Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Evenly accepted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

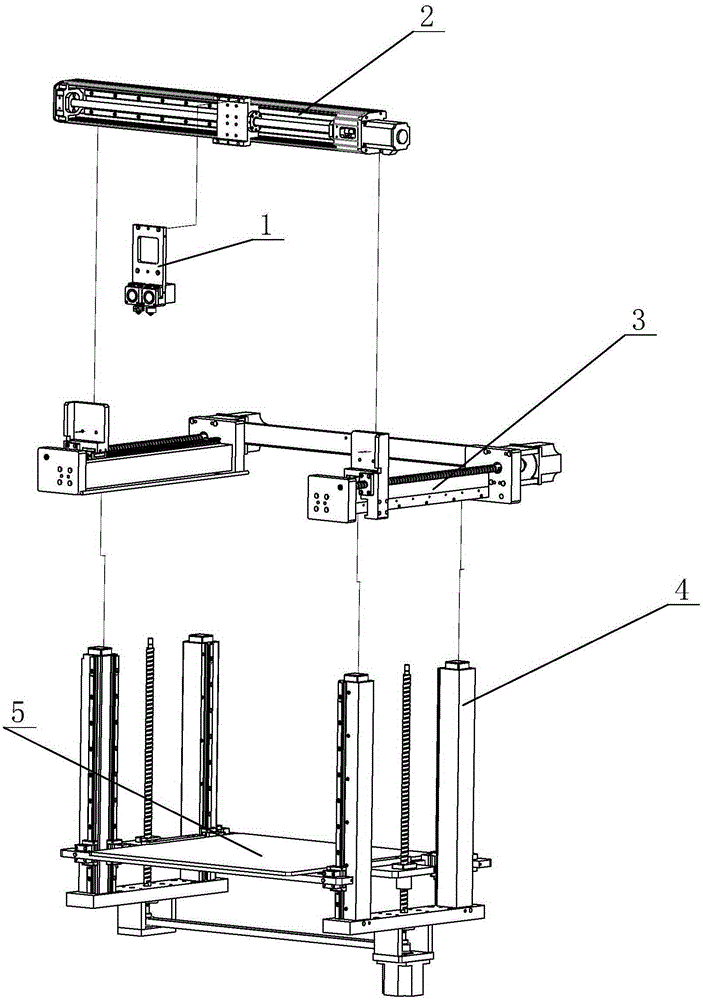

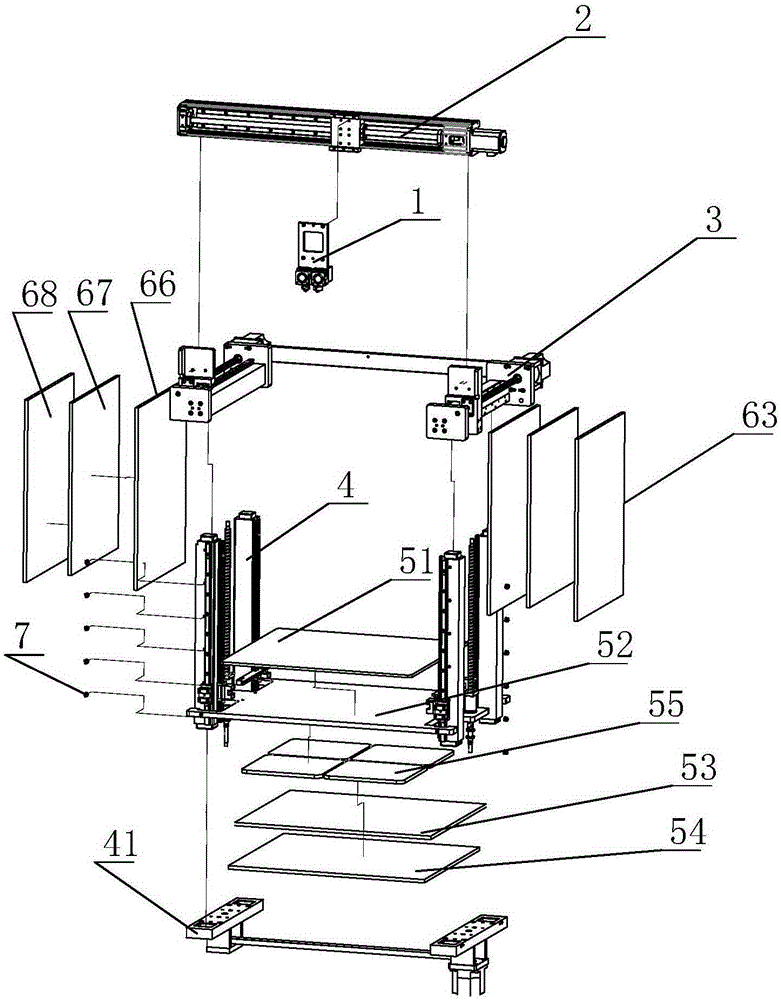

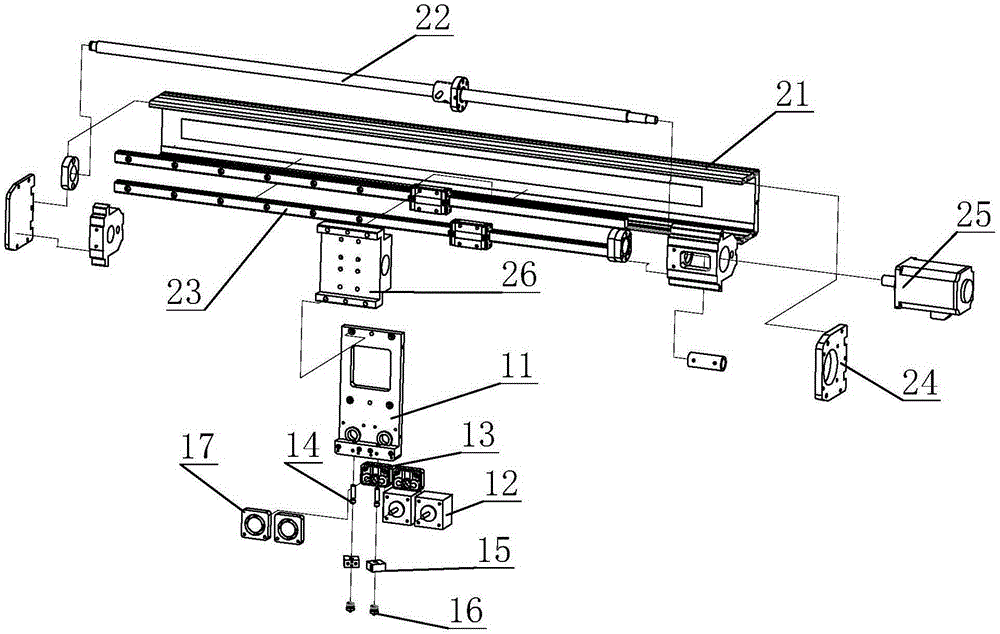

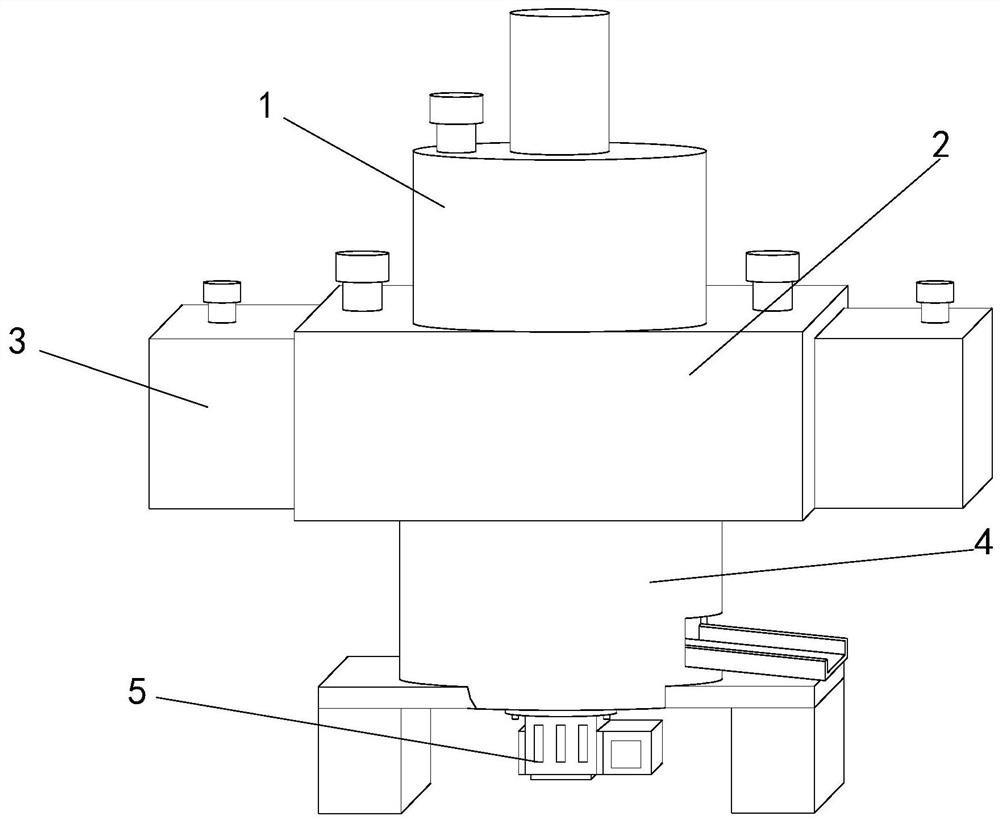

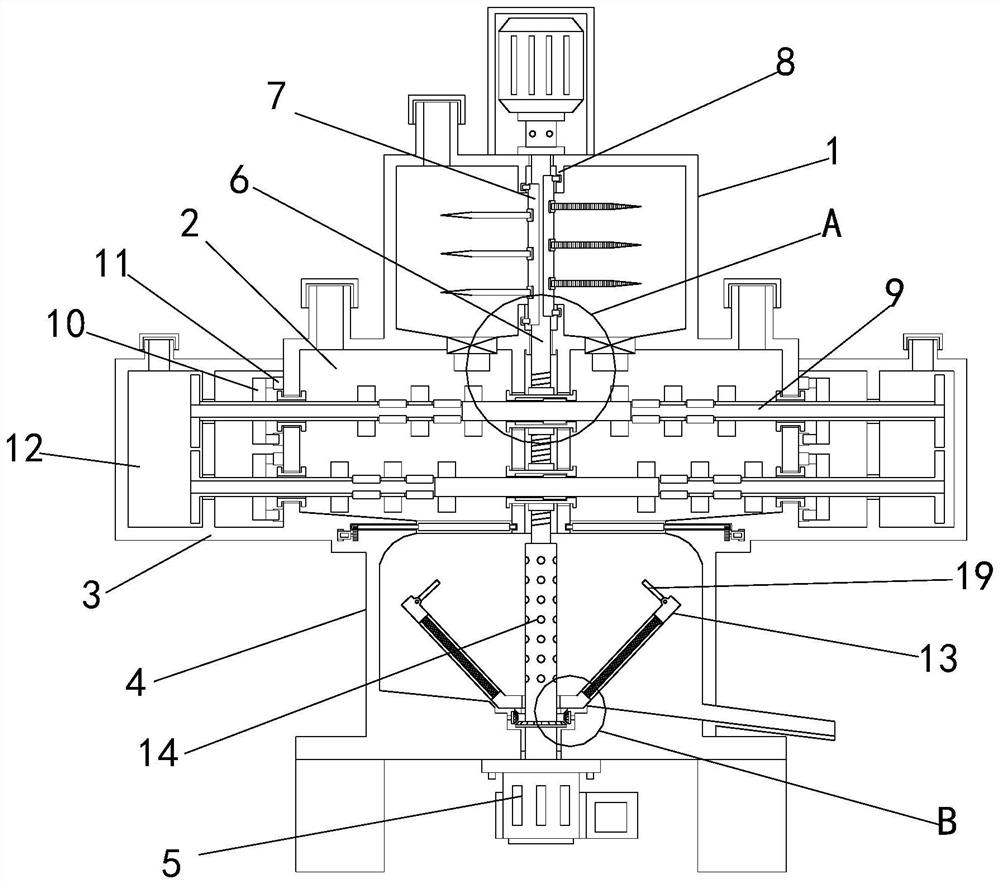

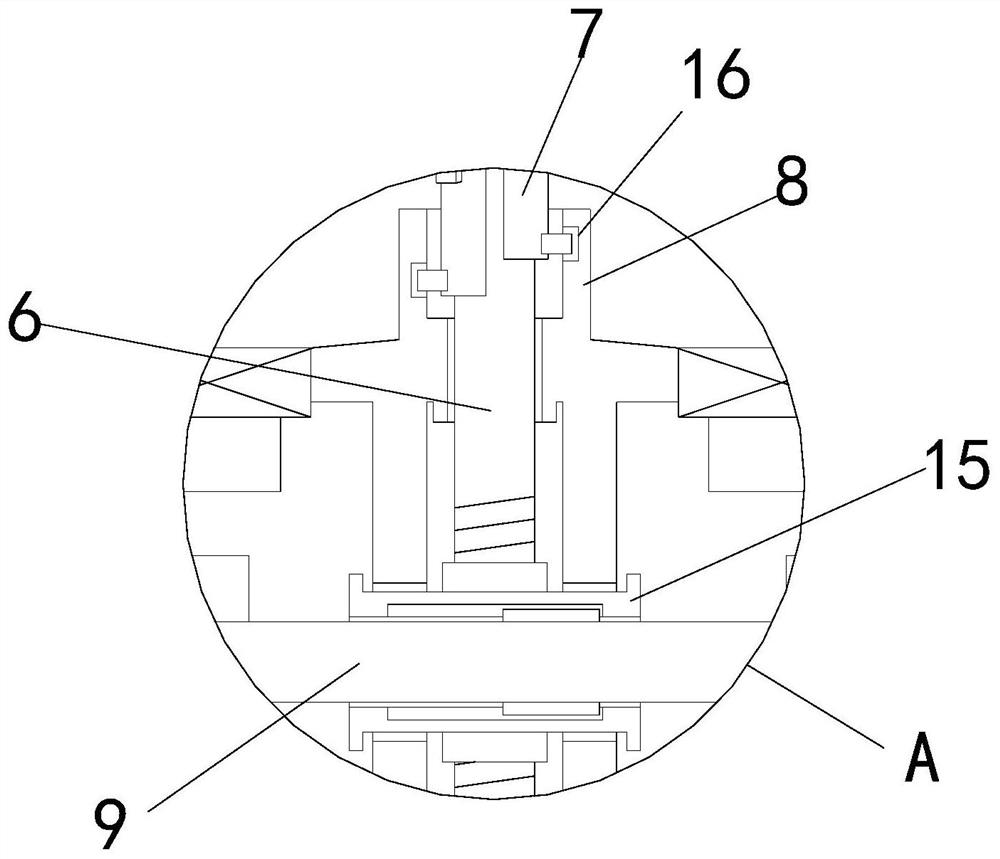

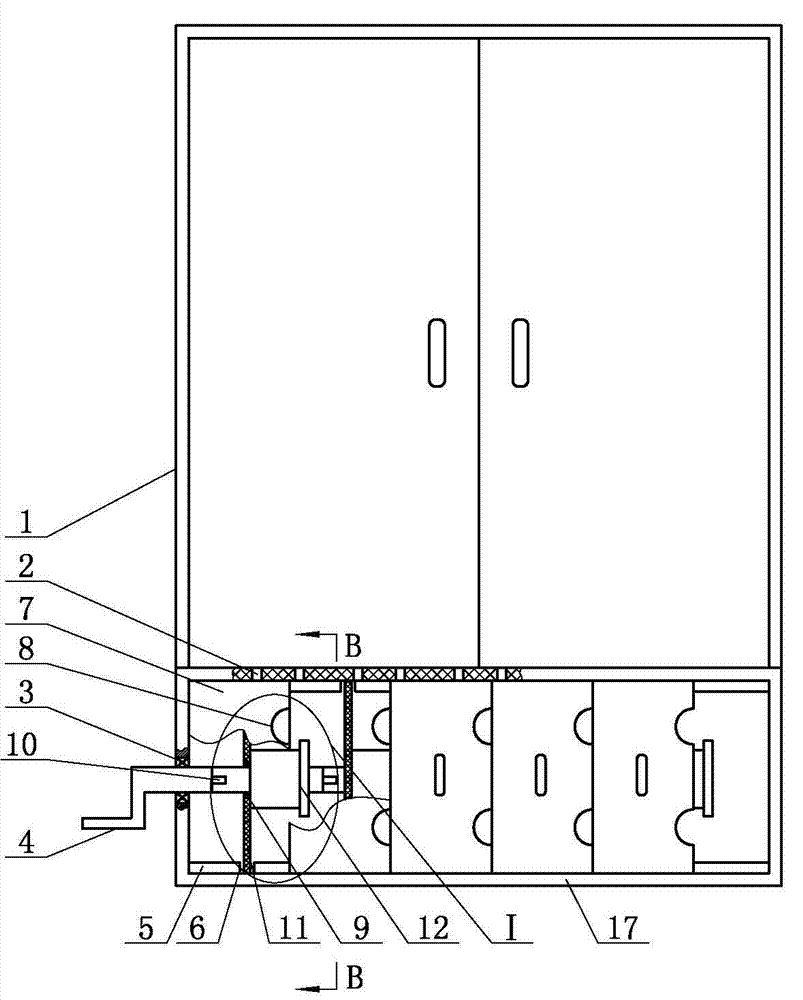

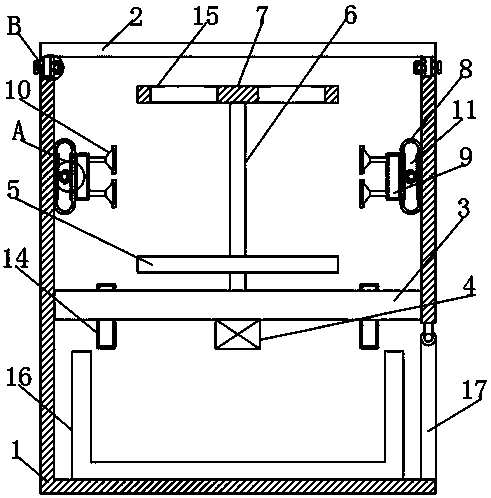

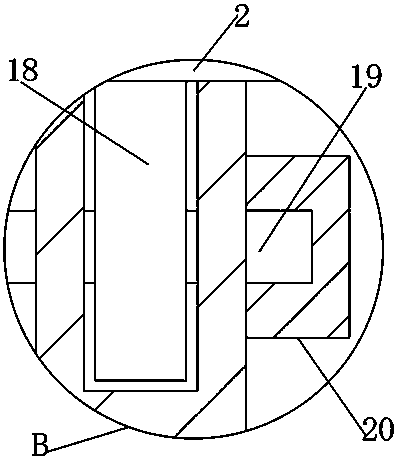

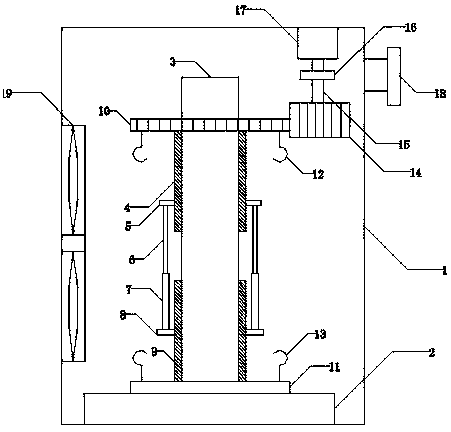

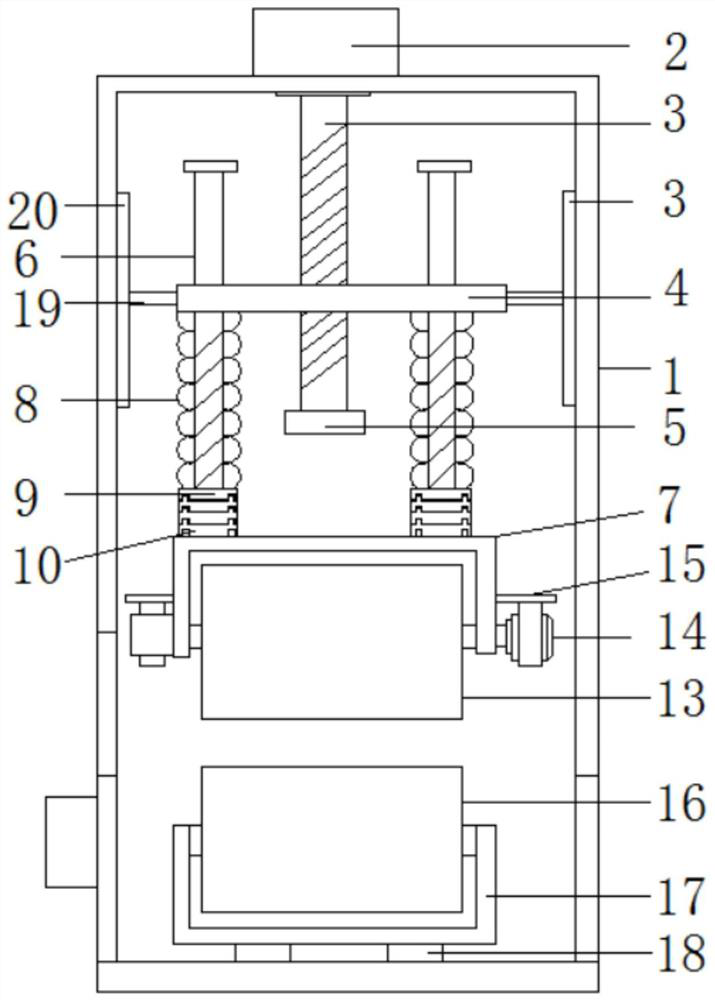

High-speed high-precision 3D printer

ActiveCN105235222AImprove rigidityImprove stabilityAdditive manufacturing apparatusBall screwEngineering

The invention discloses a high-speed high-precision 3D printer and mainly relates to the technical field of 3D printing. The high-speed high-precision 3D printer comprises an X-axis module, a Y-axis module, a Z-axis module, an extrusion mechanism, a platform mechanism and a machine casing; the Z-axis module comprises two retaining plates; a Z-axis ball screw and two Z-axis uprights are arranged on the retaining plates; the Z-axis uprights are in pin connection with the machine casing through a plurality of positioning pins; two Z-axis linear guide rails are mounted on the Z-axis uprights; a nut of the Z-axis ball screw and sliders of the Z-axis linear guide rail all are fixed on the platform mechanism; the Y-axis module is fixed at the top ends of the Z-axis uprights; the X-axis module comprises an X-axis upright that is in sliding connection with the Y-axis module in a Y-axis direction; an X-axis ball lead and two X-axis linear guide