A kind of circular seam butt welding method of seamless steel pipe

A seamless steel pipe and butt welding technology, applied in welding equipment, tubular articles, arc welding equipment, etc., can solve the problems of many incomplete penetration defects, poor inner wall formation, cutting and re-welding, etc., to reduce the amount of filler metal, Improve the welding efficiency and the effect of forming flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 The circular seam butt welding method of the steel catenary riser with remote observation and adjustment of the welding torch position and posture by the welder

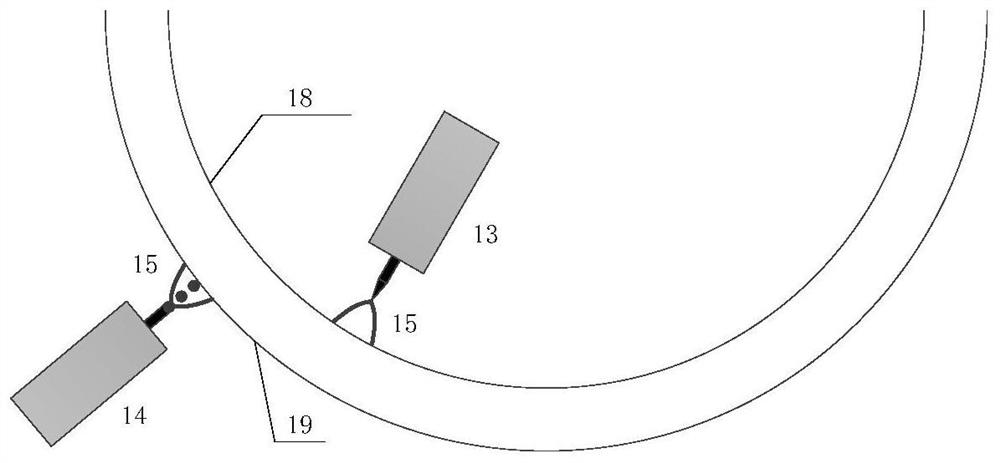

[0028] like Figure 1-2 As shown, a circular seam butt welding method in the construction of steel catenary riser pipe laying for the development of deep sea oil and gas resources, including:

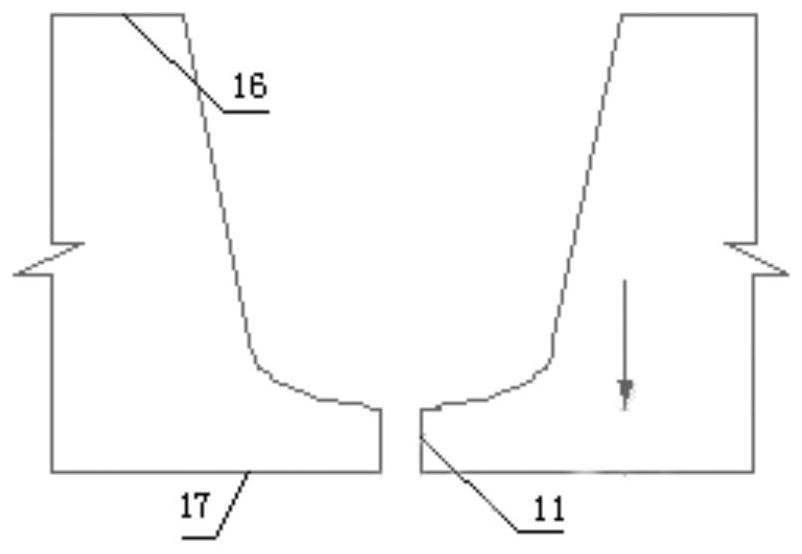

[0029] Groove processing: Groove processing is carried out on the welding joint of the steel catenary riser to be welded, and the groove is processed into such as figure 2 The U-shaped shown; the U-shaped groove is arranged at the corresponding welding place of the pipe end, and the blunt edge thickness 11 of the U-shaped groove is 3mm, and the assembly accuracy when the two pipes are assembled (ie figure 1 The narrow gap between the U-shaped bottom grooves) is controlled within 1.0mm;

[0030] Inner wall self-fluxing bottom welding: the automatic tungsten inert gas shielded welding torch installed on th...

Embodiment 2

[0032] Embodiment 2 The girth butt welding method of a high-strength pipeline that adopts seam tracking + arc voltage tracking to adjust the welding torch position and posture

[0033] Similar to Example 1, the high-strength pipeline girth butt welding is carried out, the difference is that in the step of "self-fluxing welding the inner wall of the groove", the automatic tungsten inert gas shielded welding torch is not real-time according to the results of the welder's remote observation. Instead of adjusting the pose, weld seam tracking and arc voltage tracking are used to adjust the pose in real time, that is, to use industrial cameras or line structured light to visually track the shape of the inner wall of the groove, and at the same time use the arc pressure sensor to monitor the automatic tungsten inert gas Protect the height of the welding torch from the inner wall of the groove. When the narrow gap of the U-shaped groove and the size change of the wrong side are detecte...

Embodiment 3

[0034] Embodiment 3 The circular seam butt welding method of the tension leg of the inner and outer walls of the groove welded in steps

[0035] Similar to Example 1, the circular seam butt welding in tension leg construction is carried out for the development of deep-sea oil and gas resources, the difference is that the "inner wall self-fluxing bottom welding" and the "outer wall groove welding" are not performed simultaneously. Filling welding" step, but after the "groove inner wall self-fluxing root welding" is all completed, then the "outer wall groove filling welding" step is carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com