Composite-material automobile transmission shaft formed by pulling, squeezing and winding and preparation method thereof

A composite material, pultrusion winding technology, applied in the direction of control devices, vehicle parts, transportation and packaging, etc., can solve the problem of unfavorable transverse performance and other performance composite material automobile transmission shaft manufacturing, the difficulty of accurate laying and production of 0° fibers Low efficiency and other problems, to achieve the effect of enhancing the connection strength, ensuring efficient production, and ensuring the consistency of finished product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

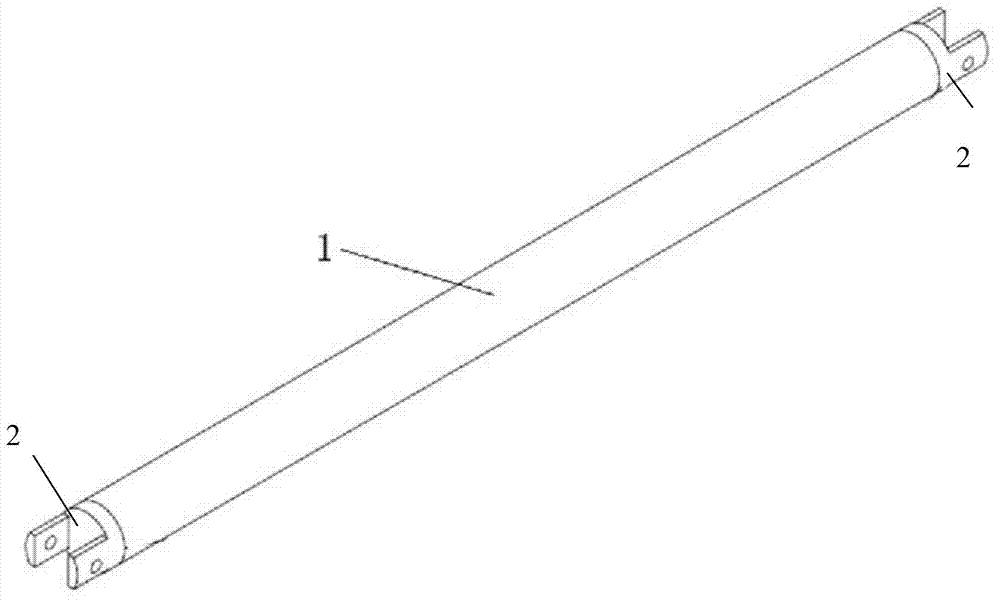

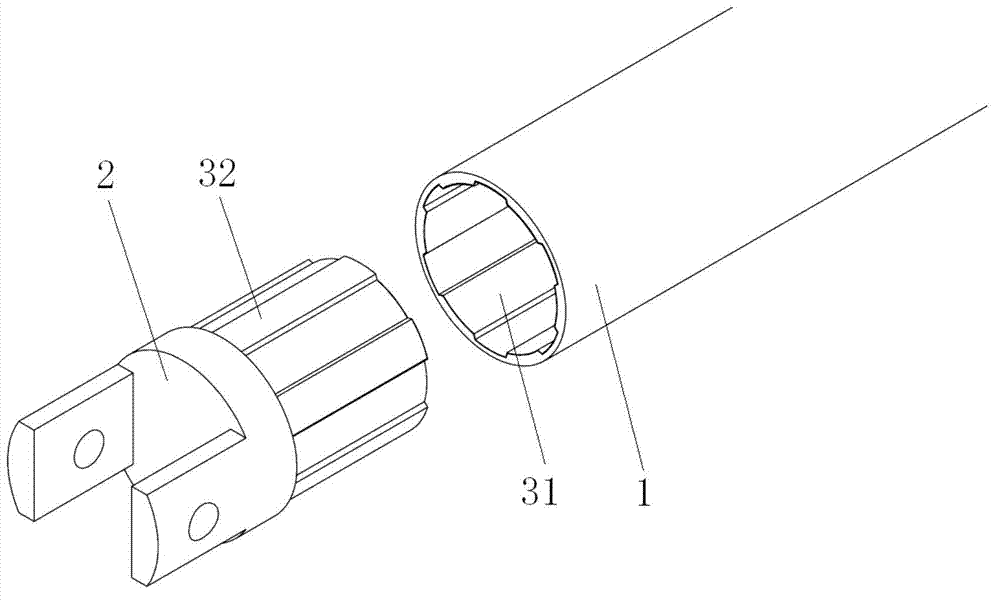

[0068] A certain composite material automobile drive shaft is assembled by a composite material shaft tube 1 with a length of 1.7m and a diameter of 76mm and metal connectors 2 at both ends. The shaft tube material of the composite material is T300 fiber-reinforced epoxy resin-based composite material, the thickness of the single-layer plate is 0.2mm, and its typical performance parameters are shown in Table 1 and Table 2:

