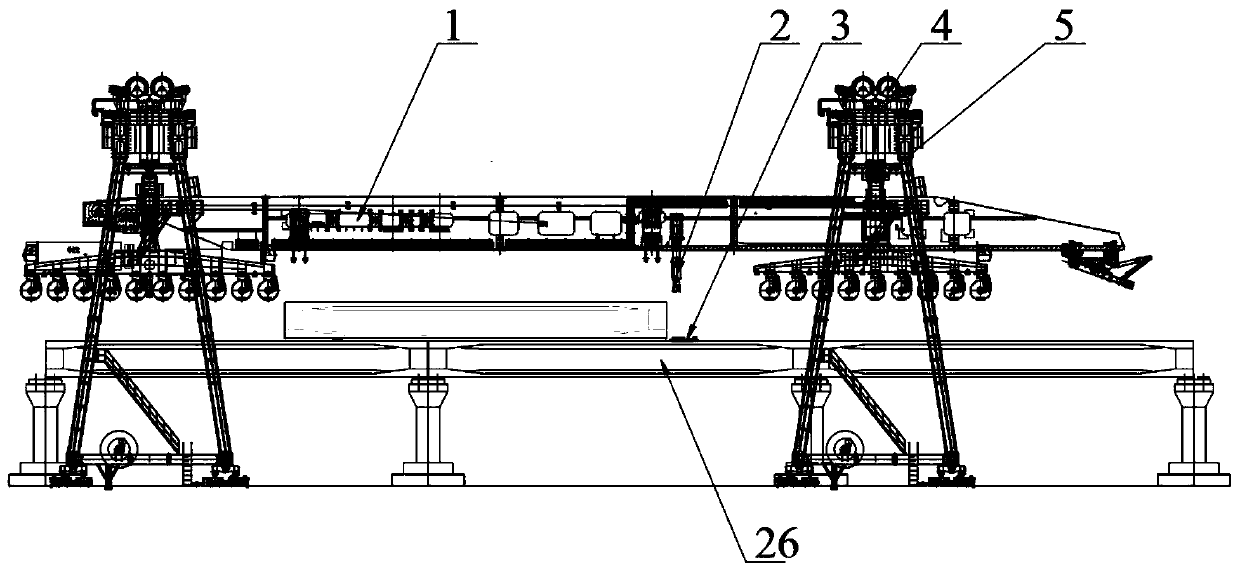

Special hoisting system for 900-ton transporting and erecting all-in-one machine

An all-in-one machine and rack transport technology, applied in the erection/assembly of bridges, buildings, bridge construction, etc., can solve the problems of reducing beam installation period, constraints and other problems, and achieve the effects of low cost, simple operation and accurate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

[0029] A special hoisting system for a 900-ton all-in-one machine, including a plurality of gantry cranes 4, and the gantry cranes are all installed on both sides of the track bridge under construction. The hoisting system also includes a hoisting adjustment unit 5 and a positioning support unit, wherein the hoisting adjustment unit The top of the hoisting unit is connected to the crane of the gantry crane, and the bottom of the hoisting unit is hoisted and connected to the bridge erecting machine 1; the positioning support unit is fixed on the top surface of the beam box 26 that has been built on the upper leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com