Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Fast on-site installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Connecting method of steel beam and existing reinforced concrete column

InactiveCN102966245AEasy to get materialsReduce wet work loadBuilding repairsReinforced concrete columnEngineering

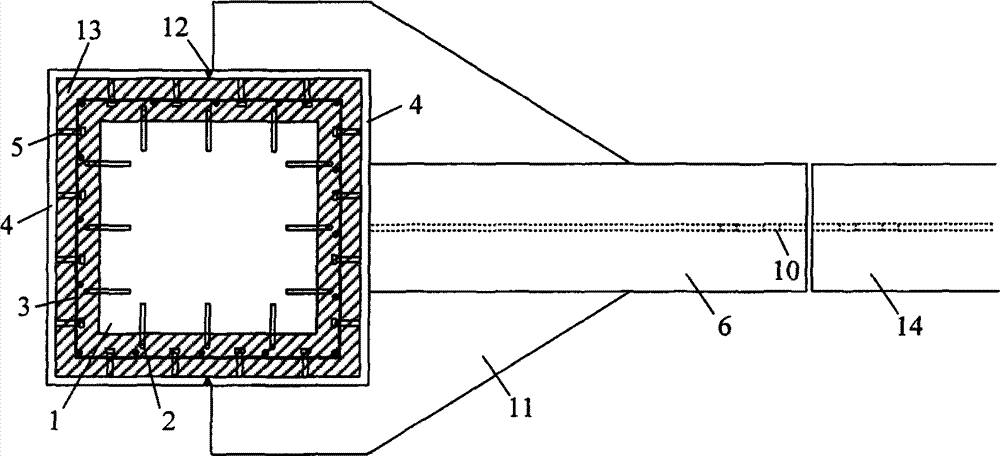

The invention relates to a connecting method of a steel beam and an existing reinforced concrete column, which can be used for reinforced modification of an existing reinforced concrete structure, and belongs to the technical field of structural engineering. The method comprises the steps of: scabbling, planting bars and binding reinforced mesh pieces on the surface around with a node connection domain of the original reinforced concrete column; processing two pieces of channel steel and welding a stud connection piece inside; extending an extending bracket and external reinforcing plate on the channel steel connected to the steel beam; buckling the two pieces of channel steel and wrapping the original reinforced concrete column; welding in an abut manner; pouring node area concrete; and finally connecting the steel beam. The method overcomes the deficiencies of the conventional connection method, is simple in structure, quick and convenient to construct, good in stress performance of the connecting node, reliable in force transfer, and can efficiently prevent a node core area from cracking and being exposed. The core area concrete is wrapped by a steel plate so that the concrete is strongly constrained, and the quake-proof ductility of the node is good. The method has high practicality and wide application prospect.

Owner:TSINGHUA UNIV

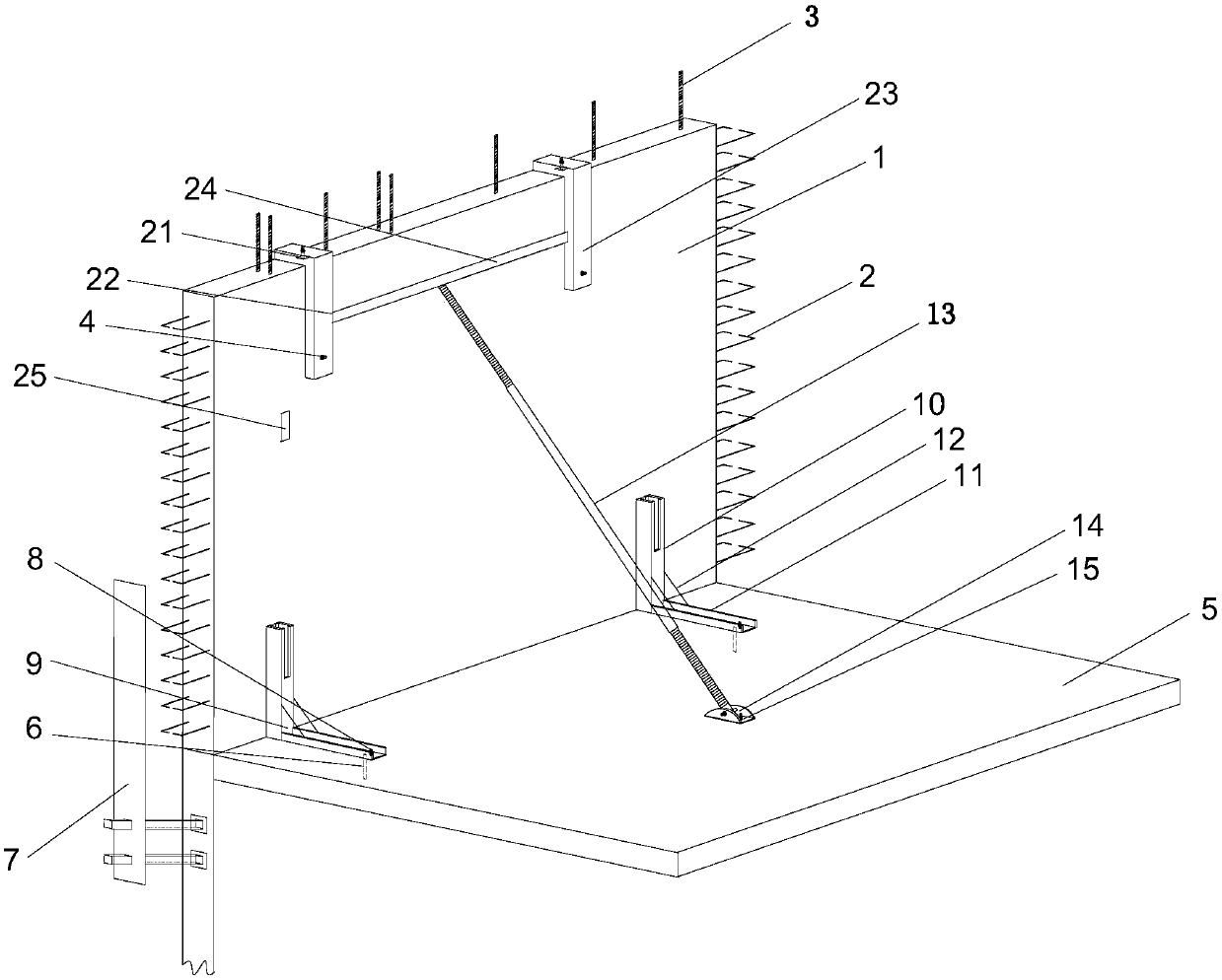

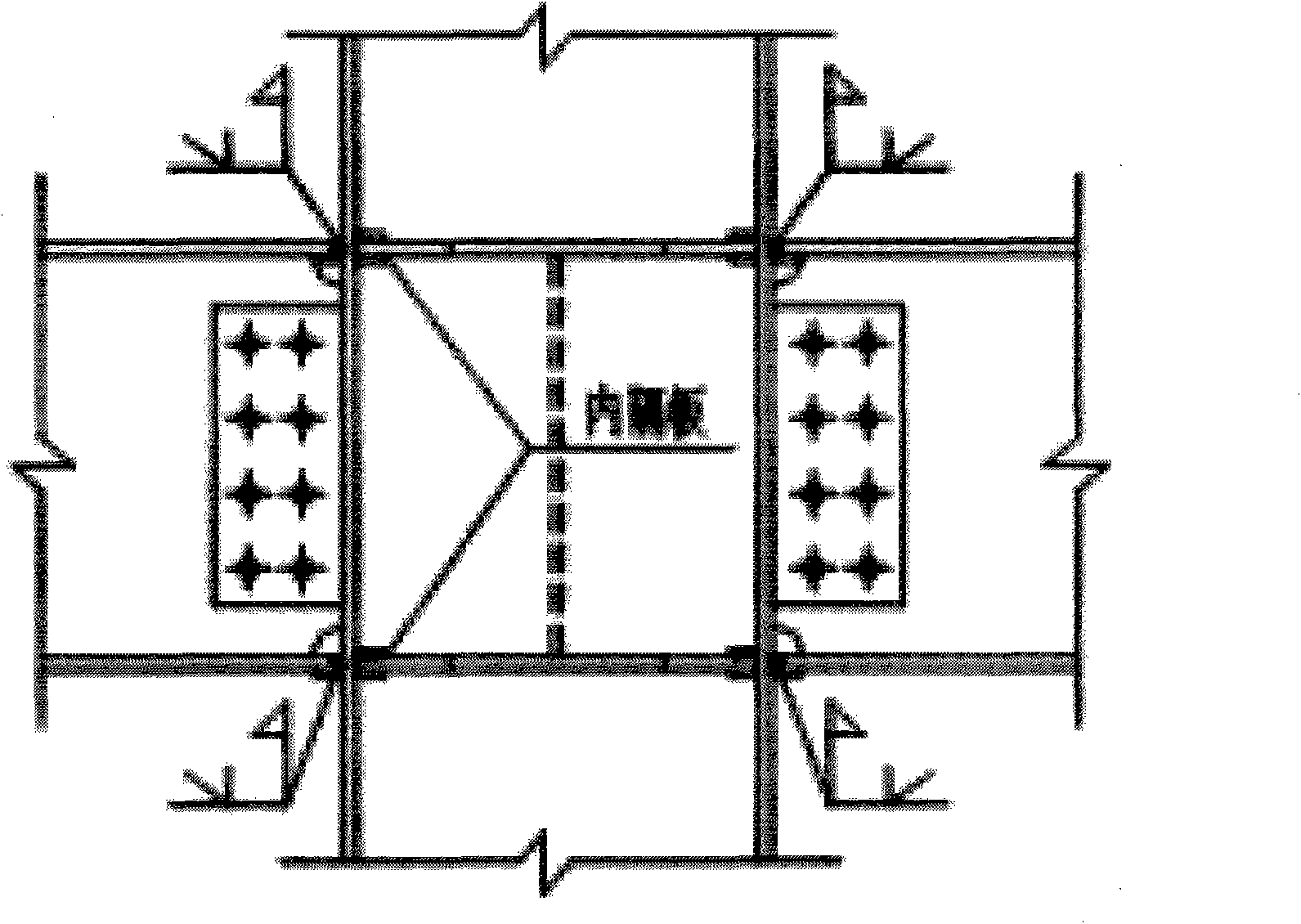

Assembled shear wall structure and construction method thereof

ActiveCN109577517AImprove positioning and installation speedPrecise positioningWallsAuxillary members of forms/shuttering/falseworksFloor slabEngineering

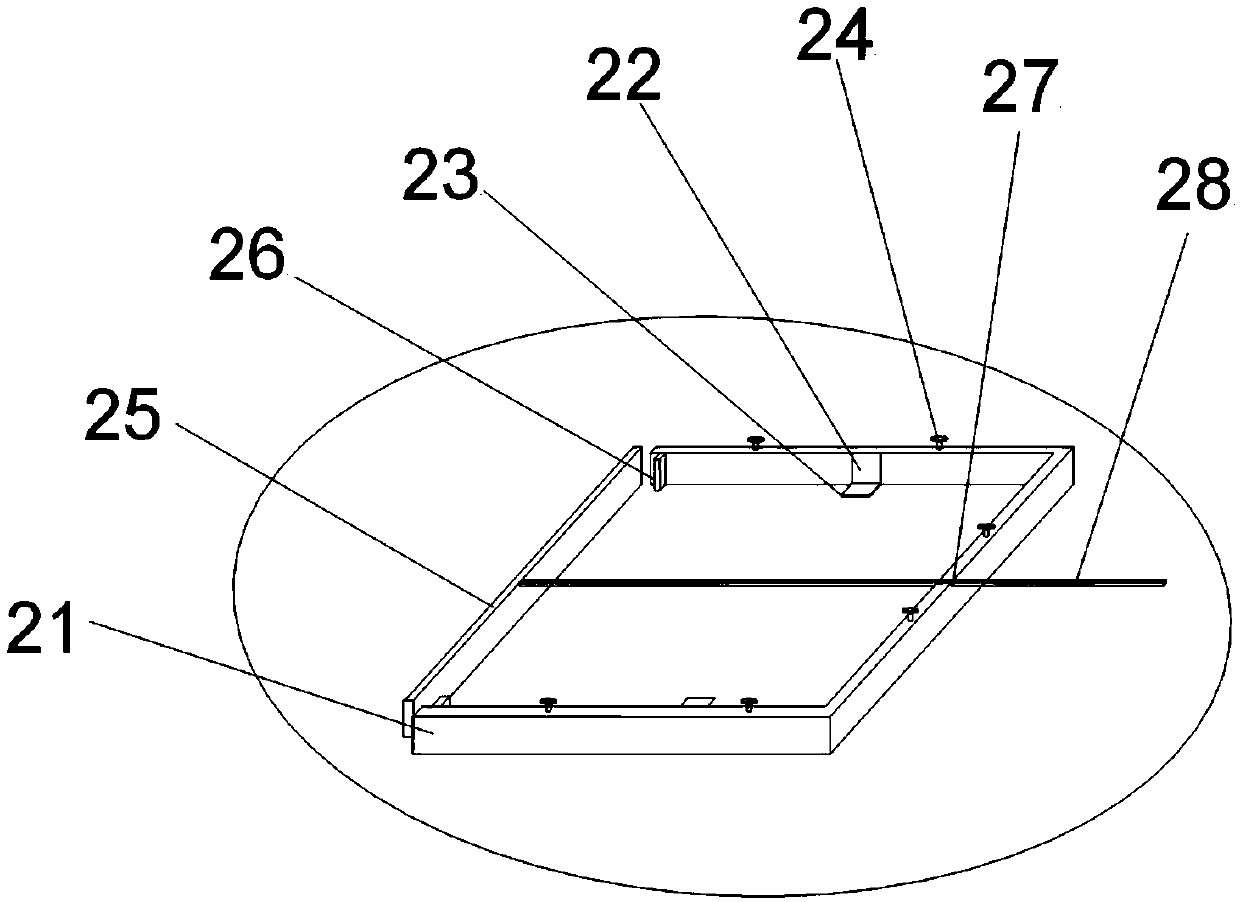

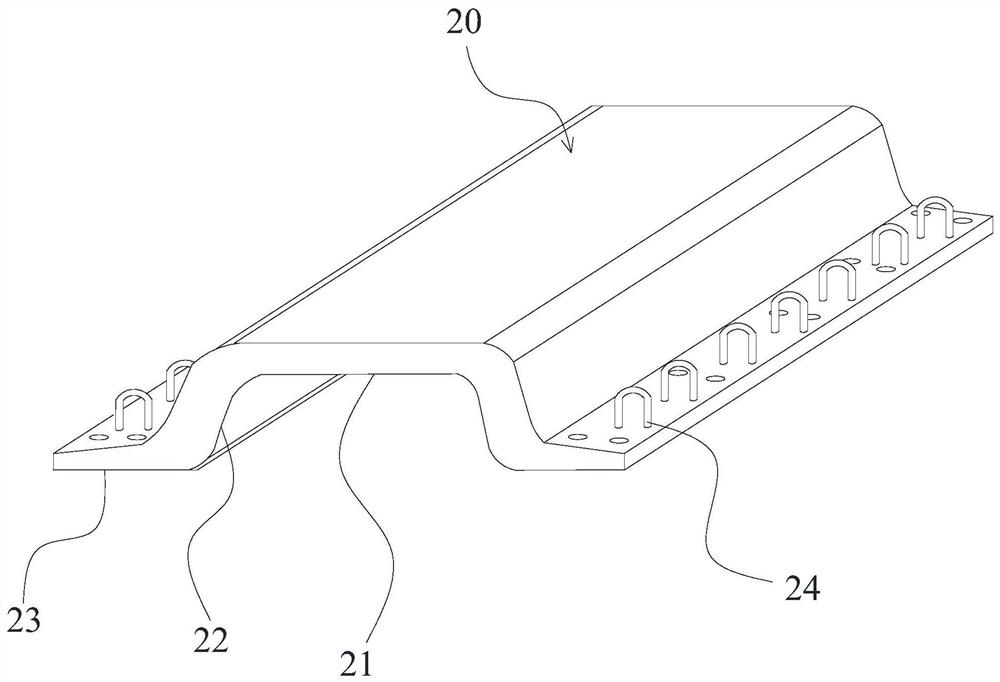

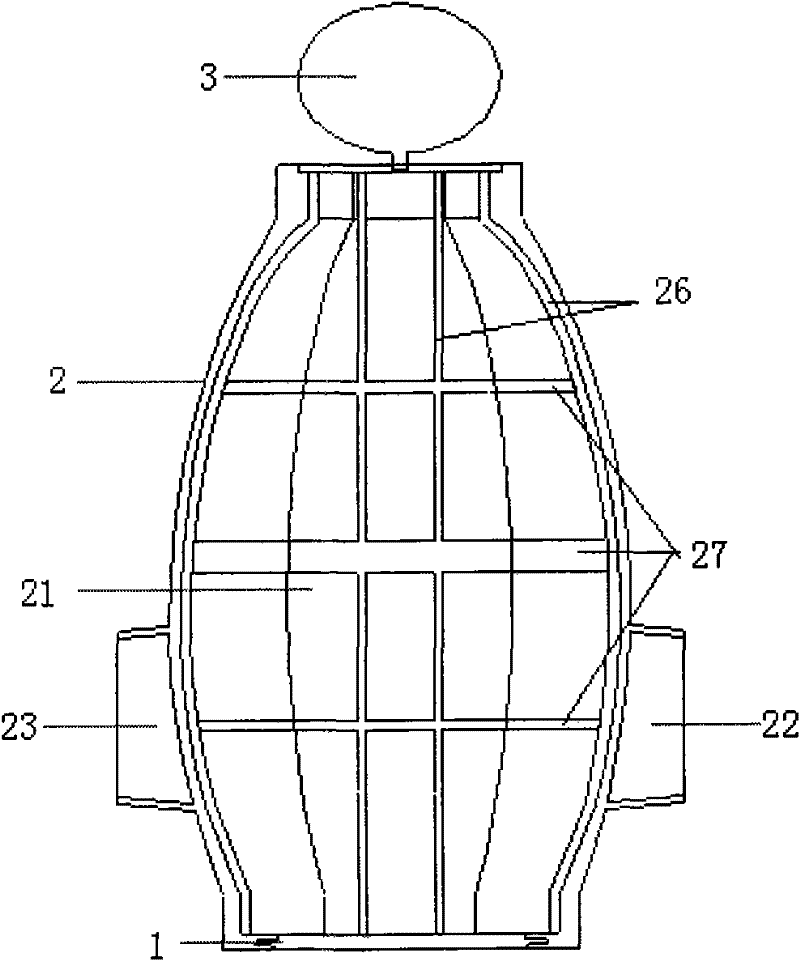

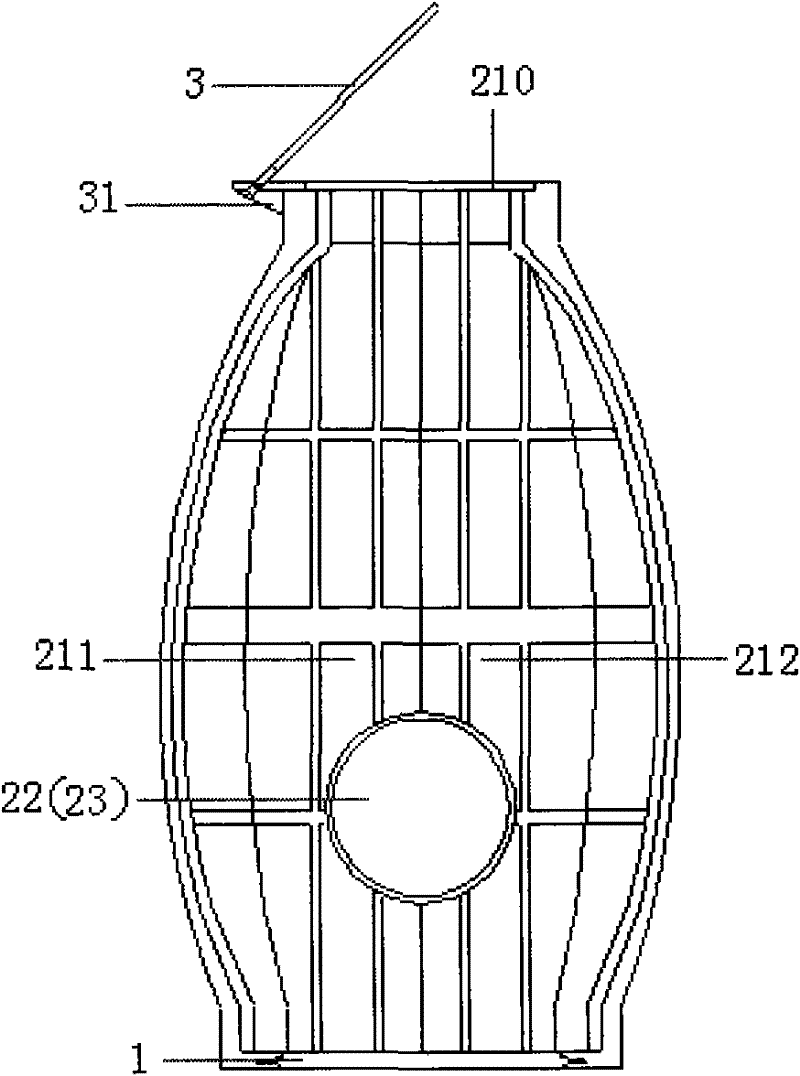

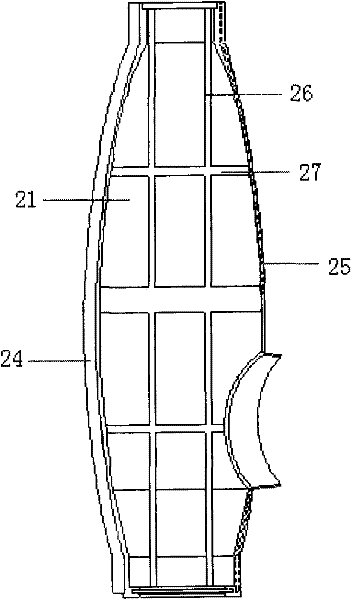

The invention relates to an assembled shear wall structure, which comprises an assembled shear wall, lateral reserved U-shaped ribs, vertical reserved connecting ribs, a floor slab, integral inner quick positioning pieces, a verticality adjusting rod, an adjusting rod base seat, frame brackets, a suspended steel bar shelving slat, an upper covering plate, an upper prefabricated wall body, a lowercast-in-situ wall body, a steel bar positioning steel plate, a prefabricated floating window and an integral adjusting and bearing support seat, wherein the lateral reserved U-shaped ribs are arrangedon the side surface of the assembled shear wall; the vertical reserved connecting ribs are arranged at the top of the assembled shear wall; the floor slab is arranged at the lower part of the assembled shear wall; and the assembled shear wall is connected with the mounted wall through a detachable shaped outer guiding frame plate for temporary guide assembly. The structure has the advantages thatby arranging the temporary guiding frame plate and connecting the integral inner quick positioning pieces, the shear force is guided to be quickly positioned and mounted, the positioning is accurate,the accuracy is guaranteed, the positioning and mounting speed of the shear wall is improved, the whole is more stable, and the quality safety is guaranteed.