rails are mounted on the X-axis upright; the extrusion mechanism is mounted on a nut of the X-axis ball screw and the sliders of the two X-axis linear guide rails. The high-speed high-precision 3D printer has the beneficial effects of stable transmission, high mechanical strength, and remarkable increase of precision and speed.

Owner:WUHU AISANDI ELECTRONICS TECH CO LTD

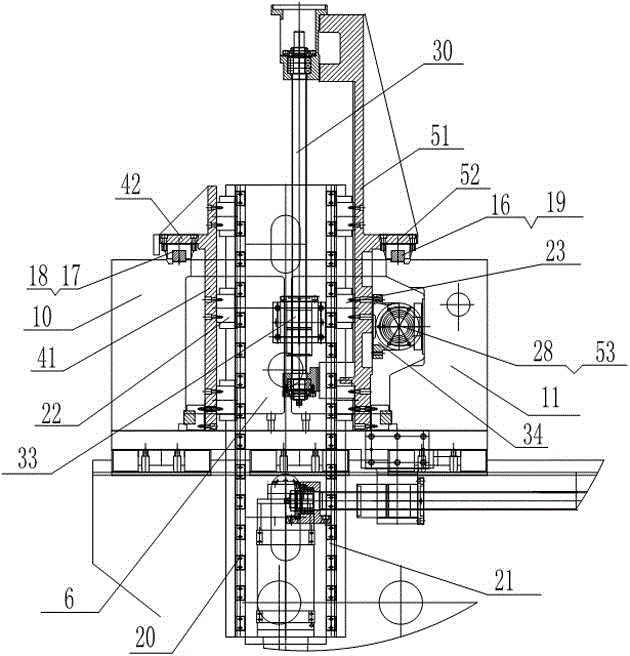

Machining device and method for double-layer casing of aero-engine

InactiveCN110774002ALoading and unloadingReasonable arrangementAircraft componentsOther manufacturing equipments/toolsAviationMechanical engineering

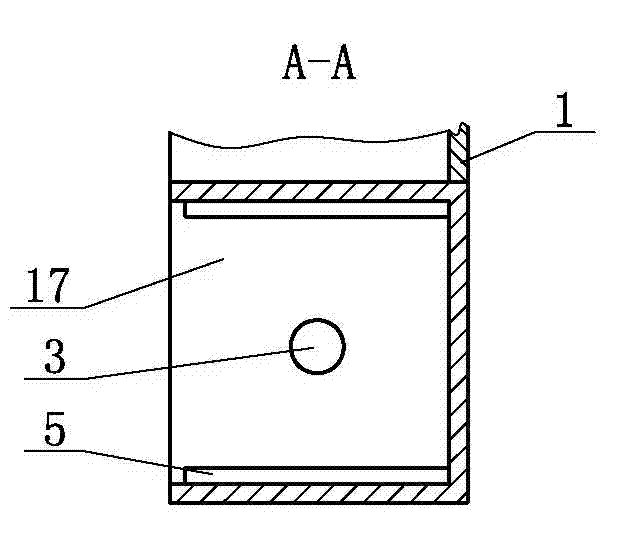

The invention discloses a machining device and method for a double-layer casing of an aero-engine. The device comprises an end surface gland, a shell, an inner sleeve, movable tensioning blocks, an air bag, a supporting rod, supporting arm nuts, supporting arms, a connecting seat, a ball head guiding rod, an inner hole fixing claw, an outer stand column, a transverse top head and a pressing plate.A turning and milling compound machining method is adopted, when an inner hole and an end surface are turned, the mode that an outer supporting is matched with the air bag for tensioning is adopted,and when an outer boss is milled, the mode that an inner supporting is matched with the air bag for tensioning is adopted; and according to the machining device, the high-quality and high-efficiency machining of the similar thin-wall double-layer casing can be achieved, and it is ensured that the circular degree of the casing meets the requirement.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

