Assembled CF autoclaved ceramic powder aerated concrete external wall hanging plate and manufacturing method thereof

A technology of aerated concrete slab and aerated concrete, which is applied in chemical instruments and methods, manufacturing tools, ceramic molding machines, etc., can solve the problems of complicated factory production process, easy entry into the thermal insulation layer, and the intermediate thermal insulation board absorbs water and becomes damp, etc. Achieve the effect of improving construction conditions and environment, simple construction process and less construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

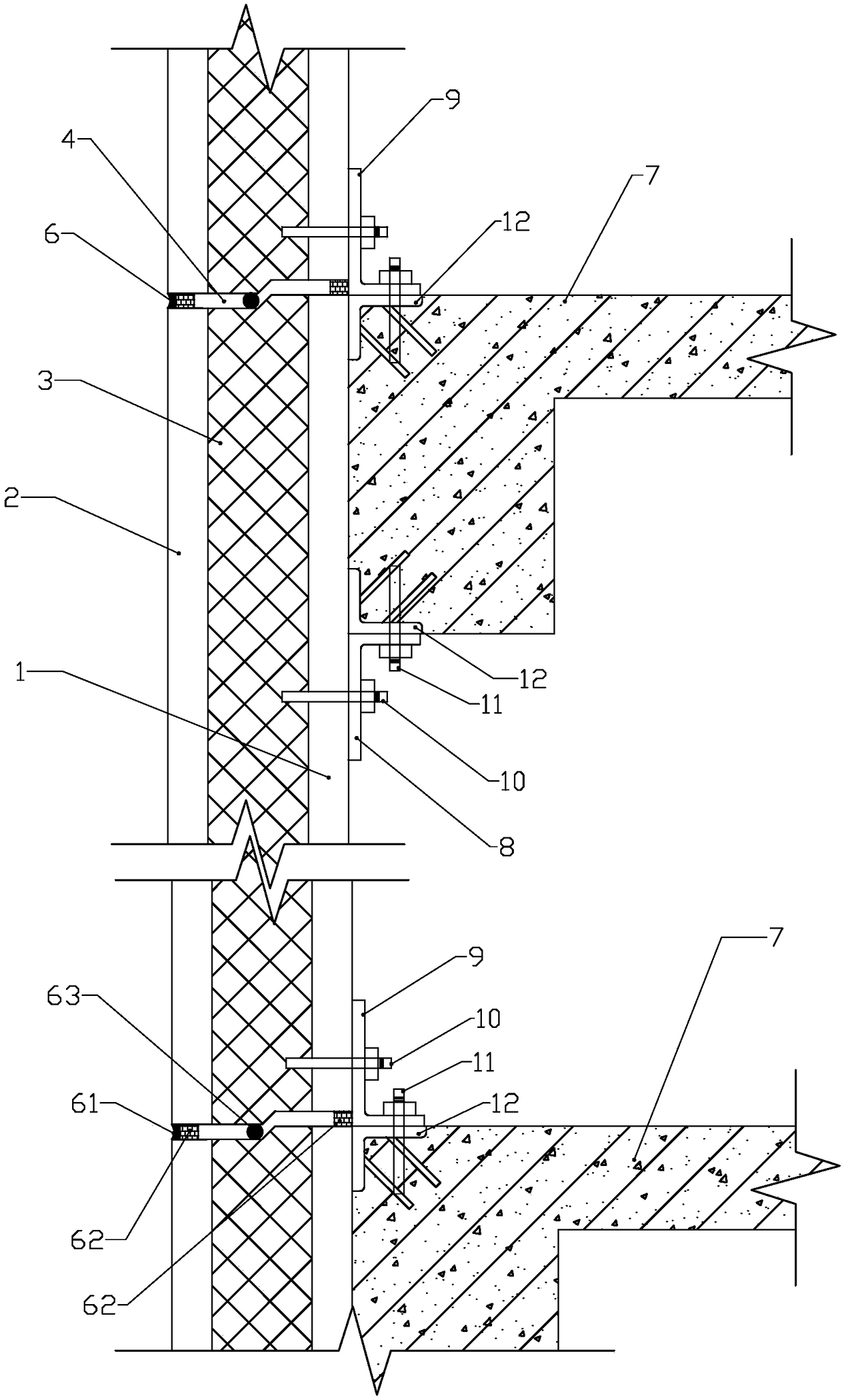

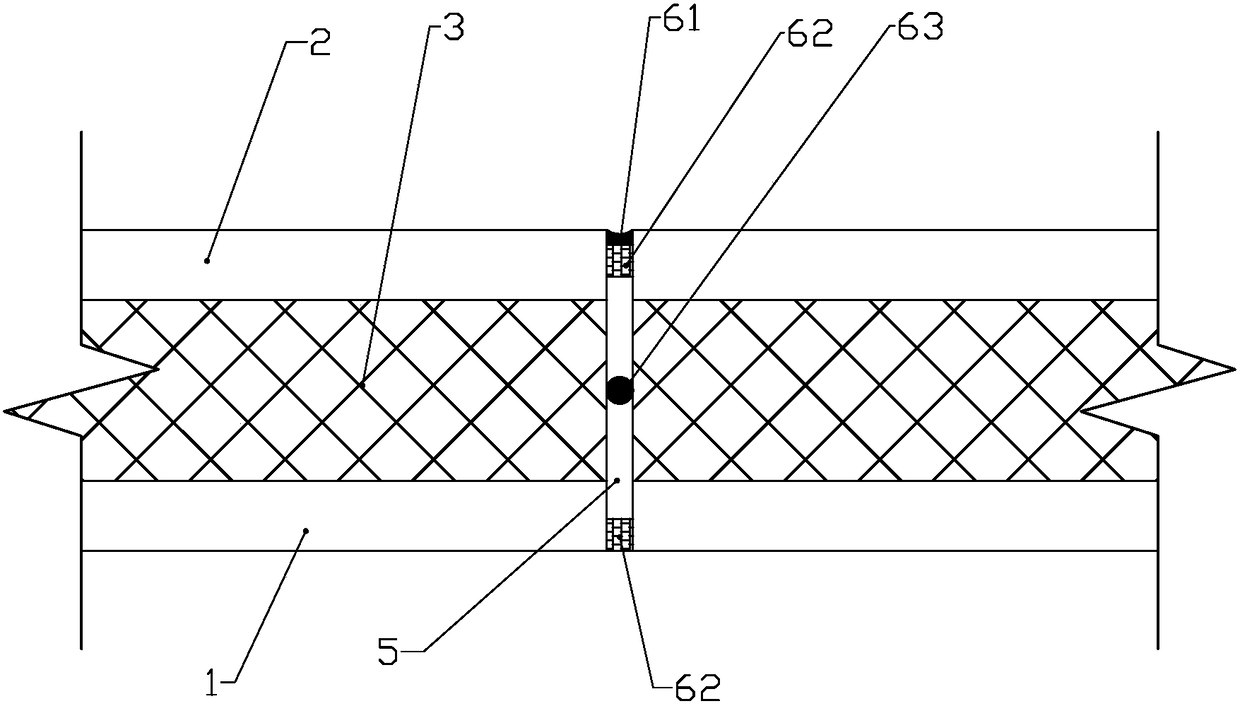

[0040] Refer to the attached figure 1 to attach Figure 8 The prefabricated CF autoclaved porcelain powder aerated concrete exterior wall hanging panel and the manufacturing method of the present invention will be described in detail below.

