Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Formed flat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Frame glasses and processing method thereof

InactiveCN102073149AFormed flatFirmly connectedFramesNon-optical partsComputer scienceCylinder pressure

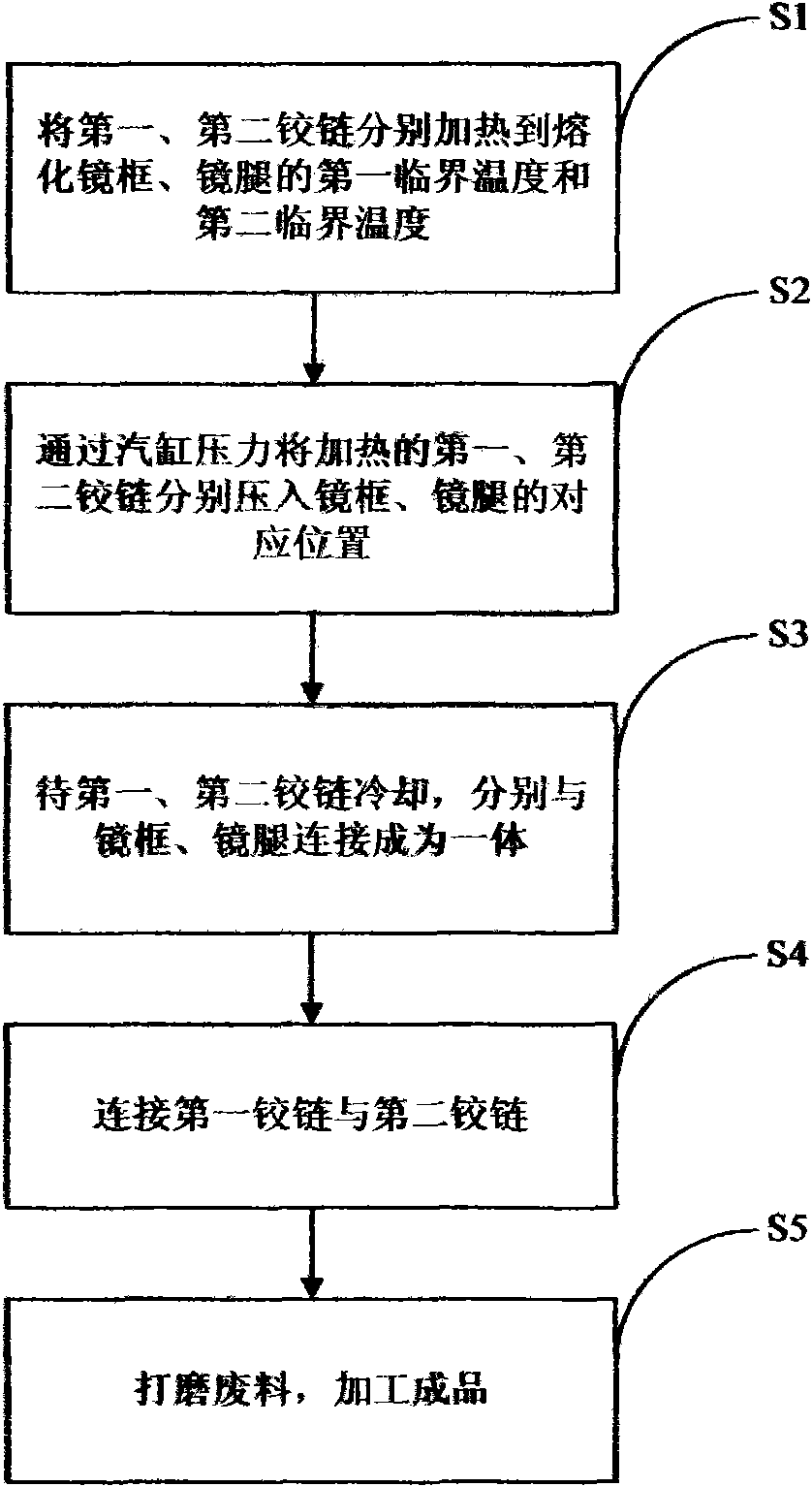

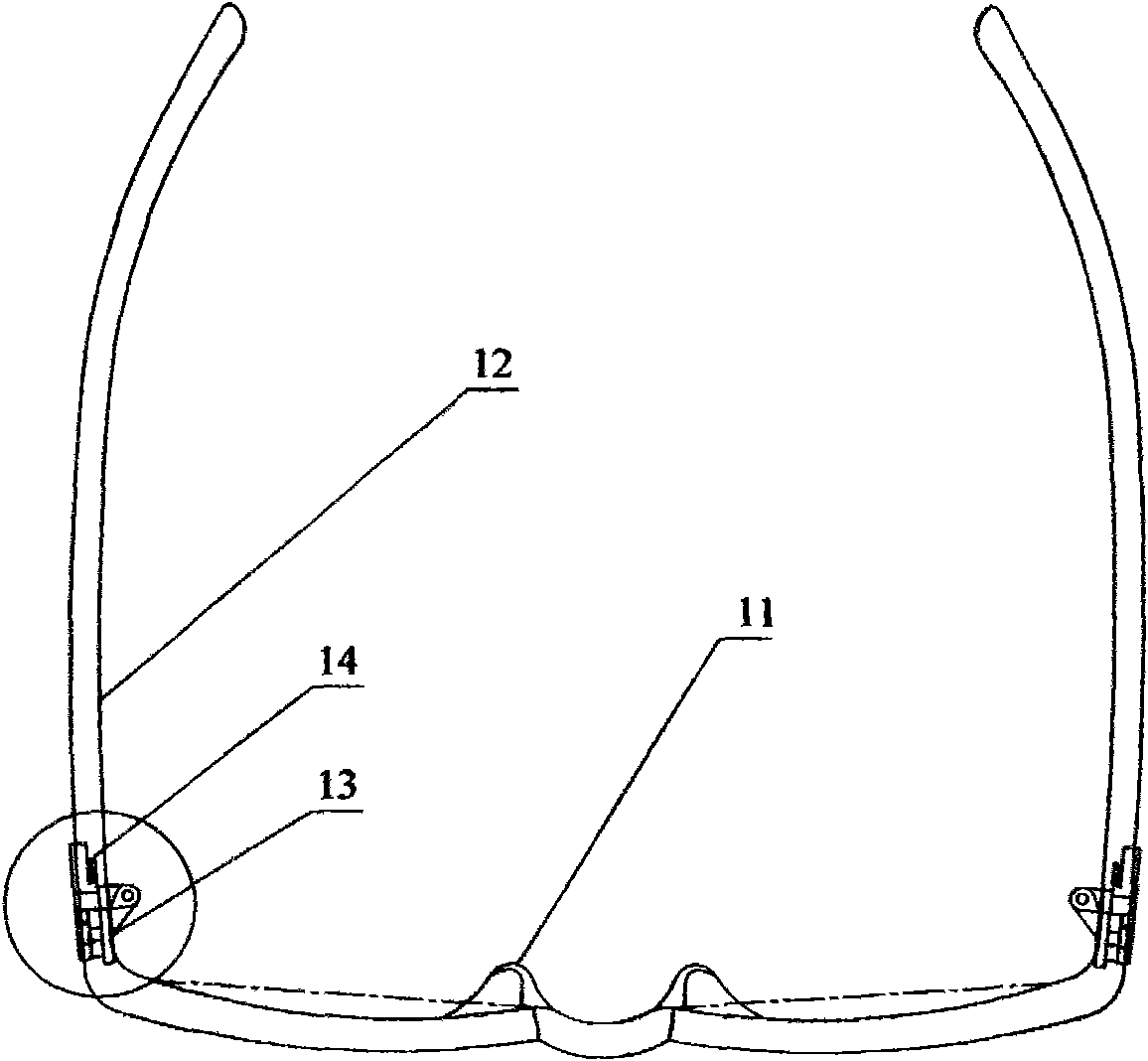

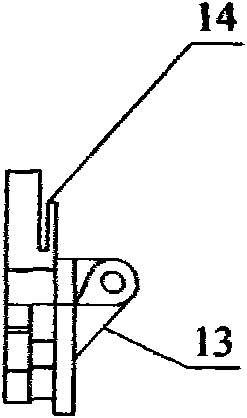

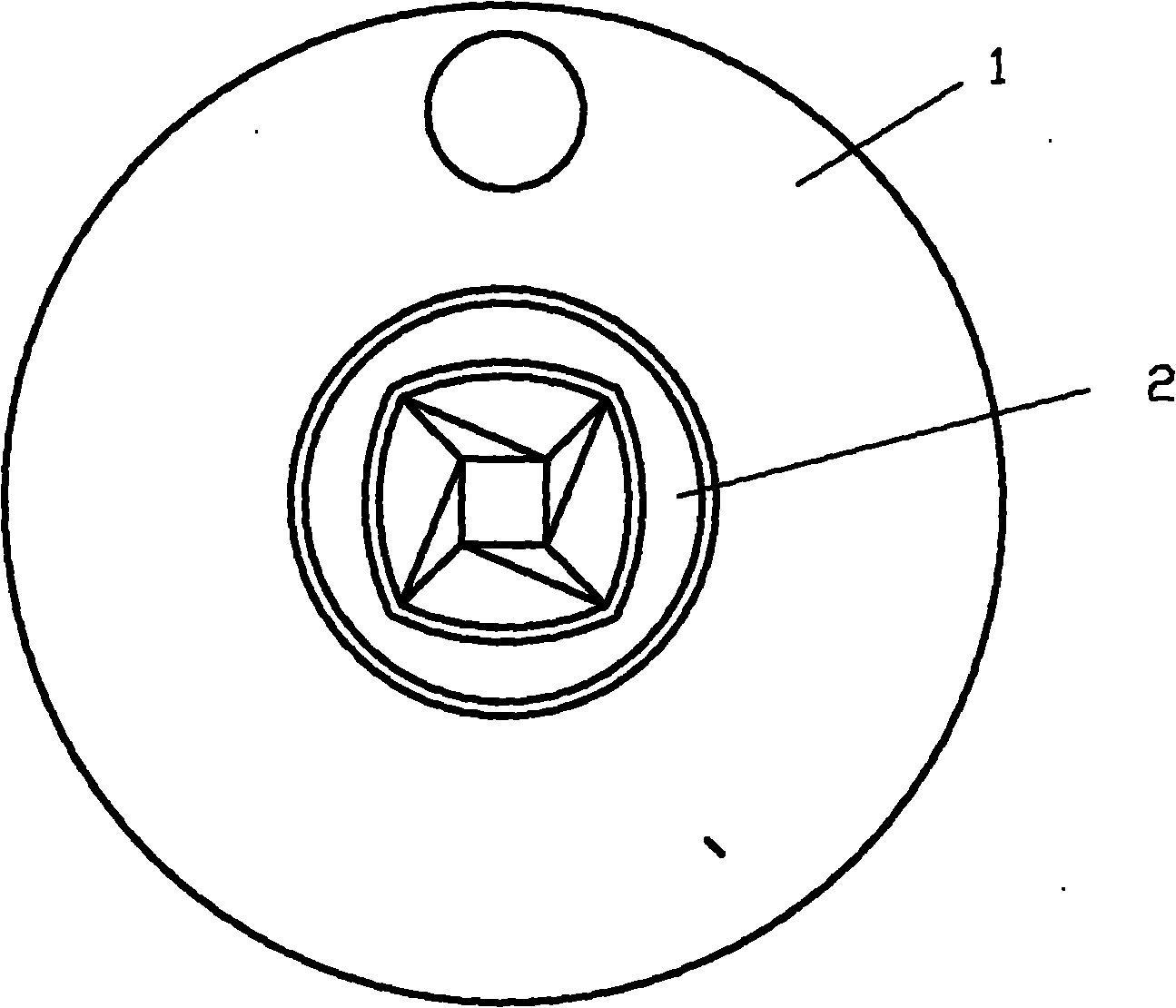

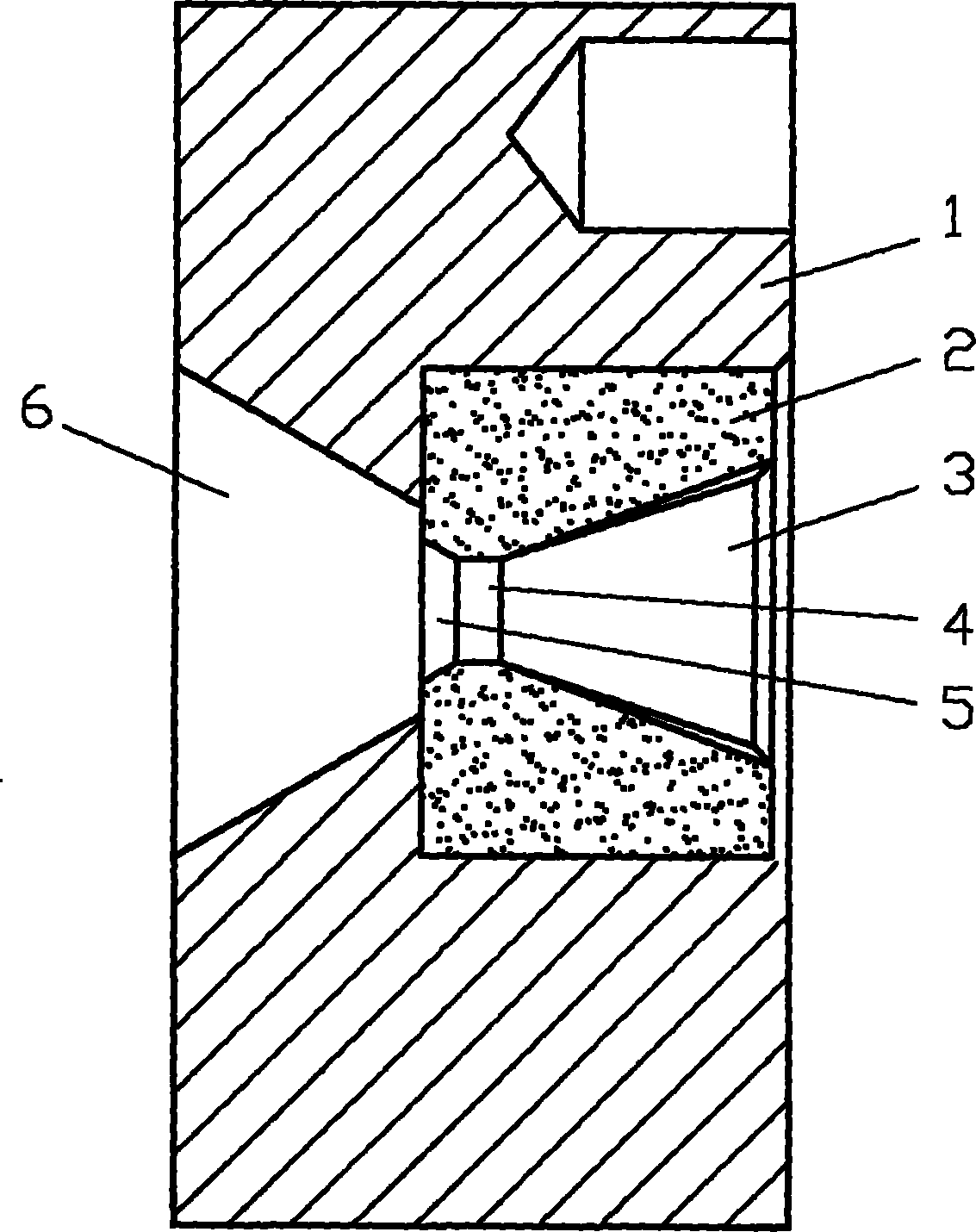

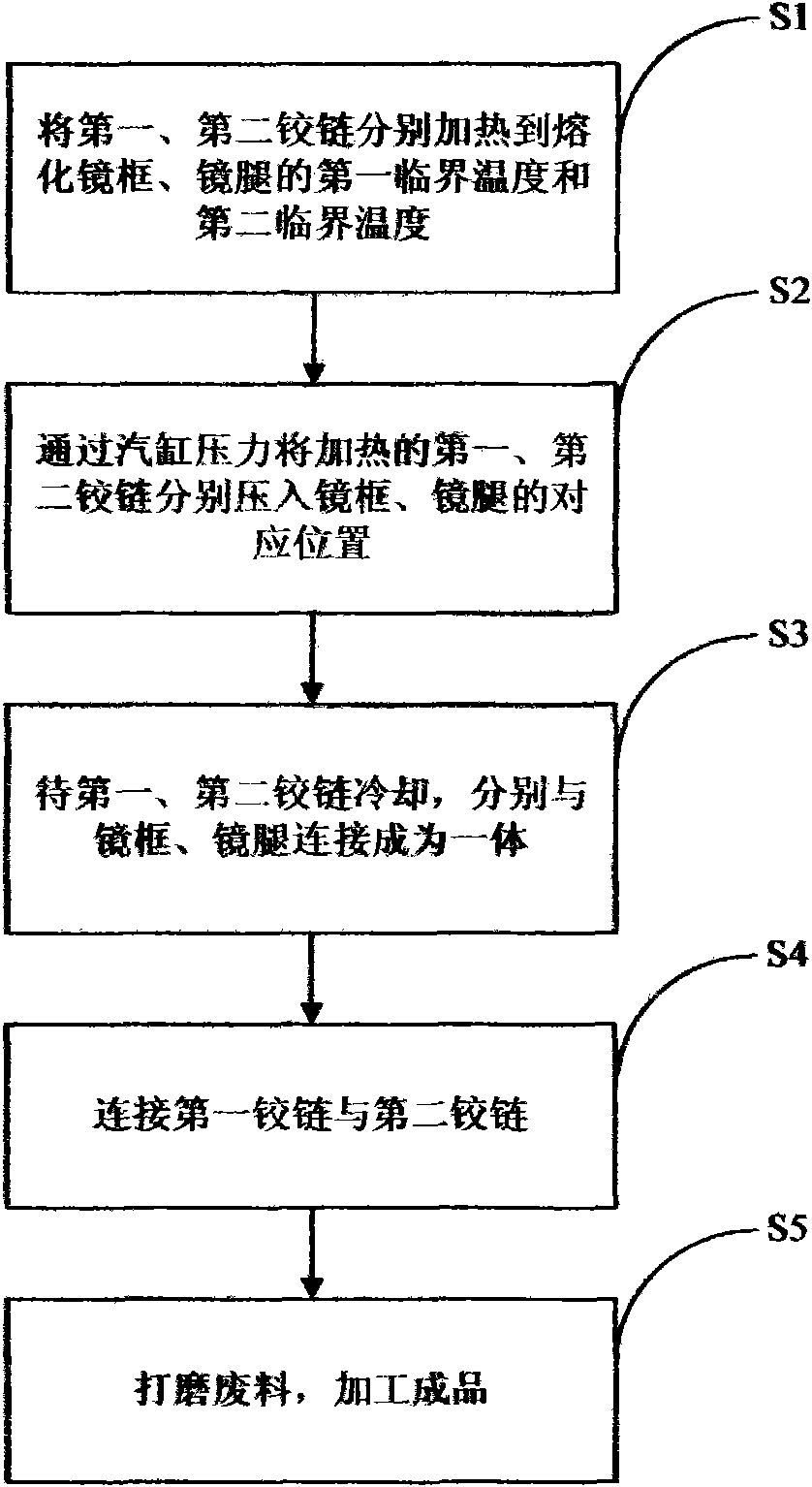

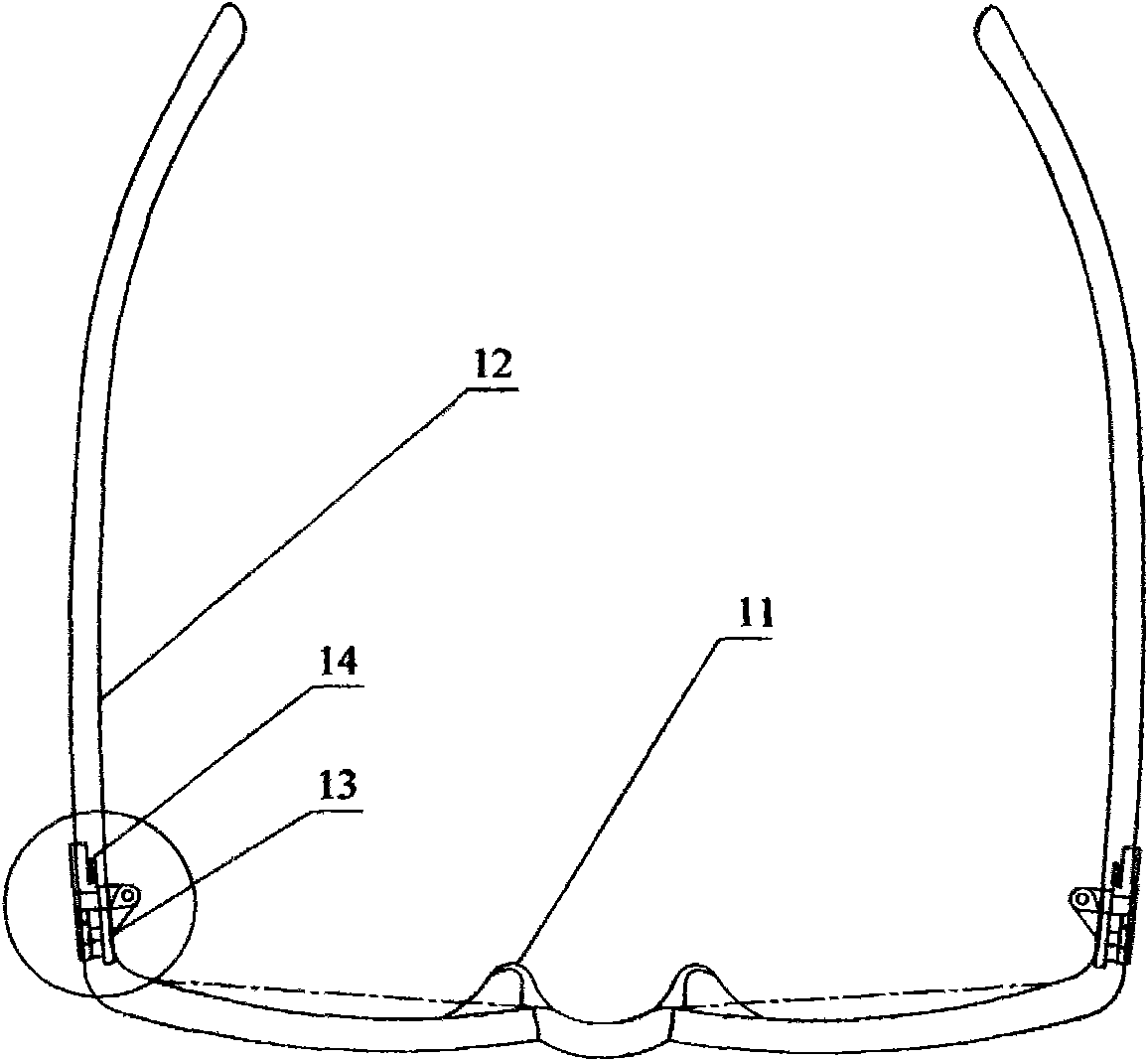

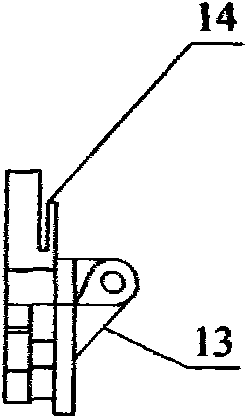

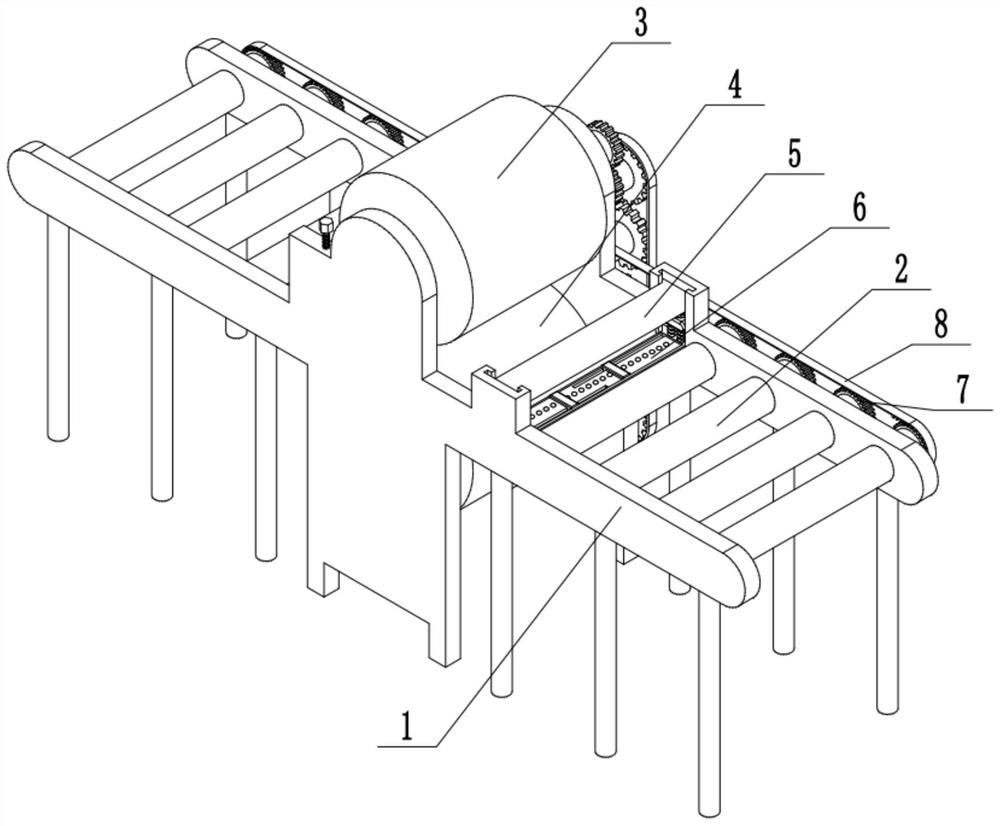

The invention relates to a processing method of frame glasses. The frame glasses comprise a glasses frame, glasses legs, first hinges and second hinges, wherein the glasses frame and the glasses legs are made of plastics, and the first hinges and the second hinges are made of metal. The method comprises the following steps: S1) heating the first hinges and the second hinges respectively to a first critical temperature and a second critical temperature, wherein the glasses frame and the glasses legs are melted at the first critical temperature and the second critical temperature respectively; S2) pressing the heated first hinges and the heated second hinges into corresponding places of the glasses frame and the glasses legs via cylinder pressure; S3) cooling the heated first hinges and theheated second hinges to connect with the glasses frame and the glasses legs respectively; and S4) connecting the first hinges with the second hinges. In the glasses frame and the processing method thereof provided by the technical scheme of the invention, a seamless hot-pressing connection is adopted between the metal hinges and the plastic glasses frame or between the metal hinges and the plastic glasses legs. The frame glasses are characterized by smooth and beautiful shaping, and the connection is tightened and the metal hinges are not easy to fall off. Meanwhile, an exterior plane of the hinge parts becomes a decoration for pile-head parts in the glasses legs and glasses frame, and the seamless effect at the periphery of the decoration is better than that of similar products in the industry.