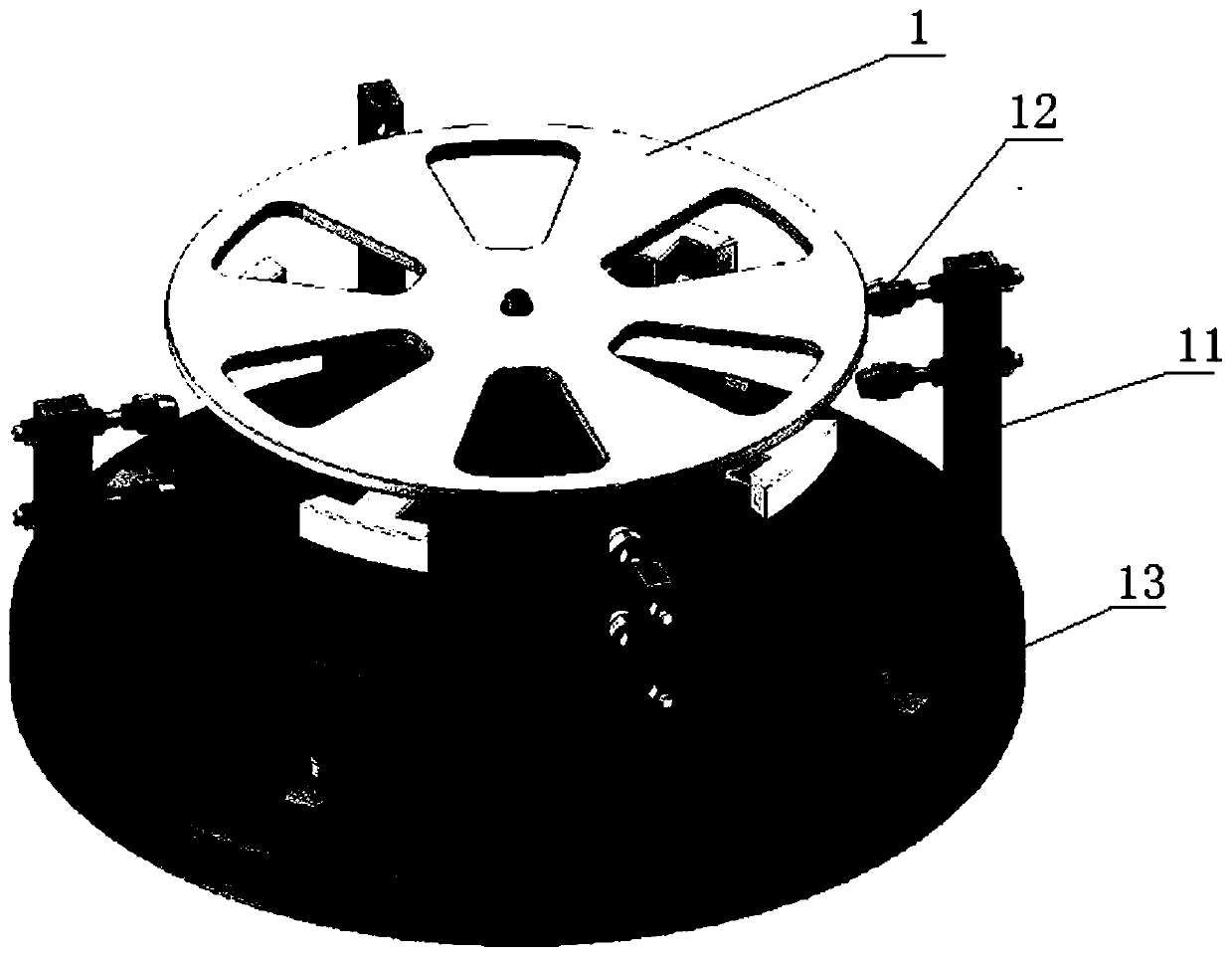

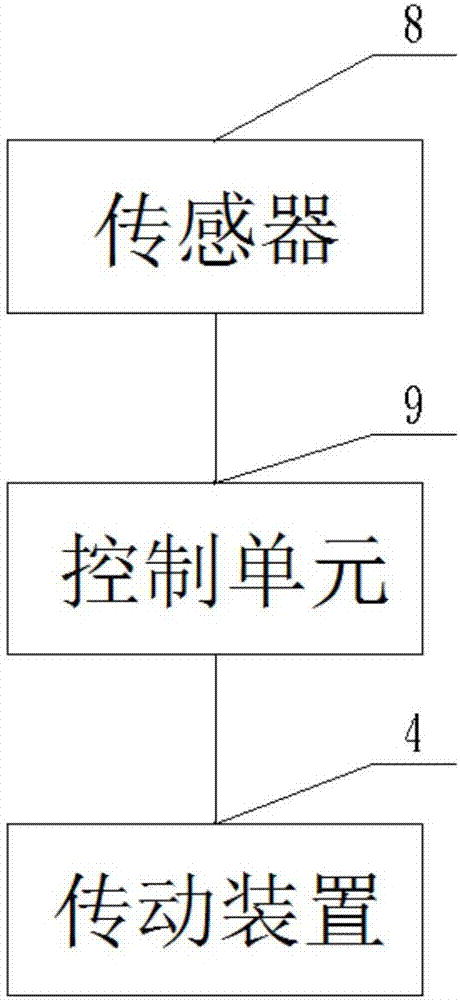

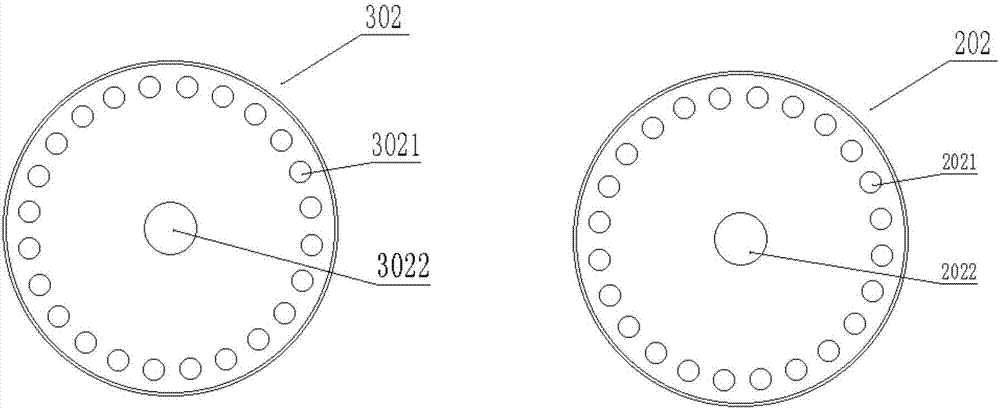

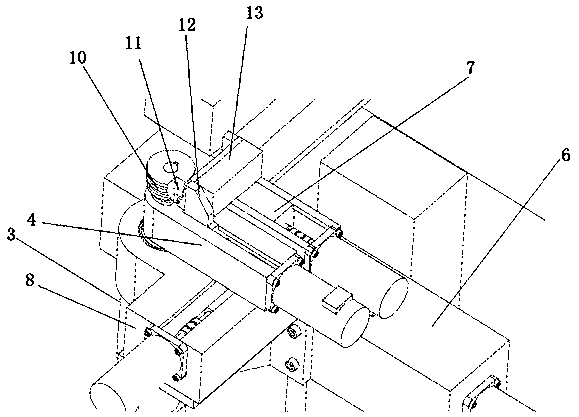

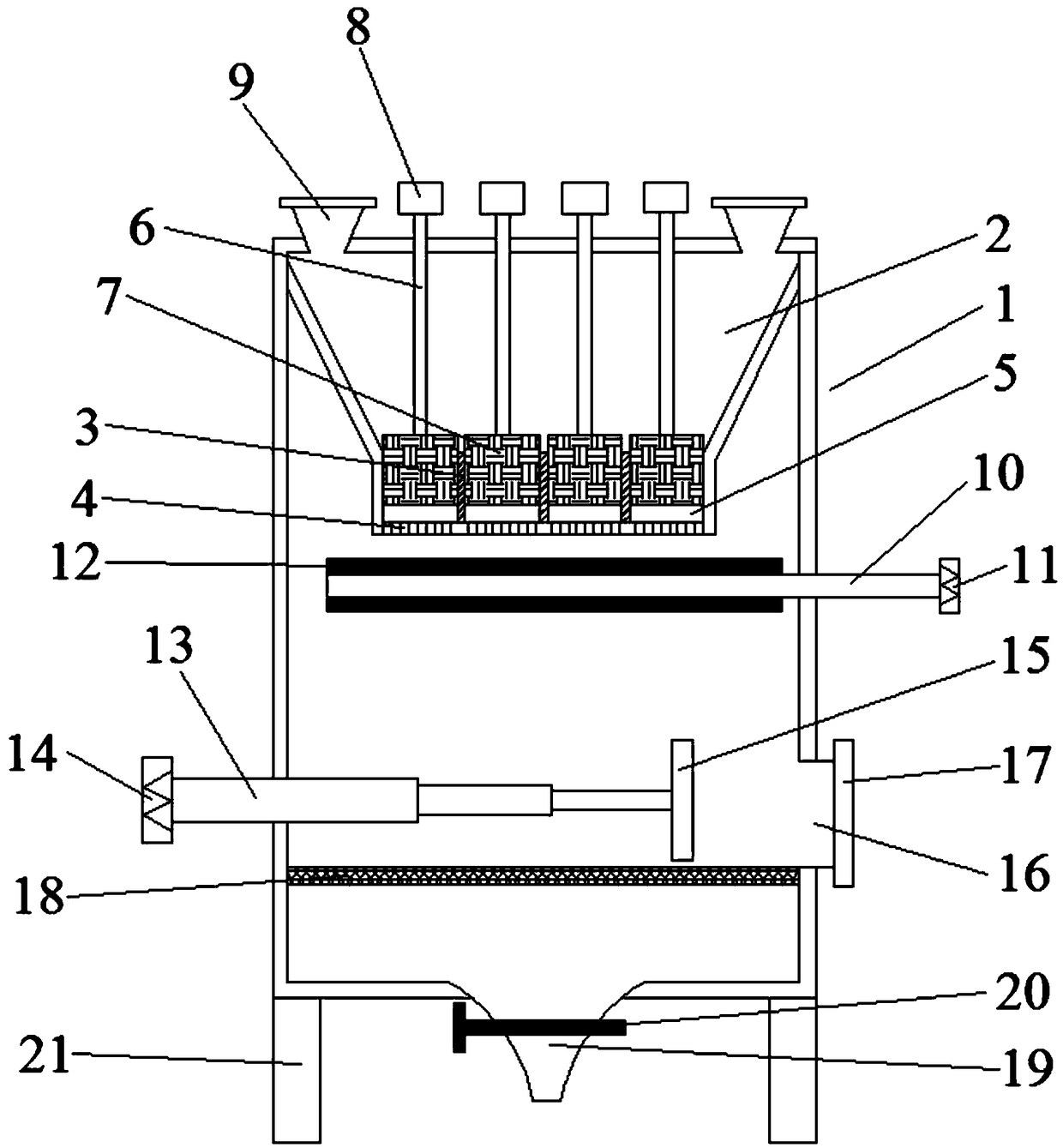

Rotary type photo-thermal power station heat absorber and uniform heat absorption control method

ActiveCN107514823AAvoid deformation damageExtended service lifeSolar heating energySolar heat collector controllersEngineeringHeating energy

The invention discloses a rotary type photo-thermal power station heat absorber and a uniform heat absorption control method. The heat absorber comprises a cavity assembly, a cool medium collecting box assembly, a hot medium collecting box assembly and a driving device. The driving device is connected with the cavity assembly and used for driving the cavity assembly to make rotary movement in the circumferential direction relative to the cool medium collecting box assembly and the hot medium collecting box assembly to enable the cavity assembly to uniformly absorb solar radiation heat energy. According to the rotary type photo-thermal power station heat absorber and the uniform heat absorption control method, the cavity assembly is arranged to be of a rotatable structure, so that radiation heat received by all components of the cavity assembly is more uniform, and the thermal stress ultralimit problem of an existing heat absorber is solved accordingly.