Owner:中建八局华南建设有限公司

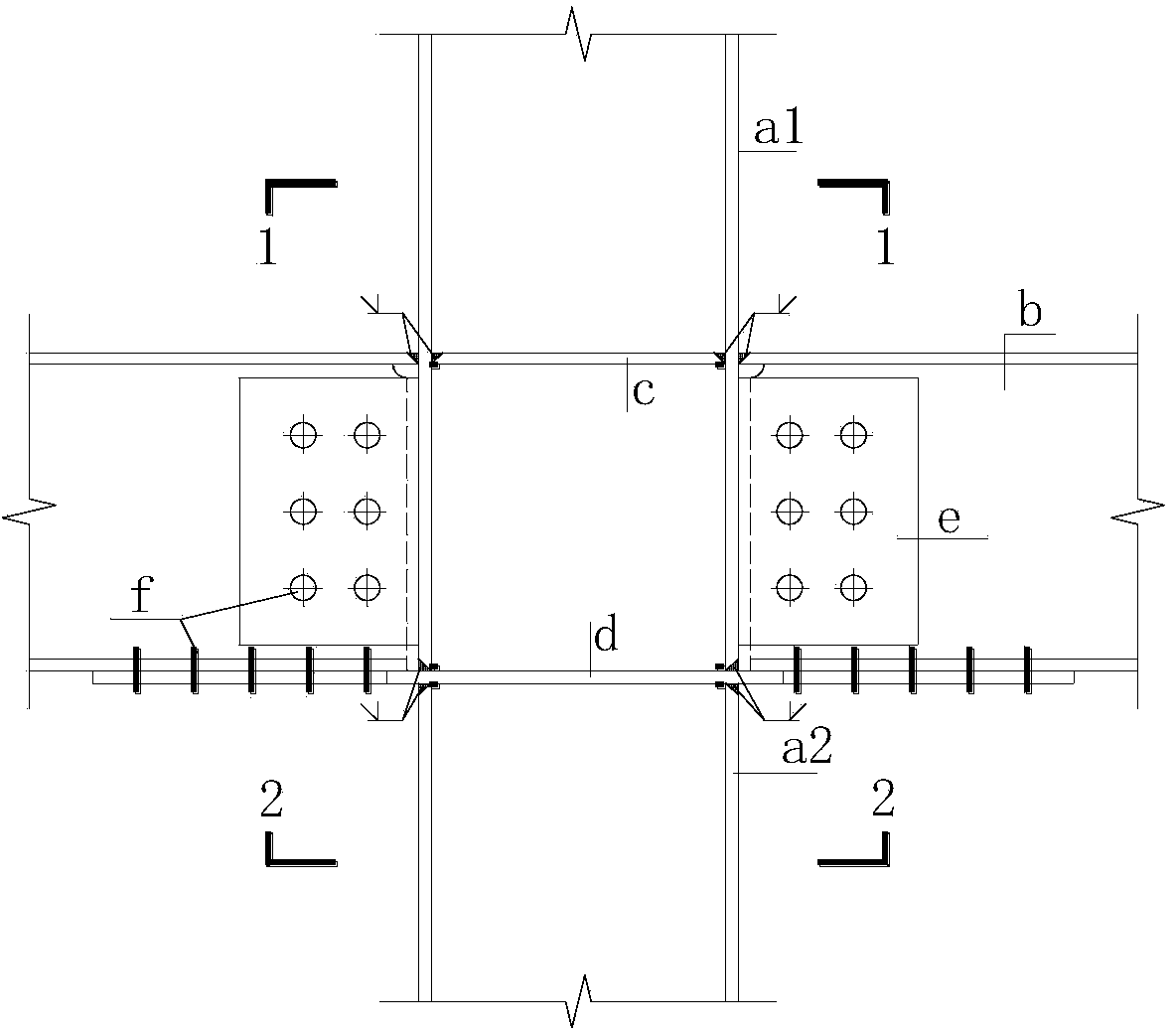

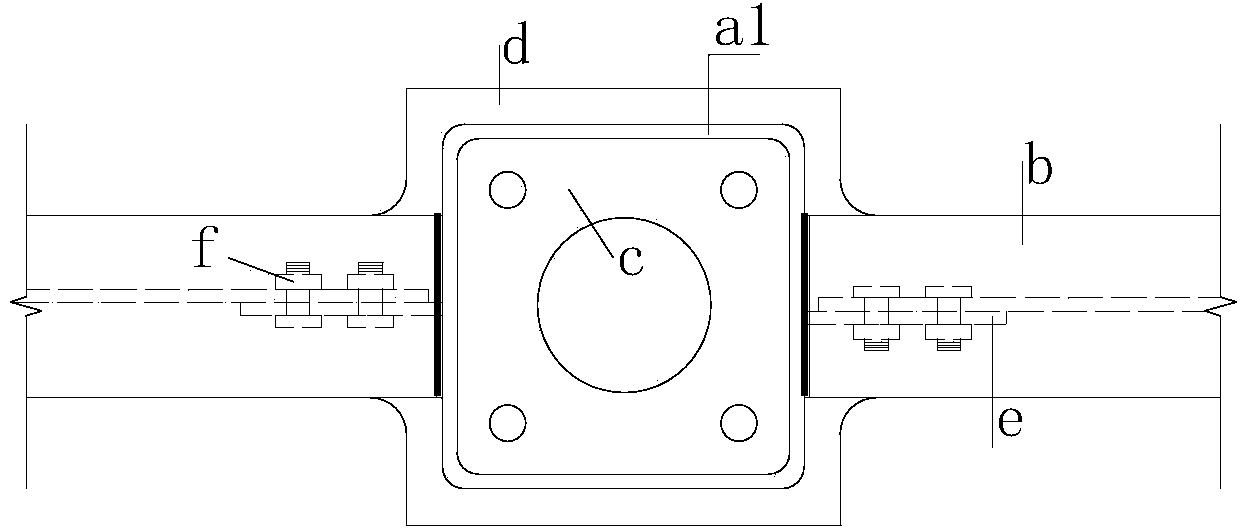

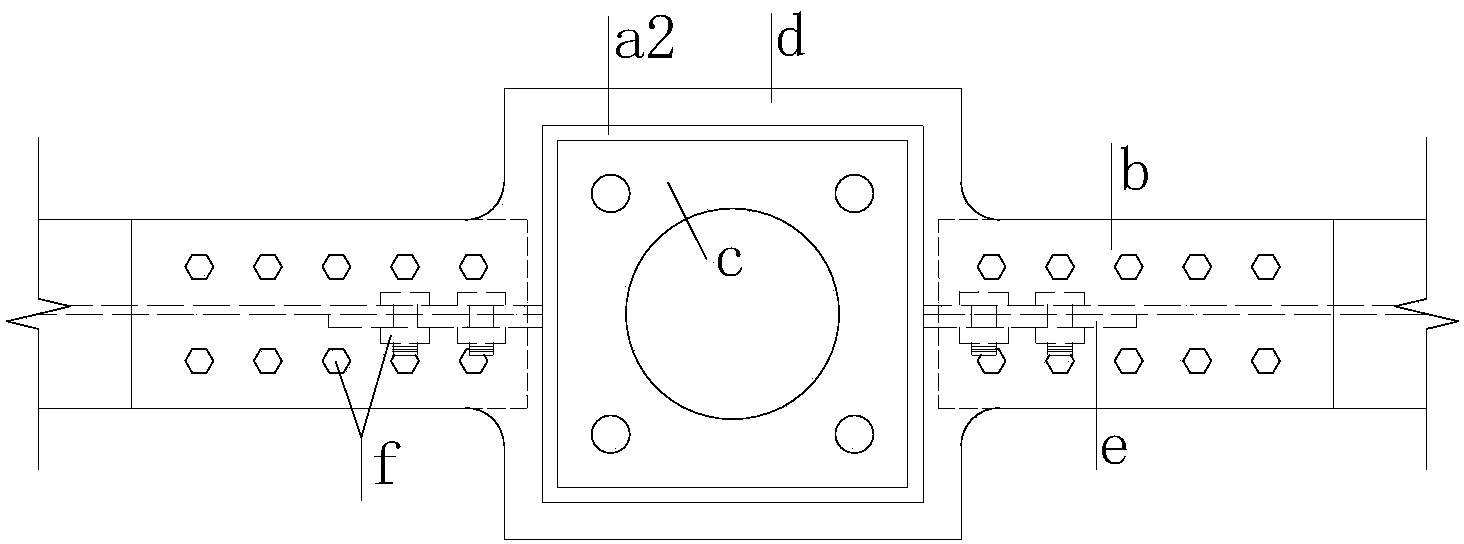

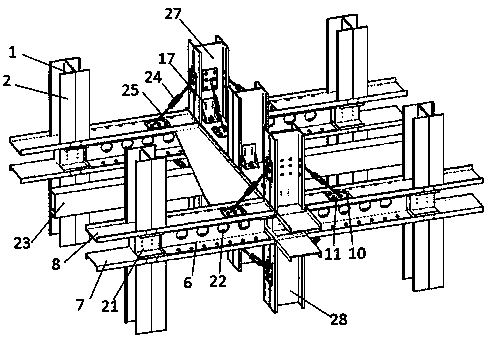

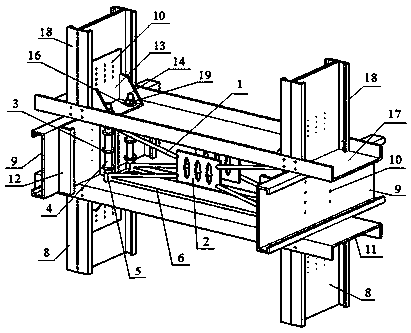

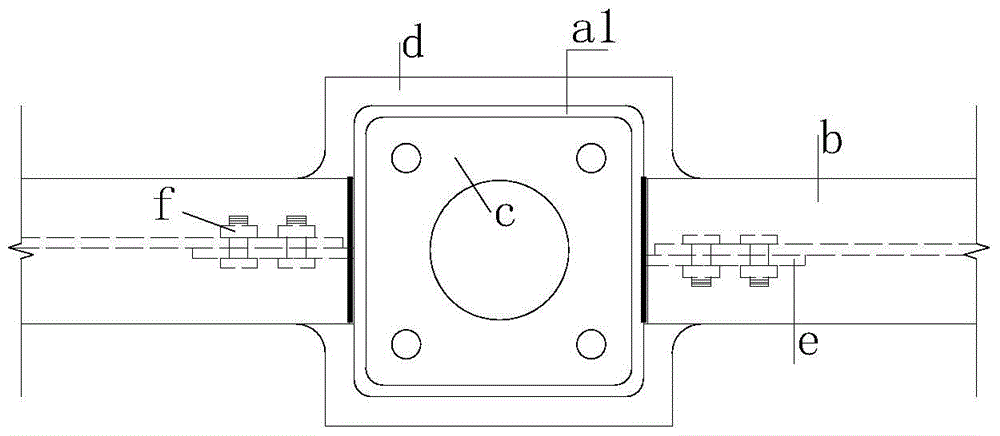

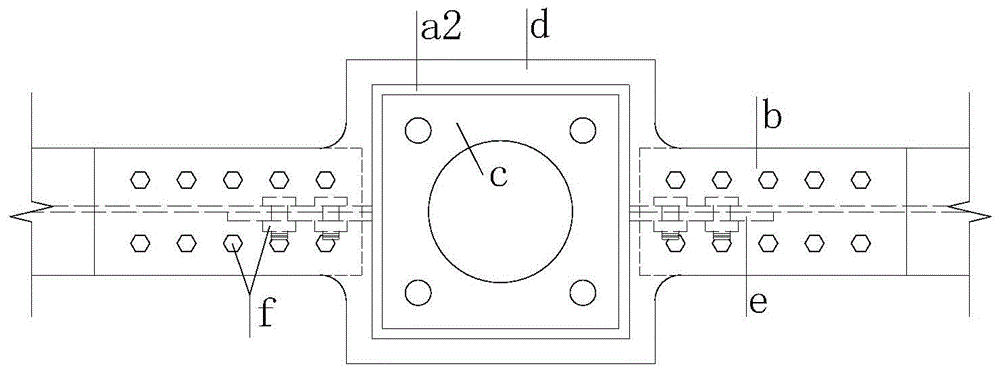

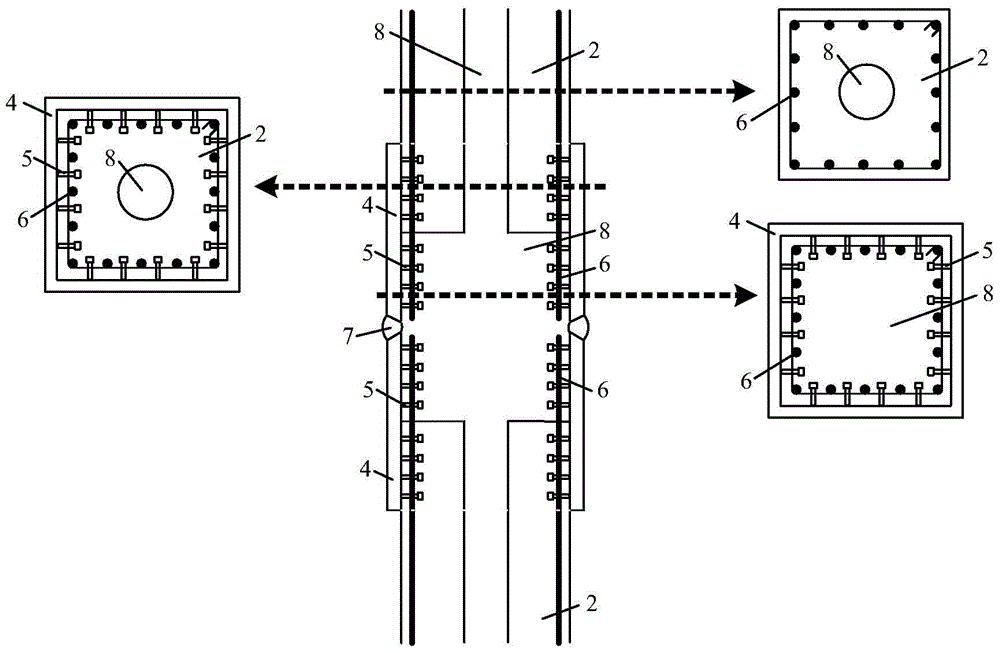

Stud welding mixed connection node of rectangular concrete filled steel tubular column and H-shaped steel girder

InactiveCN103967133AAddress stressImprove prefabrication rateBuilding constructionsArchitectural engineeringEngineering

The invention discloses a stud welding mixed connection node of a rectangular concrete filled steel tubular column and an H-shaped steel girder. The H-shaped steel girder comprises an upper flange, a web and a lower flange, wherein the upper flange, the web and the lower flange are formed together. The rectangular concrete filled steel tubular column comprises an upper steel tube and a lower steel tube which are vertically arranged adjacently. The node comprises an inner separating board welded to the bottom in the upper steel tube, a through separating board welded to the bottom end of the upper steel tube and a vertical connecting board welded to the side of the bottom of the upper steel tube. The top end of the lower steel tube is welded to the lower surface of the through separating board. The upper flange is opposite to the inner separating board and welded to the upper steel tube. The web is connected with the vertical connecting board through high strength bolts. The lower flange is fixedly connected with the through separating board. According to the node, stud welding mixed connection is adopted, the node can be fast installed in the position in a field, a construction period can be obviously shortened, and the assembly process is facilitated. Meanwhile, due to the arrangement of the through separating board, a girder-end plastic hinge is moved outwards, the steel girder is damaged before the node, and safety of the node is guaranteed.

Owner:TIANJIN UNIV

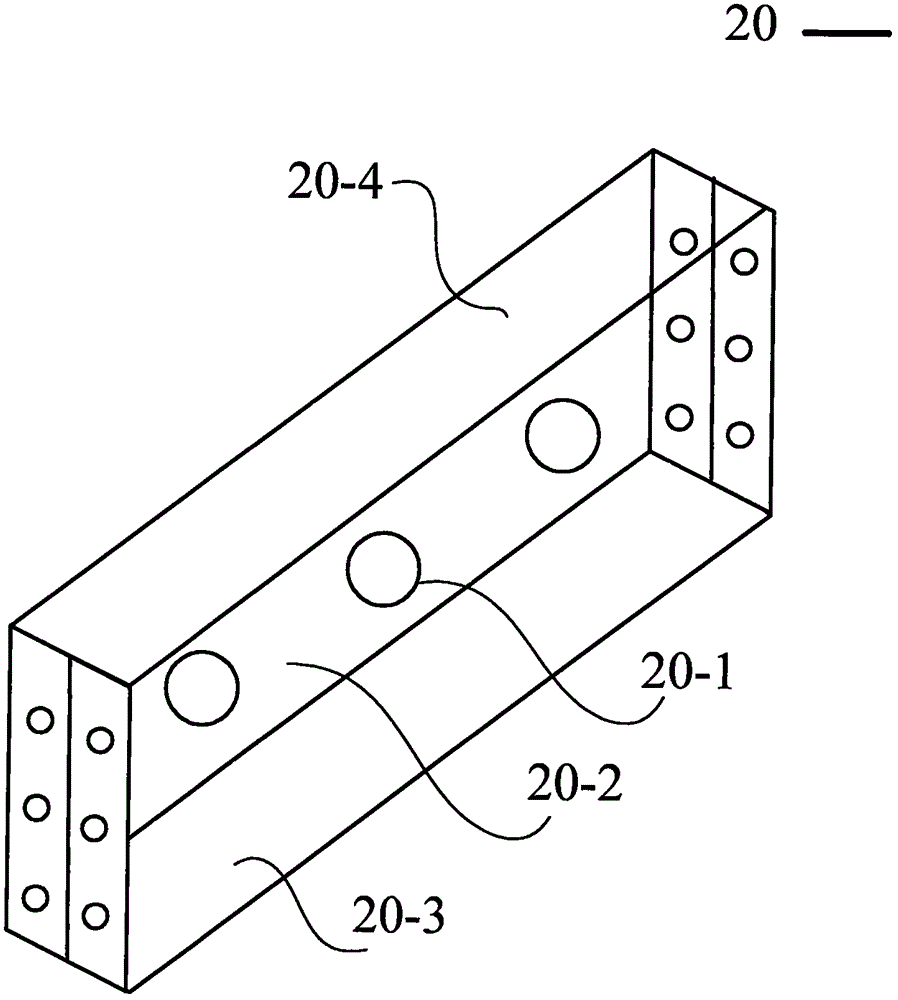

Rectangular pipe column and H-shaped steel beam vertical externally-connected rigidly-connected joint

InactiveCN101949173AThe force is clear and reasonableIncrease stiffnessBuilding constructionsArchitectural engineeringShock resistance

The invention discloses a rectangular pipe column and H-shaped steel beam vertical externally-connected rigidly-connected joint aiming to solve the problems of complex manufacturing process, long construction period, and the like in the prior art. The rectangular pipe column and H-shaped steel beam vertical externally-connected rigidly-connected joint comprises a rectangular pipe column and an H-shaped steel beam, wherein a corbel box-shaped corbel connecting member is arranged between the rectangular pipe column and the H-shaped steel beam; the box-shaped corbel connecting member comprises an upper end plate, a lower end plate and a vertical plate, wherein the vertical plate is arranged between the upper end plate and the lower end plate, one sides of the upper end plate and the lower end plate are arranged on the side surface of the rectangular pipe column, and one sides opposite to the sides and the vertical plate are respectively connected with a top flange, a bottom flange and a ventral shield of the H-shaped steel beam. The invention has the advantages of completing the internal force transmission of the joint by the arrangement of the box-shaped corbel connecting piece, preventing the stress of a welding line from centralizing, enhancing the shock resistance and the bending resistance of the joint, realizing batch production, enhancing processing efficiency, simplifyingthe process, enhancing welding quality, reducing construction difficulty and being convenient for transportation and building space arrangement, solving the problem of difficult welding of a partition board in the rectangular pipe column, achieving the combination of industrialized flow line production and field fast assembly and splicing and shortening the building construction period.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

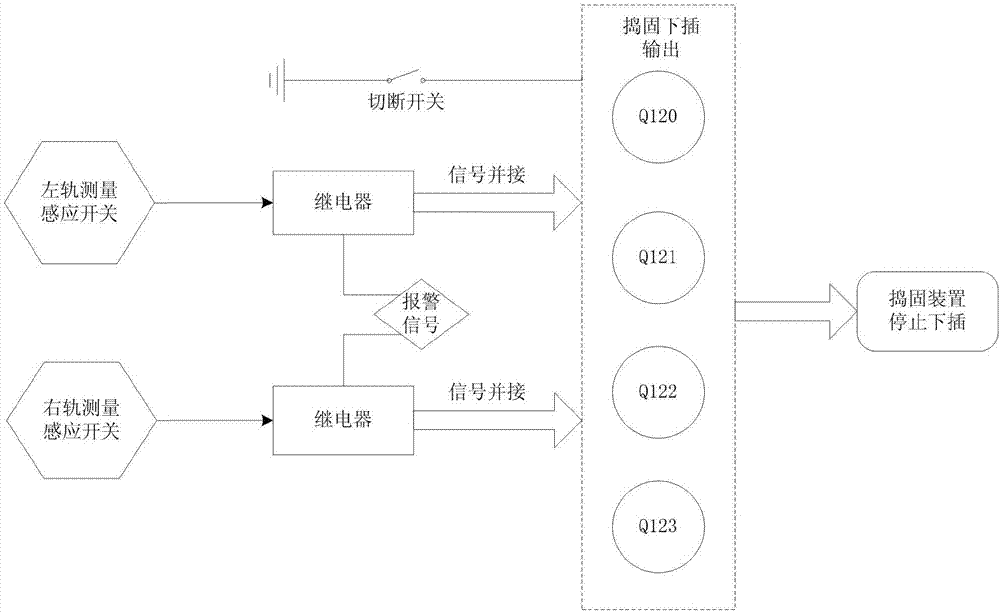

Operation protection control system for tamping wagon

ActiveCN107153394AHigh degree of automationEffective protectionProgramme controlComputer controlControl systemControl valves