Owner:丹阳市鑫隆光学眼镜有限公司

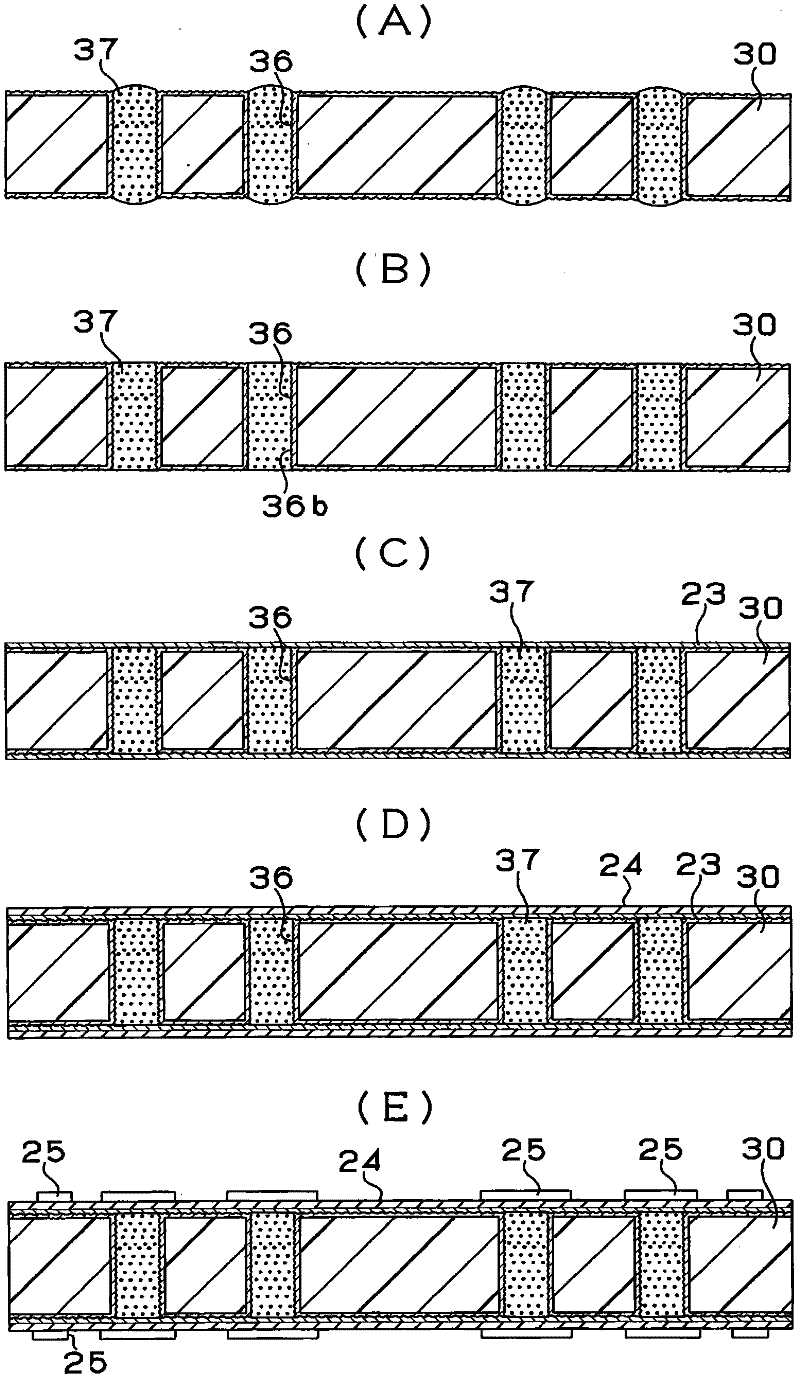

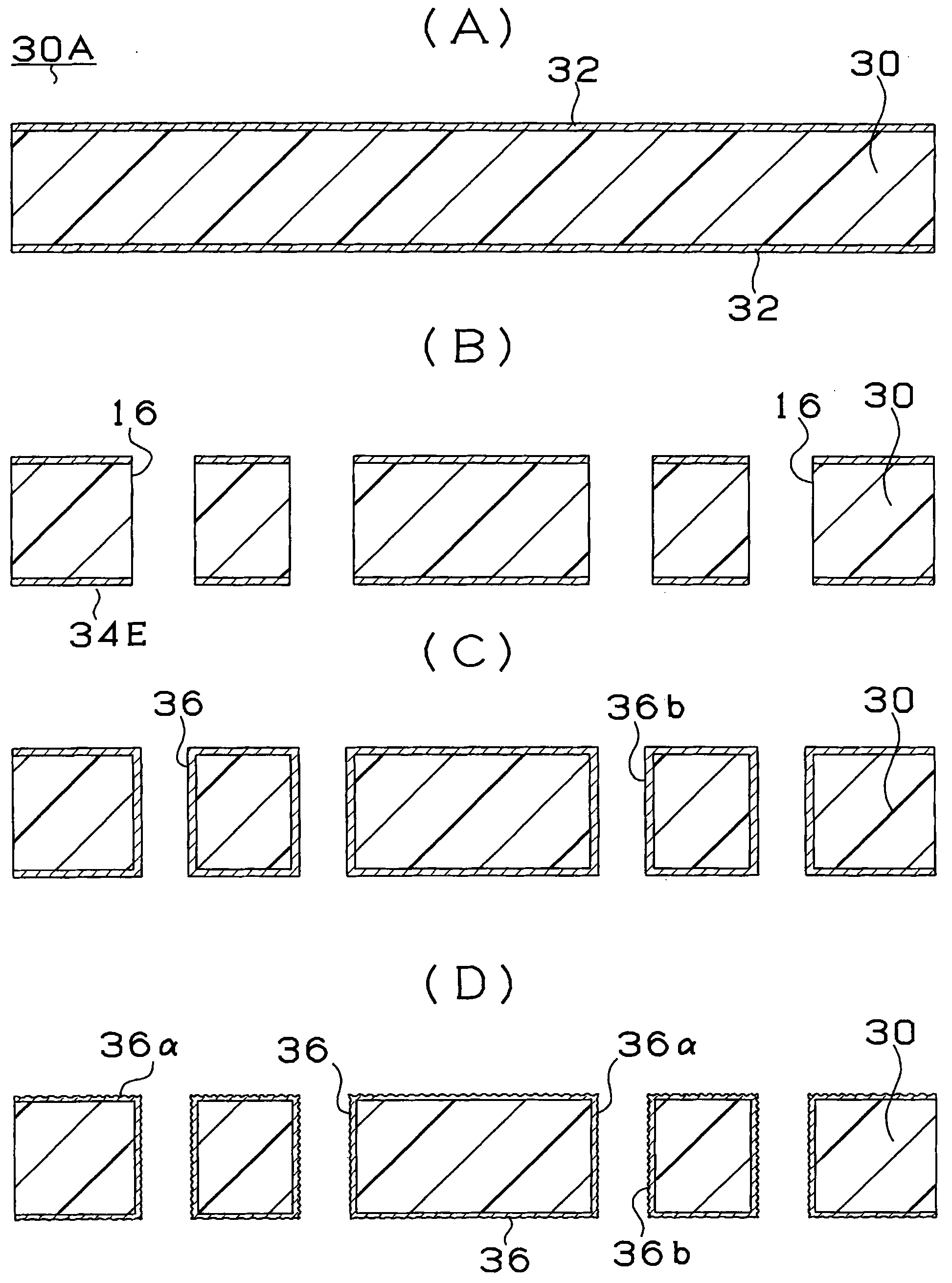

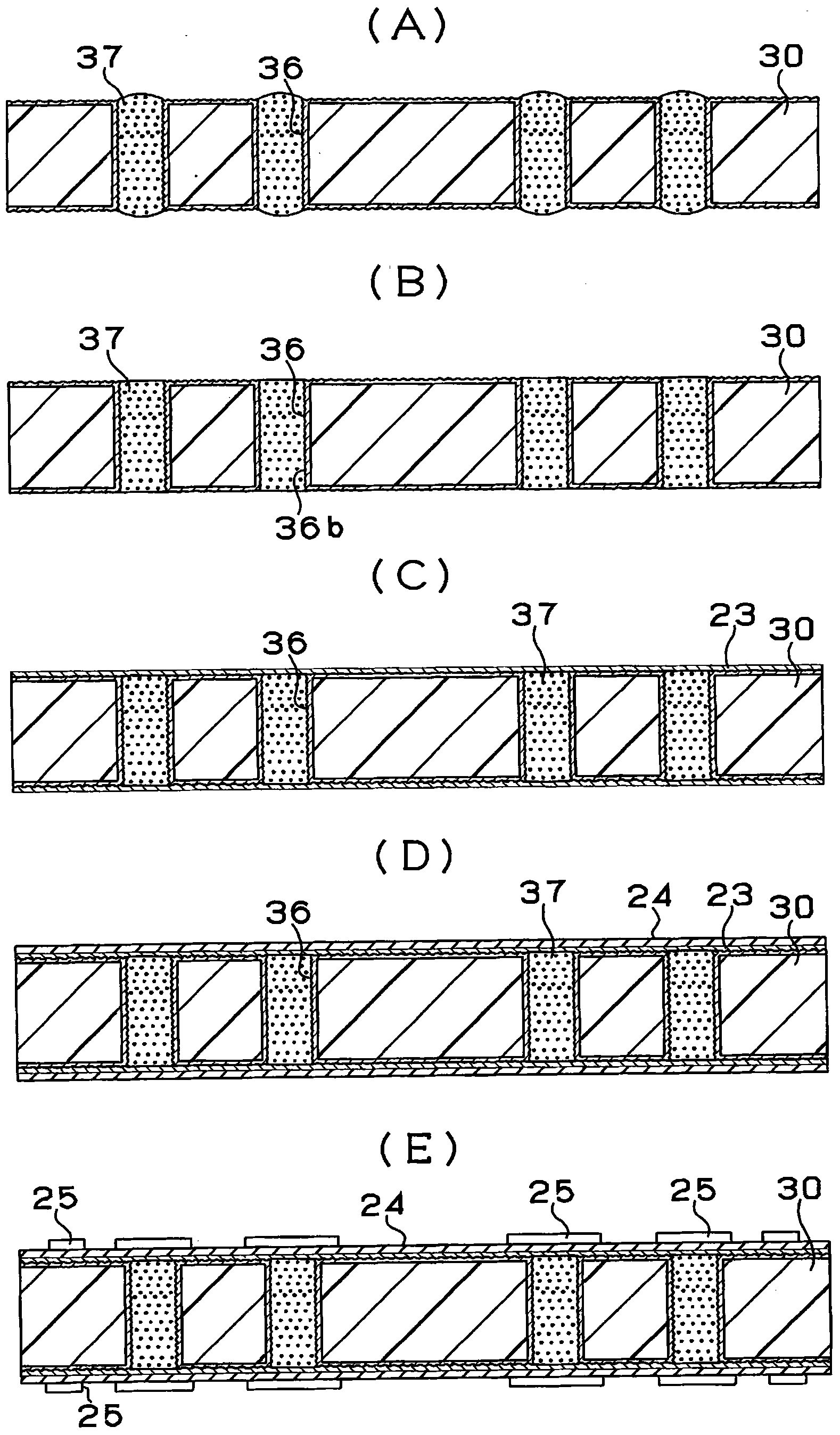

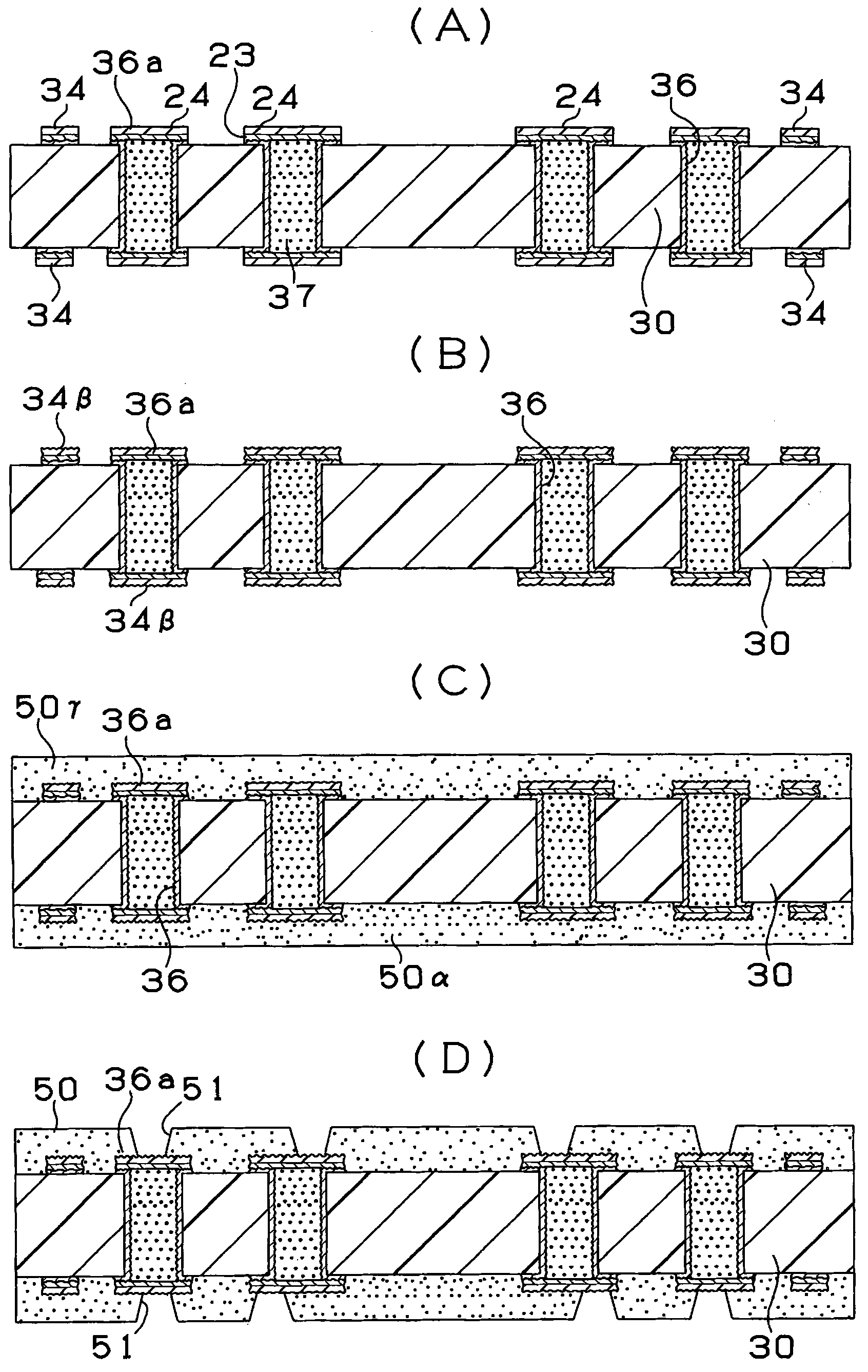

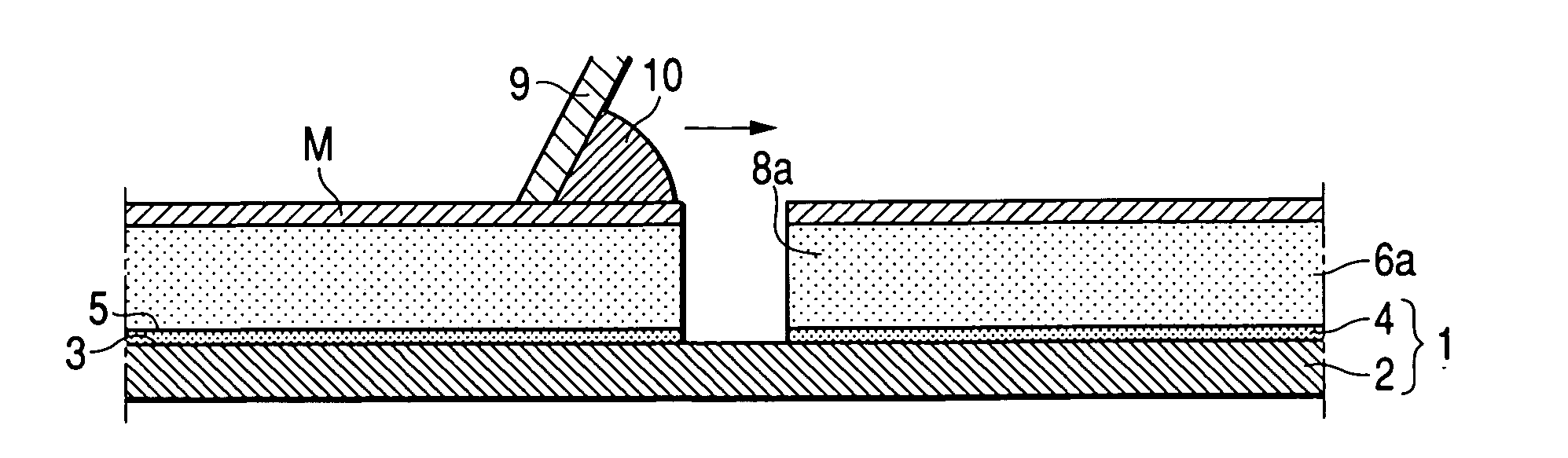

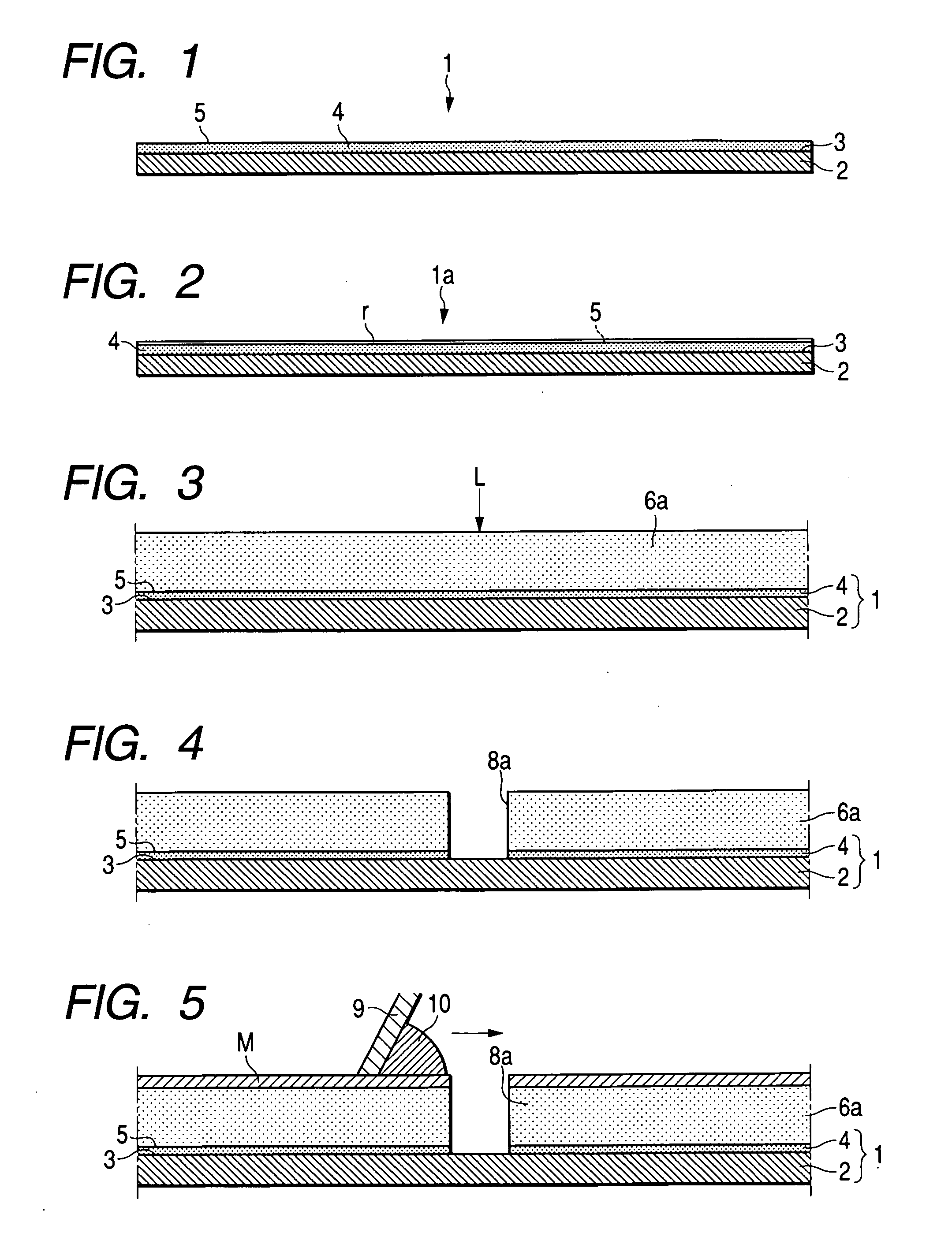

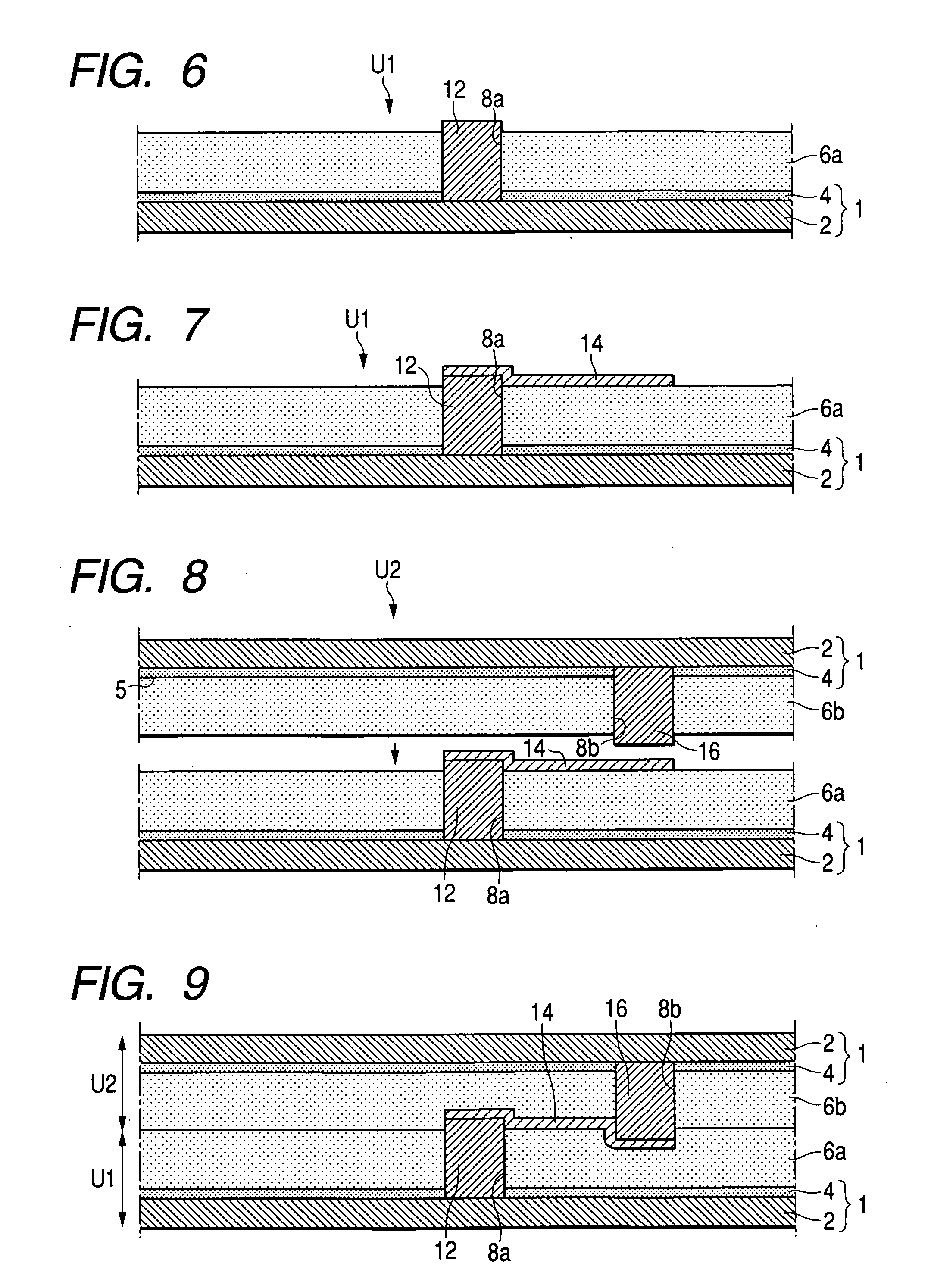

Multilayer printed wiring board and method for manufacturing multilayer printed wiring board

ActiveCN102239753AFormed flatPrecipitation of conductive materialSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorCopper plating

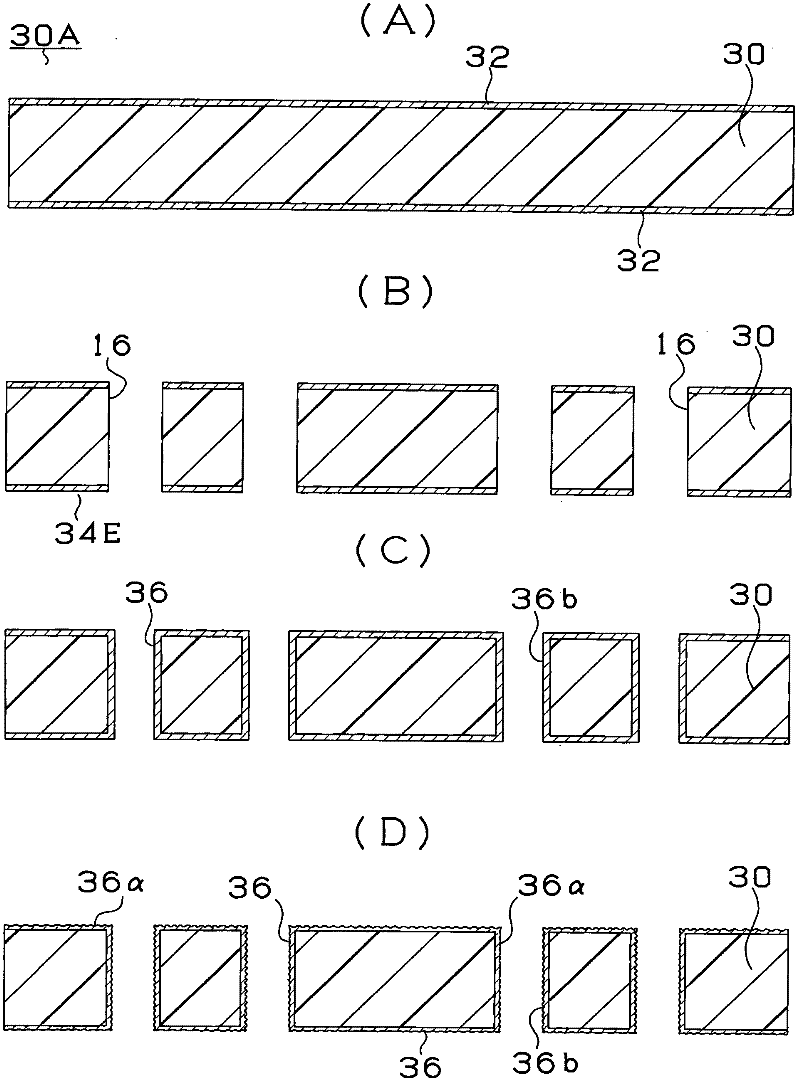

A method for manufacturing a multilayer printed wiring board, wherein a plane layer can be formed flat. A projected portion (150a) is formed in a recessed portion (153a) for plane conductor formation in an interlayer resin insulating layer (150) of an upper layer. Consequently, when the recessed portion (153a) for plane conductor formation is filled with copper plating, copper deposits not only on the side wall and the bottom surface of the recessed portion (153a) but also on the side wall of the projected portion (150a). As a result, a plane layer (159) can be formed flat.

