Reinforcing structure between longitudinal and transverse walls of cold-formed thin-walled section steel house

A technology of cold-formed thin-walled steel and reinforced structures, which is applied in building construction and construction, and can solve problems such as structural collapse, failure of connections between walls and floors, failure of side and corner wall panels, etc., to achieve easy removal , enhance the anti-torsion ability of the side outside the plane, and improve the effect of anti-damage ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

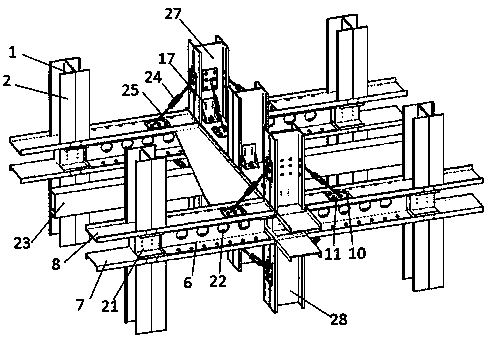

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a cold-formed thin-walled steel structure house wall strengthening method, characterized in that:

[0043] A reinforced structure between the vertical and horizontal walls of a cold-formed thin-walled steel house, including beams and wall frame columns that cooperate with each other:

[0044] The wall frame column includes the lower layer column and the upper layer column, which are composed of two C-shaped steel 2 that are back-to-back and fixed with self-tapping screws 13, and the corner wall wall frame columns are composed of four C-shaped steel 19 that are back-to-back and fixed with self-tapping screws 13 constitute;

[0045] The beams include a C-shaped steel floor beam 23, connecting the U-shaped steel top beam 7 of the lower building with the opening downwards of two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com