The invention discloses an operation protection control system for tamping wagon. The operation protection control system comprises a lower motherboard and a program-controlled motherboard, wherein the lower motherboard is used for acquiring a track lifting operation analog quantity and a track lining operation analog quantity, and converting the analog quantities into digital quantities; the lower motherboard is used for calculating a total track lifting quantity according to the track lifting operation digital quantity, calculating a total track lining quantity according to the track lining operation digital quantity, judging whether an operation blocking condition is satisfied or not according to the total track lifting quantity and the total track lining quantity, and transmitting a judgement result to the program-controlled motherboard; when the program-controlled motherboard receives an operation blocking signal, a program-controlled logical signal of a corresponding operation action is eliminated, and an electric signal of a corresponding operation control valve is cut off. By adopting the operation protection control system, the technical problems of severe accidents such as over track lifting, over track lining, even circuit damage and smashing of steel tracks since a conventional tamping wagon cannot implement self-protection during operation and an operation mechanism does not stop running in an emergency can be solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

Roof parapet and construction method thereof

The invention provides a roof parapet. The roof parapet comprises a parapet turnup, a concrete wall and an outer edge sealing plate. The parapet turnup is casted on the edge of a floor layer. The concrete wall is casted on the parapet turnup. The outer edge sealing plate is vertically connected to the floor layer. A steel bar truss is arranged in the concrete wall, and is connected with the outeredge sealing plate fixedly. The bottom of the steel bar truss is anchored into the parapet turnup. The roof parapet has the advantages that the prefabricated steel bar truss serves as a framework forbearing the horizontal force and formworks of the parapet during construction, and accordingly, on-site mounting speed is high; scaffolds do not need to be erected during construction of the parapet,so that cost is saved, and construction process is simple; workers do not need to operate form the outer side of a building, and accordingly, safety construction is guaranteed.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

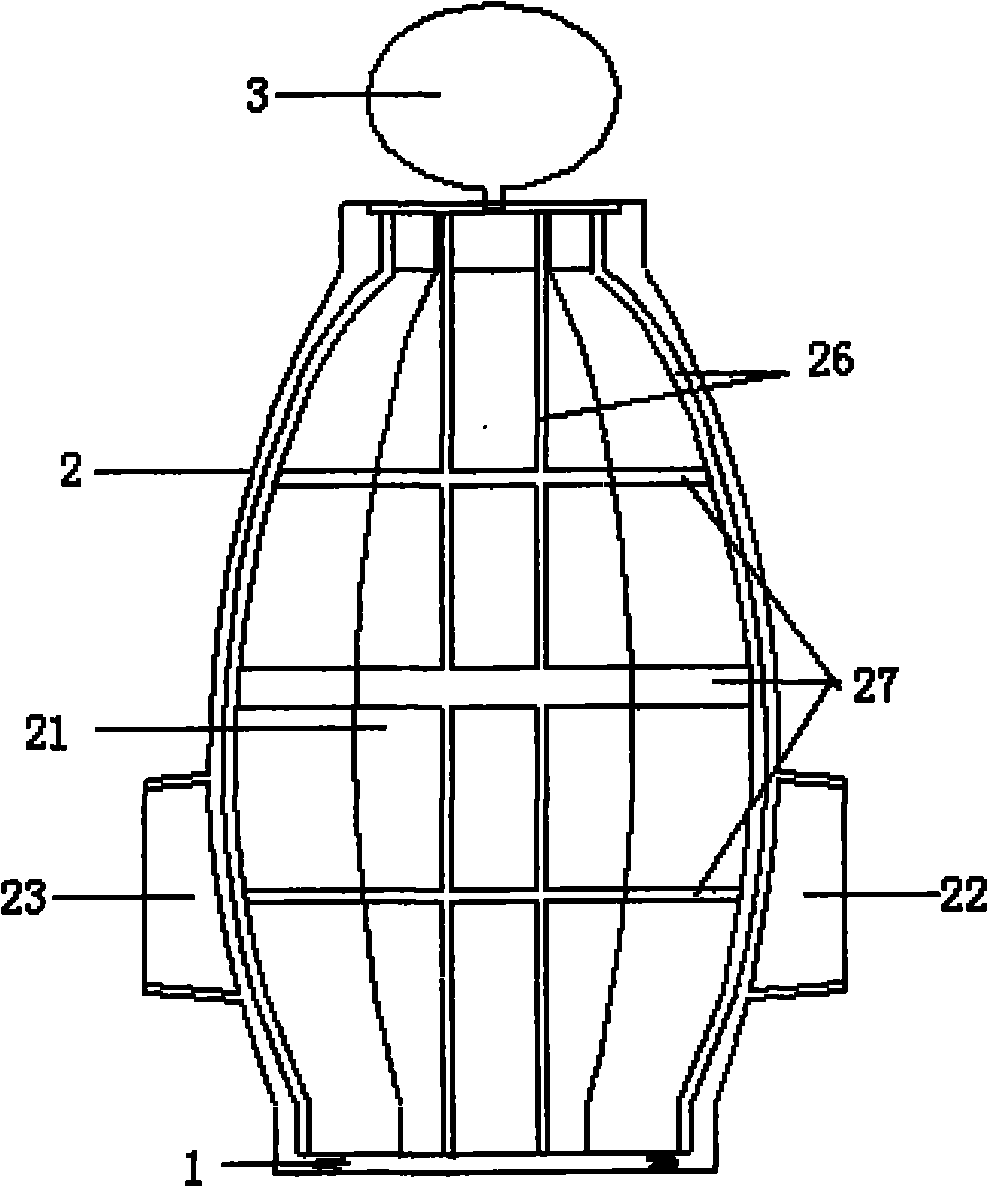

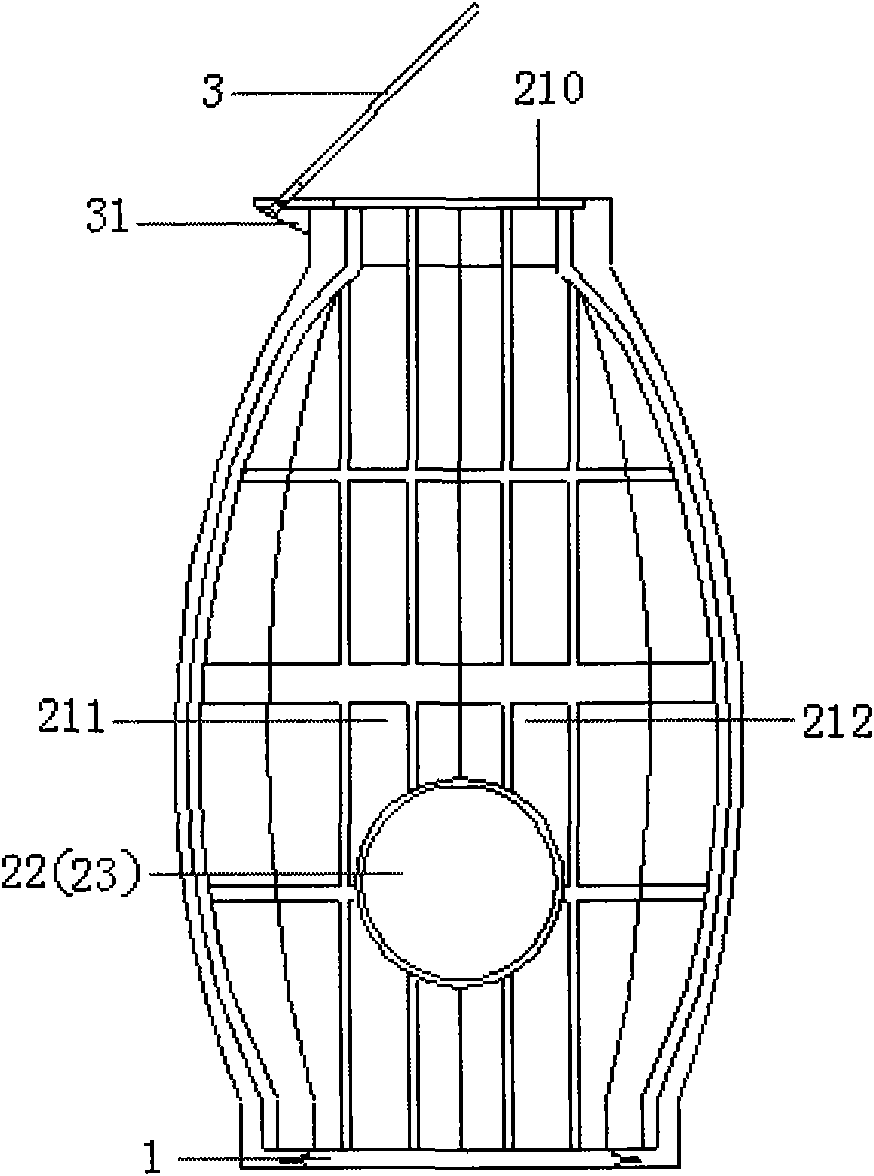

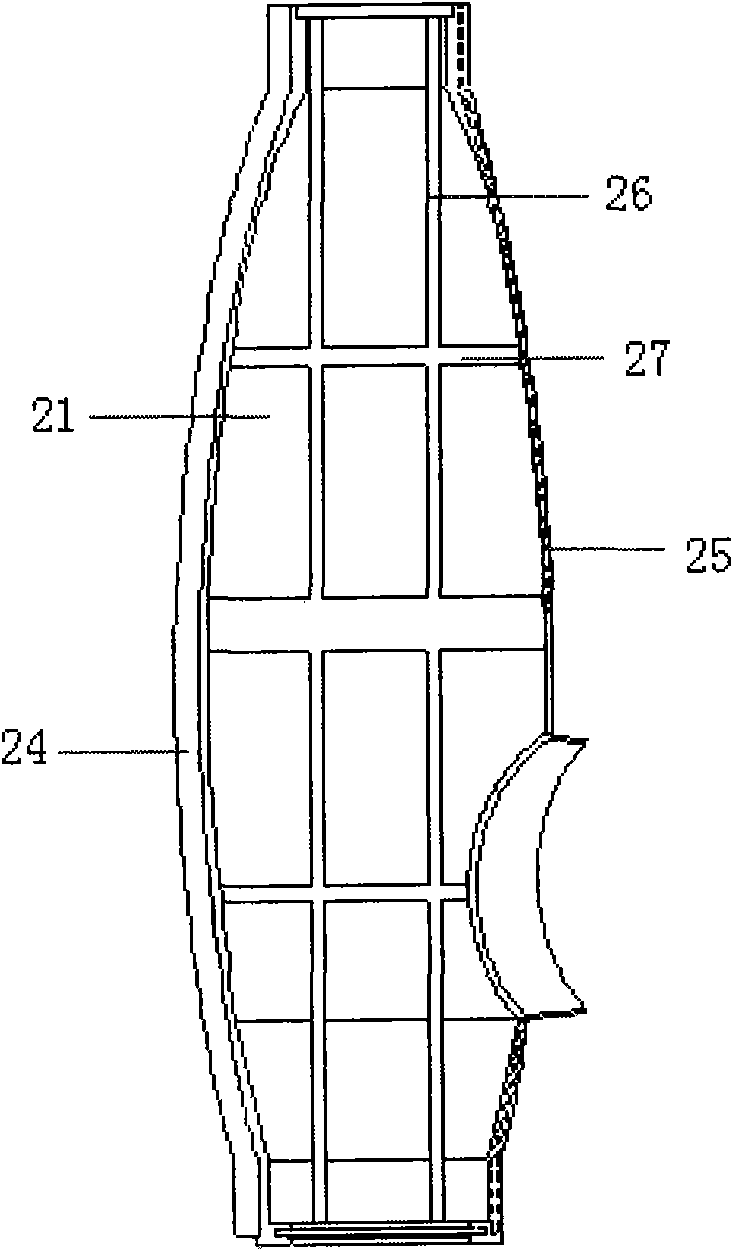

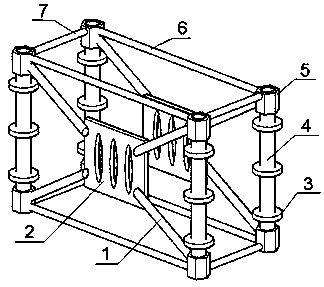

Spliced-type integrated inspection well

InactiveCN101838999AEasy constructionFast on-site installationArtificial islandsUnderwater structuresEngineeringUltimate tensile strength

The invention provides a splice-type integrated inspection well. The inspection well is an integrated piece which mainly consists of a chassis, a side wall and a cover plate, wherein the side wall is an integrated side wall formed by splicing a plurality of wall plates in the peripheral direction; and the bottom end of the side wall is spliced with the chassis, and the upper part of the side wall is connected with the cover plnate to form a sealed shape. When being applied to a project, the invention has the advantages of great convenience for construction, fast field installation, clean operational environment, no need of special maintenance and no influence on construction period; since the splicing structure of split-type components is reasonable and a convex edge is in interference with a groove, the invention has good sealing performance and can effectively prevent soil pollution caused by leakage of harmful substances contained in water body in the inspection well; and PVC plastic which is adopted as the materials for the split-type components in the invention has strength and toughness, is not easy to damage when being impacted by the water body, and has corrosion resistance, thereby the splice-type integrated inspection well almost needs not to be maintained, and saves labor.

Owner:金湖县九鼎塑胶制品有限公司

Prefabricated wall and construction method

The invention relates to a prefabricated wall and a construction method. The construction method comprises the following construction steps: accurate construction, finalized mold installation, mold cleaning and system installation, assembled internal mold installation, preparation of the prefabricated wall, installation of a prefabricated wall fixing bracket, installation of a prefabricated wall transport bracket, installation of a prefabricated wall transport protection outer frame and the like. The speed and efficiency of the preparatory construction of the prefabricated wall from manufacture to transport to on-site stack can be effectively improved, the method is safe and reliable, and relatively good economic benefits can be achieved when the method is applied to actual projects.

