A method and process for controlling the growth of polysilicon ingot

A growth control and polycrystalline ingot casting technology, which is applied in polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problem of low utilization of polycrystalline silicon ingots, affecting the yield of polycrystalline silicon ingots, and easy melting of the seed layer, etc. problem, to achieve the effect of reducing over-melting phenomenon, reducing the thickness of the red zone, and less air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, technical content of the present invention is elaborated:

[0025] 1. Conduct research on the influence of different powers on the height of polysilicon ingot casting and red zone,

[0026] 1.1. Experiment:

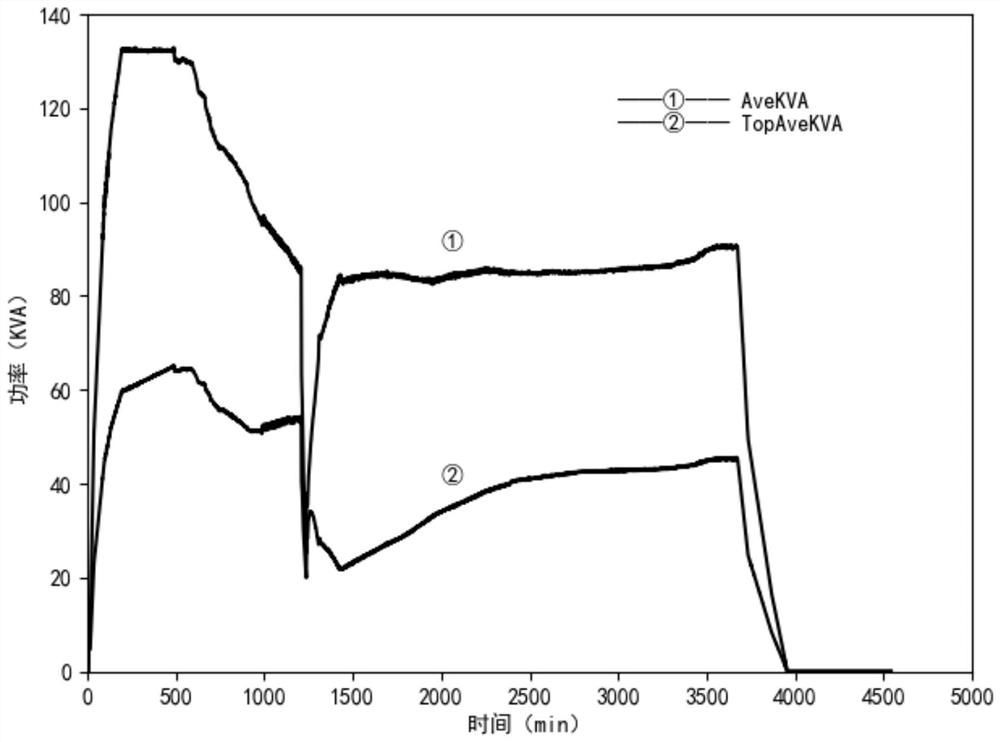

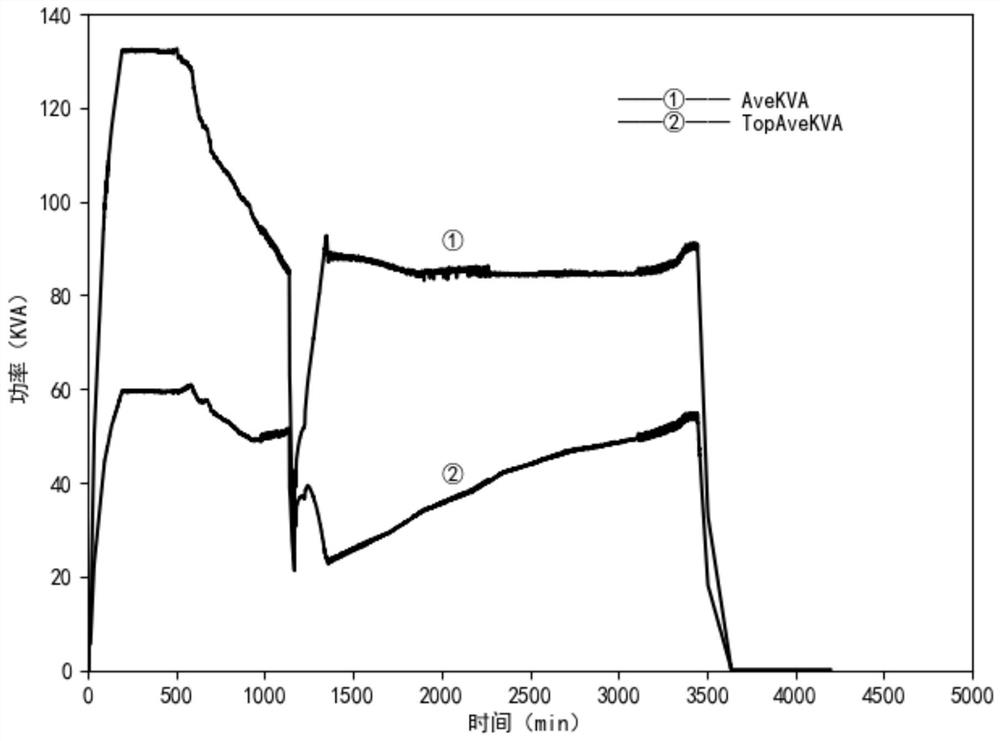

