Distributing frame

A distribution frame and wire trough technology, applied in the field of distribution frame, can solve the problems of easy formation of knots, damage of wires, intertwining of wires, etc., and achieve the effects of low manufacturing cost, easy management, and simple and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

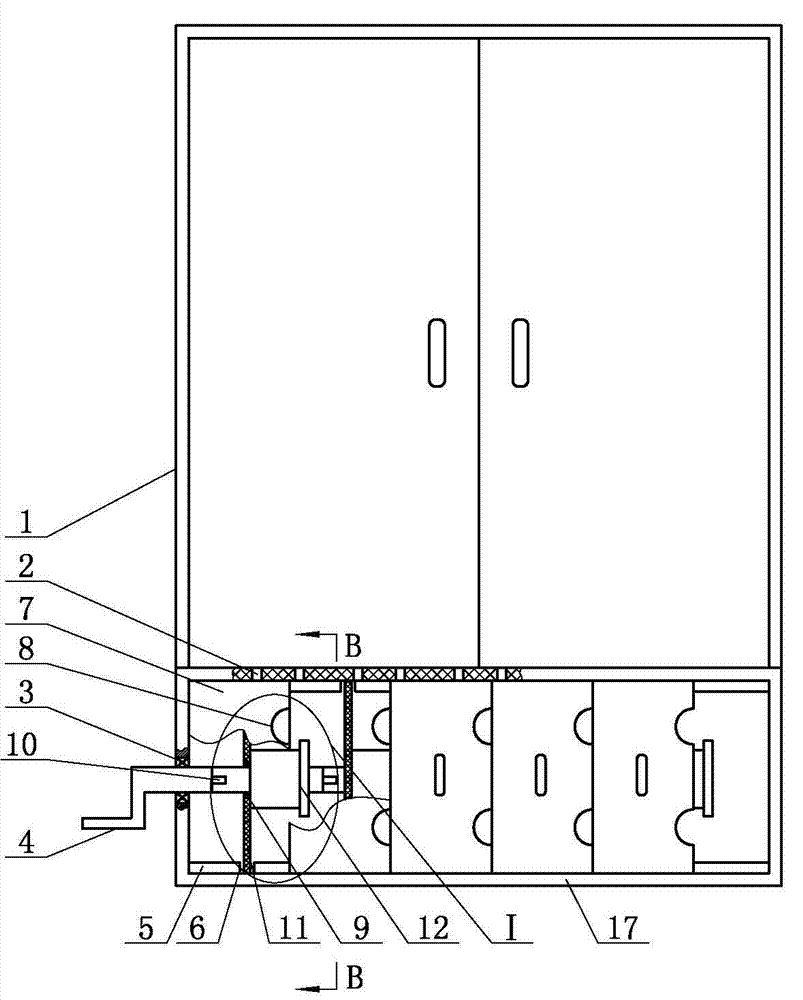

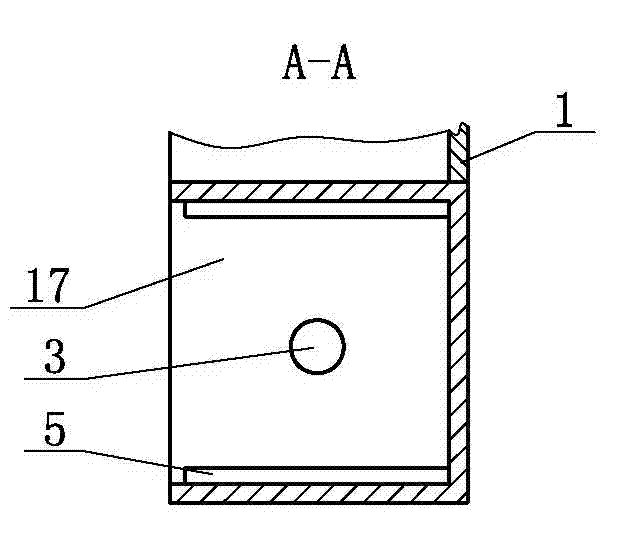

[0009] patch panels, such as figure 1 As shown, it includes a trunking box 17 with side openings, such as figure 2 and image 3 As shown, the top and the bottom in the wire trunking box 17 are provided with connecting frames 5, and several locking slots 6 are provided on each connecting frame 5, and the distance between each locking slot 6 is the same. Corresponding to the slot 6 provided on the connecting frame 6 at the bottom, the connecting plate 11 is inserted in the locking slot 6, and the line roller 12 is set on each connecting plate 11, as Figure 4 As shown, the spool of the wire roller 12 is connected with the connecting plate 11 by the first bearing 9, the first connecting shaft 13 is arranged at one end of the central axis of the wire roller 12, the second connecting shaft 15 is arranged at the other end of the central axis of the wire roller 12, and the second connecting shaft 15 is arranged at the other end of the central axis of the wire roller 12 The first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com