Owner:HANGZHOU JIANGRUN TECH LIMITED

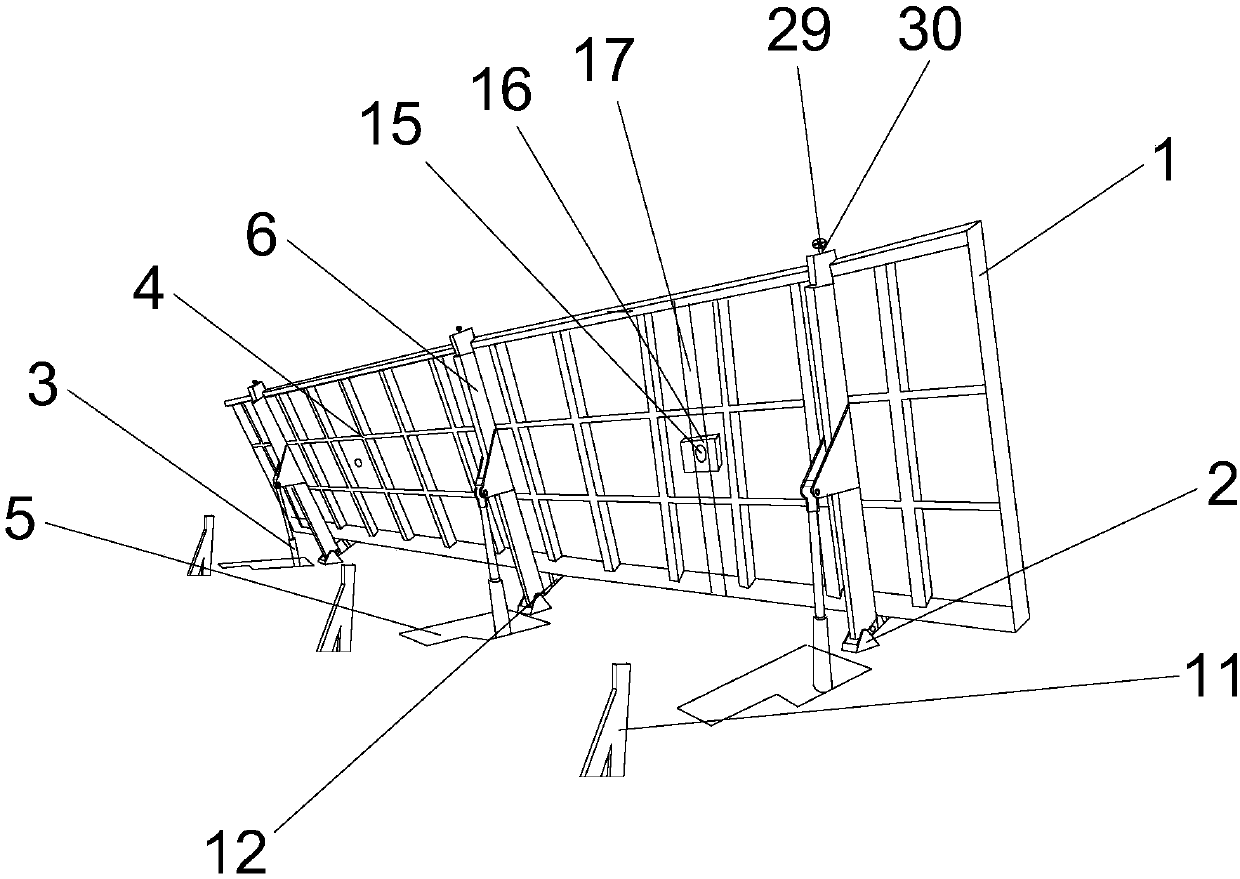

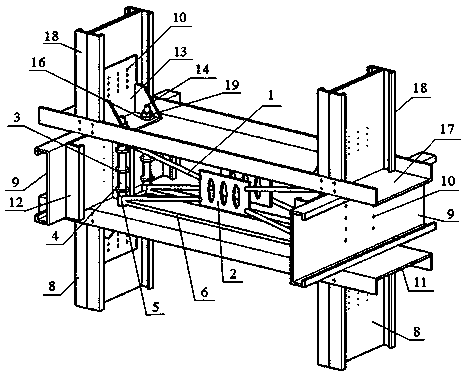

Cold-formed thin-walled steel-structure house outer wall structure system

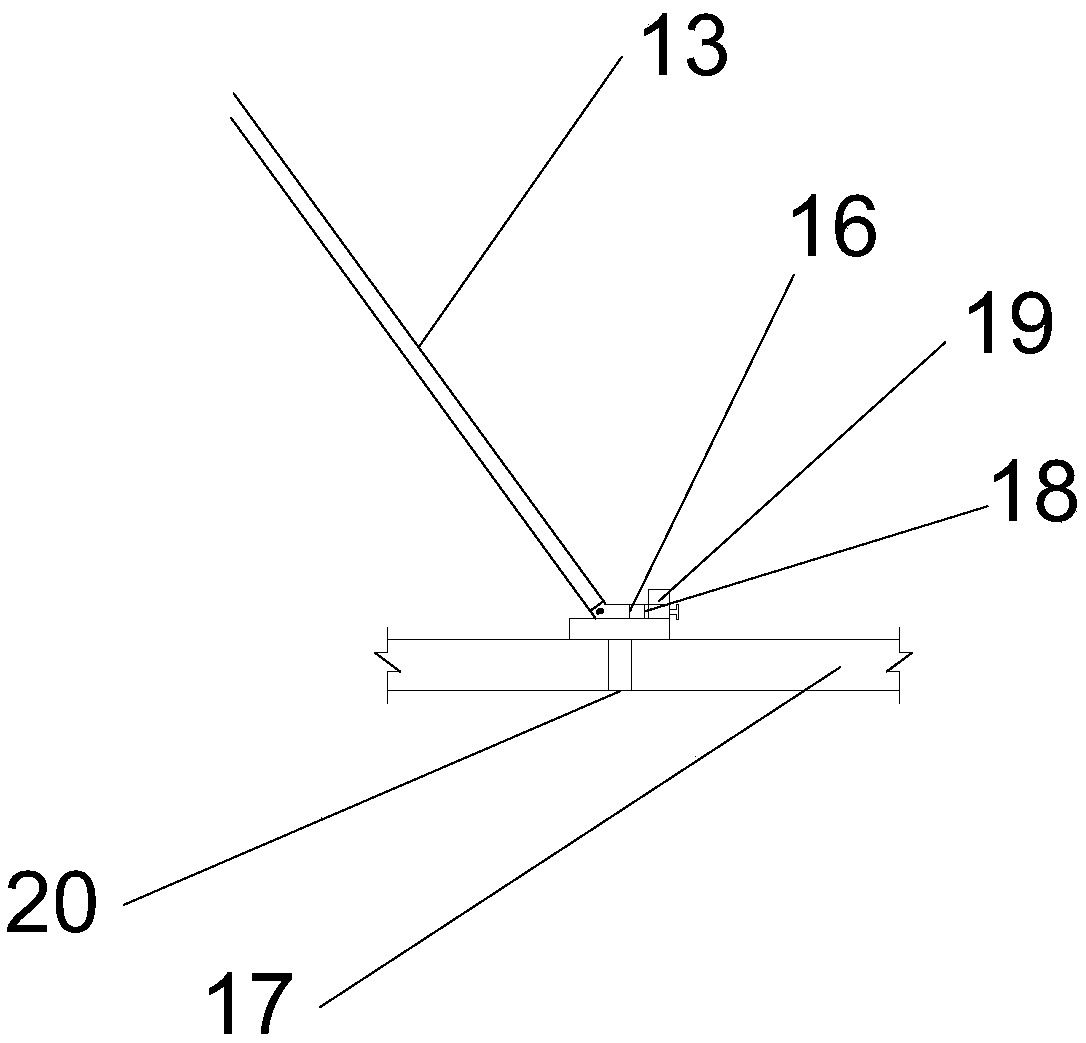

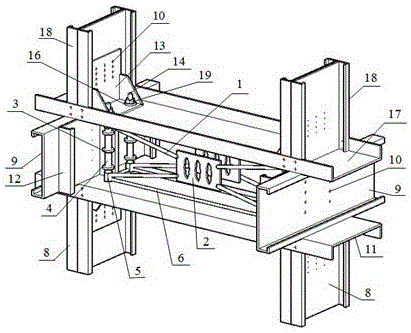

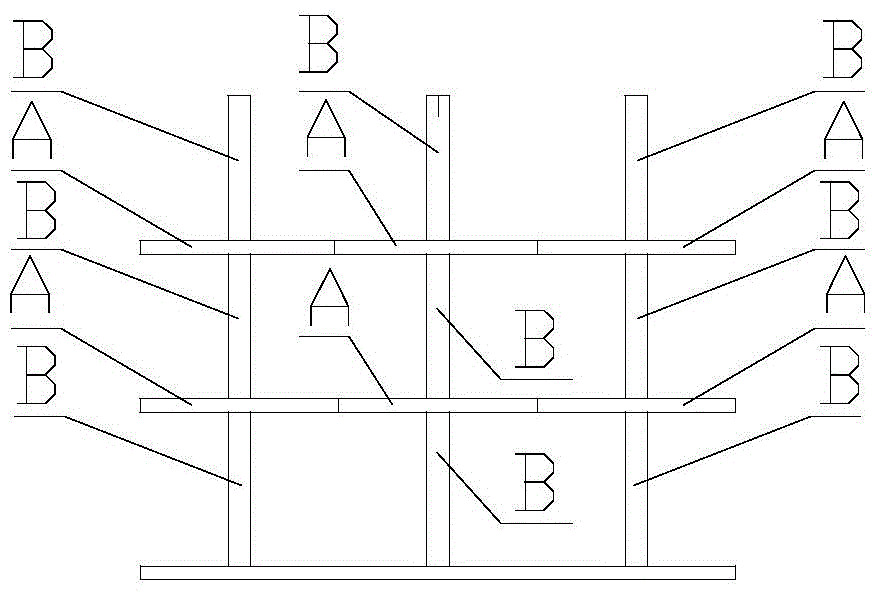

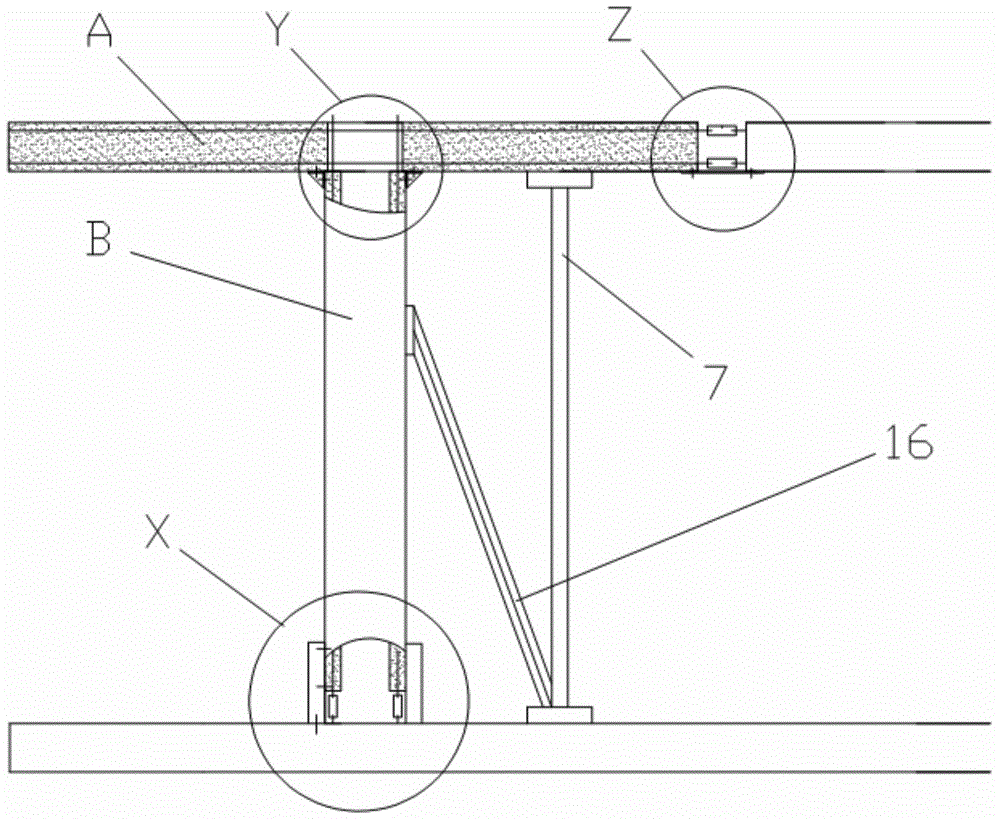

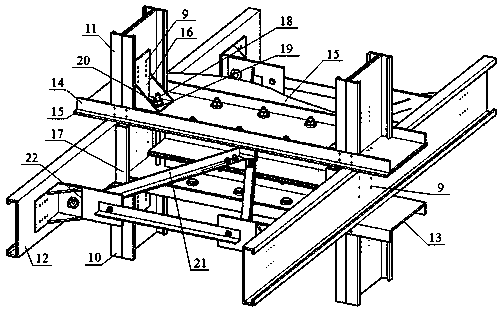

A cold-formed thin-walled steel-structure house outer wall structure system comprises beams and wall frame pillars, and the beams and the wall frame pillars are in cooperation with one another. The cold-formed thin-walled steel-structure house outer wall structure system is characterized in that the wall frame pillars comprise lower layer pillars (8) and upper layer pillars (18); the beams comprise floor beams (9), a top beam (11) and a bottom beam (17); the tops of the two adjacent lower layer pillars (8) are fixedly embedded in the top beam (11); pulling resistant pieces (13) are connected between the inner walls of the lower layer pillars (8) and the top beam (11), the floor beams (9) are fixed above the top beam (11), and the bottom beam (17) is fixed above the floor beams (9); the bottoms of the two adjacent upper layer pillars (18) are fixedly embedded in the bottom beam (17); pulling resistant pieces (13) are connected between the inner walls of the upper layer pillars (18) and the bottom beam (17); and a truss type strengthening part is installed between the top beam (11) and the bottom beam (17), and the truss type strengthening part is fixed to the top beam (11) and the bottom beam (17) through spacers (16) and nuts (19) after pulling resistant anchor bolts (14) penetrate through bolt holes (15), the top beam (11), steel sleeves (4) and the bottom beam (17).

Owner:SOUTHWEAT UNIV OF SCI & TECH

Reinforcing structure between longitudinal and transverse walls of cold-formed thin-walled section steel house

InactiveCN108755955ANo significant increase in costDoes not add significant weightBuilding constructionsCold formedEngineering

The invention discloses a reinforcing structure between longitudinal and transverse walls of a cold-formed thin-walled section steel house. The reinforcing structure comprises beams and wall frame columns, wherein the beams and the wall frame columns are mutually matched. The wall frame columns comprise lower-layer columns and upper-layer columns; the beams comprise floor beams (23), lower-layer house U-shaped beams (7) and upper-layer house U-shaped beams (8); the tops of the lower-layer columns are inlaid in openings of the U-shaped steel top beams (7) and fixed; the bottoms of the upper-layer columns are inlaid in openings of the U-shaped steel bottom beams (8) and fixed; the lower-layer columns and the upper-layer columns are connected through connecting pieces (12); anti-pulling pieces (17) are connected between the lower-layer columns and the U-shaped steel top beams (7), and anti-pulling pieces (17) are connected between the upper-layer columns and the U-shaped steel bottom beams (8); and H-shaped reinforcing components (6) between steel layers are connected between the U-shaped steel top beams (7) and the U-shaped steel bottom beams (8). The reinforcing structure is characterized in that oblique supporting pieces are connected between parts of the upper-layer columns and the U-shaped steel bottom beams (8) and / or oblique supporting pieces are connected between parts ofthe lower-layer columns and the U-shaped steel top beams (7).

Owner:SOUTHWEAT UNIV OF SCI & TECH

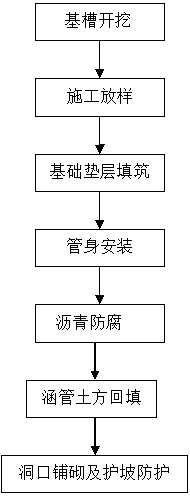

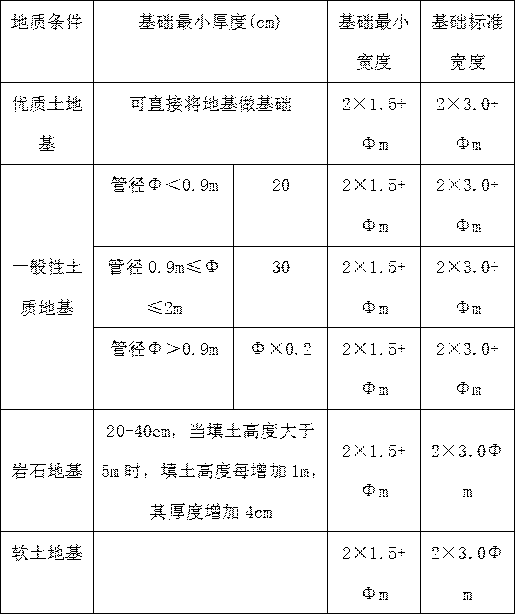

Construction process of metallic corrugated culvert pipes

The invention discloses a construction process of metallic corrugated culvert pipes. The construction process comprises the steps of foundation trench excavation, construction layout, foundation pad filling, pipe body installation, asphalt corrosion protection, culvert pipe earthwork backfilling, tunnel opening paving, slope protection and the like. The construction process disclosed by the invention has the advantages of high field installation speed, short construction period and high efficiency and is favorable for reducing the construction cost; furthermore, the later maintenance workloadis small, and the maintenance cost is low; pipe fittings are connected by adopting pipe hoops, are free of welding, pollution as well as waste gas and sewage discharge, and belong to green and environment-friendly products; and the use of conventional building materials such as cement, sand and stone is reduced, so that the construction process has profound environmental protection significance.

Owner:XINJIANG NORTH CONSTR GRP CO LTD

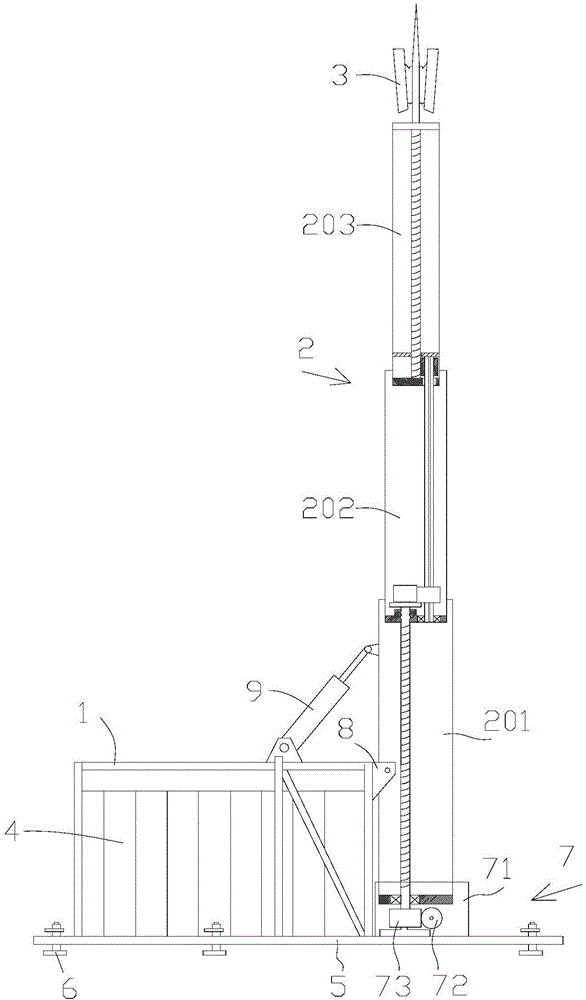

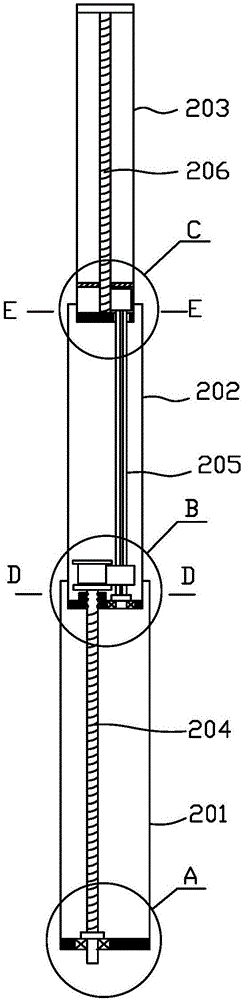

Integrated communication base station

The invention discloses an integrated communication base station and belongs to the technical field of communication base stations. The integrated communication base station comprises an engine room, a base, a support frame, a driving device, a lifting tower and an antenna; the lifting tower is connected with the support frame on the base, the antenna is arranged at the top of the lifting tower, the engine room is mounted on the base within the support frame, the lifting tower comprises a tower body and a lifting component, the tower body comprises a base segment, a first moving segment and a second moving segment all of which are hollow and are connected in sequence in sleeving manner, a transmission part is arranged in each of the base segment, the first moving segment and the second moving segment, and transmission is available among the parts so that the first moving segment and second moving segment may expand or retract relatively. The screw lifting mode is used herein, multi-stage transmission mode is employed, the problem that a single screw being too long during multi-stage lifting results in high manufacture cost is avoided; in frequent movement, the screw needs to be removed and mounted every time so as to avoid transportation being affected due to the excessive length of the screw.

Owner:GUANGXI UNIV

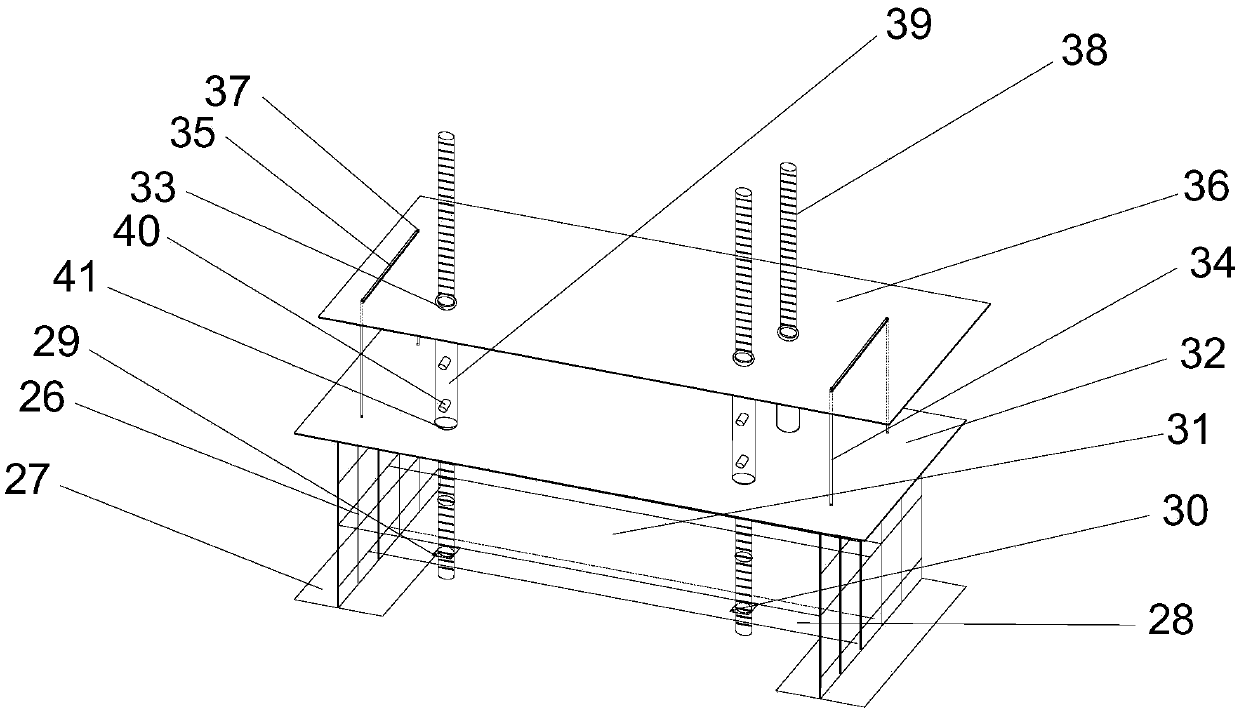

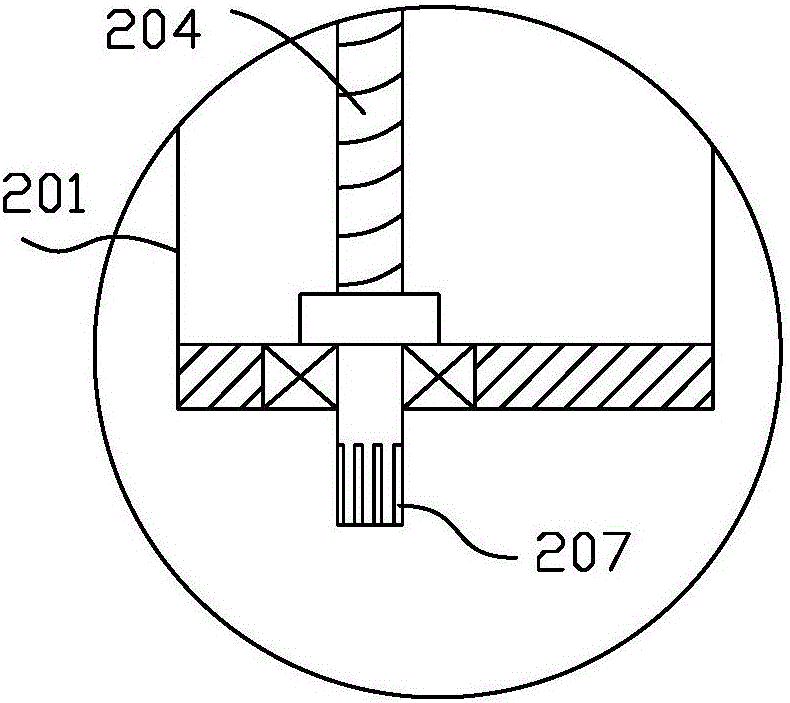

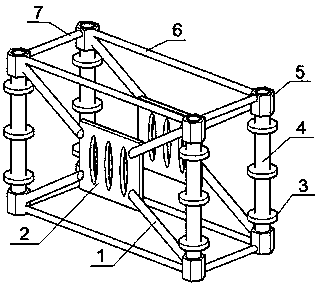

Prefabricated steel frame structure

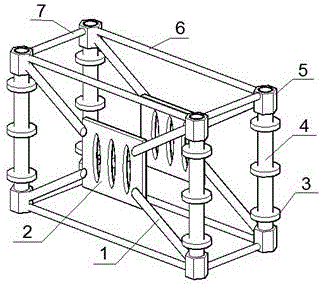

InactiveCN105696705AHigh Mechanical Engineering DegreePrecise processingBuilding constructionsSteel frameBuilding construction

The invention discloses a prefabricated steel frame structure and relates to the technical field of construction engineering. The problems in the prior art that the site splicing workload of a prefabricated framework is large and prefabricated components cannot be spliced on site due to size errors are solved. The prefabricated steel framework structure comprises prefabricated frame pillars, prefabricated top beams and prefabricated bottom beams, wherein first holes are formed in the prefabricated frame pillars; the prefabricated top beams are in a shape of a groove; second holes are formed in the groove-shaped inner parts of the prefabricated top beams; the prefabricated bottom beams are in a shape of a groove; third holes are formed in the groove-shaped inner parts of the prefabricated bottom beams; the prefabricated bottom beams are parallel with the prefabricated top beams; and the plurality of prefabricated frame pillars, the plurality of prefabricated top beams and the plurality of prefabricated bottom beams are connected together through the first holes, the second holes and the third holes, formed in the prefabricated frame pillars, the prefabricated top beams and the prefabricated bottom beams.

