Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Good gradient effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

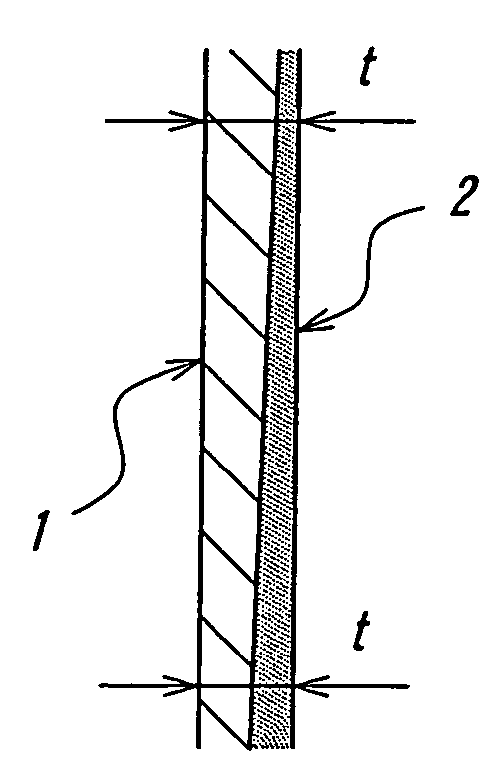

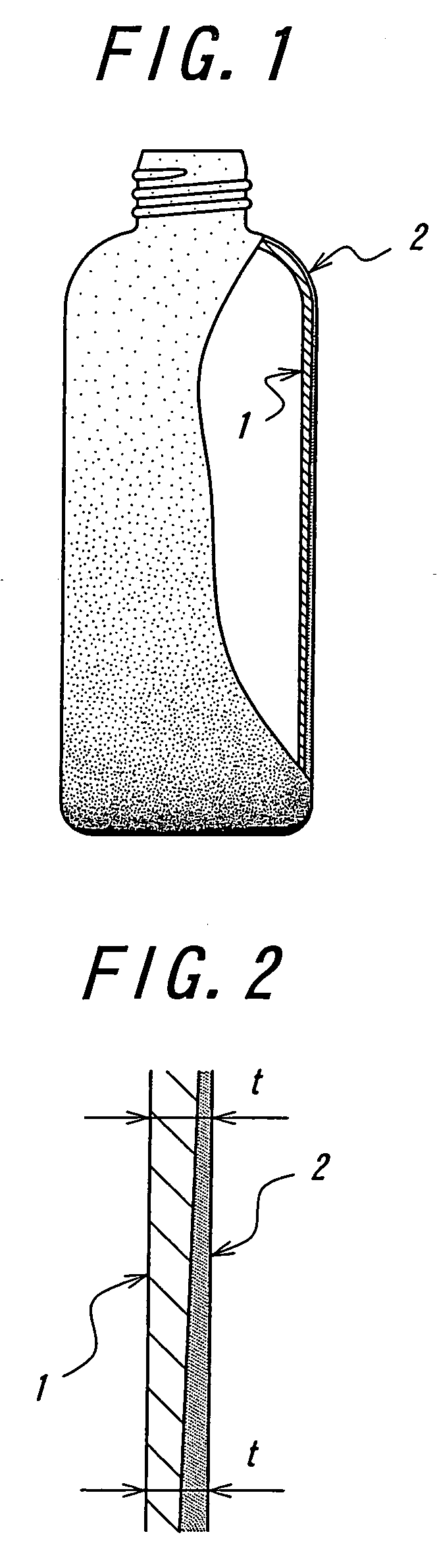

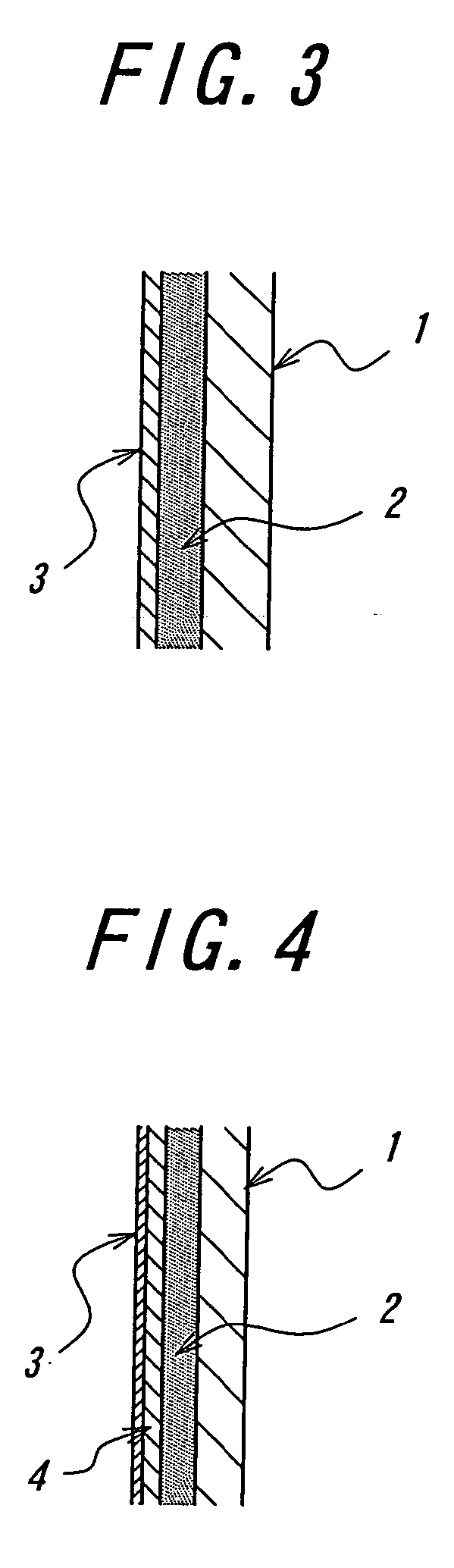

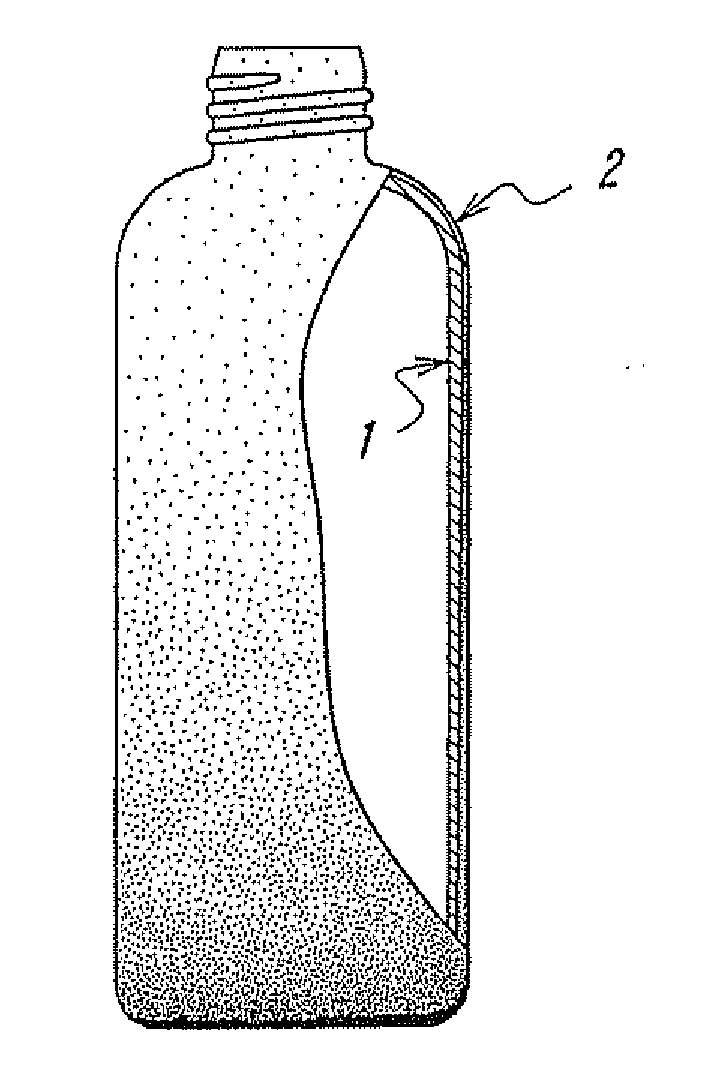

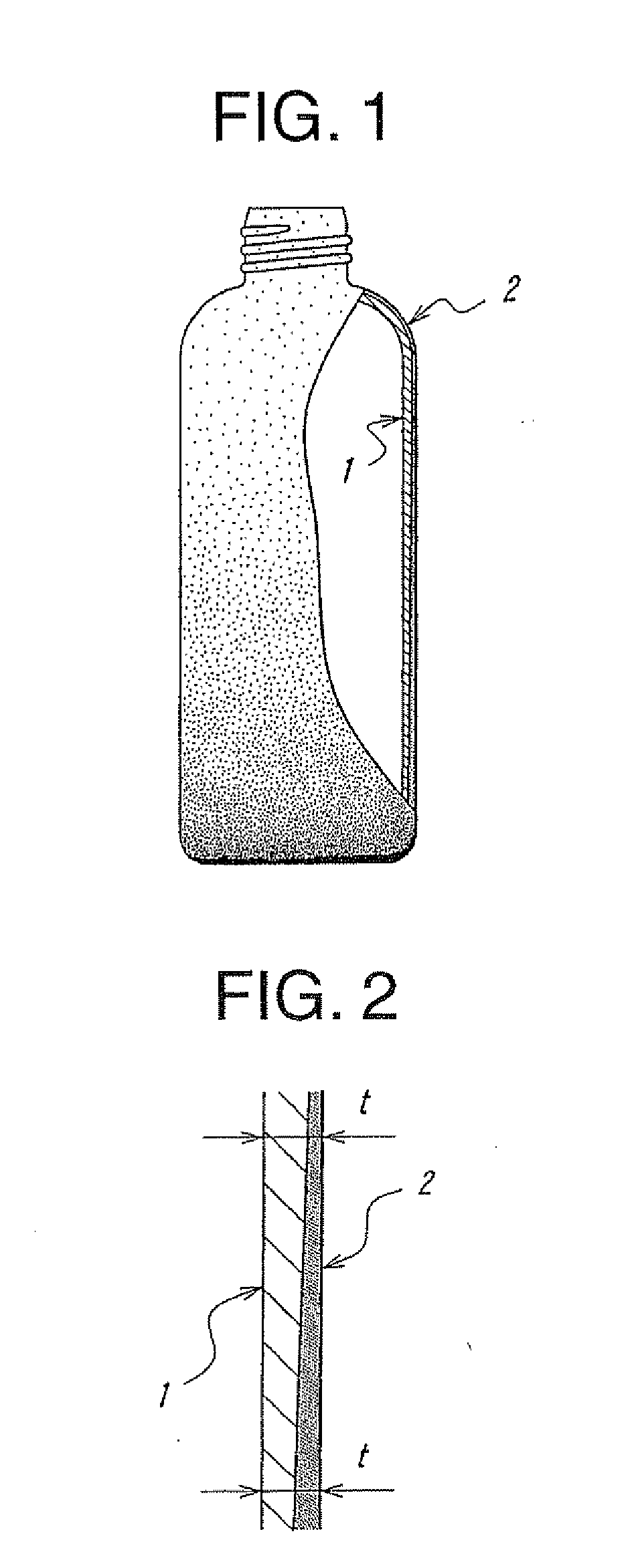

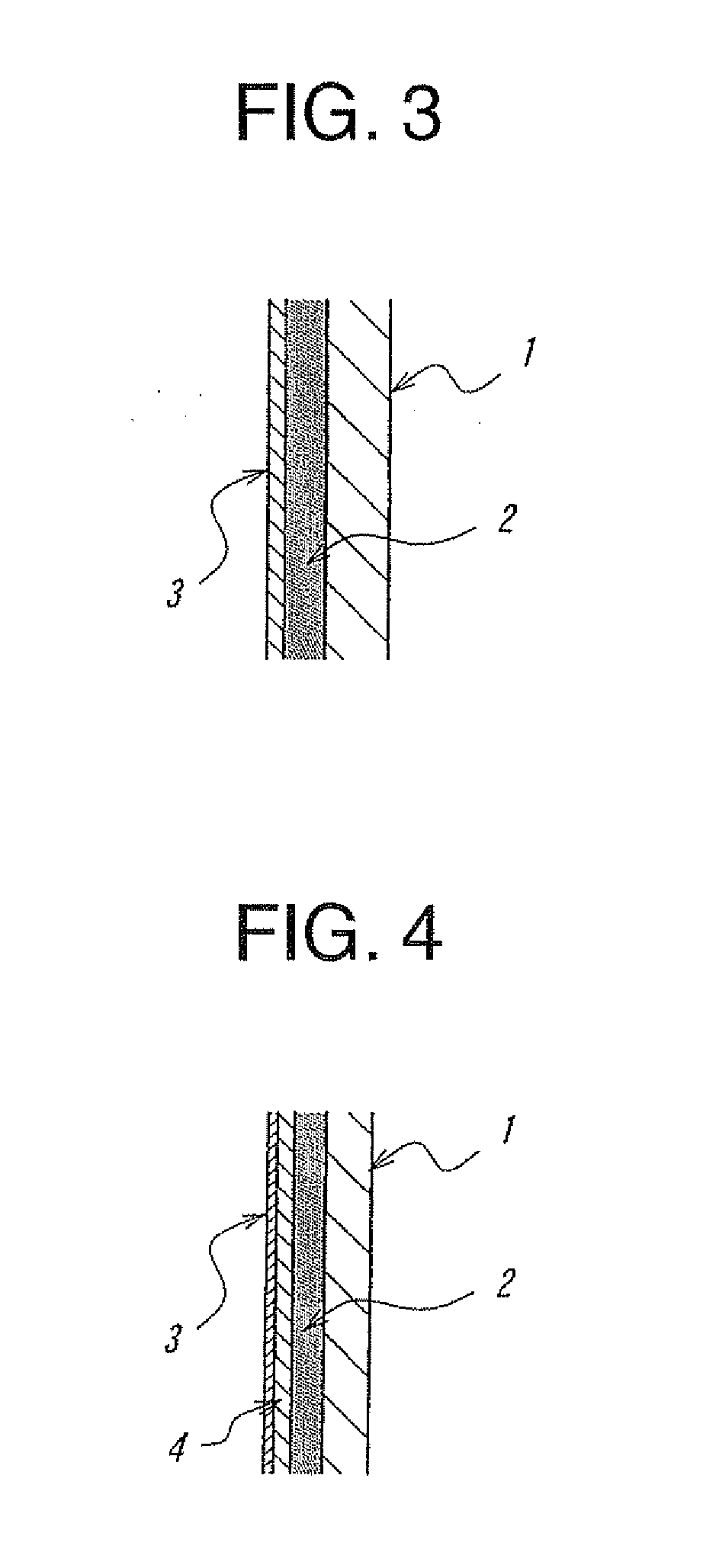

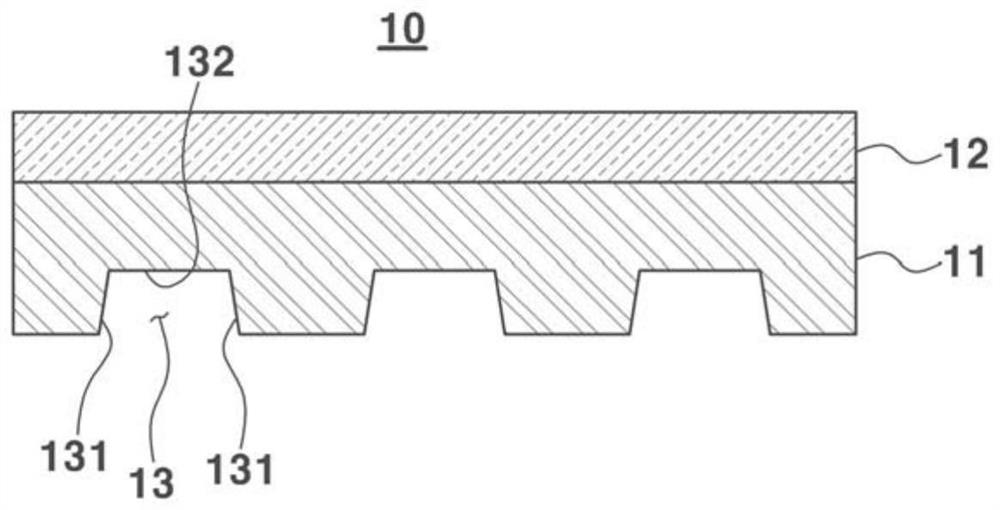

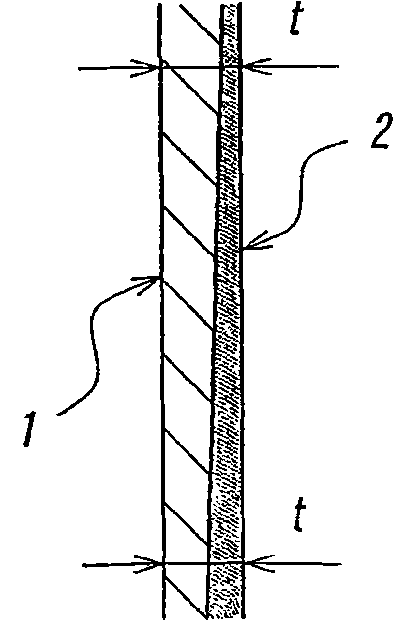

Laminated formed body and method of manufacturing the formed body

InactiveUS20050287323A1Easily and assuredly obtainImprove aesthetic appearanceBottlesSynthetic resin layered productsEngineeringBlow molding

A laminated and molded body obtained by coextruding and molding at least two kinds of resin materials is preferable as a blow-molding aimed preform, a direct-blow molded bottle, a tube, or a blow molded tube, and has at least one layer constituted of a colored layer having a thickness continuously or intermittently varied in a direction parallel to the extruding direction of the at least one layer and / or in another direction intersecting the extruding direction, thereby enhancing the gradation effect.

