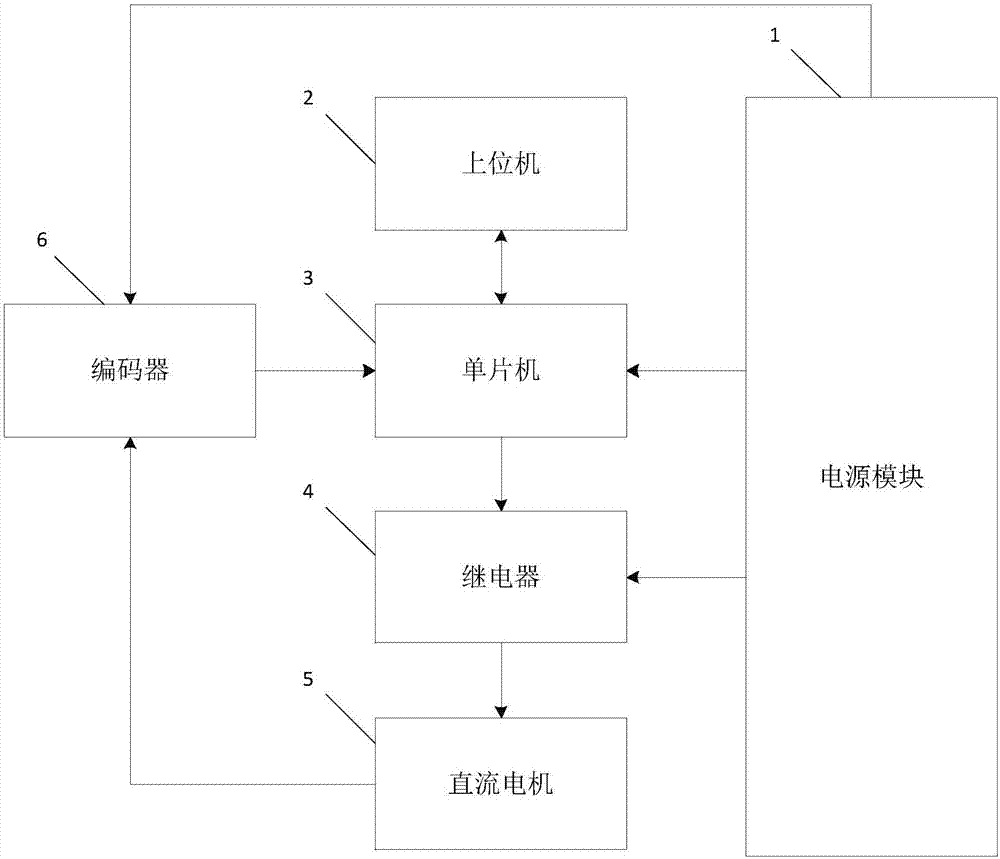

Greenhouse roller shutter control system

A control system and rolling shutter technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of large volume and high power consumption, and achieve the effects of good stability, low power consumption and fast installation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

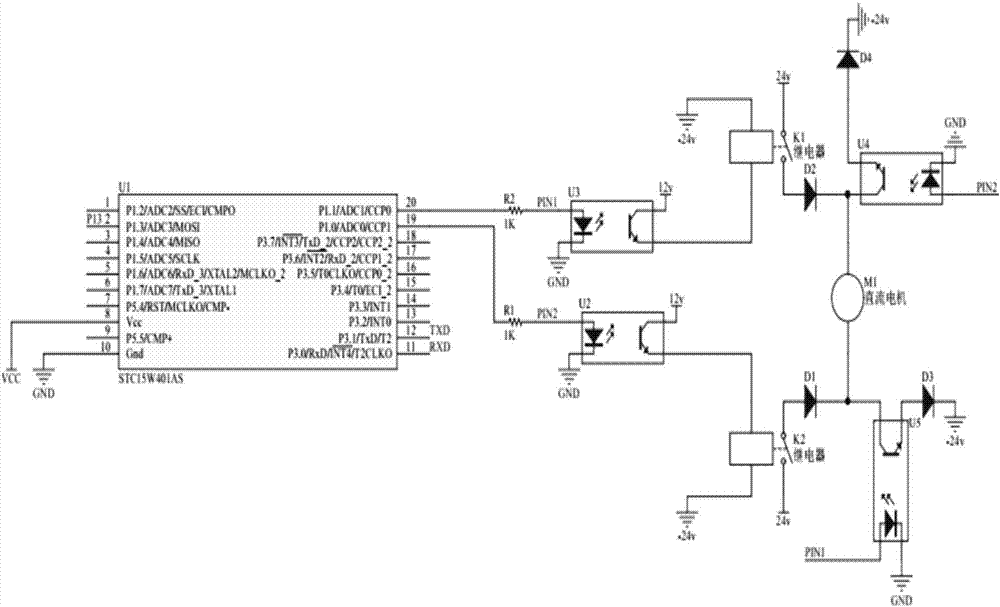

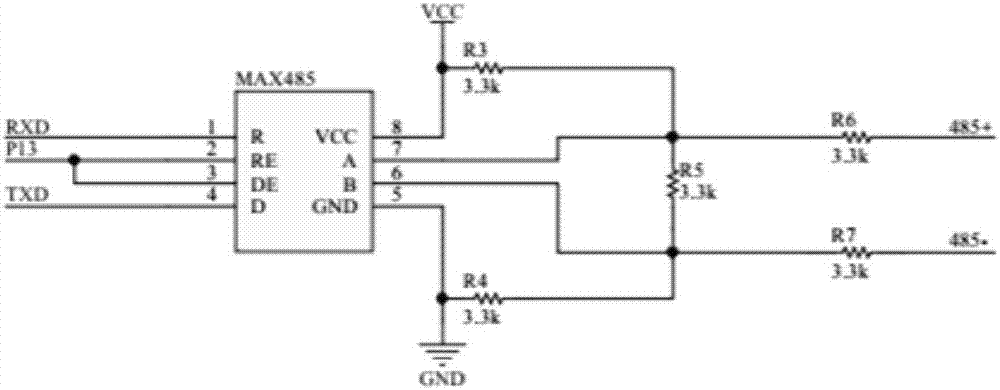

[0029] see figure 2 , image 3 The specific embodiment of the present invention shown: the single-chip microcomputer 3 includes a single-chip microcomputer U1, and the relay 4 includes a relay K1 and a relay K2. Wherein the 20th pin and the 19th pin of the single-chip microcomputer U1 are respectively connected to the relay K1 and the relay K2, and the relay K1 and the relay K2 are respectively connected to the DC motor 5 (that is, the attached figure 2 On the positive and negative power supply lines of the DC motor M1). The single-chip microcomputer U1 is connected to the upper computer 2 through the communication module. The model of microcontroller U1 is STC15W408. like image 3 As shown, the communication module is a communication interface chip modeled as MAX485, and the first pin of the communication module is connected to the eleventh pin of the single-chip microcomputer U1. The 2nd pin and the 3rd pin of the communication module are connected to the 2nd pin of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com