Owner:SHENYANG JIANZHU UNIVERSITY

An assembled uhpc steel-concrete composite bridge deck and its construction method

ActiveCN111877172BLose weightFully bonded fusionBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

Owner:NANJING TECH UNIV +2

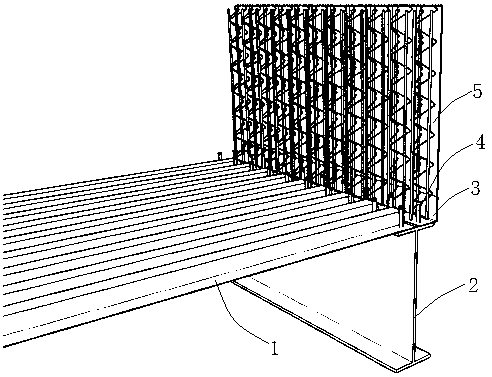

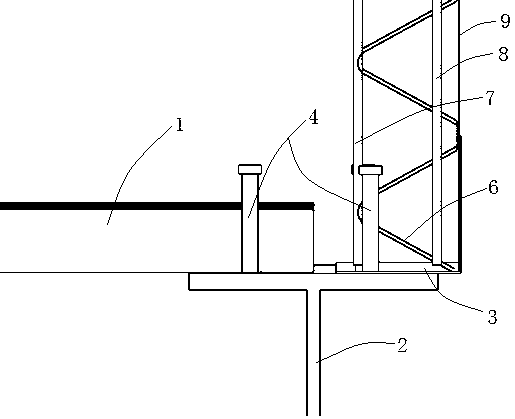

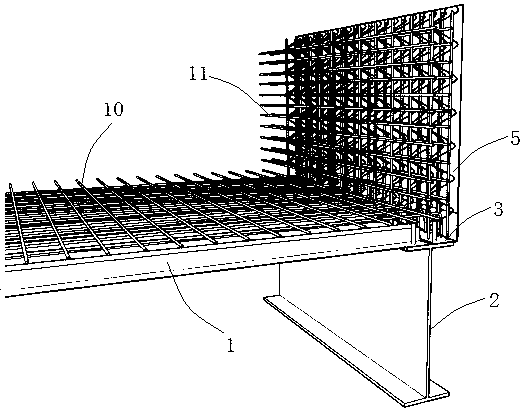

Reinforced-truss concrete precast panel, reinforced-truss concrete precast panel structure system and construction method thereof

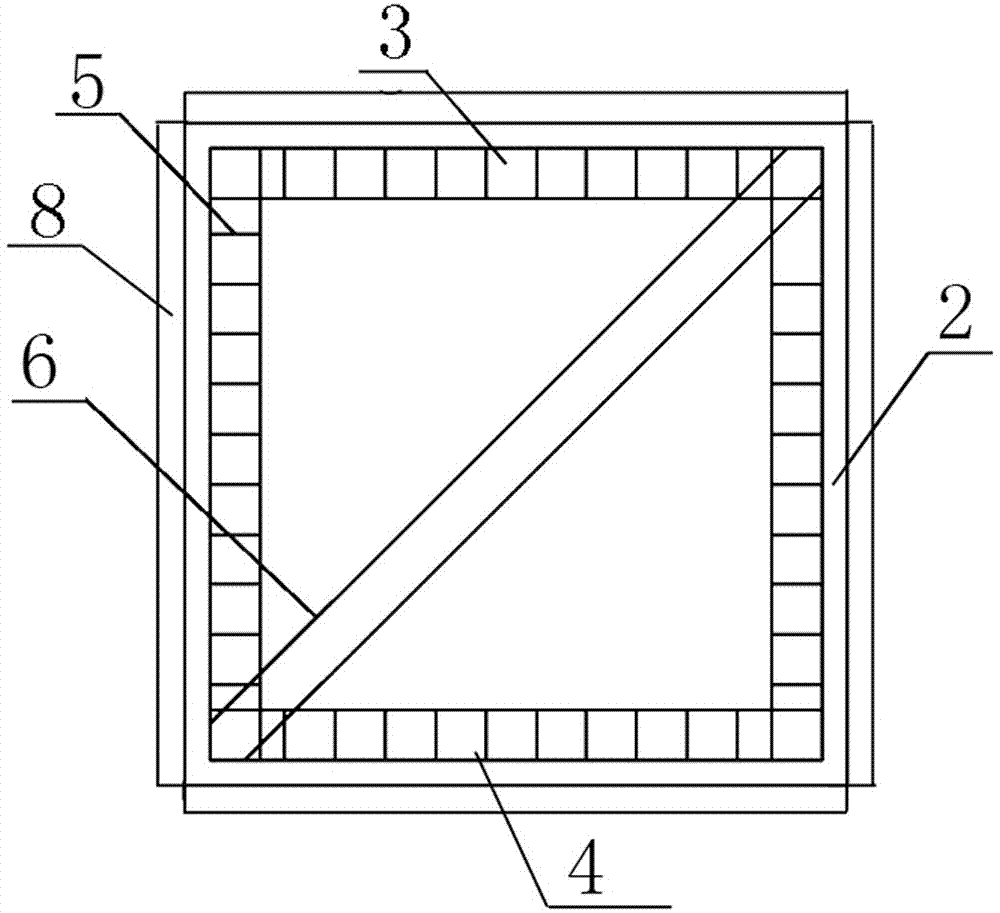

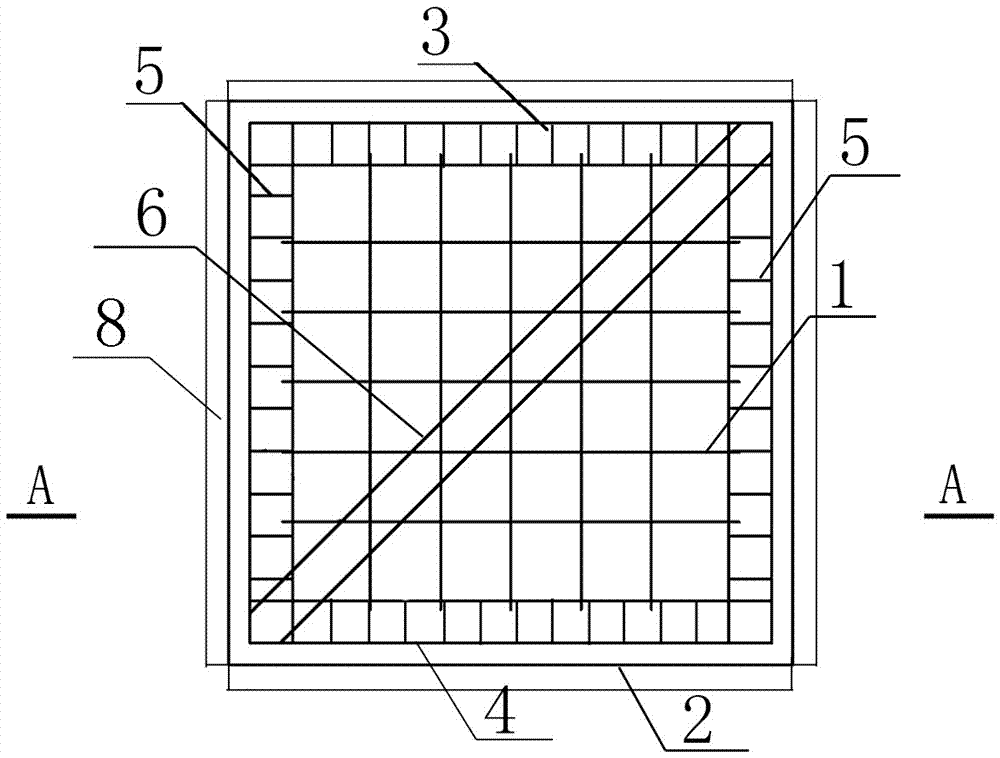

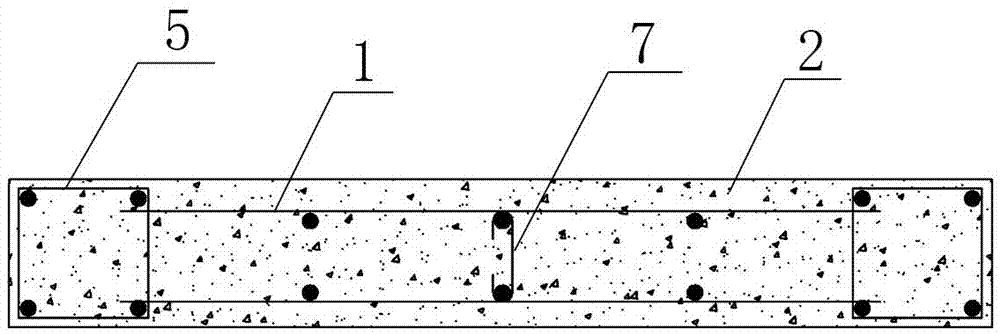

PendingCN107313551AReduce in quantityEasy to operateConstruction materialBuilding material handlingReinforced concreteArchitectural engineering

The invention discloses a reinforced-truss concrete precast panel, a reinforced-truss concrete precast panel structure system and a construction method thereof. The precast panel comprises panel concrete having a reinforced-truss framework and cast outside the reinforced-truss framework; the reinforced-truss framework comprises an upper-string reinforcement cage, a lower-string reinforcement cage and a vertical reinforcement cage connected between two ends of the upper-string reinforcement cage and the lower-string reinforcement cage; an oblique reinforcing rebar is further arranged in a frame enclosed by the upper-string reinforcement cage, the lower-ring reinforcement cage and the vertical reinforcement cage; the oblique reinforcing rebar is formed by bundle of bars or a reinforcement cage; first connecting plates are embedded in peripheral sides of the reinforced-truss concrete precast panel; the first connecting plates are arranged along the axial direction of the side face of the reinforced-truss concrete precast panel. By the arrangement, technical problems that framework engineering quantity is large, construction is difficult, building layout cannot be flexibly cooperated, construction period is long and late demolition is difficult in construction of shear walls in a traditional structure system are solved.

Owner:姚攀峰

Dual structure concrete building and building method of dual structure concrete building

The invention discloses a dual structure concrete building and a building method of the dual structure concrete building. The dual structure concrete building comprises a plurality of floor slabs and a plurality of hollow building columns, wherein each of the floor slabs and the hollow building columns is provided with steel bars extending to the outside; the floor slabs and the hollow building columns are arranged in a mutually perpendicular way; reserved holes through which the steel bars of the hollow building columns pass are formed in each floor slab; the steel bars of the upper and lower building columns are fixedly connected in the positions of the reserved holes through steel bar connecting buckles; concrete is fully injected into the reserved holes; connecting seams are reserved between the floor slabs; the steel bars of the floor slabs are fixedly connected through the steel bars in the positions of the connecting seams; and the concrete is fully injected in the positions of the connecting seams. Only two major components for production and installation are needed for the whole main body framework construction, so that compared with other assembled building technologies, the dual structure concrete building and the building method have the advantages that the structure is simple; the production is easy; the field installation speed is high; the field casting concrete quantity is small; and the cost and the manufacturing cost are low, and the like.

Owner:李聪

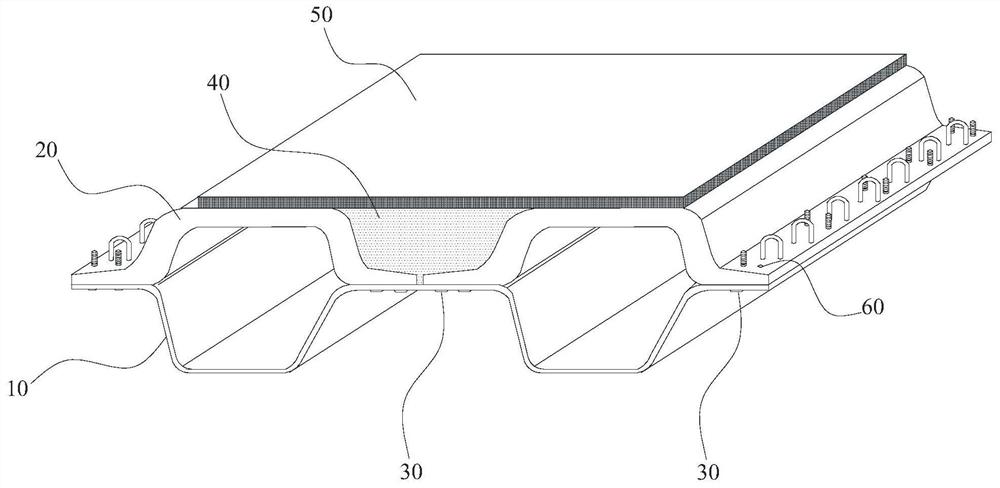

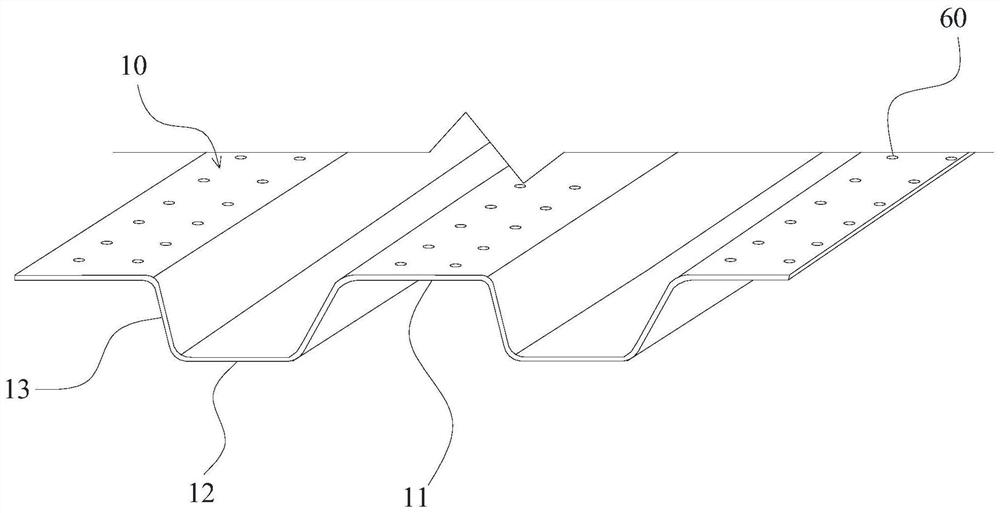

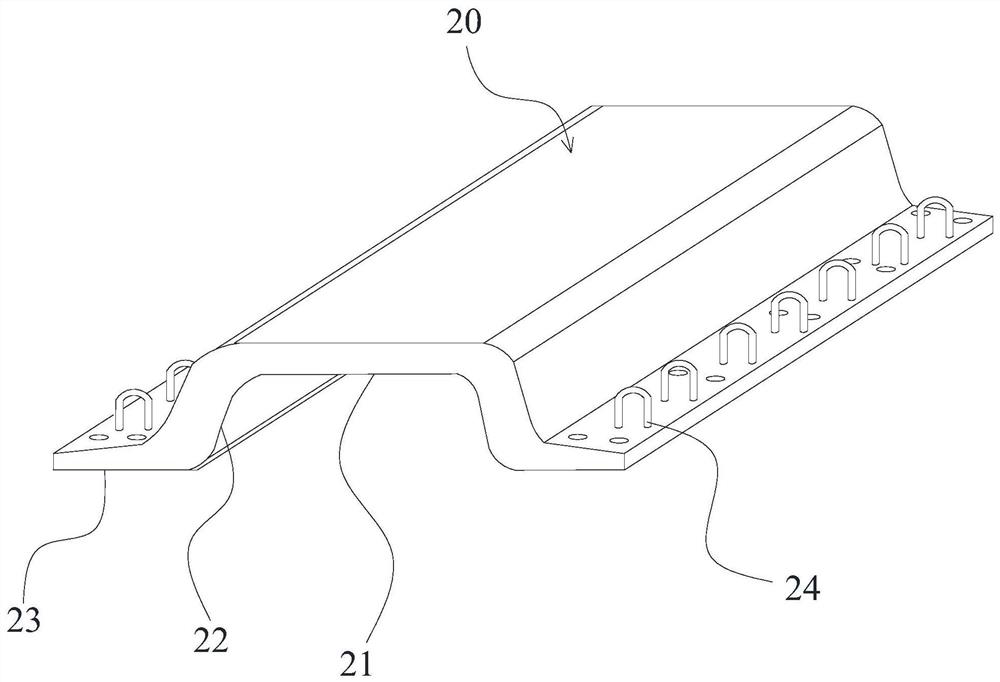

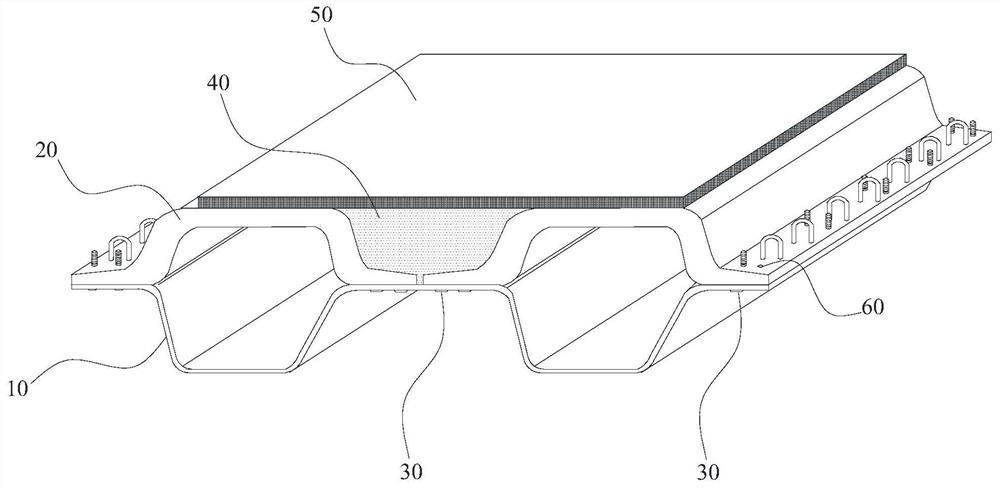

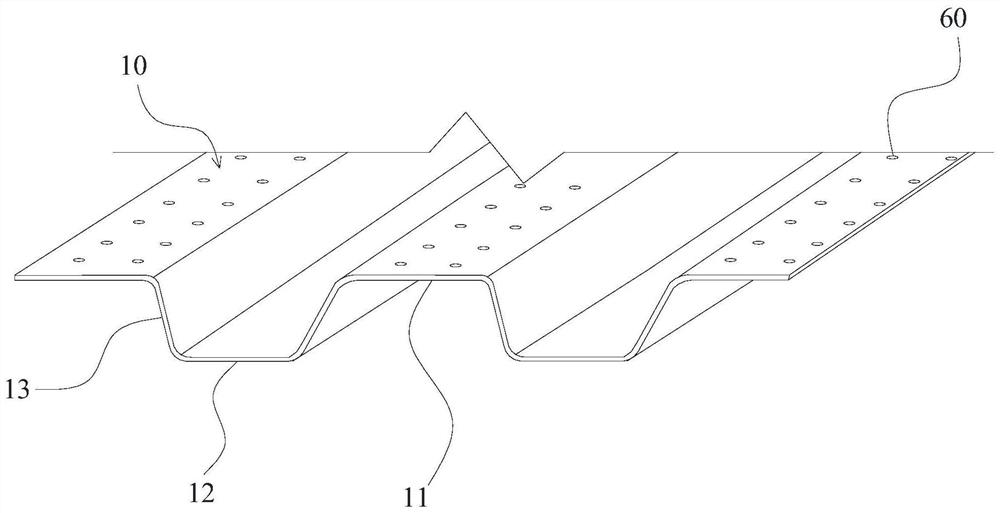

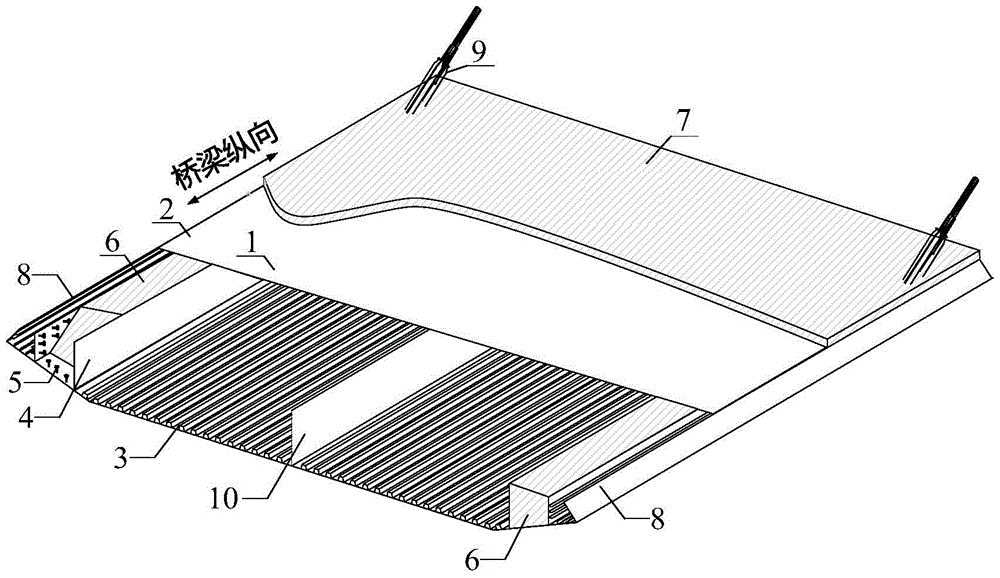

Fabricated UHPC steel-concrete composite bridge deck slab and construction method thereof

ActiveCN111877172ALose weightFully bonded fusionBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention relates to the technical field of bridge construction, in particular to a fabricated UHPC steel-concrete combined bridge deck slab, and the bridge deck slab comprises a stepped steel plate formed through continuous film pressing; a prefabricated inverted-U-shaped UHPC bridge deck slab which is arranged above the stepped steel plate, wherein the inverted-U-shaped UHPC bridge deck slabis connected with the upper surface of the stepped steel plate through high-strength bolts; C40 concrete is poured between the inverted-U-shaped UHPC bridge decks, so the whole steel-concrete combined bridge decks form a whole, and an asphalt pavement layer is laid on the whole steel-concrete combined bridge decks. The inverted U-shaped UHPC bridge deck slab is connected with the stepped steel plates, so the bending rigidity of the bridge deck slab can be improved, and the fatigue resistance is improved; the inverted-U-shaped UHPC bridge deck slab is prefabricated and formed in a factory, sothe quality of components is easy to guarantee, and the on-site installation speed is high; the UHPC prefabricated plate is connected with the steel plate through the high-strength bolts, so maintenance and replacement are convenient. The invention further provides a construction method of the assembly type UHPC steel-concrete composite bridge deck slab.

Owner:NANJING UNIV OF TECH +2

Spliced-type integrated inspection well

InactiveCN101838999BEasy constructionFast on-site installationArtificial islandsUnderwater structuresUltimate tensile strengthToughness

Owner:金湖县九鼎塑胶制品有限公司

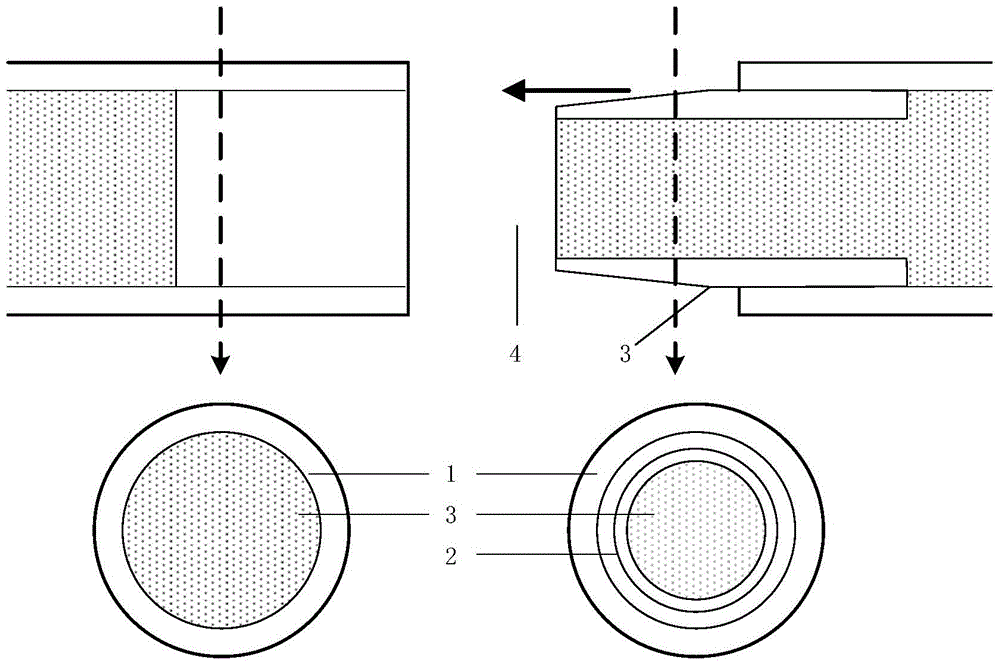

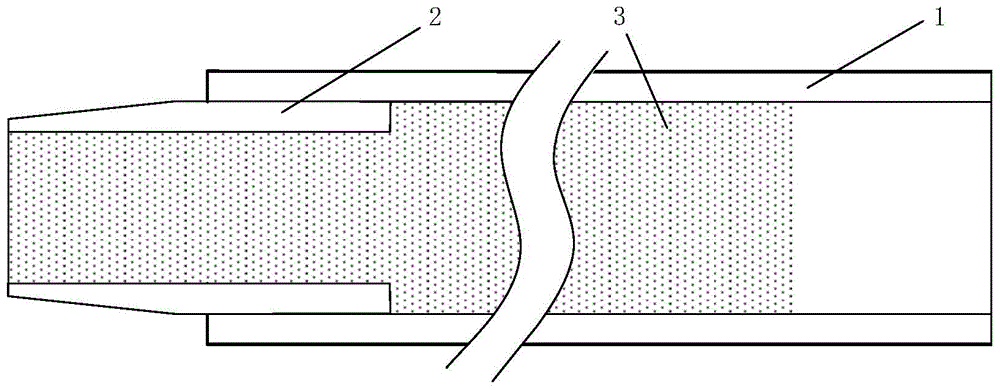

Connector with prefabricated steel pipe concrete beam segment and connecting method thereof

The invention relates to a prefabricated steel pipe concrete beam field connecting method, the method is suitable for a large span bridge decking, can realize a steel pipe concrete structure prefabricated assembling construction mode, and belongs to the structure engineering technical field; the method comprises the following steps: one end of an outer steel pipe in the prefabricated steel pipe concrete is welded with a segment of cone lining steel pipe; pouring concrete in the steel pipe in a vertical state; two segments in the construction field are centered and spliced, and the outer steel pipe is connected through a butt joint welding slit; high-strength mortar or high-strength grouting material are poured into a grouting port until the mortar overflows from a stock outlet, then the grouting port and the stock outlet are welded and sealed; a proper gap between the inner and outer steel pipes is used for correcting structure axis misalignment; a mud jacking process can ensure tight contact of the filled concrete of the two segments; the method is simple in structure, less in steel bar consumption, convenient in construction, fast in filed mounting speed, small in moisture wet working amount, excellent in force bearing performance, reliable in force transmission, and can less affect surrounding environment.

