A steel box-concrete composite main girder and construction method for long-span cable-stayed bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

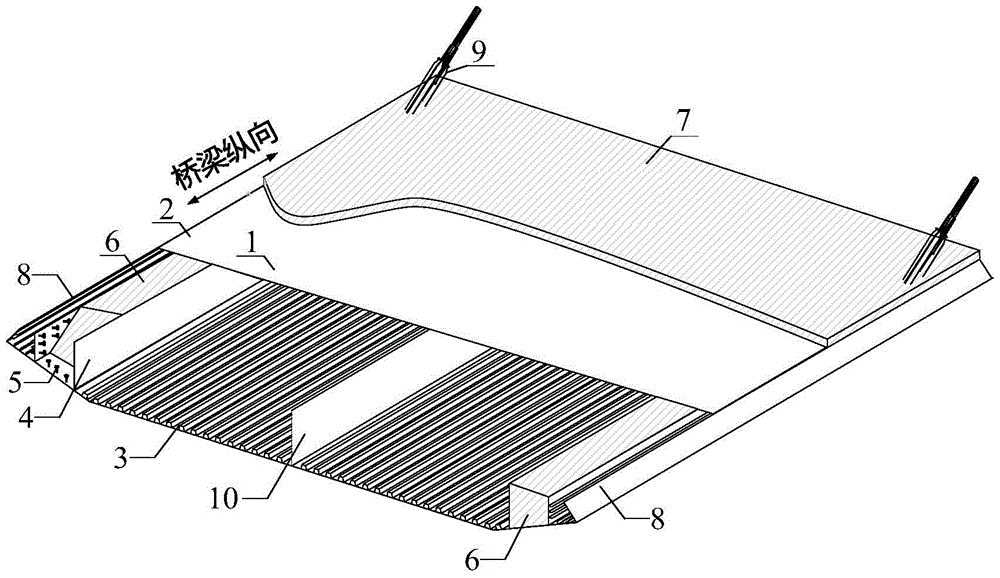

[0033] Steel box-concrete composite girder for long-span cable-stayed bridges, the composite girder includes single-box multi-chamber streamlined flat steel box girder 1, side web 4, such as figure 1 , 2 As shown, the single-box multi-room streamlined flat steel box girder includes steel roof 2, steel bottom plate 3, bridge deck system 7, air nozzle 8, and middle web 10, and the side webs are welded on both sides of the single-box multi-room streamlined flat steel box girder The plate 4 forms a box chamber, and the shear connector 5 is welded on the inside of the box chamber, and the concrete 6 is poured to form a whole, which jointly bears the coupling effect of the compression and bending load, and avoids the buckling of the steel plate.

Embodiment 2

[0035] Steel box-concrete composite girder for long-span cable-stayed bridges, the composite girder includes split double-box steel box girder 11, side web 4, such as image 3 , 4 As shown, the split-type double-box steel box girder includes steel roof 2, steel bottom plate 3, bridge deck system 7, air nozzle 8, and transverse connector 12, which are formed by welding side webs 4 on both sides of the split-type double-box steel box girder. The box chamber is formed by welding shear connectors 5 and pouring concrete 6 on the inside of the box chamber to jointly undertake the coupling effect of compression and bending loads and avoid buckling of the steel plate. The transverse connecting member 12 may be an I-beam, a diaphragm or a diagonal bar type transverse connecting system.

[0036] The deck system described in the above embodiments is an orthotropic steel deck pavement system or a steel-concrete composite deck system.

[0037] In the above embodiment, the height of concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com