Owner:YOSHINO KOGYOSHO CO LTD

Laminated and molded body and manufacturing method therefor

InactiveUS20120256356A1Improve aestheticsEasy to getBottlesFilament/thread formingBlow moldingBottle

A laminated and molded body obtained by coextruding and molding at least two kinds of resin materials is preferable as a blow-molding aimed preform, a direct-blow molded bottle, a tube, or a blow molded tube, and has at least one layer constituted of a colored layer having a thickness continuously or intermittently varied in a direction parallel to the extruding direction of the at least one layer and / or in another direction intersecting the extruding direction, thereby enhancing the gradation effect.

Owner:YOSHINO KOGYOSHO CO LTD

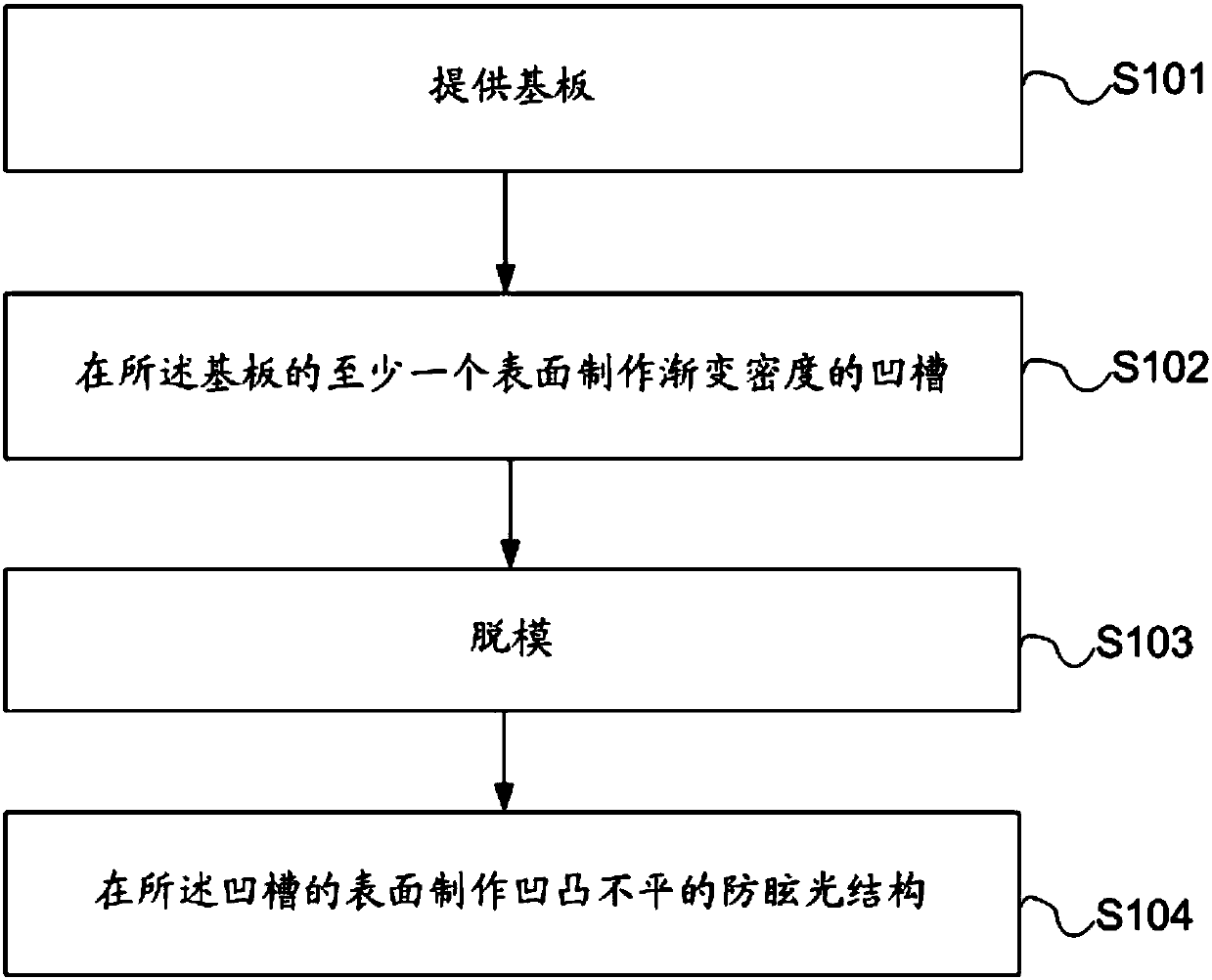

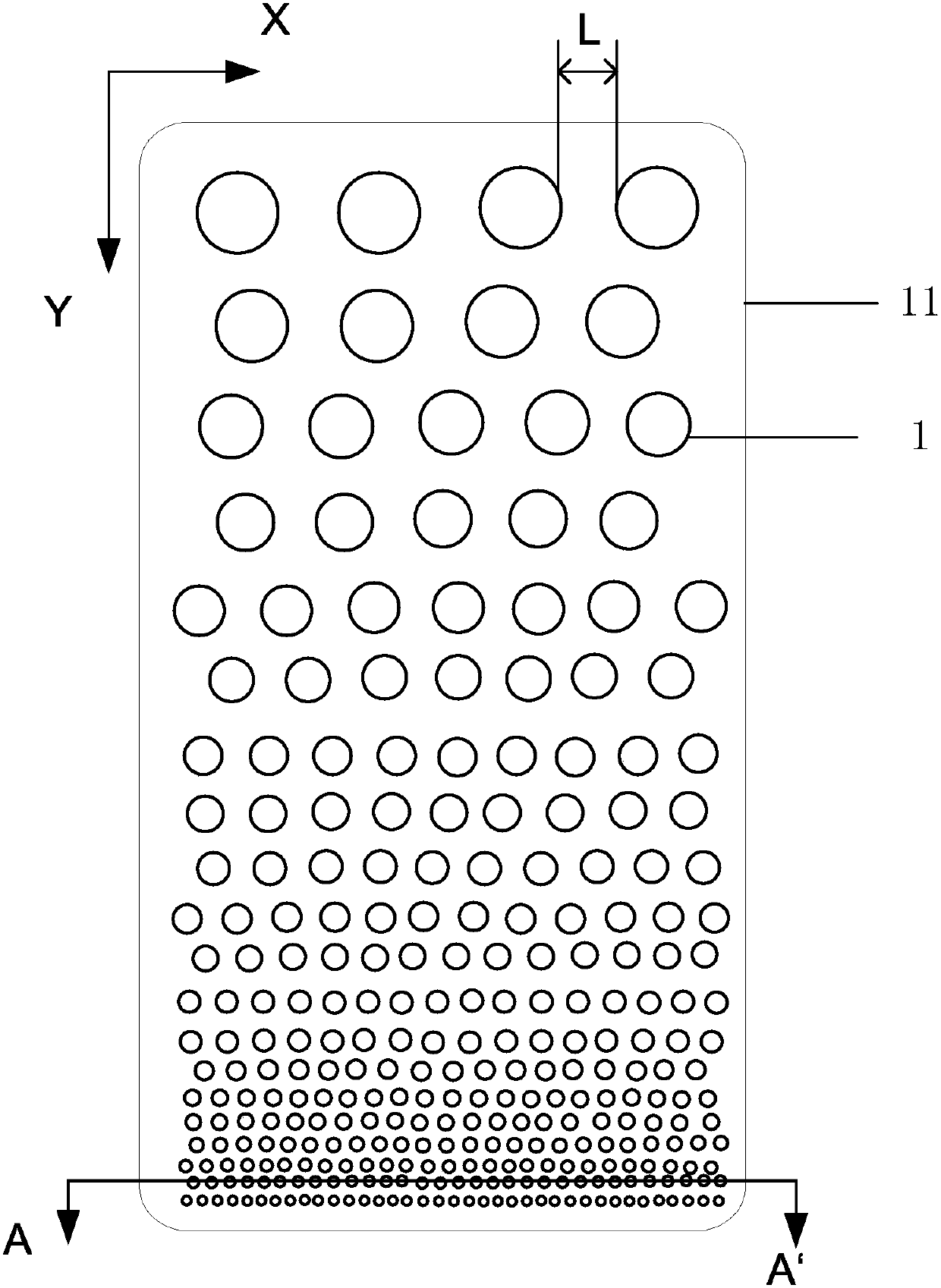

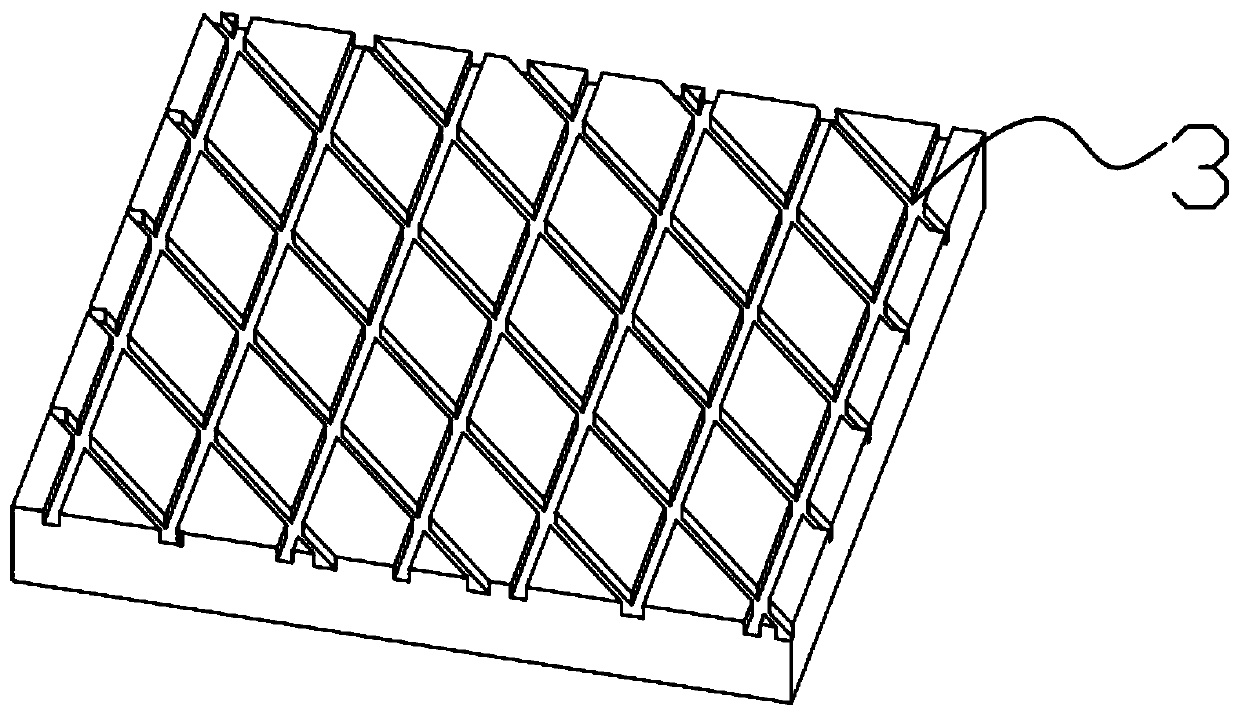

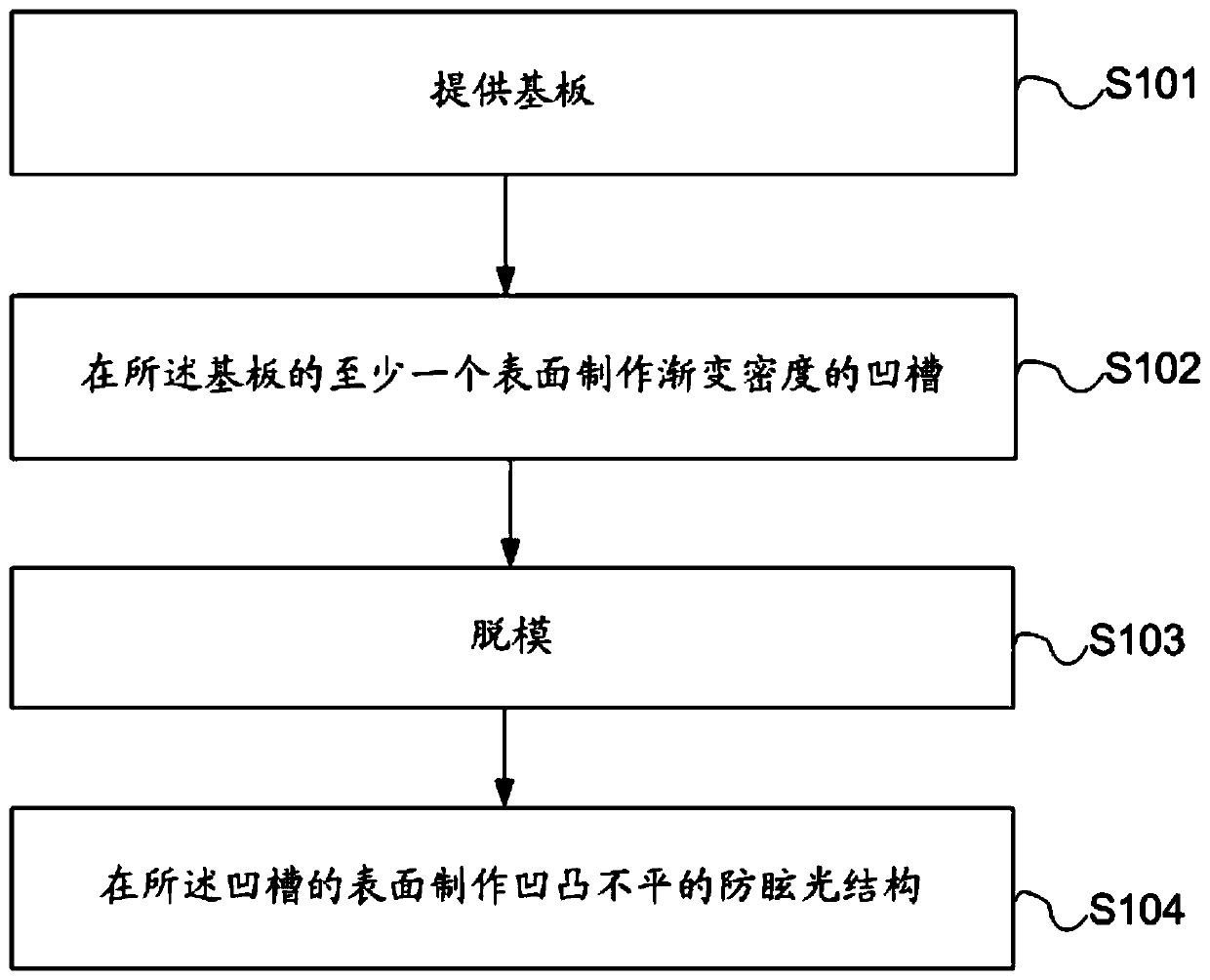

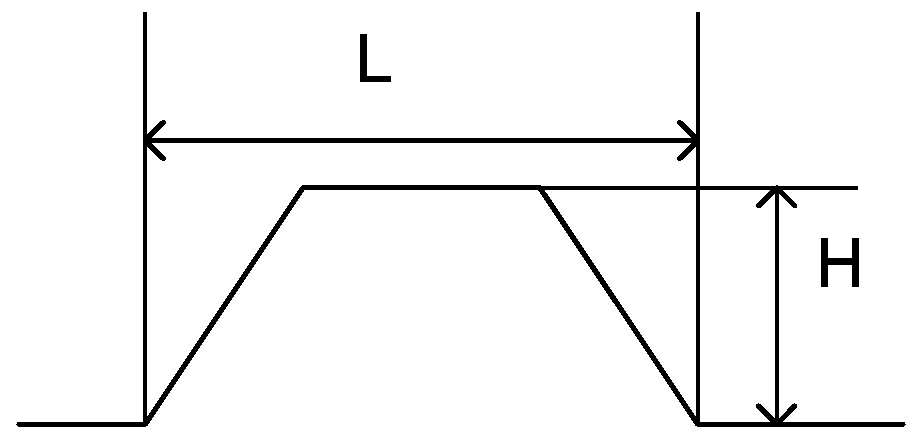

Gradient anti-glare cover plate and making method thereof as well as electronic equipment

ActiveCN107608013AAchieve natural gradientsTo achieve a gradient effectDiffusing elementsPhotomechanical apparatusDiffuse reflectionEngineering

The application provides a gradient anti-glare cover plate and a making method thereof as well as electronic equipment. The making method comprises the following steps: providing a substrate; making graded-density grooves in at least one surface of the substrate, wherein the distance between the every two adjacent grooves is less than 5 microns; demoulding; making uneven anti-glare structures on the surfaces of the grooves. The graded-density grooves are firstly formed before anti-glare production, and the distance between the every two adjacent grooves is less than 5 microns, so that the natural gradual change of light can be realized, a gradual change effect is achieved, and the appearance of the gradient anti-glare cover plate is enabled to be more attractive; therefore, the gradient anti-glare cover plate is more greatly different from cover plates of other electronic products, and a homogenization phenomenon is further avoided. Furthermore, the anti-glare effect of the gradient anti-glare cover plate is realized mainly by means of irregular rugged small salient points directly formed in the grooves, and a diffuse reflection function is realized; the gradient and anti-glare effect is realized only by combining the two processes, so that the making technology is simple.

