Dual structure concrete building and building method of dual structure concrete building

A dual structure and building technology, applied in the direction of building structure, construction, etc., can solve the problems of large pouring volume, low degree of industrialization, slow installation speed, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, the structure and construction method of binary structure concrete building of the present invention are further described:

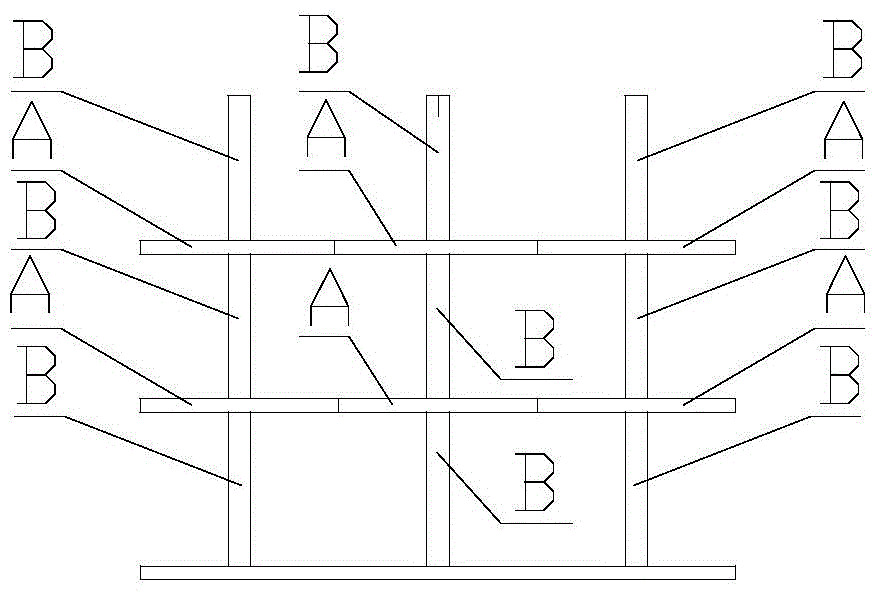

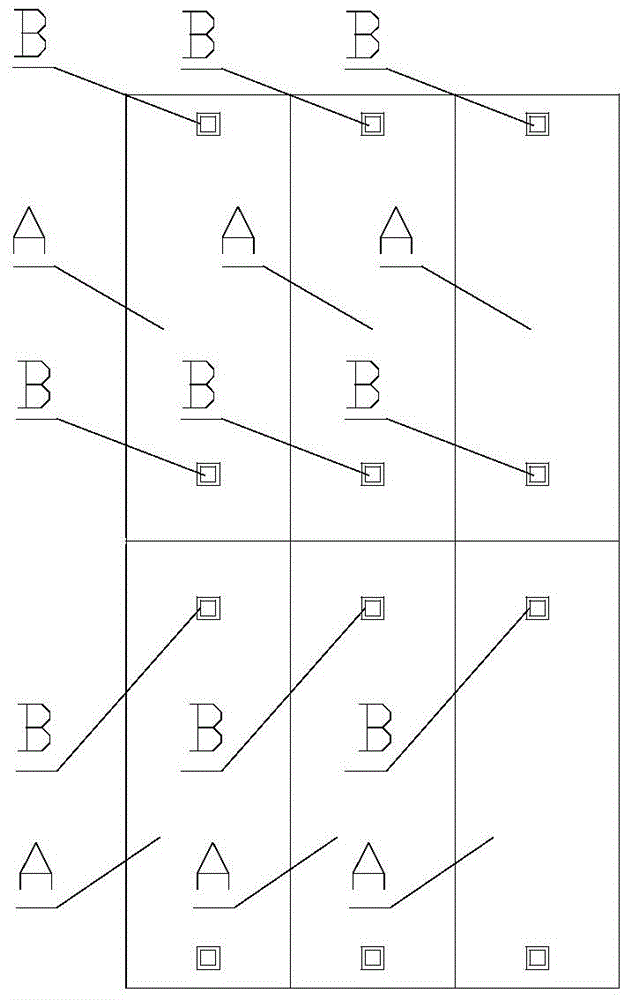

[0045] Such as figure 1 and figure 2 As shown, the dual-structure concrete building of the present invention includes several floor slabs A and several hollow building columns B, the floor A and the hollow building columns B are all provided with steel bars protruding from the outside, and there is a shape between the floor slab A and the hollow building columns B. Install perpendicular to each other.

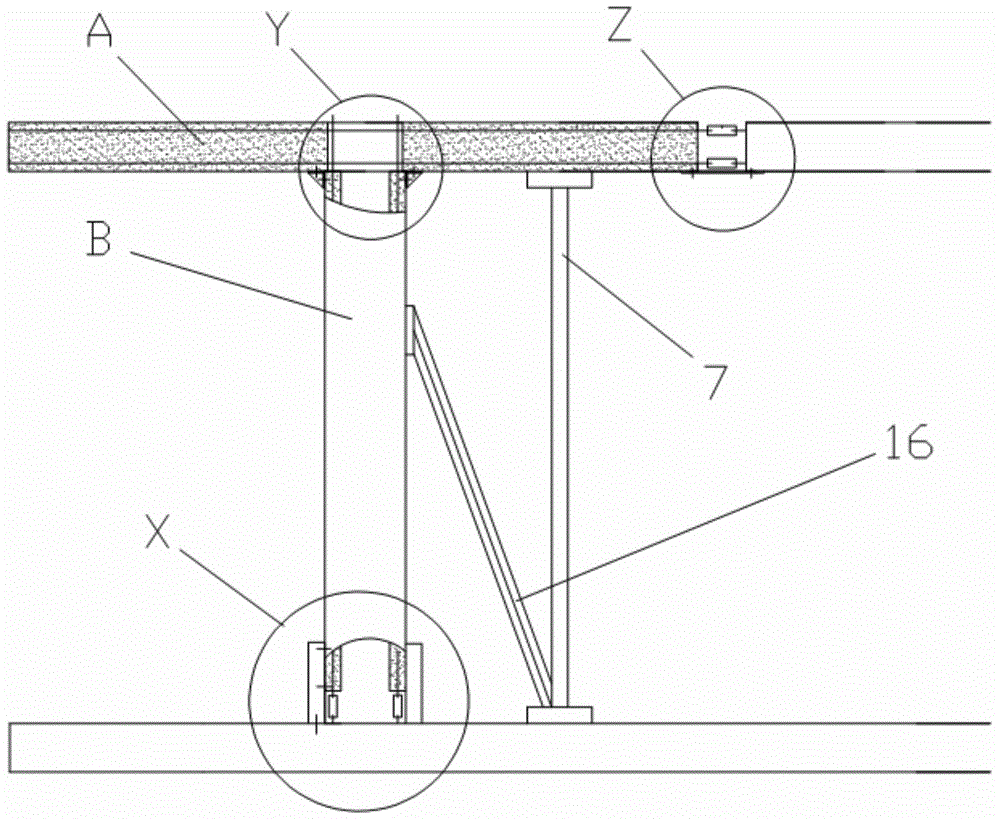

[0046] Such as image 3 and Figure 4 As shown, there is a reserved hole on the slab A for the steel bars protruding from the hollow building column B to pass through, and the steel bars of the upper floor column and the lower floor column form a fixed connection through the steel bar connection buckle 4 at the reserved hole, and in the The reserved hole is filled with concrete, and joints are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com