Rectangular pipe column and H-shaped steel beam vertical externally-connected rigidly-connected joint

A technology of rectangular tubes and steel beams, which is applied in the field of vertical external rigid joints, which can solve the problems of large size, inconvenient handling, and influence of interior decoration of houses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

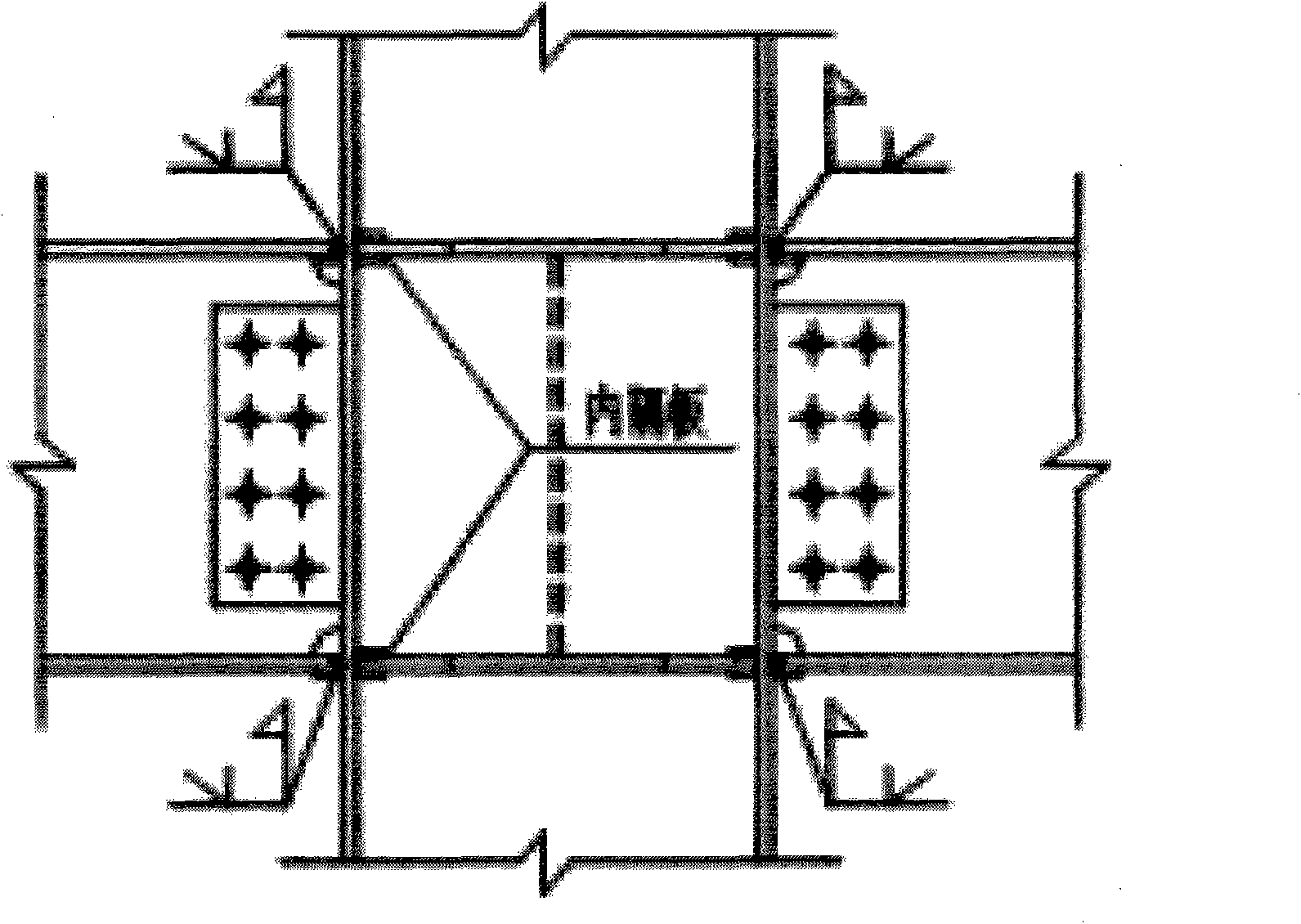

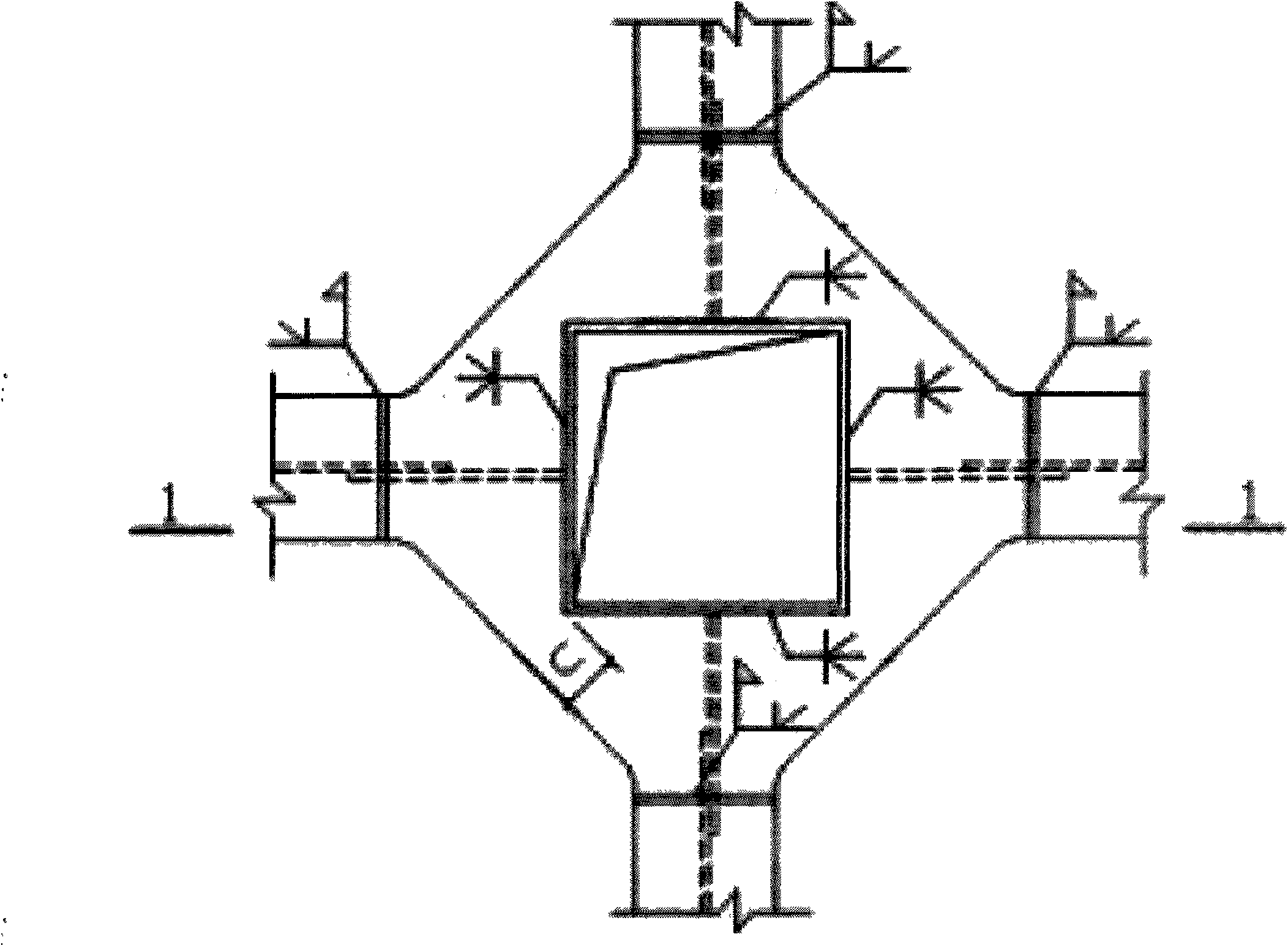

[0034] Such as Figure 1-13 As shown, the vertically externally rigidly connected node between the rectangular pipe column and the H-shaped steel beam of the present invention includes the rectangular pipe column 2 connected to the steel structure and the H-shaped steel beam 3 connected to the side of the rectangular pipe column, as In the first specific embodiment of the present invention, a box-shaped corbel connecting piece 1 is arranged between the rectangular pipe column and the H-shaped steel beam to form a limb node, and the box-shaped corbel connecting piece includes The upper end plate 11 and the lower end plate 12 arranged vertically to the center line of the pipe column and the vertical plate 13 arranged between the upper and lower end plates, the upper and lower end plates are all in the shape of a hexagon, and the hexagon consists of a trapezoid and a side b a Composed of a rectangular combination consistent with the long base of the trapezoid, the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com