Owner:TRULY OPTO ELECTRONICS

Surface decoration processing method of electronic equipment housing

The invention discloses a surface decoration processing method of an electronic equipment housing, which comprises the following steps of nickel-tin alloy plating: a nickel-tin alloy layer is plated on an insulating substrate film, titanium oxide layer plating: a titanium oxide layer is plated on the nickel-tin alloy layer, voltage bombardment: the titanium oxide layer is bombarded via voltage, and ink printing: an ink layer is printed in a set area of the voltage bombarded titanium oxide layer. In some embodiments, the insulating substrate film is not easy to crack; the ink layer can be stably attached to the titanium oxide layer, so that a complete NCVM (non-conductive vacuum metallization) layer can be formed; and a stable and better gradient effect can be achieved. In certain embodiments, the side height of the manufactured electronic equipment housing can reach 9mm with a better gradient effect, and the surface hardness can reach 3-4H.

Owner:SUZHOU TAIKAN MACHINERY CO LTD

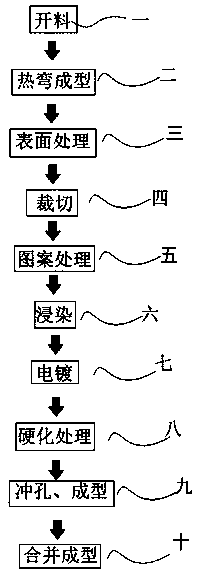

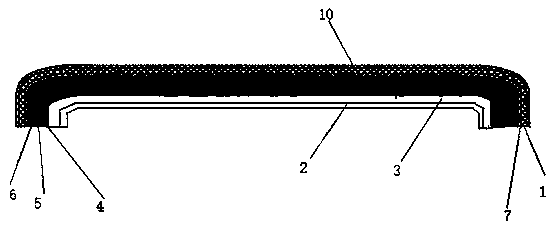

3D gradient color mobile phone rear cover forming process and mobile phone rear cover

InactiveCN111107197ANot easy to cause feverGood lookingTelephone set constructionsEngineeringComputer science

The invention discloses a 3D gradient color mobile phone rear cover forming process and a mobile phone rear cover. The 3D gradient color mobile phone rear cover forming process comprises the followingsteps: cutting; hot bending forming; surface treatment; cutting is conducted; pattern processing; dip dyeing; electroplating is conducted; hardening treatment; punching and forming are conducted; merging molding. According to the 3D gradient color mobile phone rear cover, the glass rear cover and the PET film do not interfere with signals, so that the signals of a mobile phone are relatively strong, wireless charging can be realized, the 3D gradient color mobile phone rear cover is suitable for being applied to different networks, and the mobile phone rear cover has the effects of light weight, thinness, scratch resistance and heat dissipation, and is not easy to cause heating of the mobile phone. According to the 3D gradient color mobile phone rear cover forming process, the gradient color process is realized through dip dyeing; the mobile phone rear cover is provided with the gradient color layer, the dyed product is uniform in coloring and good in gradient effect, multiple colors can be dyed at the same time, the mobile phone rear cover has multiple colors, the appearance effect is more obvious, and the requirement of people for the mobile phone rear cover with the multi-colorgradient appearance is met.

Owner:SHENZHEN ATES SCI & TECH CO LTD

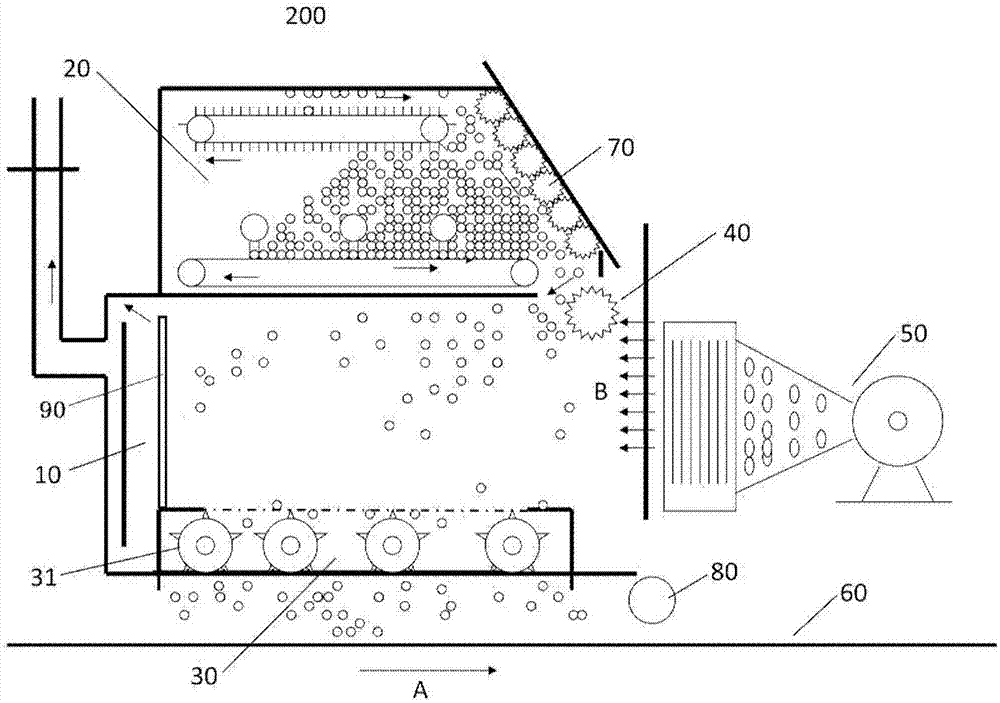

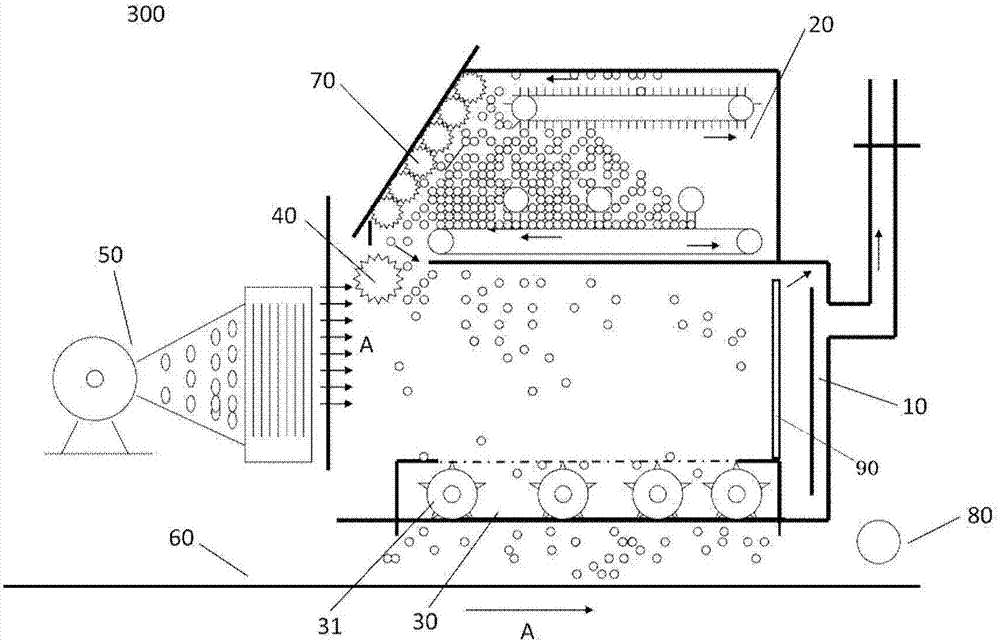

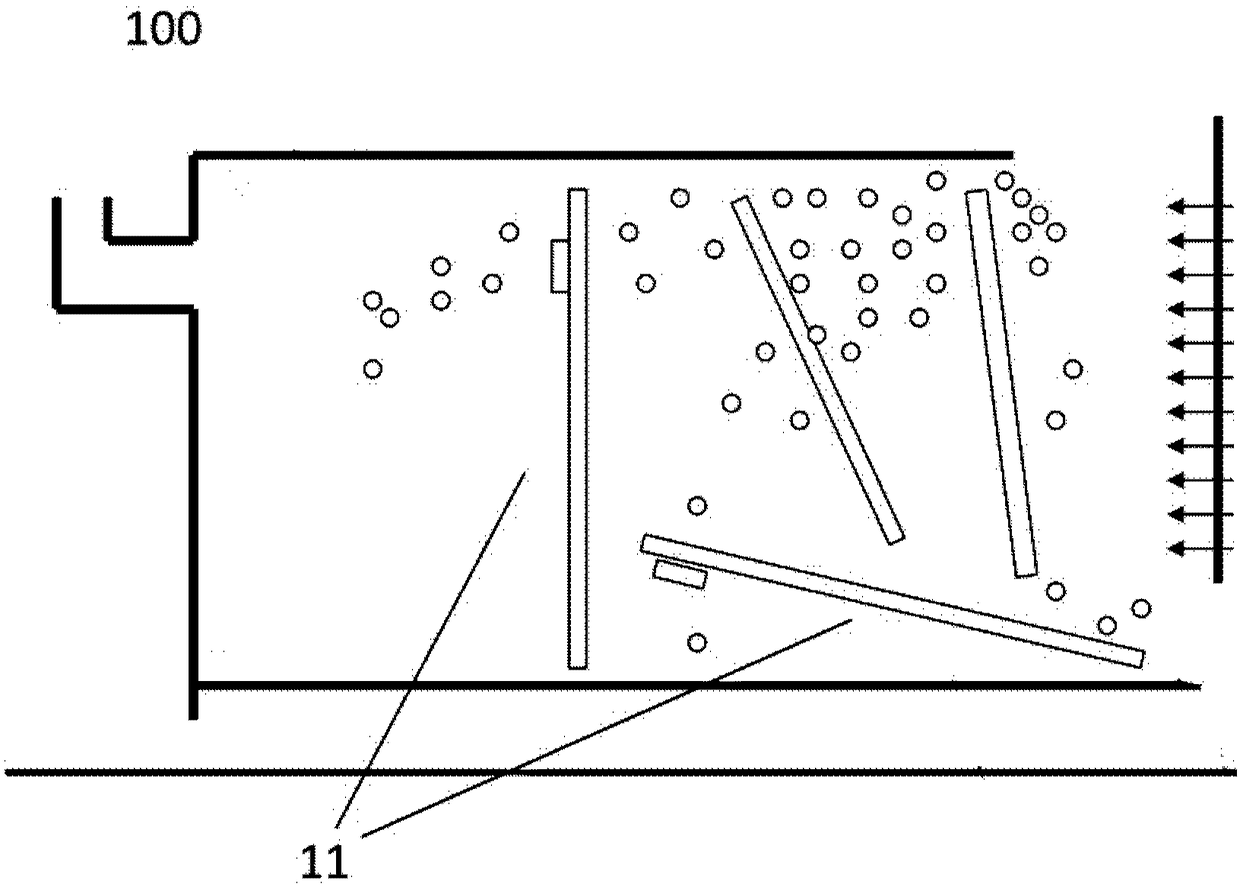

Slab paving device and paving system

PendingCN107984593AAvoid cloggingSimple structureWood working apparatusDomestic articlesSurface layerAirflow

The invention provides a slab paving device for paving upper surface layers or lower surface layers to form slabs. The slab paving device comprises a paving box, a paving bin arranged at the upper part of the paving box and used for providing paving materials to the paving box, an airflow generating device arranged on one side of the paving box and used for generating air currents in a paving direction or an opposite direction in the paving box to sort the paving materials, and a classification paving module for classification pavement of the paving materials sorted by the airflow generating device. The invention further provides a slab paving system comprising the slab paving device.

Owner:WANHUA STRAW ECOBOARD IND CO LTD

Process for preparing composite materials with self radial gradient by in situ crystallization

A technology for preparing the autogenous composition with radial gradient features that after molten autogenous composition is poured in the SiC mould which is arranged in an induced HF magnetic field and has a temp measuring unit, the active temp range of said HF magnetic field is controlled by said temp measuring unit to maintain the thermal balance in composition for obtaining high gradient effect.

Owner:SHANGHAI JIAO TONG UNIV

3D printing production process of gradient-color mobile phone rear cover

The invention relates to the technical field of mobile phone rear covers, in particular to a 3D printing production process of a gradient-color mobile phone rear cover. The process comprises the following steps of (1) cutting; (2) LOGO printing; (3) varnish printing; (4) 3D printing; (5) electroplating; (6) cover bottom printing; (7) high-pressure treatment, specifically, a substrate is arranged on a high-pressure forming machine to be subjected to high-pressure forming, and an arc side is formed; (8) reinforcement, specifically, hardening liquid is sprayed on the substrate to be curved to form a hardened film; and (9) CNC cutting, specifically, the substrate is subjected to numerical control cutting, and the gradient-color mobile phone rear cover is obtained. The gradient-color process isachieved through 3D digital printing, a product printed by 3D digital printing is colored evenly, the gradient effect is good, a plurality of color gradients can be printed, the production cost is low, the efficiency is high, and industrial production is facilitated.

Owner:SHENZHEN ATES SCI & TECH CO LTD

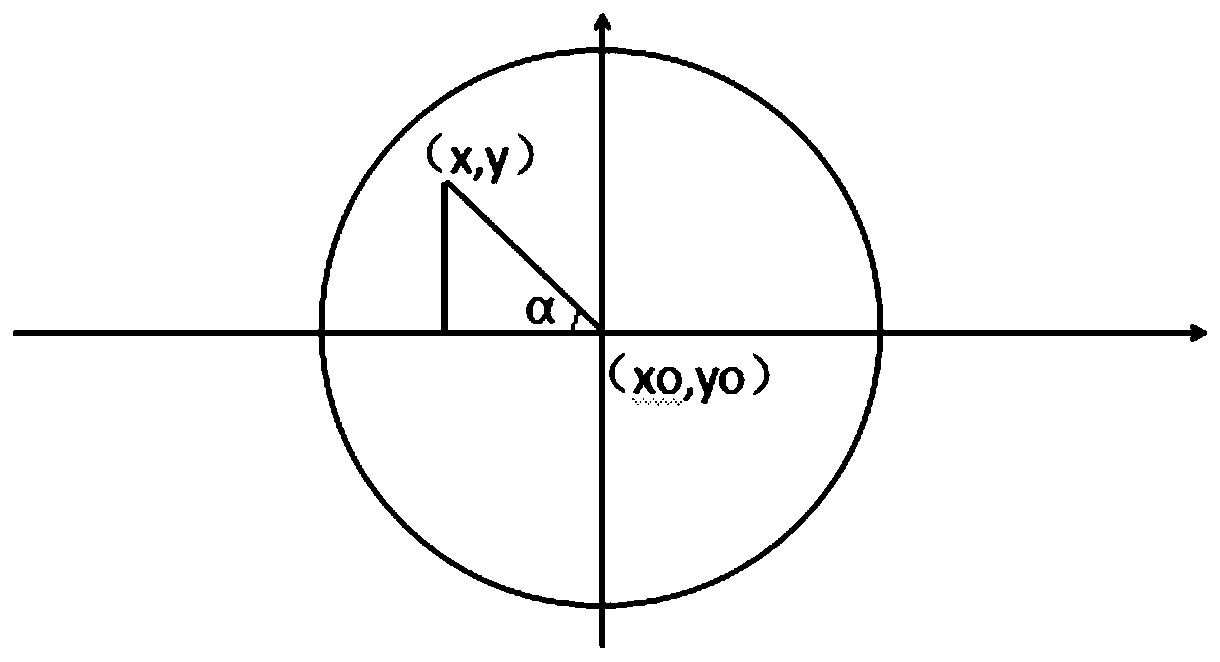

Gradient circular ring display method based on instrument, medium, instrument and device

ActiveCN110539639ARealize the gradient ring effectGuaranteed uptimeSoftware engineeringVehicle componentsVisual perceptionLiquid crystal

The invention relates to a gradient circular ring display method based on an instrument, a medium, the instrument and a device. The method comprises the following steps: acquiring a to-be-processed circular ring and a preset starting pixel point of the to-be-processed circular ring, and computing a deflection angle, in relative to the preset starting pixel point, of the to-be-processed pixel point; computing target transparency of the to-be-processed pixel point according to the deflection angle; adjusting the transparency of the to-be-processed pixel point as the target transparency, therebyacquiring and displaying the target gradient circular ring. A computer program is stored on the medium to execute the above method steps; the instrument comprises the storage medium and a processor; the processor realizes the above method steps when executing the computer program on the storage medium. Through a certain targeted algorithms, the gradient circular ring is displayed in the instrument, a demand on a liquid crystal instrument display effect by a user is satisfied, and the vision experience of the user is improved; the use resource is less, the system overhead is greatly reduced, and the smooth running of the entire software can be guaranteed.

