Rescue evacuation facility on fabricated railway bridge and construction method

A railway bridge, prefabricated technology, applied in bridge construction, bridges, bridge parts, etc., can solve the problems of difficult to control the vibrating quality of concrete pouring, poor stability, large scale of cast-in-place supports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

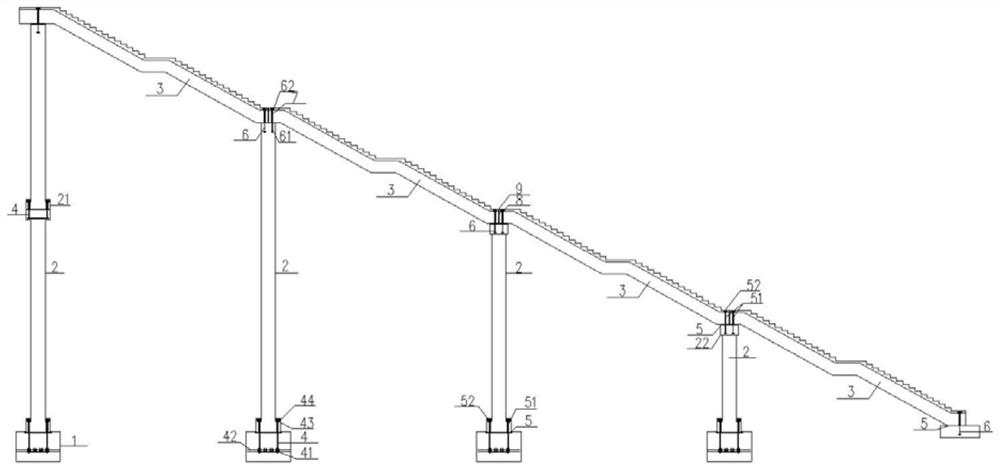

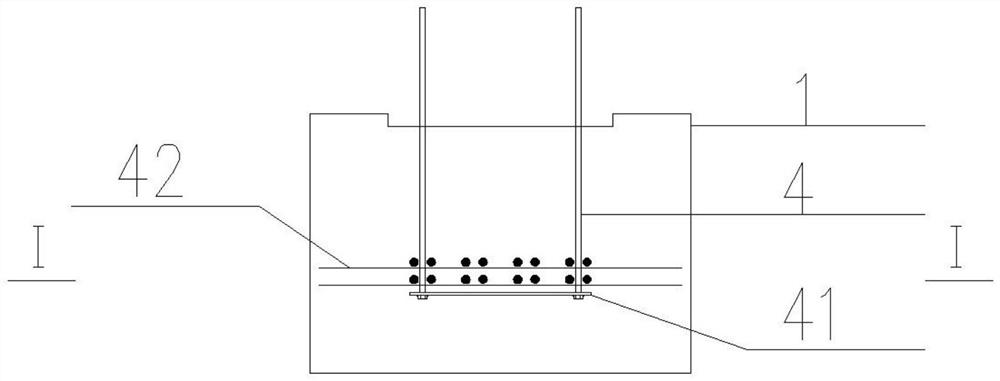

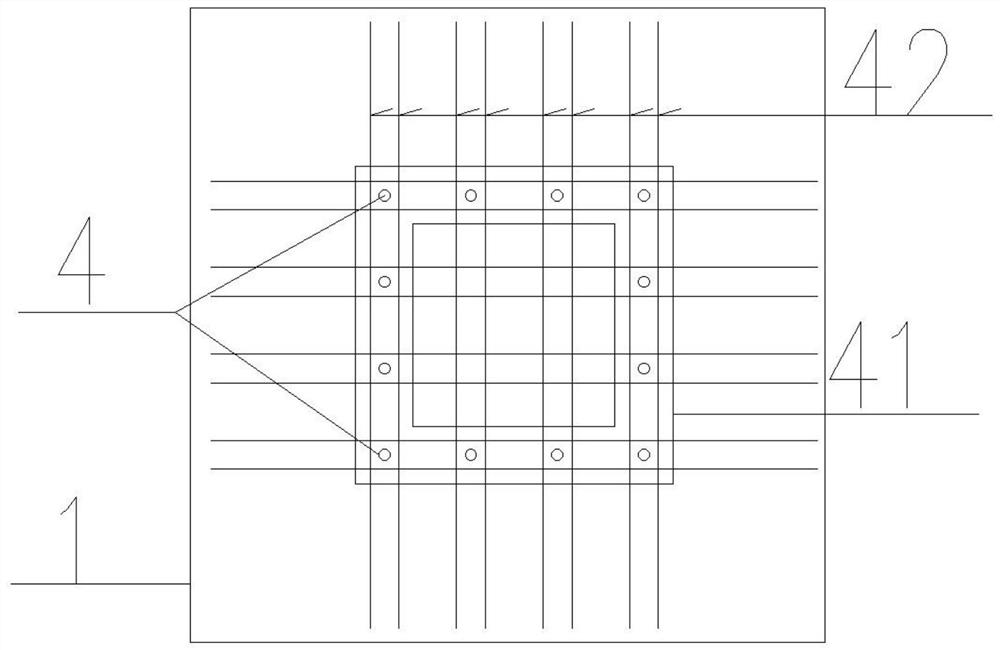

[0039] Such as Figure 1-6 As shown, the present invention is an assembled railway bridge rescue evacuation facility and a construction method, including the base body 1, the column 2 and the stairs 3, the base body 1 is a rectangular structure, and the connection key is disposed in the base body 1 4, and the connection key 4 is free ends the upper surface of the base 1, and the bottom portion is provided with a connecting post 21, and a plurality of pre-projected holes 7 are provided on the connecting post 21, and the reserved hole 7 and the connection key within the base body 1 are provided. 4 One-one, the top of the column 2 is provided with a shear key 6, and the top of the shear key 6 is free ends the top surface of the column 2, and the stairs 3 are disposed on the top of the column 2 and the stairs 3 is provided with a reserve hole 7. The upper free end of the shear key 6 corresponds to the reserved hole 7 at the bottom of the stairs 3, and the upper surface of the base body...

Embodiment 2

[0053] Such as Figure 7 In still, the beam 22 is the L-type structure, and there is a shear key 6 in which the stair 3 is the interleave structure, and the lower end is connected to the beam 22, and the beam 22 is provided with a reserved hole 7. The stairs 3 are laid in the horizontal region of the beam 22, and the fill seam 8 and the sealant 9 are provided in the vertical region of the stair 3 and the beam 22, and the shear bond 6 penetrates into the reserved hole 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com