Owner:IBIDEN CO LTD

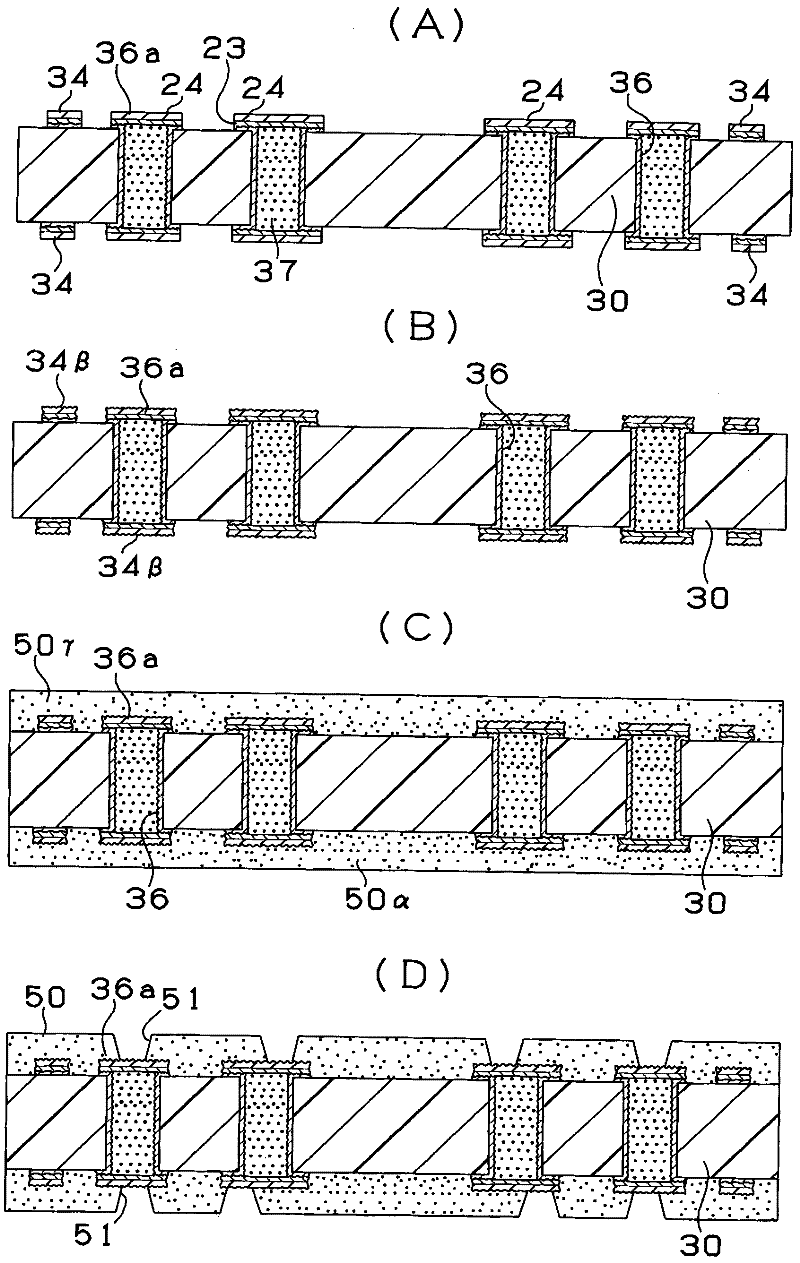

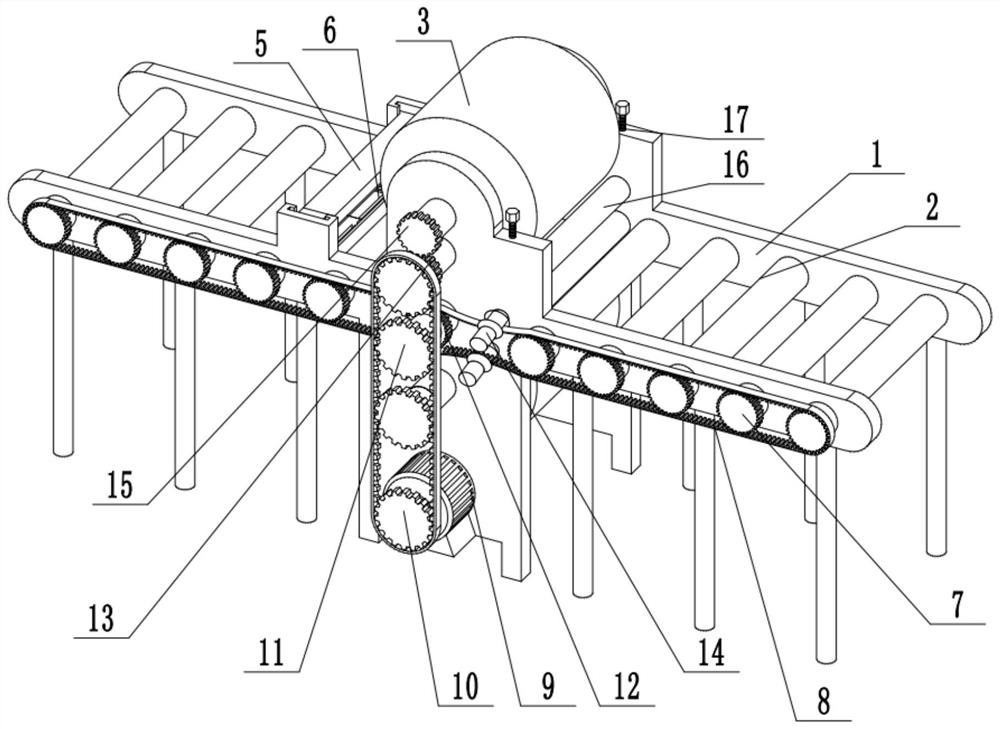

Injection molding equipment for buttons

The invention relates to the production equipment field of buttons, and especially discloses an injection molding equipment for buttons. Characterized by simple structure, high production efficiency, and low production cost, the injection molding equipment comprises a hopper. A heater is connected below the hopper, and the bottom of the heater is provided with a discharge pipe. Two rotary chain wheels are disposed below the discharge pipe at a same horizontal position. A chain is wound on the rotary chain wheels, and molding dies are arranged on the chain at intervals. An electromagnetic valve is disposed at the outlet of the discharge pipe, and a flowmeter is disposed on the discharge pipe at the upper end of the electromagnetic valve. The two rotary chain wheels have the same rotation speed and the same rotation direction, and the chain on the upper sides of the rotary chain wheels are at a tension state. The injection molding equipment for buttons melts raw materials by the heater, then the materials are injected into the molding dies through the discharge pipe, and at the same time of a chain transmission process, the buttons in the molding dies gradually cool, and when the molding dies rotate to positions below the rotary chain wheels, the buttons are poured out from the molding dies, thus finishing injection molding of the buttons.

Owner:嘉善县西塘四方服装辅料厂

Method for producing refractive PU synthetic leather

ActiveCN102517921AImprove textureSoft glossLamination ancillary operationsLaminationWork in processRelease liner

The invention relates to a method for producing polyurethane (PU) synthetic leather, in particular to a method for producing refractive PU synthetic leather. According to the method for producing the refractive PU synthetic leather, the prepared refractive PU synthetic leather has exquisite grains, soft glossiness, flat shape and good reflective glossiness. The method comprises the following steps of: selecting materials, conveying release paper to a No. 1 coating head, coating a layer of surface material, conveying the release paper to a No. 2 coating head, coating a layer of bottom material on the surface material, preheating the treated release paper to combine a base surface material and the release paper coated with the surface material and the bottom material, drying in an oven to obtain a dry semi-finished product, embossing the dry semi-finished product through a pair of embossing rollers, cooling the embossed semi-finished product, coiling, and thus obtaining a finished product.