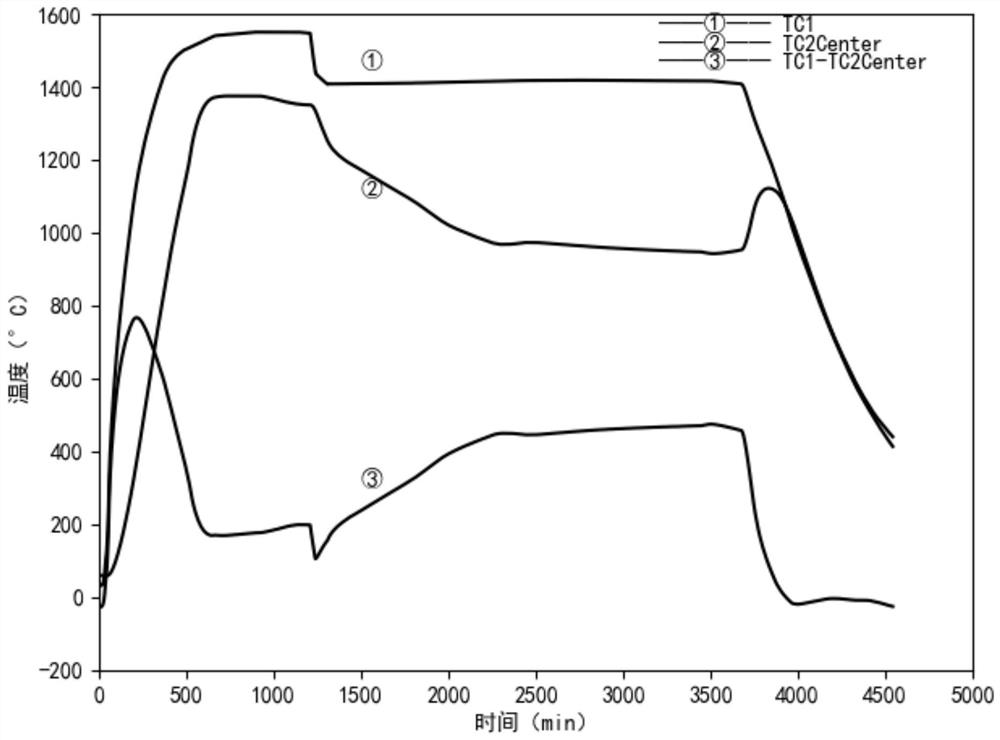

[0027] By using the G6-850 dual-power ingot casting furnace, the experimental equipment uses 850kg, and vacuumizes until the air pressure in the cavity is lower than 0.008mbar; 2) The silicon material is melted, and the heaters on the top and side walls of the dual-power ingot casting furnace are respectively controlled The power is heated for 1213 minutes and 1150 minutes until the silicon material is completely melted; the heating process can be divided into two stages: first, the furnace temperature is raised to 1150°C to remove organic impurities, moisture, etc., and then the furnace temperature is further raised to 1540°C Melting the silicon material, the control of the melting degree of the silicon material, mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com