Method for producing magnetic multilayer film

A manufacturing method and multilayer film technology, applied in the direction of magnetic thin film, application of magnetic film to substrate, manufacture/processing of electromagnetic devices, etc., can solve problems such as hindering the function of magnetic multilayer film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described below in conjunction with the accompanying drawings. In addition, in each drawing used for explanation below, in order to make the size of each component recognizable, the scaling ratio of each component is appropriately changed.

[0048] (Magnetic multilayer film)

[0049] First, a tunnel junction element including a TMR film, which is an example of a multilayer film including a magnetic layer, and an MRAM including the tunnel junction element will be described.

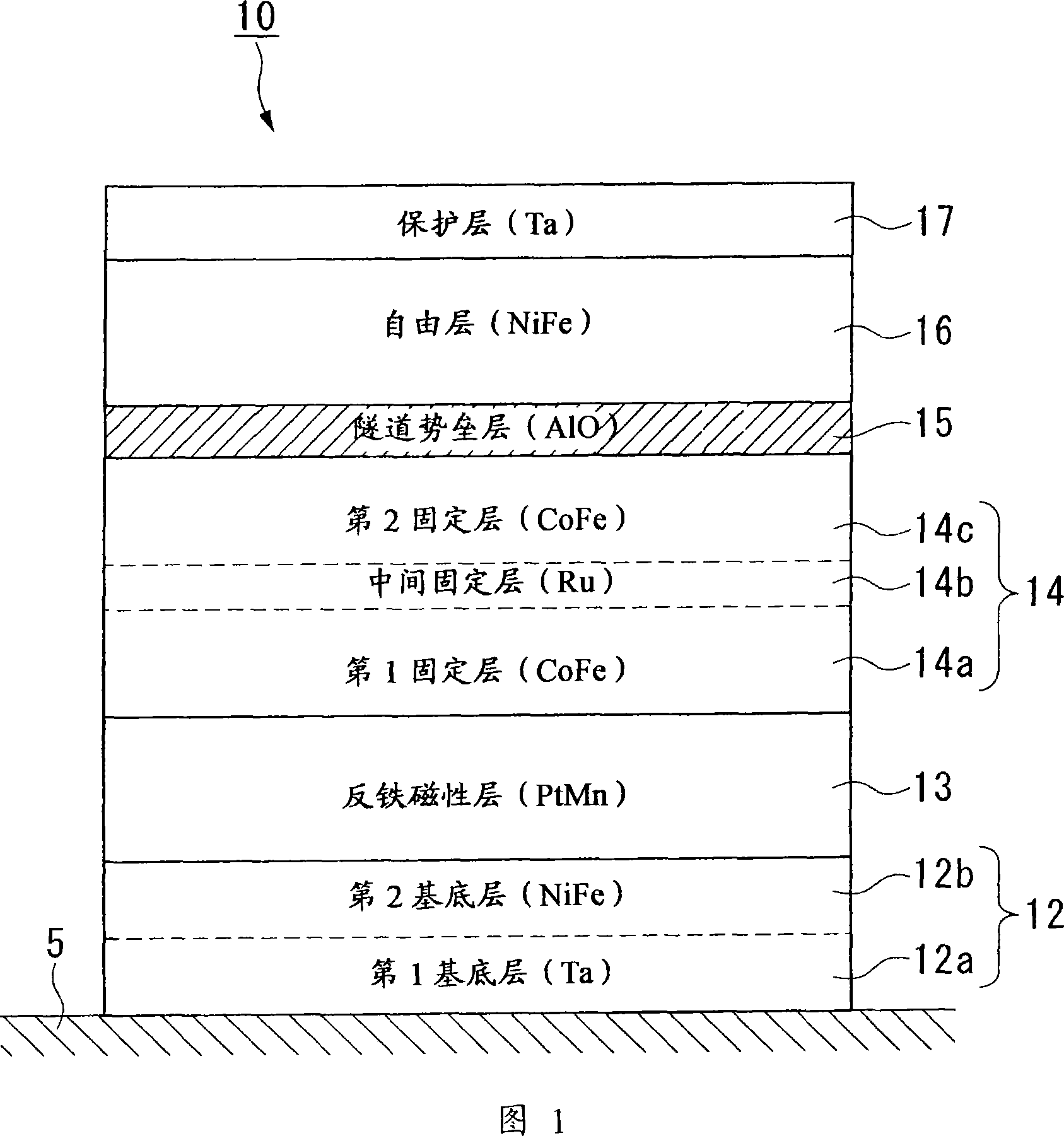

[0050] Figure 1 is a side sectional view of a tunnel engaging element. In the tunnel junction element 10 , an underlayer 12 is formed on the surface of the substrate 5 . The base layer 12 includes a first base layer 12a composed of Ta or the like and a second base layer 12b composed of NiFe or the like. An antiferromagnetic layer 13 composed of PtMn, IrMn, or the like is formed on the surface of the base layer 12 . The second base layer 12 b has a fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com