Owner:福建兰峰制革有限公司

Wiring structure of wire harness and wire harness

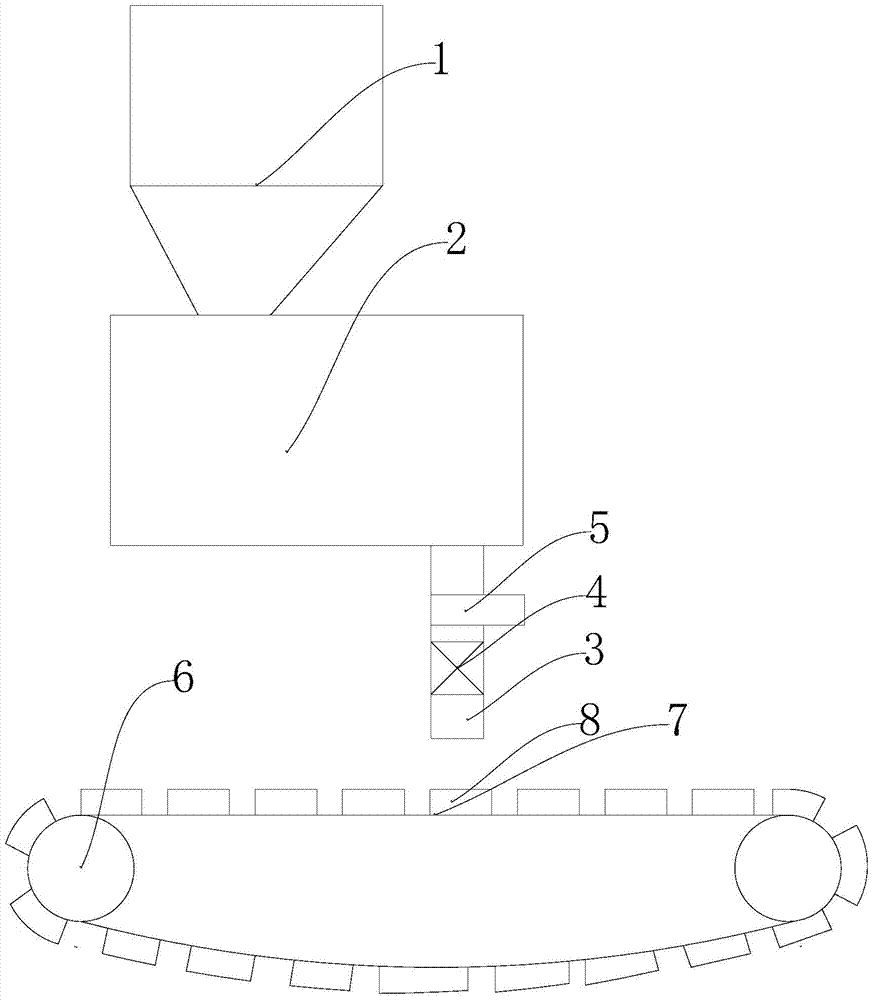

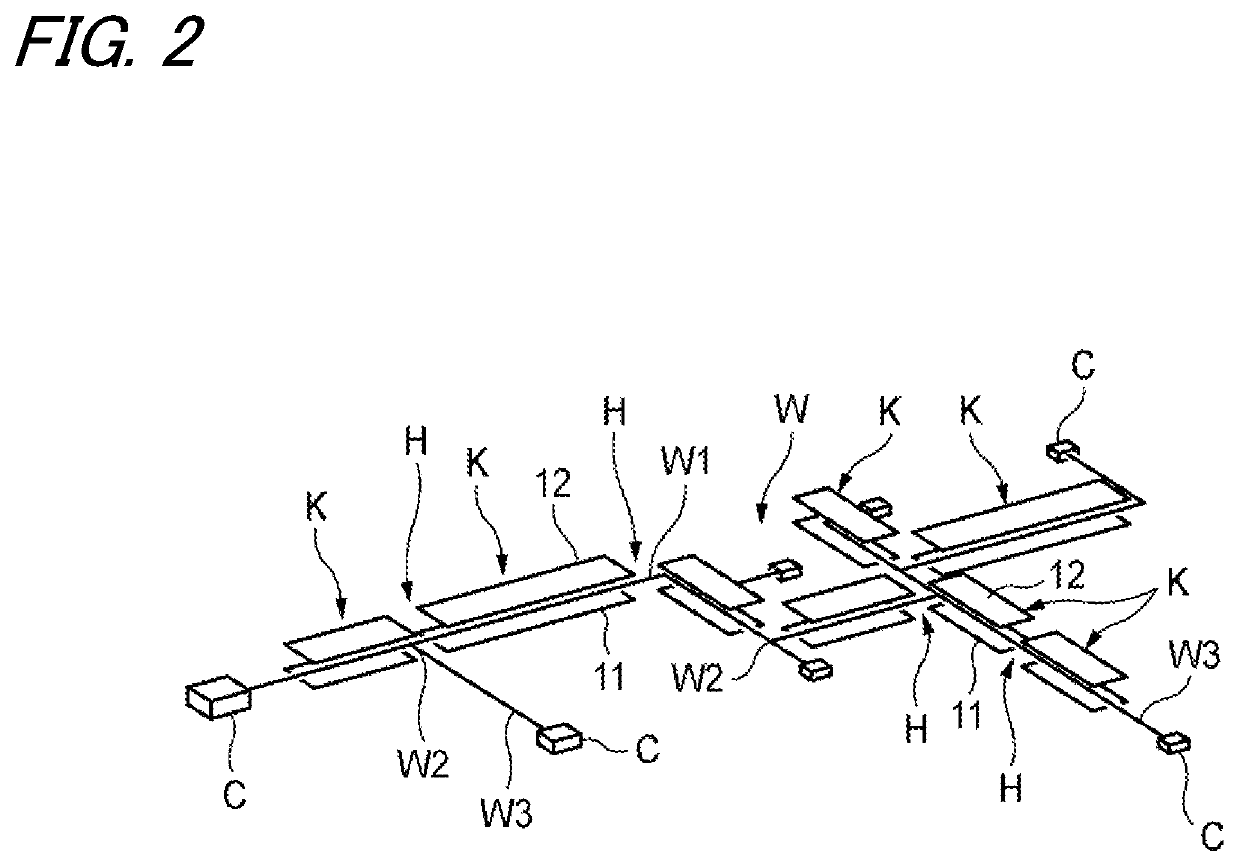

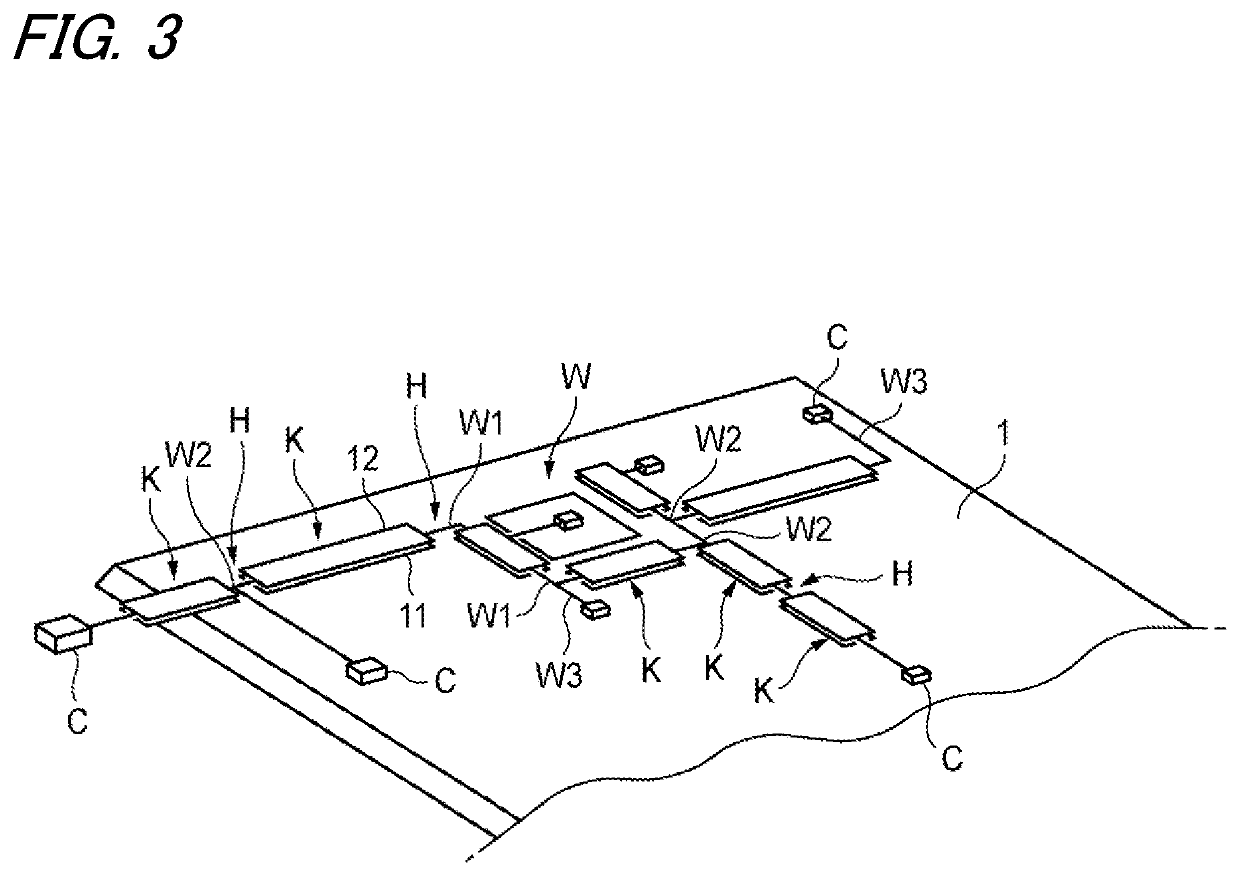

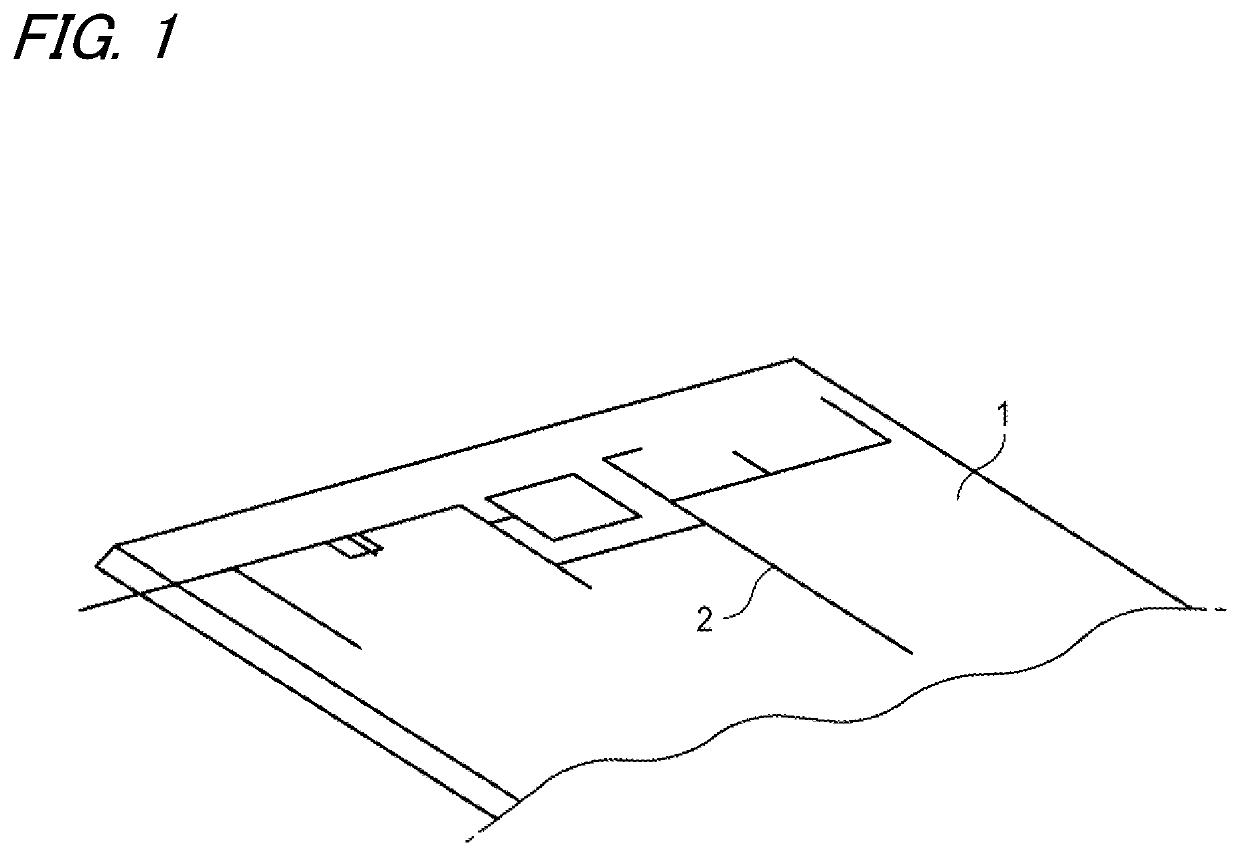

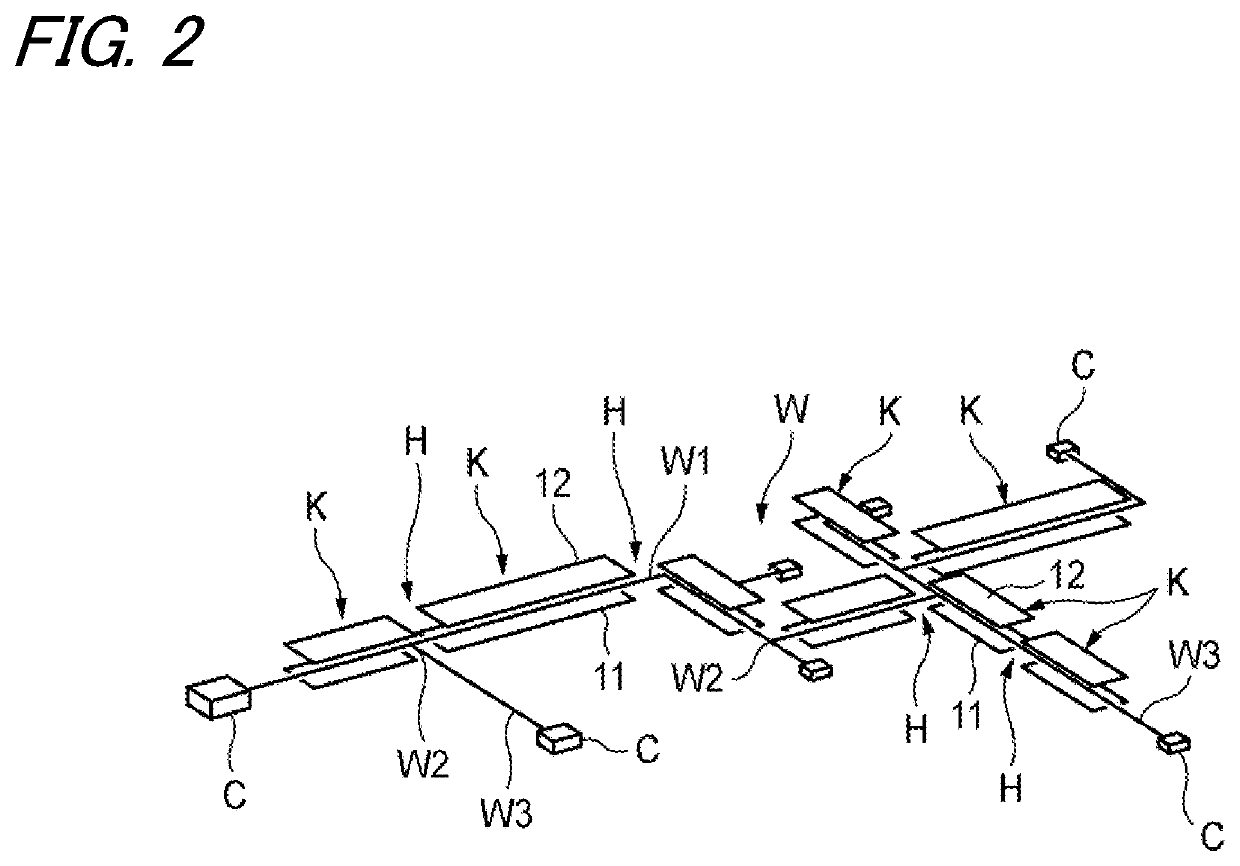

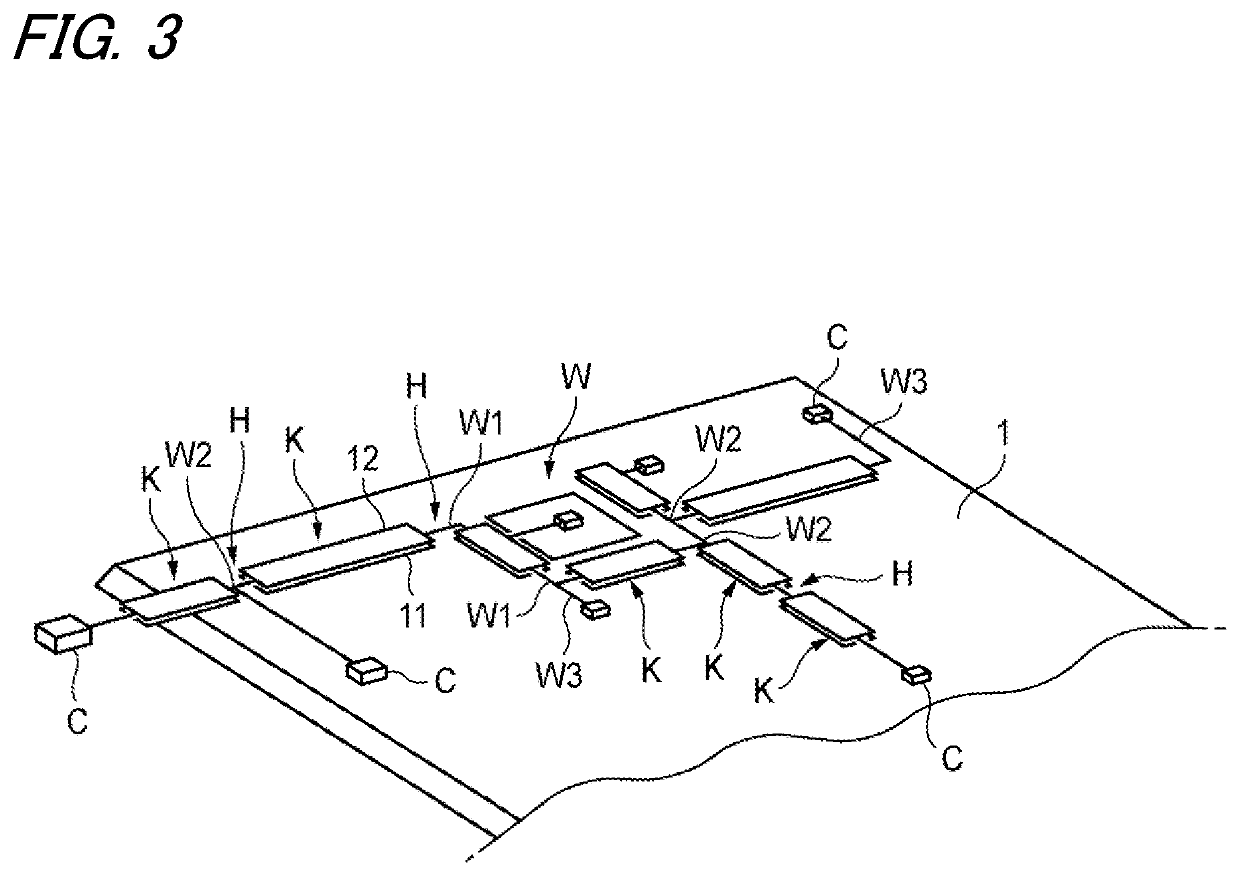

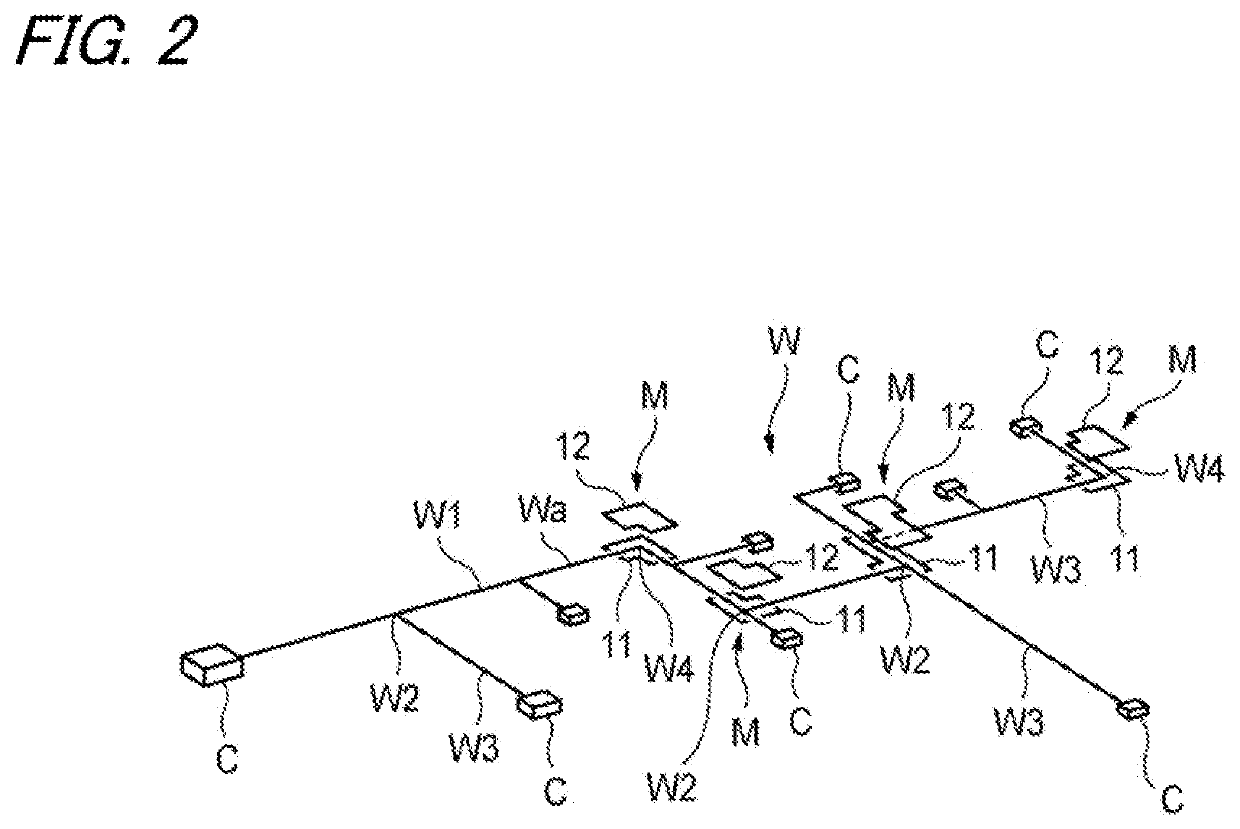

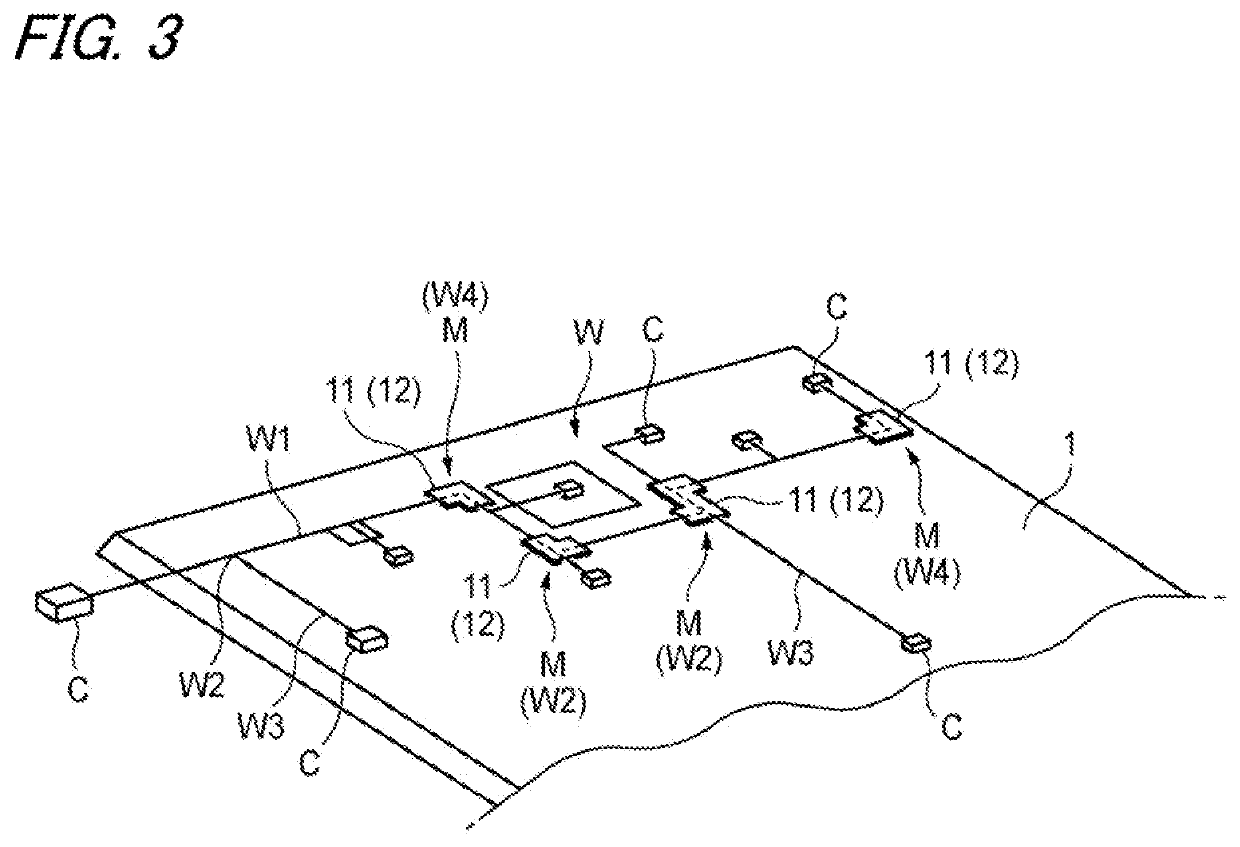

ActiveUS11370370B2High strengthFormed flatInsulated cablesElectric/fluid circuitAdhesive beltStructural engineering

A wiring structure of a wire harness in which the wire harness is wired by being fixed to an adhesive member laid on a surface of a roof lining of an automobile is provided. At least a part of a plurality of electric wires constituting the wire harness in a length direction are sandwiched between two belt-shaped tapes in which both side edges in the width direction are fixed to each other, are arranged side by side in the width direction of the tapes, and are attached to an adhesive surface provided on an inner surface of at least one of the two tapes, thereby holding the bundle of the electric wires in a flat shape, and an outer surface of one of the two tapes is attached to the adhesive member, whereby the wire harness is fixed to the surface of the roof lining.

Owner:YAZAKI CORP

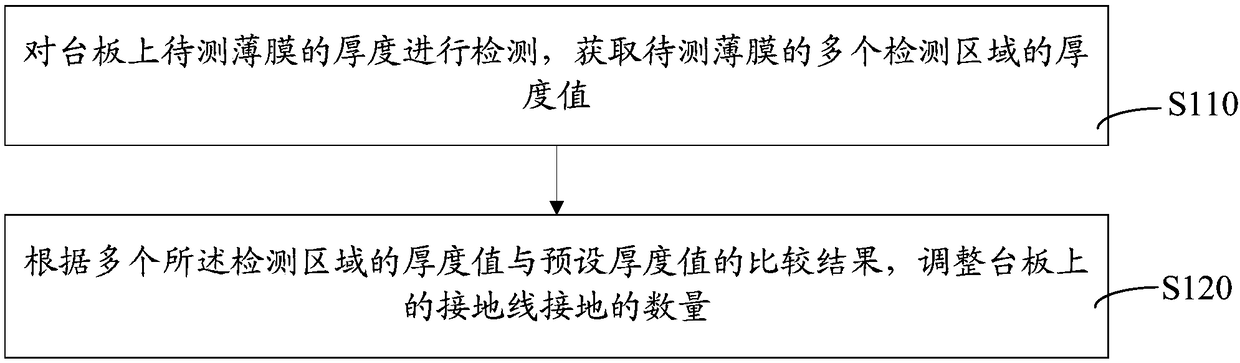

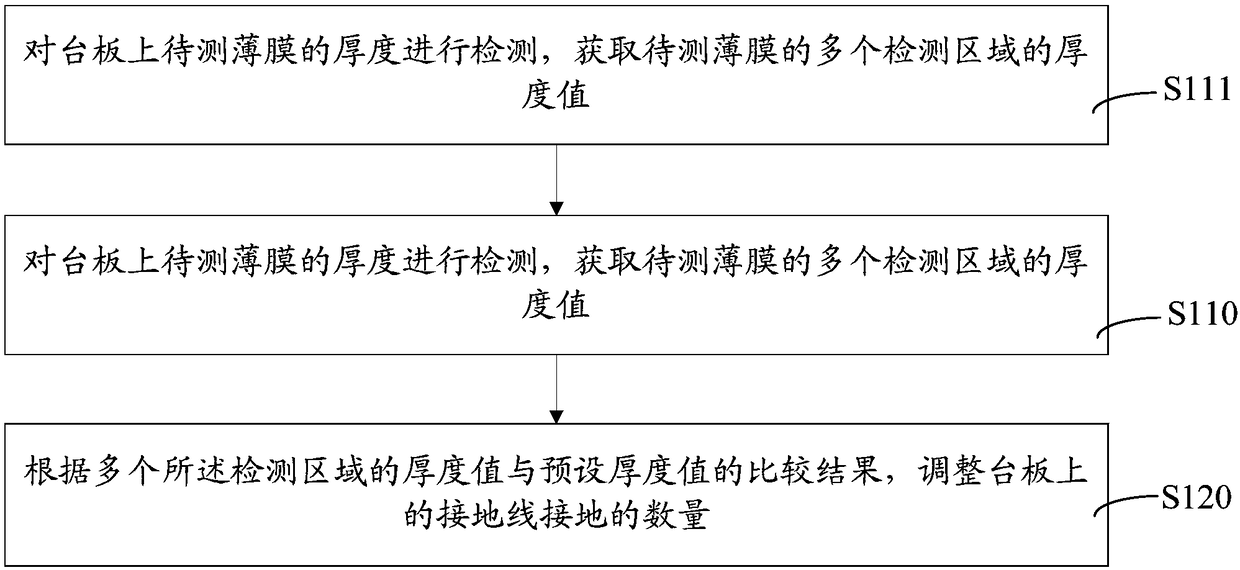

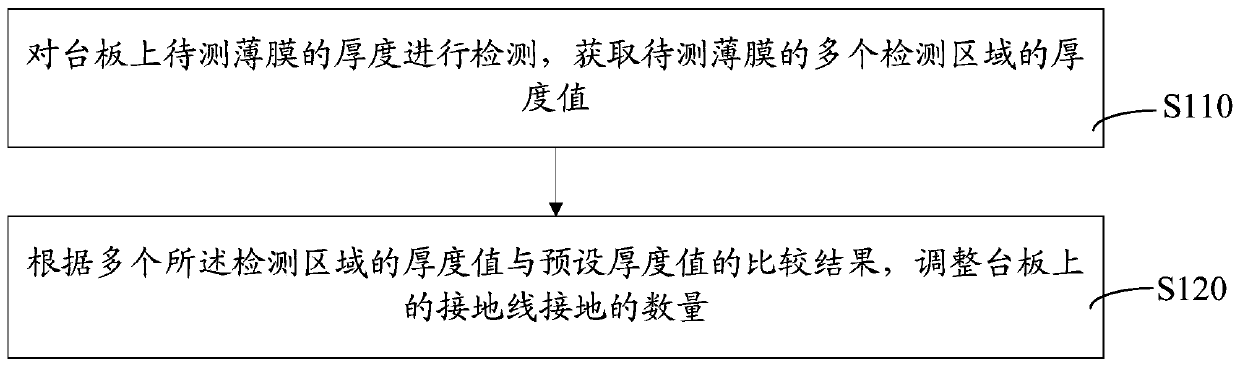

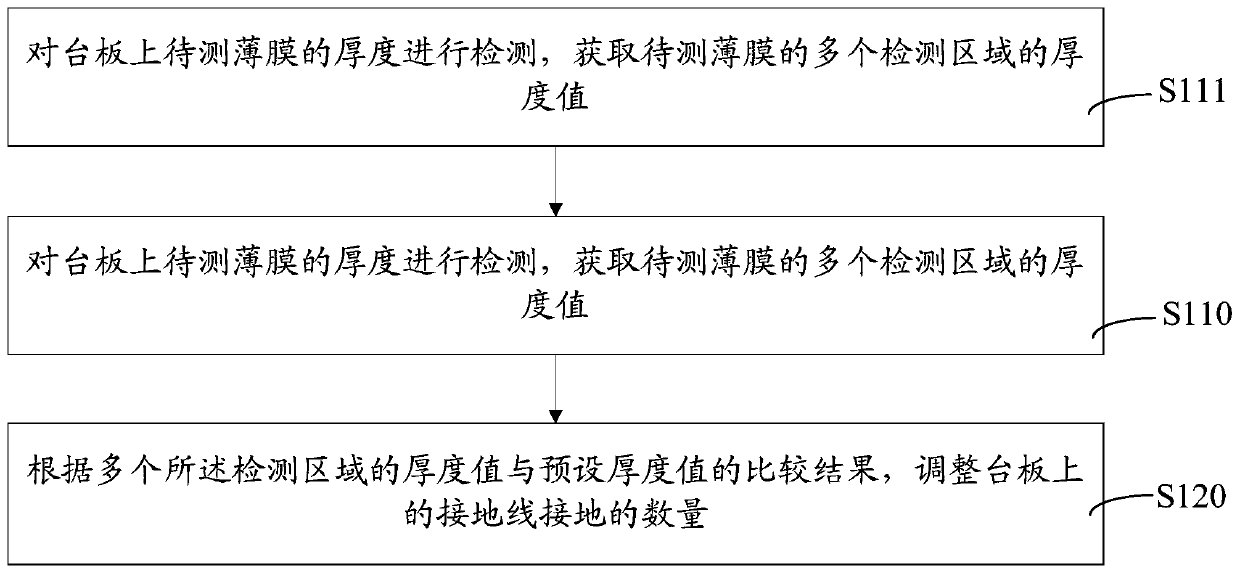

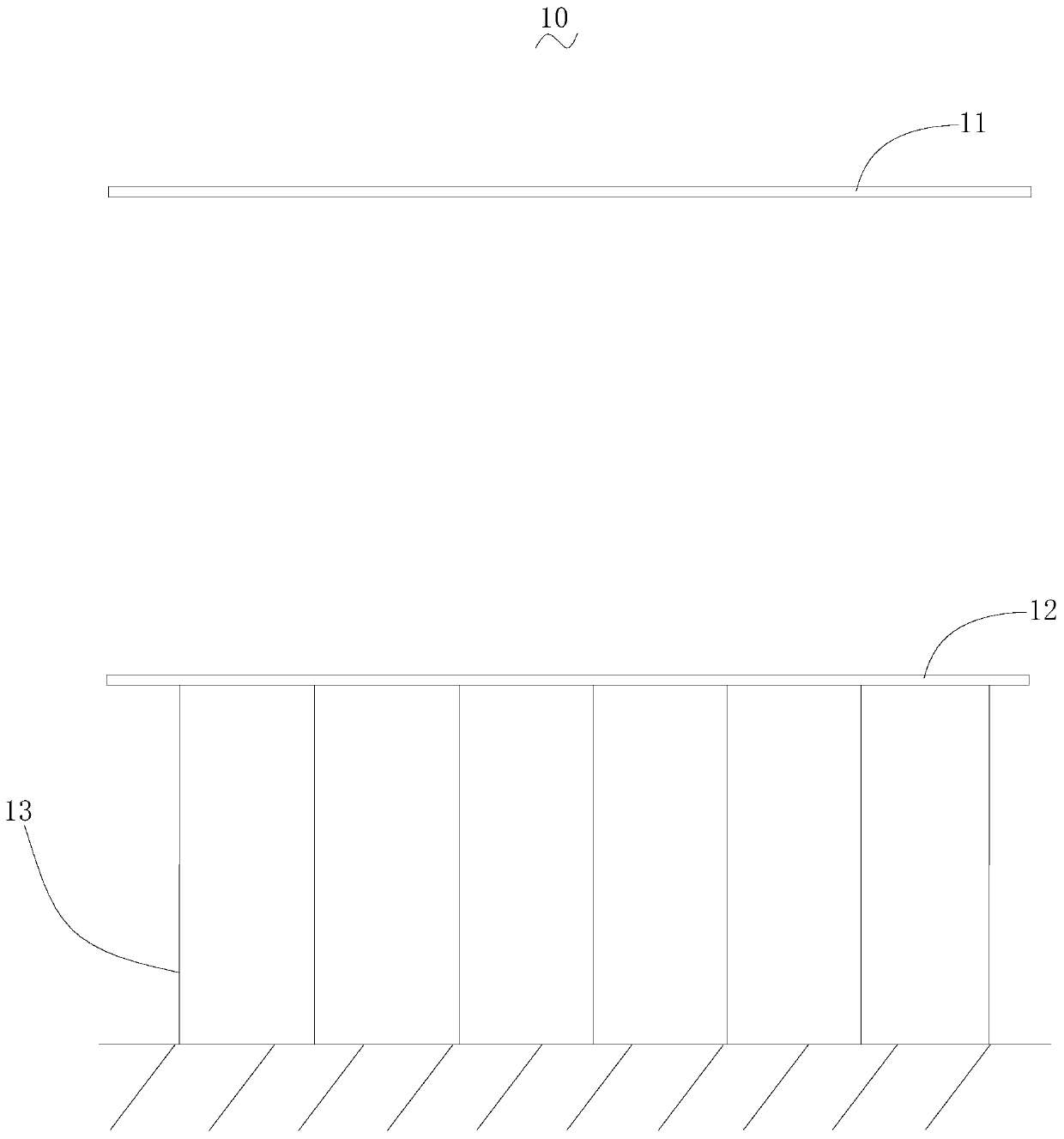

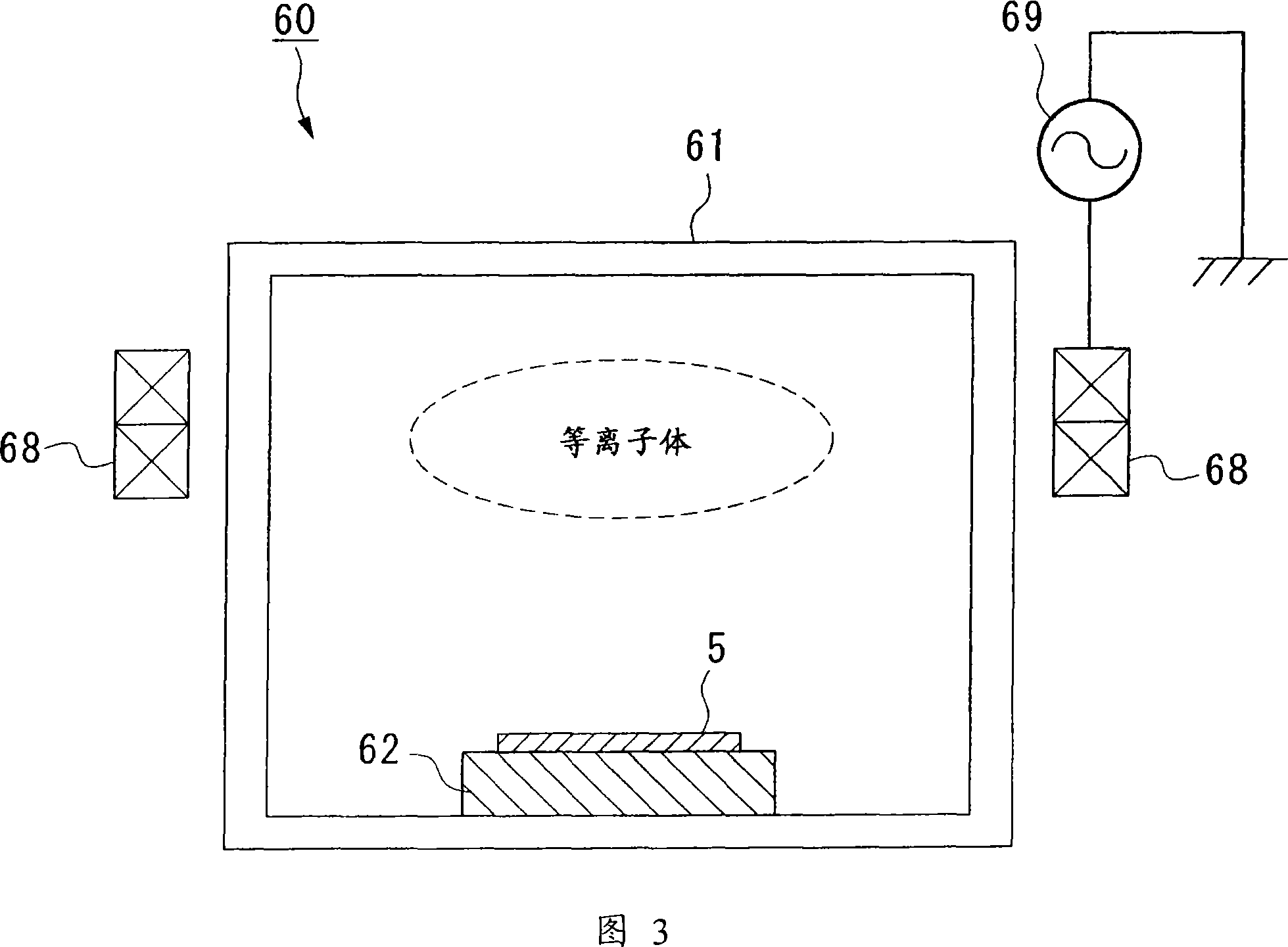

Film making method and film forming device

The invention relates to a film making method and a film forming device adopting the film making method. The film making method comprises the steps that the thickness of a to-be-measured thin film iscompared with the preset thickness through the film making method to judge whether the thickness of the formed thin film is consistent with the expected thickness of the thin film or not, so that adjusting grounding wires in a test area and adjusting the thickness during plasma forming the thin film on a table plate are determined, and by adjusting the number of the grounding wires and changing the charge amount guided away by the plasma, the obtained thickness of the thin film is matched with the preset thickness. As for the film forming device, devices for being movably connected with the grounding wires are arranged on the table plate and a metal frame, so that forming of the thin film is smoother, namely, the uniformity of the thin film is high, and the quality of a thin film transistor is improved; and in this way, the problem of local anomaly of film-forming plasma distribution due to the factors such as change of the equipment chamber environment, difference of parts and aging of the parts can be effectively solved, the uniformity of film forming is improved accordingly, and the quality of the thin film transistor is improved.