Owner:中广核工程有限公司 +1

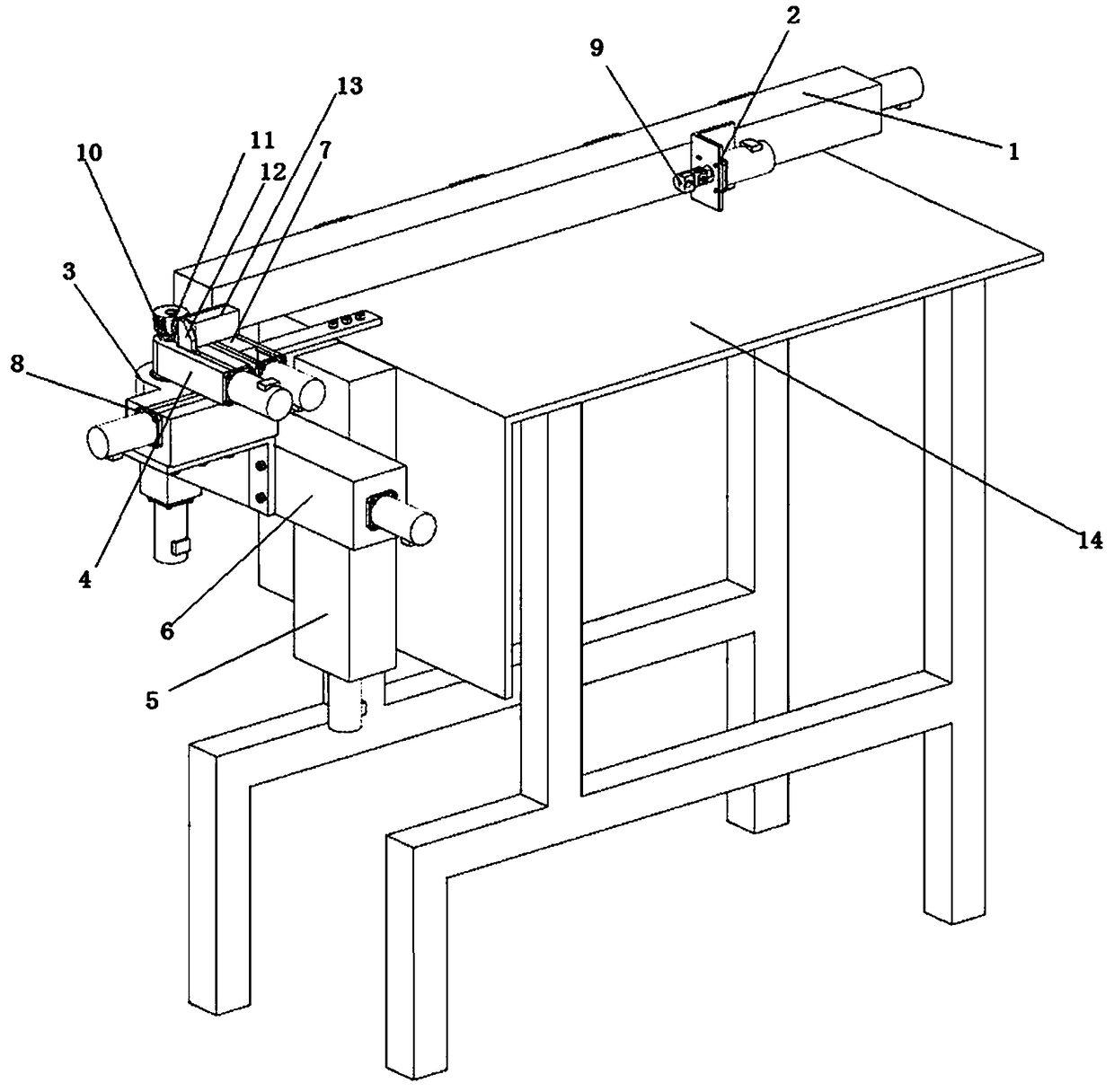

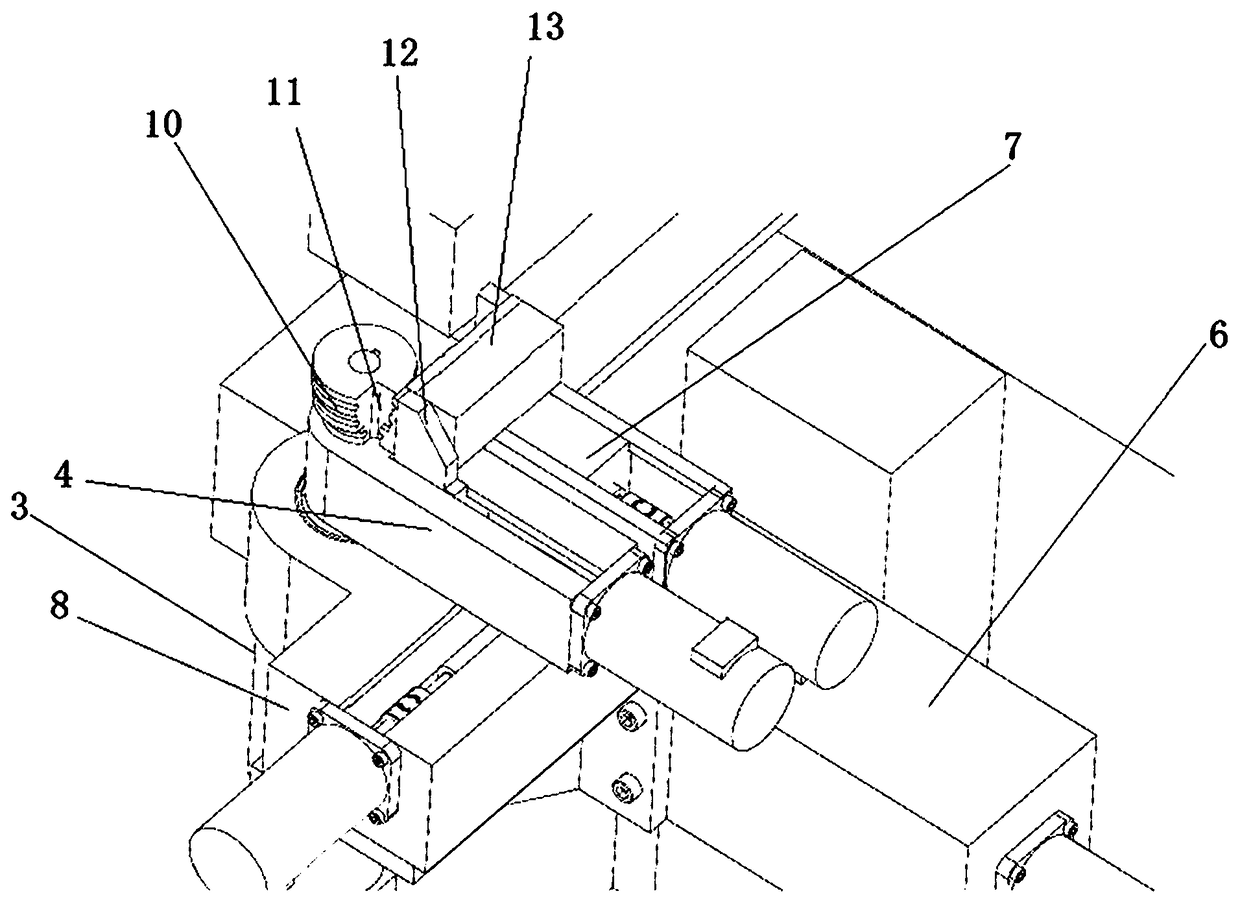

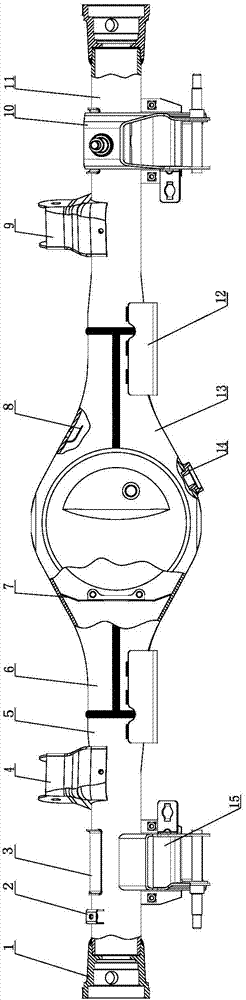

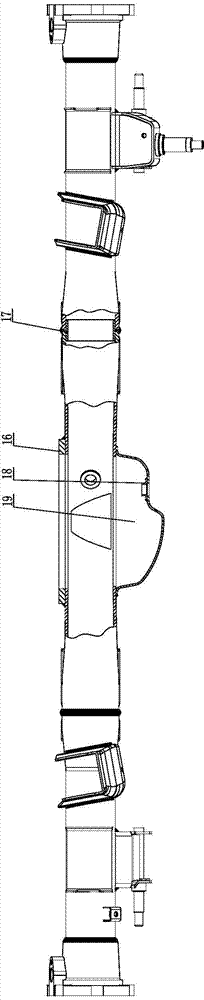

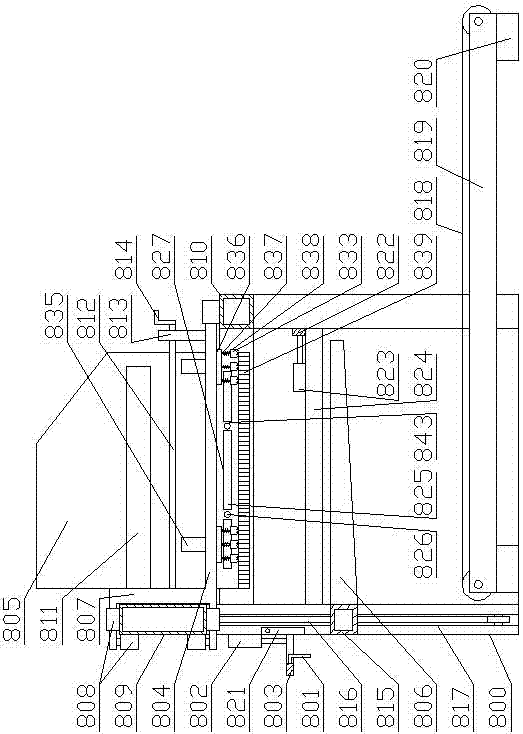

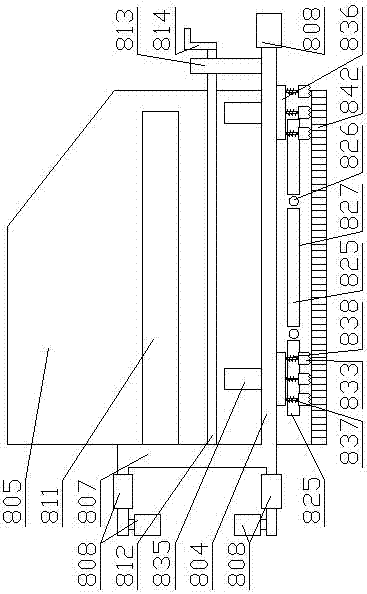

Full-servo numerical control pipe bending machine

InactiveCN109108120AEnsure consistencyReduce mistakesMetal-working feeding devicesPositioning devicesNumerical controlEngineering

The invention discloses a full-servo numerical control pipe bending machine, and relates to the technical field of pipe bending processing. The device comprises a feeding mechanism, an angle rotatingmechanism, a pipe bending mechanism, a clamping mechanism, a lifting mechanism, a horizontal moving mechanism, a backup plate mechanism and a servo mechanism. According to the pipe bending machine, 8-axis servo control is adopted to complete the movement of different angles and positions, bending machining of any angle and radius can be realized, and machining precision is guaranteed; and meanwhile, a pipe bending die and a feeding clamp can be quickly replaced on the structure, so that the pipe bending machine has a function of welding before bending.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

High temperature flate pressing print technique for bamboo product

InactiveCN100503263CImprove adhesionRealistic colorsDecorative surface effectsPattern printingFiberPulp and paper industry

The high temperature flat pressing printing process for bamboo product includes the following steps: 1. polishing the bamboo product; 2. printing the pattern on paper; 3. cleaning the bamboo product and electrostatically spraying UV or PU paint; 4. covering the printed paper onto the surface of the painted bamboo product; 5. transferring the pattern from the paper to the surface of the bamboo product inside a high temperature flat pressing equipment at controlled temperature, pressure and time; and 6. spraying UV or PU paint to the bamboo product and twice color fixing treatment. Compared with traditional technology, the present invention has one increased surface curing treatment step, and thus homogeneous flat pressing force at high temperature and high quality of the printed pattern.

Owner:王建刚

Method and device for preparing Chao-flavor type baijiu

PendingCN113308325AImprove crushing efficiencyImprove efficiencyDigestive systemAlcoholic beverage preparationMechanical engineeringBiotechnology

The invention relates to the field of baijiu brewing equipment, and especially relates to a method and a device for preparing Chao-flavor type baijiu. The device comprises a crushing part, a driving rotating shaft is mounted at the middle end in the crushing part, a moving plate is mounted on the outer side of the upper end of the driving rotating shaft, a mixed cooking part is connected below the crushing part, feeding boxes are connected to two sides of the mixed cooking part, a stirring rod is mounted in the mixed cooking part, driving turntables are connected to the two sides of the stirring rod, triangular convex blocks are arranged on one sides of the driving turntables, and convex blocks which are the same as convex blocks on the driving turntables are arranged on the two sides of the mixed cooking part, when the stirring rod rotates, the convex blocks on the driving turntables can be driven to be in contact with the convex blocks on the mixed cooking part, and the stirring rod can move left and right while rotating, so that the stirring effect is improved; and meanwhile, the two ends of the stirring rod are attached to the inner side of the liquid cavity, water and juice in a Chao-flavor mixture can be pressed into the mixing cooking part from the liquid cavity, the intensity of pressure in the mixed cooking part is improved, and the mixing effect of wine brewing raw materials and aroma enhancement materials is improved.

Owner:辽宁永椿酒业有限公司

Distributing frame

The invention relates to a distributing frame which comprises a wire chase tank, wherein an opening is formed in the side edge of the wire chase tank, connecting frames are arranged in the wire chase tank, clamping grooves are formed in each connecting frame, connecting plates are spliced in the clamping grooves, a wire roller is arranged on each connecting plate, a spool of the wire roller is connected with the connecting plate through a first bearing, a first connecting shaft is arranged at one end of a central shaft of the wire roller, a second connecting shaft is arranged at the other end of the central shaft of the wire roller, a first lug is installed on the first connecting shaft, a groove with the same shape as the first lug is formed in the second connecting shaft, a rocking handle is arranged at an end part of the wire chase tank, a horizontal rod of the rocking handle is matched with the wire chase tank through a second bearing, and a second lug with the same shape as the first lug is arranged at an end part of the horizontal rod of the rocking handle. The distributing frame is provided with the independent wire rollers; the wires on the wire rollers are orderly arranged in the distributing frame, so as to be convenient for management; as the wires can be rotatably coiled or uncoiled simultaneously / independently between every two wire rollers, the operation is convenient; and the wires are evenly arranged when uncoiled, so as to avoid the electricity leakage, short circuit and other dangers due to the damaged wires and ensure the normal electrical work.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Numerical control pipe-bending machine control system

InactiveCN109127812AReduce springback deformationEnsure consistencyMetal-working feeding devicesPositioning devicesNumerical controlMachine control

The invention discloses a numerical control pipe-bending machine control system, and relates to the technical field of pipe bending machining. The numerical control pipe-bending machine control systemcomprises a central controller, external inputting equipment, external outputting equipment and a pipe-bending machine executing part. The pipe-bending machine executing part comprises a feeding servo mechanism, an angle rotating servo mechanism, a pipe-bending servo mechanism, a clamping servo mechanism, a lifting servo mechanism, a horizontal moving servo mechanism, a plate backing servo mechanism and a follow-up servo mechanism. According to the numerical control pipe-bending machine control system, moving at different angles and positions is completed through eight-axis servo control, bending machining at any angle and radius can be achieved, and the machining precision is guaranteed; and meanwhile, quick replacing of a pipe-bending mold and a feeding clamp can be structurally achieved, and thus, a pipe-bending machine has the function of welding prior to bending.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

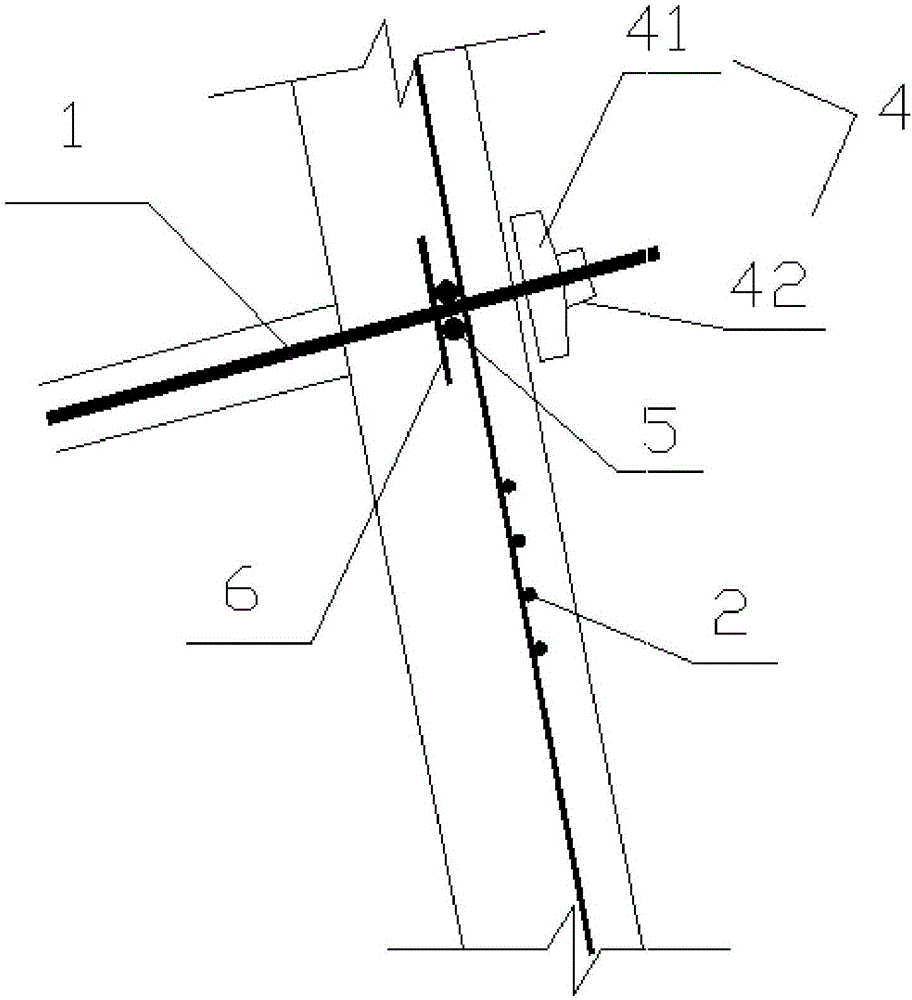

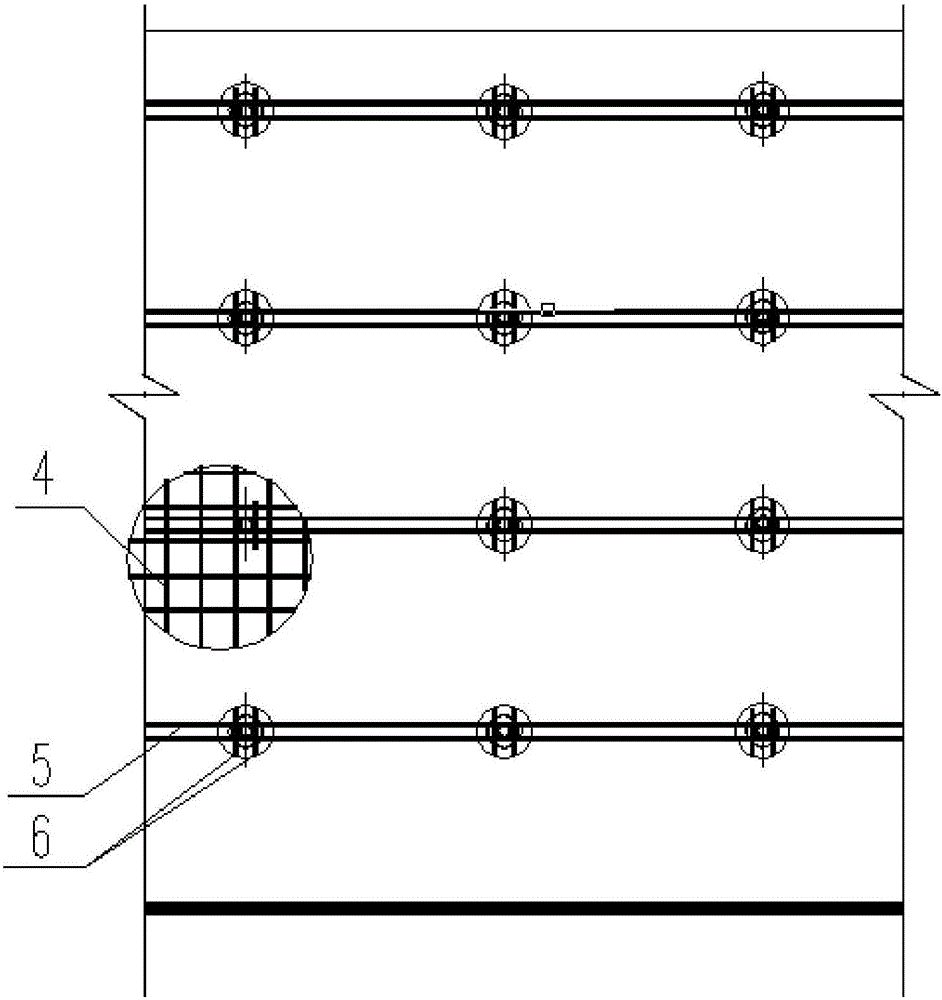

Soil nailing wall supporting structure and construction method

InactiveCN106836245AHigh tensile strengthImprove corrosion resistanceExcavationsBulkheads/pilesSoil nailingGlass fiber

The invention provides a soil nailing wall supporting structure and a construction method. The construction method comprises the steps as follows: a plurality of deep holes are formed in a to-be-supported surface, GFRP (glass fiber reinforced plastic) ribs penetrate through the deep holes, grouting is performed, and soil nailing bodies are formed; reinforcing meshes are hung on the supported surface; the reinforcing meshes are fixed with rod pieces, exposed out of the supported surface, of all GFRP ribs, and a concrete surface layer of the supported surface is formed by performing guniting on the reinforcing meshes; outer ends of the GFRP ribs are exposed out of the concrete surface layer to form anchoring ends, and the soil nailing bodies and the concrete surface layer form a whole through cooperation of anchoring parts and the anchoring ends of the GFRP ribs. Compared with the prior art, the GFRP ribs have higher tensile strength, can improve the overall support performance of a soil nailing wall after being applied to the soil nailing wall and are stable in performance, high in corrosion resistance and long in service life. More importantly, the GFRP ribs have weak shear capacity and can be cut off easily when nearby underground engineering construction is interfered by the soil nailing wall, and a lot of manpower and material resources are saved.