Owner:TSINGHUA UNIV

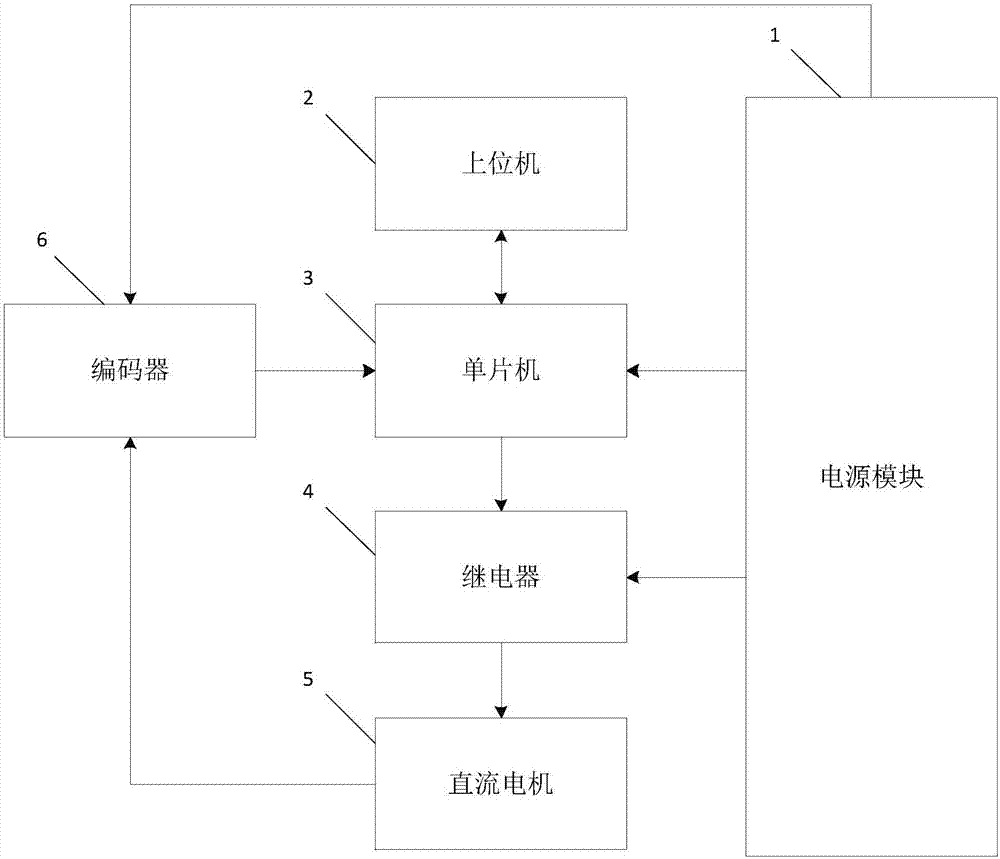

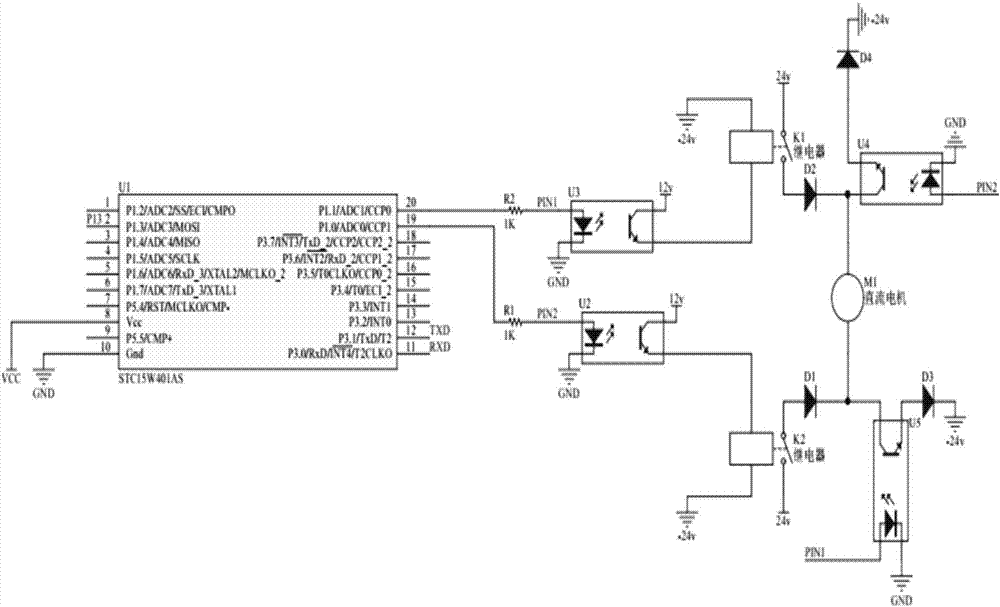

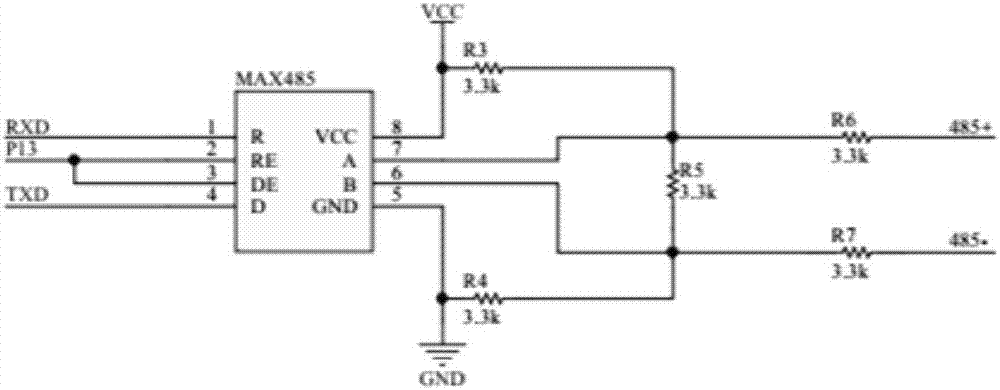

Greenhouse roller shutter control system

InactiveCN106959648AGood effectImprove stabilityProgramme controlComputer controlMicrocontrollerControl signal

The invention discloses a greenhouse roller shutter control system which comprises a power supply module, an upper computer, a single-chip microcomputer, a relay, an encoder and a DC motor for driving the greenhouse roller shutter. The output end of the power supply module is connected with the relay and the single-chip microcomputer, thereby supplying electric power to the relay and the single-chip microcomputer. The output end of the power supply module is connected with the DC motor through the relay, thereby supplying electric power to the DC motor through the relay. The encoder is mounted on the motor shaft of the DC motor for detecting a real-time operation state of the DC motor. The signal output end of the encoder is connected with the single-chip microcomputer for transmitting the operation state to the single-chip microcomputer. The single-chip microcomputer is connected with the upper computer and the relay for receiving a control signal which is transmitted from the upper computer for controlling the operation state, and controls the operation state of the DC motor through the relay. The greenhouse roller shutter control system has advantages of high stability, low cost, low power consumption, low heating amount, no requirement for complicated programming, high field mounting speed, high effect and high suitability for actual production.

Owner:SHANDONG YANTAI AGRI SCI & TECH INST

Cold-formed thin-walled steel structure building exterior wall structure system

A cold-formed thin-walled steel-structure house outer wall structure system comprises beams and wall frame pillars, and the beams and the wall frame pillars are in cooperation with one another. The cold-formed thin-walled steel-structure house outer wall structure system is characterized in that the wall frame pillars comprise lower layer pillars (8) and upper layer pillars (18); the beams comprise floor beams (9), a top beam (11) and a bottom beam (17); the tops of the two adjacent lower layer pillars (8) are fixedly embedded in the top beam (11); pulling resistant pieces (13) are connected between the inner walls of the lower layer pillars (8) and the top beam (11), the floor beams (9) are fixed above the top beam (11), and the bottom beam (17) is fixed above the floor beams (9); the bottoms of the two adjacent upper layer pillars (18) are fixedly embedded in the bottom beam (17); pulling resistant pieces (13) are connected between the inner walls of the upper layer pillars (18) and the bottom beam (17); and a truss type strengthening part is installed between the top beam (11) and the bottom beam (17), and the truss type strengthening part is fixed to the top beam (11) and the bottom beam (17) through spacers (16) and nuts (19) after pulling resistant anchor bolts (14) penetrate through bolt holes (15), the top beam (11), steel sleeves (4) and the bottom beam (17).

Owner:SOUTHWEAT UNIV OF SCI & TECH

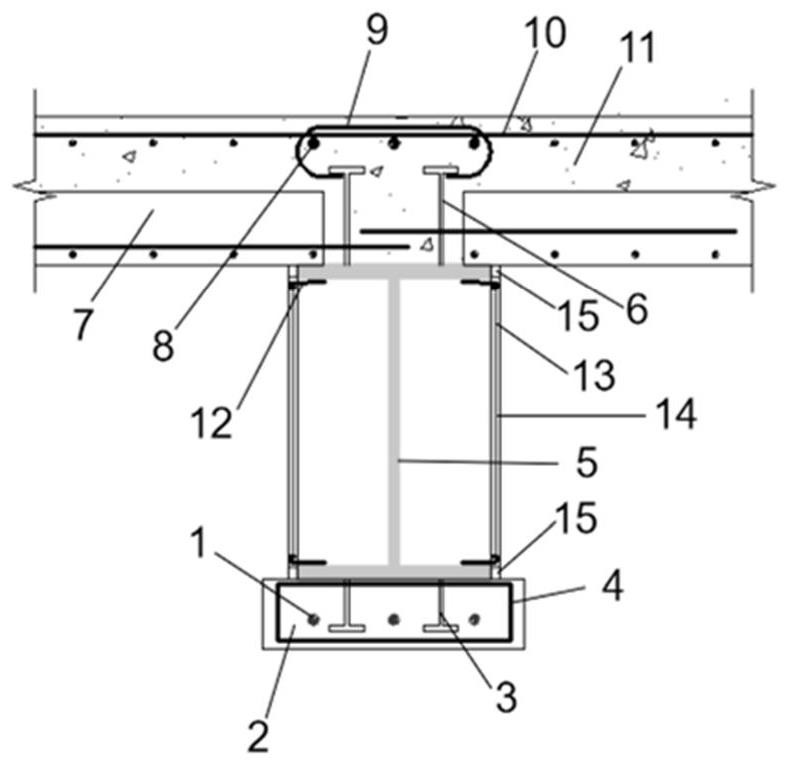

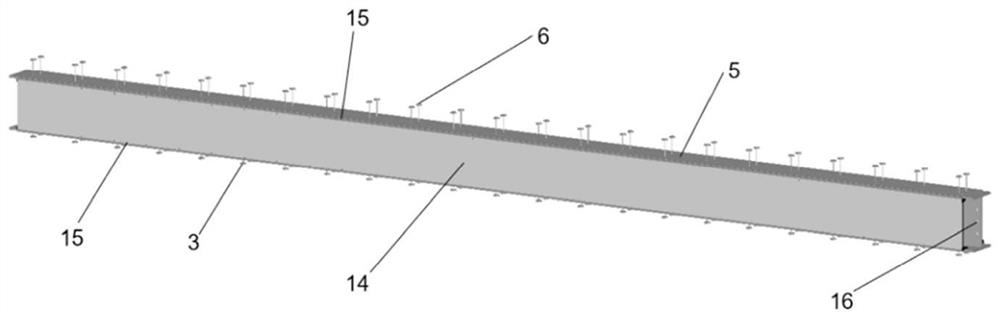

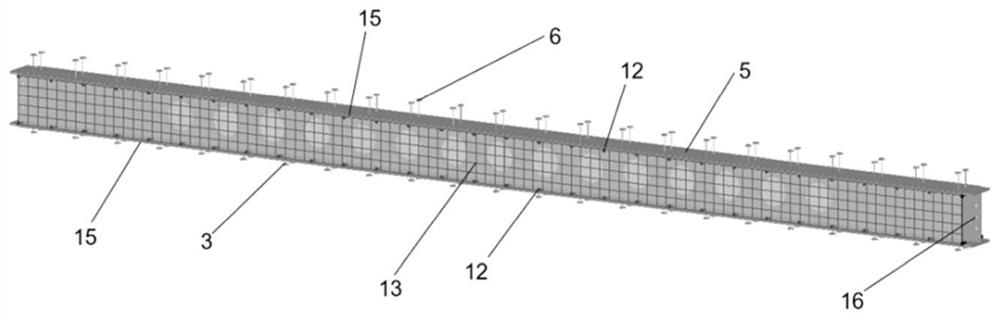

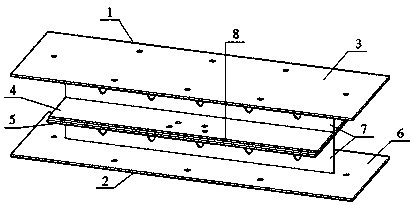

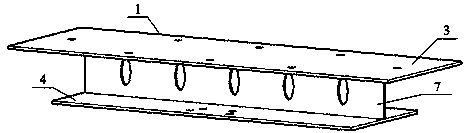

Bearing-fireproof integrated prefabricated prestressed steel-concrete combined secondary beam and manufacturing method thereof

PendingCN114809443AGood for strengthImprove on-site hoisting efficiencyLoad-supporting elementsCeramic shaping apparatusFoam concretePre stress

The invention belongs to the field of constructional engineering, and particularly relates to a bearing-fireproof integrated prefabricated prestressed steel-concrete combined secondary beam and a manufacturing method. The combined secondary beam comprises a middle section steel assembly, a pre-tensioned prestressed concrete strip and a concrete assembly, wherein the pre-tensioned prestressed concrete strip and the concrete assembly are located at the bottom end of the middle section steel assembly. The pre-tensioned prestressed concrete strip and the middle section steel assembly extend in the same direction; a foam concrete fireproof thin plate is arranged between an upper flange and a lower flange of the H-shaped steel; the upper flange of the H-shaped steel is mounted with the concrete component through the upper flange stud connecting piece; the reinforcing stirrups are connected with the upper flange stud connecting pieces in a welded mode, and the upper flange portions, facing the H-shaped steel, of the reinforcing stirrups are provided with secondary beam longitudinal bars arranged orthogonally with the reinforcing stirrups. And the cast-in-place concrete is poured on an upper flange of the H-shaped Pre-tensioning prestress is utilized, concrete on the two sides of the H-shaped steel web is omitted, the large-span and light-weight prefabricated prestress secondary beam is formed, the material strength can be brought into play, the field hoisting efficiency is improved, and the construction cost is reduced.

Owner:SOUTHEAST UNIV

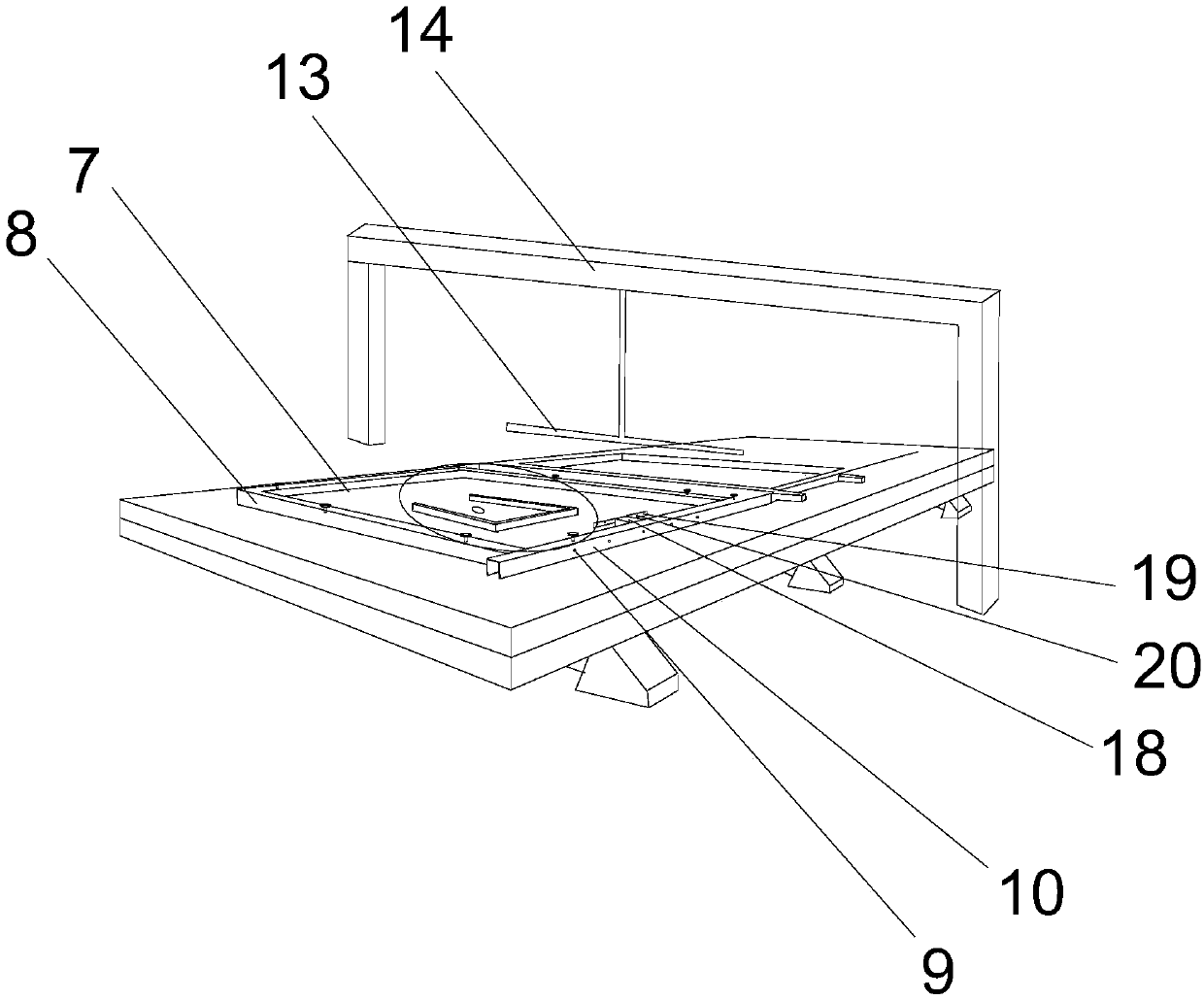

Cold-formed thin-walled steel structure building interior wall structure system

A cold-bent thin-walled steel-structured housing interior wall structural system comprises beams and wall frame columns mating with the beams, and is characterized in that each wall frame column includes a lower column (10) and an upper column (11), and the beams include C-shaped steel floor beams (12), as well as a U-shaped steel top beam (13) and a U-shaped steel bottom beam (14) which are used for connecting the two adjacent wall frame columns; anti-pull parts (16), floor structural boards (15), connectors and H-beam stack weld-combined stiffeners are also included in the system; the U-shaped steel top beam (13) is fixed to the two adjacent lower columns (10); the U-shaped steel bottom beam (14) is fixed to the two adjacent upper columns (11); the H-beam stack weld-combined stiffeners are mounted between the U-shaped steel top beam (13) and the floor structural boards (15) and are fixed to them through washers (19) and nuts (20) via anti-pull anchor bolts (18) which are passed through the anti-pull parts (16), the U-shaped steel top beam (13), the H-beam stack weld-combined stiffeners, the floor structural boards (15) and the U-shaped steel bottom beam (14).

