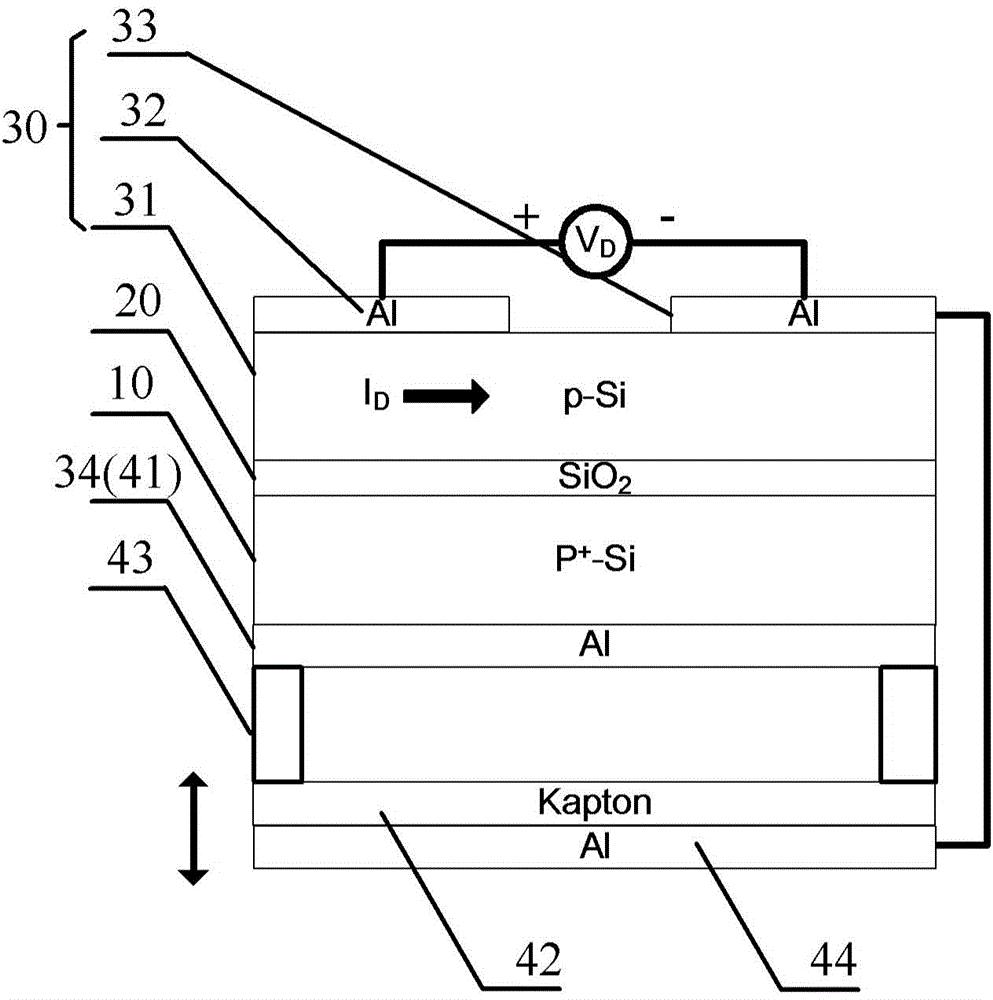

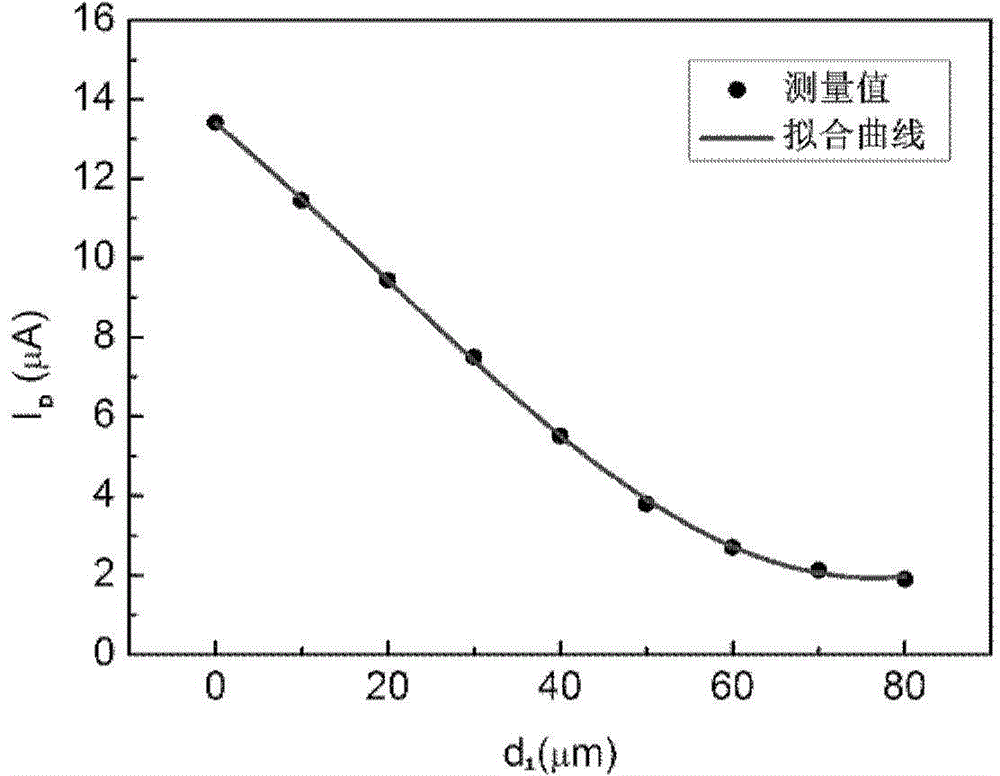

[0035] In a first exemplary embodiment of the present invention, a back gate field effect transistor based on contact electrification is provided. figure 1 It is a schematic structural diagram of a back gate field effect transistor based on contact electrification according to the first embodiment of the present invention. Such as figure 1 As shown, the back gate field effect transistor based on contact electrification in this embodiment includes: a conductive substrate 10; an insulating layer 20 formed on the front surface of the conductive substrate 10; a field effect transistor assembly 30 including: a channel layer 31 formed on the insulating layer The top of the layer 20; the drain 32 and the source 33 are formed above the channel layer 31, the two are separated by a preset distance, and a preset potential difference is maintained; the gate 34 is formed on the back of the conductive substrate 10; The triboelectric power generation assembly 40 includes: a static friction ...