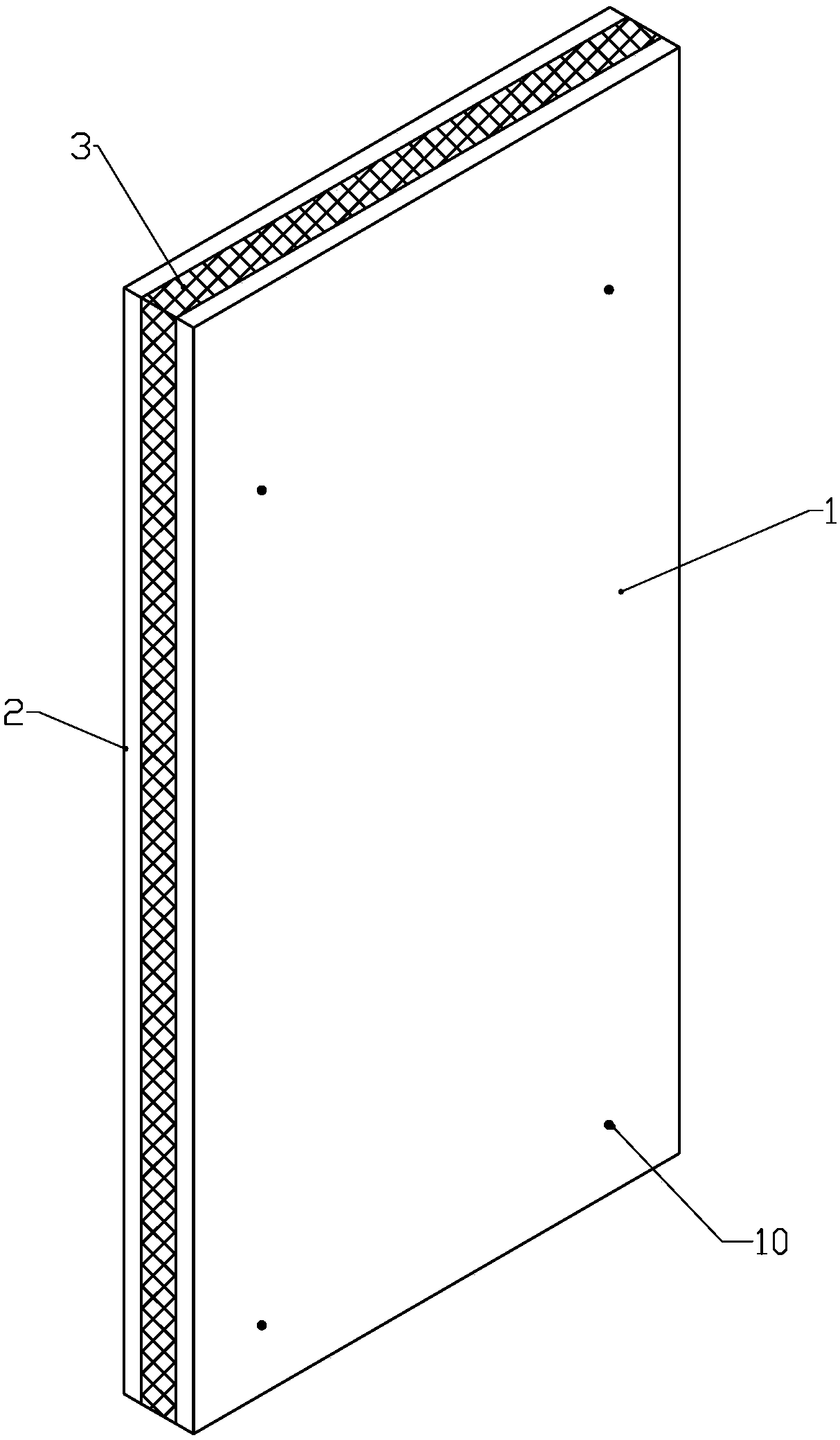

[0041] An assembled CF autoclaved porcelain powder aerated concrete exterior wall siding of the present invention comprises a plurality of interconnected exterior wall siding bodies, and each exterior wall siding body includes an inner leaf plate 1 and an outer leaf plate 2 respectively and the middle insulation board 3, the inside and outside of the middle insulation board 3 are respectively provided with an inner blade 1 and an outer blade 2, the inner blade 1 and the outer blade 2 are reinforced concrete thin plates, and the concrete thin boards are provided with Steel wire mesh, the middle insulation board 3 adopts CF autoclaved porcelain powder aerated concrete board, the horizontal joint 4 between the two adjacent exterior wall han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com