Owner:WUHAN SOUTH SAGITTARIUS INTEGRATION CO LTD

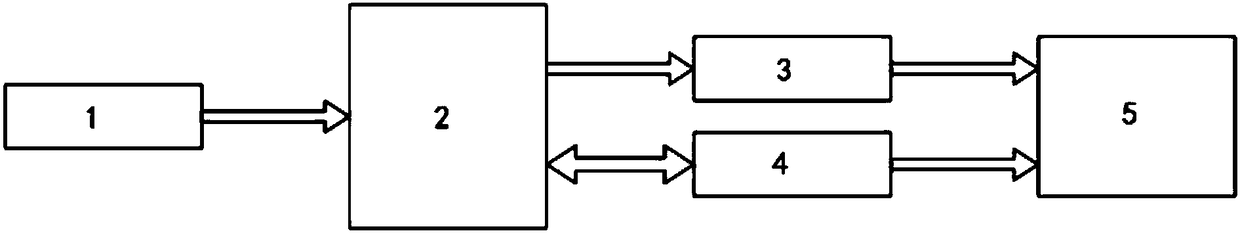

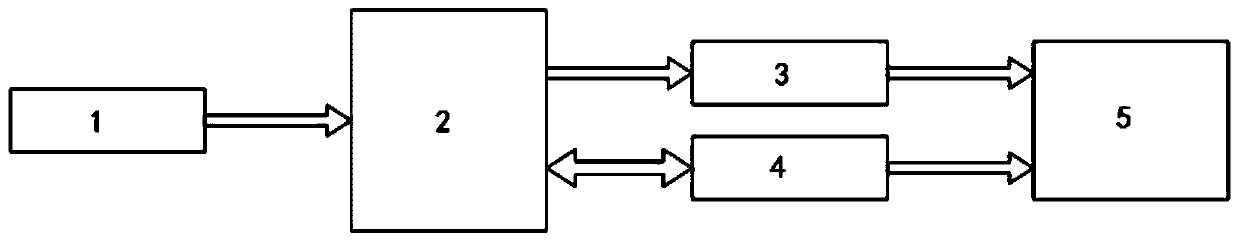

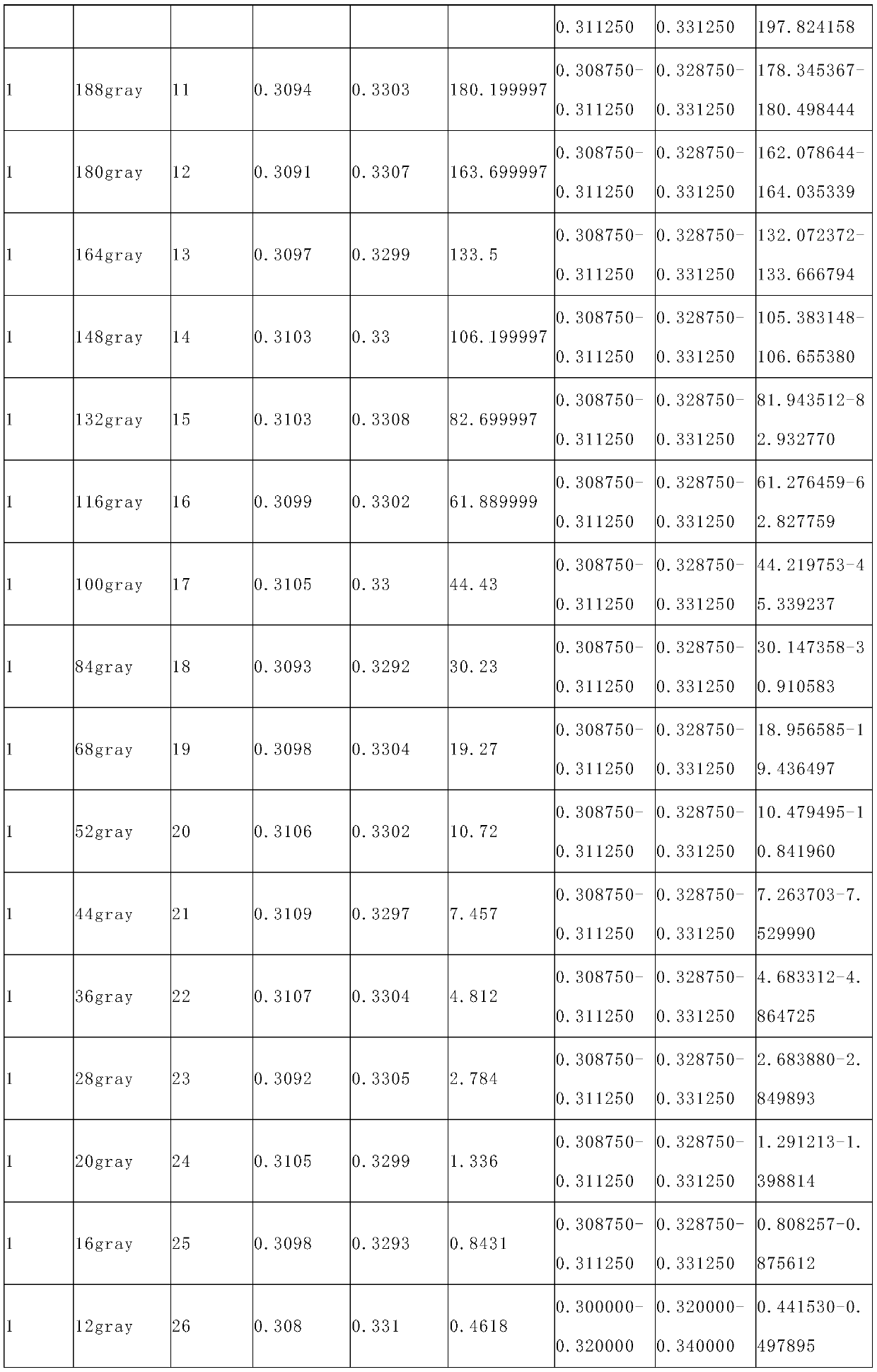

Gamma adjusting and recalibrating method and system of OLED module based on multi-objective relational mathematic model

ActiveCN108597442AOvercoming problems such as poor consistencyIncrease production capacityStatic indicating devicesMathematical modelBiobjective optimization

The invention discloses a Gamma adjusting and recalibrating method and a Gamma adjusting and recalibrating device of an OLED module based on a multi-objective relational mathematic model. The method comprises the following steps: (1) establishing an objective function; and (2) establishing a constraint condition, wherein R, G and B register values of all the binding points of the module are in positive linear or negative linear dependence, the multi-objective relation optimization is converted into single-objective optimization, the double-objective optimization is converted into single-objective optimization, and finally, the R, G and B register values corresponding to F are solved and are output to R, G and B registers corresponding to the gray scale binding point m in a module chip according to setting. According to the technical scheme, the diversified mode of gamma adjustment is supported, the features of platformization and parallelism are realized, and the method and the systemhave the advantages of efficiency and stability in adjusting and good gradual change effect. The experimental result shows that with the provided mathematic model, the complexity can be effectively reduced, the conventional algorithm is converted into algorithm and calculation, the adjusting and recalibrating efficiency is very ideal, and the problems including that the module is poor in consistency are solved.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

Cover plate coloring method, cover plate and electronic equipment

ActiveCN111225534AIncrease brightnessGood gradient effectElectrolytic inorganic material coatingCasings/cabinets/drawers detailsStructural engineeringMechanical engineering

The invention provides a cover plate coloring method, a cover plate and electronic equipment, and relates to the technical field of electronic equipment parts. The cover plate coloring method comprises the steps of manufacturing a hollowed-out pattern layer on a first surface of a cover plate body; screen-printing a semi-permeable ink layer on the hollowed-out pattern layer; electroplating a reflecting film on the semi-permeable ink layer; and turning up the ink layer at the bottom of an ink cover on the reflecting film. According to the scheme, fine patterns can be made on the cover plate, the gradual change effect of the cover plate is enhanced, and the appearance effect of the cover plate is improved.

Owner:VIVO MOBILE COMM CO LTD

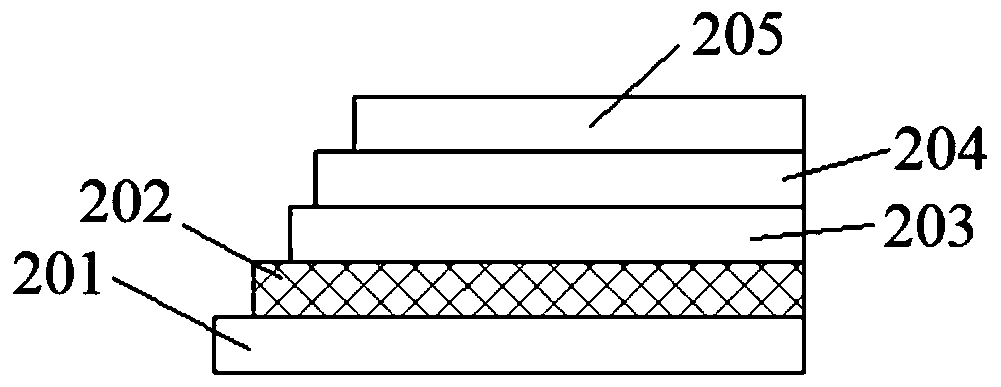

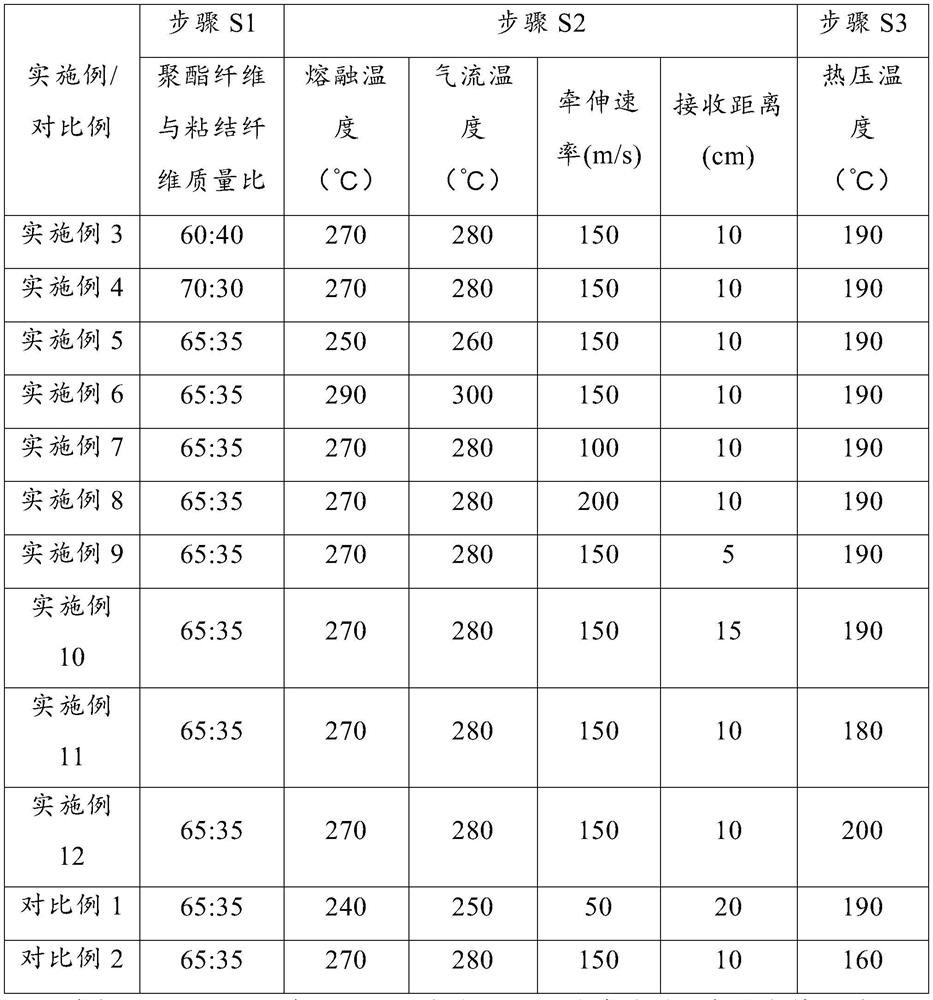

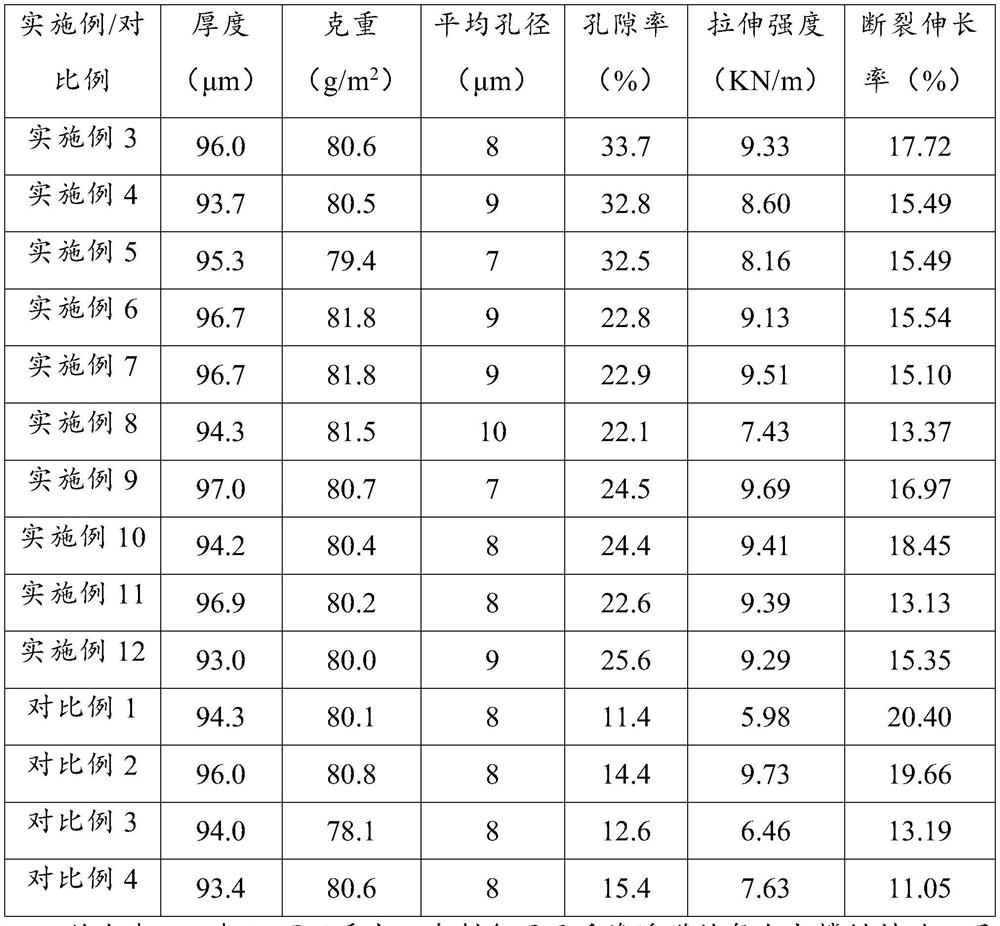

Composite support material for reverse osmosis membrane and preparation method of composite support material

ActiveCN113332865AHigh porosityHigh mechanical strengthMembranesSemi-permeable membranesPolyesterSpinning

The invention provides a preparation method of a composite support material for a reverse osmosis membrane. According to the invention, polyester non-woven fabric is prepared by adopting a papermaking method, and melt-blown spinning is performed on an ethylene-methyl acrylate copolymer or a modified ethylene-methyl acrylate copolymer to prepare a melt-blown non-woven fabric; and superposing the melt-blown non-woven fabric on the upper surface of the polyester non-woven fabric, and carrying out hot pressing treatment to prepare the composite support material for the reverse osmosis membrane. Through the mode, the hot-pressing treatment process can be utilized to enable the adhesive fibers in the polyester non-woven fabric to permeate into the melt-blown non-woven fabric, so that the pore structure is further optimized while the bonding strength between the polyester non-woven fabric and the melt-blown non-woven fabric layer is effectively improved, so that the support material with small average pore size, high porosity, high mechanical strength and good corrosion resistance is formed, production of reverse osmosis membrane products with large flux, high desalination rate and long service life is facilitated, and the support material has high practical application value.