no. 3 example

[0075] In the third exemplary embodiment of the present invention, another back gate field effect transistor based on contact electrification is also provided. Figure 5 It is a schematic structural diagram of a back gate field effect transistor based on contact electrification according to the third embodiment of the present invention. Such as Figure 5 As shown, the back gate field effect transistor based on contact electrification in this embodiment is similar to the structure of the first embodiment, the difference is that the static friction layer is made of polyimide polymer material, fixed on the gate 34, and can move The friction layer is an aluminum plate, which is isolated from the static friction layer by springs, and the aluminum plate is directly electrically connected to the source 33 through wires.

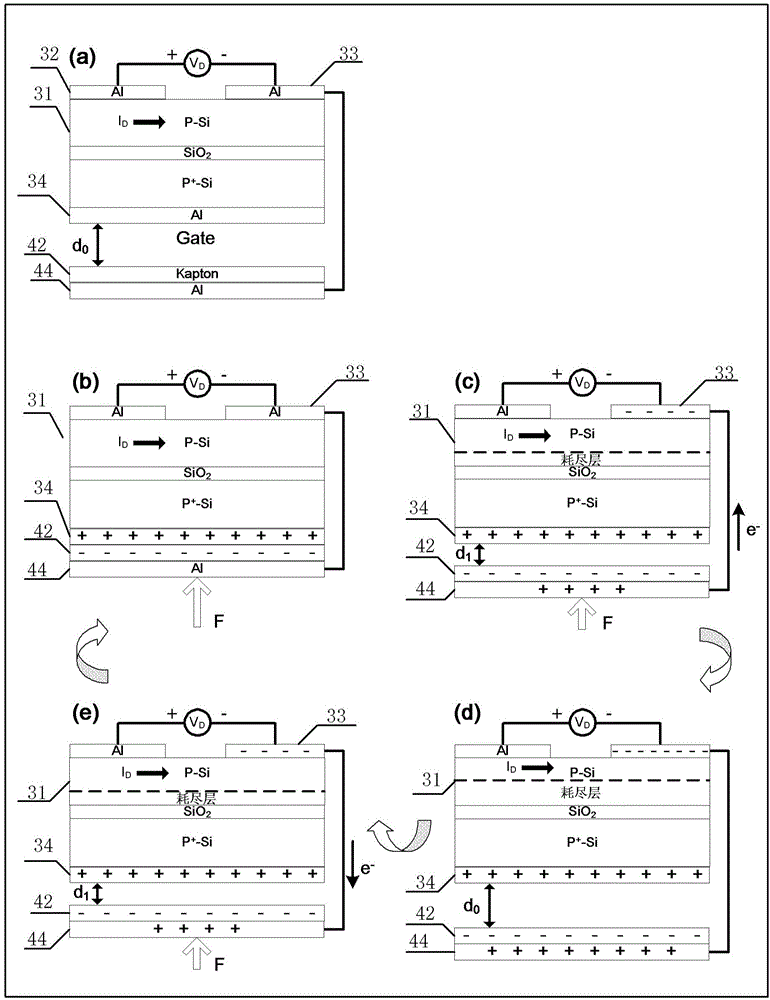

[0076] Figure 6 for Figure 5 Schematic diagram of the operation of the back-gate field-effect transistor shown. Combine the following Figure 6 To introduce ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com