Construction process of metallic corrugated culvert pipes

A technology of corrugated culverts and construction technology, which is applied in the direction of buildings and road floors, etc., can solve the problems of low service life of metal corrugated culverts, increased maintenance workload, and low construction efficiency, achieving far-reaching environmental protection significance, small maintenance workload, and low construction short term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

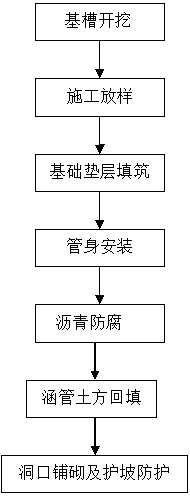

[0023] Such as figure 1 Shown, a kind of construction technique of metal corrugated culvert comprises the following steps:

[0024] Step 1. Foundation trench excavation

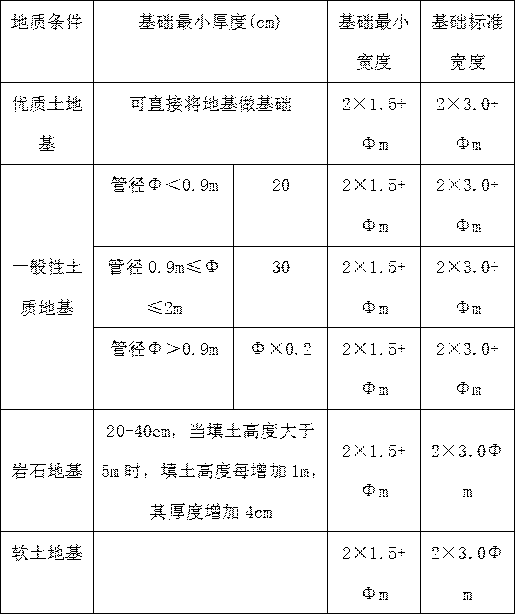

[0025] 1) When there are design requirements, excavate the foundation trench according to the design requirements; when there is no design requirement, refer to the following table for the excavation width of the foundation trench and the thickness of the foundation foundation. In order to facilitate mechanical rolling, it is recommended to use the standard width of the foundation.

[0026]

[0027] 2) Excavation of the foundation trench shall be carried out in accordance with the requirements. When the base soil is bad soil layer such as silt, it shall be replaced and over-excavated shall be avoided as far as possible. Submit to supervision and design unit for approval.

[0028] 3) The soil foundation pit dug to the elevation shall not be exposed, disturbed or soaked for a long time, and the size, eleva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com