Fully assembled steel structure connection components and installation methods

A technology for connecting components and steel structures, applied in building structures, buildings, etc., can solve the problems that affect the bearing capacity of nodes and the overall seismic capacity, the initial defects are easily generated in the node area, and the quality of welds is difficult to ensure, and the quality of components is easy to achieve. Guaranteed, convenient and convenient selection, the effect of preventing local stress concentration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

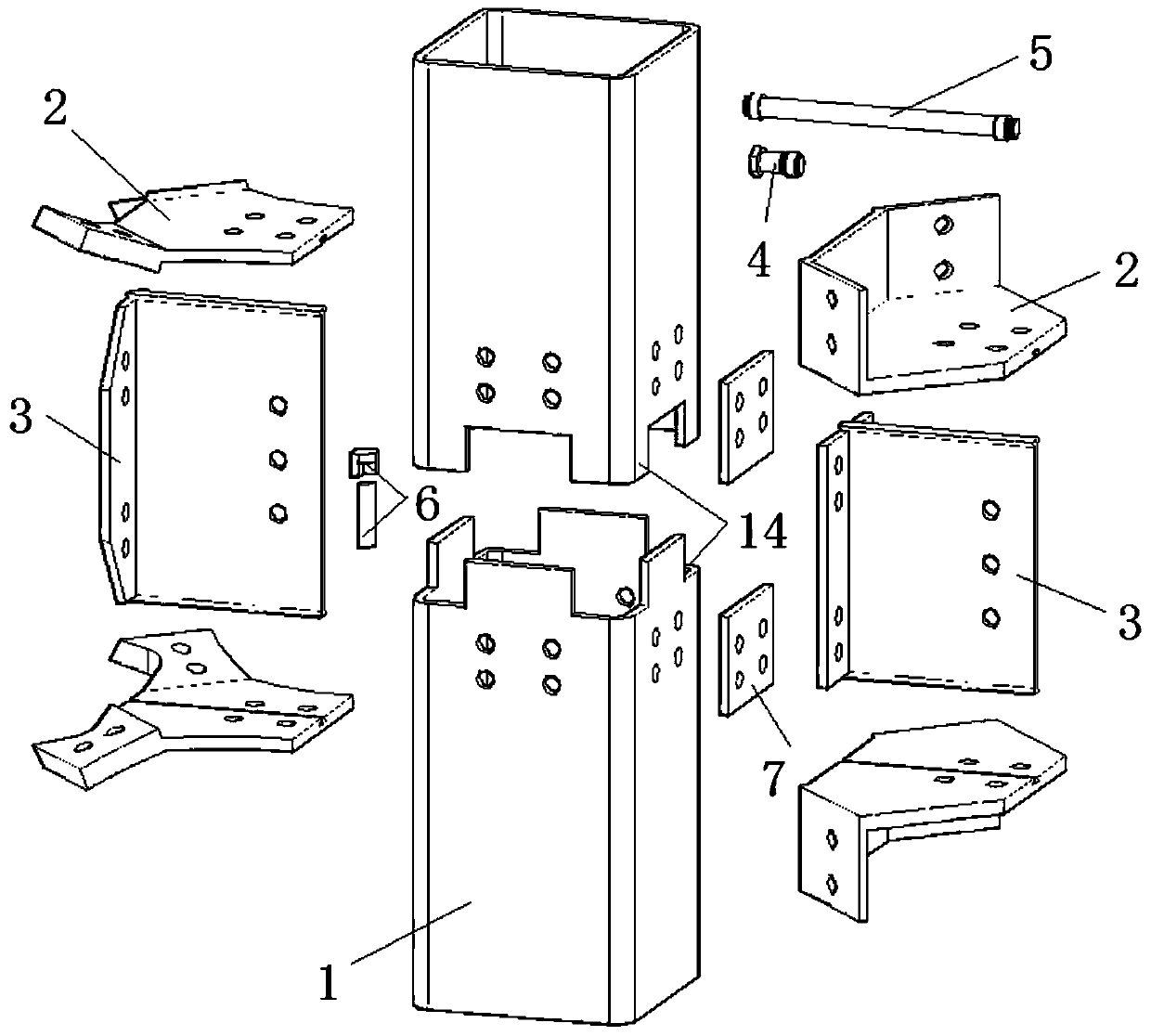

[0052] Such as Figure 1-3 , 22, a fully assembled steel structure connection assembly according to the present invention includes 2 square steel pipe columns 1, an outer ring plate assembly and several connecting members, and the upper and lower square steel pipe columns are along the steel pipe at the splicing end. The column wall is provided with corresponding concave-convex grooves 14, so that the adjacent joints present regular concave-convex and broken-line shapes. When splicing, the protrusion (depression) of the lower section of the square steel pipe is inserted into the depression (protrusion) of the upper section of the steel pipe, making the connection of the two sections of square steel pipe more precise. The square steel pipe column is formed by plugging the upper and lower square steel pipes through the splicing auxiliary device 6, and is fixed by bolting with the riser assembly of the outer ring plate at the same time. The splicing auxiliary device is a pair of...

