Ribbed steel bar welded mesh

A technology of welded steel mesh and welded mesh, which is applied in the direction of building reinforcements, structural elements, building components, etc., can solve problems such as potential safety hazards, easy dislocation or distortion of longitudinal and transverse bars, deformation of welded mesh, etc., and achieve the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

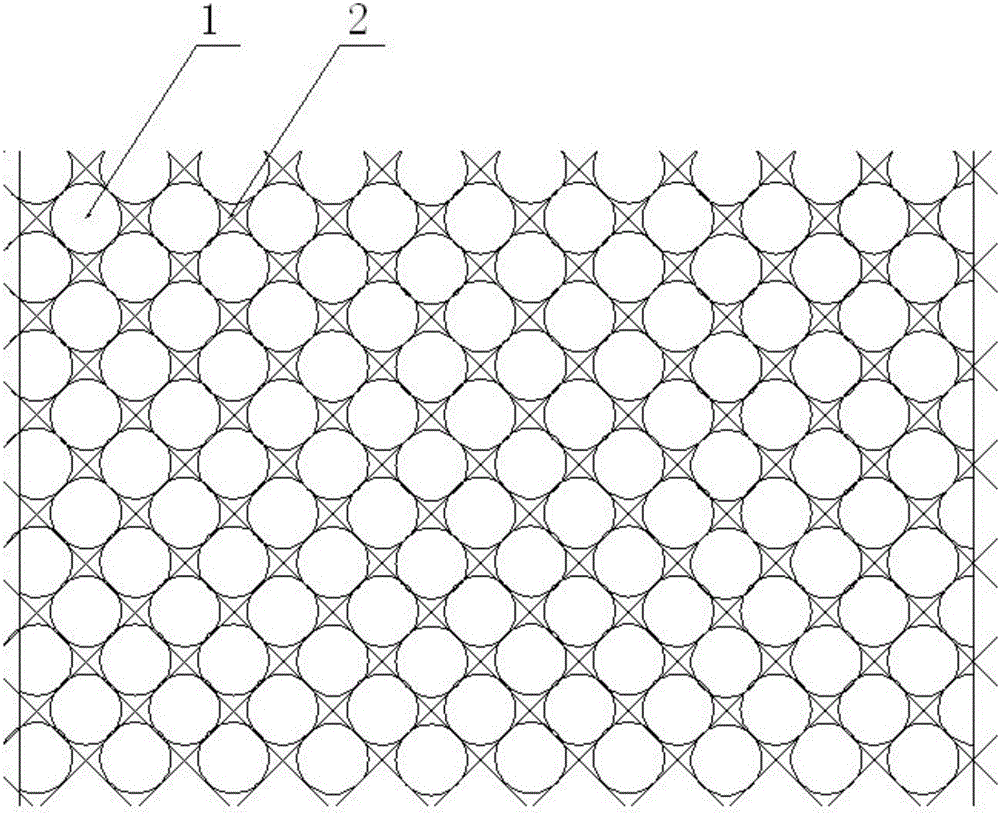

[0011] A ribbed steel welded mesh, in which a ring 1 is welded in each mesh of the welded mesh 2, the welded mesh reinforcement around the ring is tangent to the ring, and the mesh of each welded mesh is the The circumscribed square of the inner ring of the mesh, when the welded mesh is stressed, the pressure on the supporting ribs can be decomposed orthogonally, so that the steel bars around it can be balanced to avoid deformation, even if there is a slight deformation, its The structure tangent to the reinforcement can still satisfy the existing support effect.

[0012] Although the embodiments and drawings of the present invention are disclosed for the purpose of illustration, those skilled in the art can understand that various replaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com