Owner:TRULY HUIZHOU SMART DISPLAY

Wiring structure of wire harness and wire harness

ActiveUS20210309168A1Improve the fixing strengthFormed flatInsulated cablesElectric/fluid circuitAdhesive beltStructural engineering

A wiring structure of a wire harness in which the wire harness is wired by being fixed to an adhesive member laid on a surface of a roof lining of an automobile is provided. At least a part of a plurality of electric wires constituting the wire harness in a length direction are sandwiched between two belt-shaped tapes in which both side edges in the width direction are fixed to each other, are arranged side by side in the width direction of the tapes, and are attached to an adhesive surface provided on an inner surface of at least one of the two tapes, thereby holding the bundle of the electric wires in a flat shape, and an outer surface of one of the two tapes is attached to the adhesive member, whereby the wire harness is fixed to the surface of the roof lining.

Owner:YAZAKI CORP

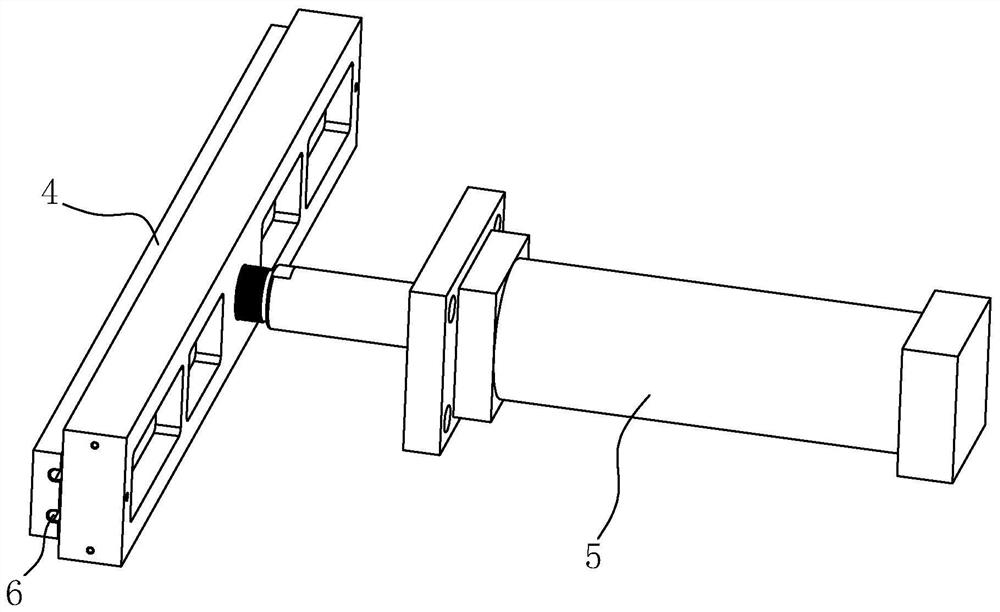

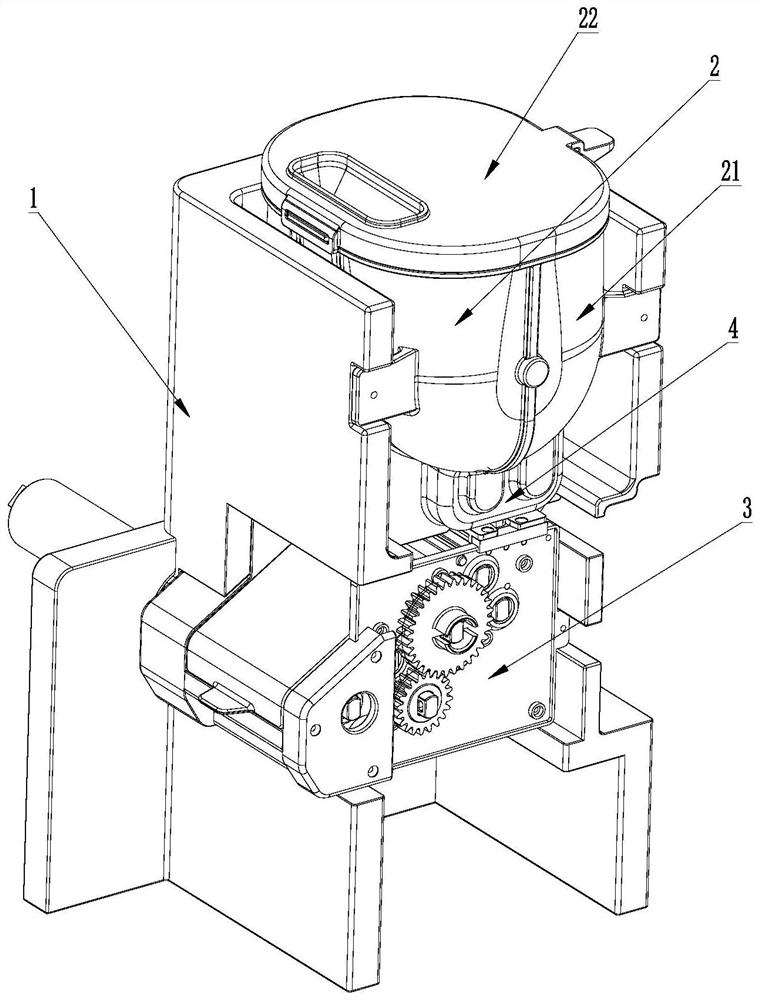

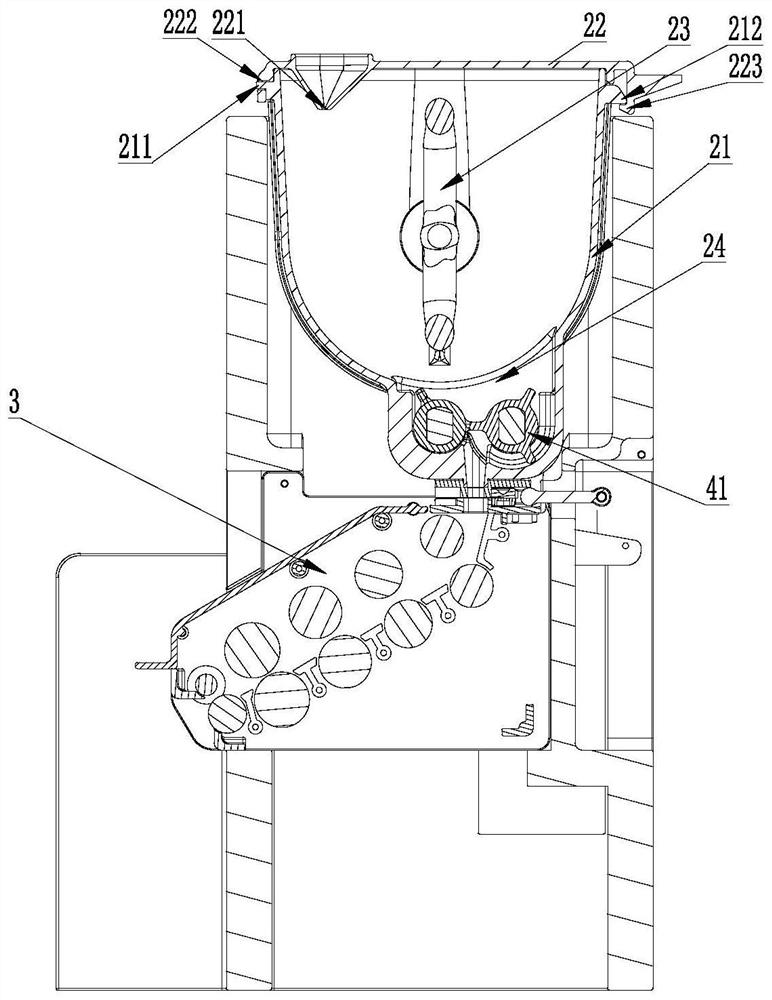

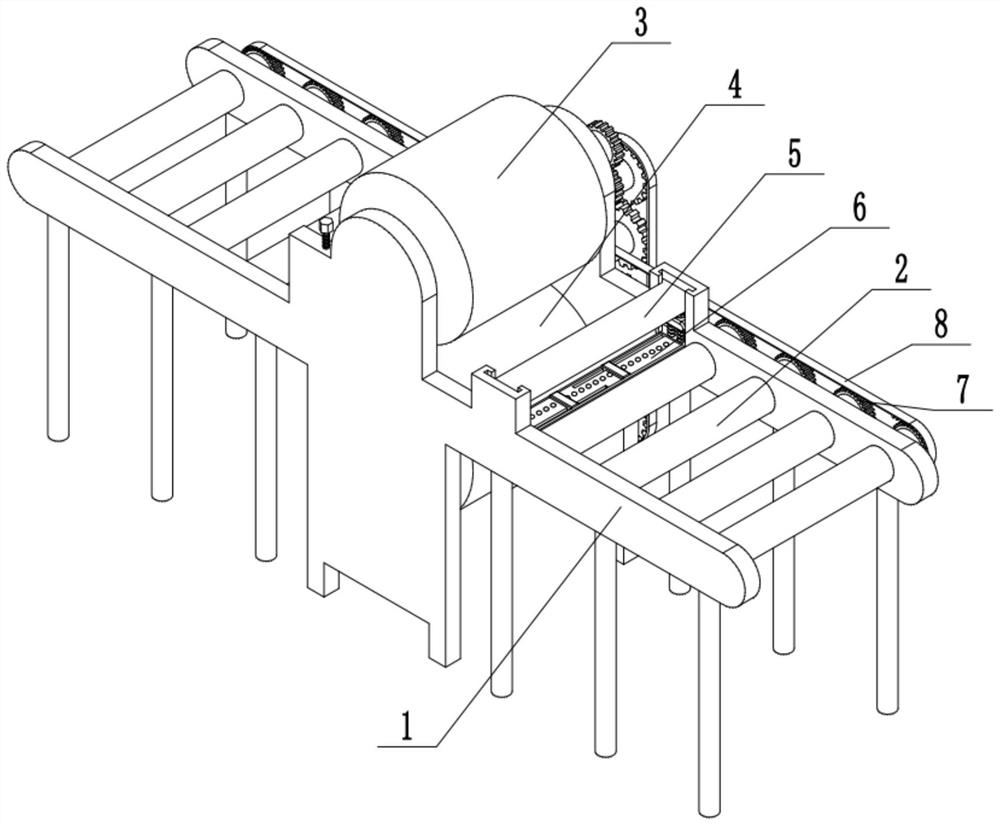

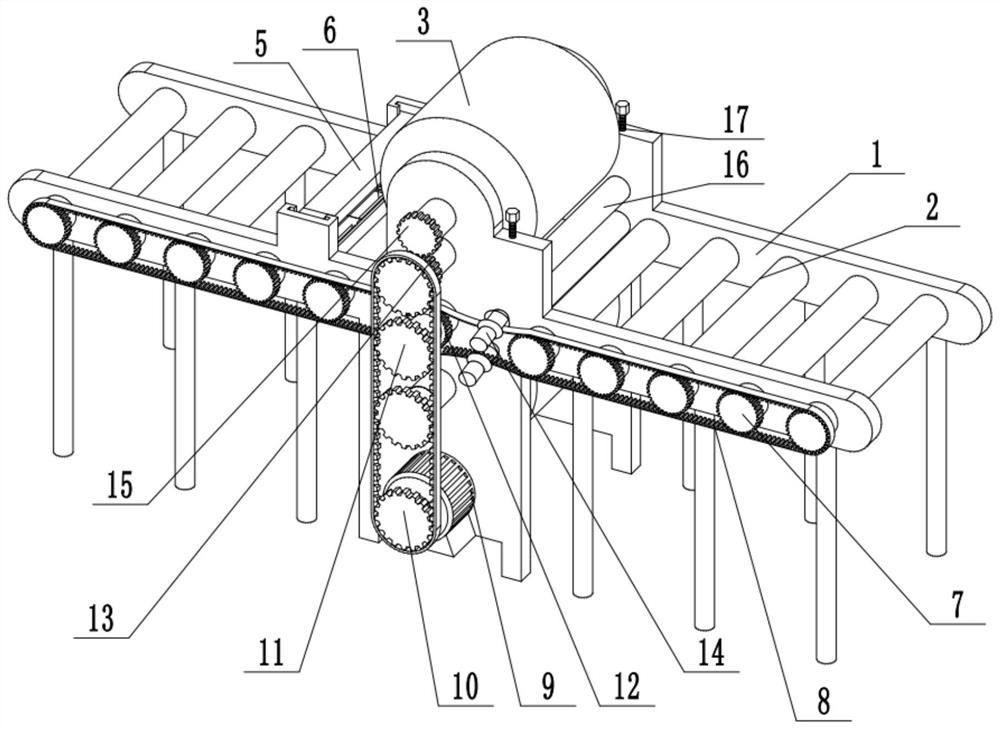

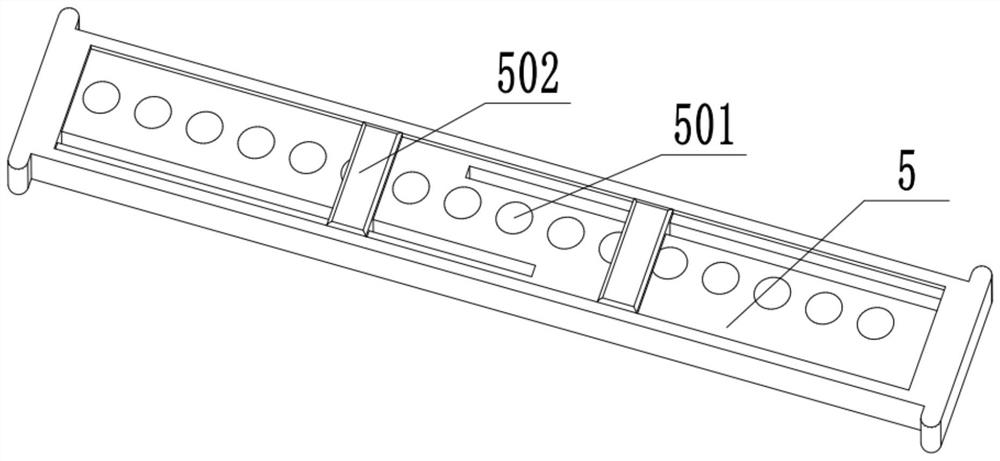

Machine used for making cooked wheaten food and capable of realizing quick processing

ActiveCN113057187AIncrease extrusion speedGreat tasteDough-sheeters/rolling-machines/rolling-pinsMixing/kneading with vertically-mounted toolsProcess engineeringMouthfeel

The invention relates to a machine used for making cooked wheaten food and capable of realizing quick processing. The machine comprises a host machine internally provided with a power unit, a dough kneading assembly in power connection with the host machine and an extrusion assembly in power connection with the host machine, wherein a dough inlet of the extrusion assembly communicates with a dough outlet of the dough kneading assembly; and the extrusion assembly comprises at least three groups of continuously arranged dough pressing rollers, the extrusion gaps of the dough pressing rollers are sequentially reduced from front to back, and the extrusion speeds of the dough pressing rollers are sequentially increased from front to back. According to the invention, at least three groups of continuously arranged dough pressing rollers are arranged, so dough is formed by extruding and extending, and noodles are more in line with the pursuit of people for the taste of the noodles and are more chewy. Meanwhile, the dough is continuously processed through the multiple stages of dough pressing rollers, and different dough pressing rollers have different extrusion gaps, so the purposes of dough kneading, extrusion and forming can be achieved through one-time processing, repeated extrusion and extrusion gap adjustment are not needed, processing efficiency is high, personnel participation is reduced, and a processing speed is high.

Owner:JOYOUNG CO LTD

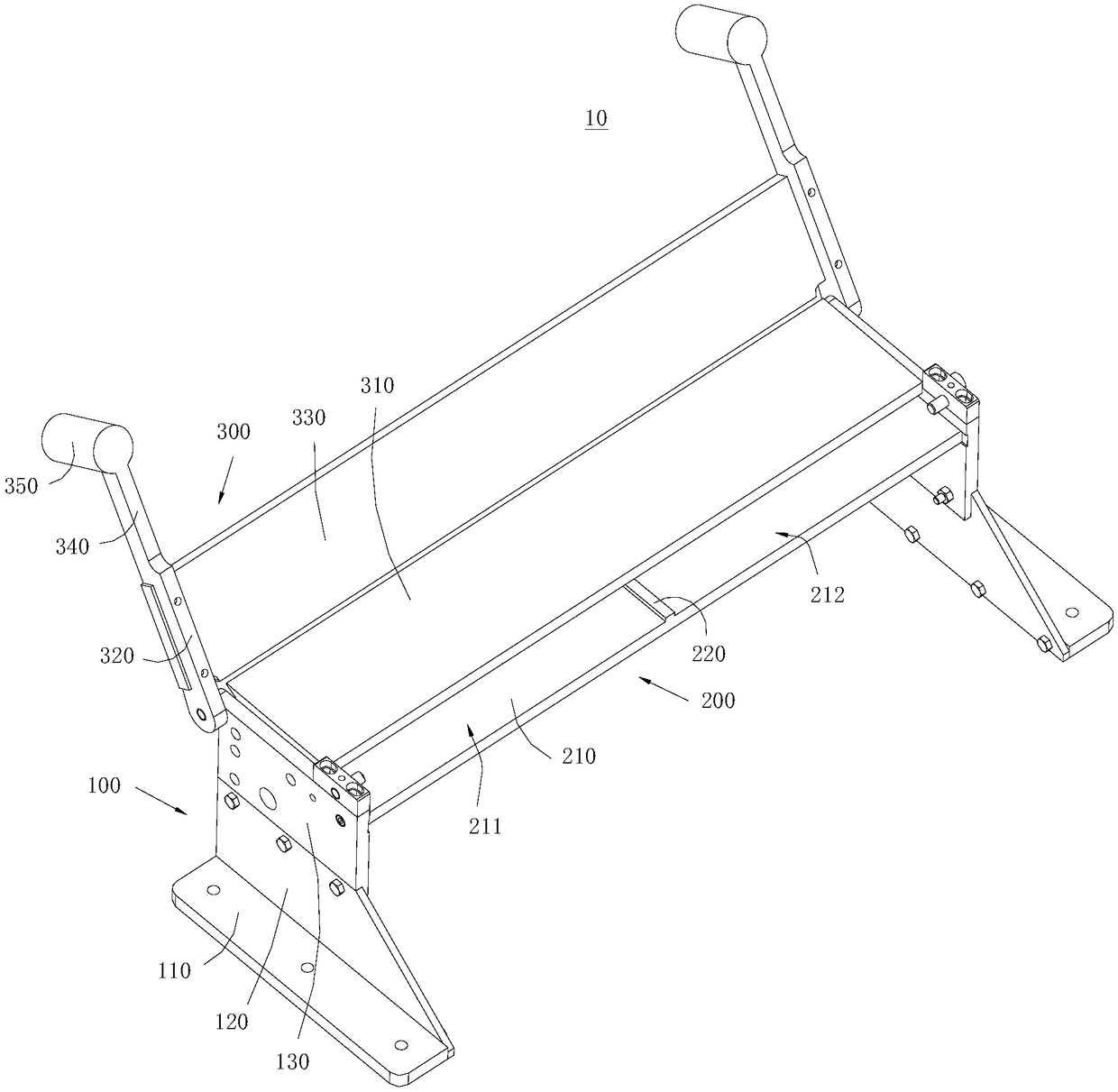

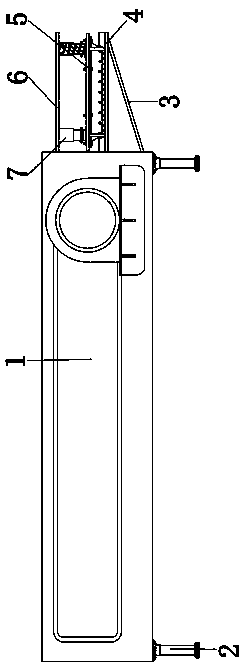

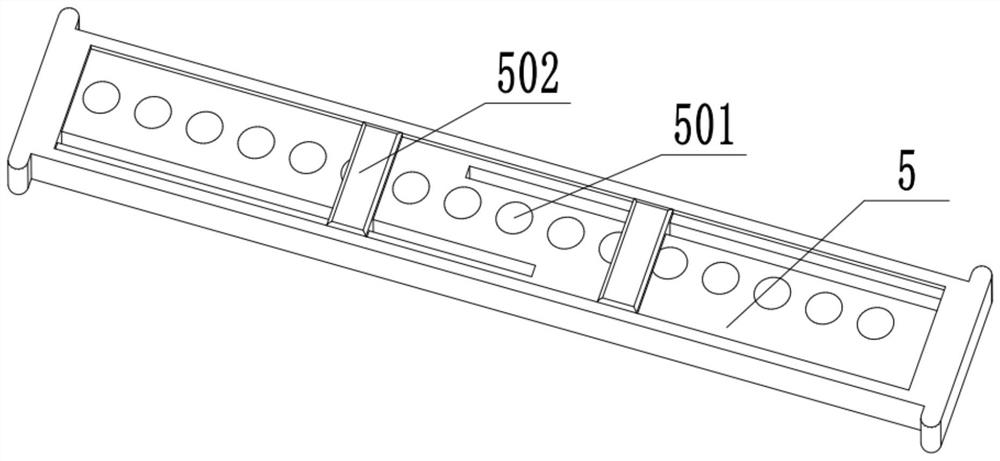

Plant specimen holding device

InactiveCN109243277AFormed flatEasy to operateDead plant preservationEducational modelsEngineeringPlant specimen

A plant specimen holding device comprises a supporting assembly, a placing assembly and a holding assembly. The placing assembly comprises a placing plate body and a partition member. The partition member partitions the placing plate body into a specimen holding area to be pressed and a specimen holding area to be pressed. A pressure holding assembly includes a pressure bearing plate, rotating shaft, press the handrail and counterweight, Before pressing fresh plants into specimens, Fresh plants need to be cleaned up in the area where specimens are to be pressed, and put it in a certain shape,which can then be positioned on the holding assembly for pressing, Fresh plants of a fixed type are placed on a pressure plate, Pull the holding handrail, The pressure holding plate is brought into contact with the pressure bearing plate, so that fresh plants are pressed between the pressure holding plate and the pressure bearing plate, and under the gravity of a counterweight block at the other end of the pressure handrail, the pressure holding plate tightly presses fresh plants on the pressure bearing plate, so that the operation of preparing a specimen is simple, and the pressed specimen can be molded more smoothly.