Owner:HUAIBEI YUXIN NEW MATERIAL

Spraying equipment for electric cabinet coating production

InactiveCN108838007AIncrease the degree of atomizationEasy to disassemble and overhaulSpray boothsBiochemical engineeringElectric machinery

The invention discloses spraying equipment for electric cabinet coating production. The spraying equipment comprises a box body, a first through hole communicating with the outside is formed in the upper end of the box body, and a box cover matched with the first through hole is arranged at the opening position of the first through hole; a horizontally-arranged fixing plate is arranged inside thebox body, moreover, the two ends of the fixing plate are fixedly connected with the inner walls of the two sides of the box body, a first driving motor is fixedly connected to the bottom wall of the fixing plate, and the output end of the first driving motor penetrates through the fixing plate and is fixedly connected with a horizontally arranged first supporting plate; and a supporting rod whichis vertically arranged is fixedly connected to the side wall of the upper side of the first supporting plate, moreover, one end, far away from the first supporting plate, of the supporting rod is fixedly connected with a second supporting plate which is horizontally arranged, two symmetrically-arranged clamping grooves are formed in the second supporting plate, and the clamping grooves are matchedwith the electric cabinet. According to the equipment, an electric cabinet body can be uniformly coated, and recycling of painting is convenient, the environment is prevented from being polluted, andresources are prevented from being wasted.

Owner:JIANGSU YAFENG TECH GRP CO LTD

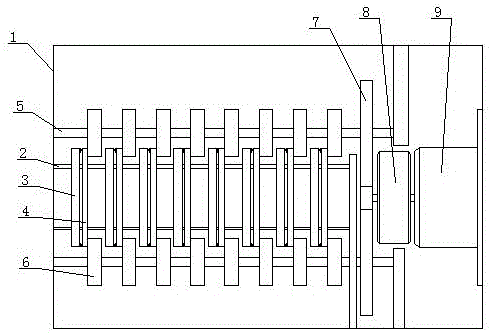

Filter press for achieving solid-liquid separation of wastewater

InactiveCN105879447AImprove the effectImprove efficiencyFiltration separationMechanical engineeringFilter press

The invention discloses a filter press for solid-liquid separation of waste water. The invention comprises a frame, four guide rollers are arranged on the frame, and a plurality of filter mechanisms are set on the guide rollers. The filter mechanism It includes a filter frame and a filter plate body, the filter frame and the filter plate body are sleeved on the guide roller, the surroundings of the filter plate body protrude outward to form a frame, and the four corners of the frame are provided with positioning holes. The upper end and the lower end of the frame are respectively provided with an upper chute and a lower chute, the upper chute and the lower chute are provided with a plate body, the upper chute is provided with a first elastic pressure block, and the lower chute is provided with a There is a second elastic pressing block, the length of the first elastic pressing block is greater than the length of the second elastic pressing block, the ends of the upper chute and the lower chute are equipped with locking blocks; the center of the plate body is provided with A feeding hole, a plurality of filter holes are evenly arranged around the feeding hole, and the filter holes are equipped with a filter cloth; the frame is also provided with a filter press mechanism.

Owner:SICHUAN KAIMING MACHINERY MFG

Framing machining method of core-shell structure door and window profiles

InactiveCN106801568AAchieve clampingApply pressure evenlyDoors/windowsEngineeringUltimate tensile strength

The invention discloses a framing machining method of core-shell structure door and window profiles, relates to the field of building decoration engineering, and aims to solve the problems that existing door and window profiles are not reasonable in assembly process, and door and window profile corners are not high in bonding strength and accuracy, close in sealing, attractive and durable. The framing machining method includes the steps: S1 cutting the profiles; S2 machining the ends of the profiles; S3 preassembling the machined profiles; S4 starting a framing device; S5 mounting a profile frame; S6 clamping the profile frame; S7 applying pressure to the frame; S8 releasing the pressure. By the aid of the steps, longitudinal parallel rods and transverse parallel rods relatively motion through hydraulic transmission, the assembled door and window profiles can be effectively assembled in the device, and the method solves the quality problems that in a traditional assembly process, force is unequally applied, errors are large, the ends of the profiles are easily damaged, connectors have biased and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

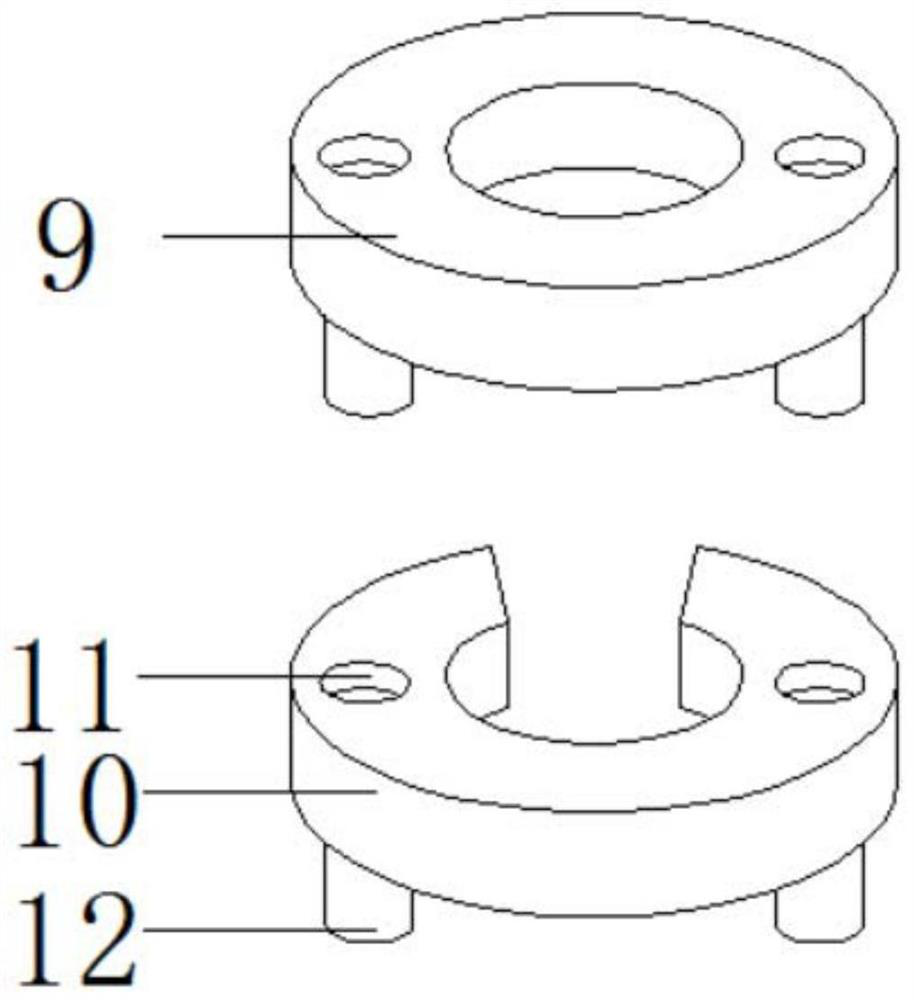

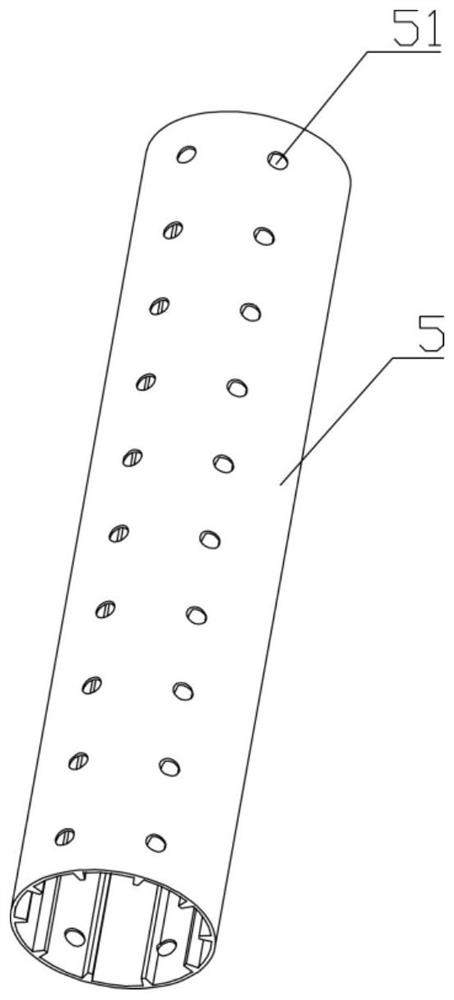

High-efficiency spring drying device

InactiveCN109696044AImprove drying rateReceive heat evenlyDrying chambers/containersDrying machines with non-progressive movementsEngineeringMoisture

The invention discloses a high-efficiency spring drying device. A heat source mechanism is arranged in an oven body; a moisture exhausting opening is formed in the side wall of the oven body; a base is arranged at the inner bottom end of the oven body; a vertical column which vertically extends upwards is arranged at the central position of the top end of the base; a lower rotating cylinder is connected to the bottom end of the vertical column in a sleeving manner; an upper rotating cylinder is connected to the top end of the vertical column in a sleeving manner; an upper flange is arranged onthe outer wall of the upper rotating cylinder; a lower flange is arranged on the outer wall of the lower rotating cylinder; hydraulic mechanisms are arranged between the upper flange and the lower flange; a lower positioning ring is fixedly arranged at the bottom end of the lower rotating cylinder; an upper toothed ring is fixedly arranged at the top end of the upper rotating cylinder; a drivingmotor is arranged at the top end of the oven body; the top end of a rotating shaft is fixed on an output shaft of the driving motor through a coupling; and a driving gear is fixedly arranged at the bottom end of the rotating shaft, and is in meshing connection with the upper toothed ring. The high-efficiency spring drying device has the advantage that the drying speed is increased.

