Hand die wax and preparing method and application thereof

A hand mold, wax liquid technology, applied in decorative art, decorative structure and other directions, can solve problems such as high brittleness, and achieve the effect of smooth molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

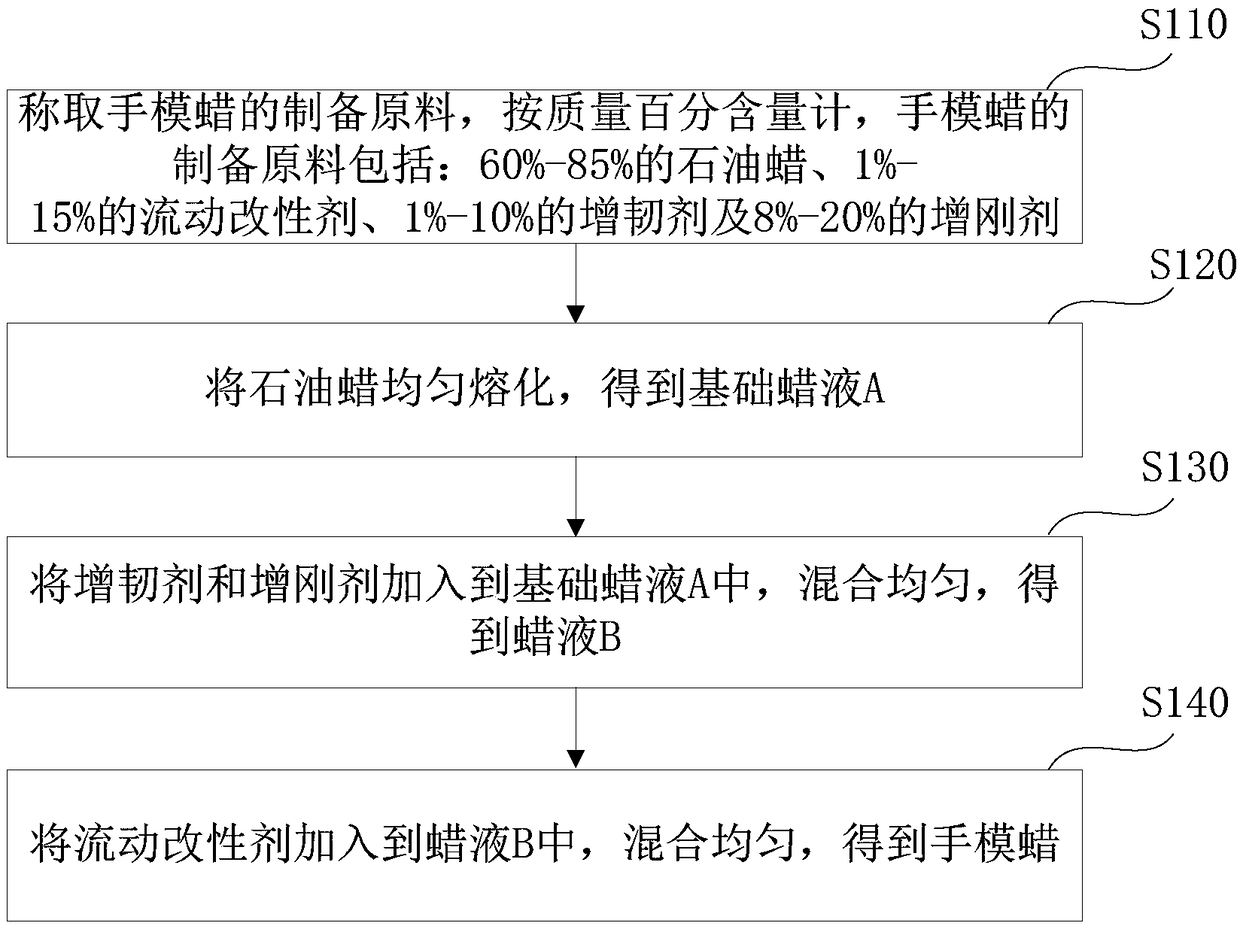

[0038] refer to figure 1 , the preparation method of the hand model wax of one embodiment comprises the steps:

[0039]S110. In terms of mass percentage, weigh the raw materials for the preparation of hand mold wax. The raw materials for the preparation of hand mold wax include: 60% to 85% of petroleum wax, 1% to 15% of flow modifier, 1% to 10% toughening agent and 8% to 20% of the stiffening agent.

[0040] Wherein, the petroleum wax is selected from at least one of fully refined paraffin wax with a melting point lower than 55°C, semi-refined paraffin wax with a melting point lower than 55°C and microcrystalline wax with a melting point lower than 80°C. Specifically, the fully refined paraffin wax with a melting point lower than 55°C is selected from at least one of 52# fully refined paraffin wax and 54# fully refined paraffin wax, and the semi-refined paraffin wax with a melting point lower than 55°C is selected from 52# semi-refined paraffin wax and 54# At least one of se...