[0069] Table 1

[0070] E. 1 (GPa)

E. 2 (GPa)

G 12 (GPa)

v 12

t p (mm)

ρ (kg / mm 3 )

125

8

5

0.3

0.2

1550

[0071] Table 2

[0072] x t (MPa)

x c (MPa)

Y t (MPa)

Y c (MPa)

S (MPa)

1600

1000

40

220

80

[0073] The forming method of the composite shaft tube and the assembly method of the composite shaft tube and the metal connector are as follows:

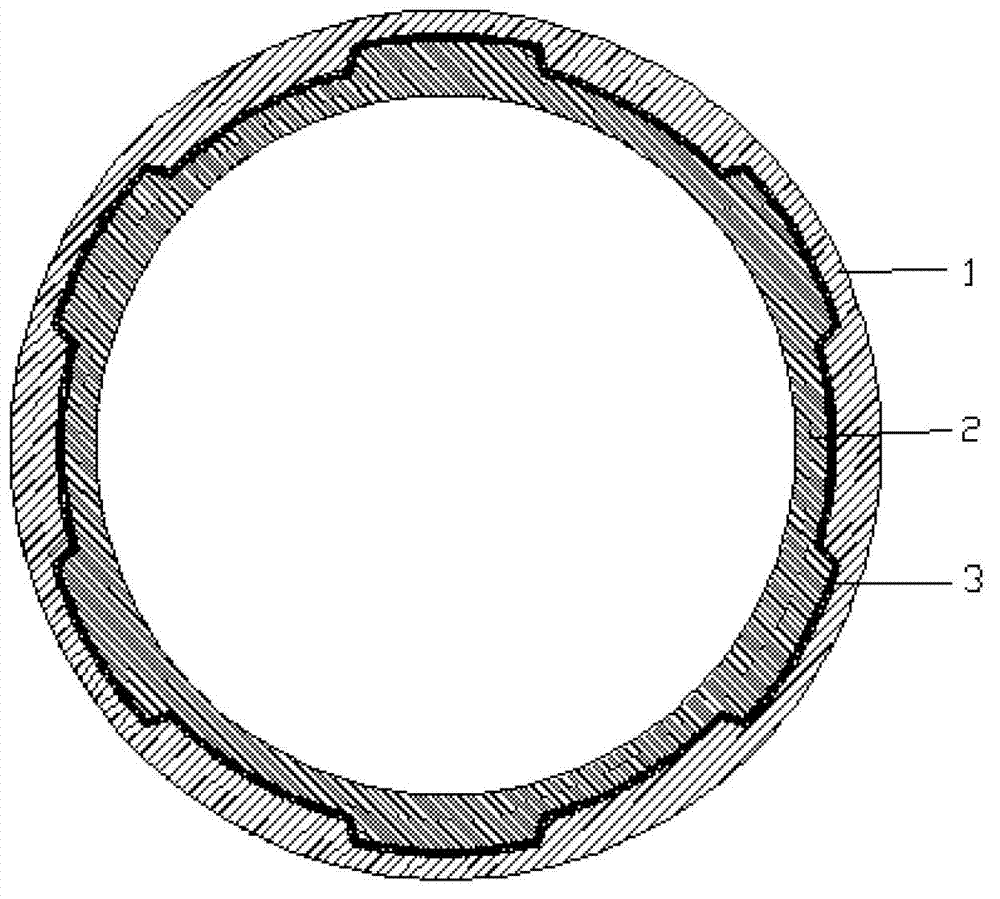

[0074] (1) The inner layer of the shaft tube 1 is in...

Embodiment 2

[0092] A composite automobile transmission shaft is assembled from a composite shaft tube with a length of 1.4m and a diameter of 76mm and metal connectors at both ends. The shaft tube material of the composite material is T300 fiber reinforced epoxy resin based composite material and glass fiber reinforced epoxy resin based composite material, forming a fiber hybrid structure. The thickness of the two single-layer boards is 0.2mm. Typical performance parameters of glass fiber reinforced epoxy resin matrix composites are shown in Table 4 and Table 5:

[0093] Table 4

[0094] E. 1 (GPa)

E. 2 (GPa)

G 12 (GPa)

v 12

t p (mm)

ρ (kg / mm 3 )

45

10

5

0.3

0.19

2000

[0095] table 5

[0096] x t (MPa)

x c (MPa)

Y t (MPa)

Y c (MPa)

S (MPa)

1100

675

35

120

80

[0097]The forming method of the composite shaft tube and the assembly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com