High-performance concrete arc-shaped fabricated gravity retaining wall and construction method

A high-performance concrete and retaining wall technology, used in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of low material strength utilization, long pouring and maintenance construction period, and difficult to guarantee construction quality, and achieve the quality of components. Easy to guarantee, save shipping costs, fast installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

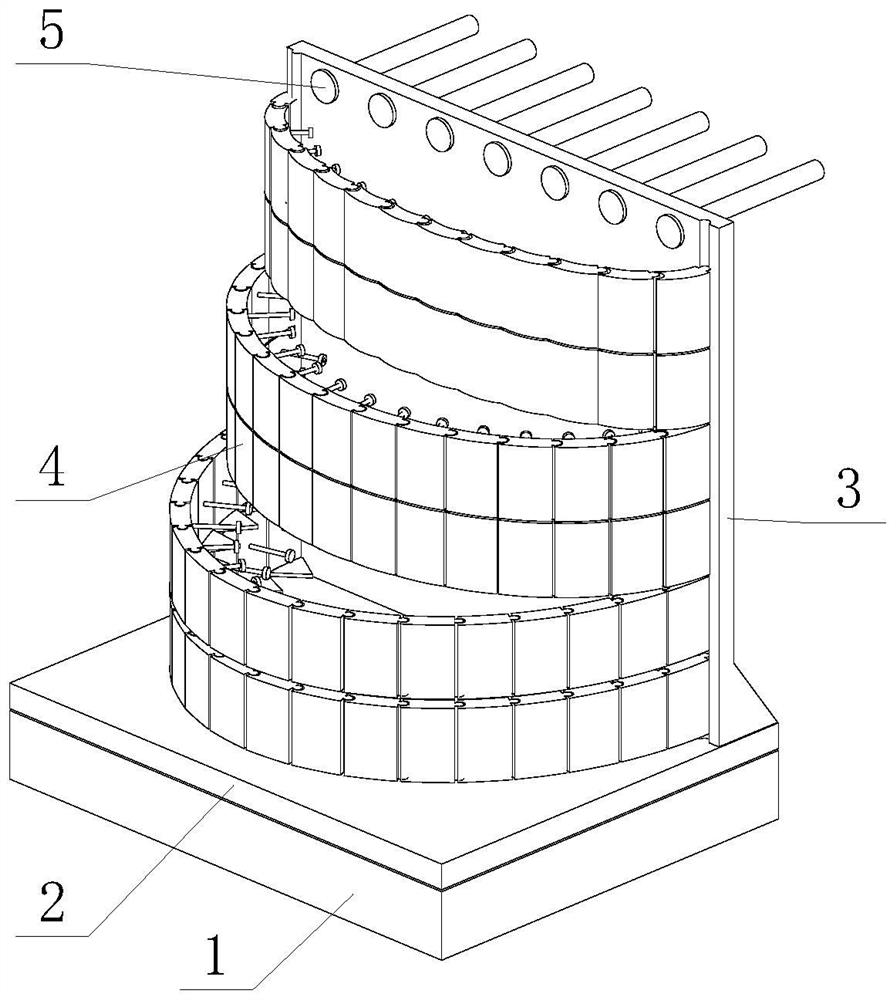

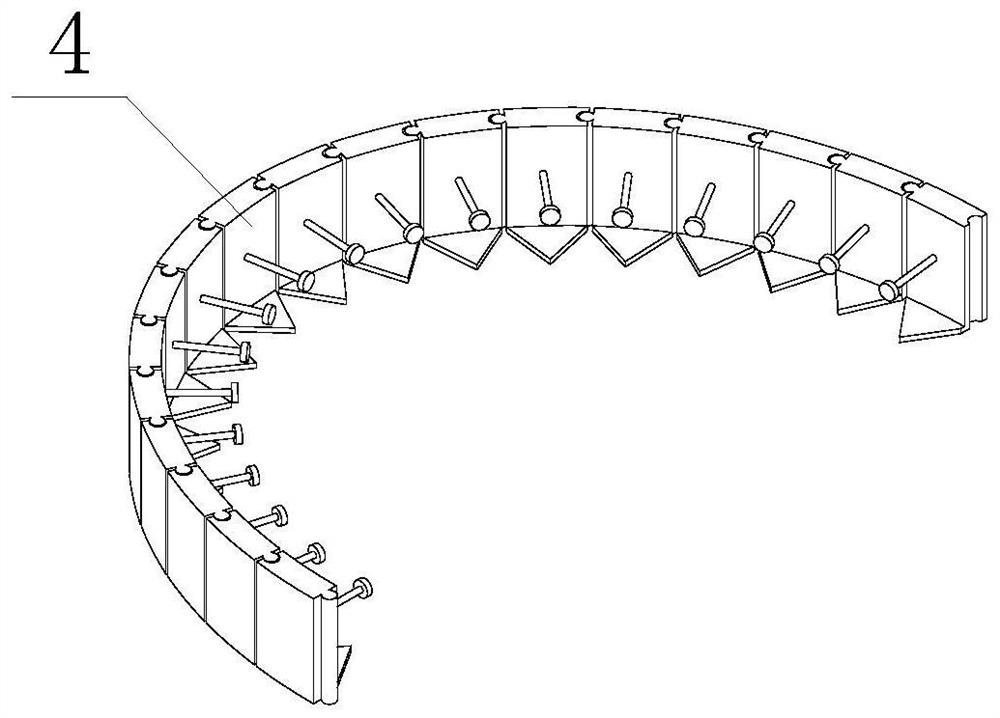

[0030] like Figure 1~4 As shown, the present invention provides a high-performance concrete arc-shaped assembled gravity retaining wall and a construction method thereof. The high-performance concrete assembled gravity-type retaining wall includes