3D gradient color mobile phone rear cover forming process and mobile phone rear cover

A mobile phone back cover and molding process technology, which is applied to the structure of telephones, telephone communications, electrical components, etc., can solve the problems of monotonous and boring colors, poor wear resistance, and insufficient strength, and achieve obvious appearance effects, good gradient effects, and high-quality uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

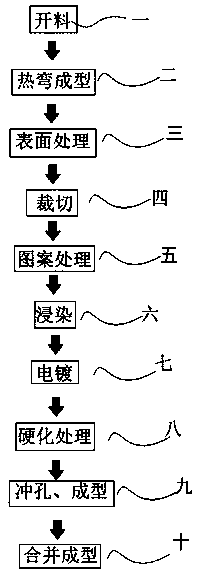

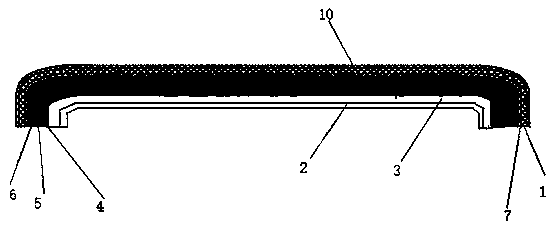

[0029] Examples, see attached Figure 1~Figure 2 , a 3D gradient mobile phone back cover molding process, which comprises the following steps:

[0030] 1. Cutting: use a glass cutting machine to cut the glass, and cut out a glass piece that matches the size of the back cover of the mobile phone when it is spread out. The thickness of the glass is 0.5-1.0mm;

[0031] 2. Hot bending forming: Use a glass hot bending machine to hot bend the glass sheet in step 1. When hot bending, put the glass sheet in step 1 at 80°C, 100°C, 200°C, 300°C, 400°C in sequence Heating and softening at lower temperature, followed by multiple downward hot pressing at 500°C for micro-deformation, and finally multiple downward hot pressing at 680°C to form a semi-finished glass back cover 1 whose shape matches the shape of the back cover o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com