Owner:SOUTHWEAT UNIV OF SCI & TECH

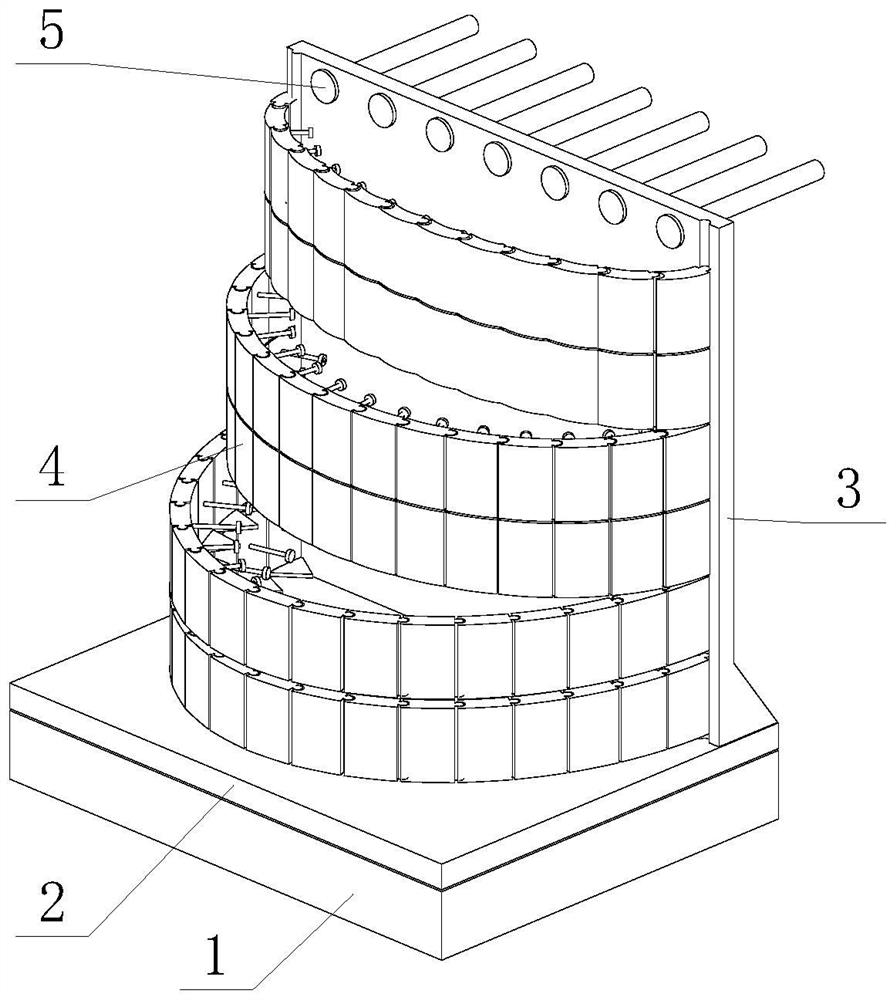

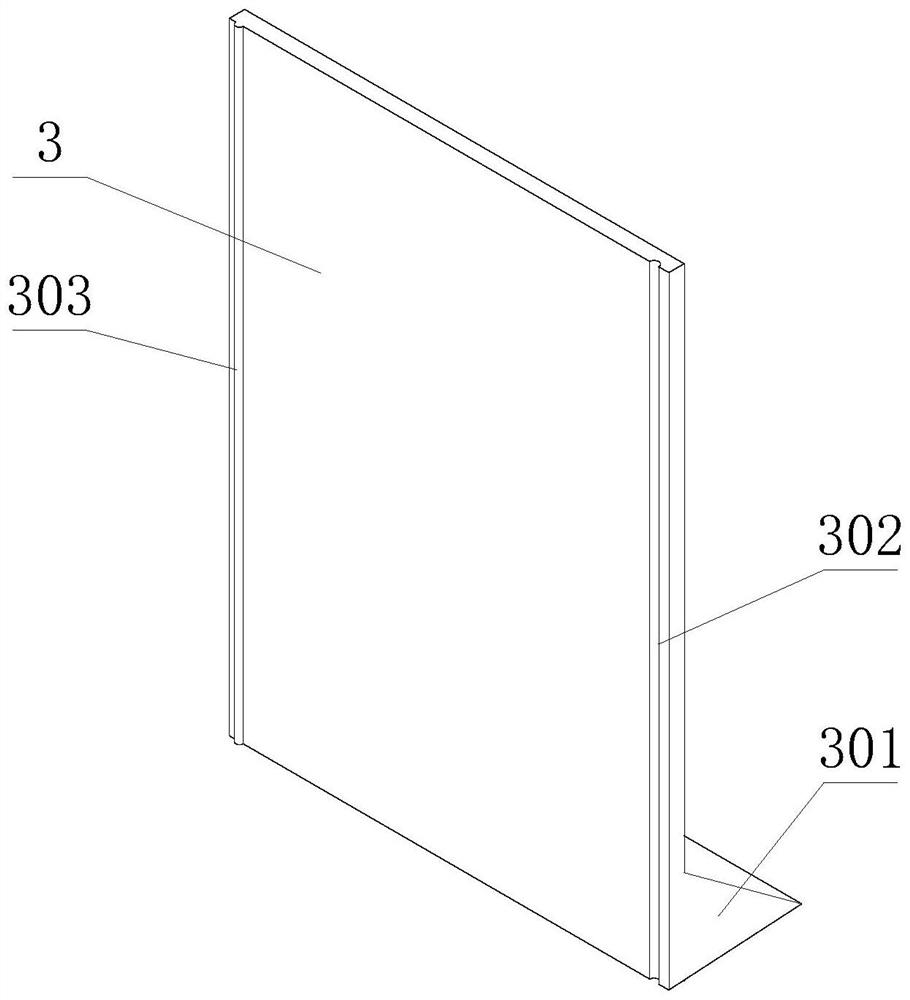

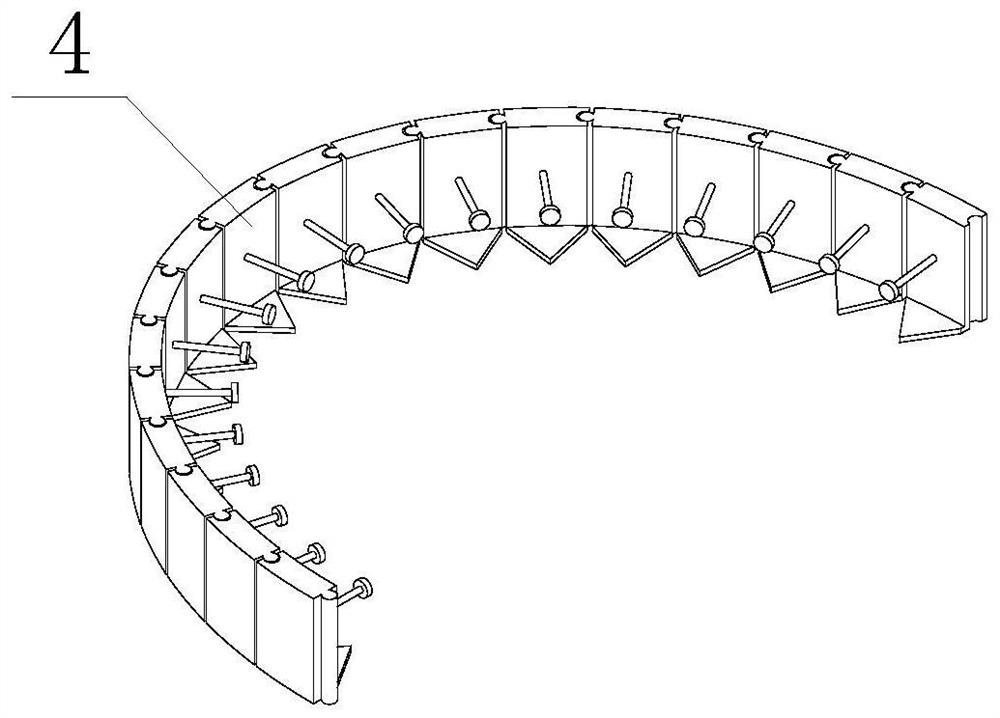

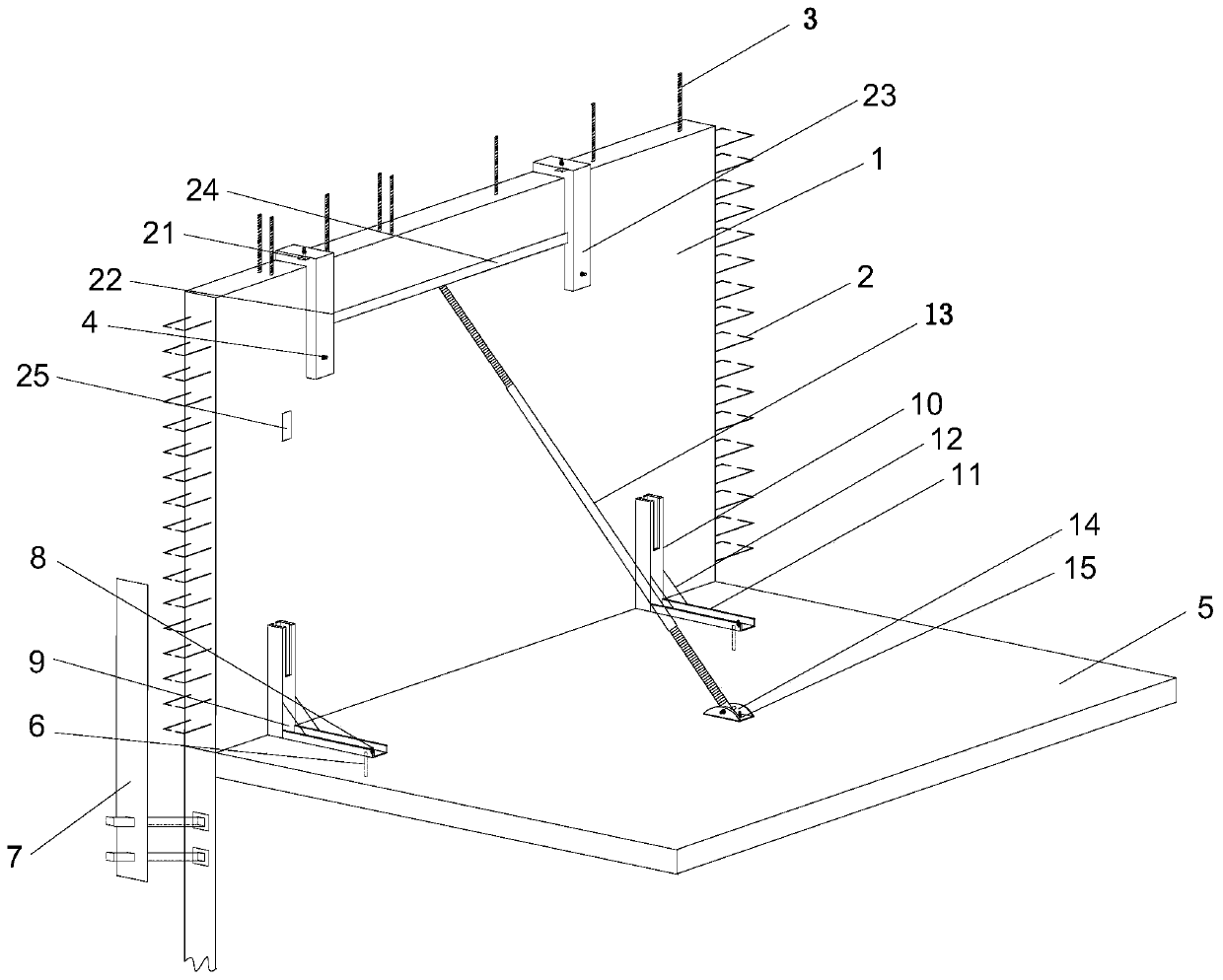

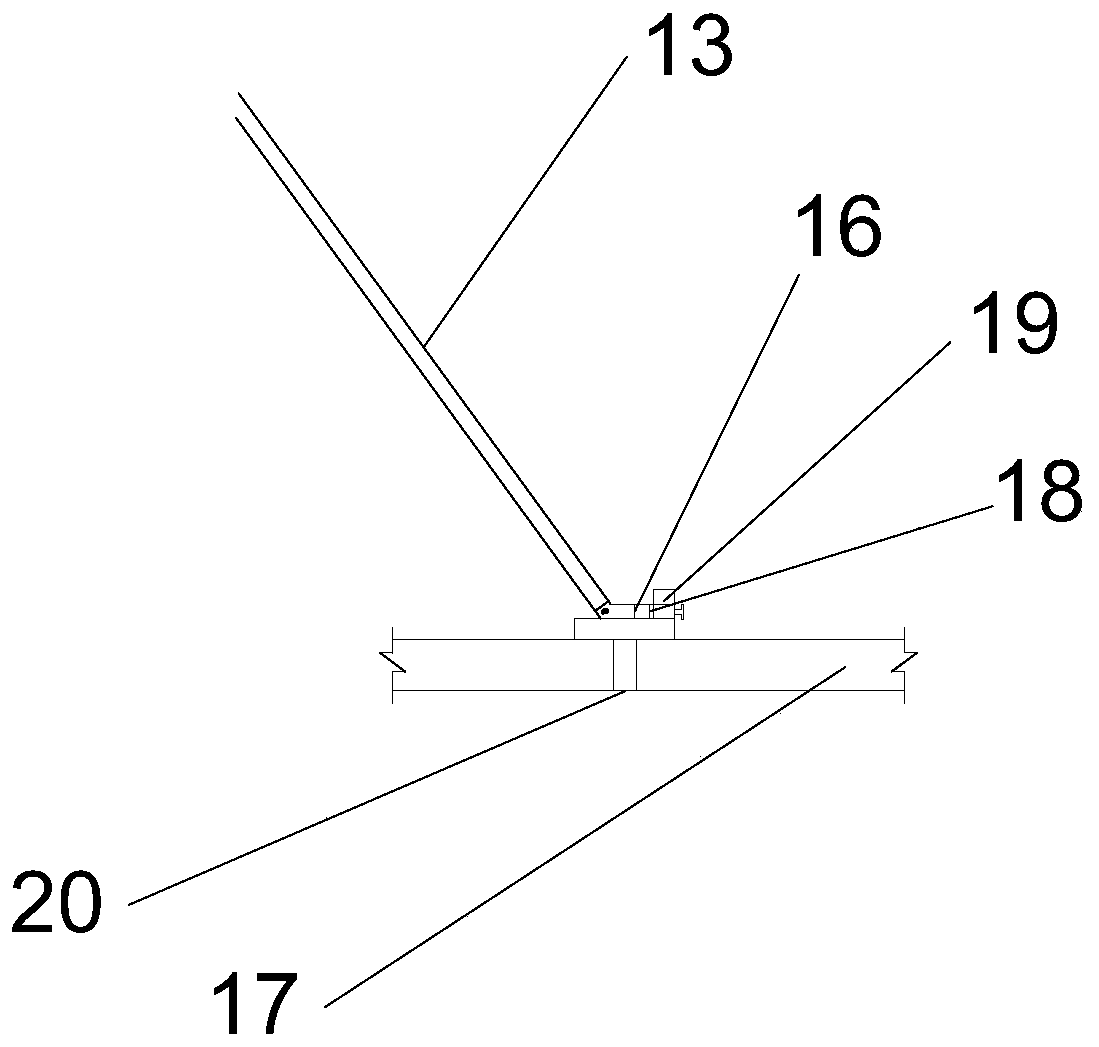

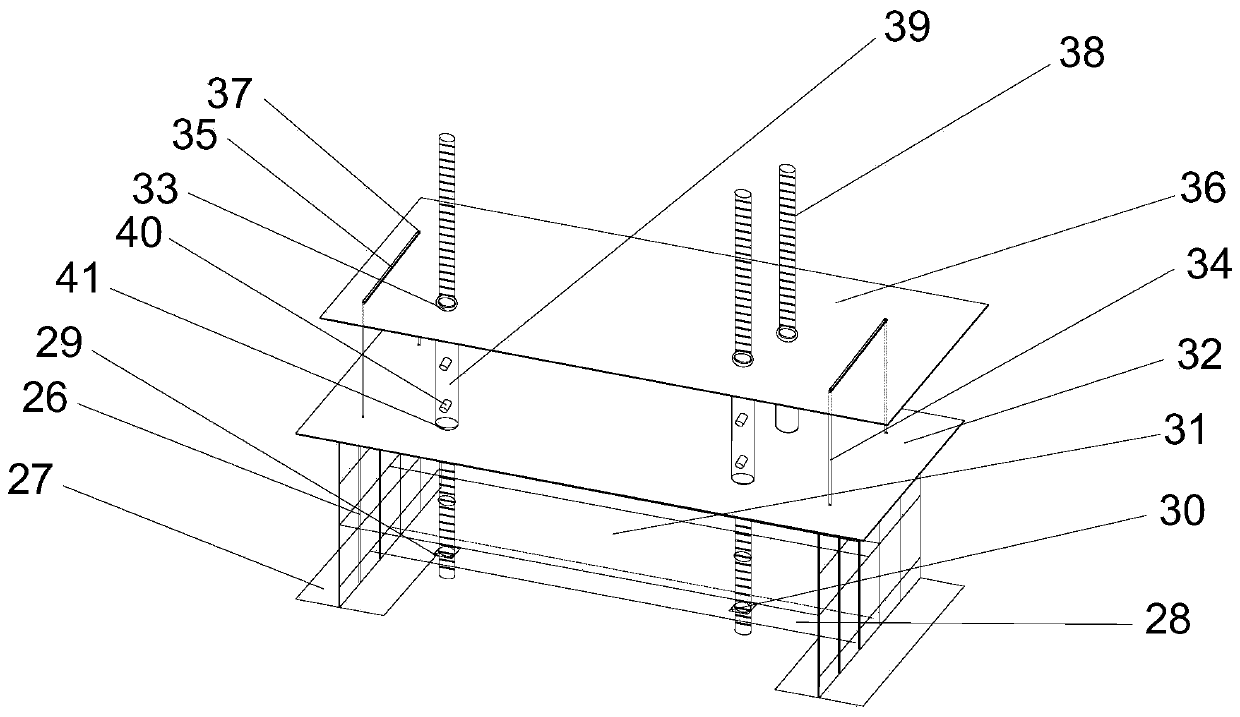

High-performance concrete arc-shaped fabricated gravity retaining wall and construction method

PendingCN113565129AComponent quality is easy to guaranteeFast installationArtificial islandsUnderwater structuresRetaining wallWaste material

The invention relates to the field of slope treatment and slope protection, in particular to a high-performance concrete arc-shaped fabricated gravity retaining wall and a construction method. The defects that a traditional concrete gravity type retaining wall wastes materials, the material strength utilization rate is low, the pouring and maintenance period is long, the construction quality is not easy to guarantee, and waste materials and waste slag are relatively large are overcome. The high-performance concrete arc-shaped fabricated gravity retaining wall is arranged on the broken stone hardcore and the concrete leveling layer and comprises a prefabricated panel and a plurality of connecting plate units, the multiple connecting plate units are spliced into connecting plate unit sets in an arc shape, the connecting plate unit sets are installed on the prefabricated panel in a step shape, and concrete or other waste slag and waste soil are poured into the connecting plate unit sets; and the prefabricated panel is attached to the slope body, and a pull rod on the prefabricated panel is inserted into the slope body to stabilize the prefabricated panel. The fabricated gravity retaining wall structure is adopted, so that each unit can be prefabricated, the construction period is shortened, and the construction cost is reduced; and meanwhile, the construction slag can be fully utilized, and transportation of the construction slag is reduced.

Owner:甘肃省交通规划勘察设计院股份有限公司

Prefabricated shear wall structure and construction method

ActiveCN109577517BImprove positioning and installation speedPrecise positioningWallsAuxillary members of forms/shuttering/falseworksFloor slabRebar

The invention relates to an assembled shear wall structure, which comprises an assembled shear wall, lateral reserved U-shaped ribs, vertical reserved connecting ribs, a floor slab, integral inner quick positioning pieces, a verticality adjusting rod, an adjusting rod base seat, frame brackets, a suspended steel bar shelving slat, an upper covering plate, an upper prefabricated wall body, a lowercast-in-situ wall body, a steel bar positioning steel plate, a prefabricated floating window and an integral adjusting and bearing support seat, wherein the lateral reserved U-shaped ribs are arrangedon the side surface of the assembled shear wall; the vertical reserved connecting ribs are arranged at the top of the assembled shear wall; the floor slab is arranged at the lower part of the assembled shear wall; and the assembled shear wall is connected with the mounted wall through a detachable shaped outer guiding frame plate for temporary guide assembly. The structure has the advantages thatby arranging the temporary guiding frame plate and connecting the integral inner quick positioning pieces, the shear force is guided to be quickly positioned and mounted, the positioning is accurate,the accuracy is guaranteed, the positioning and mounting speed of the shear wall is improved, the whole is more stable, and the quality safety is guaranteed.