Embodiment 2

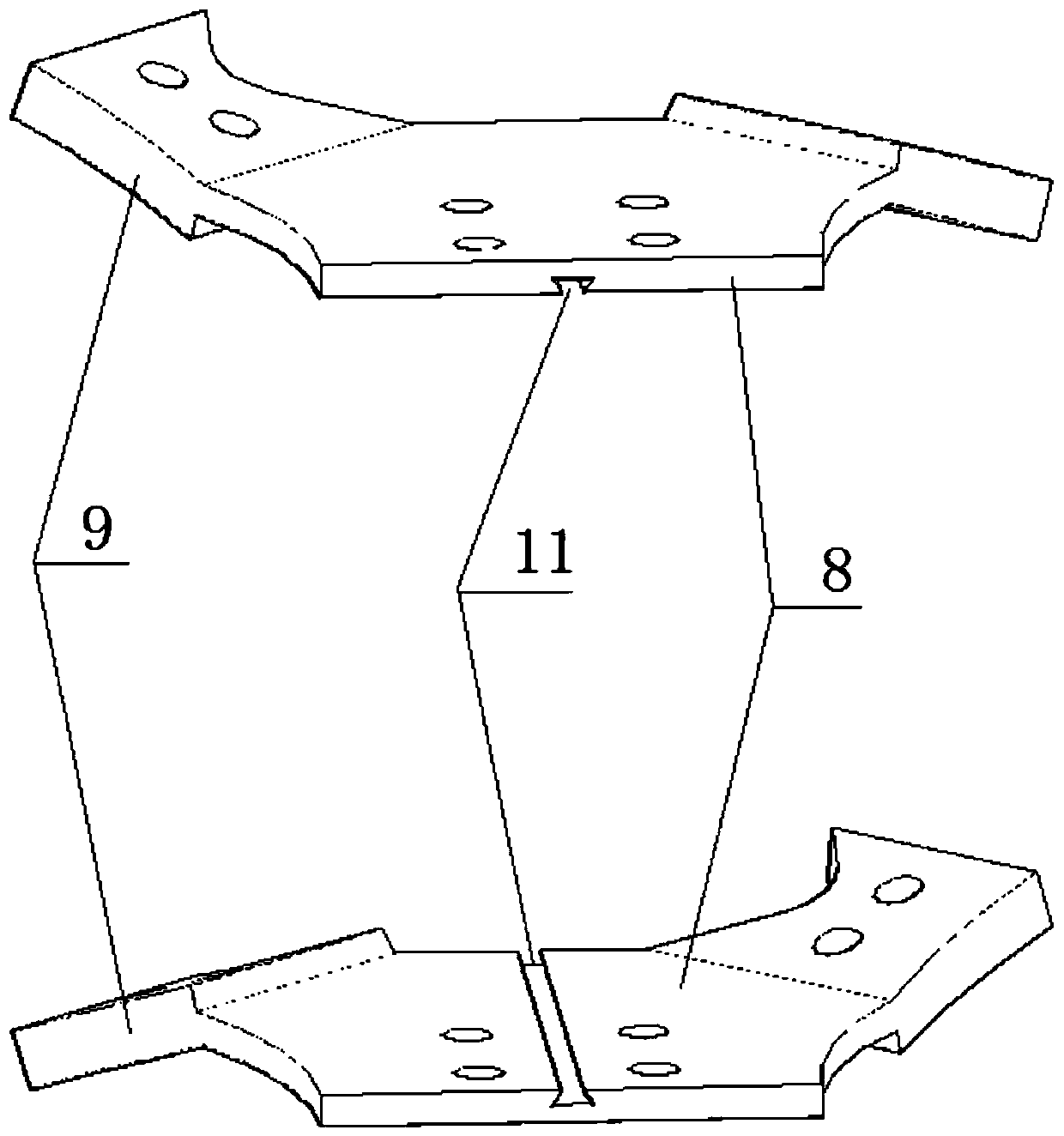

[0060] Such as figure 1 , 12 , 13, the difference from Embodiment 1 is that the horizontal veneer is structural form B, including three connecting plates, the connecting plates and the horizontal plate are in the shape of a bucket, and the connecting plates on both sides and the middle connecting plate are respectively perpendicular to the horizontal The connecting plates on both sides are bent outward relative to the middle connecting plate, and respectively form the same angle with the middle connecting plate. Connect the connecting plates on both sides of one single board with the connecting plates of the other two single boards with bolts, which can be assembled in the vertical direction, and ensure that the horizontal boards of each horizontal single board assembly remain horizontal and at the same height on the plane.