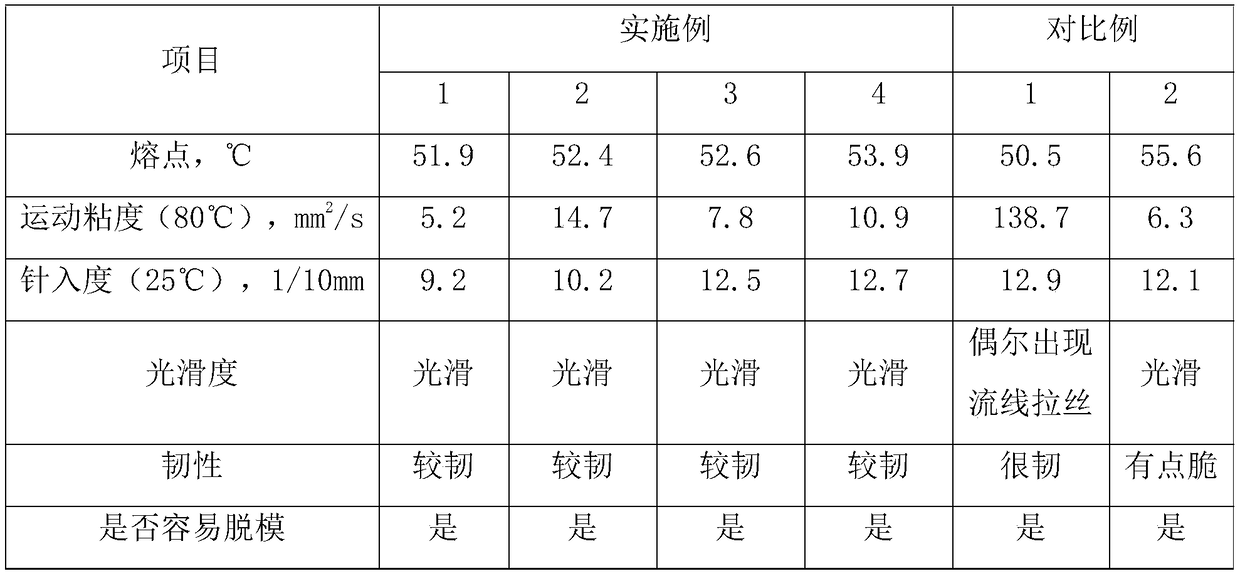

example 1

[0055] (1) In terms of mass percentage, weigh 85% of 52# fully refined paraffin wax, 5.6% of amorphous α-olefin copolymer, 8% of stearic acid, 0.1% of dibutyl hydroxytoluene, 0.1 % of toner and 1.2% of C5 hydrogenated petroleum resin;

[0056] (2) Add 52# fully refined paraffin into the reactor, adjust the working temperature of the reactor to 100° C., so that the 52# fully refined paraffin is evenly melted, and the basic wax liquid A is obtained;

[0057] (3) Add amorphous α-olefin copolymer, stearic acid, dibutyl hydroxytoluene and toner to basic wax solution A, control the temperature at 100°C, and stir at a stirring speed of 450r / min for 1h to obtain Wax solution B;

[0058] (4) Add C5 hydrogenated petroleum resin to the wax solution B, and adjust the kinematic viscosity of the wax solution at 80°C to 5.2mm 2 / s, continue stirring at 100°C for 1 h, and cool to room temperature to obtain hand mold wax.

example 2

[0060] (1) By mass percentage, take 54.7% of 52# fully refined paraffin wax, 5.3% of W445 microcrystalline wax, 9.8% of oligomers, 12.8% of stearic acid, 2.1% of low molecular weight polyphenylene Ethylene, 0.5% tert-butyl hydroquinone, 0.2% toner, 9.8% terpene resin and 4.8% diisononyl phthalate;

[0061] (2) Add 52# fully refined paraffin wax and W445 microcrystalline wax into the reaction kettle, adjust the working temperature of the reaction kettle to 100° C. to melt each wax evenly, and obtain the basic wax liquid A;

[0062] (3) Add oligomers, stearic acid, low-molecular polystyrene, tert-butylhydroquinone and toner to the basic wax solution A, control the temperature at 110°C, and stir at a stirring speed of 550r / min 1h, obtain wax solution B;

[0063] (4) Add terpene resin and diisononyl phthalate to wax liquid B, and adjust the kinematic viscosity of the wax liquid at 80°C to 14.7mm 2 / s (80°C), continue stirring at 110°C for 1h, and cool to obtain hand mold wax.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com