Owner:中建八局华南建设有限公司

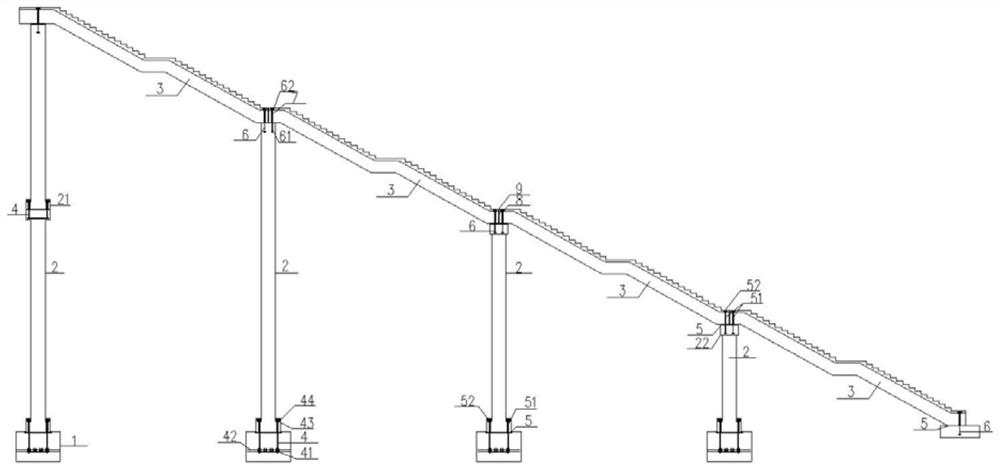

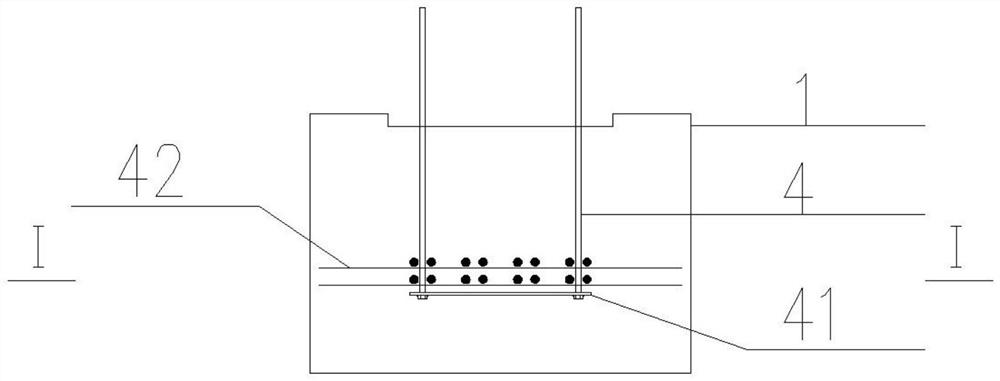

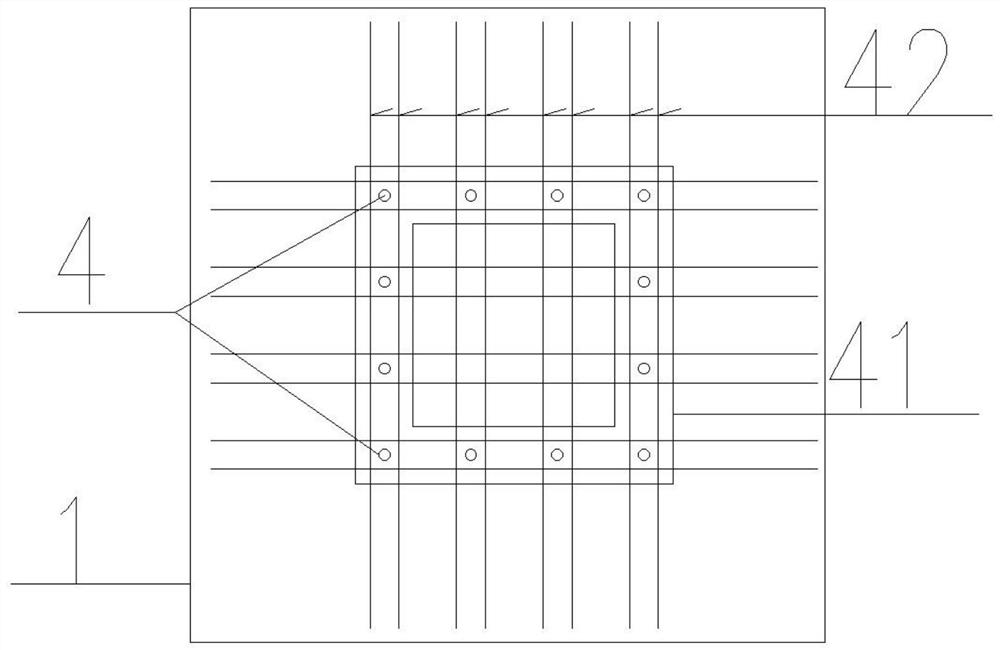

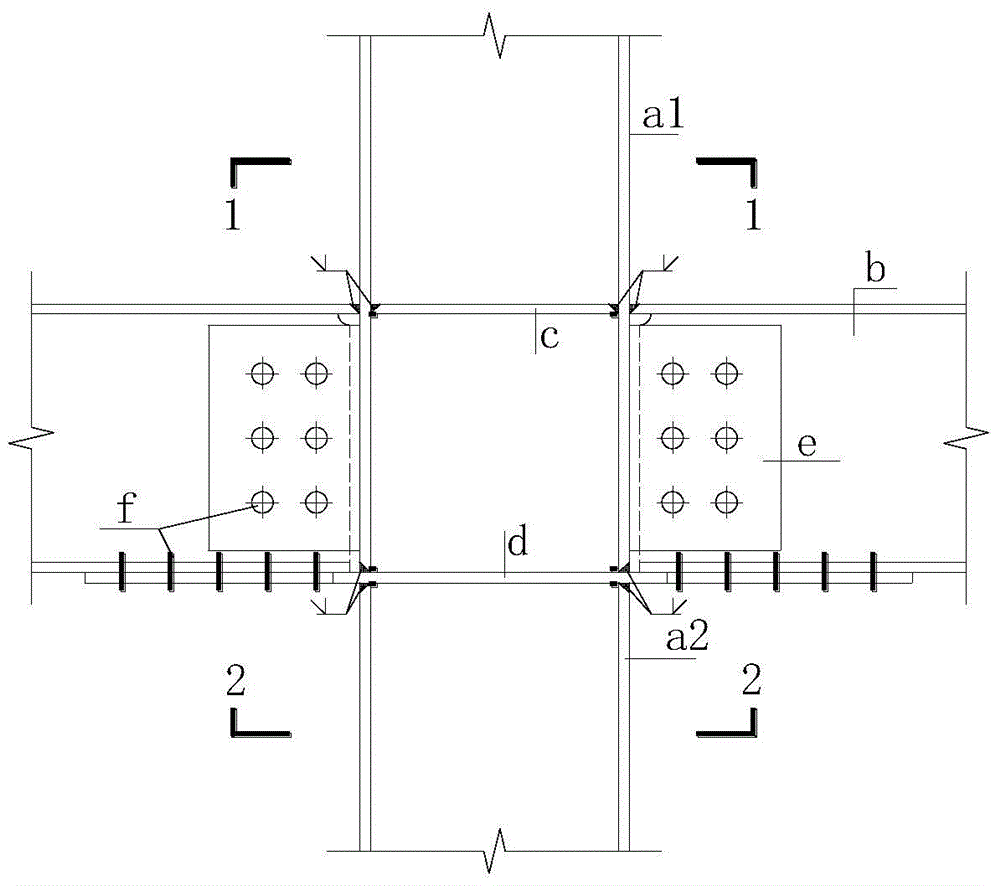

Rescue evacuation facility on fabricated railway bridge and construction method

PendingCN112458884AHas traffic effectSmall sizeBridge structural detailsStairwaysArchitectural engineeringGrout

The invention provides a rescue evacuation facility on fabricated railway bridge and a construction method. The rescue evacuation facility comprises a foundation body, stand columns and stairs, connecting columns are arranged at the bottoms of the stand columns, preformed holes correspond to connecting keys in the foundation body in a one-to-one mode, the stairs are arranged at the tops of the stand columns, and preformed holes are formed in the two sides of the bottoms of the stairs; shear key top free ends are arrange in a one-to-one corresponding manner with the bottoms of the stairs; Splicing seams are formed between the upper surface of the foundation body and the bottoms of the stand columns, the upper surface of the foundation body and the bottoms of the stand columns are spliced and connected with the connecting keys through the splicing seams, splicing seams are formed between the tops of the stand columns and the bottoms of the stairs, and the tops of the stand columns and the bottoms of the stairs are spliced and connected with the shear keys through the splicing seams; and grouting materials are arranged in the preformed holes of the connecting columns provided with theconnecting keys. The stand columns in an evacuation passage are high in height and small in size, the stand columns are prefabricated in factories and hoisted and assembled on site, supports do not need to be erected, and safety is high; stairs in the evacuation channel are of a continuous structure, prefabricated stairs are adopted, hole-by-hole hoisting and erection construction are conducted,and the site construction time is obviously shortened.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Hybrid connection joint between rectangular steel tube concrete column and h-shaped steel beam bolted and welded

InactiveCN103967133BImprove prefabrication rateTo achieve the effect of assemblyBuilding constructionsArchitectural engineeringStud welding

Owner:TIANJIN UNIV

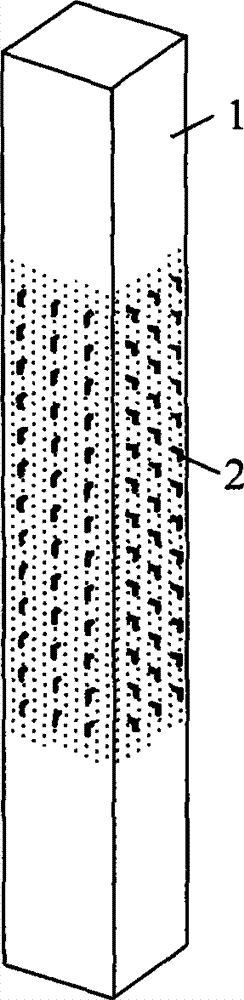

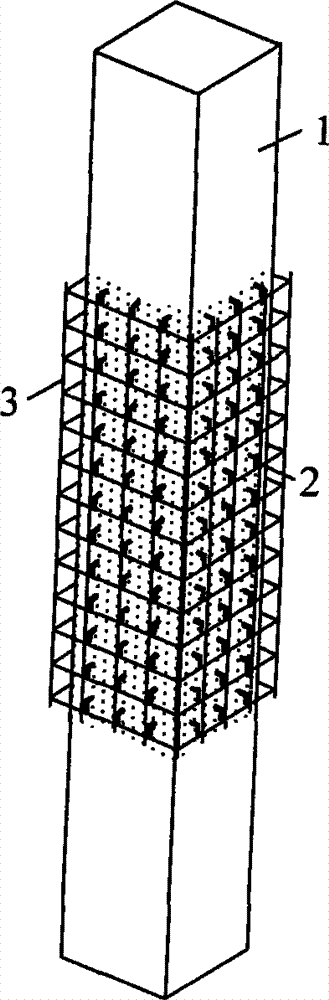

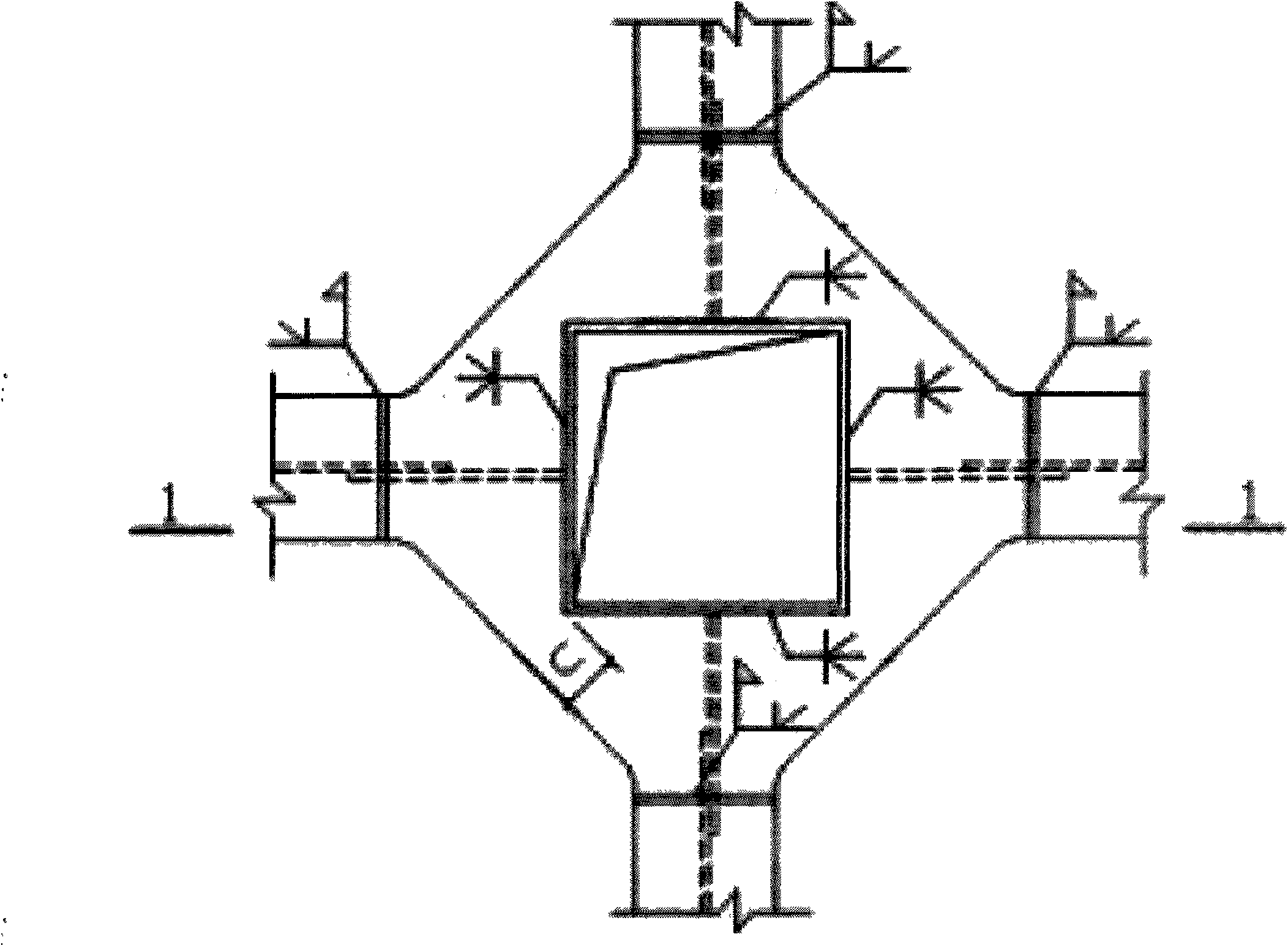

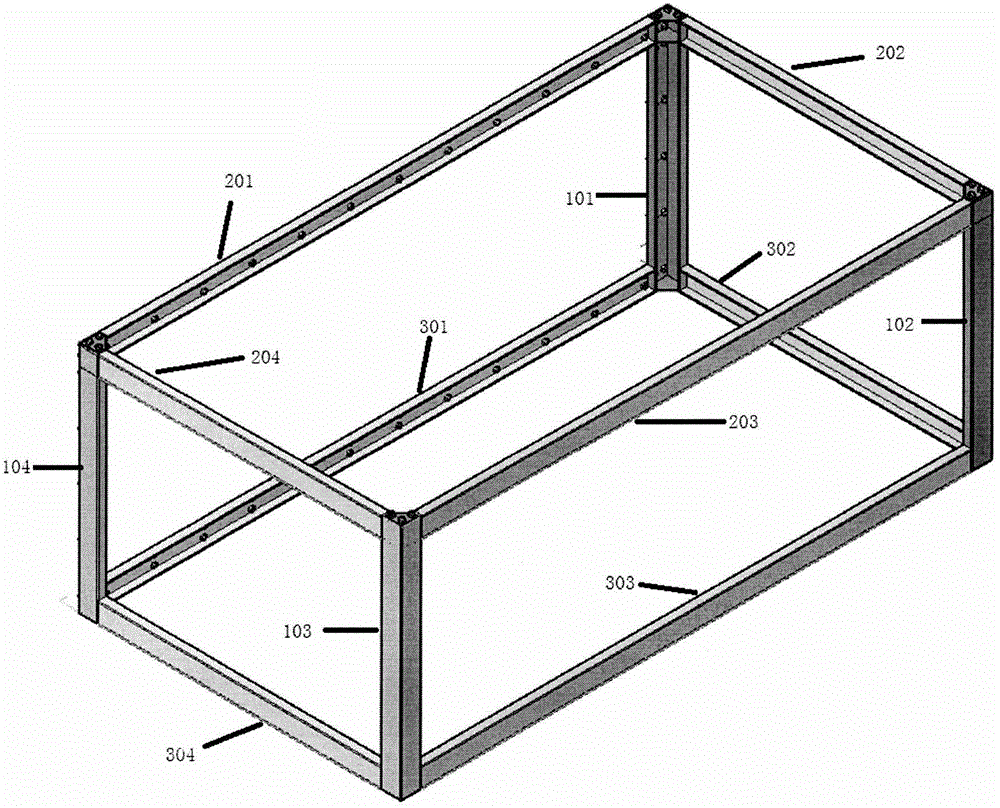

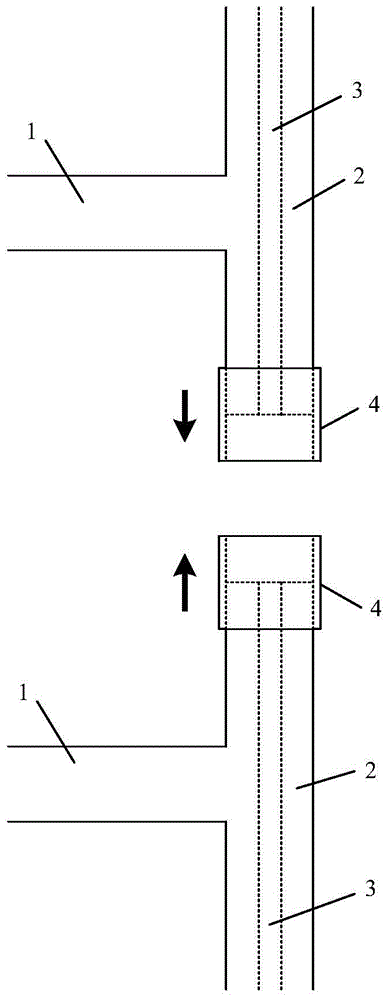

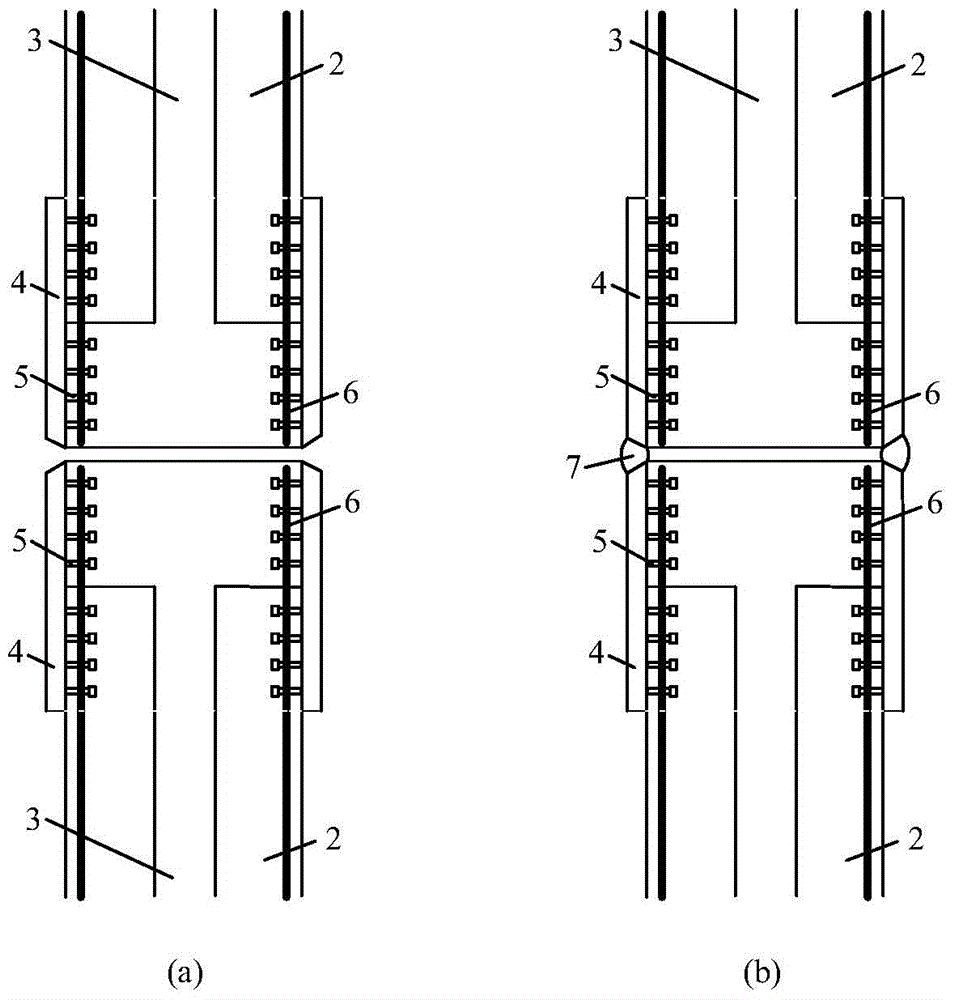

A Field Connection Method Between Prefabricated Reinforced Concrete Columns

ActiveCN104775516BAvoid pour-in-place constructionAvoid exposed cracksBuilding constructionsReinforced concrete columnButt welding

The invention relates to a field connecting method among prefabricated reinforced concrete columns, facilitates to realize a novel prefabricated assembly technology mode of node factory prefabrication-beam column field connection, prevents the scene casting of concrete in a beam column node area, and belongs to the technical field of structural engineering. The method comprises the following steps: through long round hole ways are reserved in the prefabricated reinforced concrete columns; the ends are coated with steel sleeves; beam column nodes serve as a whole prefabricated unit for lifting on the scene; the steel sleeves at the ends of the upper and lower layers of columns are connected through butt welding joints after being aligned; and finally, concrete is cast in the round hole ways and cavities of the steel sleeves. The method has the advantages of simple configuration, convenience for construction, high field installation speed, low concrete wet operation load, little influence on surrounding environments, excellent stress performance, reliable force transfer, prevention of exposure of concrete cracks in connection areas by means of the steel sleeves, provision of restraint effect, convenience for material taking and processing, low use level of steels and good economical efficiency.

Owner:TSINGHUA UNIV

A steel box-concrete composite main girder and construction method for long-span cable-stayed bridges

ActiveCN105544373BImprove axial stiffnessImprove carrying capacityCable-stayed bridgeBridge structural detailsBridge engineeringArchitectural engineering

The invention relates to a steel box-concrete composite girder for a long-span cable-stayed bridge and a construction method, belonging to the technical field of bridge engineering. The steel box-concrete composite girder comprises a single-box multi-chamber streamlined flat steel box beam and is characterized by also comprising side webs and shear connectors, wherein the side webs are positioned at the two sides of the single-box multi-chamber streamlined flat steel box beam so as to encircle a closed chamber; and the shear connectors are welded at the inner side of the chamber, and concrete is poured. The concrete in the steel box beam provided by the invention has large axial rigidity and high carrying capacity, can bear the huge axial force and bending moment in a longitudinal bridge direction, obviously reduces the thickness of steel plates of the steel box beam, the quantity of stiffening ribs, transverse diaphragms and welded seams, the steel consumption and the like, reduces the cross section height, and has obvious economic benefits.

Owner:TSINGHUA UNIV

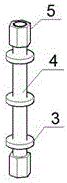

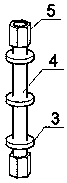

Cold-formed thin-walled steel building interstory reinforcement components

The invention discloses an interlayer reinforcement component of a cold-bent thin-wall type steel house. The interlayer reinforcement component is characterized by being of a truss type structure and comprising four upright steel bushings (4) with rectangular projections, and hollow supports (5) which are fixed at two ends of the steel bushings (4) and are coaxial with the steel bushings (4), wherein horizontal transverse steel bars (6) or horizontal longitudinal steel bars (7) are welded between every two adjacent hollow supports (5); oblique steel bars (1) with equal lengths are welded on the hollow supports (5) at four corners of each of front and rear side walls formed by the horizontal transverse steel bars (6) and the steel bushings (4) along the diagonal direction; the far end of each oblique steel bar (1) is welded on a perforated steel plate (2); reinforcement hoops (3) are welded alternately on the steel bushings (4). The reinforcement component is applicable to the cold-bent thin-wall type steel house which is of a multilayer house beam column structure; the force transmission path is direct and reliable; the lateral resistant ability and the capability of bearing the vertical load action of the whole structure can be obviously improved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com