a crushed stone cushion 1, a concrete leveling layer 2, a prefabricated panel 3 and connecting Plate unit 4. The specific structure is as follows.

[0031] like figure 1 As shown, the crushed stone cushion 1 and the concrete leveling layer 2 need to be laid on the bottom of the slope body, the crushed stone cushion 1 is laid first, and the concrete leveling layer 2 is poured on the crushed stone cushion 1. Fix the prefabricated panel 3 on the concrete screed 2.

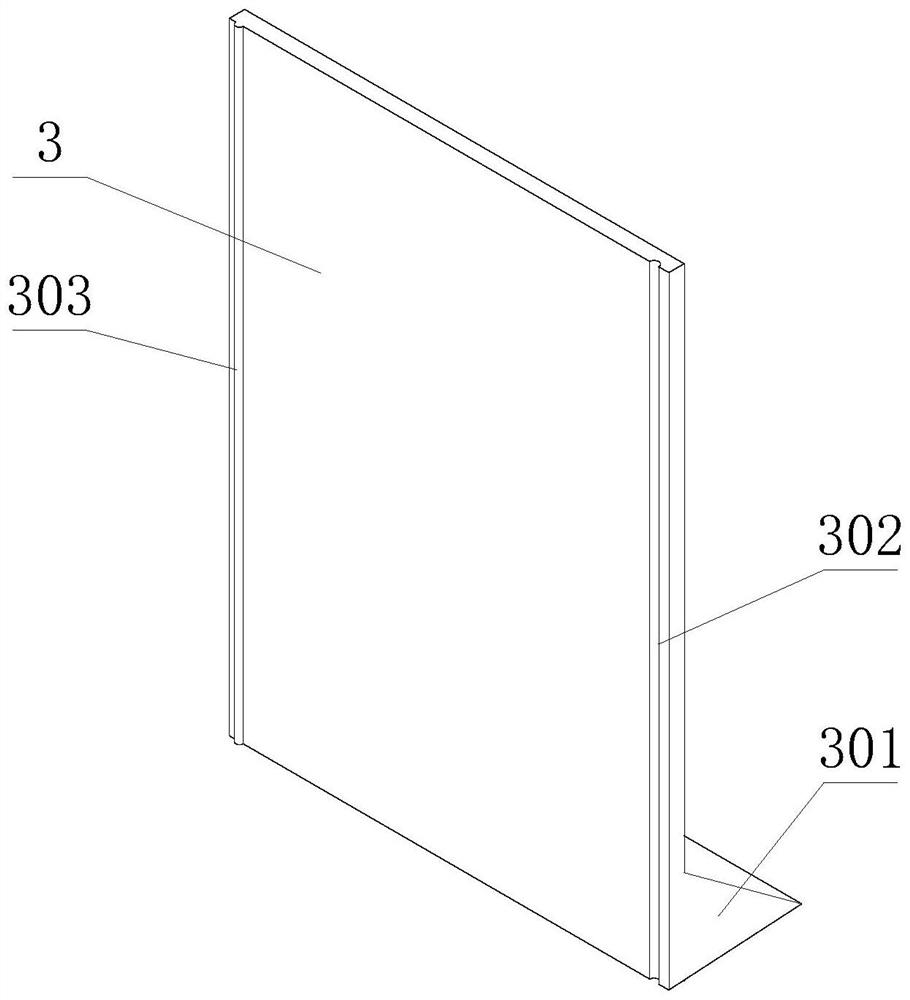

[0032] The structure of the prefabricated panel 3 is as follows figure 2 As shown, the bottom is a triangular base 301, the triangular base 301 is fixed on the concrete leveling layer 2, the triangular base 301 and the panel slot 302 are arranged on both sides of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com