Owner:惠州市康提家居科技有限公司

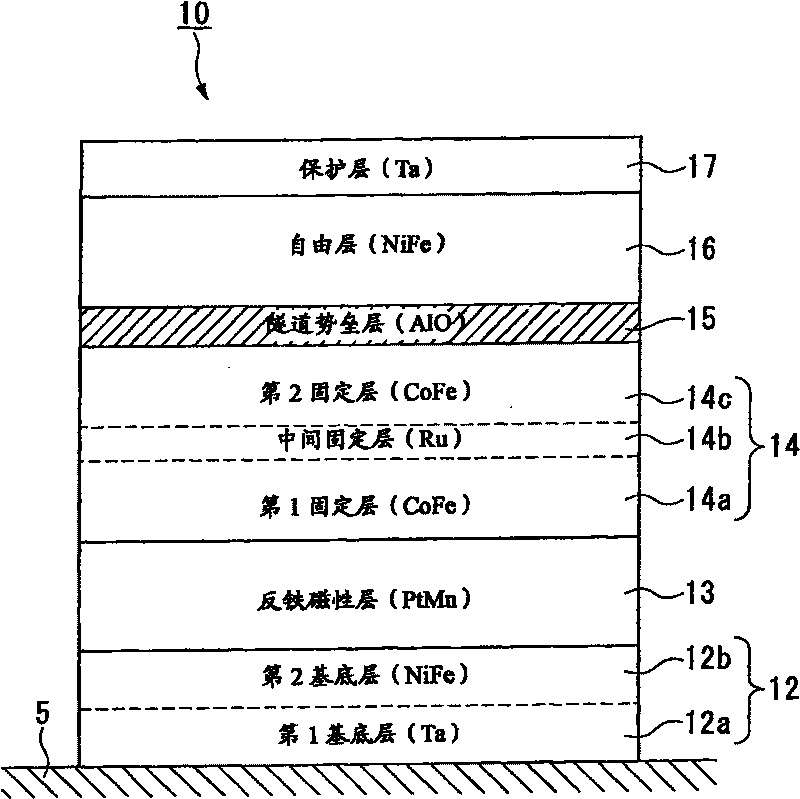

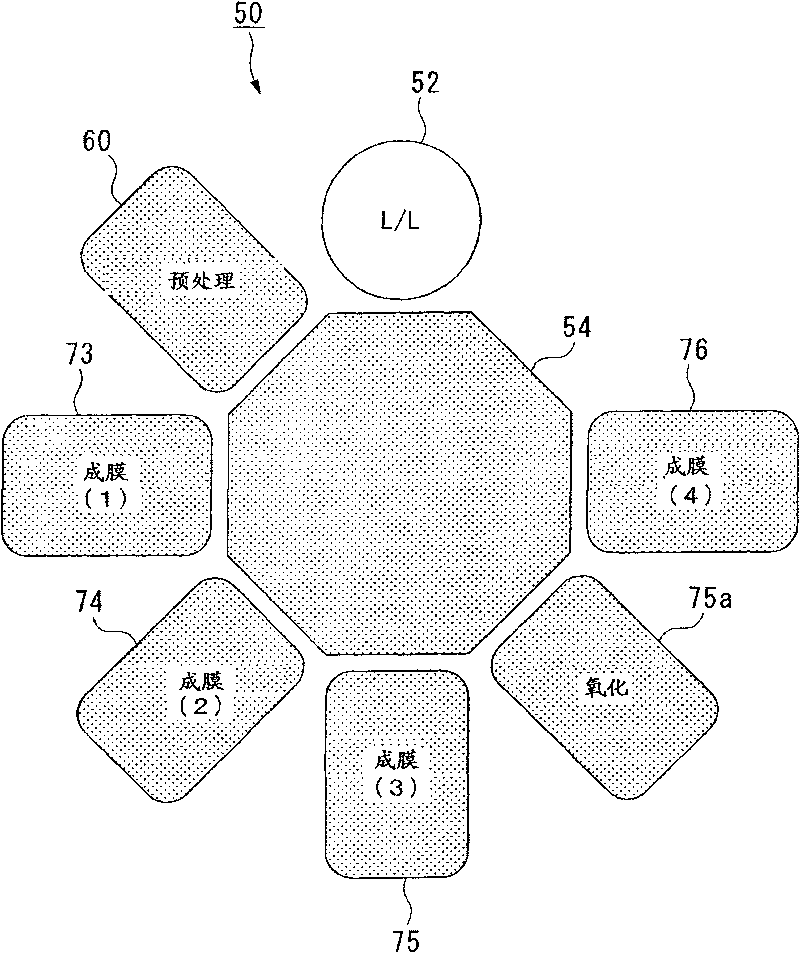

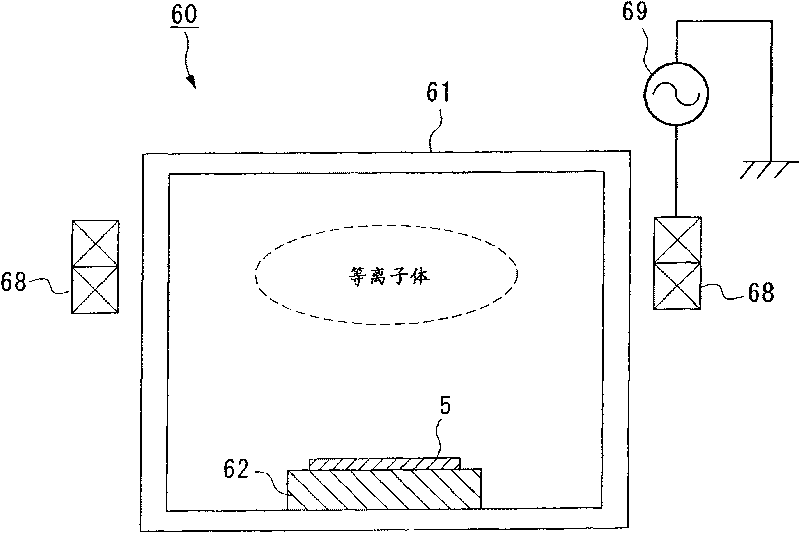

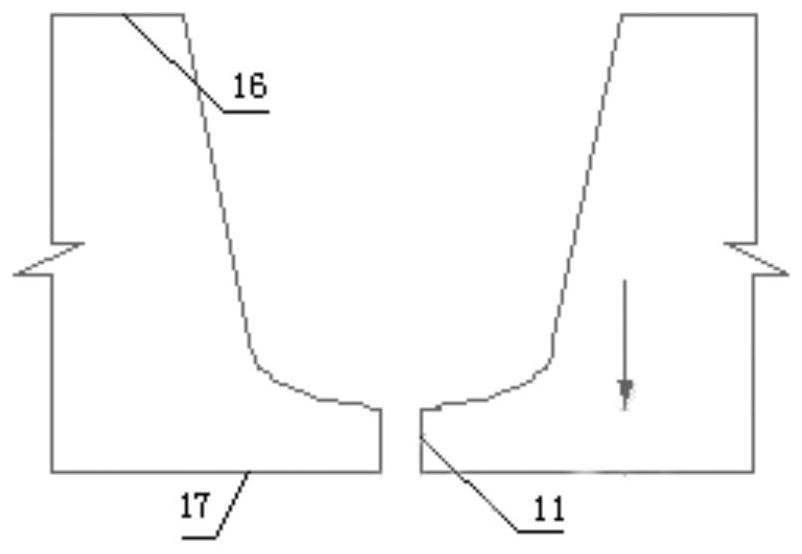

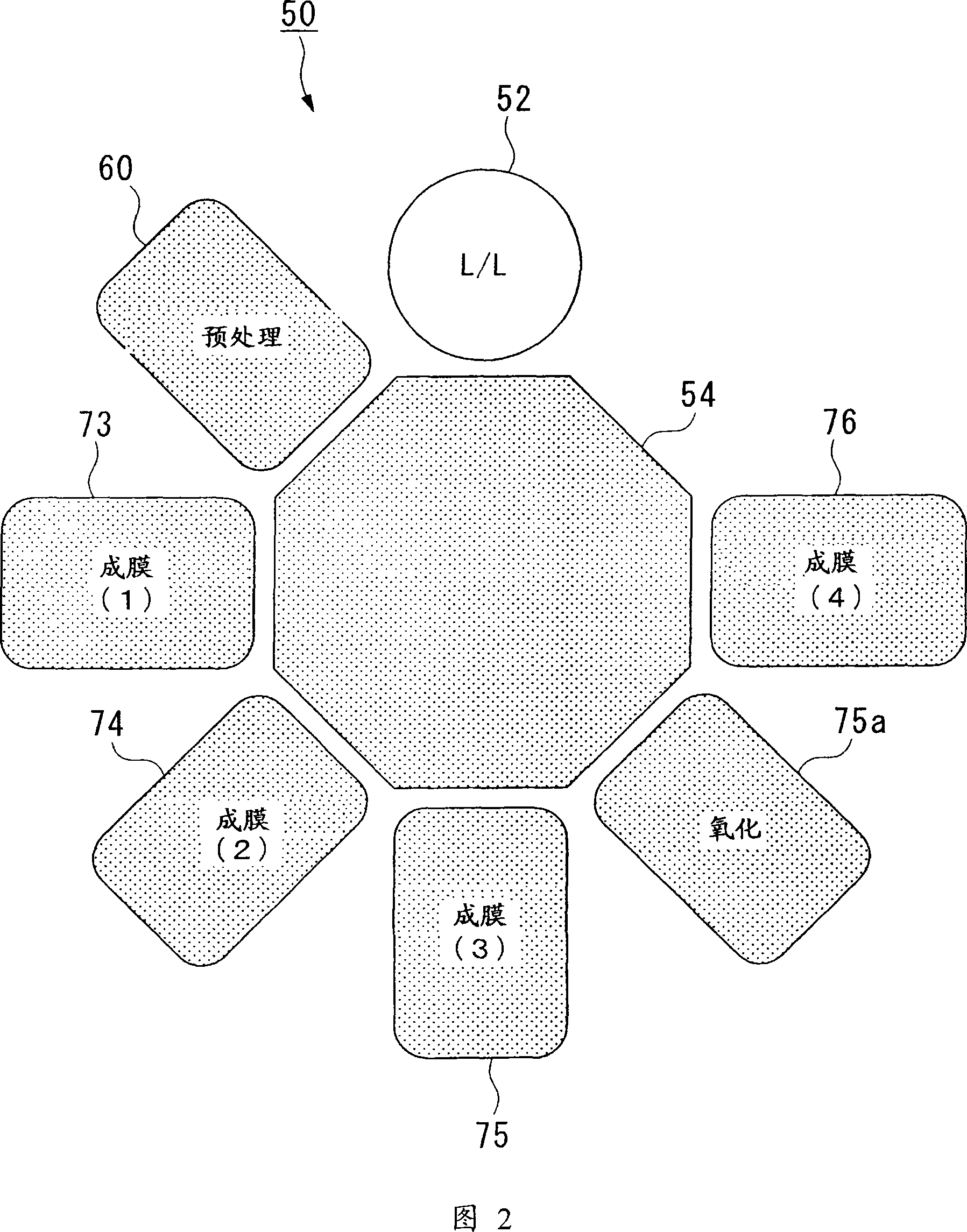

Method for producing magnetic multilayer film

Disclosed is a method for producing a magnetic multilayer film comprising a first magnetic layer formation step for forming a first magnetic layer on a substrate, a nonmagnetic layer formation step for forming a nonmagnetic layer on the first magnetic layer, and a second magnetic layer formation step for forming a second magnetic layer on the nonmagnetic layer. This method for producing a magneticmultilayer film is characterized in that it further comprises, before the nonmagnetic layer formation step, a plasma processing step wherein the substrate is placed in a plasma processing apparatus and processed with an inductively coupled plasma while being kept electrically insulated from the plasma processing apparatus.

Owner:ULVAC INC

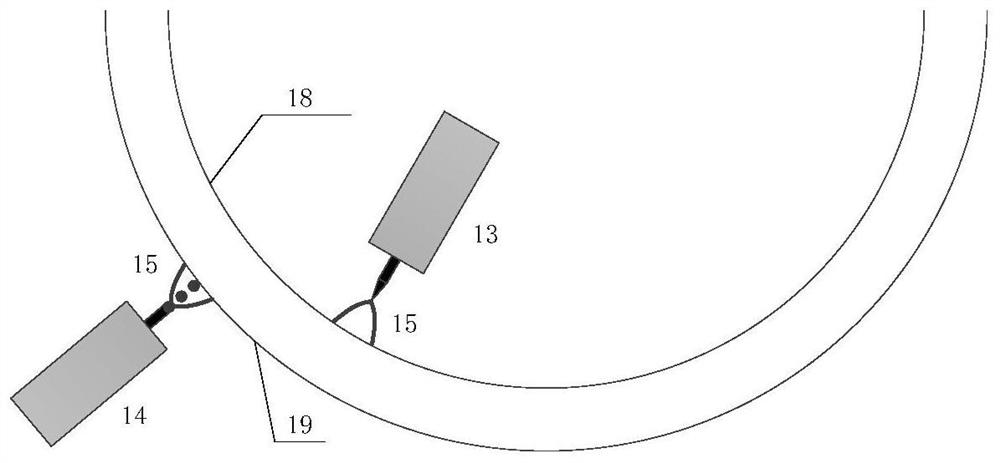

A kind of circular seam butt welding method of seamless steel pipe

ActiveCN112122750BSmooth transitionImprove fatigue strengthArc welding apparatusMetal working apparatusButt weldingEngineering

The invention discloses a method for circular seam butt welding of seamless steel pipes, which comprises: processing a U-shaped groove on the welded joint of a seamless steel pipe to be welded; using an automatic tungsten inert gas shielded welding torch to perform self-fluxing welding on the inner wall of the groove, according to The welder remotely observes or adopts seam tracking and arc voltage tracking to adjust the position and posture of the welding torch in real time; the gas shielded welding torch is used to perform filling and capping welding in the groove of the outer wall of the pipeline. The "inner wall self-fluxing root welding" and the "outer wall groove filling welding" steps can be performed at the same time, or the "outer wall groove filling welding" step can be performed after all self-fluxing welding of the inner wall of the groove is completed.

Owner:TIANJIN UNIV

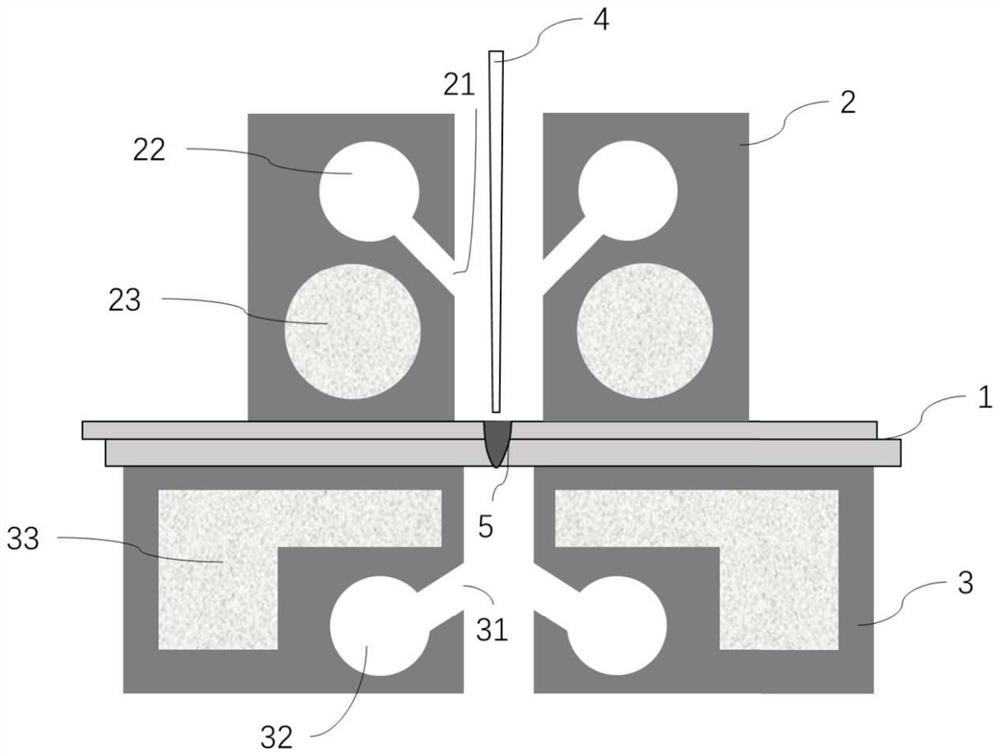

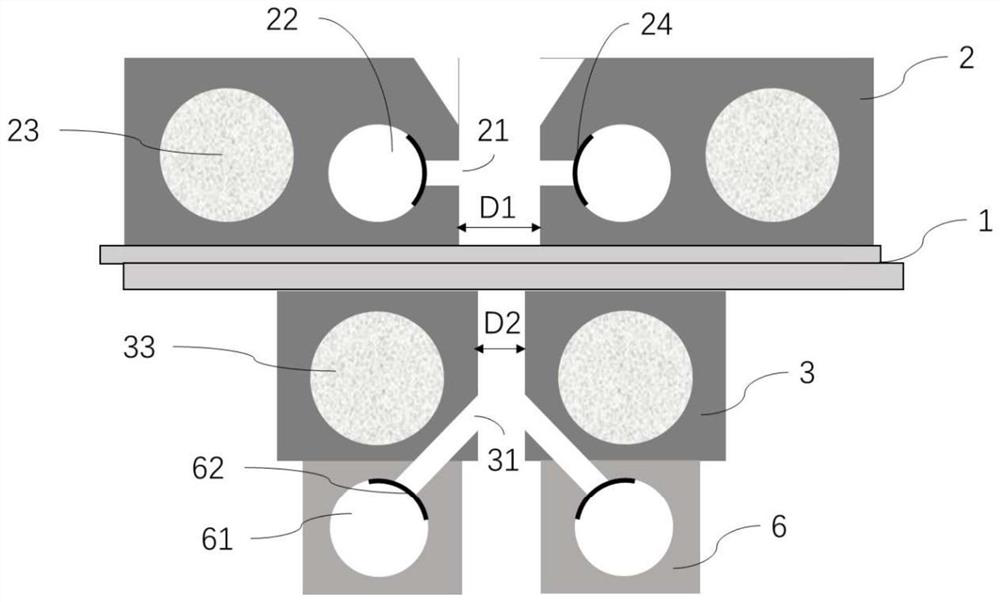

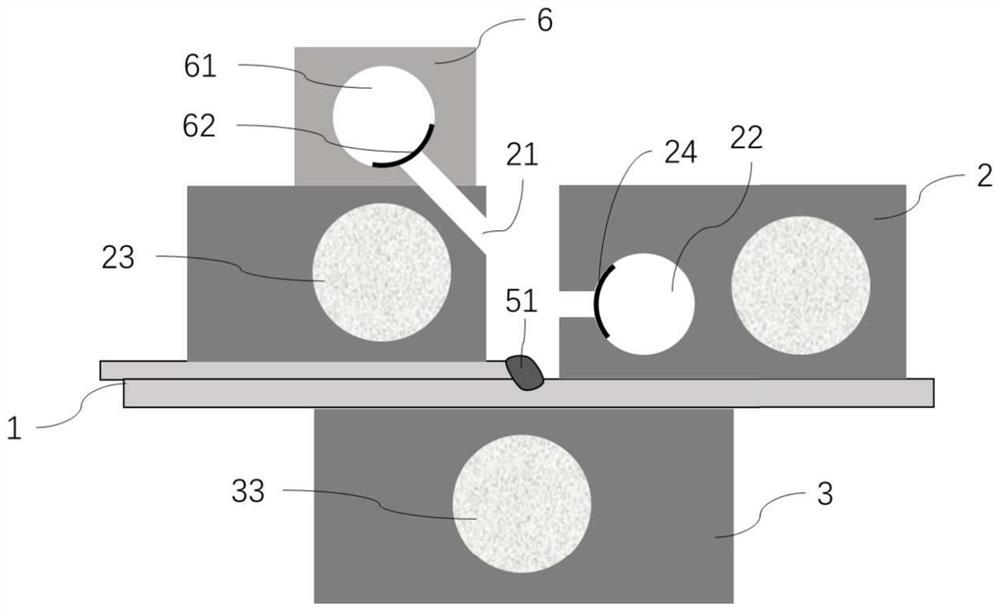

Sheet lamination combination laser welding method and device

ActiveCN114799517APrevent collapsePrevent overheating of the molten poolLaser beam welding apparatusEnergy regulationThin slab

The invention discloses a thin plate lamination combination laser welding method and device, and the method comprises the steps: enabling a laser beam to act on a welding area on the upper surface of a thin plate along a periodic repeated path, and forming a welding seam; and the thin plates are laminated and fixed, and smoke dust and splashing generated in the welding process are absorbed. The atmosphere environment in the welding seam forming process is controlled; and cooling and / or heating control is carried out on heat generated in the lamination and welding process of the thin plates. The welding process method which adopts a periodic repeated path and modulates laser energy is suitable for continuous sealing welding of a multi-layer sheet lamination combination, and has two characteristics of energy regulation and control to prevent a molten pool from being overheated and periodic scanning of laser beams to avoid small hole collapse; and control over the lamination combination temperature and welding fume is assisted, so that elimination of air holes and cracks of the welding seam is truly achieved, and the requirement for sealing and no leakage of the welding seam is met.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Film-making method and film-forming device

ActiveCN108359963BFormed flatImprove uniformityChemical vapor deposition coatingThin membraneEngineering

Owner:TRULY HUIZHOU SMART DISPLAY

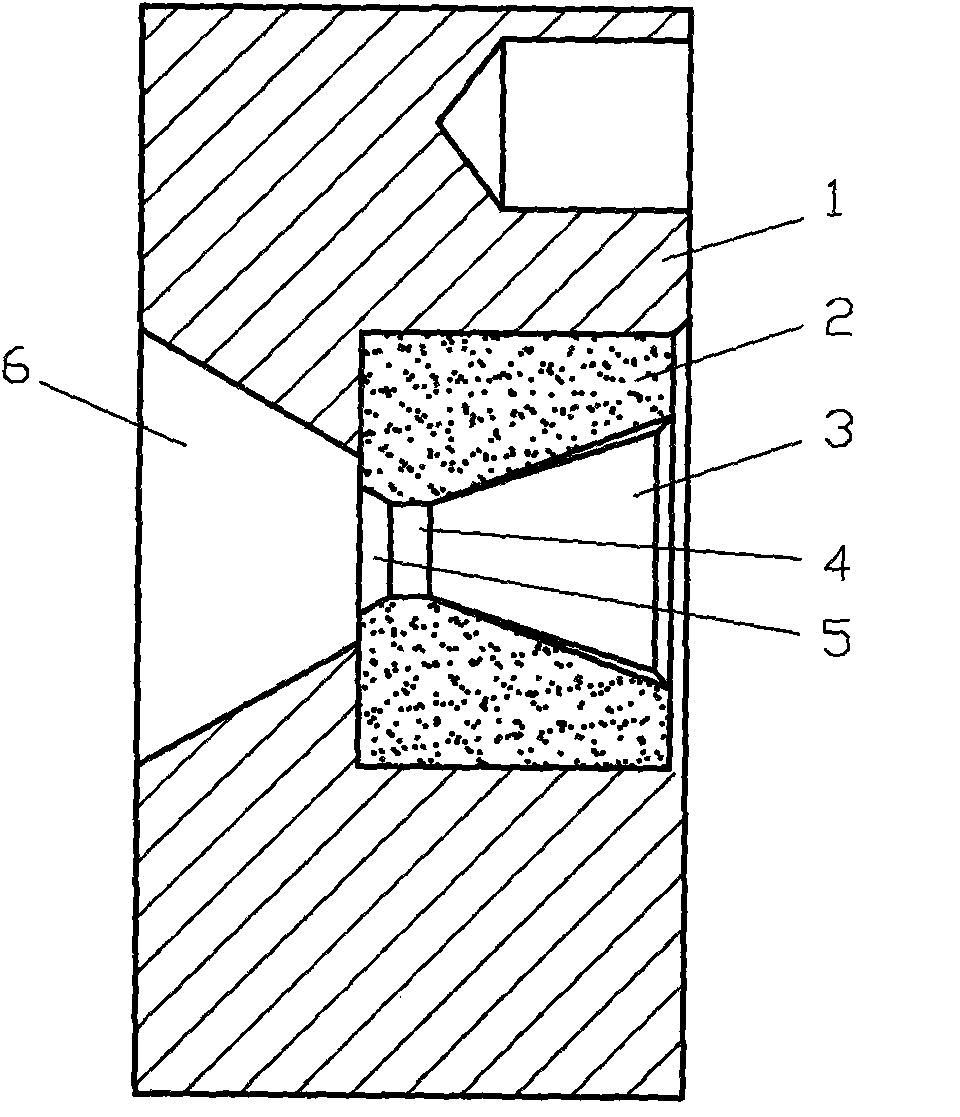

Cold-drawing die

The invention relates to a cold-drawing die, and can cold-draw and draw an altitude wire rod into a hemp flower-shaped reinforcing steel bar. The cold-drawing die comprises a drawing die sleeve and a drawing die; the drawing sleeve is provided with a drawing die groove and a cone-shaped discharge hole communicated with the drawing die groove; the drawing die groove is in interference fit with the drawing die internally; the drawing die is provided with a drawing die hole; the drawing die hole is provided with a transition section, a sizing section and a guide section of talcum powder from the inlet to the outlet; the transition section is a flared arc plane, can prevent the altitude wire rod from rubbing to burn out the surface of the drawing die because of the shortage of the talcum powder; the sizing section is a hemp flower-shaped arc plane; and the guide section of the talcum powder is a flared arc plane, and the guide section of the talcum powder is externally provided with a discharge hole of the drawing die sleeve. The drawing die does not need to add a rotary apparatus, and has simple structure, accurate space between the cross-bar hemp flowers, long service life and less consumption of the talcum powder.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Weather-resistant natural composite material integrated wall panel and preparation method thereof

The invention relates to a weather-resistant natural composite material integrated wall panel and a preparation method thereof. The weather-resistant natural composite material integrated wall panel is characterized by comprising the following raw materials and components in parts by weight: 50 parts of light calcium carbonate, 50 parts of a recycled autogenous grinding material, 25 parts of SG-8polyvinyl chloride resin, 8 parts of log bamboo powder, 25 parts of PVC tube material, 2.5 parts of CS-108 tubular product PVC efficient rear earth compound stabilizer, 0.4 part of a yellow foaming agent, 0.3 part of a white foaming agent, 3.9 parts of ZB-760 PVC foaming conditioning agent, 0.05 part of PE WAX PE wax and 0.32 part of 1840 type stearic acid. The wall panel is mold-proof and waterproof, the elasticity and plasticity of wall are increased, the effect after construction is uniform and attractive in appearance, and the promotion of brightness is extremely obvious. Rejected materials are adopted as the raw materials mostly, the cost is low, secondary utilization of the rejected materials is reached, the environment is protected, and the economical benefit is remarkable.