[0061] All the other technical features are the same as in Embodiment 1.

Embodiment 3

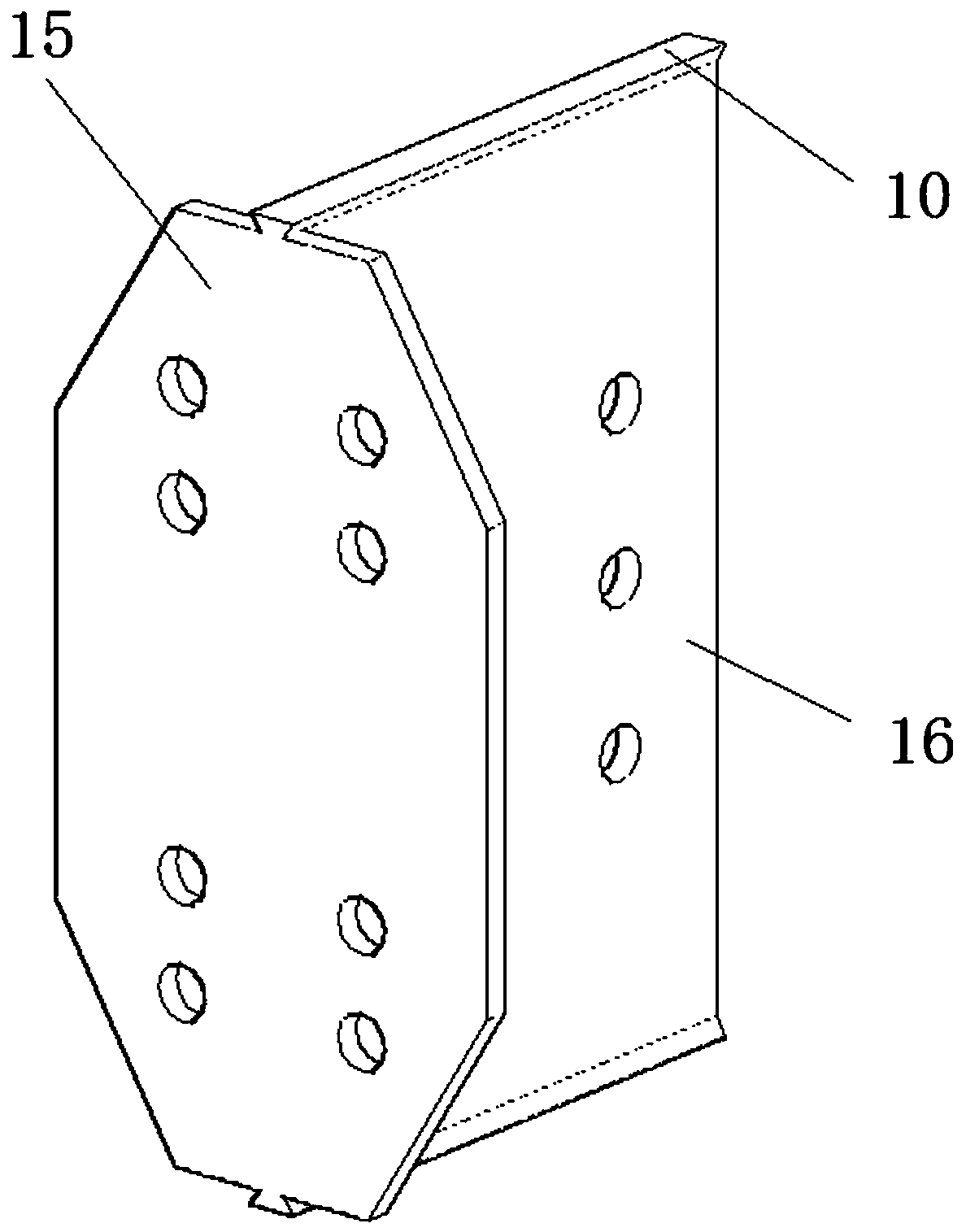

[0063] Such as image 3 As shown, the upper and lower surfaces of the outer plate are provided with protruding prisms 10, and the cross-section of the prisms is isosceles trapezoidal. The corresponding position on the bottom surface of the horizontal plate is provided with a chute 11 corresponding to the shape of the prisms. The chute is an isosceles trapezoidal chute.

[0064] All the other technical features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com