Owner:安徽清澜新材料科技有限公司

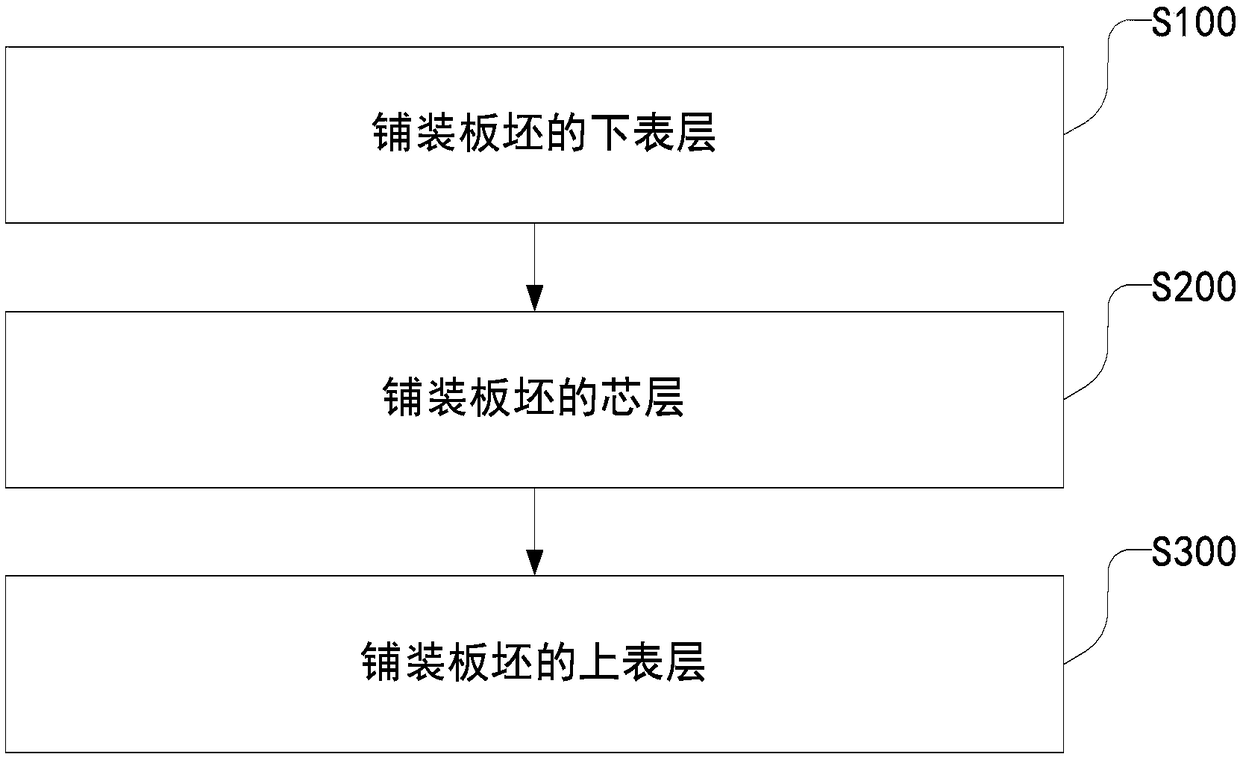

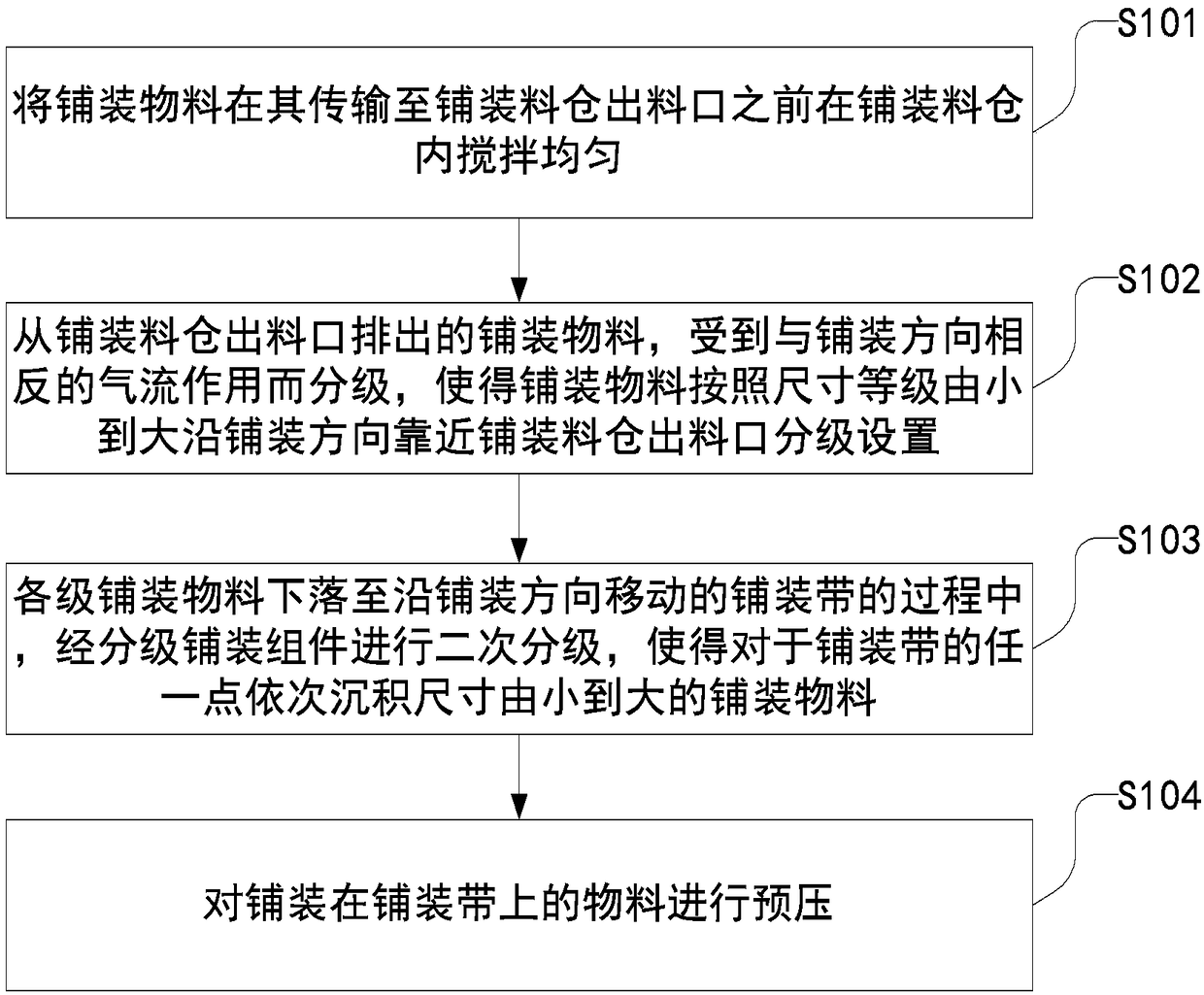

Plate blank paving method

InactiveCN108162128AGood gradient effectAvoid cloggingFlat articlesDomestic articlesSurface layerCivil engineering

The invention provides a plate blank paving method. The plate blank paving method comprises the following steps of paving a lower surface layer of a plate blank; paving a core layer of the plate blank; and paving an upper surface layer of the plate blank, wherein the step of paving at least one of the lower surface layer of the plate blank and the upper surface layer of the plate blank comprises the following steps of grading paving materials through gas flow; performing secondary grading on the paving materials subjected to gas-flow grading through a grading paving assembly; and paving the paving materials subjected to secondary grading to form a surface layer of the plate blank.

Owner:万华生态板业集成设备有限公司

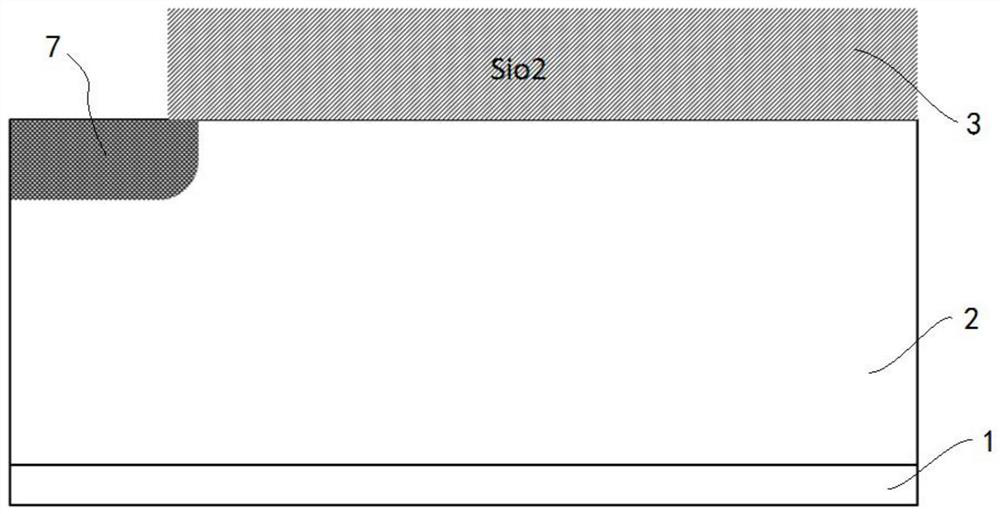

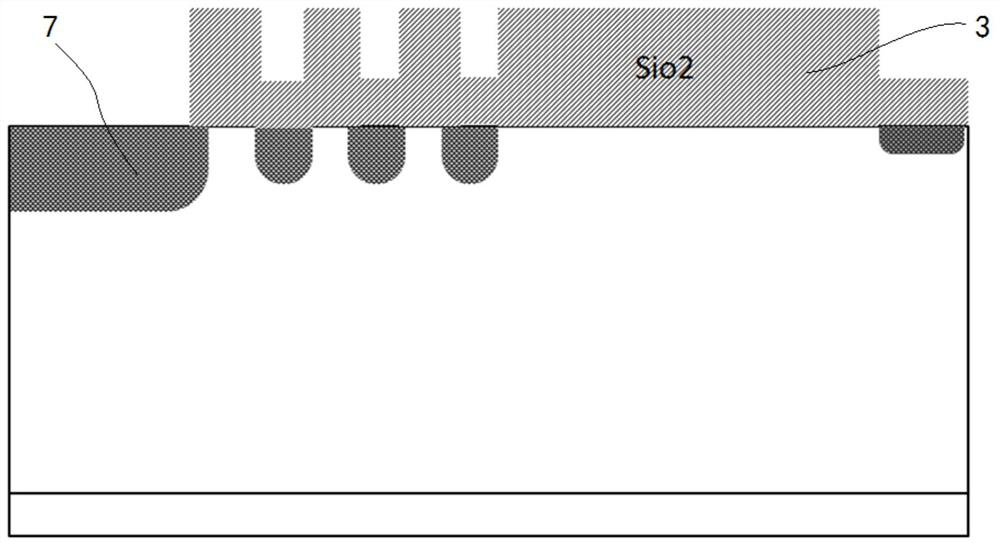

Semiconductor terminal structure and preparation method thereof

PendingCN112713186AGood gradient effectSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorMaterials science

The invention provides a semiconductor terminal structure and a preparation method thereof. The preparation method comprises the following steps of growing an epitaxial layer on a substrate layer, growing a first oxide layer with a preset thickness on the epitaxial layer, etching the first oxide layer to form a plurality of junction terminal injection ports which are distributed in a step shape along a preset direction, and injecting ions through the junction terminal injection ports, so that a plurality of junction terminal expansion structures which are distributed at intervals along a preset direction and of which the concentrations are decreased progressively are formed on the epitaxial layer. By etching the first oxide layer, a plurality of junction terminal injection ports which are distributed in a step shape along the preset direction can be formed, and the junction terminal injection ports are distributed in a step shape of which the heights are sequentially increased, so that the depths of the junction terminal injection ports on the first oxide layer are different; and the depths of the injected ions diffused to the epitaxial layer from the junction terminal injection ports with different depths are sequentially reduced, so that different junction terminal expansion structures of which the concentration gradients are progressively changed are formed, and the gradual change effect of the concentration gradients is good.

Owner:GREE ELECTRIC APPLIANCES INC +1

A kind of surface decoration processing method of electronic equipment shell

ActiveCN103818177BAvoid crackingGood gradient effectSpecial ornamental structuresElectrical apparatus casings/cabinets/drawersAlloyPrinting ink

The invention discloses a surface decoration processing method of an electronic equipment housing, which comprises the following steps of nickel-tin alloy plating: a nickel-tin alloy layer is plated on an insulating substrate film, titanium oxide layer plating: a titanium oxide layer is plated on the nickel-tin alloy layer, voltage bombardment: the titanium oxide layer is bombarded via voltage, and ink printing: an ink layer is printed in a set area of the voltage bombarded titanium oxide layer. In some embodiments, the insulating substrate film is not easy to crack; the ink layer can be stably attached to the titanium oxide layer, so that a complete NCVM (non-conductive vacuum metallization) layer can be formed; and a stable and better gradient effect can be achieved. In certain embodiments, the side height of the manufactured electronic equipment housing can reach 9mm with a better gradient effect, and the surface hardness can reach 3-4H.

Owner:SUZHOU TAIKAN MACHINERY CO LTD

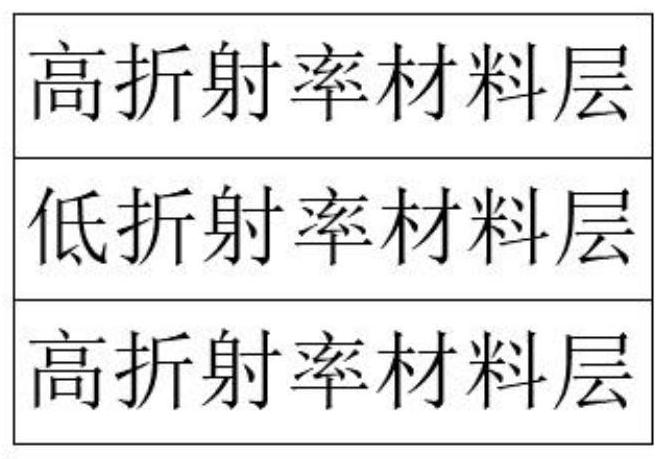

Preparation method of gradually-varied PET film

InactiveCN112048699AWith gradient effectGood gradient effectVacuum evaporation coatingSputtering coatingRefractive indexOptical thin film

The invention discloses a preparation method of a gradually-varied PET film. The preparation method includes the following steps of: S1, flatly paving a PET film, and plating the PET film with a material layer with refractive index; S2, preparing a UV transfer-printed texture layer on the other surface of the PET film; S3, depositing an optical thin film layer on the surface of the UV transfer-printed texture layer; S4, forming an optical thin film layer of which the thickness is uniformly changed on the optical thin film layer through chemical corrosion; S5, spraying a coloring layer on the optical thin film layer; and S6, forming a laser effect layer on the coloring layer through mold pressing. According to the preparation method disclosed by the invention, the PET film is plated with the material layer with the refractive index, and the material layer with the refractive index consists of a material layer with a high refractive index and a material layer with a low refractive indexalternately; therefore, the obtained PET film achieves the effect of gradually changing colors by refracting light.

