Stereoscopic bright line coating process

A bright line and coating technology, applied in the printing process, printing of special varieties of printed matter, printing, etc., can solve the problems of low strength of three-dimensional graphics, easy to fall, short service life, etc., to achieve enhanced graphics Three-dimensional effect, prolonging service life, and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not limited to the present invention.

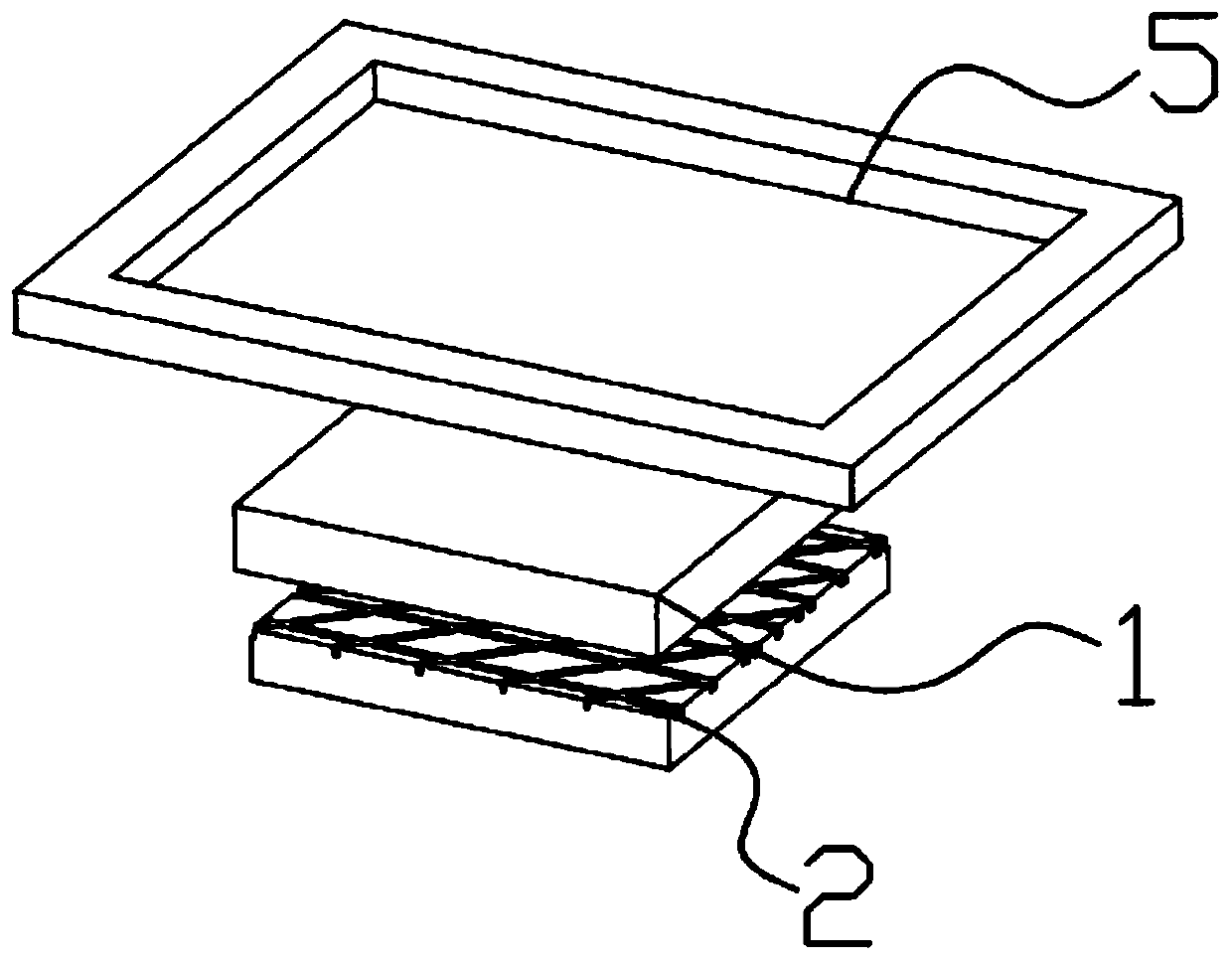

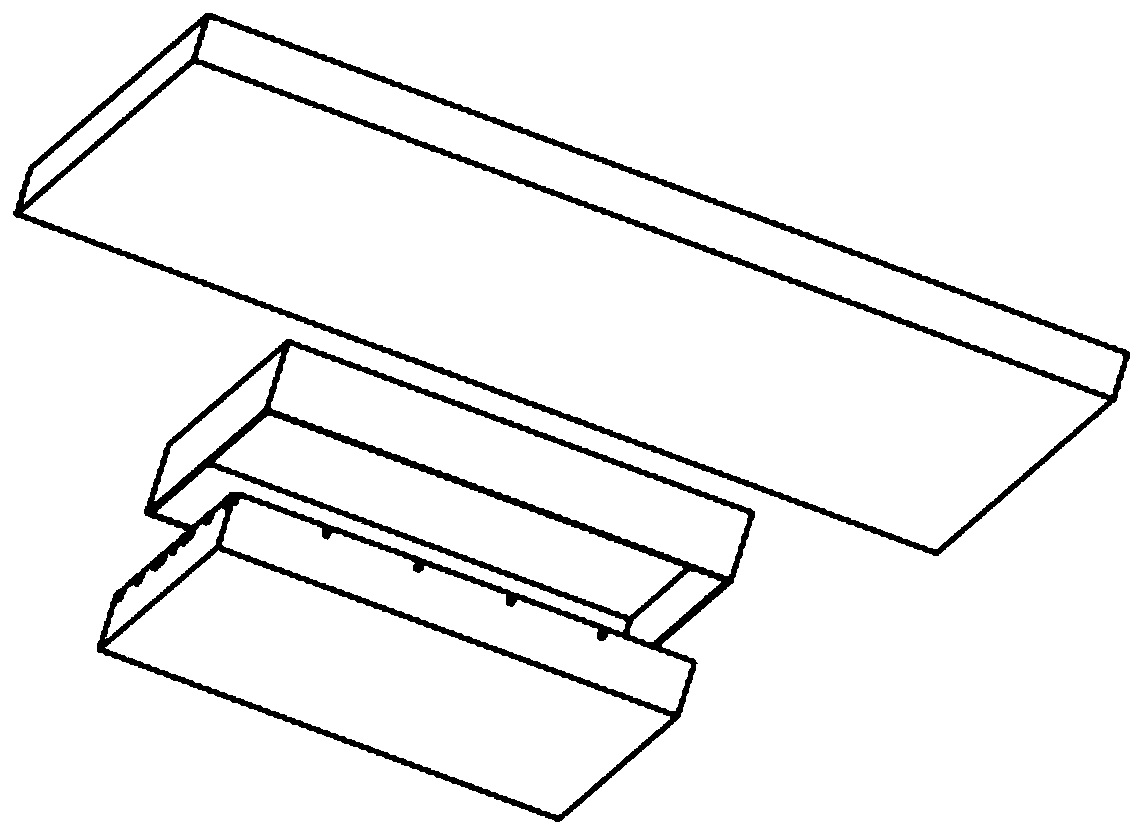

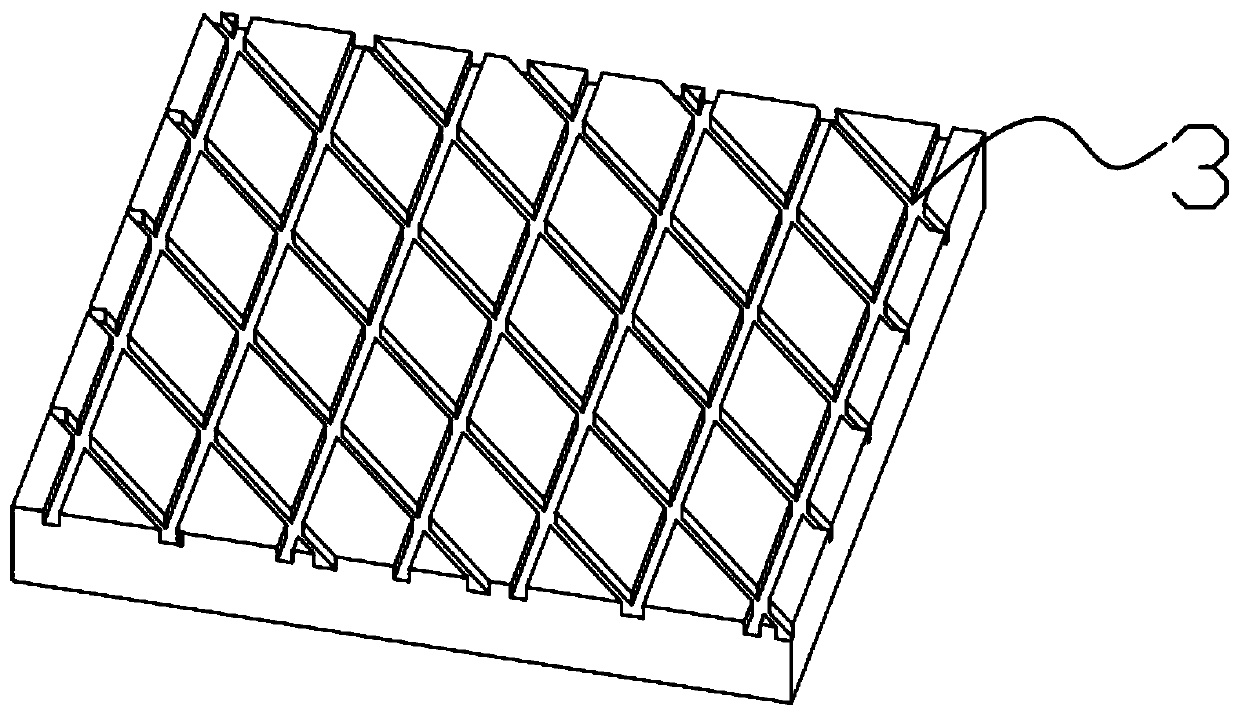

[0027] In view of the fact that the existing screen printing and thermal transfer printing processes can only produce simple graphics and text effects, and the aesthetics is not enough, it is not easy to attract customers, and the graphics and texts are not strong enough, easy to drop, and lack durability. The scheme designs a three-dimensional bright line coating process, which is realized through the following comprehensive steps: see Figure 1-Figure 4 ;

[0028] S1: The magnetic fixture is fixed on the workbench; wherein, a suitable and matching magnetic fixture is designed according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com