Buffer material forming process

A molding process and buffer material technology, applied in the direction of machining/deformation, etc., can solve the problems of the workpiece's easy rebound structure strength, lack, molding effect and protection effect can not meet the ideal requirements, and achieve reasonable baking time and temperature, Appropriate extrusion force and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

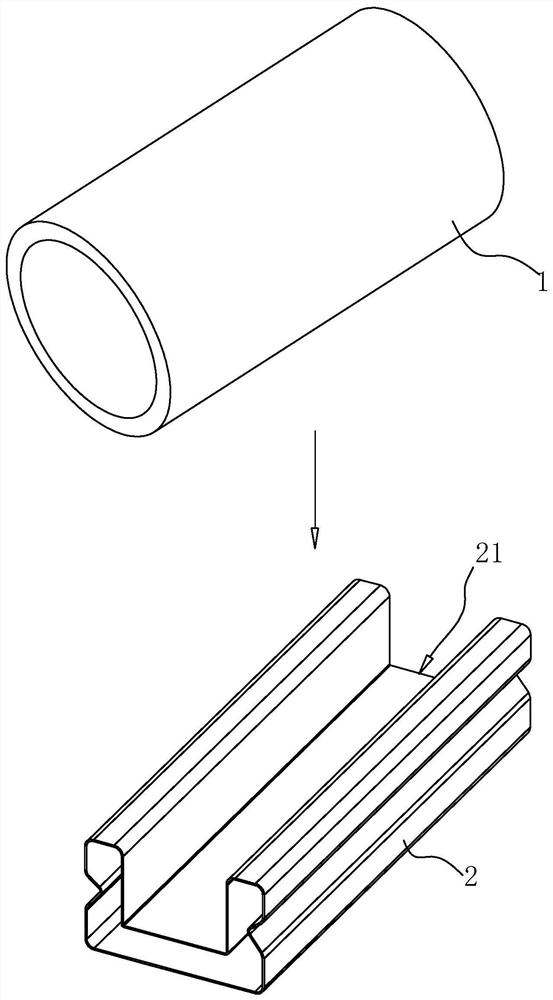

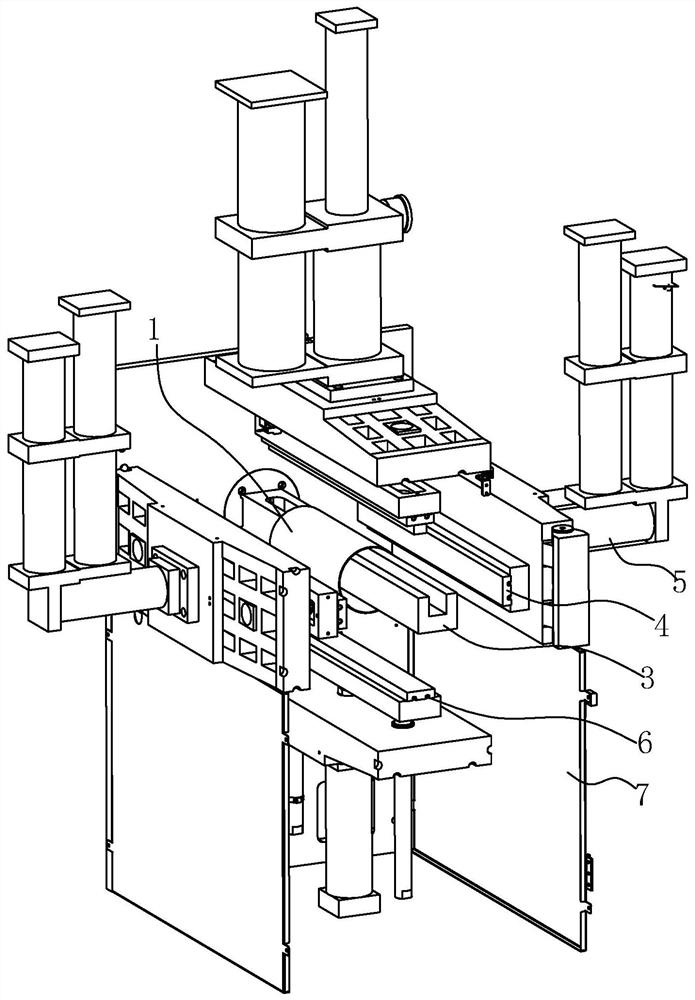

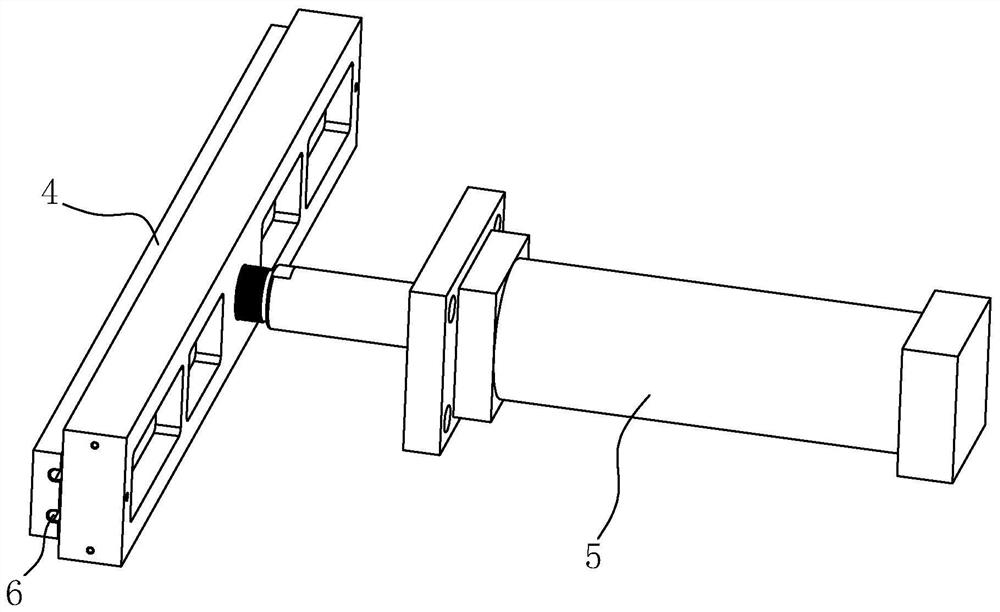

[0044] The embodiment of the present application discloses a buffer material forming process. refer to figure 2, is a kind of molding equipment used in the implementation of this process, including core mold 3, side pressure mold 4, hydraulic cylinder 5, heating rod 6 and frame 7 and other components, wherein, core mold 3 and side pressure mold 4 They are all arranged in the shape of long straight rods. The core mold 3 and the side pressure mold 4 are made of heat-conducting metal materials. For example, in this embodiment, the core mold 3 and the side pressure mold 4 are made of cast iron, and they can also be made of aluminum alloy or Made of copper alloy material. The mandrel 3 is arranged along the horizontal direction, and one end of the mandrel 3 is fixedly installed on the frame 7. The cross section of the mandrel 3 is arranged in a U-shape, which is consistent with the shape of the inner edge of the packaging buffer material 2. The mandrel 3 is used for The paper su...

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 is that the working pressure of the hydraulic cylinder is 2.5 tons, the thickness of the paper tube is 2 mm, the baking temperature is 120 degrees Celsius, and the holding time of the extrusion action is set to 60 s.

[0064] Experiments have shown that if a 24-inch display screen is selected, the buffer packaging material is set to the side of the display screen, and the display screen is dropped from a height of 0.5 meters. After repeated 10 times, the screen display is normal and undamaged, which meets the requirements Requirements.

Embodiment 3

[0066] The difference between this embodiment and Embodiment 1 is that the working pressure of the hydraulic cylinder is 3 tons, the thickness of the paper tube is 3 mm, the baking temperature is 130 degrees Celsius, and the holding time of the extrusion action is set to 70 s.

[0067] Experiments have shown that if a 24-inch display screen is selected, the buffer packaging material is set to the side of the display screen, and the display screen is dropped from a height of 0.5 meters. After repeated 10 times, the screen display is normal and undamaged, which meets the requirements Requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com