Owner:TIANJIN ZHONGYI SPRING SHOCK ABSORBER

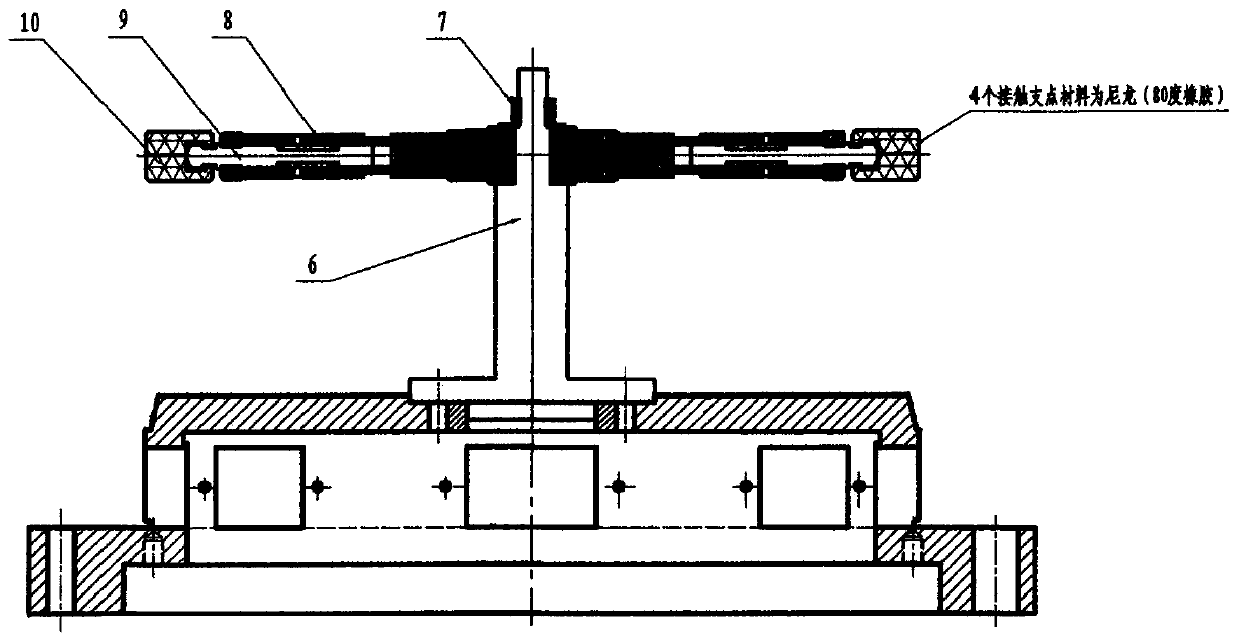

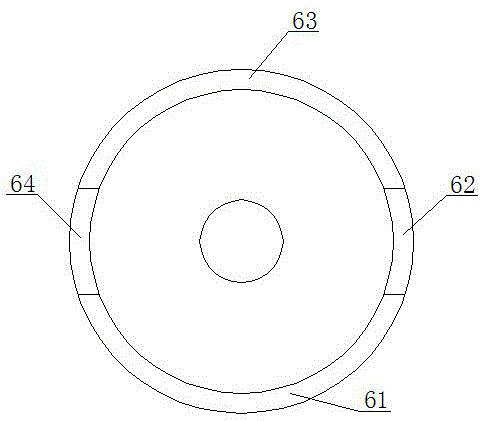

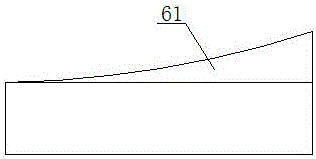

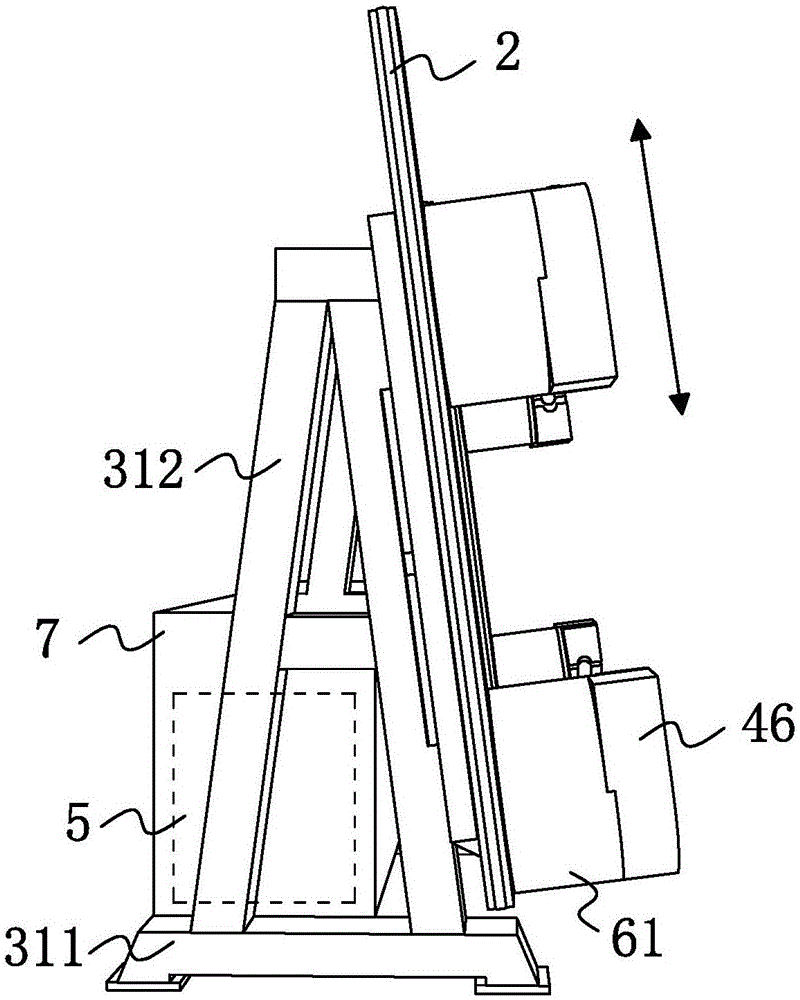

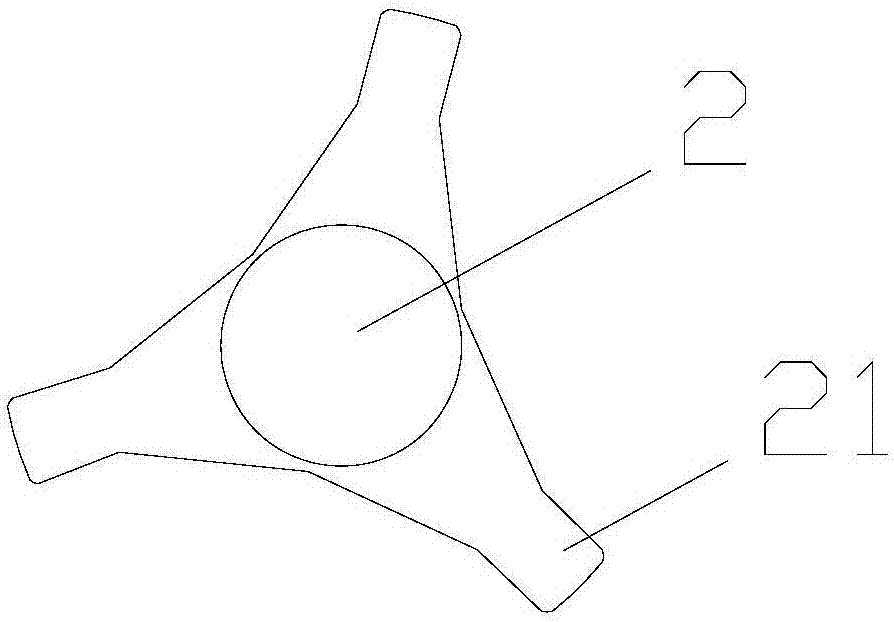

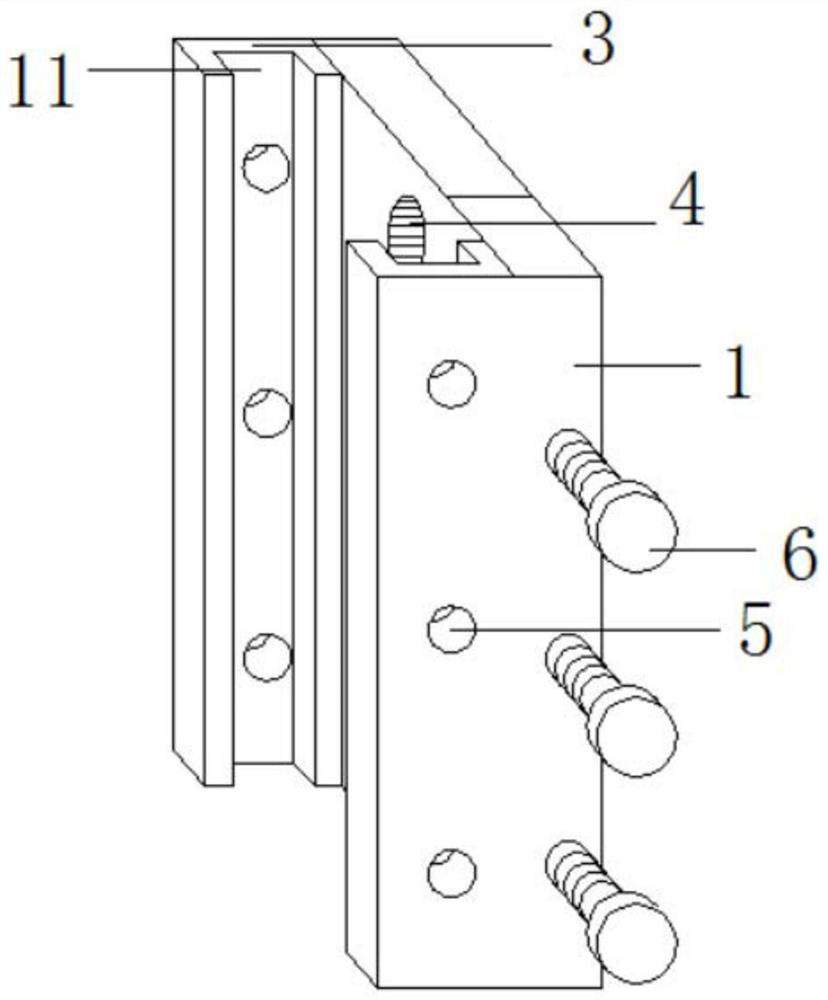

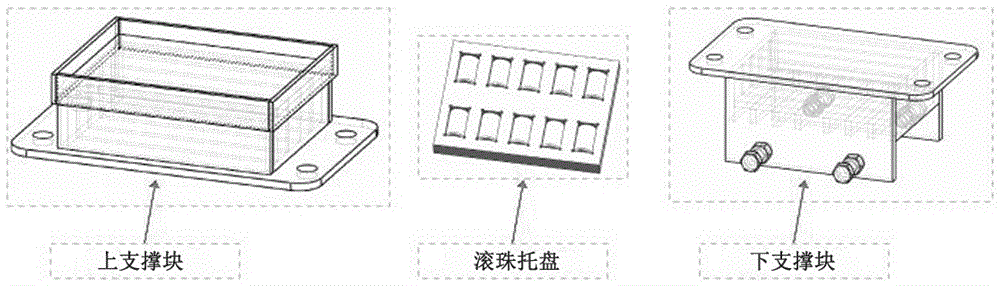

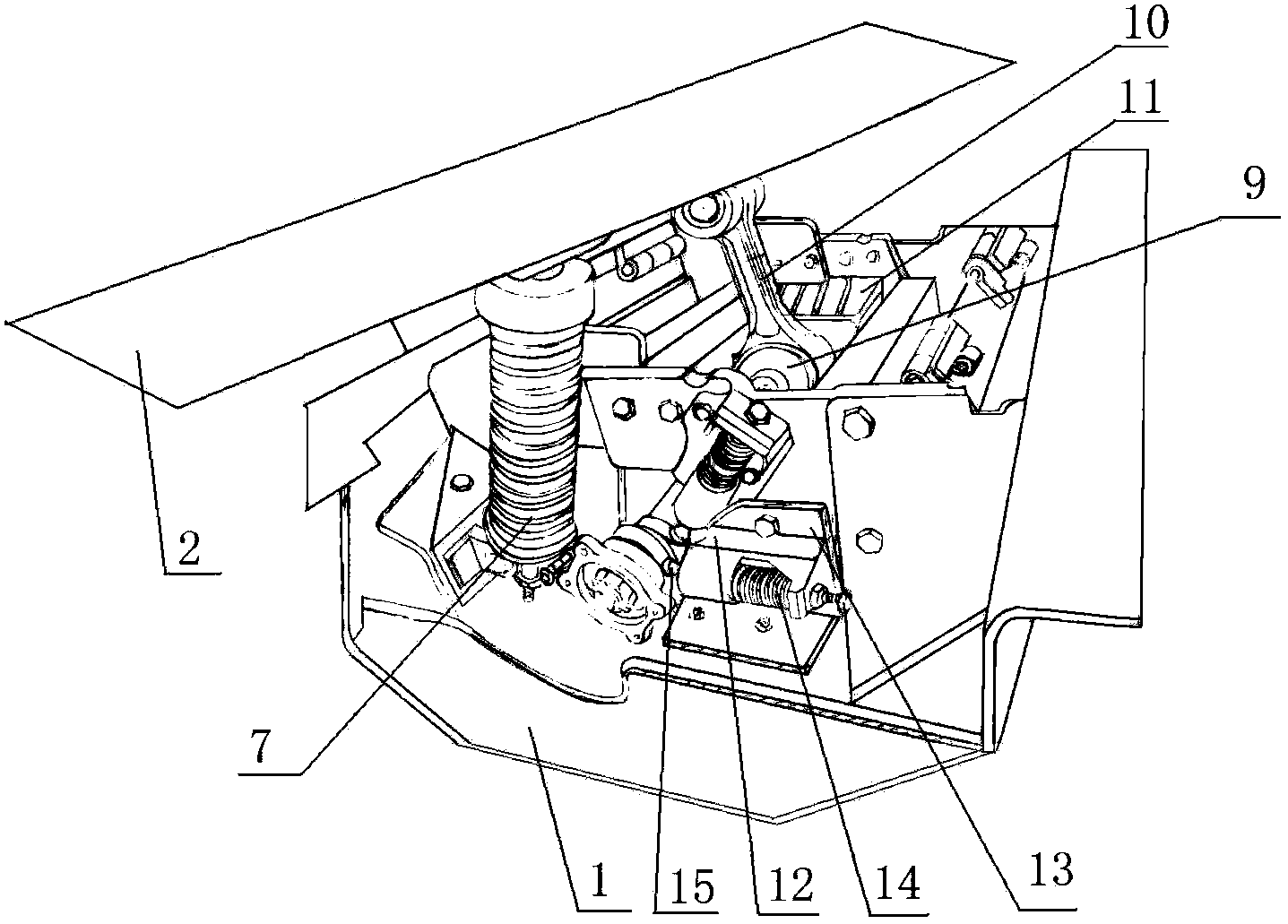

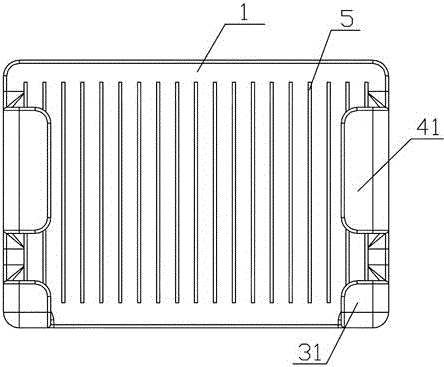

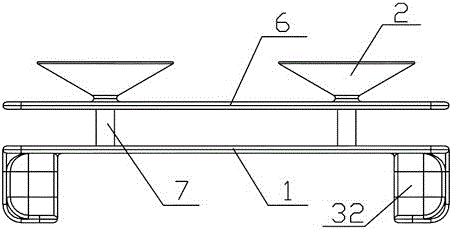

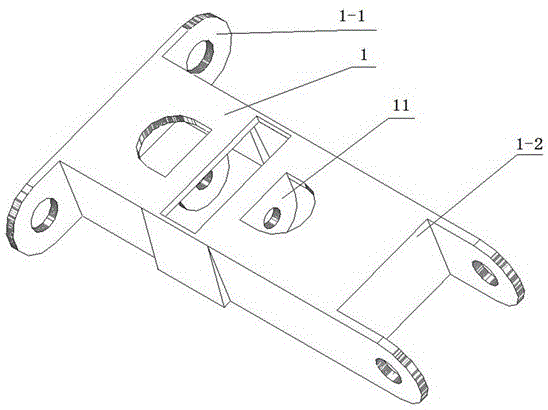

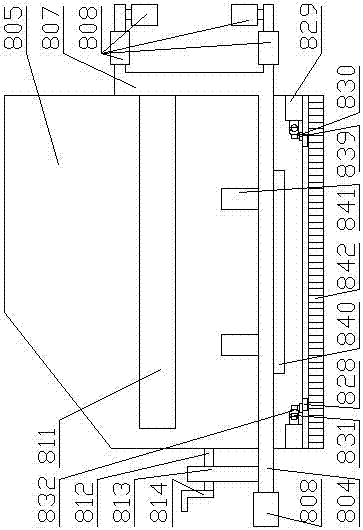

Pull type clutch assembly test tool

PendingCN106950059AEvenly acceptedThe test result is accurateMachine gearing/transmission testingMaterial strength using tensile/compressive forcesClutchStructural engineering

The invention discloses a pull type clutch assembly test tool comprising a base, a clutch assembly fixing support and a detection part. The clutch assembly fixing support is arranged on the base. A lower fixing support is connected with a limiting member through a connecting rod. The center of the limiting member is provided with a detection through hole. The clutch assembly is fixed between the lower fixing support and the limiting member through a fixing end. The detection part is arranged on the clutch assembly and positioned in the detection through hole. The test tool is installed on detection equipment in detection, the lower fixing support is arranged on the base, the clutch assembly is fixed on the lower fixing support by the installing hole through the edge of the clutch cover of the fixing end, then the limiting member is arranged on the fixing support, the detection part is arranged on the clutch assembly and the detection part is positioned in the detection through hole so that force bearing of the clutch assembly is enabled to be uniform in testing, the test result is accurate, and finally the pressing column of the detection equipment is abutted against the center of the detection part to perform pressing detection.

Owner:WUHU DAJIE CLUTCH

3D (three-dimensional) softening finishing process of yarn-dyed jacquard fabric

InactiveCN104452138AReduce dosageSmall shrinkageLiquid/gas/vapor removalTextile treatment by spraying/projectingSpray nozzleYarn

The invention relates to a 3D (three-dimensional) softening finishing process of a yarn-dyed jacquard fabric. The process includes the steps of 1, automatically spraying softener; placing the yarn-dyed jacquard fabric on a bench, clamping the fabric with a fabric carrier, pulling the fabric at constant speed through a spray nozzle, and allowing the spray nozzle to spray the softener to the fabric; 2, drying the sprayed fabric in a dryer at 120 DEG C; 3, stentering and shaping the dried fabric on a steam stenter; 4, discharging the fabric, inspecting the fabric and packaging and delivering the fabric. Compared with the prior art, the 3D softening finishing process has the advantages such that the finished fabric is richly stereo, soft and comfortable.