Owner:苏州裕信宏塑料包装有限公司

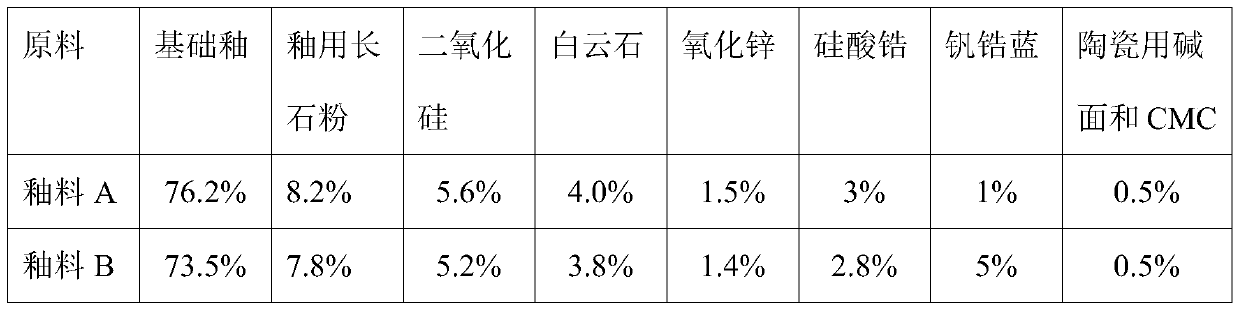

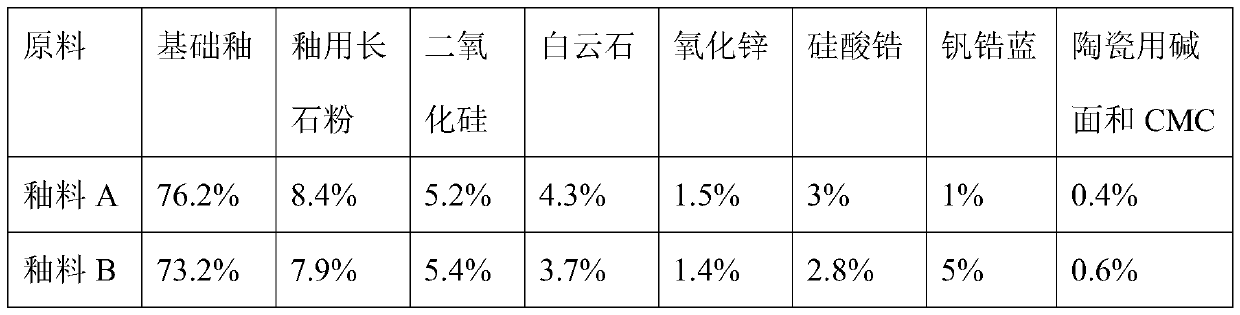

A kind of preparation method of blue gradient glaze sanitary ceramics

The invention discloses a preparation method of blue gradient glaze sanitary ceramic. A glaze material is prepared from basic glaze, silicon dioxide, dolomite, zinc oxide, zirconium silicate, feldsparpowder for glaze, vanadium-zirconium blue and the like; glaze slurry A and glaze slurry B, which have different vanadium-zirconium blue content, are prepared through the glaze material; the glaze slurry A and the glaze slurry B are sprayed on the surface of a sanitary ceramic white body in sequence, wherein the spraying amount of the glaze slurry A is gradually reduced from the top to the bottomof a white body spraying region and the spraying amount of the glaze slurry B is gradually increased from the top to the bottom of the white body spraying region; then the glazed white body is fired in a tunnel kiln at 1202 DEG C to 1250 DEG C for 15h to 18h to obtain a blue gradient glaze sanitary ceramic product. The obtained product meets the processing and utilization performance requirementsof the sanitary ceramic, has a good gradient effect and an extremely good decoration effect, and meets the requirements of individualized bathrooms.

Owner:JOMOO KITCHEN & BATHROOM

Gradient printing ink and gradient printing method

PendingCN111471352AAdhesive enoughStrong enoughInksOther printing apparatusPolymer sciencePrinting ink

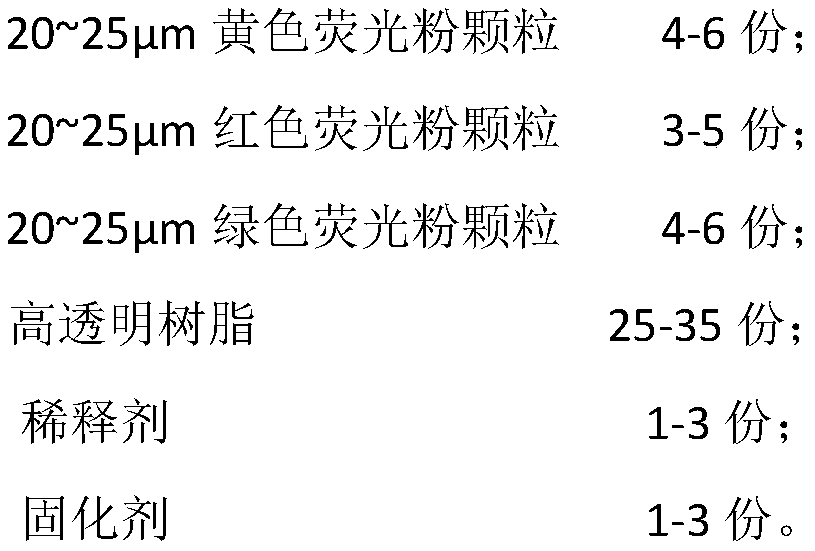

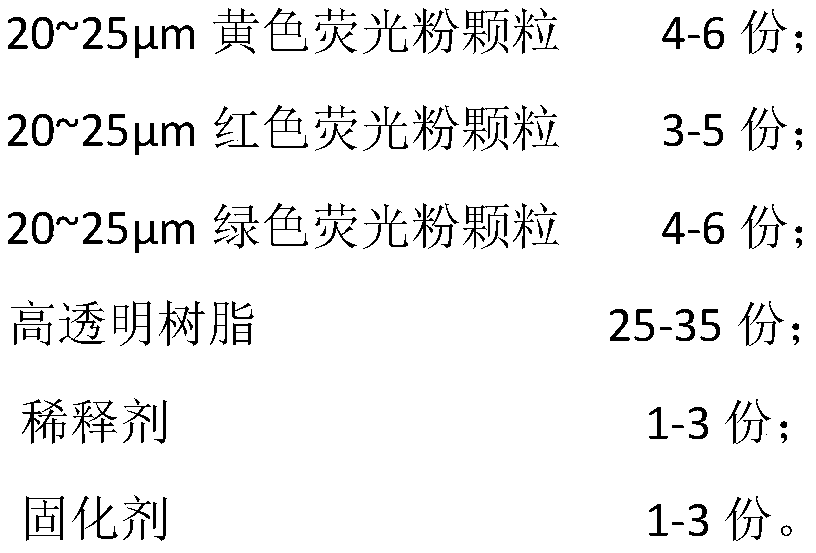

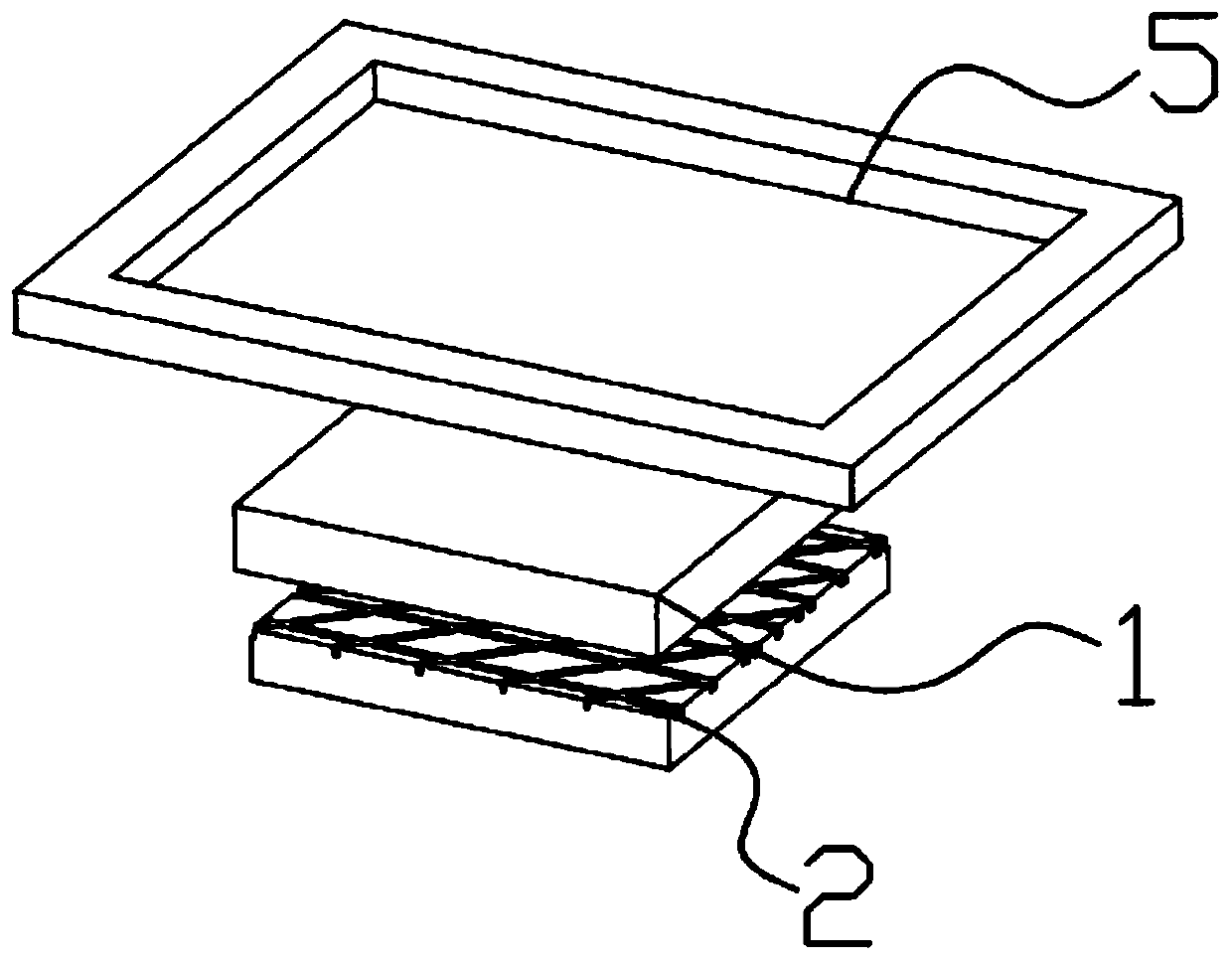

The invention discloses gradient printing ink, which is characterized by comprising the following components by weight: 40-60 parts of fluorescent ink; 30 to 50 parts of cured resin; 5-15 parts of a solvent. The fluorescent ink comprises the following components in parts by weight: 4-6 parts of yellow fluorescent powder particles of 20-25 [mu]m; 3-5 parts of red phosphor particles of 20-25 [mu]m;4-6 parts of green fluorescent powder particles of 20-25 [mu]m; 25 to 35 parts of high-transparency resin; 1-3 parts of a diluent; 1-3 parts of a curing agent. The invention also provides a preparation method and a printing method of the gradient printing ink. The gradient printing ink disclosed by the invention is sufficient in adhesive property, enough in firmness and wear resistance, good in anti-cracking degree and transfer effect and remarkable in gradient effect. Meanwhile, the invention further provides a gradient printing method of the gradient printing ink, the whole process is simple, a large amount of manual operation is not needed, the cost is low, and the gradient appearance effect is good.

Owner:江苏帝摩斯光电科技有限公司

Stereoscopic bright line coating process

InactiveCN110667276AImprove the three-dimensional effectNot easy to dropPattern printingScreen printingGraphics

The invention discloses a stereoscopic bright line coating process. The process is realized by the following steps of S1, fixing a magnetic fixture on a workbench; S2, laying a print substrate on themagnetic fixture for positioning; S3, printing magnetic paint on the print substrate to form a first pattern by screen printing and heat transfer printing; S4, finalizing the first pattern by magneticadsorption of the magnetic fixture; S5, drying the first pattern after going through the step S4; and S6, spraying UV gloss paint on the surface of the first pattern after going through the step S4,and thus enhancing the surface strength and surface brightness of the first pattern. Magnetic lines corresponding to text and graphics printed on the print substrate are designed on the magnetic fixture, and the magnetic lines carry out magnetic absorption and design finalizing for the text and graphics printed by the magnetic paint, so that the stereoscopic effect of the text and graphics is enhanced, the text and graphics are not easy to fall off, the service life is prolonged. Meanwhile, a variety of pigments can be added to the magnetic paint to enhance the texture of the text and graphicsand the gradient effect of bright lines, improve the product aesthetics, and attract customers.

Owner:珠海赛德诚科技有限公司

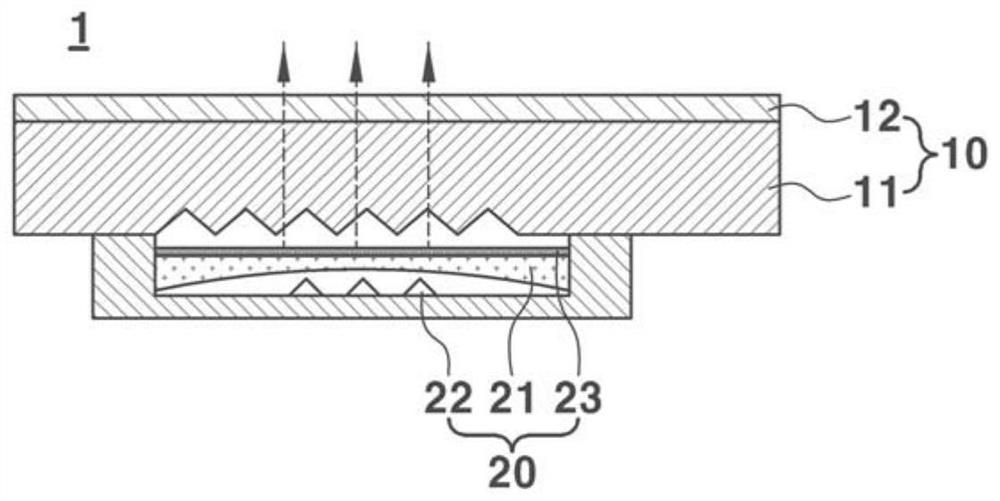

Vehicle panel emitting light in three-dimensional gradient pattern

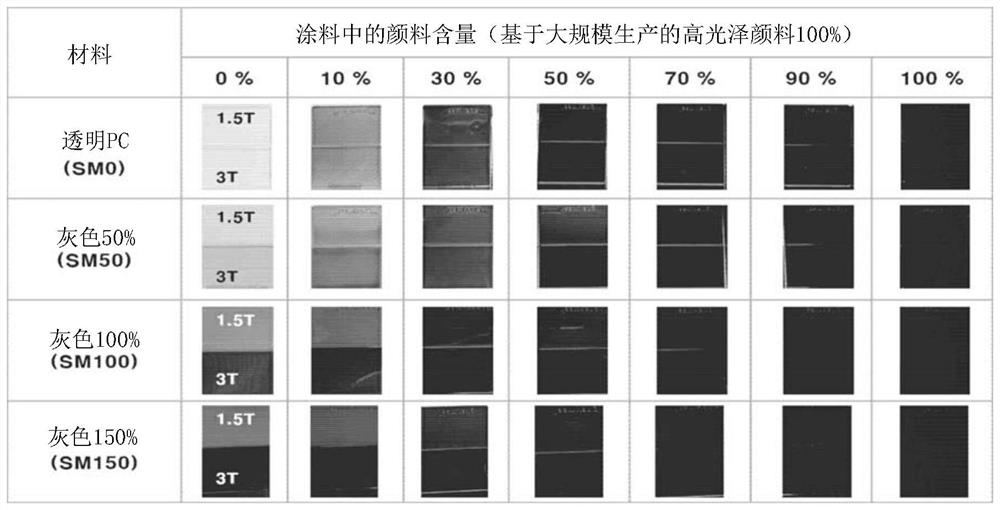

PendingCN114506266ALow mass productivityReduce lossesPassenger/driving compartment lightingsLight guidesEngineeringMaterials science

The present application relates to a vehicle panel emitting light in a three-dimensional gradient pattern, the vehicle panel comprising: a panel main body comprising a three-dimensional pattern portion and a coating portion, the three-dimensional pattern portion comprising a three-dimensional pattern engraved on a rear surface of the three-dimensional pattern portion, and a coating portion coated on an upper surface of the three-dimensional pattern portion, and an illumination portion provided so that light is emitted from an inner surface of the panel main body, in which the illumination portion includes: a diffusion plate provided to be spaced apart at a position corresponding to the panel main body, and a light source provided to emit light from the inner surface of the panel main body; the light source is located on the inner side of the diffusion plate and arranged to be separated from the diffusion plate.

