Gradient printing ink and gradient printing method

A technology for printing ink and fluorescent ink, applied in the directions of printing, ink, and post-processing of printing, etc., can solve problems such as the influence of gradation effect, and achieve the effects of low cost, good crack resistance and transfer effect, and sufficient wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Another object of the present invention is to provide a preparation method of the gradient printing ink, which is characterized in that it includes the following steps: after mixing the components uniformly by weight, ultrasonically for 10-20 minutes, and then after 40-60 Stirring at ℃ for 2-4 hours to obtain gradient printing ink.

[0036] Another object of the present invention is to provide a gradient printing method of the gradient printing ink, which is characterized in that it includes the following steps: printing the gradient ink layer on the substrate with the gradient printing ink: adjusting the screen printing speed and screen printing Pressure, the substrate is under the blank screen and the distance is 2-6mm, the length of the printing silicone scraper is 40-60mm longer than the size of the printed product, and the scraper is kept at an angle of 45-55 degrees to the screen surface of the blank screen; after printing Quickly send it to the drying tunnel for ...

Embodiment 1

[0041] Embodiment 1 provides a kind of gradient printing ink, is characterized in that, it comprises the component of following weight portion content:

[0042] Fluorescent ink 40 parts;

[0043] 30 parts of curing resin;

[0044] 5 parts of solvent.

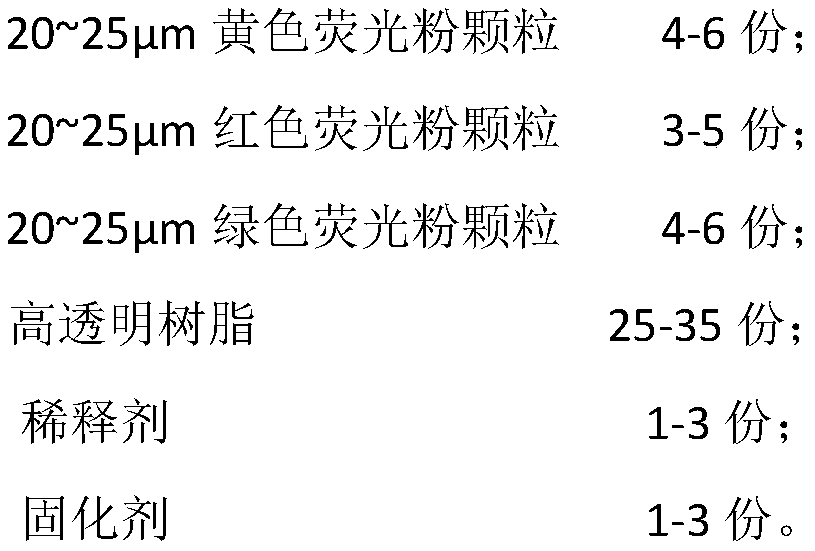

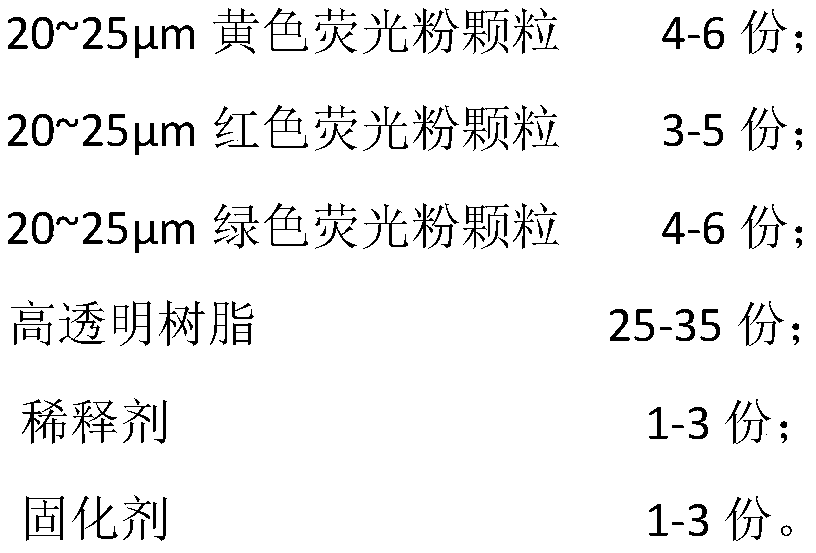

[0045] The fluorescent ink comprises the following components in parts by weight:

[0046]

[0047] The highly transparent resin is bisphenol A type epoxy resin; the diluent is acetone; the curing agent is 2,2-bis[4-(4-aminophenoxy)phenyl]-1,1, 1,3,3,3-hexafluoropropane; the cured resin is amino-terminated polyurethane; the solvent is toluene.

[0048] A preparation method of the gradient printing ink is characterized in that it comprises the following steps: after uniformly mixing the components by weight, ultrasonication for 10 minutes, and stirring at 40° C. for 2 hours to obtain the gradient printing ink.

[0049]A gradient printing method of the gradient printing ink, characterized in that it comprises the following ...

Embodiment 2

[0051] Embodiment 2 provides a kind of gradual printing ink, and its formula and printing method are substantially the same as embodiment 1, and difference is, described it comprises the component of following weight part content:

[0052] Fluorescent ink 45 parts;

[0053] 35 parts of curing resin;

[0054] 8 parts of solvent.

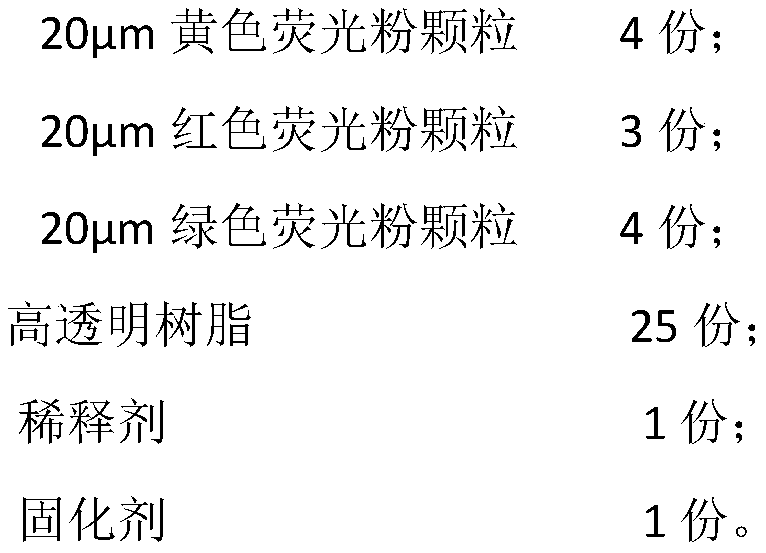

[0055] The fluorescent ink comprises the following components in parts by weight:

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com