Owner:SHANGHAI SKYTEX FASHION TECH CO LTD

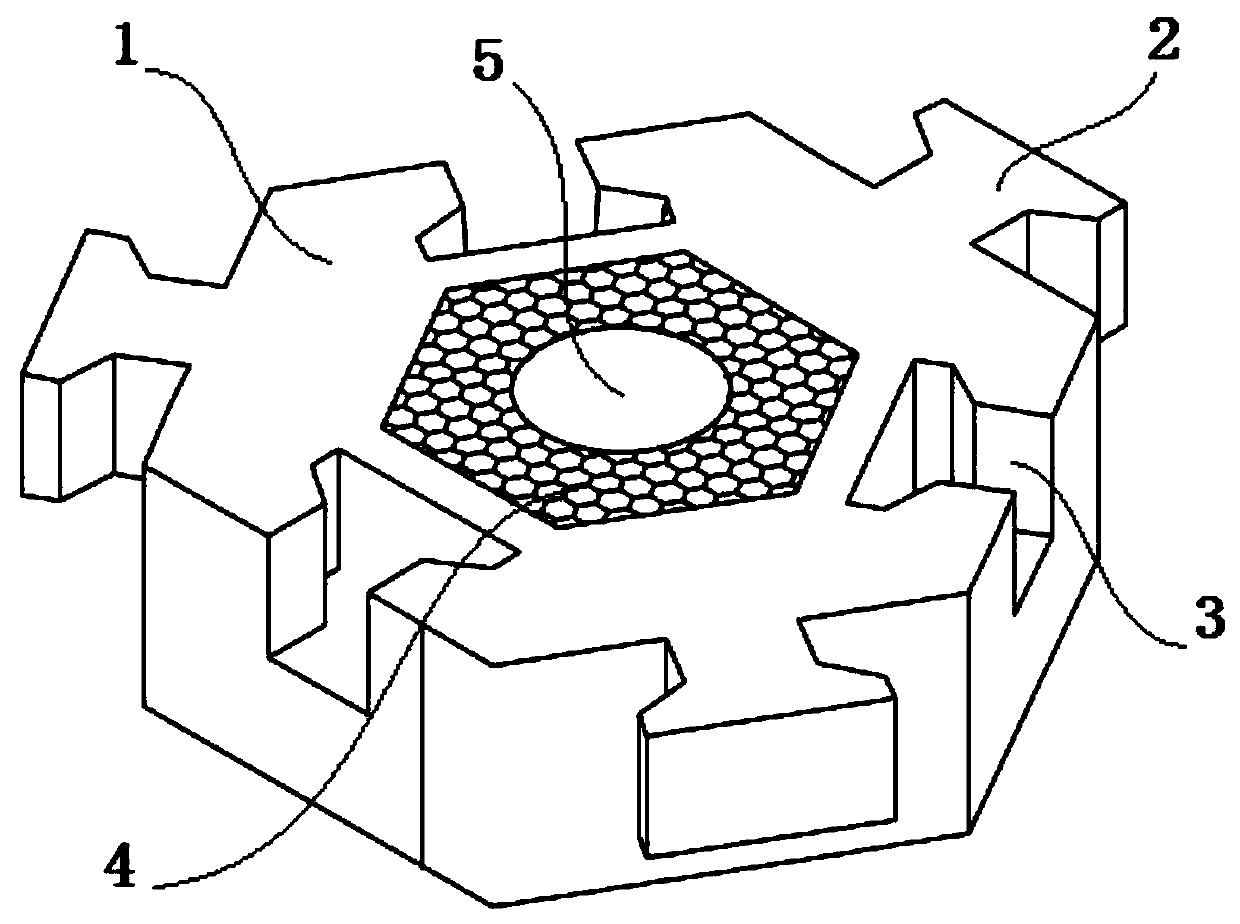

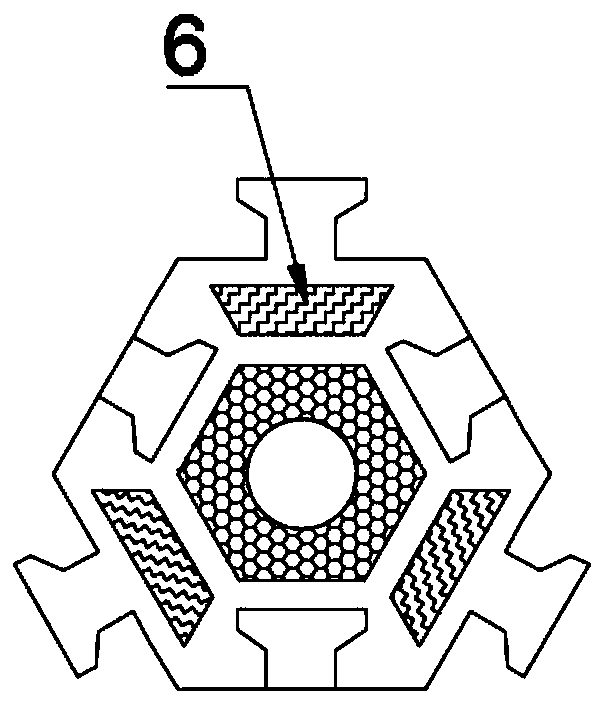

Omnibearing interlocking ecological slope protection brick and preparation method thereof

InactiveCN110093901AIncrease contact areaImprove stabilityCoastlines protectionCeramic shaping apparatusManufacturing cost reductionBrick

The invention relates to the technical field of slope protection bricks, in particular to an omnibearing interlocking ecological slope protection brick and a preparation method thereof. The omnibearing interlocking ecological slope protection brick is composed of a main body, clamping blocks, grooves, a soil stabilizing protection plate and planting holes; the main body is a positive hexagonal prism and is provided with a front side face, a front left side face, a rear left side face, a rear side face, a rear right side face and a front right side face; the clamping blocks are arranged on thefront left face, the rear face and the front right face and extend in the direction away from the center of the main body; and the grooves are formed in the front face, the rear left face and the rearright face and sunken in the direction close to the center of the main body. The problem that a current slope protection brick cannot achieve omnibearing occlusion is structurally solved, building waste is further recycled to serve as a raw material for preparing the slope protection brick, thus the manufacturing cost is lowered, economic benefits are increased, and the ecological environment isprotected.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

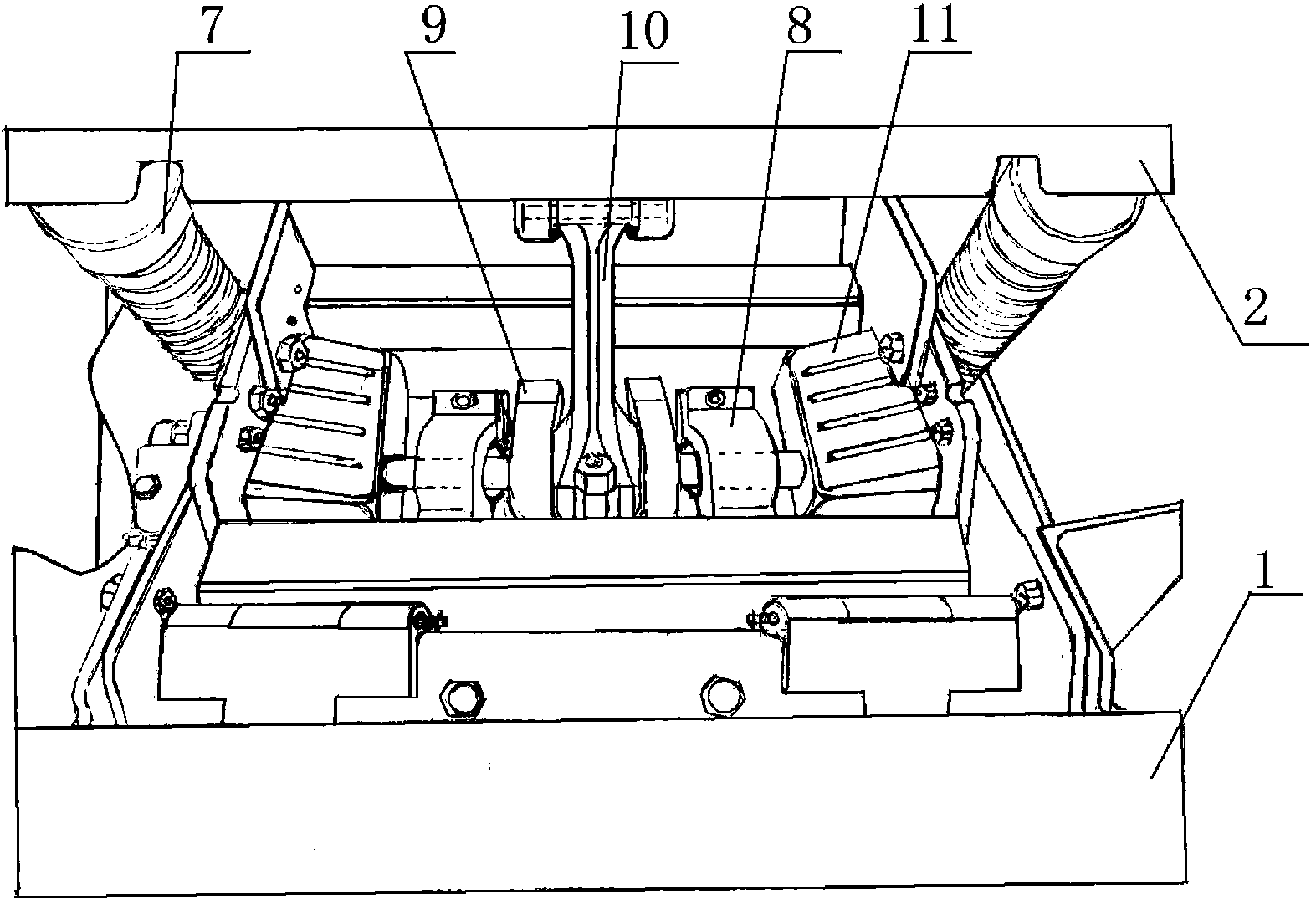

Rear axle housing assembly

InactiveCN104742655AAchieve double reinforced connectionEvenly distributedAxle unitsTrailing armButt welding

The invention discloses a rear axle housing assembly. The rear axle housing assembly comprises a rear upper axle housing body, a rear lower axle housing body, a rear left axle housing tube, a rear right axle housing tube and half-shaft casing flange plates. The rear upper axle housing body and the rear lower axle housing body are in a butt welding mode to form a rear axle housing body. The half-shaft casing flange plates are welded to the two ends of the formed rear axle housing body through the rear left and right axle housing tubes respectively. Reinforcing rings are arranged at the rear portion of the rear upper axle housing body and the rear portion of the rear lower axle housing body so as to connect the rear upper axle housing body with the rear lower axle housing body. The rear lower axle housing body is provided with an oil drain plug base. A left upper trailing arm support is arranged on the upper surface of the rear left axle housing tube. A left lower trailing arm support welding assembly is arranged on the lower surface of the rear left axle housing tube. A right upper trailing arm support is arranged on the upper surface of the rear right axle housing tube. A right lower trailing arm support welding assembly is arranged on the surface of the front side of the rear right axle housing tube. The connection portion is reinforced doubly, all the components are distributed more evenly and reasonably, firmness of axle connection is improved, balanced stress of an axle is facilitated, and operation stability is improved.

Owner:ZHUCHENG CITY FURI MACHINERY

Equipment for detecting ink explosion of paper

InactiveCN112710607AEvenly acceptedAvoiding uneven admissions issuesUsing mechanical meansMaterial analysisElectric machineryEngineering

The invention relates to the technical field of printing, particularly to paper ink explosion detection equipment, which comprises a detection cavity, wherein the top end of the detection cavity is fixedly connected with a first motor, the lower end of the first motor penetrates into the detection cavity through a lead screw and is fixedly connected with a limiting block, the upper end of the limiting block is located outside the lead screw and slidably connected with a reciprocating plate, two movable rods penetrate through the two ends of the reciprocating plate correspondingly, and the lower ends of the two movable rods are fixedly connected with a driving cavity. According to the invention, pressure is applied to a driving cavity through the elastic force of a spring, so that a first roller in the driving cavity is stressed more evenly, and the problem of uneven stress caused by a traditional mechanical transmission extrusion mode is solved; and a pressure sensor effectively detects the stress condition of a second roller and visually displays the stress condition through a display screen, and personnel can adjust the elastic length of two springs through the superposition number of auxiliary rings, so that the calibration of the elastic force of the springs is realized.

Owner:无锡市春阳印刷包装有限公司

Method and device for slitting plank

InactiveCN103056928AEnsure processing safetyQuality assuranceCircular sawsGear driveEnvironmental quality

The inventing discloses a method and a device for slitting plank. A transmission gear drives a pinch roller assembly to rotate, and the transmission gear presses the plank tightly and drives the plank to rotate through the pinch roller assembly, and then the plank is cut into strips by a cutting disk assembly. The method and the device for slitting the plank need not pressing through manpower, thus processing safety of workers is ensured and labor intensity of the workers is reduced. The pinch roller drives the plank to move at constant speed so that slitting quality is improved. A plurality of cutting disks slit one plank simultaneously and can cut the plank into a plurality of strips one time, and thus processing efficiency is improved greatly. A collecting cover is used for recycling the bits of wood, thus not only is environmental quality improved, but also energy is saved.

Owner:董金奎

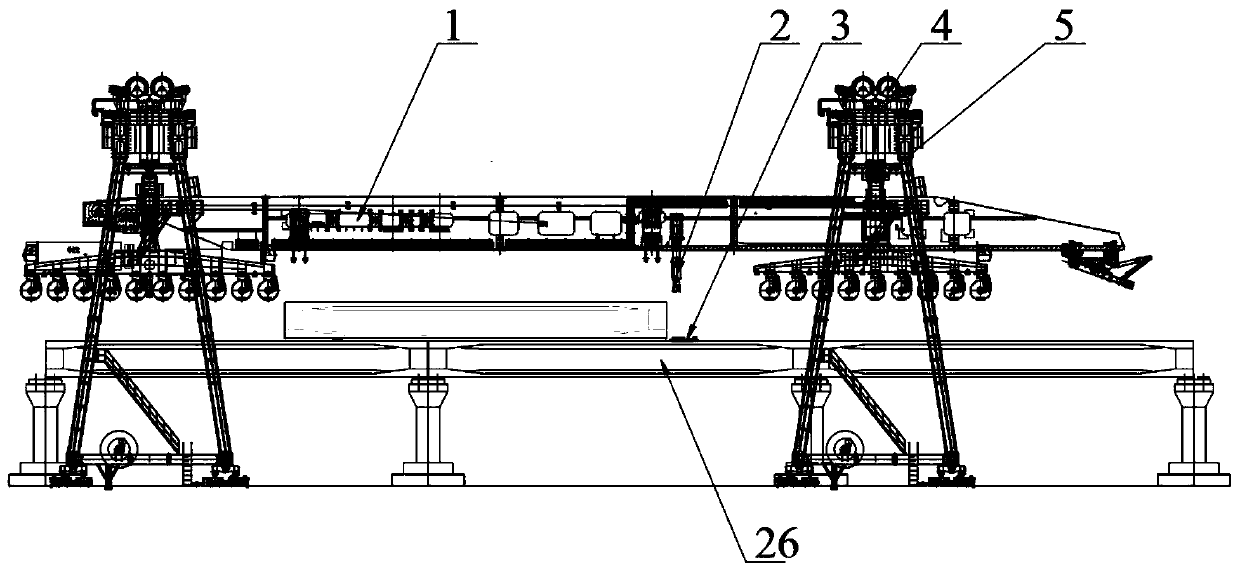

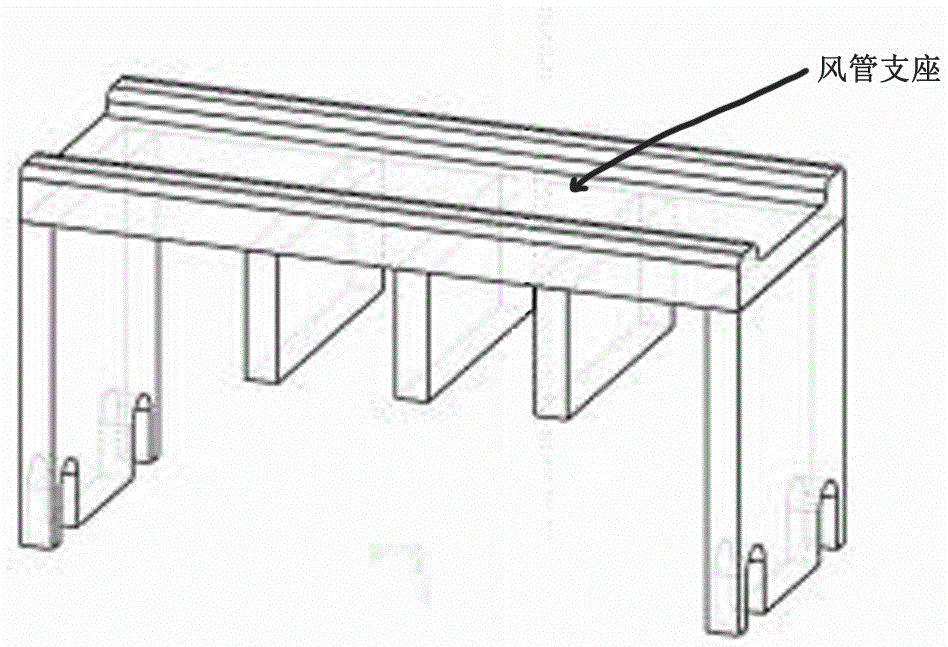

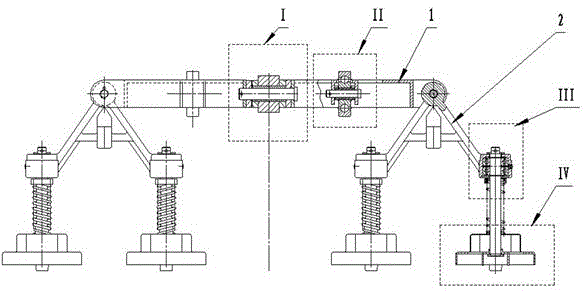

Special hoisting system for 900-ton transporting and erecting all-in-one machine

InactiveCN111535194ASolve stuckSolve problems that cannot be advancedBridge erection/assemblyControl engineeringEconomic benefits