Owner:HYUNDAI MOTOR CO LTD +1

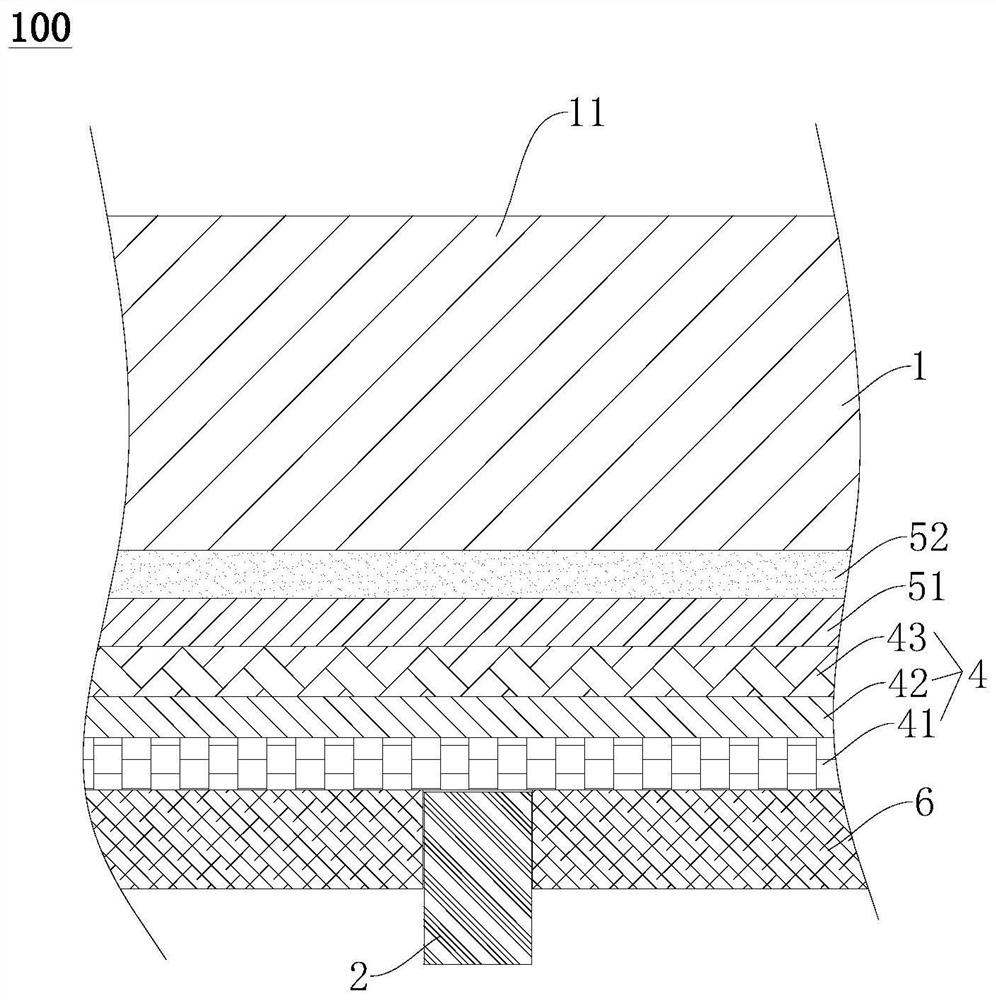

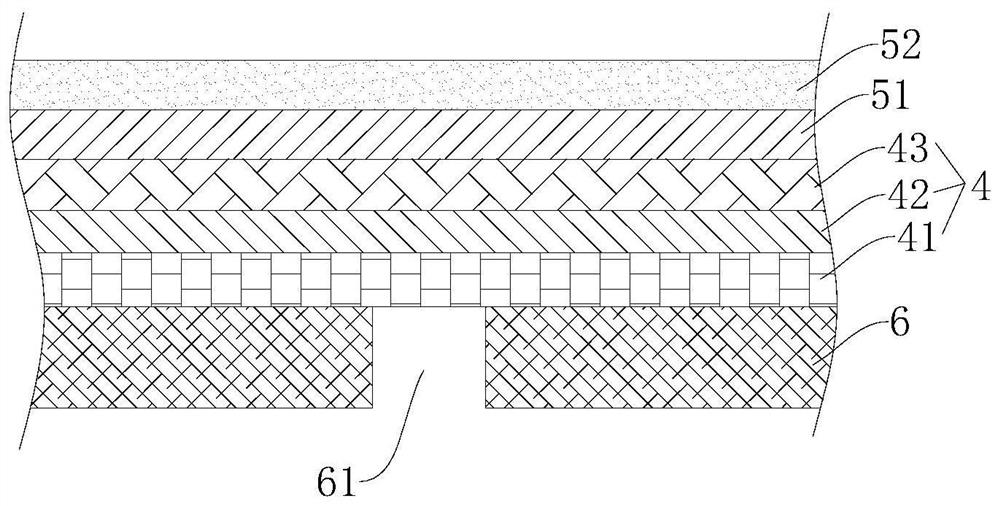

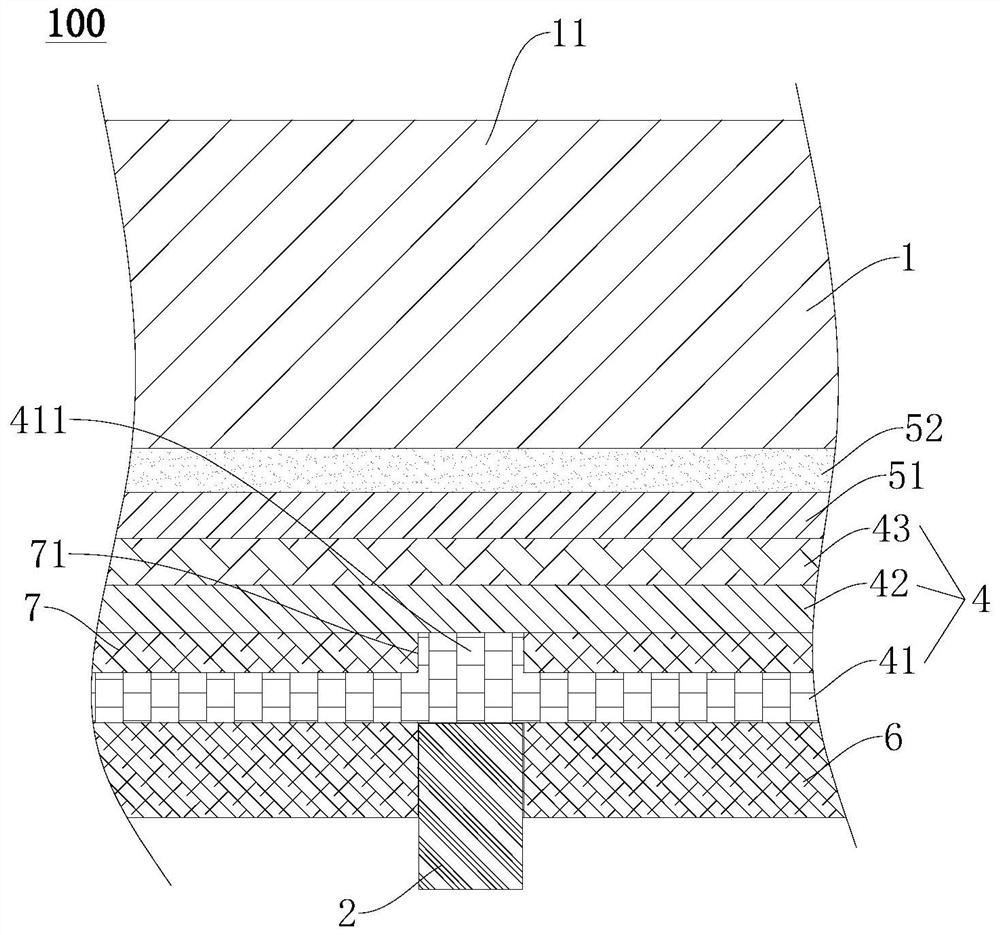

Housing assembly, electronic device and method for manufacturing housing assembly

The application discloses a housing assembly, an electronic device and a manufacturing method of the housing assembly. The housing assembly includes: a housing, a light guide module and a light emitting device. The housing has a light-transmitting part, and the light-guiding module and the light-emitting device are arranged on the inside of the housing. Relatively arranged, the light-emitting device is adjacent to the light-incident surface, and the light generated by the light-emitting device presents a gradient color after being guided by the light-guiding module. According to the housing assembly of the electronic device according to the embodiment of the present application, the light-transmitting part of the housing presents a gradient color in appearance, which improves the appearance of the housing assembly. In the case of weak ambient light, the housing assembly can still appear Good gradient effect. In addition, the light-emitting device can be used as a breathing light, and since the appearance shows that the light-emitting area can be set larger, it can play a good role in reminding users.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

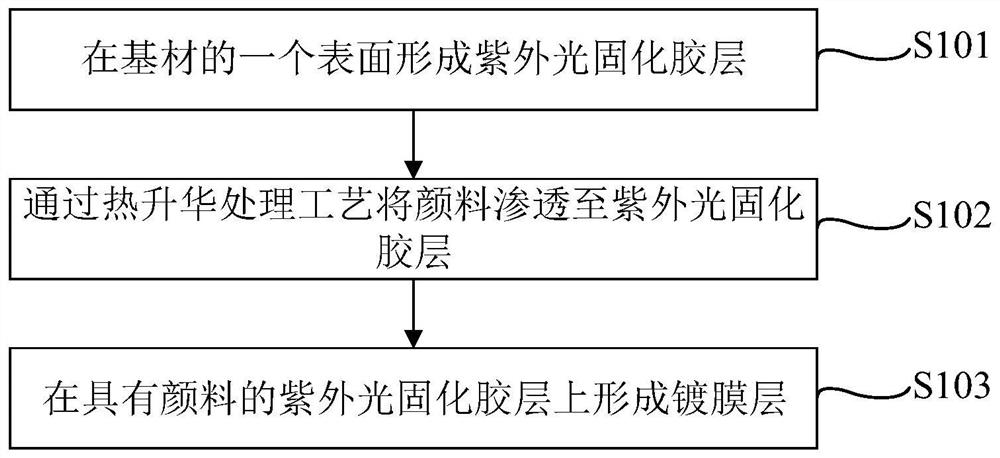

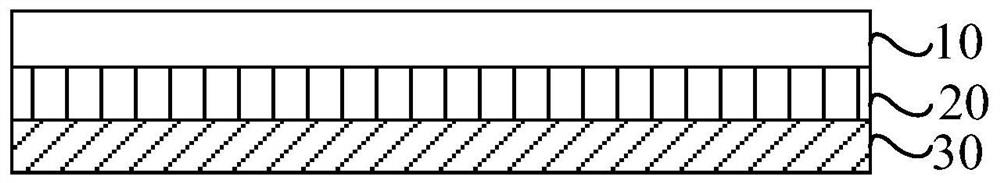

Manufacturing method of casing, casing and electronic device

ActiveCN111016485BUniform penetrationExpand the scope of activitiesNatural patternsCasings/cabinets/drawers detailsPhotopigmentEngineering

Owner:VIVO MOBILE COMM CO LTD

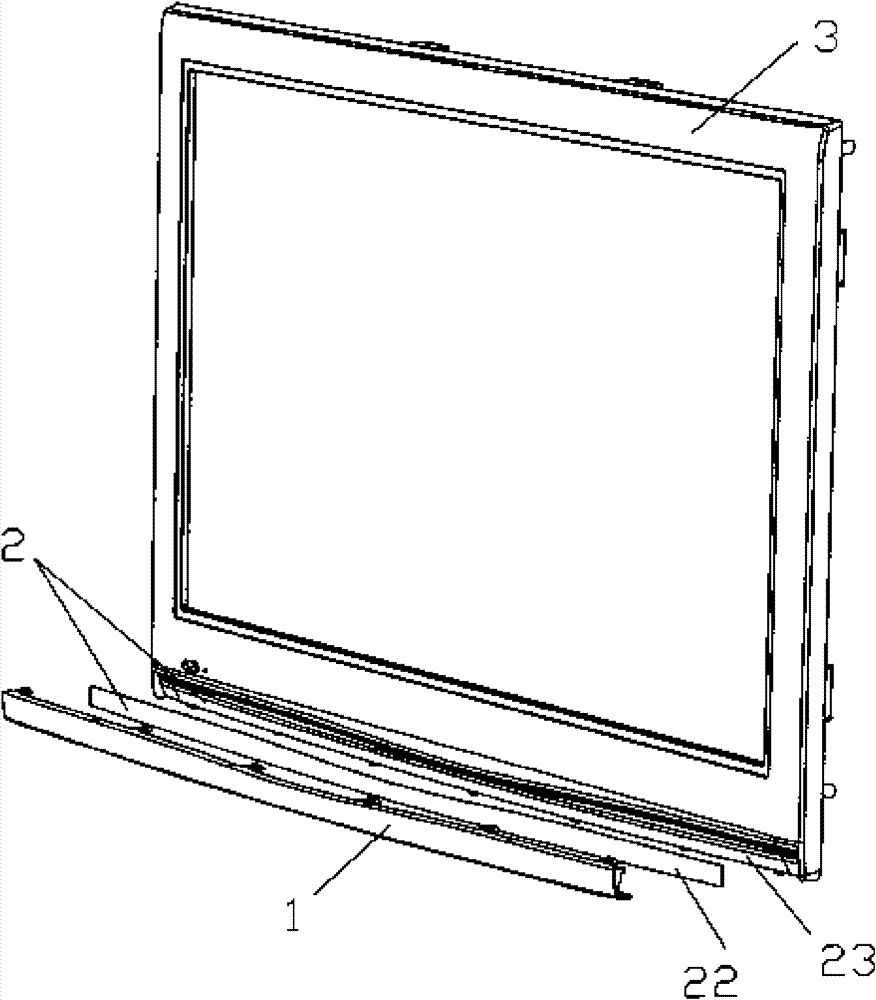

Decorative body structure capable of realizing gradual change of color

ActiveCN101941356BReduce manufacturing costGood gradient effectTelevision system detailsLight effect designsDark colorEngineering

The invention discloses a decorative body structure capable of realizing the gradual change of color, which comprises a front decorative body, a rear decorative body and a housing body; the rear decorative body is accommodated in a notch of the front decorative body, a reflecting surface which is manufactured by adopting a reflecting material is arranged on the front wall surface of the rear decorative body, a gap which is gradually increased from top to bottom is arranged between the front wall surface of the rear decorative body and the rear wall surface of the front wall of the front decorative body, the rear wall surface of the front wall of the front decorative body is shaped like an arc which is concave inwards, the thickness of the front wall of the front decorative body is gradually contracted from the top to the bottom, and the front wall surface of the rear decorative body is gradually inclined backwards from the top to the bottom and forms an included angle of about 70 degrees with the horizontal plane. The structure can lead a person to obtain the effect of the gradual change of the color of the front decorative body on the impression effect, that is the color is gradually changed from dark color to light color or gradually changed from dark to blue from the top to the bottom, and the decorative body structure has the characteristics of low manufacturing cost, easy realization and good gradual change effect; simultaneously, the structure can effectively improve the competitiveness of an electronic product, and be applicable to flat-panel televisions or other electronic products.

Owner:XIAMEN PRIMA TECH

Gradient anti-dazzle glass, and preparation method and application thereof

The invention relates to a gradient anti-dazzle glass, and a preparation method and application thereof. The preparation method of the gradient anti-dazzle glass comprises the following steps: carrying out chemical polishing treatment on uniformly frosted glass, wherein the chemical polishing treatment comprises the following steps: carrying out gradient polishing: moving the glass at a speed of 0.2-0. 5 m / min, and carrying out gradient polishing on the glass by enabling chemical polishing liquid to flatly flow in a liquid knife manner above the moving direction of the glass; and performing water washing: moving the glass subjected to gradual change polishing treatment at the speed of 4-5 m / min, and enabling pure water to flatly flow above the moving direction of the glass in a liquid knife manner so as to clean the glass subjected to gradual change polishing treatment. In the preparation method, the glass slowly moves, so that the chemical polishing reaction time of one end and the other end of the anti-dazzle surface is gradually changed, and a gradual change effect is formed. The manufacturing method of the gradient anti-dazzle glass is simple in process, automation can be achieved, the manufactured gradient anti-dazzle glass is good in gradient effect, the haze of the glass is in uniform transition, and no obvious boundary exists.