Owner:宣恩九发科技有限公司

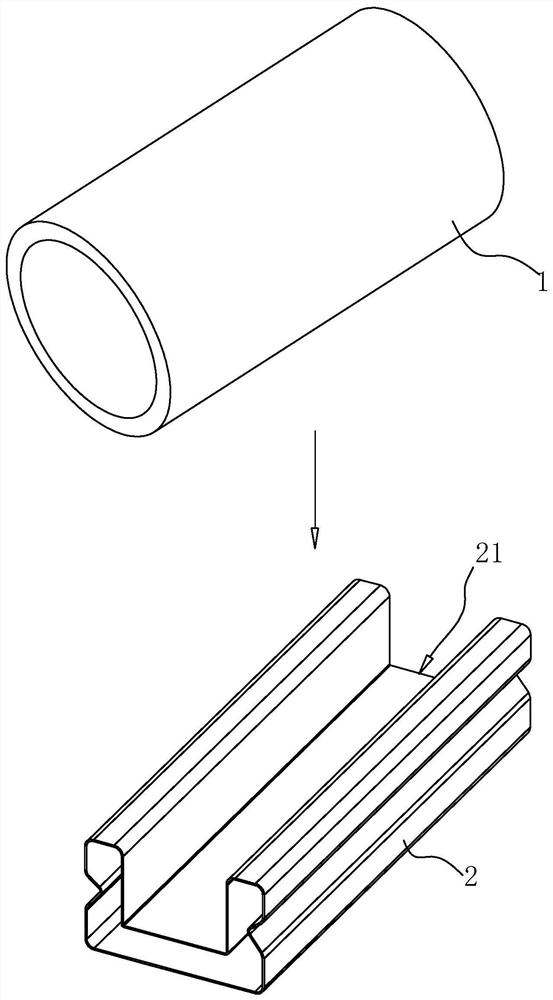

Buffer material forming process

ActiveCN112829386AImprove buffering effectImprove product qualityMechanical working/deformationKraft paperIndustrial engineering

The invention relates to the field of paper product forming processes, in particular to a buffer material forming process. According to the technical scheme, the buffer material forming process is characterized by comprising the following steps that S1, a base material is prepared, a paper tube is used as the base material, and the paper tube is a kraft paper tube; S2, equipment is debugged, equipment is provided with a core mold and side pressing molds located at one side of the core mold, the number of the side pressing molds is four, the four side pressing molds are located at the upper side, the lower side, the left side and the right side of the core mold correspondingly, and the side pressing molds and the core mold are heated; S3, the base material is placed, specifically, the paper tube is connected to the core mold in a sleeving manner so as to be placed; S4, the equipment is started, so that the side pressing molds move towards the core mold and are combined with the core mold, and the paper tube is extruded and deformed; S5, the extrusion action is kept, and the paper tube is baked and hardened through the side pressing molds and the core mold; S6, the equipment is started, and the side pressing molds return; and S7, a workpiece is taken out of the core mold. The process has the effects of improving the production process of a buffer material and further improving the production quality of the buffer material.

Owner:DONGGUAN WANGQUAN PAPER PROD CO LTD

Forming press

The invention discloses a forming press. The forming press comprises a forming press body and a mounting plate, wherein the right side surface of the forming press body is welded with a mounting plate; the right side of a first rotary rod is equipped with a second rotary rod; left and right ends of the second rotary rod are welded and connected with a bracket; a second rotary roller sleeves the periphery of the outer surface of the second rotary rod; the second rotary roller is in clearance fit to the second rotary rod; a rubber sleeve sleeves the outer surface of the first rotary roller; theupper end of the supporting rod is welded with an ejector block; the upper end of the ejector block is welded with an ejector plate; a spring sleeves the periphery of the outer surface of the ejectorblock; and upper and lower ends of the spring are separately fitted to the ejector plate and a cushion plate. According to the forming press disclosed by the invention, the spring pushes the cushion plate downwards, and the bracket downwards extrudes a formed board under pushing of the cushion plate, so that flattening treatment can be performed on bumps caused in a forming process, of the boardsunder extrusion of the first rotary roller and the second rotary roller, and therefore, the boards can be formed and flattened.

Owner:大连鑫宏利船舶工程有限公司

Frame glasses and processing method thereof

InactiveCN102073149BFormed flatFirmly connectedFramesNon-optical partsComputer scienceCylinder pressure

The invention relates to a processing method of frame glasses. The frame glasses comprise a glasses frame, glasses legs, first hinges and second hinges, wherein the glasses frame and the glasses legs are made of plastics, and the first hinges and the second hinges are made of metal. The method comprises the following steps: S1) heating the first hinges and the second hinges respectively to a first critical temperature and a second critical temperature, wherein the glasses frame and the glasses legs are melted at the first critical temperature and the second critical temperature respectively; S2) pressing the heated first hinges and the heated second hinges into corresponding places of the glasses frame and the glasses legs via cylinder pressure; S3) cooling the heated first hinges and theheated second hinges to connect with the glasses frame and the glasses legs respectively; and S4) connecting the first hinges with the second hinges. In the glasses frame and the processing method thereof provided by the technical scheme of the invention, a seamless hot-pressing connection is adopted between the metal hinges and the plastic glasses frame or between the metal hinges and the plastic glasses legs. The frame glasses are characterized by smooth and beautiful shaping, and the connection is tightened and the metal hinges are not easy to fall off. Meanwhile, an exterior plane of the hinge parts becomes a decoration for pile-head parts in the glasses legs and glasses frame, and the seamless effect at the periphery of the decoration is better than that of similar products in the industry.

Owner:丹阳市鑫隆光学眼镜有限公司

A double-sided laminating machine

ActiveCN113352748BLaminating steps are consistentFormed flatPrinting press partsGear driveGear wheel

The invention relates to the technical field of laminating machines, and specifically discloses a double-sided laminating machine. The drive roller that drives the printed product to move and the drive mechanism that can drive the film roller and the drive roller to rotate. There are also guide blocks that are slidably connected up and down symmetrically between the support frames. The guide blocks are all provided with cavities, and motors are fixed in the cavities. , The output shafts of the motors are coaxially connected with transmission gears, the transmission gears are symmetrically meshed with racks, the free ends of the racks are fixed with connecting rods, and the free ends of the connecting rods are protruding from the guide block The push plate that is pushed has an air bag in the cavity, the connecting rod is fixed with a piston rod, one end of the piston rod extends into the air bag and is connected with a piston in a sliding seal, and the side wall of the guide block is provided with an air inlet and an air outlet. It solves the problem that the film is easily wrinkled during the laminating process of the traditional double-sided laminating machine, which affects the lamination effect.

Owner:CHONGQING YIJU DOOR

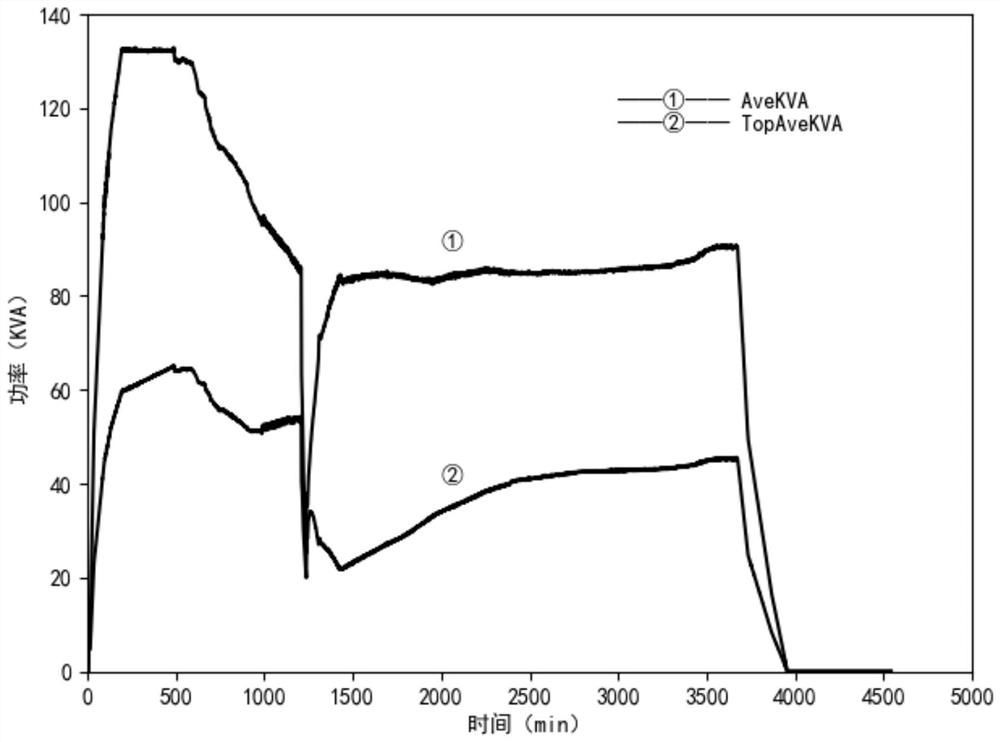

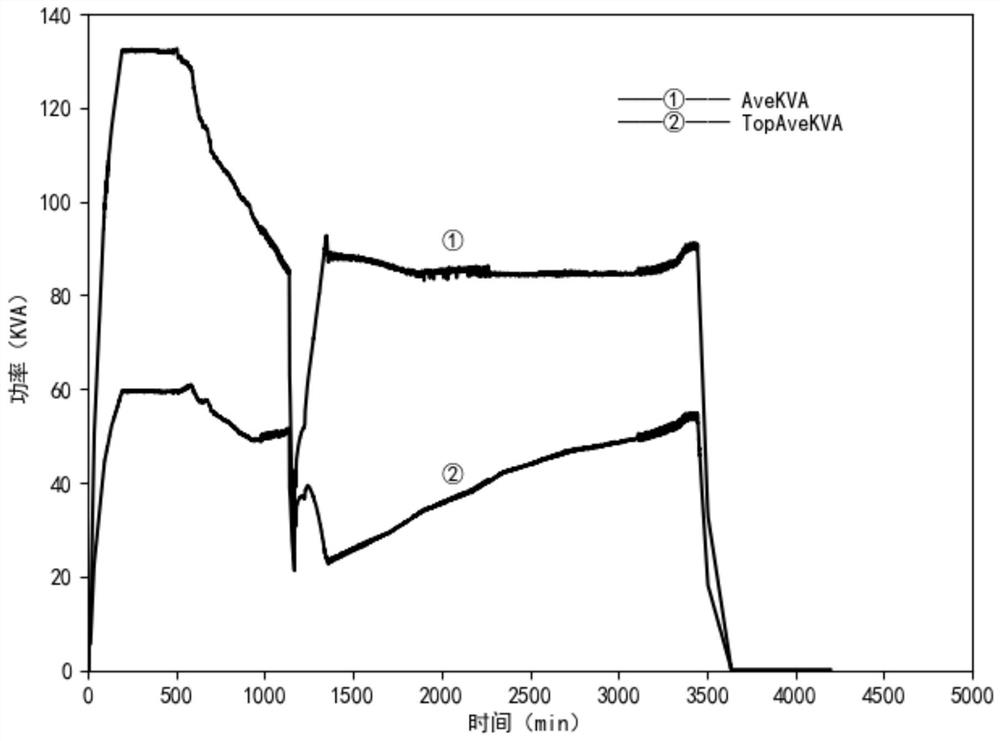

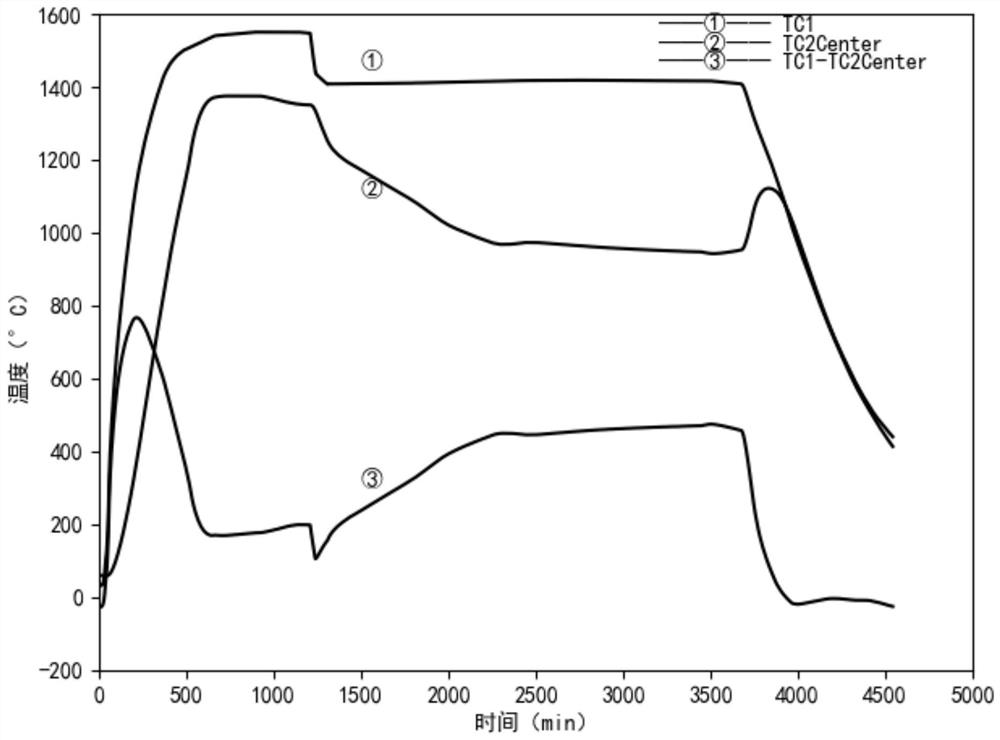

A method and process for controlling the growth of polysilicon ingot

ActiveCN108425148BAvoid chippingReduce overmeltingPolycrystalline material growthSingle crystal growth detailsIngot castingCrucible

Owner:南通友拓新能源科技有限公司

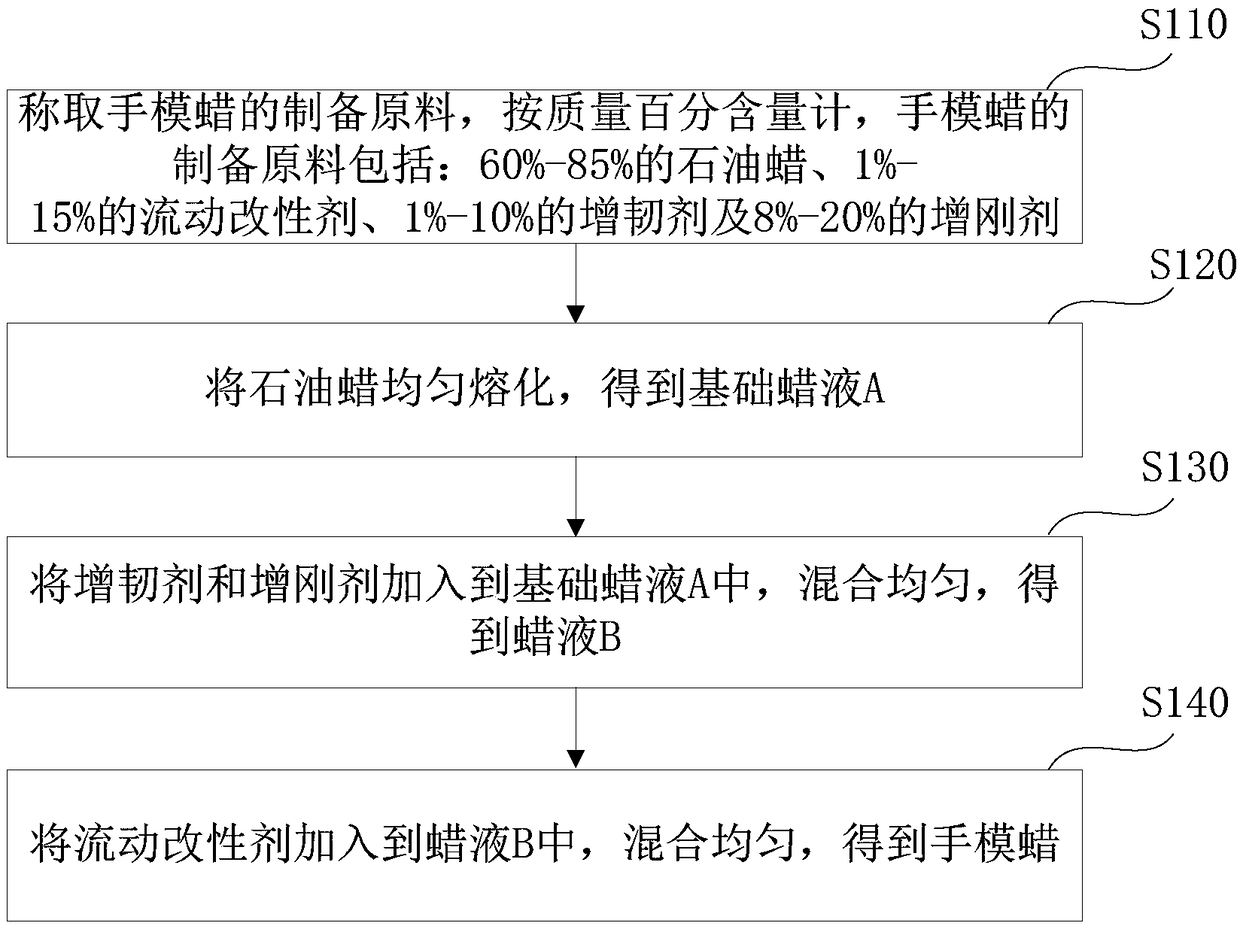

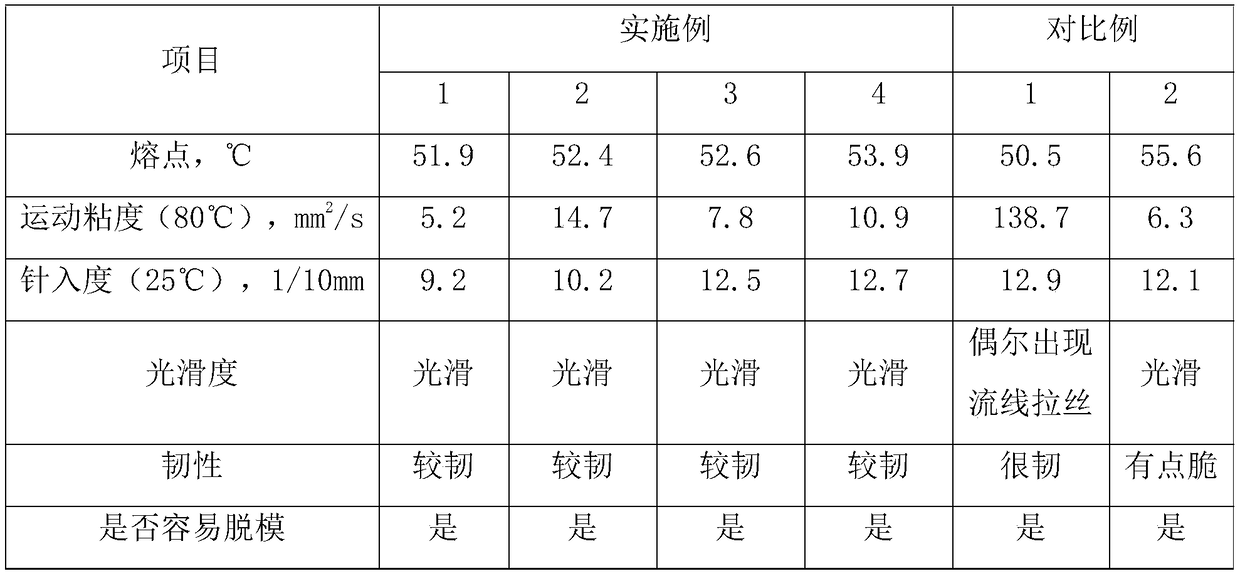

Hand die wax and preparing method and application thereof

The invention relates to hand die wax and a preparing method and application thereof. According to the mass percent, raw materials for preparing the hand die wax include 60%-85% of petroleum wax, 1%-15% of a flow modifier, 1%-10% of a toughening agent and 8%-20% of a stiffening agent. In the hand die wax, the toughening agent, the stiffening agent and the flow modifier are added, a certain proportion is adopted, the tenacity and rigidity of the hand die wax can be adjusted through the toughening agent and the stiffening agent, the rigidity and the tenacity of the prepared hand die wax are balanced, and accordingly during hand die wax shell stripping, the hand die wax cannot be damaged. Through the flow modifier, the hand die wax can have certain mobility when achieving certain bonding performance, so that the hand die wax is smoothly formed, and the phenomenon of flow line filament drawing is avoided.

Owner:GUANGZHOU DEXIN WAX PROD

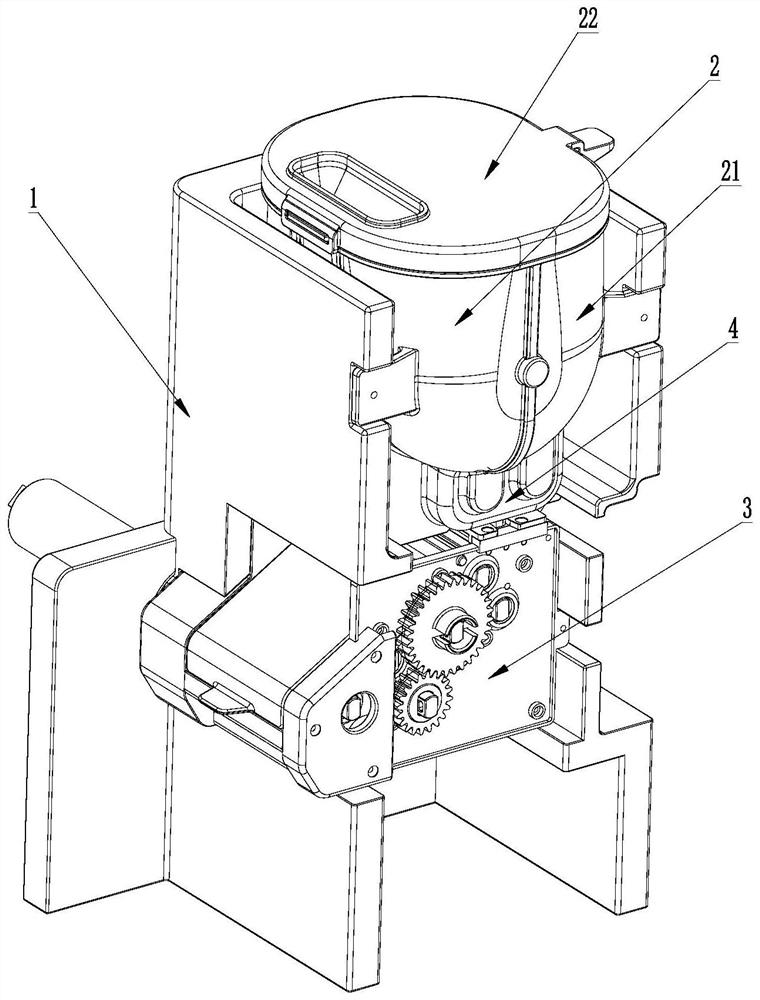

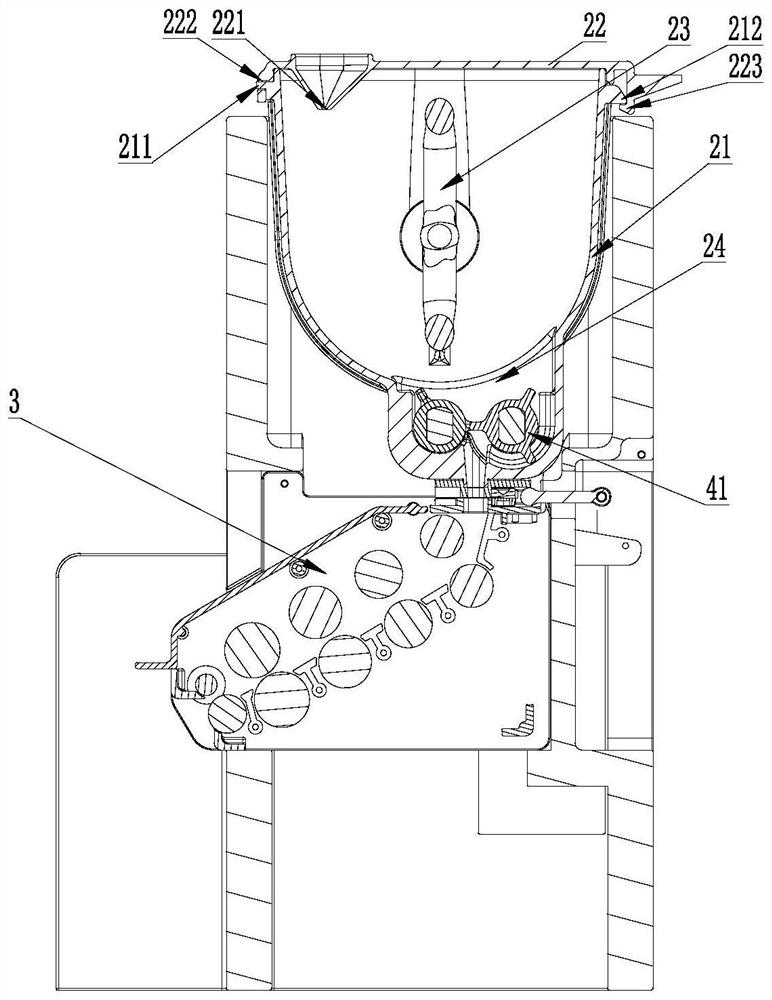

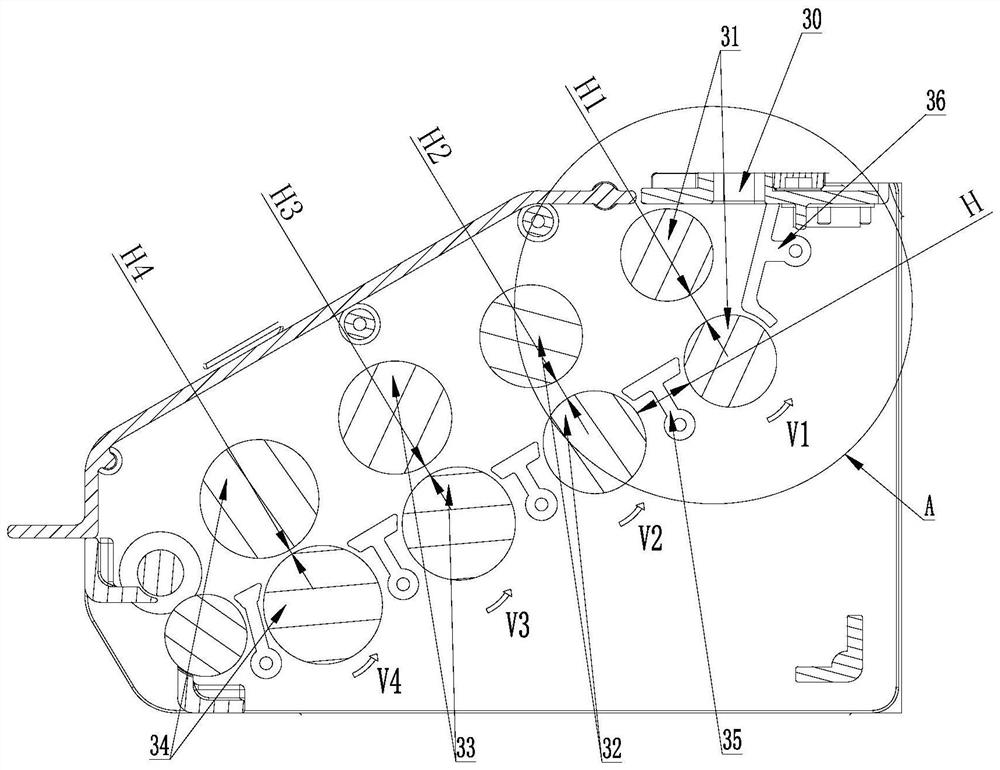

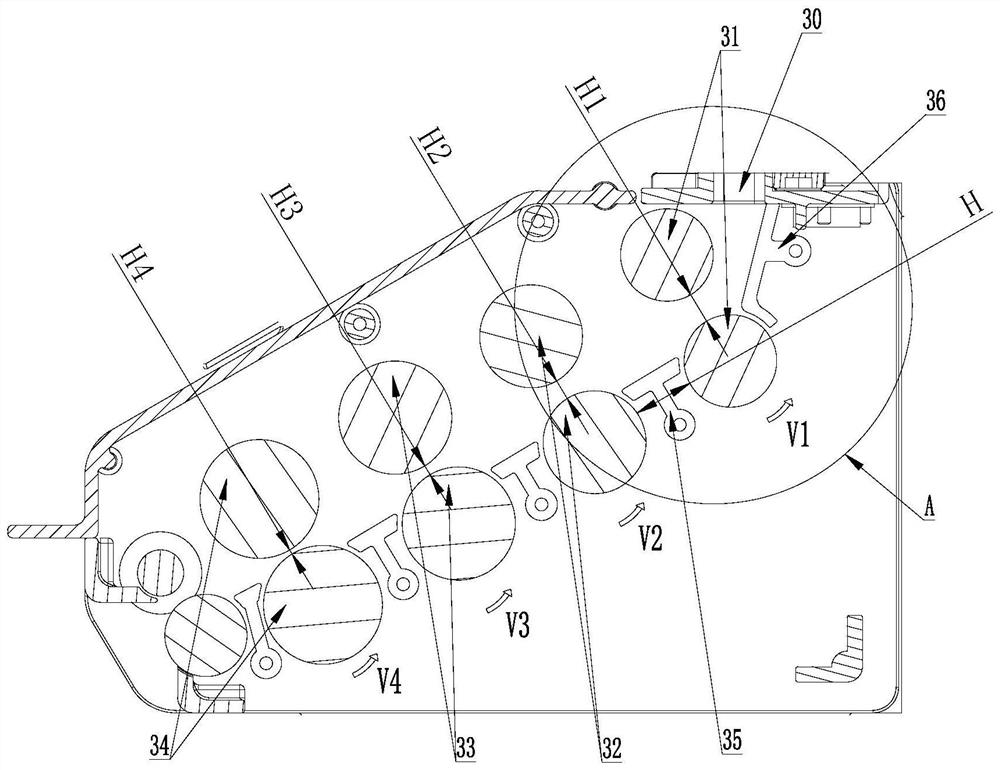

Tissue box capable of rapidly switching locking modes

PendingCN114158970AEasy to useExtended service lifeDomestic applicationsComputer hardwareRolling paper