A special hoisting system for a 900-ton transporting and erecting all-in-one machine comprises a plurality of gantry cranes, the gantry cranes are arranged on two sides of a track bridge under construction in a striding mode, the hoisting system further comprises a hoisting adjusting unit and a positioning supporting unit, the top of the hoisting adjusting unit is connected with a crane of the gantry cranes, and the bottom of the hoisting unit is connected with a bridge erecting machine in a hoisting and hanging mode. And the positioning and supporting unit is fixedly arranged on a top surfaceof a beam box built at a previous stage and provides positioning and supporting for rear supporting legs of the bridge erecting machine. According to the hoisting system, a problem that the all-in-one machine is constrained and limited by environmental conditions in a hoisting process can be solved, the 900-ton transporting and erecting all-in-one machine can normally feed beams and accurately hoist and locate the beams, bridge climbing and beam erecting and transporting construction is facilitated, the construction problems of beam feeding and beam erecting and transporting under complex working conditions are effectively solved, the structure is simple, operation is easy, a beam loading period is remarkably shortened, and wide economic benefits are achieved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

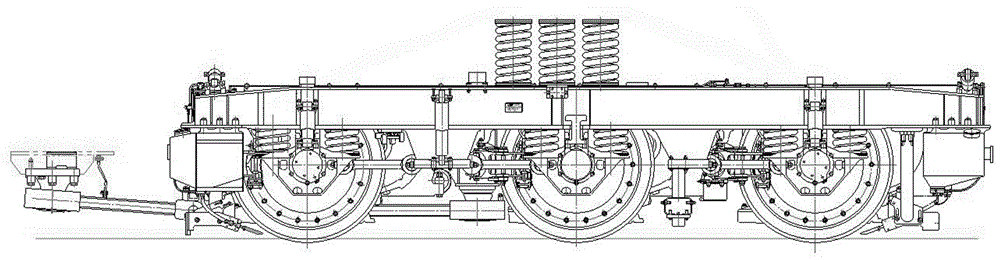

Method for hanging wheel set of locomotive vehicle

InactiveCN106143433ARun at low speedGet back up and running quicklyVehicle fittings for liftingBogiesBogieLow speed

The invention discloses a method for hanging a wheel set of a locomotive vehicle. The failed wheel set is separated from a rail through the vertically upward support force supplied by a jack, is in a hung state over the rail and then tightly tied to a running gear bogie through an auxiliary fastening device, a support device is installed on a normal wheel set adjacent to the failed wheel set, therefore, the running gear bogie is in an inclined state to share the pressure of the whole locomotive vehicle on the running gear bogie, and then the locomotive vehicle can run at low speed in the state that a failed wheel is hung.

Owner:ZHTWY BEIJING TECH

Road deceleration strip

ActiveCN103410106AAvoid damageReduce vibrationTraffic signalsRoad signsHost machineAutomotive engineering

The invention relates to the field of road equipment, in particular to a road deceleration strip. The road deceleration strip comprises a U-shaped gravity host machine oil groove, wherein a cross plate is fixed on one upper edge of the gravity host machine oil groove through a hinge; a telescopic buckle plate is fixed on the other edge of the gravity host machine oil groove through a hinge; a chute is formed in the telescopic buckle plate; a roller is arranged in the chute of the telescopic buckle plate; grooves are formed in the telescopic buckle plate; convex pieces are arranged on the edge, facing the telescopic buckle plate, of the cross plate, inserted into the grooves, and fixed with the roller; a return spring is arranged in the gravity host machine oil groove; one end of the return spring is fixed on the surface of the gravity host machine oil groove; the other end of the return spring is fixed on the cross plate; the return spring enables the cross plate and the telescopic buckle plate to protrude upwards. The road deceleration strip has the benefits that when an automobile passes through the road deceleration strip, vibration of the automobile is reduced, and damage to the automobile and the discomfort of passengers are lowered.

Owner:重庆市大足区汉中汽车修理厂

Numerical control high-speed carving and milling machine of bridge type elevated cross beam moving gantry

ActiveCN105562791AVertical stabilityImprove motion rigidityMilling machinesLarge fixed membersNumerical controlBridge type

The invention discloses a numerical control high-speed carving and milling machine of a bridge type elevated cross beam moving gantry. The numerical control high-speed carving and milling machine comprises a base, a left wall, a right wall, a cross beam, a front sliding seat, a rear sliding seat, a ram and a spindle. A workbench is arranged on the base, the left wall and the right wall are arranged on the base in parallel, and the workbench is located between the left wall and the right wall. The two ends of the cross beam are arranged on the left wall and the right wall, and horizontal moving pairs are formed by the two ends of the cross beam, the left wall and the right wall. The front sliding seat and the rear sliding seat are arranged in parallel, a horizontal moving pair is formed by the front portion of the front sliding seat and the cross beam, and a horizontal moving pair is formed by the rear portion of the rear sliding seat and the cross beam. The ram is located between the front sliding seat and the rear sliding seat, a vertical moving pair is formed by the front portion of the ram and the front sliding seat, and a vertical moving pair is formed by the rear portion of the ram and the rear sliding seat. The spindle is arranged on the lower portion of the ram and used for being provided with a carving and milling cutter. The numerical control high-speed carving and milling machine has the beneficial effects that due to the fact that the cross beam in the machine is supported by the left wall and the right wall, the down milling precision and the up milling precision of a workpiece are the same.

Owner:南京诚友数控设备有限公司

Heat insulation stirring device based on honey heating and use method thereof

The invention provides a heat insulation stirring device based on honey heating and a use method thereof, and relates to the technical field of honey processing. The heat insulation heating device comprises a honey tank body, wherein a honey tank opening is formed in the upper end of the honey tank body; a heat insulation layer is arranged on the inner wall of the honey tank body; a heating circulation cavity is arranged at one side of the heat insulation layer; a stirring shaft is arrange inside the heating circulation cavity; the lower end of the stirring shaft is provided with a stirring paddle; a baking plate is arranged on the surface of the rotating shaft; a pipe opening is formed in one side of the rotating shaft; a heat radiation plate is arranged on the surface of a sensing chamber; a switch is arranged at one side of the honey tank body; a photoelectric fusion measuring instrument is arranged at one side of a honey discharging cavity; an extraction plate is arranged on the surface of the honey discharging cavity. The device solves the problems that the honey heating in the existing market is manual heating; the tank body is made of glass substances, so that the temperature cannot be easily mastered; the nutrition ingredients of the honey are influenced; the disadvantages are caused on the mouthfeel of the honey; a great number of precipitates are decomposed; bacteriagrow; harm is caused on the body when people with poor spleen and stomach conditions eat the honey.

Owner:MINGGUANG HAOHAO BEES

Novel wire rod based on electronic information transmission

PendingCN114283982AEvenly acceptedAvoid damageInsulated cablesCommunication cablesWire rodEngineering

The invention discloses a novel wire rod based on electronic information transmission, and belongs to the technical field of wire rods, the wire rod comprises a wire core and a shielding layer wound outside the wire core, the shielding layer is wrapped by a skeleton, gaps of the skeleton are filled with an anti-gnawing layer, the skeleton is wrapped by an extrusion belt, and the extrusion belt is wrapped by a rubber belt. The inner surface of the extrusion belt is provided with an extrusion boss, the tip end of the extrusion boss faces the wire core and penetrates into the anti-gnawing layer, the extrusion belt is wrapped with a protective sleeve, and the mechanical performance is not reduced while rodents are effectively prevented from gnawing.

Owner:中科检测技术服务(重庆)有限公司

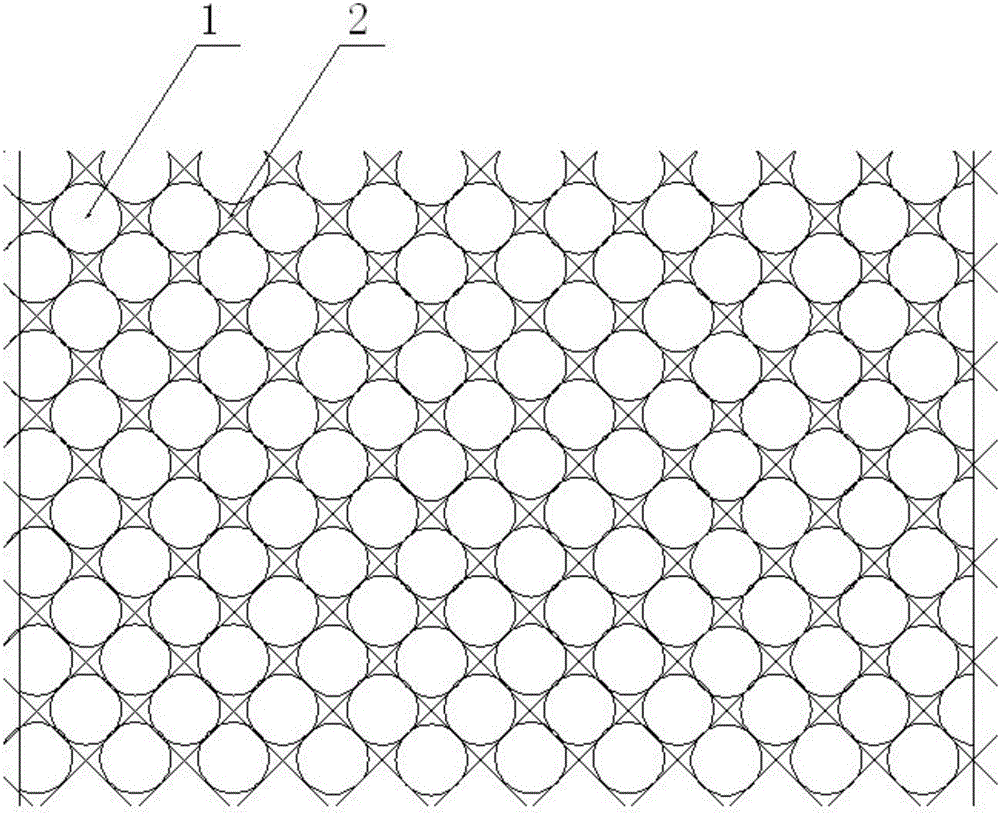

Ribbed steel bar welded mesh

The invention relates to a ribbed steel bar welded mesh. A circular ring is welded in each mesh hole of the welded mesh; the steel bars of the welded mesh on the periphery of the circular ring are all tangent to the circular ring. According to the ribbed steel bar welded mesh provided by the invention, the steel bar welded mesh adopts circular supporting ribs; the circular supporting rib in each mesh hole is in the relationship of an internally tangent circle with the mesh hole; when the welded mesh is stressed, the stressed pressure of the supporting rib can be orthogonally decomposed; therefore, the steel bars on the periphery of the supporting rib are stressed uniformly, deformation is avoided, and even the steel bars deform slightly, the existing supporting effect can still be achieved by the tangent structure of the supporting rib with the steel bars.

Owner:TIANJIN SHUGUANG METAL PROD CO LTD

Wall-suction type router bracket

PendingCN106658233ASo as not to damageImprove stabilitySelection arrangementsEngineeringWall suction

The invention discloses a wall-suction type router bracket, comprising a support frame body (1), wherein more than one suckers (2) for adsorbing the whole bracket on the wall surface are arranged at the back surface of the support frame body (1), a supporting plate (3) for providing upward support force for the router is respectively arranged at two right angles at the lower end of the support frame body (1), and a baffle (4) which is used for preventing the router from moving in the horizontal direction and is provided with an L-shaped cross section is respectively arranged on two sides of the front part of the support frame body (1). The wall-suction type router bracket disclosed by the invention has the following beneficial effects: according to the router bracket, the router is arranged on the bracket and cannot generate displacement in any direction without applying external force manually, and thus relatively good stability can be achieved; and the router bracket is adsorbed on the wall surface through the sucker, and thus the wall surface cannot be damaged.

Owner:MORAL ELECTRICAL APPLIANCE KUNSHAN

Pharmaceutical squeezing granulator realizing uniform granularity

The invention discloses a pharmaceutical squeezing granulator realizing uniform granularity, and belongs to the technical field of medical equipment. The squeezing granulator comprises a tank, whereina collecting hopper is arranged at the upper part in the tank, the bottom of the collecting hopper is divided into a plurality of pressing cavities through a plurality of partitions, a plurality of through holes are formed in the bottom of each pressing cavity, a driving mechanism is arranged above each pressing cavity, a pressing block matched with the corresponding pressing cavity is arranged at the bottom of each driving mechanism, and a cutting mechanism is arranged below bottoms of the pressing cavities; a pushing mechanism is arranged at the lower part of the tank, a plurality of feeding ports are formed in the top of the tank, a discharging port is formed in the side wall, opposite to the pushing mechanism, of the tank, a sealing door is arranged at the discharging port, and a controller is arranged on the outer wall of the tank. By means of the plurality of pressing cavities as well as the driving mechanisms arranged above the pressing cavities and the pressing blocks, each pressing block has small area and uniform stress, and the prepared pharmaceutical particles have good hardness uniformity and good pressing effect.

Owner:华蓥市铜堡初级中学

A connection device between drag chain and tire mold in latex production line

A connecting device for drag chains and tire molds in a production line of latex products, including brackets, auxiliary support bearing parts, movable forks, movable fork bearing chamber components, rotating shafts and rotating disk components, and is characterized in that the brackets are symmetrically arranged on the production line drag Both sides of the chain; the inner end of the bracket is provided with a connecting plate, and the inner chain plate, outer chain plate and connecting plate of each drag chain are connected by the drag chain pin shaft; the outer end of the bracket is hinged with two movable forks Frame; connect the movable yoke bearing chamber assembly at the bottom of the movable yoke. The invention has the advantages of detachable parts, simple structure, and convenient maintenance and replacement; the bracket of the device is connected with the outer chain plate through the pin shaft of the production line chain, and can move synchronously with the production line, the positioning is more accurate, and the operation of the whole production line is more efficient. Stable; it is more convenient to replace the tire mold when the tire mold is suspended and the product is changed. It is suitable for the transformation of the old production line of latex products and the manufacture of new production lines.

Owner:LIAONING NAISI PRECISION MACHINERY MFG

Stacking device of wood board stacking production line

ActiveCN107265128ARealize automatic palletizing operationReduce labor intensityConveyorsStacking articlesVertical projectionProduction line

The invention discloses a stacking device of a wood board stacking production line. The stacking device comprises supporting columns on the four sides. A row of interval strip falling devices are transversely arranged on the top in the range defined by the supporting columns. A row of stacking supporting rods are vertically and movably connected within the range defined by the supporting columns and below the interval strip falling devices. A row of stacking discharging conveying chains are arranged below the stacking supporting rods. The vertical projections of the stacking supporting rods and the vertical projections of the stacking discharging conveying chains are arranged at intervals. The stacking discharging conveying chains stretch out from the stacking discharging end. The sides, located at the stacking feeding end, of the supporting columns are vertically and movably connected with a row of feeding stop rods. It can be known from the above structure that the stacking device of the wood board stacking production line achieves the automatic wood board stacking operation, the production efficiency is improved, the size requirement after stacking is guaranteed, and meanwhile the labor intensity of operators is lowered.

Owner:江苏爱美森木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com