Owner:WGTECH JIANGXI

Laminated formed body and method of manufacturing the formed body

InactiveCN1678445BChange thicknessGood gradient effectBottlesSynthetic resin layered productsPolymer scienceCo extrusion

Owner:YOSHINO KOGYOSHO CO LTD

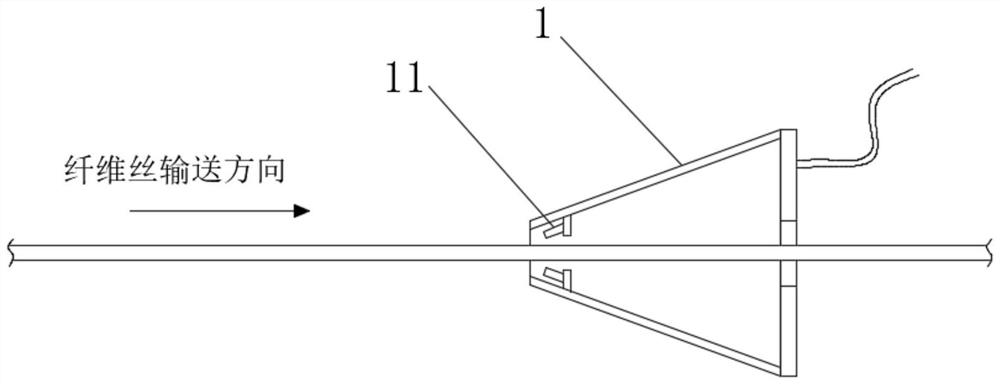

Production method of gradient color spinning fabric

PendingCN114016228AGood gradient effectImprove dyeing uniformityTextile treatment machine arrangementsTextile treatment by spraying/projectingYarnFiber

The invention relates to a production method of gradient color spinning fabric. The method comprises the following production steps: S1, color pastes of different pigments are prepared according to gradient colors, the color pastes are placed in sequence, and cellosilk is immersed into the color pastes for dip dyeing; S2, fibers are taken out and conveyed, steam is obliquely sprayed to the surfaces of the fibers in the conveying process, so that the color pastes on the surfaces of the fibers are evenly distributed, and the joints of different color pastes are mutually fused; and S3, after the fibers are dried, a spinning machine is used for spinning the multiple fibers into the gradient color spinning fabric. Steam is used for spraying the dyed fiber yarn, when the steam acts on the joint of the two kinds of color paste, the dark color paste can be gradually blown to the outer portion of the light color paste, two colors are fused, natural gradient is formed, the obtained gradient color fiber yarn is good in gradient effect, natural and vivid and can be used for tedious gradient color treatment, the process is simple, and the equipment cost is low.

Owner:GAOFAN (ZHEJIANG) INFORMATION TECH CO LTD

OLED module gamma adjustment method and system based on multi-objective correlation mathematical model

ActiveCN108597442BOvercoming problems such as poor consistencyIncrease production capacityStatic indicating devicesRound complexityLinear correlation

The invention discloses a Gamma adjusting and recalibrating method and a Gamma adjusting and recalibrating device of an OLED module based on a multi-objective relational mathematic model. The method comprises the following steps: (1) establishing an objective function; and (2) establishing a constraint condition, wherein R, G and B register values of all the binding points of the module are in positive linear or negative linear dependence, the multi-objective relation optimization is converted into single-objective optimization, the double-objective optimization is converted into single-objective optimization, and finally, the R, G and B register values corresponding to F are solved and are output to R, G and B registers corresponding to the gray scale binding point m in a module chip according to setting. According to the technical scheme, the diversified mode of gamma adjustment is supported, the features of platformization and parallelism are realized, and the method and the systemhave the advantages of efficiency and stability in adjusting and good gradual change effect. The experimental result shows that with the provided mathematic model, the complexity can be effectively reduced, the conventional algorithm is converted into algorithm and calculation, the adjusting and recalibrating efficiency is very ideal, and the problems including that the module is poor in consistency are solved.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

Gradient anti-glare cover plate, manufacturing method thereof, and electronic device

ActiveCN107608013BAchieve natural gradientsTo achieve a gradient effectDiffusing elementsPhotomechanical apparatusEngineeringDiffuse reflection

The application provides a gradient anti-glare cover plate and a making method thereof as well as electronic equipment. The making method comprises the following steps: providing a substrate; making graded-density grooves in at least one surface of the substrate, wherein the distance between the every two adjacent grooves is less than 5 microns; demoulding; making uneven anti-glare structures on the surfaces of the grooves. The graded-density grooves are firstly formed before anti-glare production, and the distance between the every two adjacent grooves is less than 5 microns, so that the natural gradual change of light can be realized, a gradual change effect is achieved, and the appearance of the gradient anti-glare cover plate is enabled to be more attractive; therefore, the gradient anti-glare cover plate is more greatly different from cover plates of other electronic products, and a homogenization phenomenon is further avoided. Furthermore, the anti-glare effect of the gradient anti-glare cover plate is realized mainly by means of irregular rugged small salient points directly formed in the grooves, and a diffuse reflection function is realized; the gradient and anti-glare effect is realized only by combining the two processes, so that the making technology is simple.

Owner:TRULY OPTO ELECTRONICS

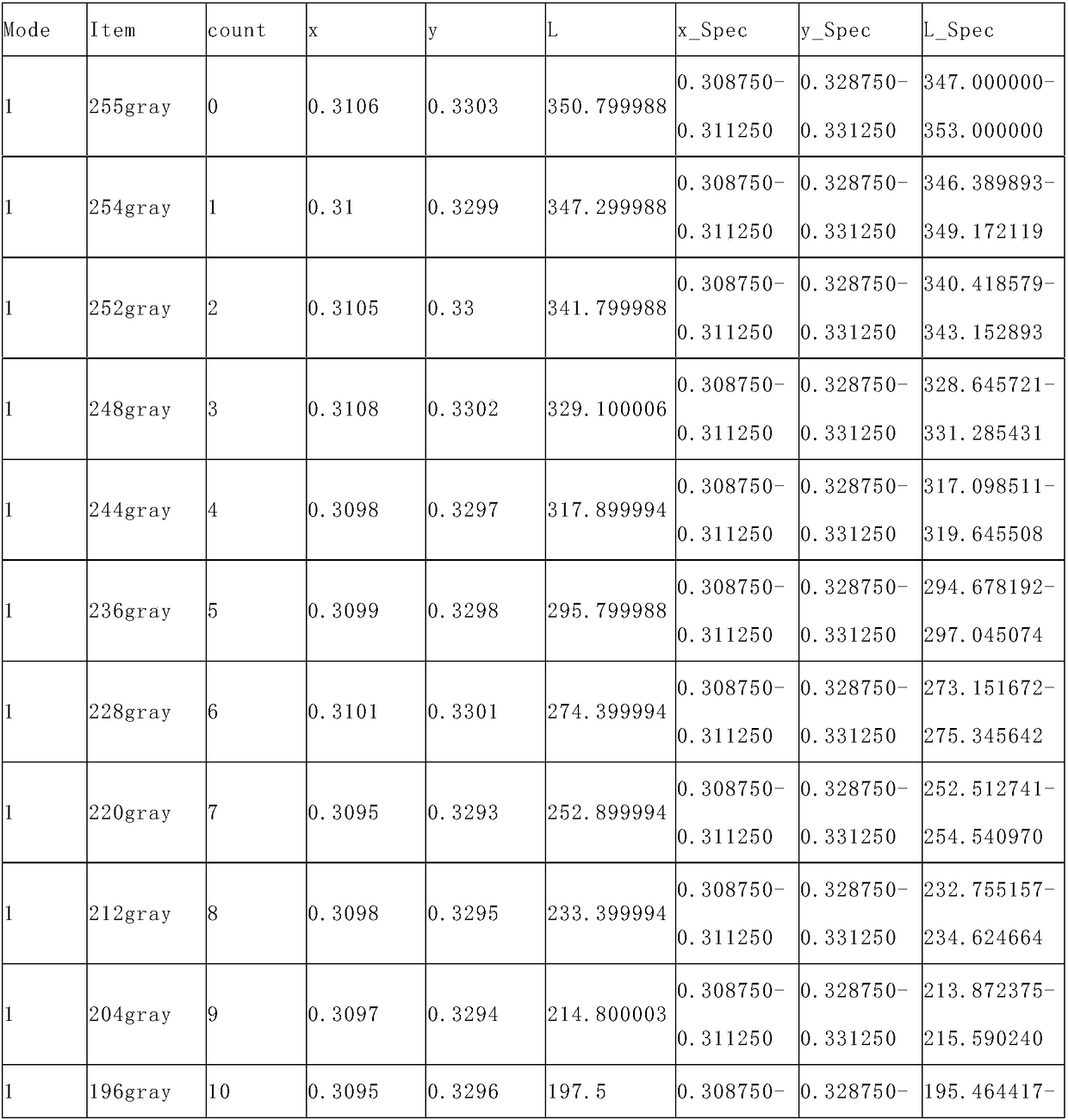

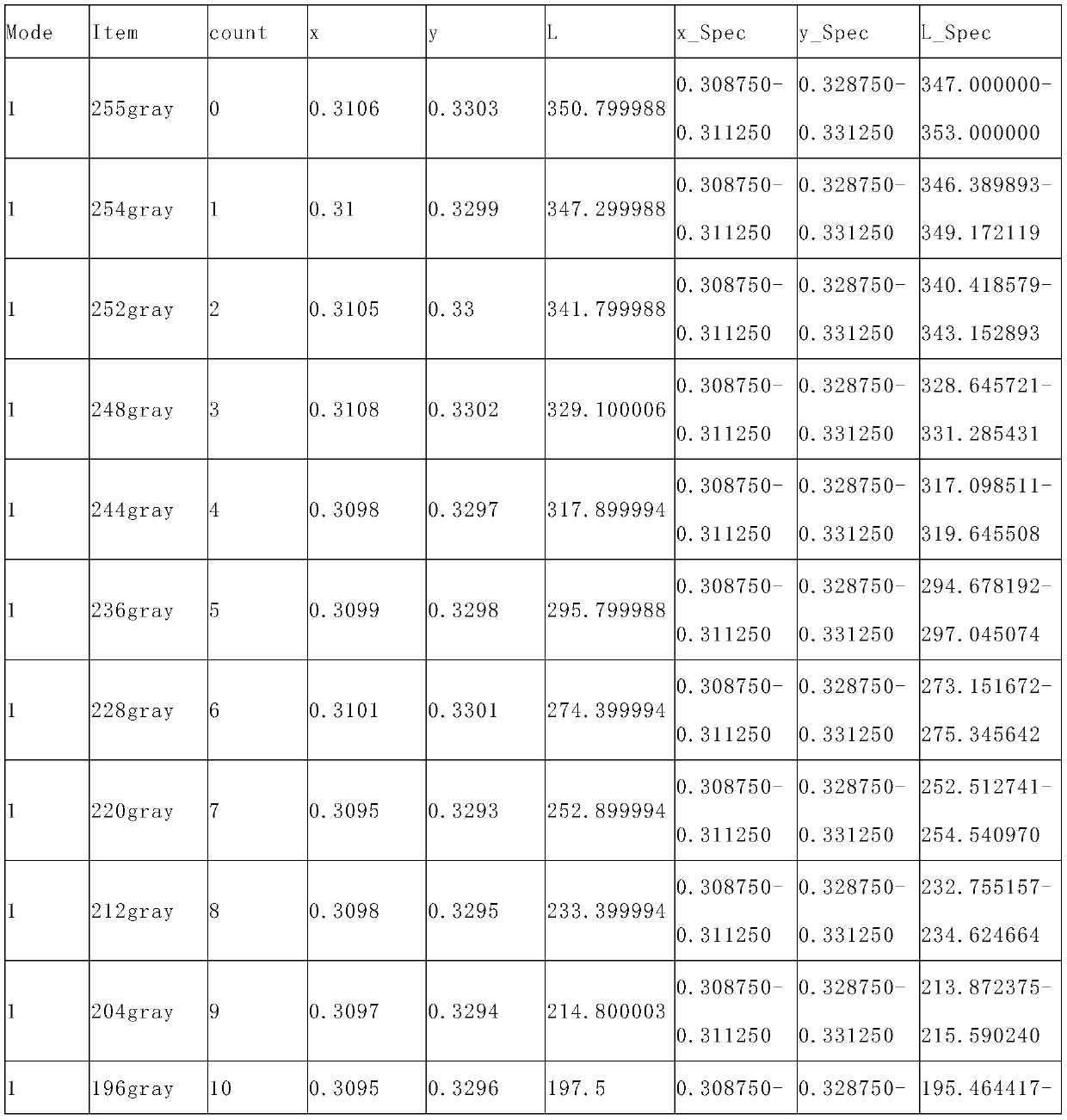

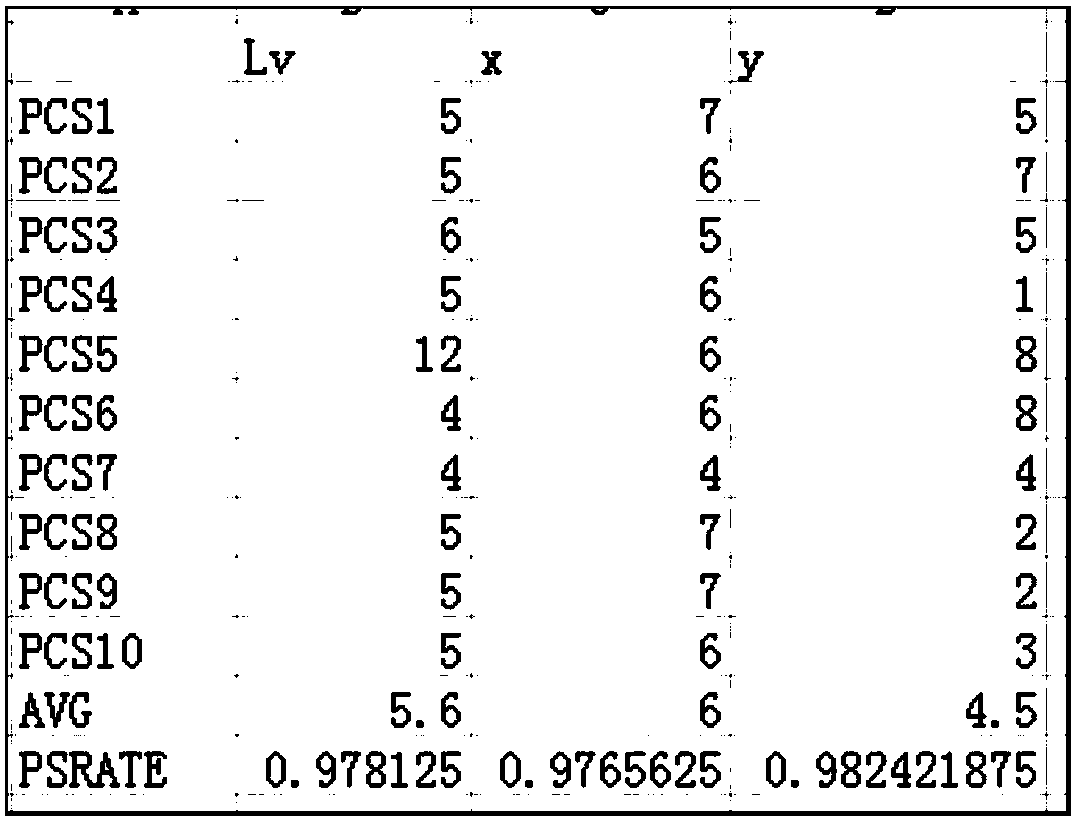

Color-sensitive oled module gamma adjustment method

ActiveCN106297664BHigh precisionThick white streaks disappearStatic indicating devicesProcessor registerPass rate

The invention discloses a color-sensitive OLED module gamma tuning method. The color-sensitive OLED module gamma tuning method includes the steps of: adjusting white balance to determine the highest gray-scale brightness value and the lowest gray-scale brightness value, based on the highest gray-scale brightness value and the lowest gray-scale brightness value, determining the brightness Lv, the color coordinates x and y, and the target values of stimulus values X, Y and Z of each target tie point, conducting the gamma tuning for each target tie point until the brightness Lv, the color coordinates x and y, and the current values of stimulus values X, Y and Z of all target tie points are within the error range of the target value, finally, executing OTP burning, to backup the adjusted register values to IC of an OLED module. The adjusting efficiency is high, and the passing rates of gray-scale brightness and color coordinates are high. The color-sensitive OLED module gamma tuning method can effectively solve the problems of the occurrence of colored ribbon and coarse white strip phenomenon, the gray-scale gradient effect is good, the color-sensitive OLED module gamma tuning method is allowed to normalize the adjusted data in a graphical way and plot the curve, supports the manual debugging and reading of backup device, and is allowed to record the adjustment process and result in Excel form, thus being conducive to bulk data statistics.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

Process for preparing composite materials with self radial gradient by in situ crystallization

The invention discloses a process for preparing self-generated radially gradient composite materials by an in-situ crystallization method, which belongs to the field of composite material preparation. Specifically: after remelting the self-generated composite material, the remelting temperature is 50-150°C above the liquidus line, pouring it into a SiC casting mold; generating an induced high-frequency magnetic field through a high-frequency power supply and a cylindrical axisymmetric induction coil, and then With the reduction of the power supply of the induced high-frequency magnetic field by 7Kw~2Kw, the preheating temperature of the casting mold is increased linearly by 30℃~300℃; the temperature measuring device of the single-channel SiC casting mold is used to monitor the temperature of the self-generated composite material. When the temperature of the self-generated composite material drops close to the eutectic temperature of the material, the high-frequency magnetic field is turned on, and the action time is 4s-32s. When the temperature of the self-generated composite material rises close to the liquidus temperature, the effect of the high-frequency magnetic field is terminated; finally, the self-generated composite material Solidification molding in SiC casting mold. The invention significantly increases the effective action time of the high-frequency magnetic field and improves the yield of materials.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com