Pharmaceutical squeezing granulator realizing uniform granularity

A technology of granulation and granulation machine, applied in the direction of raw material extrusion granulation, etc., can solve the problems of poor effect and uneven hardness of drug granules, and achieve the effect of good compression effect, good hardness uniformity, and uniform acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

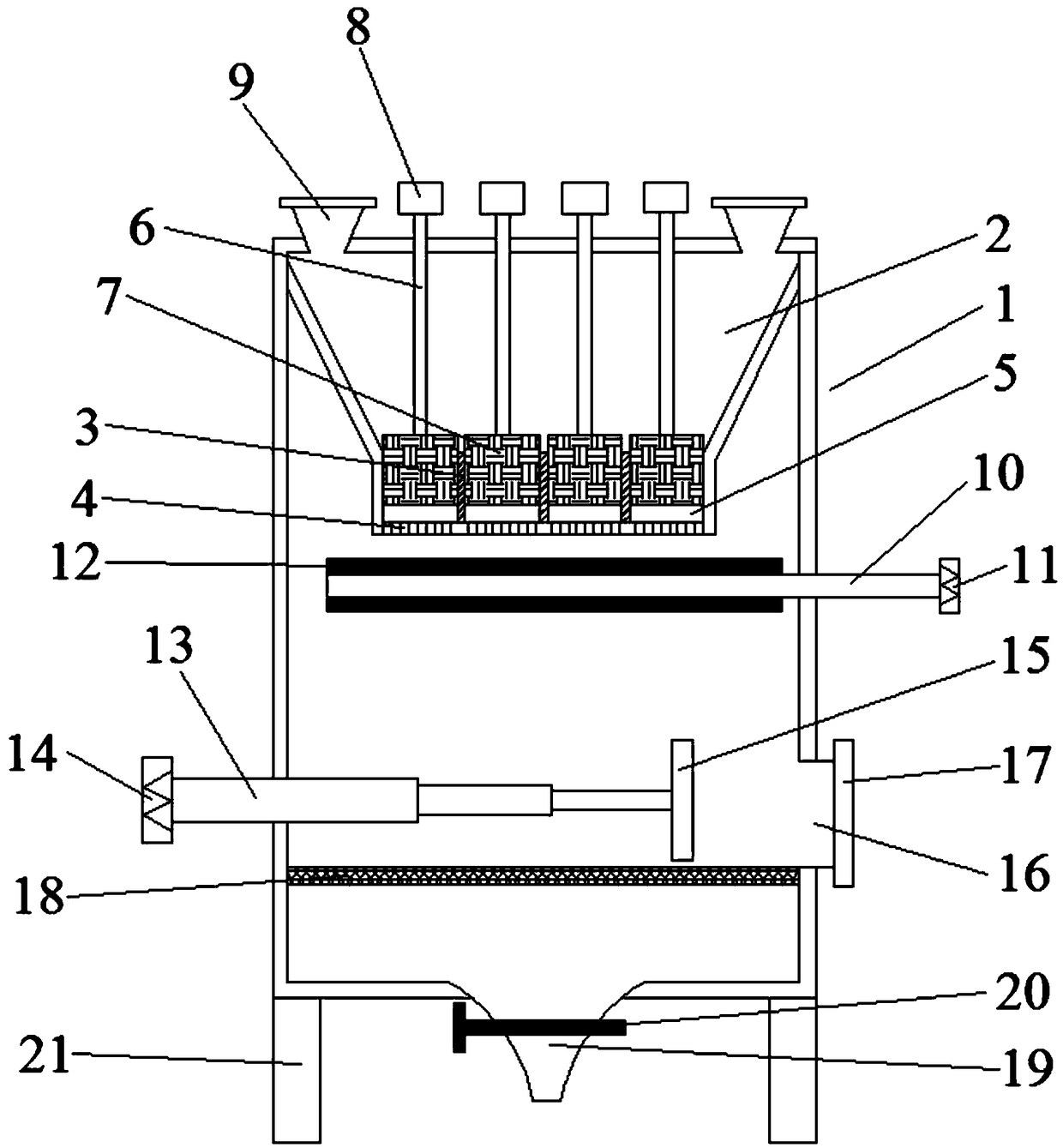

[0018] Such as figure 1 As shown, a pharmaceutical extrusion granulator with uniform particle size includes a box body, and a collecting hopper is arranged on the upper part of the box body, and the bottom of the collecting hopper is divided into a plurality of pressing chambers by a plurality of partitions, The bottom of each of the pressing chambers is provided with a plurality of through holes, the top of each of the pressing chambers is provided with a driving mechanism, and the bottom of each of the driving mechanisms is provided with a briquetting, the bottom of the pressing chamber is provided with a cutting mechanism, the lower part of the box is provided with a pushing mechanism, the top of the box is provided with a plurality of feeding ports, and the box on the opposite side of the pushing mechanism A discharge port is provided on the side wall of the body, a sealed door is provided on the discharge port, and a controller is provided on the outer wall of the box.

...

Embodiment 2

[0021] Based on Example 1, such as figure 1 As shown, a filter screen is provided under the pushing mechanism in the box, a slag discharge pipe is provided at the bottom of the box, and a valve is provided on the slag discharge pipe.

[0022] The filter is set so that the small particle impurities in the drug granulation pass through the filter, fall to the bottom of the box, and are discharged from the slag discharge pipe at the bottom of the box. The pushing mechanism pushes the material back and forth on the filter to prevent the filter from clogging.

Embodiment 3

[0024] Based on Example 1, such as figure 1 As shown, the pushing mechanism includes a telescopic rod positioned above the filter net, a push plate positioned at one end of the telescopic rod and a second motor positioned at the other end of the telescopic rod, and the other end of the telescopic rod extends to outside of the box.

[0025] The second motor drives the telescopic rod to expand and contract back and forth, and at the same time drives the push plate to push the material back and forth to prevent drug granulation from clogging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com