The invention relates to a tissue box capable of rapidly switching locking modes, which comprises a box body and a flip cover, a locking module is arranged between the box body and the flip cover, the locking module comprises a button opening and closing mode and a key opening and closing mode, and a switcher for switching the button opening and closing mode and the key opening and closing mode is arranged on the locking module. The switcher is detachably connected with the locking module, and the locking module is detachably connected with the box body. By the adoption of the technical scheme, the switcher is inserted into the locking module in different scenes so that the two opening and closing modes of button opening and closing and key opening and closing can be switched, when the locking module is damaged, the locking module and the box body can be detached for replacement, the service life is long, and when the key opening and closing mode serves as a common mode, the operation is convenient. The roll paper in the tissue box is prevented from being taken away by people to cause loss and increase the operation cost and management difficulty of a management party, operation is easy, use is convenient, button and key opening and closing are integrated, applicability is higher, operation is convenient, the structure is simplified, cost is reduced, and popularization and consumption are easier.

Owner:제지앙인터하사인텔리전트테크놀로지컴퍼니리미티드

Method for producing refractive PU synthetic leather

ActiveCN102517921BImprove textureSoft glossLamination ancillary operationsLaminationWork in processRelease liner

The invention relates to a method for producing polyurethane (PU) synthetic leather, in particular to a method for producing refractive PU synthetic leather. According to the method for producing the refractive PU synthetic leather, the prepared refractive PU synthetic leather has exquisite grains, soft glossiness, flat shape and good reflective glossiness. The method comprises the following steps of: selecting materials, conveying release paper to a No. 1 coating head, coating a layer of surface material, conveying the release paper to a No. 2 coating head, coating a layer of bottom material on the surface material, preheating the treated release paper to combine a base surface material and the release paper coated with the surface material and the bottom material, drying in an oven to obtain a dry semi-finished product, embossing the dry semi-finished product through a pair of embossing rollers, cooling the embossed semi-finished product, coiling, and thus obtaining a finished product.

Owner:福建兰峰制革有限公司

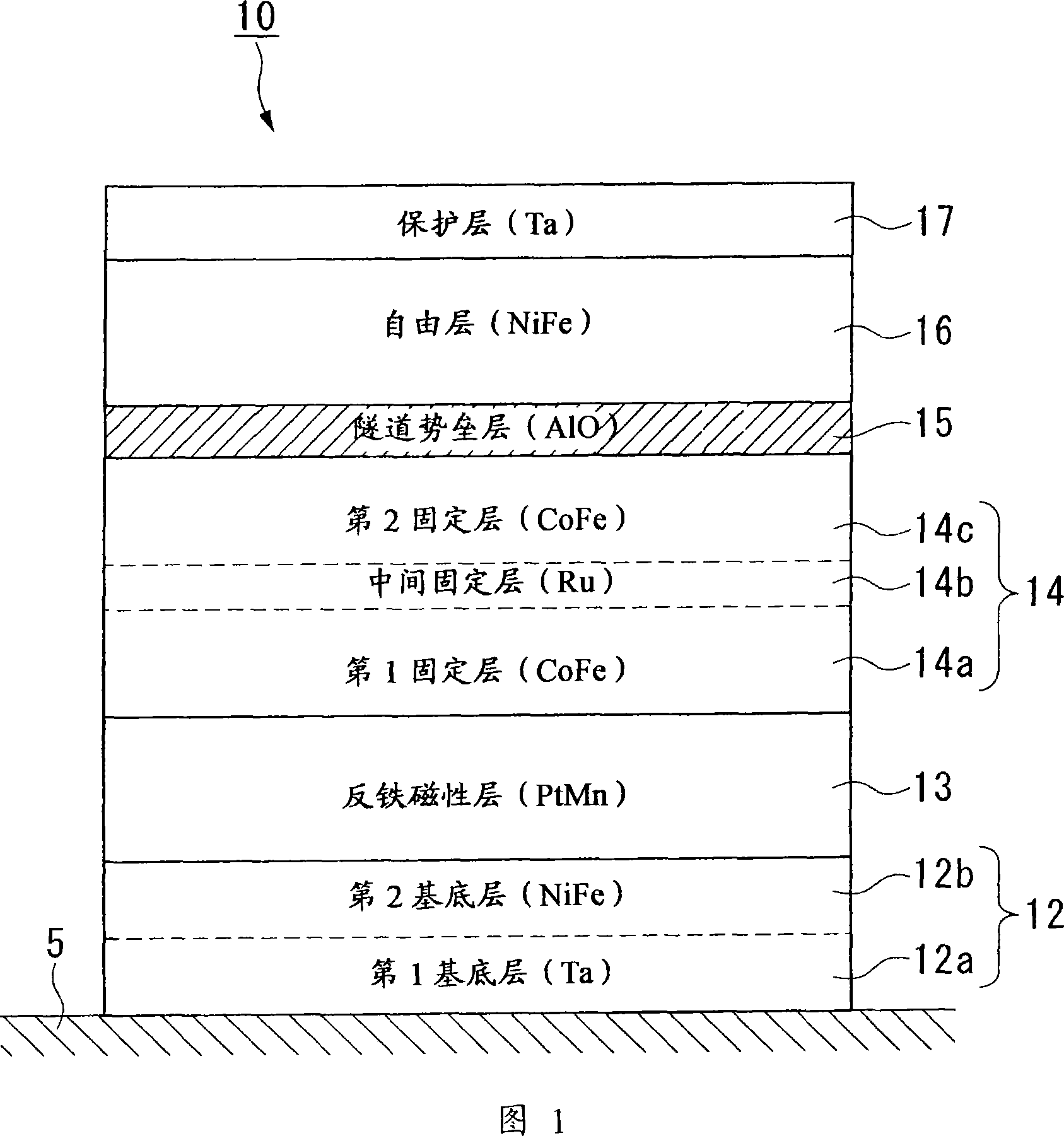

Method for producing magnetic multilayer film

Disclosed is a method for producing a magnetic multilayer film comprising a first magnetic layer formation step for forming a first magnetic layer on a substrate, a nonmagnetic layer formation step for forming a nonmagnetic layer on the first magnetic layer, and a second magnetic layer formation step for forming a second magnetic layer on the nonmagnetic layer. This method for producing a magnetic multilayer film is characterized in that it further comprises, before the nonmagnetic layer formation step, a plasma processing step wherein the substrate is placed in a plasma processing apparatus and processed with an inductively coupled plasma while being kept electrically insulated from the plasma processing apparatus.

Owner:ULVAC INC

A fast-processing pasta machine

ActiveCN113057187BIncrease extrusion speedGreat tasteDough-sheeters/rolling-machines/rolling-pinsMixing/kneading with vertically-mounted toolsProcess engineeringPower unit

The invention relates to a fast-processing pasta machine, which comprises a main machine with a built-in power unit, a dough mixing assembly connected with the main machine power, and an extrusion assembly connected with the main machine power, the noodle inlet of the extrusion assembly and the The outlet of the noodle assembly is connected, and the extruding assembly includes at least three sets of noodle rollers arranged continuously, the extrusion gap of the noodle rollers decreases from front to back, and the extrusion speed of the noodle rollers increases from front to back. increase sequentially. There are at least three sets of noodle-pressing rollers arranged continuously, which ensures that the dough is formed by extrusion and extension, so that the noodles are more in line with the personnel's pursuit of noodle taste, and the noodles are stronger. At the same time, the dough is continuously processed by multi-stage pressing rollers, and different pressing rollers have different extrusion gaps. The purpose of kneading, extruding, and forming can be completed in one process, without repeated extrusion and adjustment of the extrusion gap. High efficiency, reduced personnel participation, fast processing speed.

Owner:JOYOUNG CO LTD

Double-sided film laminating machine

ActiveCN113352748ALaminating steps are consistentFormed flatPrinting press partsGear driveGear wheel

The invention relates to the technical field of film laminating machines, and particularly discloses a double-sided film laminating machine. The double-sided film laminating machine comprises supporting frames which are symmetrically arranged, a thin film roller which is rotationally connected between the supporting frames in an up-down symmetrical mode, a plurality of transmission rollers which are rotationally connected between the supporting frames and can drive a printed product to move, and a driving mechanism which can drive the thin film roller and the transmission rollers to rotate, wherein guide blocks are further connected between the supporting frames in an up-down symmetrical sliding mode; cavities are formed in the guide blocks; motors are fixedly connected in the cavities; output shafts of the motors are coaxially connected with transmission gears; the transmission gears are symmetrically meshed with racks; the free ends of the racks are fixedly connected with connecting rods; the free ends of the connecting rods extend out of the guide blocks and are provided with push plates capable of being pushed on the surface of a thin film; air bags are arranged in the cavities; the connecting rods are fixedly connected with piston rods; one end of each piston rod extends into the corresponding air bag and is connected with a piston in a sliding and sealing mode; and air inlet holes and air outlet holes are formed in the side walls of the guide blocks. The problem that in the film laminating process of a traditional double-sided film laminating machine, the thin film is prone to wrinkling, and the film laminating effect is affected is solved.

Owner:CHONGQING YIJU DOOR

Multilayer printed wiring board and method for manufacturing multilayer printed wiring board

ActiveCN102239753BFormed flatPrecipitation of conductive materialSemiconductor/solid-state device detailsPrinted circuit aspectsCopper platingElectrical conductor

Owner:IBIDEN CO LTD

Wiring structure of wire harness and wire harness

ActiveUS20210309169A1Improve the fixing strengthReliable maintenanceInsulated cablesElectric/fluid circuitStructural engineeringElectric wire

A wiring structure of a wire harness in which a wire harness is fixed to an adhesive member laid on a surface of a roof lining of an automobile is disclosed, wherein on at least a part of a bent portion, the plurality of electric wires are sandwiched between two belt-shaped tapes in which both side edges are fixed to each other, are spread side by side in the width direction, and are attached to an adhesive surface provided on an inner surface of at least one of the two tapes, thereby providing a restraint portion in which the bundle of the electric wires is held in a flat shape, a portion excluding the restraint portion is a non-restraint portion in which the electric wires are unrestrained, and an outer surface of one of the two tapes in the restraint portion is attached to the adhesive member.

Owner:YAZAKI CORP

Wiring substrate, process for manufacturing the wiring substrate, and carrier sheet for green sheet used in the manufacturing process

InactiveUS20050032258A1Reduce protrusionPrevent gap formationLine/current collector detailsSemiconductor/solid-state device manufacturingForming faceMetal foil

A carrier sheet for green sheet having a green sheet forming face on which a green sheet is to be formed, comprising: metal foil; and a resin film stacked on a first surface of said metal foil on a side of said green sheet forming face having a smaller thickness than that of said metal foil.

Owner:NGK SPARK PLUG CO LTD

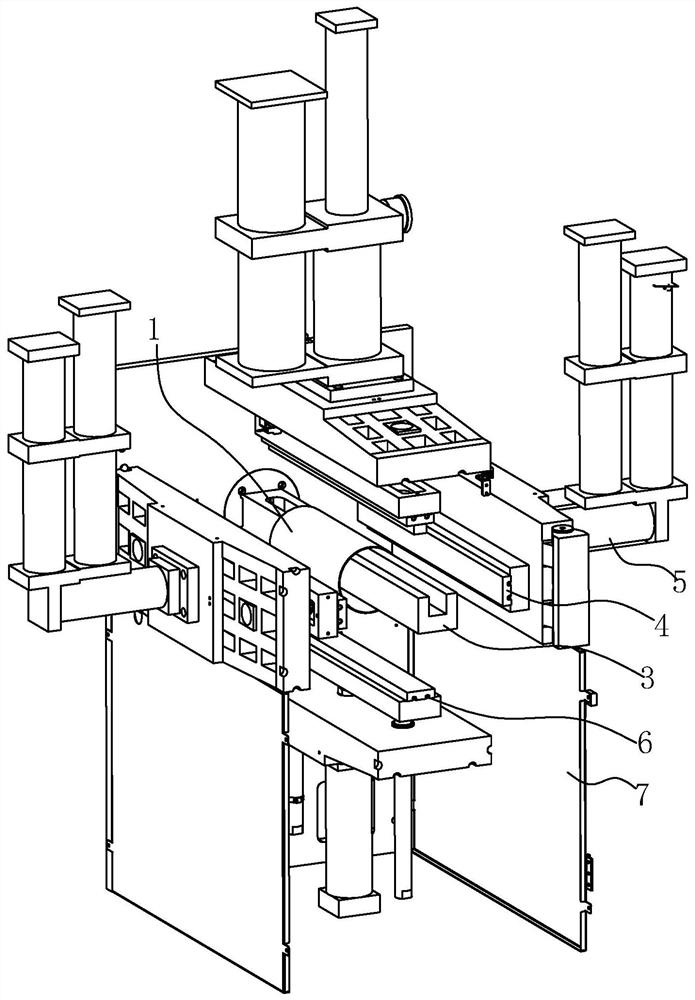

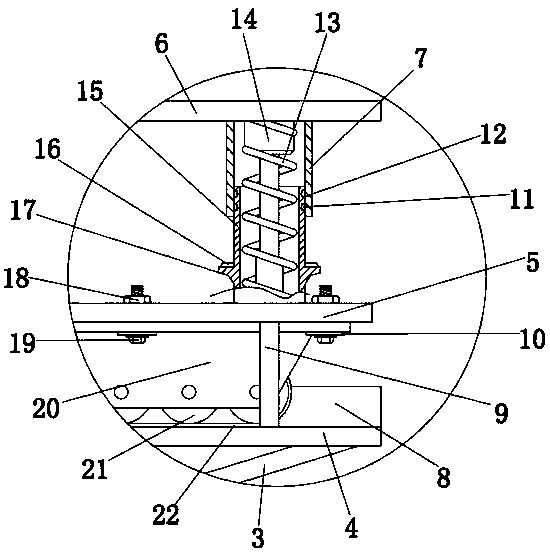

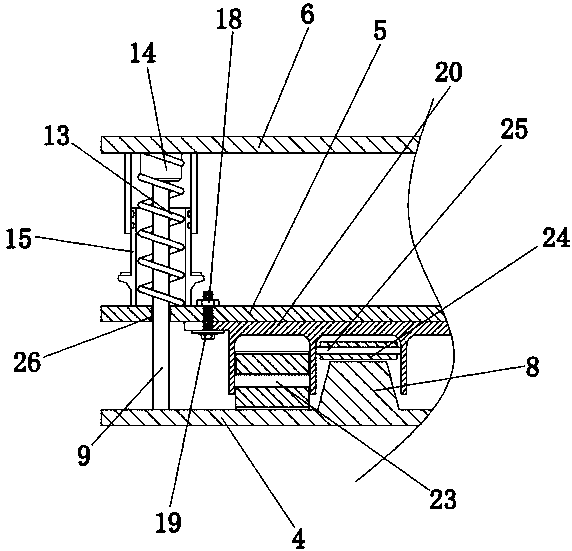

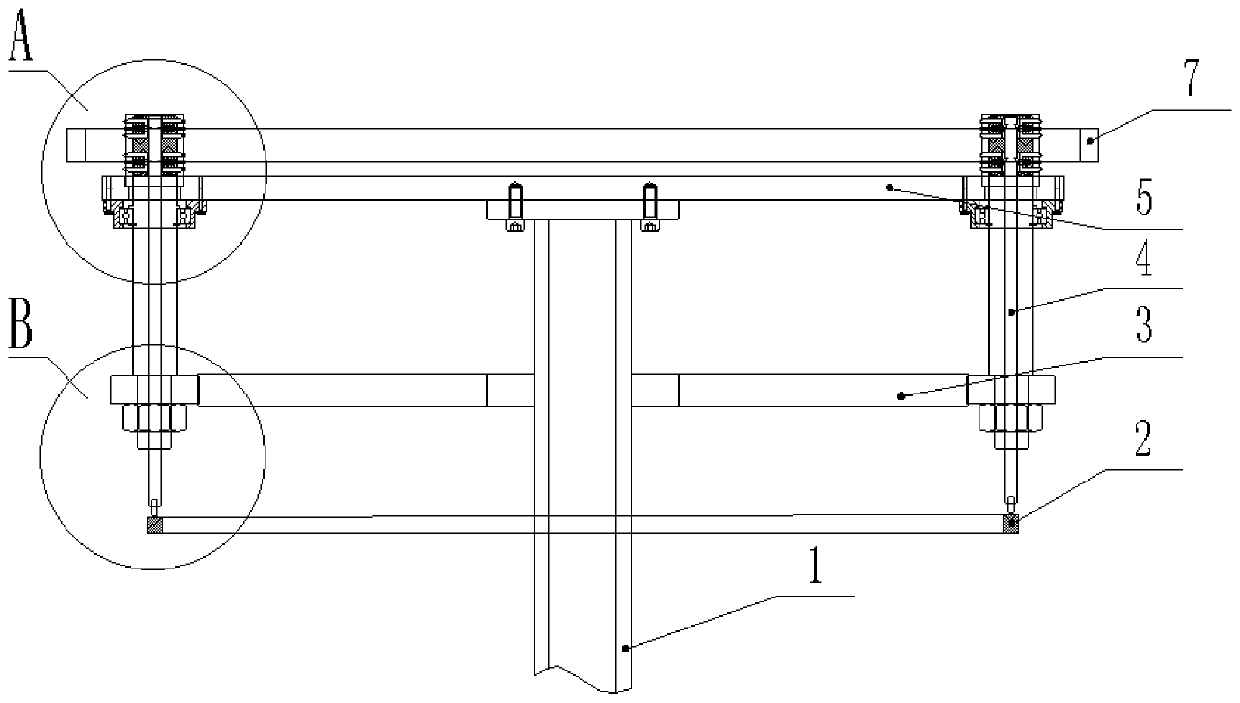

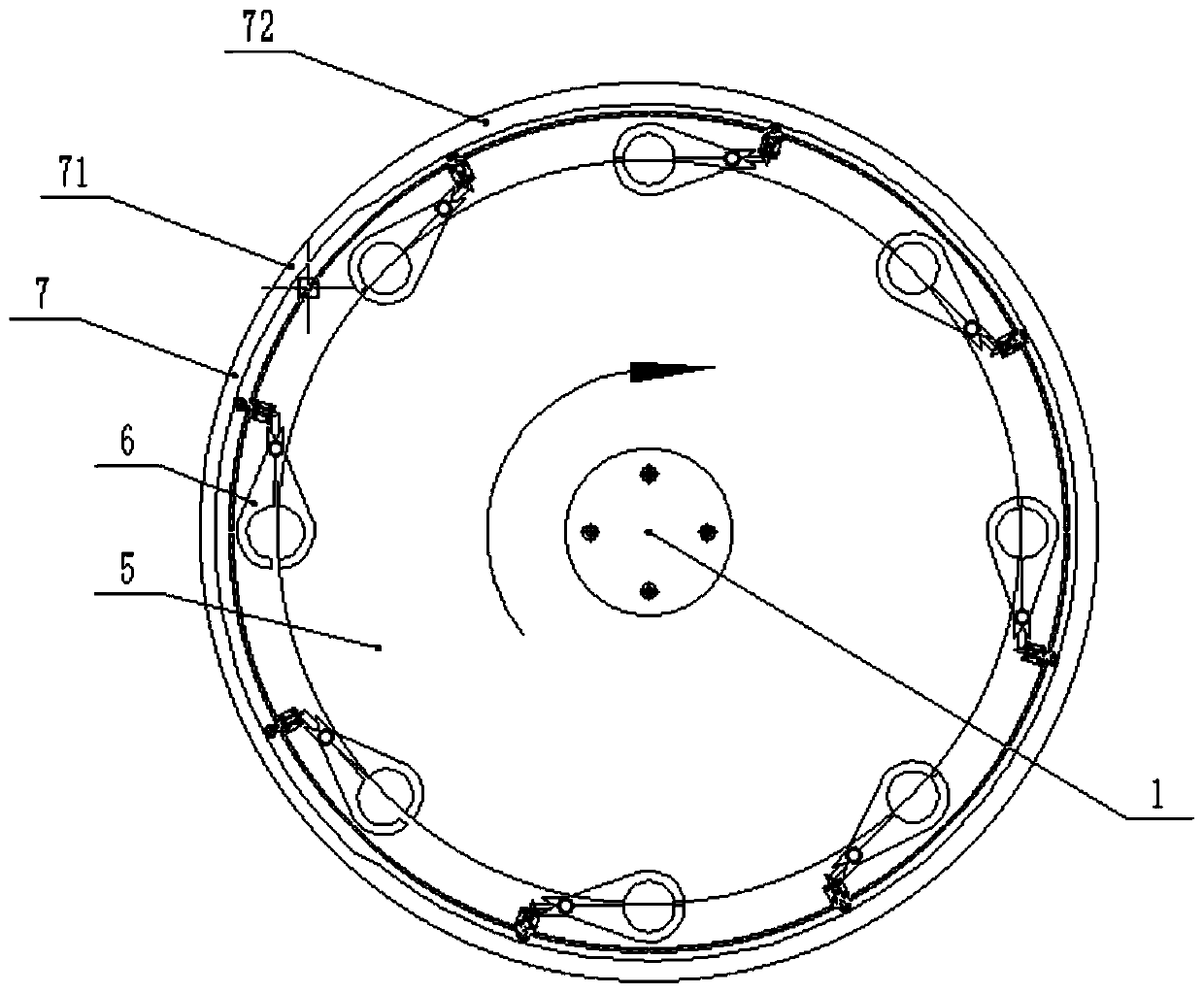

Rotary thin-wall tank forming device

InactiveCN110523824AImprove work efficiencyReduce labor intensityHollow articlesThin walledEngineering

The invention discloses a rotary thin-wall tank forming device. The device comprises a turntable, a coaming, a large gear, a jacking rail, a tank clamping mechanism and a rotary jacking mechanism, positioning holes are uniformly formed in the turntable; the coaming is divided into a feeding and discharging section and a processing section; the tank clamping mechanism comprises a rotating shaft, two clamps rotating relative to the rotating shaft, and a movable shaft for driving the clamps to rotate; rolling bearings are fixed at the outer end of the movable shaft; the rotary jacking mechanism comprises an outer shaft sleeve, an inner shaft and a forming frame, a pressure spring I is mounted on the forming frame, the outer shaft sleeve is further sleeved with a rolling bearing I, the rollingbearing I is connected with the rotary disc through a bearing seat, a pinion is fixed to the lower end of the outer shaft sleeve and meshed with the fixed large gear, and a jacking wheel is mounted at the bottom of the inner shaft and rolls in a jacking rail all the time; the device is rotary forming equipment, compared with a single machining mode in the prior art, the working efficiency is greatly improved, the design of the device is ingenious, and the forming effect is good.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com